BOPP film capable of being directly used for paper-plastic compounding and preparation method thereof

A paper-plastic composite and film technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem of increasing the energy consumption of the pre-coating film process, difficult to control the processing process, and affecting the brightness of the pre-coating film, etc. problem, to achieve high-tech anti-counterfeiting function, beautiful appearance effect, improve the effect of anti-scratch performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

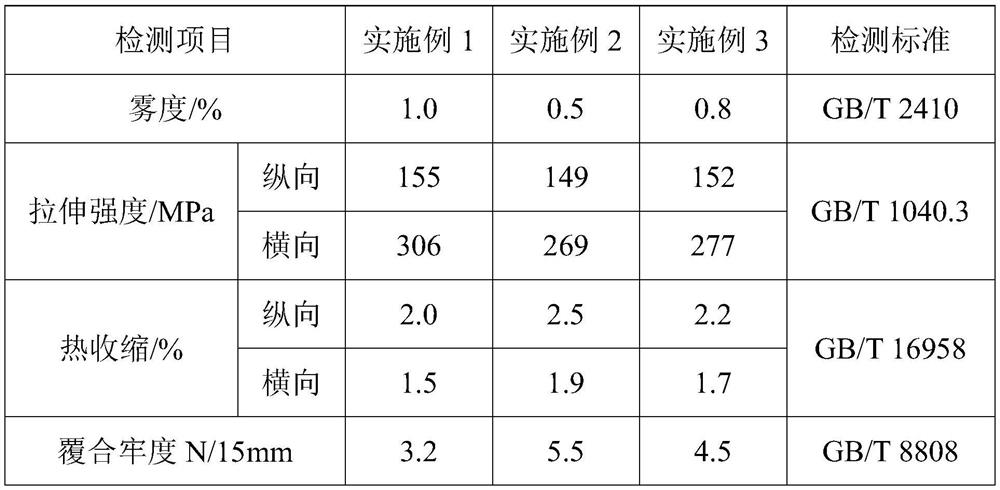

Embodiment 1

[0026] A BOPP film that can be directly used for paper-plastic composite proposed by the present invention is composed of an upper surface layer, a core layer and a lower surface layer; in terms of the total thickness of the BOPP film, the thickness ratios of each layer are: the upper surface layer 15%, the core layer 70% %, lower surface layer 15%.

[0027] The material of the upper surface layer is composed of the following components by weight percentage: homopolypropylene 90%, anti-adhesive masterbatch 10%; wherein, the anti-adhesive masterbatch is composed of homopolypropylene and hollow ceramic microspheres with a particle size of 2 μm ;

[0028] The material of the core layer is composed of homopolypropylene;

[0029] The material of the lower surface layer is composed of the following raw materials in weight percentage: 40% of ethylene-ethyl acrylate copolymer, and 60% of low-density polyethylene; wherein, the low-density polyethylene is bimodal linear low-density pol...

Embodiment 2

[0036] A BOPP film that can be directly used for paper-plastic composite proposed by the present invention is composed of an upper surface layer, a core layer and a lower surface layer; in terms of the total thickness of the BOPP film, the thickness ratios of each layer are: 5% for the upper surface layer and 90% for the core layer %, lower surface layer 5%.

[0037] The material of the upper surface layer is composed of the following components by weight percentage: homopolypropylene 97%, anti-adhesive masterbatch 3%; wherein, the anti-adhesive masterbatch is composed of homopolypropylene and hollow ceramic microbeads with a particle size of 1 μm ;

[0038] The material of the core layer is composed of homopolypropylene;

[0039] The material of the lower surface layer is composed of the following raw materials in weight percentage: 65% of ethylene-ethyl acrylate copolymer, and 35% of low-density polyethylene; wherein, the low-density polyethylene is bimodal linear low-densi...

Embodiment 3

[0046] A BOPP film that can be directly used for paper-plastic composite proposed by the present invention is composed of an upper surface layer, a core layer and a lower surface layer; in terms of the total thickness of the BOPP film, the thickness ratios of each layer are: 10% for the upper surface layer and 80% for the core layer %, lower surface layer 10%.

[0047] The material of the upper surface layer is composed of the following components by weight percentage: homopolypropylene 95%, anti-adhesive masterbatch 5%; wherein, the anti-adhesive masterbatch is composed of homopolypropylene and hollow ceramic microbeads with a particle size of 3 μm ;

[0048] The material of the core layer is composed of homopolypropylene;

[0049]The material of the lower surface layer is composed of the following raw materials in weight percentage: 50% of ethylene-ethyl acrylate copolymer, and 50% of low-density polyethylene; wherein, the low-density polyethylene is bimodal linear low-dens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com