Patents

Literature

101results about How to "Reduce subsequent processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for carrying out vacuum cleaning, oil removal and wax removal by modified hydrocarbon cleaner

The invention relates to the technical field of electroplating pretreatment, in particular to a process for carrying out vacuum cleaning, oil removal and wax removal by a modified hydrocarbon cleaner. The process comprises degassing ultrasonic cleaning, vacuum cleaning, vacuum steam flushing, vacuum drying and the like. A plurality of flows are carried out in the vacuum environment with a certain vacuum degree and are matched with a degassing ultrasonic cleaning and vacuum cleaning technology and the modified hydrocarbon cleaner. For the cleaning process, in the whole process, harmful substances of halogen and the like, such as trichloroethylene, methylene chloride, tetrachloroethylene and the like, cannot be used and additional drying equipment is not required. Particularly, the process has excellent cleaning effect on irregular articles with blind holes, joints, gaps, cracks and the like. Meanwhile, the defects of oil removal and wax removal of the conventional process are overcome.

Owner:广东新球清洗科技股份有限公司

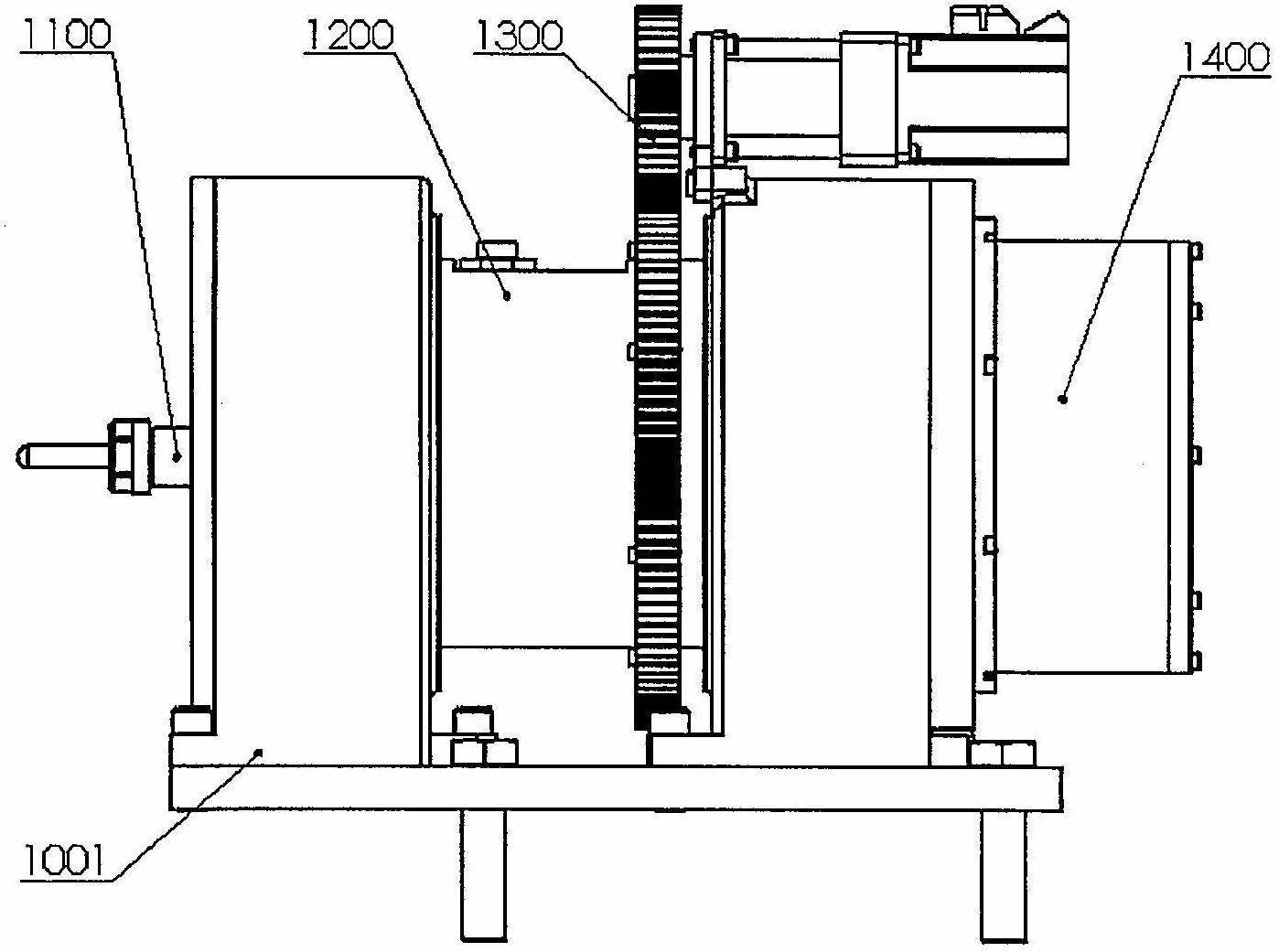

