Preparation method of salt-tolerant amphoteric polycarboxylate high-performance water reducer

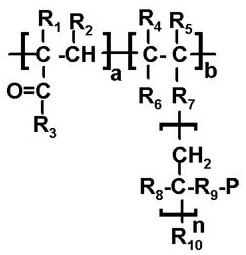

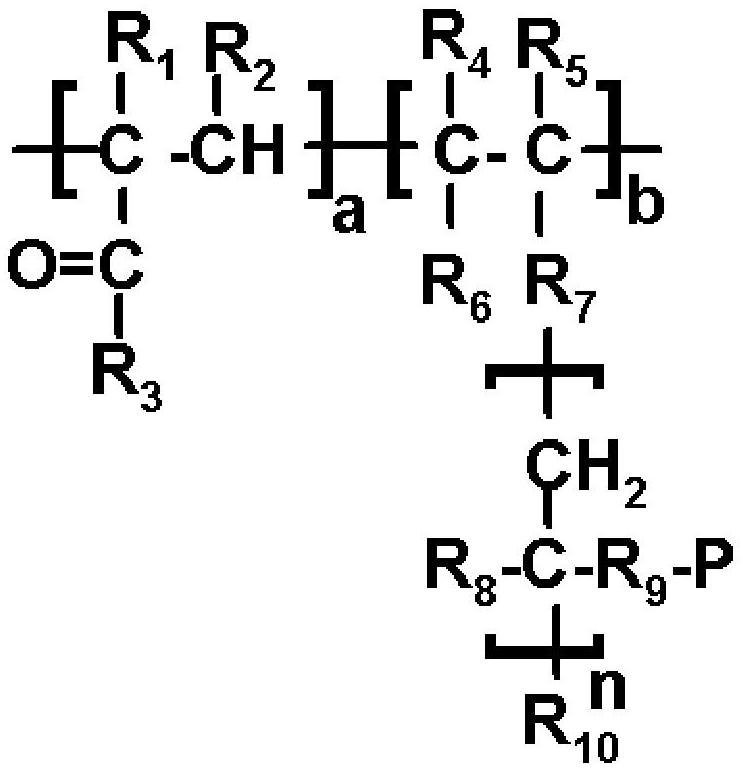

A technology of amphoteric polycarboxylic acid and water reducing agent, which is applied in the field of salt-tolerant amphoteric polycarboxylic acid high-performance water reducing agent, can solve the problem of restricting the development and application of the theoretical technology of amphoteric water reducing agent, and has not yet shown dispersion and dispersion stability. It can improve the side chain extension ability, rich species and narrow molecular weight distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

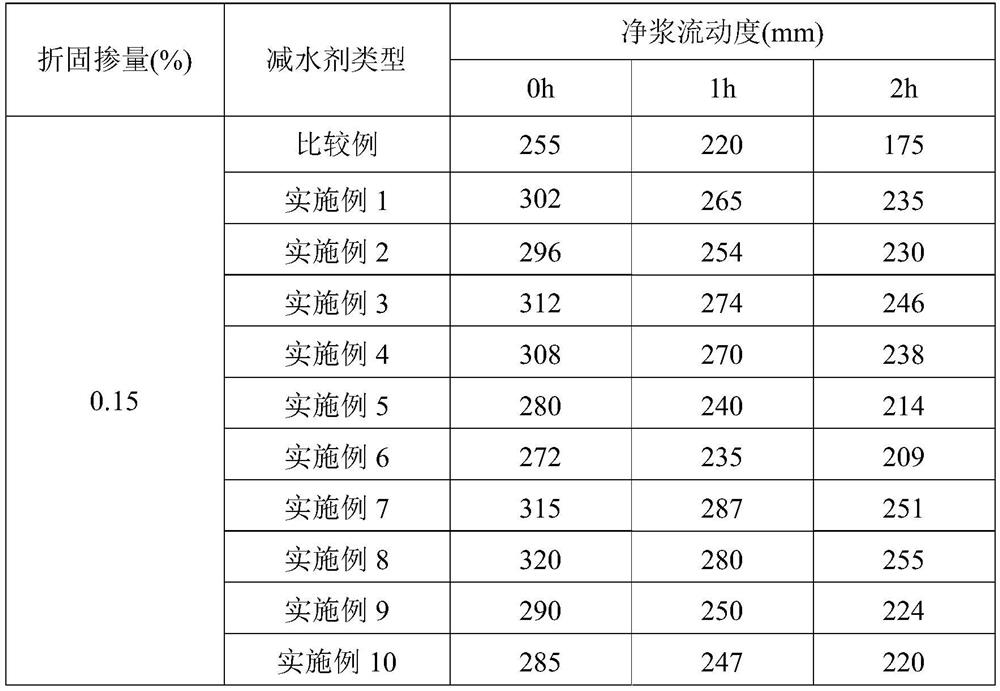

Examples

Embodiment 1

[0025] First, mix 162.76g of trimethylallyl ammonium chloride with 244.14g of water, then mix 0.91g of methallyl chloride, 8.63g of ferrous bromide, 6.93g of N,N,N,N,N-five Methyldivinyltriamine was added to the reactor, and the reactor was deoxygenated 4 times in an ice-water bath for 20 minutes, then stirred for 20 minutes until it was evenly mixed, sealed under nitrogen protection, and continued to heat up to 40°C for polymerization reaction. Hours, desalination and vacuum distillation to remove the solvent to obtain the cationic macromonomer; then mix the cationic macromonomer with 180.03g of water evenly, then add 5.76g of acrylic acid and 0.14g of mercaptoacetic acid, heat up to 55°C and drop Add 3.42g mass fraction and be 20% ammonium persulfate aqueous solution, react for 2 hours and then keep warm for 4 hours, cool to 25°C, add 23.49g water to dilute to obtain the salt-tolerant type amphoteric polycarboxylic acid high-performance reducing agent with a concentration of ...

Embodiment 2

[0027] After storing the 45% salt-tolerant amphoteric polycarboxylate high-performance water reducer solution obtained in Example 1 at 5°C for 30 days, its implementation effect was measured.

Embodiment 3

[0029] First, mix 77.47g of acryloyloxyethyltrimethylammonium chloride, 83.08g of methacryloyloxyethyltrimethylammonium chloride with 189.37g of water, then mix 0.61g of allyl bromide, 0.75g of 1- Bromo-3-methyl-2-butene, 0.72g cuprous bromide, 0.49g cuprous chloride, 1.73g N,N,N,N,N-pentamethyldivinyltriamine were added to the reactor, The reactor was filled with nitrogen in an ice-water bath for 3 times and deoxygenated repeatedly for 30 minutes, then stirred for 25 minutes until it was evenly mixed, sealed under the protection of nitrogen and continued to heat up to 50°C for polymerization reaction, reacted for 15 hours, desalted and distilled off under reduced pressure After solvent, the cationic macromonomer is obtained; then mix the cationic macromonomer with 140.53g of water evenly, then add 2.14g of acrylamide, 2.16g of acrylic acid and 0.21g of mercaptopropionic acid, raise the temperature to 70°C and add 1.62g of it dropwise Potassium persulfate aqueous solution with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com