Irradition initiating process for preparing cationic starch

A cationic starch and radiation-induced technology, applied in the fields of papermaking and textile pulp, can solve the problems of high equipment process requirements, high production costs, and low reaction conversion rates, and achieve the effects of no pollution to the environment, low cost, and simple production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

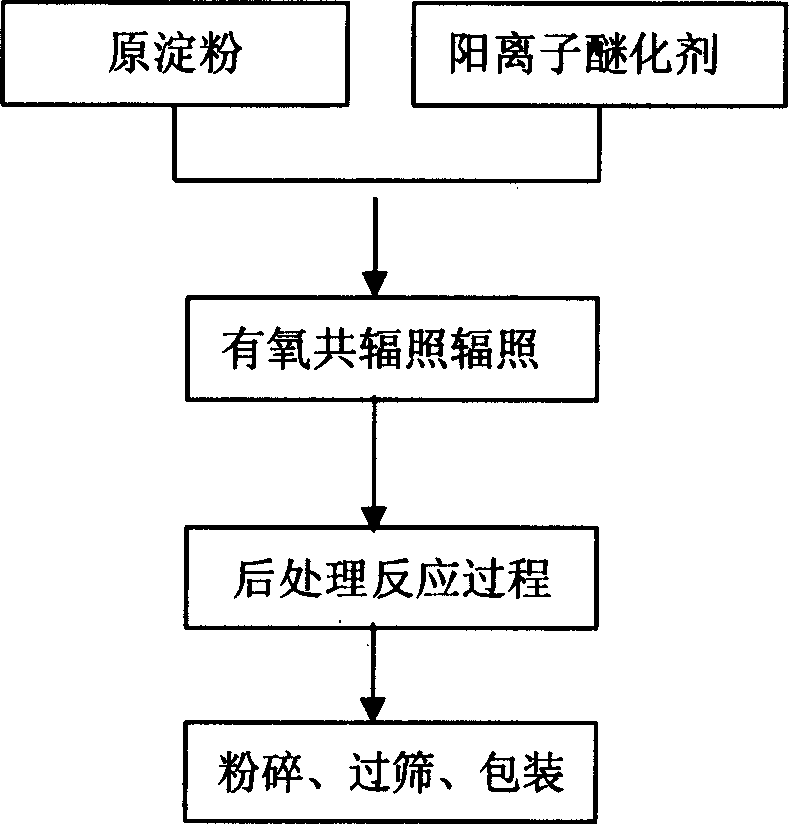

[0018] Such as figure 1 As shown, in a 1000 milliliter beaker, add 285 grams of corn raw starch, the raw starch moisture content is 14%, take by weighing 15 grams of cationic etherification agent (2,3-epoxypropyltrimethylammonium bromide ) liquid is poured into the original starch, and the blend is fully stirred with a glass rod for 30 minutes, so that the mixture is fully and uniformly mixed to prepare a mixture of 5% etherifying agent by mass percentage; then the mixture is packed into a polyethylene self-sealing plastic bag , seal; place the plastic bag containing the mixture in 60 Co irradiation field ( 60 CO-γ-ray irradiation field) to irradiate, under aerobic conditions, control the irradiation dose to 5KGy; pour the irradiated blend into a sealed container, place it in a constant temperature oven at 140°C, and dry Dry for 2 hours, then cool at normal temperature, pulverize and sieve, pass through a 100-mesh sieve, and pack to obtain a heated gelatinized cationic starc...

Embodiment 2

[0020] In a 1000 ml beaker, add 285 grams of raw corn starch, the water content of the raw starch is 14%, take 15 grams of cationic etherification agent (2,3-epoxypropyltrimethylammonium chloride) liquid and pour into the original starch, and fully stir the blend with a glass rod for 30 minutes, so that the mixture is fully and uniformly mixed to prepare a mixture with a mass percentage of 5% etherifying agent content; then put the mixture into a polyethylene self-sealing plastic bag and seal it; Place the plastic bag containing the blend in 60 Irradiate in a Co irradiation field, and control the irradiation dose to 5KGy under aerobic conditions; pour the irradiated blend into a sealed container, place it in a constant temperature oven at 190°C, and dry it for 2 hours. Then it is cooled at normal temperature, crushed, sieved and packaged to obtain a cold water soluble cationic starch product. Degree of substitution DS = 0.025.

Embodiment 3

[0022] Take 291 grams of potato native starch with a water content of 13%, add 9 grams of 2,3-epoxypropyltrimethylammonium chloride cationic etherification agent, and stir well to obtain a mixture; place the mixture in 60 Irradiate in the Co irradiation field, initiate the reaction under aerobic conditions, and control the irradiation dose by controlling the irradiation time, so that the irradiation dose is 15KGy to obtain a blend; place the blend at 150 ° C Dry in an oven and stir to decompose the peroxide and fully react the free radicals. Finally, pulverize and pass through a 100-mesh sieve to obtain cationic starch with a degree of substitution of 0.014.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com