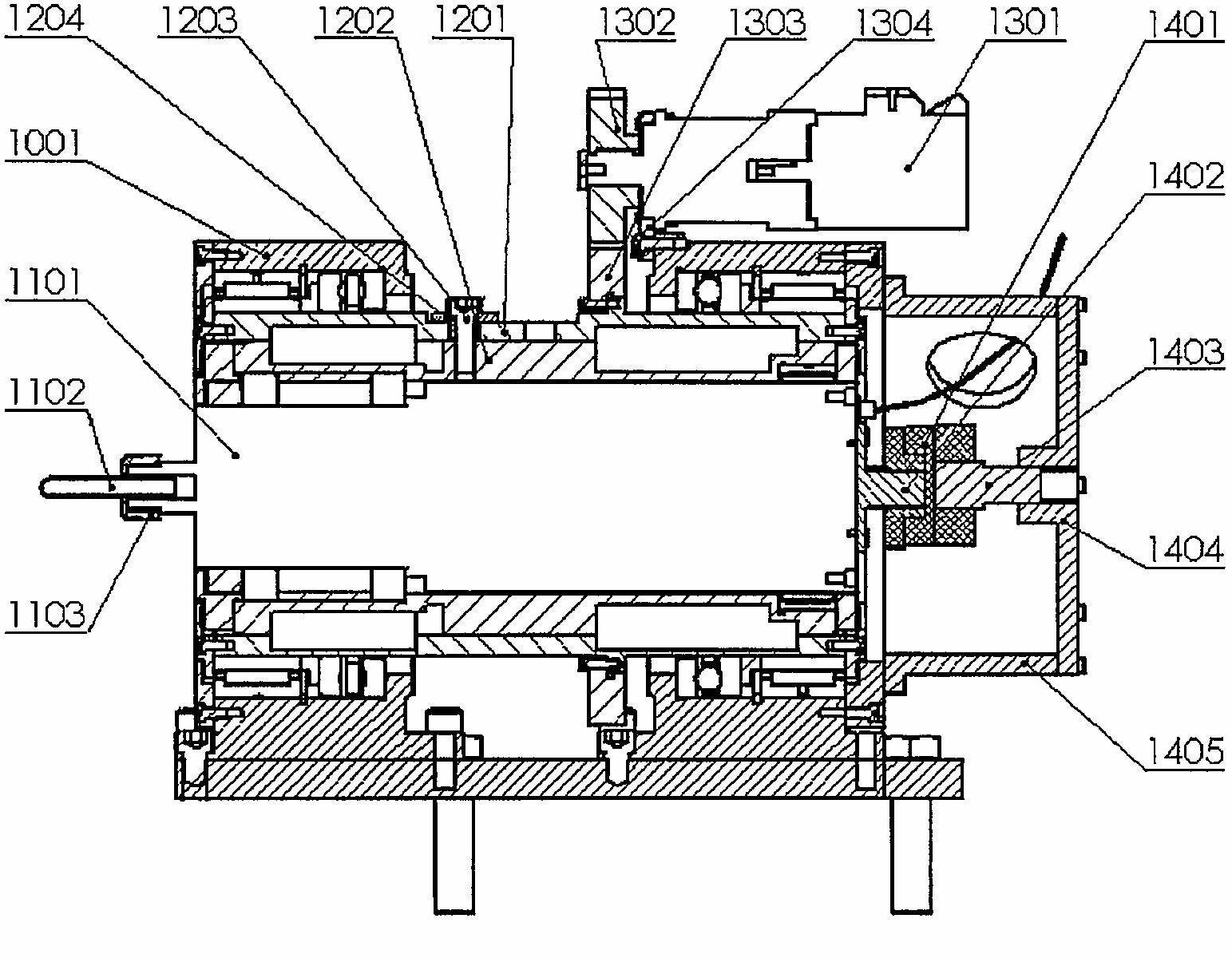

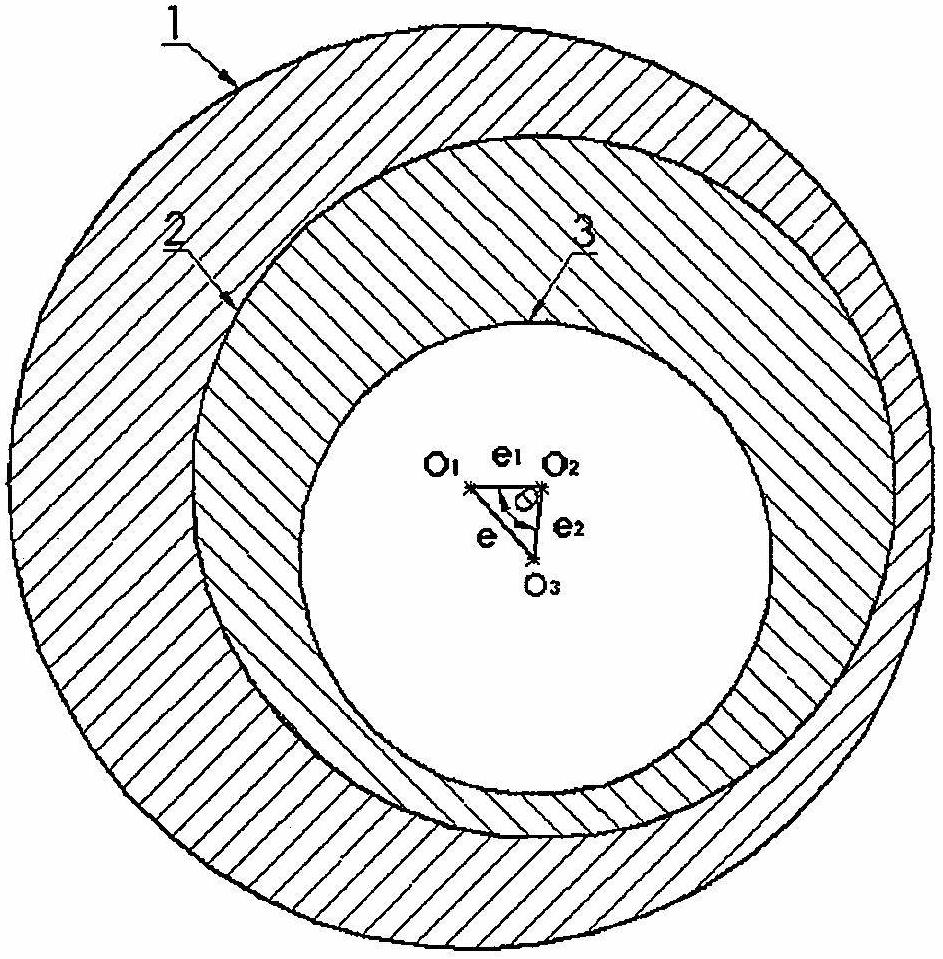

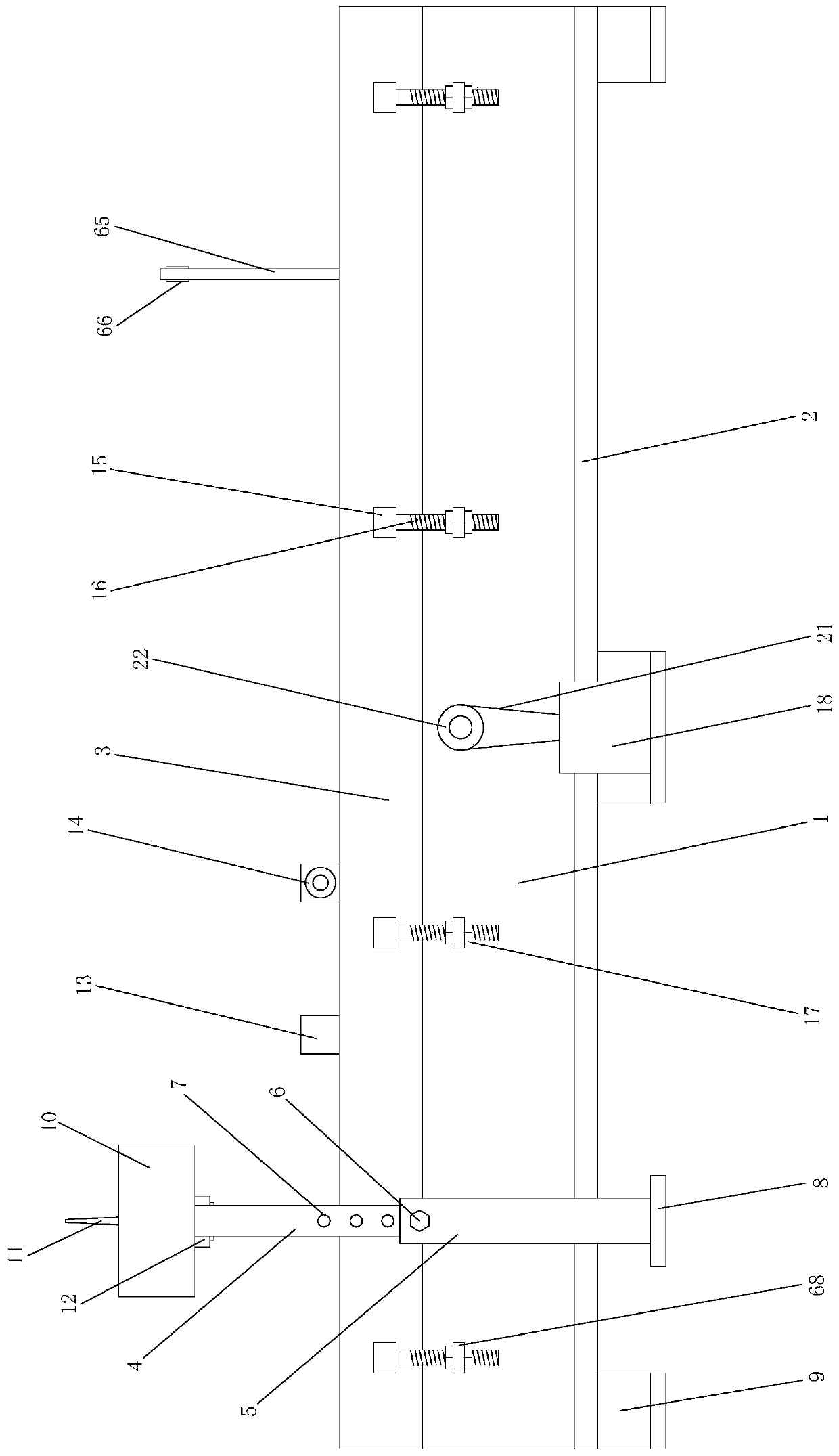

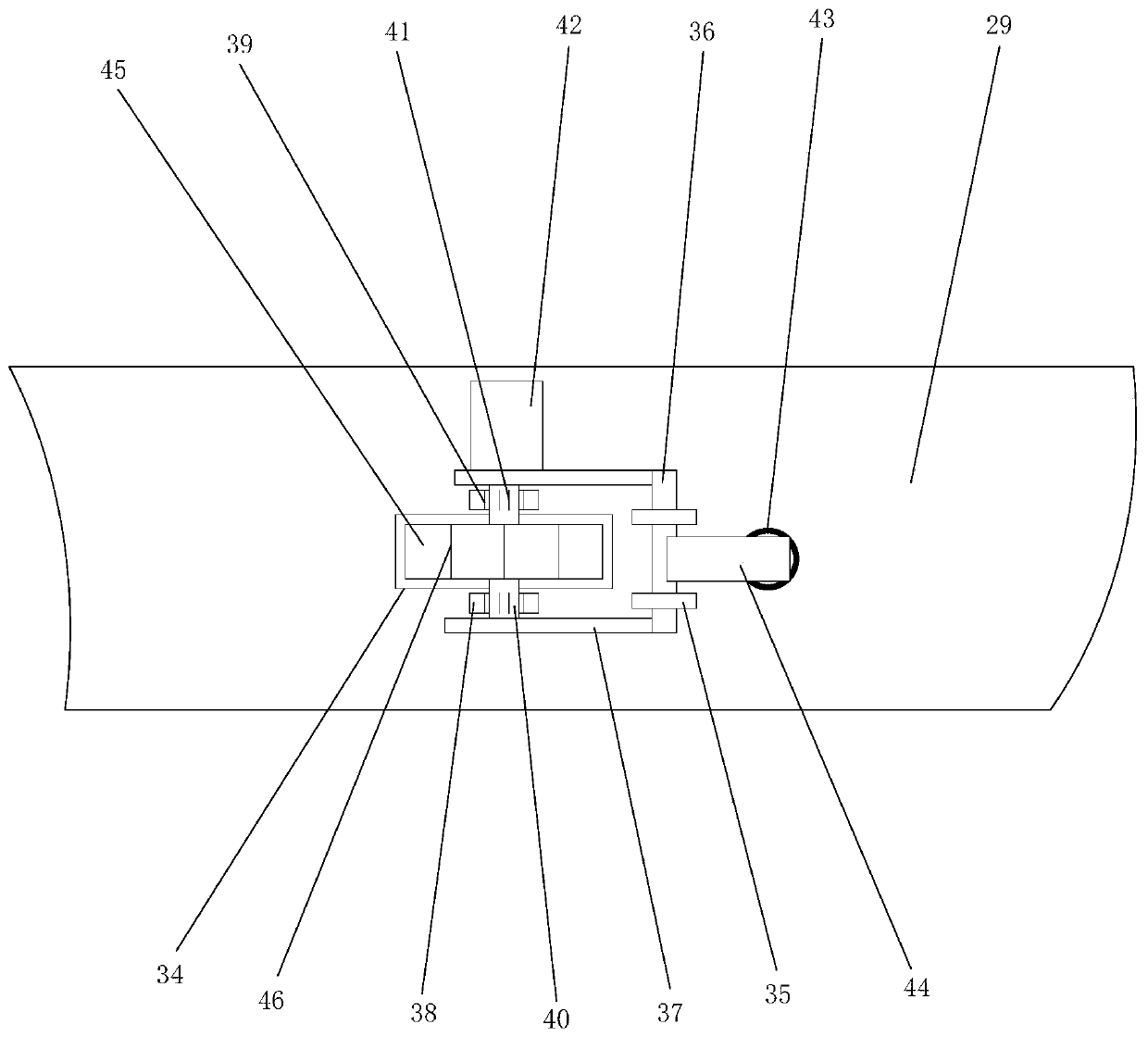

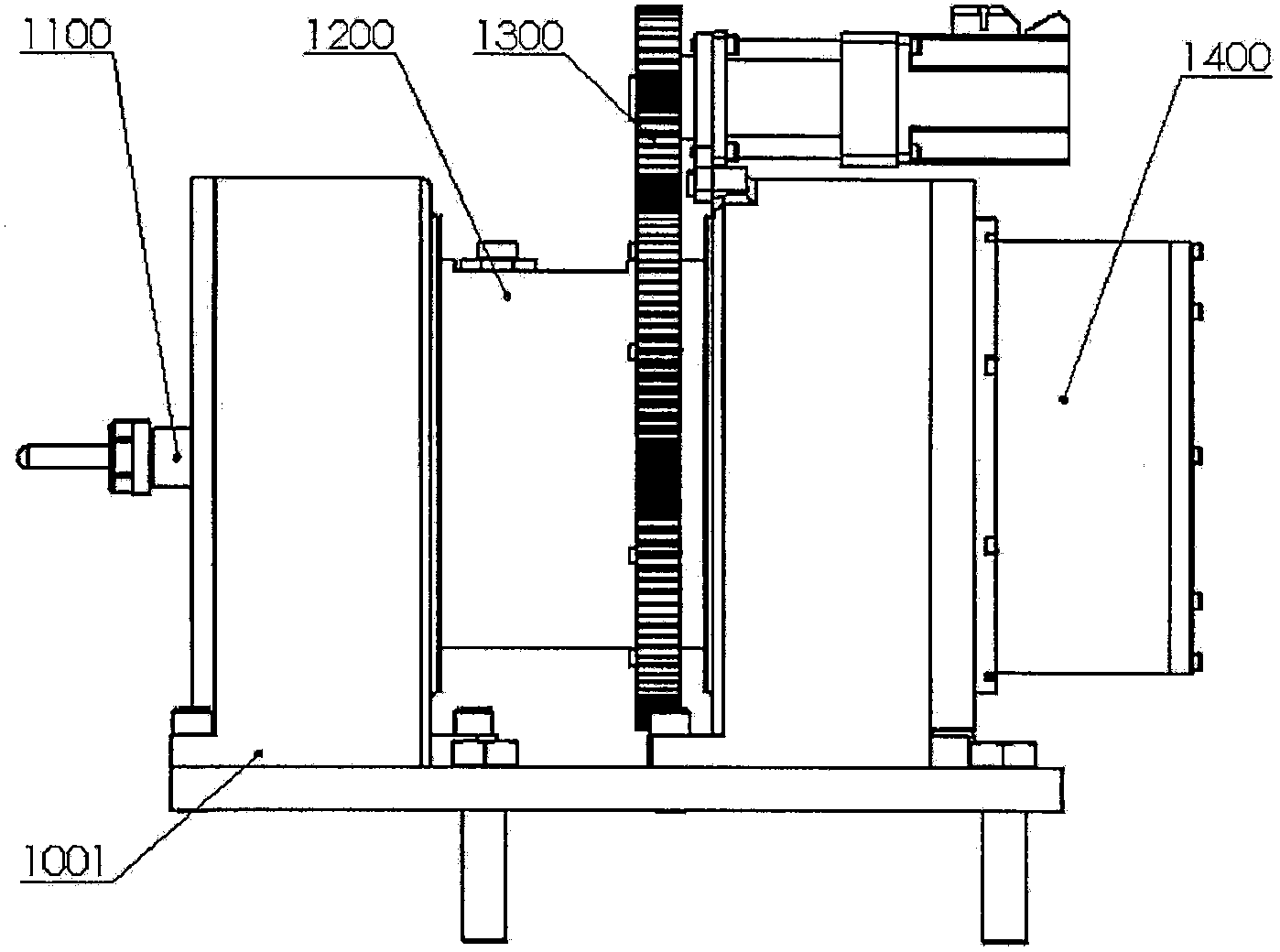

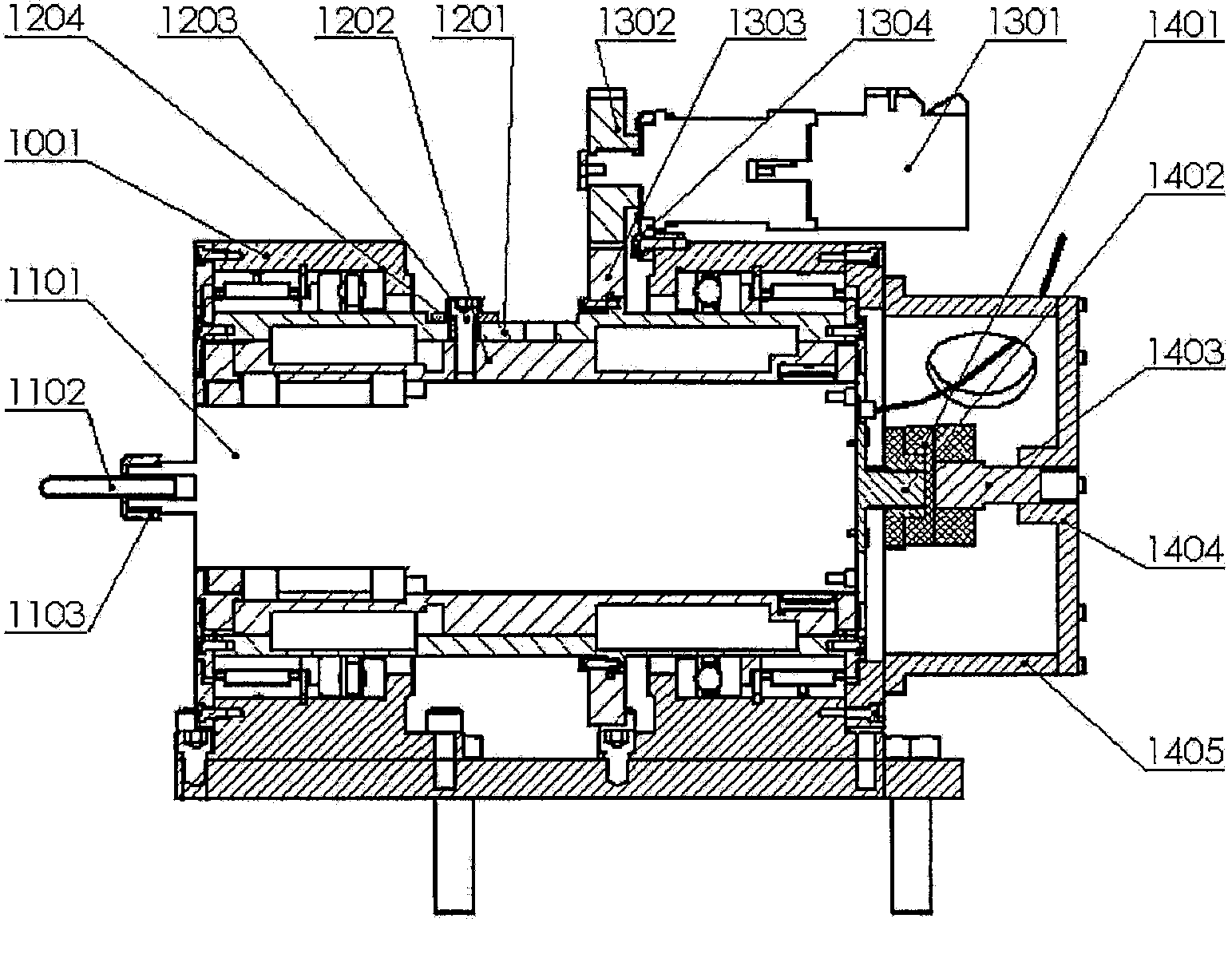

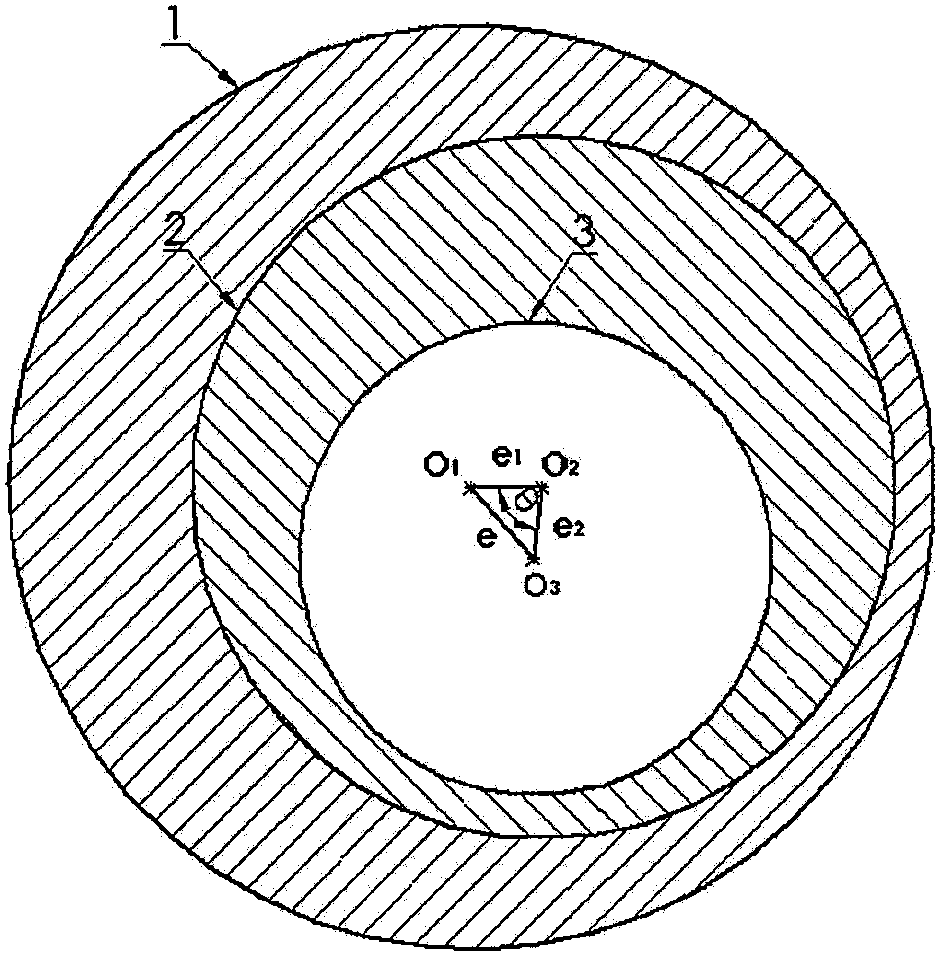

Hole helical milling device

ActiveCN102689040AImprove hole making efficiencyReduce processing costsMilling machinesNumerical controlMilling cutter

