Continuous ursol dissolving device and method

A p-phenylenediamine and dissolving device technology, which is applied in the direction of dissolving, dissolving, and driving the agitator to dissolve, can solve the problems of unfavorable stability of PPTA resin, and achieve the effect of ensuring color consistency, ensuring stability, and achieving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

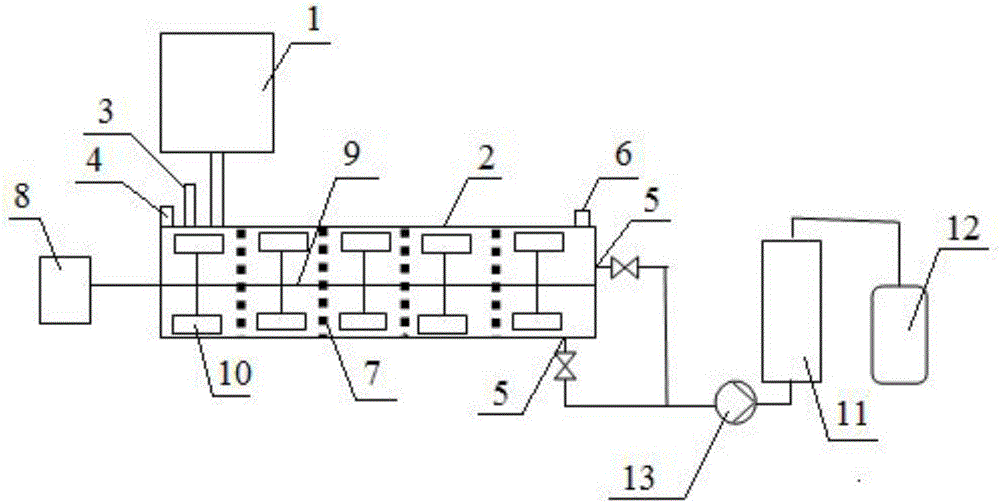

[0020] A continuous dissolving device for p-phenylenediamine, which comprises a weighing system, a dissolving system, a cooling system and a storage system;

[0021] Described weighing system comprises feed bin 1;

[0022] The dissolving system comprises a continuous dissolving tank 2, the continuous dissolving tank 2 is provided with a feed inlet 3, a gas inlet 4, a discharge port 5 and a gas outlet 6; the continuous dissolving tank 2 is provided with a stirring device and a grid 7; The stirring device includes a motor 8, a stirring shaft 9 and a stirring paddle 10; the grid 7 is a porous disk fixed on the wall of the kettle; the stirring shaft 9 passes through the center of the grid 7 and is kept with the grid 7 1mm gap;

[0023] The feed bin 1 is connected with the feed port 3 through a pipeline;

[0024] The discharge port 5 is sequentially connected with the cooling system 11 and the storage system 12 through pipelines.

[0025] The aspect ratio of the continuous disso...

Embodiment 2

[0031] A continuous dissolving device for p-phenylenediamine, which comprises a weighing system, a dissolving system, a cooling system and a storage system;

[0032] Described weighing system comprises feed bin 1;

[0033] The dissolving system comprises a continuous dissolving tank 2, the continuous dissolving tank 2 is provided with a feed inlet 3, a gas inlet 4, a discharge port 5 and a gas outlet 6; the continuous dissolving tank 2 is provided with a stirring device and a grid 7; The stirring device includes a motor 8, a stirring shaft 9 and a stirring paddle 10; the grid 7 is a porous disk fixed on the wall of the kettle; the stirring shaft 9 passes through the center of the grid 7 and is kept with the grid 7 10mm gap;

[0034] The feed bin 1 is connected with the feed port 3 through a pipeline;

[0035] The discharge port 5 is sequentially connected with the cooling system 11 and the storage system 12 through pipelines.

[0036] The aspect ratio of the continuous diss...

Embodiment 3

[0042] A continuous dissolving device for p-phenylenediamine, which comprises a weighing system, a dissolving system, a cooling system and a storage system;

[0043] Described weighing system comprises feed bin 1;

[0044]The dissolving system comprises a continuous dissolving tank 2, the continuous dissolving tank 2 is provided with a feed inlet 3, a gas inlet 4, a discharge port 5 and a gas outlet 6; the continuous dissolving tank 2 is provided with a stirring device and a grid 7; The stirring device includes a motor 8, a stirring shaft 9 and a stirring paddle 10; the grid 7 is a porous disk fixed on the wall of the kettle; the stirring shaft 9 passes through the center of the grid 7 and is kept with the grid 7 5mm gap;

[0045] The feed bin 1 is connected with the feed port 3 through a pipeline;

[0046] The discharge port 5 is sequentially connected with the cooling system 11 and the storage system 12 through pipelines.

[0047] The aspect ratio of the continuous dissol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com