Dysprosium complex of n-hydroxyphthalimide and preparation method thereof

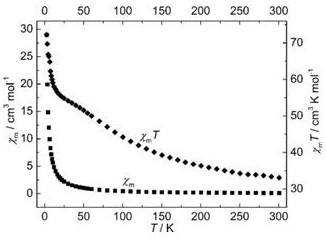

A technology of dysprosium hydroxyphthalimide and hydroxyphthalimide is applied in the field of magnetic materials to achieve the effects of improving performance and optimizing synthesis routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

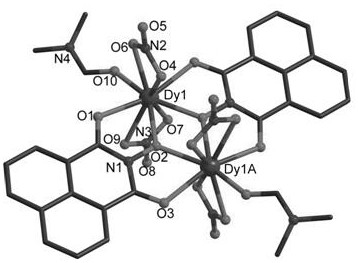

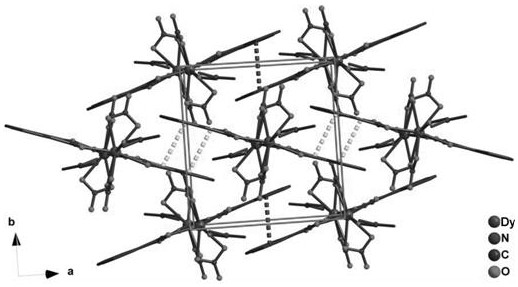

[0020] Embodiment 1: take by weighing Dy(NO 3 ) 3 ·5H 2 O (0.1 mmol, 0.0439 g), fully dissolved with 0.5 mL DMF, added to the glass tube containing N-hydroxy-1,8-naphthalimide (0.05 mmol, 0.0106 g) , shake the glass tube to dissolve the HL weighed in the tube completely; after the solution in the tube turns into a light yellow clear liquid, add 0.5 mL CH 3 OH and 0.5 mL CH 3 CN, shake well, let stand. Subsequently, while evacuating, the other end of the glass tube was sealed with a liquefied gas flame. Place it in an oven at 60°C for reaction, take it out three days later (or place it in an oven at 80°C for reaction, take it out after 24 hours), and slowly cool down in the incubator for 24 hours to obtain yellow regular cuboid crystals; wash A pure regular single crystal was selected and dried naturally to obtain the N-hydroxyphthalimide dysprosium complex. The yield was 82% based on HL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com