The invention provides a hole helical milling device, which comprises a frame, a main shaft system, a deviation regulating mechanism, a revolution system and an anti-winding mechanism. The main shaft system includes an electric main shaft and a milling cutter fixed to the free end of the electric main shaft, and the electric main shaft drives the miller cutter to rotate. The deviation regulating mechanism includes an inner cylinder and an outer cylinder, the inner cylinder surrounds the electric main shaft, the outer cylinder surrounds the inner cylinder, the inner circle and the outer circle of the outer cylinder are eccentrically arranged, and the inner circle and the outer circle of the inner cylinder are eccentrically arranged. The revolution system includes a driving motor, a pinion and a bull gear, the driving motor drives the pinion to drive the bull gear so as to realize revolution of the main shaft system, and an eccentric distance exists between the axial line of rotation of the milling cutter and the axial line of the revolution of the main shaft system. The device disclosed by the invention can be mounted on a mechanical arm, realizes accurate positioning of hole center and axial milling feeding by CNC (computer numerical control) during hole formation, is suitable for work occasions where a large number of series hole-diameter hole structures are rapidly manufactured.

Owner:SHANGHAI AIRCRAFT MFG +1

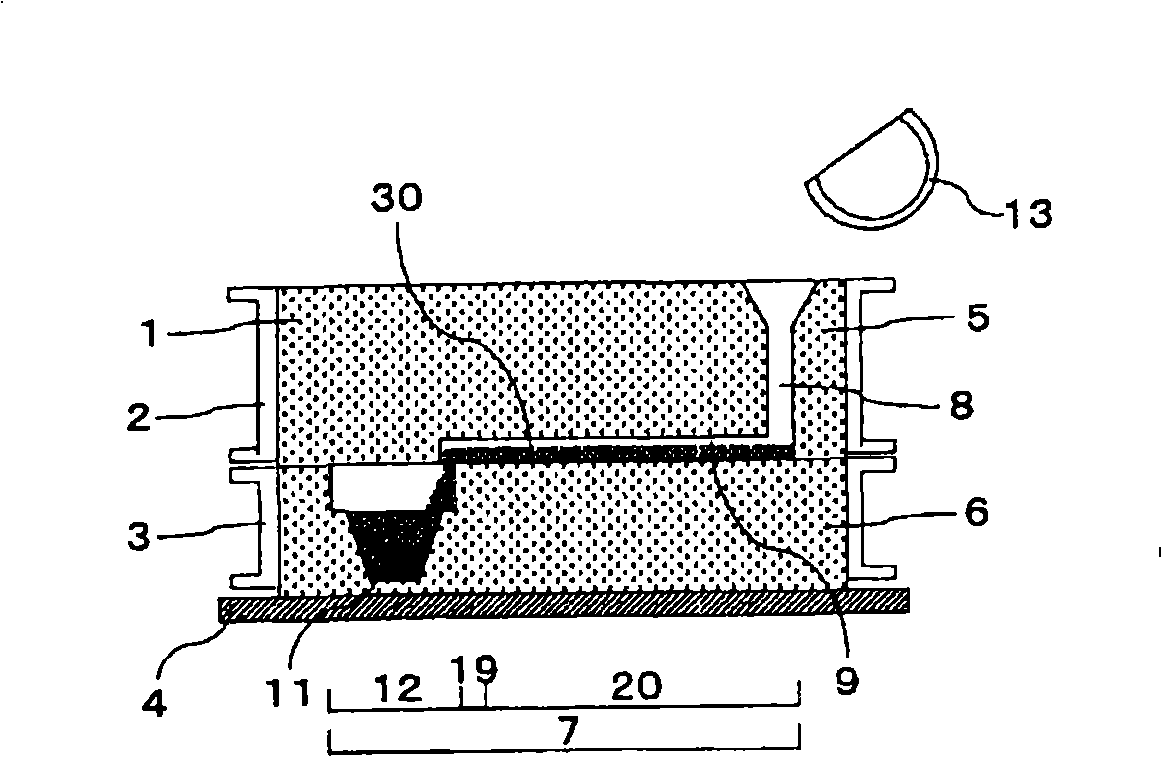

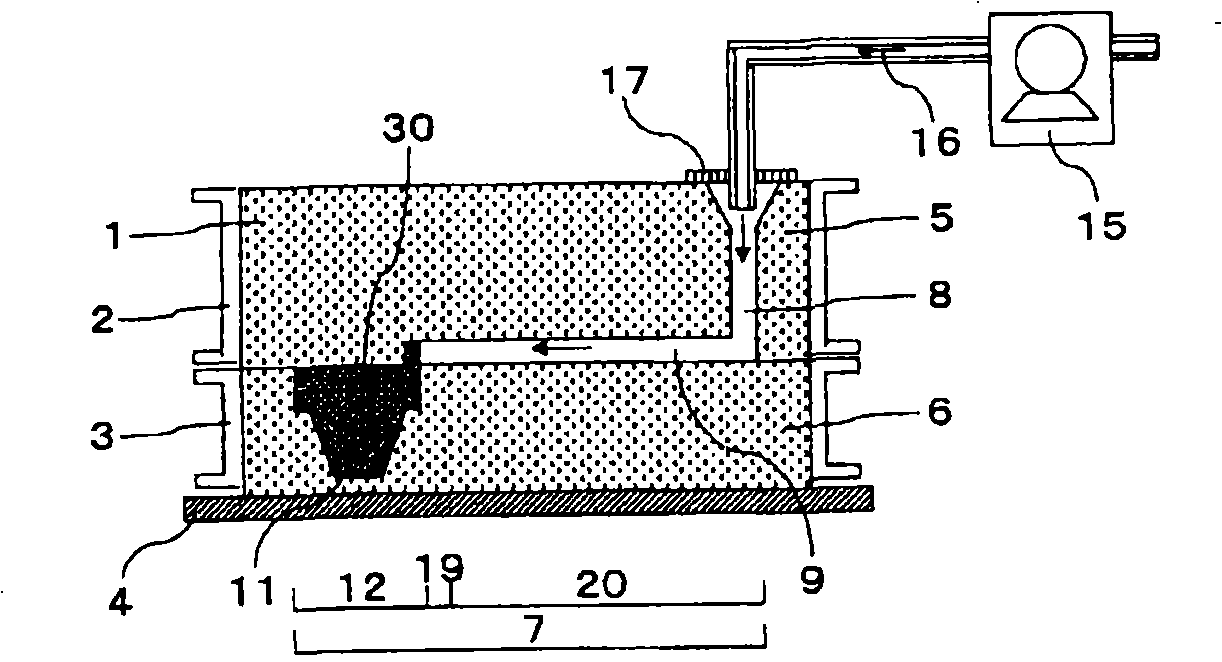

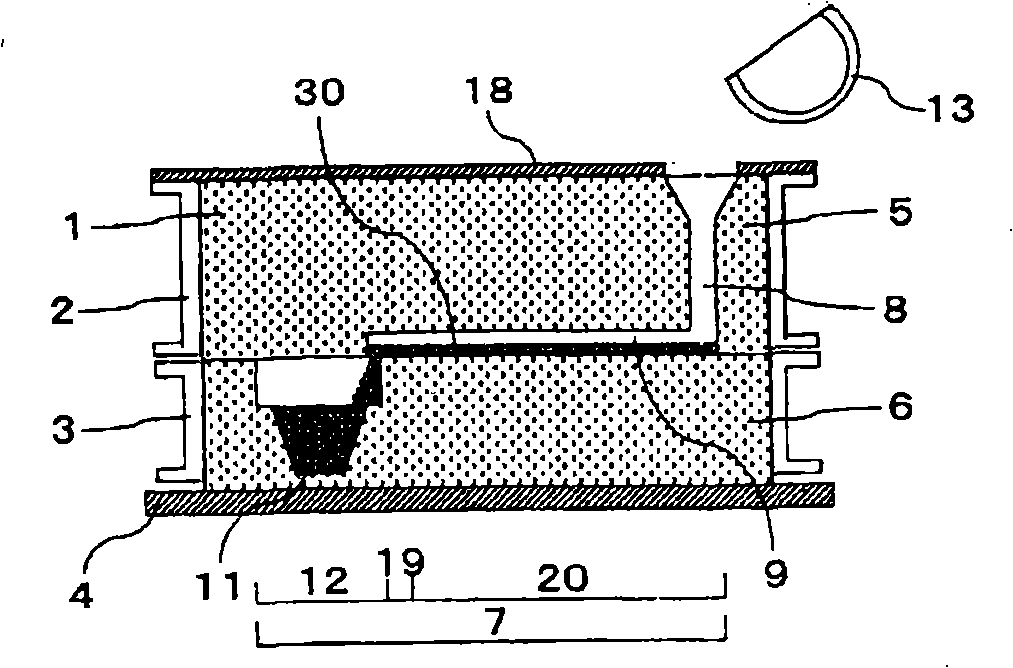

Casting method

InactiveCN101262968APouring pass rate is lowPouring pass rate increasedFoundry mouldsFoundry coresCasting moldCastner process

To provide a casting method based on gravity casting with an air-permeable mold, wherein a melt is charged into only a desired part of the mold cavity and solidified. [MEANS FOR SOLVING PROBLEMS] A melt in a volume approximately equal to the volume of a cavity part which is desired to be filled with the melt is poured. Thereafter, a compressed gas is supplied through the melt-inlet part to fill the desired cavity part with the melt. The melt is then solidified. According to need, the cavity is evacuated before and after the casting.

Owner:五家 政人

Water-based coating for lost foam cast steel

InactiveCN101569919AAvoid crackingSolve the problem of surface microporosityFoundry mouldsFoundry coresWater basedSodium Bentonite

