Method for preparing rapidly crosslinkable and easily breakable macromolecule thickener

A polymer and thickener technology, applied to drilling equipment, etc., can solve the problems of difficult removal of solid powder, long storage period, low emulsion stability, etc., and achieve low gel filtration loss and low cross-linking environmental requirements Harsh, good viscosity and temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

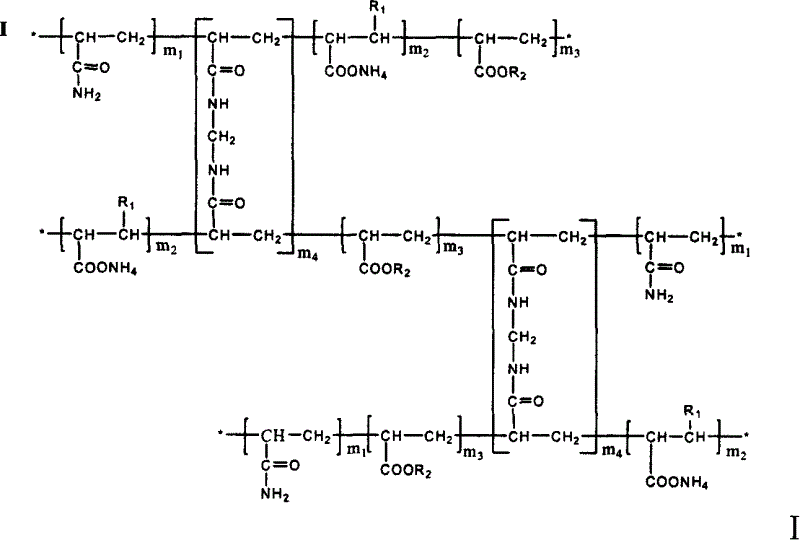

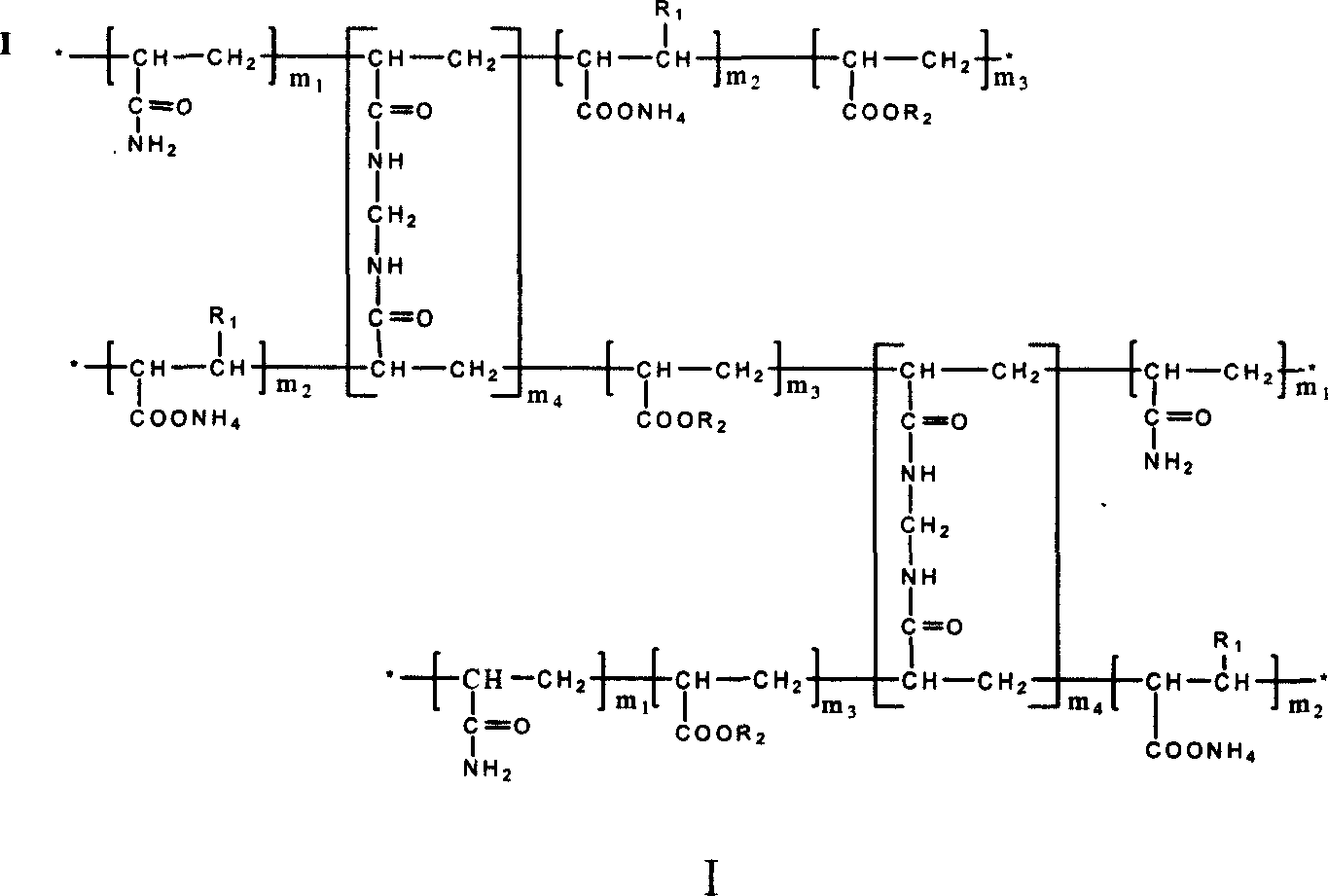

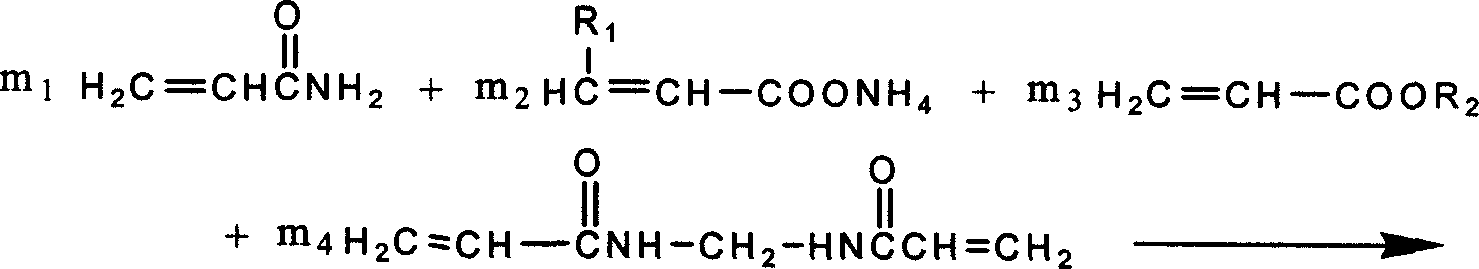

Method used

Image

Examples

Embodiment 1

[0032] In the 250ml four-necked bottle, add 30 parts of white oil by mass, 4 parts of Span80, 1 part of OP-7, 1 part of OS-15, 1 part of methyl acrylate, and then add 80 parts of water phase (the water Contain 10 parts of distilled water in the phase, 20 parts of acrylamide, 25 parts of acrylic acid, 25 parts of 25wt% ammonia water); 2 Oxygen was exhausted for 0.5 hours, 0.02 part of ammonium persulfate was added, the reaction was initiated by heating to 40° C., and the polymerization reaction was carried out for 5 hours to obtain a uniform and stable inverse emulsion product.

Embodiment 2~15

[0034] The contents of acrylamide, acrylic acid, and N, N-methylenebisacrylamide were changed respectively, and the polymerization reaction as in Example 1 occurred to obtain a series of inverse emulsion products, which were characterized. The results are listed in Table 1:

[0035] Reality

Embodiment 16

[0037] Dissolve latex or solid powder in water to prepare a 1wt% aqueous solution, let it stand for 20 minutes to increase the viscosity, adjust the pH value to 5-7, and add Cr with a mass ratio of 0.6‰ 3+ The cross-linking agent is cross-linked at a room temperature of 25°C to obtain a thickener jelly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com