The invention belongs to the technical field of coating compositions for lost foam, is applicable to forming EPS foam pattern coatings of lost foam steel castings, and particularly discloses a water-based coating for lost foam cast steel. The water-based coating for the lost foam cast steel comprises the following components (calculated as the weight): 100 portions of quartz powder, 2 to 3 portions of lithium bentonite, 1 to 2 portions of white latex, 1 to 1.2 portions of sodium carboxymethyl cellulose, 2 to 3 portions of water soluble phenolic resin, 0.1 to 0.15 portion of aluminum powder, 0.08 portion of glass fiber, 0.02 to 0.03 portion of active agent, and 0.02 to 0.03 portion of defoaming agent. The coating ensures that the surface quality of castings is improved, meets the technical requirement of the castings, saves subsequent treatment procedures, improves production efficiency, improves the working environment of laborers, more importantly, eliminates the potential safety hazard during the subsequent use, and also improves the economic benefit of enterprises.

Owner:山东醴泉机械科技有限公司

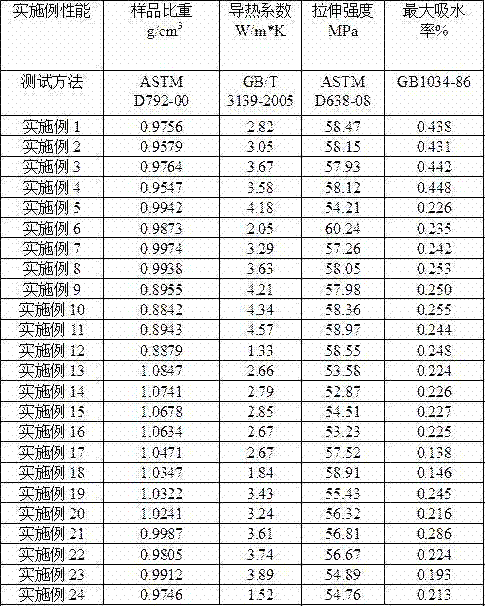

Thermoplastic polymer matrix heat conduction composite material, and preparation method and application thereof

The invention discloses a thermoplastic polymer matrix heat conduction composite material, and a preparation method and an application thereof. The heat conduction composite material contains a matrix and a filler filled in the matrix, the matrix is a thermoplastic polymer, the filler is modified hollow glass microspheres, and the modified hollow glass microspheres are hollow glass microspheres with the surface coated with heat conduction powder, obtained after the modification treatment of the surface by the heat conduction powder. The adoption of a thermoplastic plastic as the matrix realizes the good dispersion of the heat conduction powder and guarantees the processing performances of the material; and the adoption of the reasonable matching of the modified hollow glass microspheres and the heat conduction powder makes the material have the advantages of light weight, corrosion resistance, high heat conduction efficiency, good mechanical properties, easy machine shaping, no pollution, low cost, high precision, long life, good electric insulation and the like, so the material can be used in electronic and electric appliance product radiating fins, LED light fixture heat radiation pedestals, bearing heat radiation layers, and other fields having high heat conduction requirements.

Owner:SUZHOU XINENG ENVIRONMENTAL SCI & TECH CO LTD

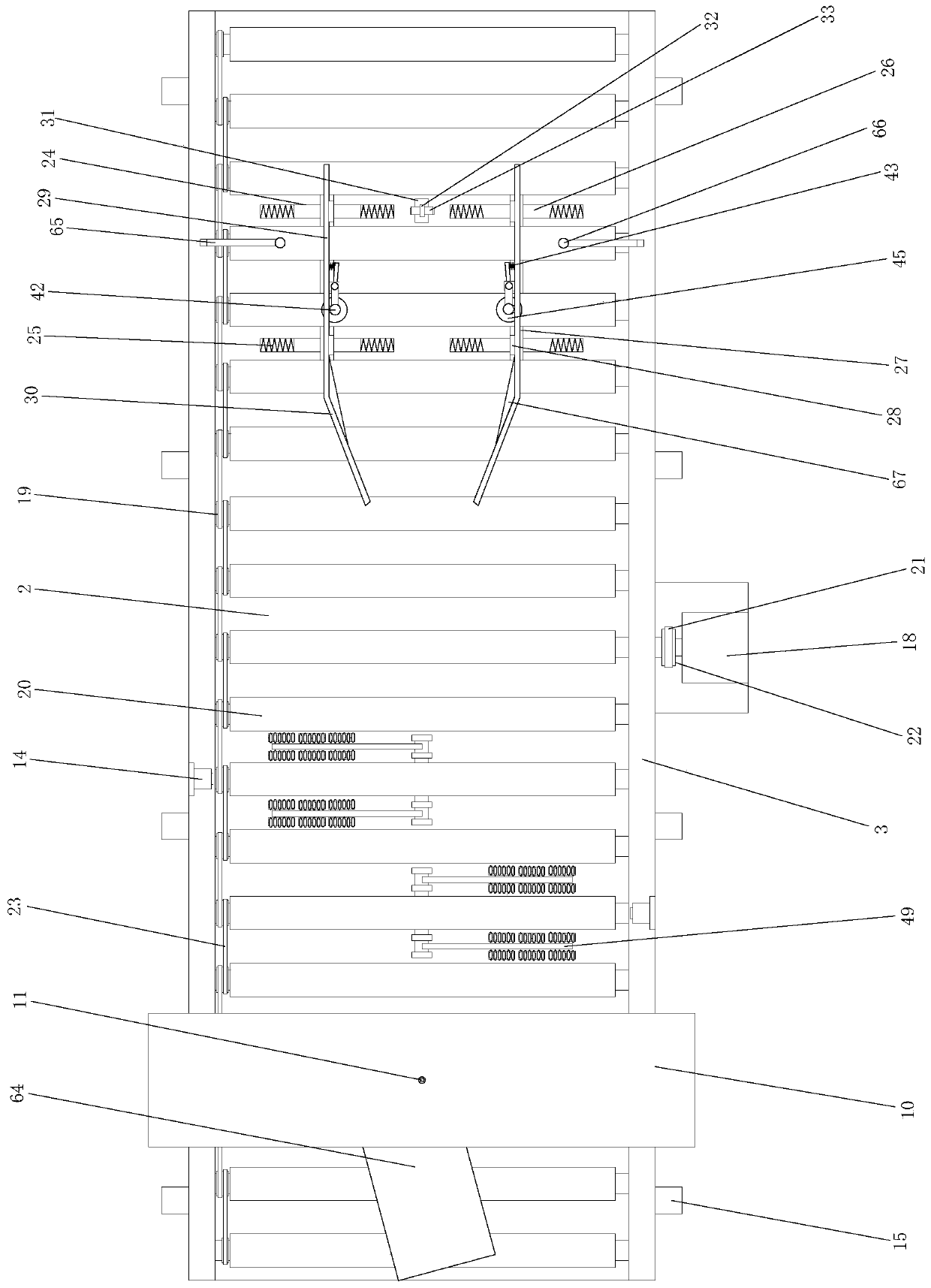

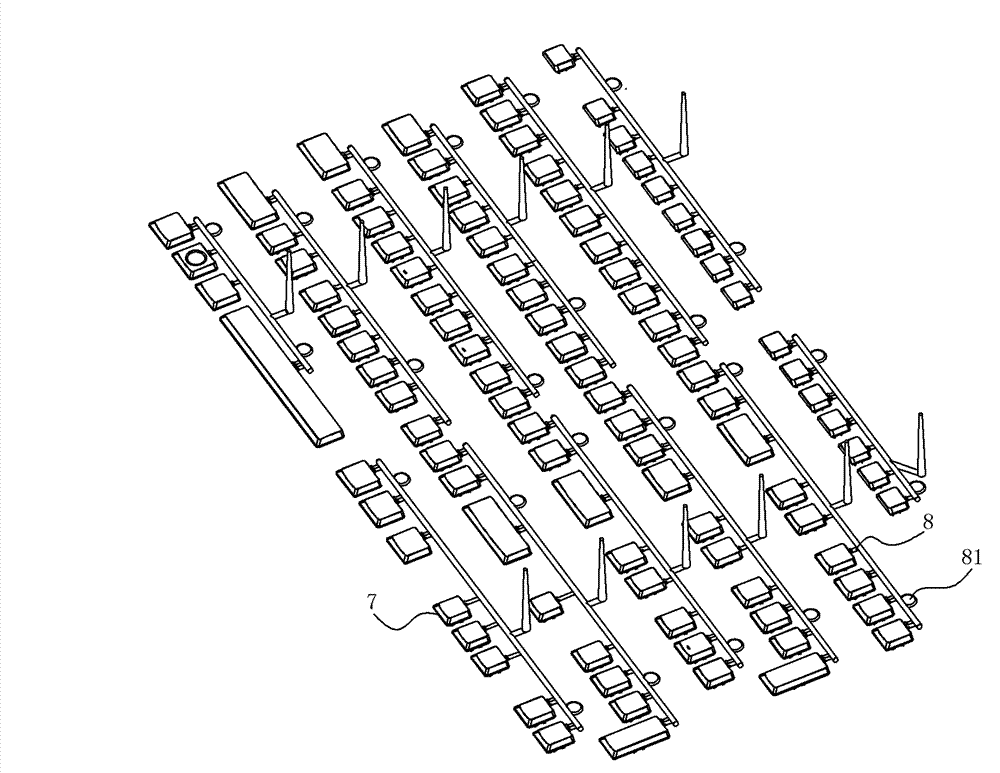

Product identification device on conveying line

ActiveCN110523649AImprove distributionEasy to divide left and rightSortingSize measurementEngineering

The invention provides a product identification device on a conveying line. The product identification device comprises a conveying roller bed, an image identification mechanism, a product allocatingmechanism and size measurement mechanisms, the image recognition mechanism comprises a control box body, a recognition mounting bracket and an area array camera; the product allocating mechanism is mounted on the conveying roller bed and is used for carrying out left-right allocation on two types of packaged products on the conveying roller bed according to an identification result of the image identification mechanism; the size measurement mechanisms are installed on the left side and the right side of the conveying roller bed and used for measuring the sizes of packaged products conveyed onthe left side and the right side of the conveying roller bed. According to the product recognition device on the conveying line, specification recognition is conducted on packaged products conveyed onthe supporting rollers through the image recognition mechanism; therefore, the product allocating mechanism can conveniently allocate packaged products of two specifications leftwards and rightwards,allocating is conducted in the transportation process at the same time, subsequent independent identifying and allocating are not needed, subsequent processes are reduced, and the working efficiencyis effectively improved.

Owner:苏州南师大科技园投资管理有限公司 +1

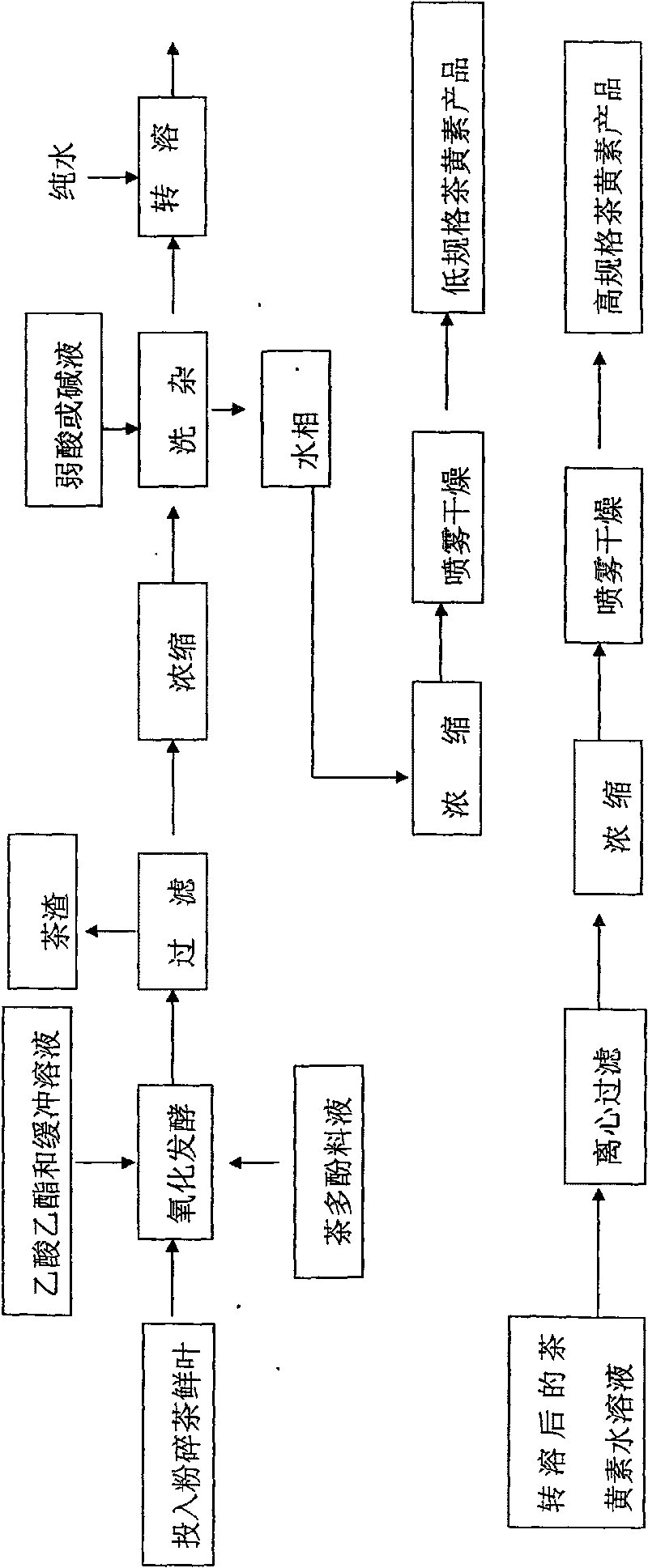

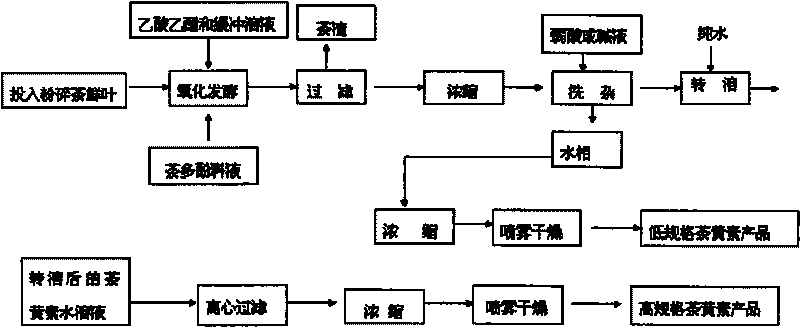

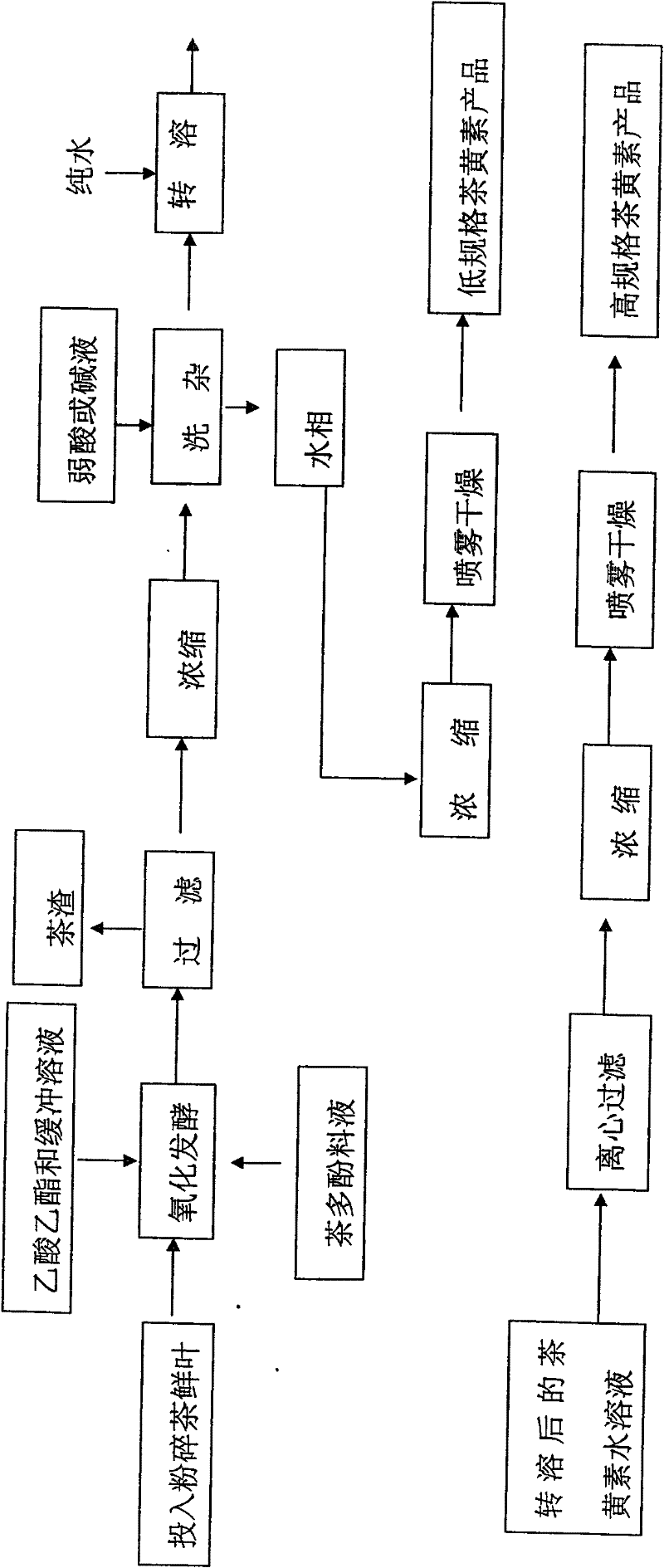

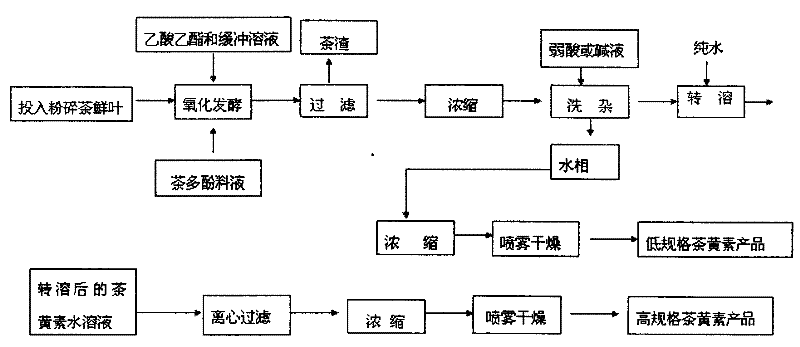

Industrial preparation method of theaflavin

InactiveCN101691591AReduce generationEnsure gentlenessOrganic chemistryFermentationAcetic acidTheaflavin

The invention relates to an industrial preparation method of theaflavin, which comprises the following steps: (1) preparing an ethyl acetate solution containing rich tea polyphenol; (2) respectively adding pulverized fresh tea leaves and the ethyl acetate solution into a oxidation-fermentation tank, orderly adding ethyl acetate and a buffering solution, introducing air at normal temperature, and stirring, oxidizing and fermenting to obtain the theaflavin ester-phase solution; (3) filtering the theaflavin ester-phase solution, concentrating and washing to remove impurities; (4) concentrating the water-phase solution, and spray-drying to obtain low-specification dry theaflavin powder; (5) concentrating the ester-phase solution to recycle ethyl acetate, and adding water so that the theaflavin is dissolved in the water; (6) centrifugally filtering the theaflavin water solution to obtain a pure theaflavin solution; (7) and concentrating the theaflavin solution, and spray-drying to obtain the dry theaflavin powder. The method of the invention simultaneously enhances the yield and the quality of the theaflavin, saves the energy and the man hours and reduces the emission of waste water.

Owner:ZHEJIANG PAINUO BIO TECH

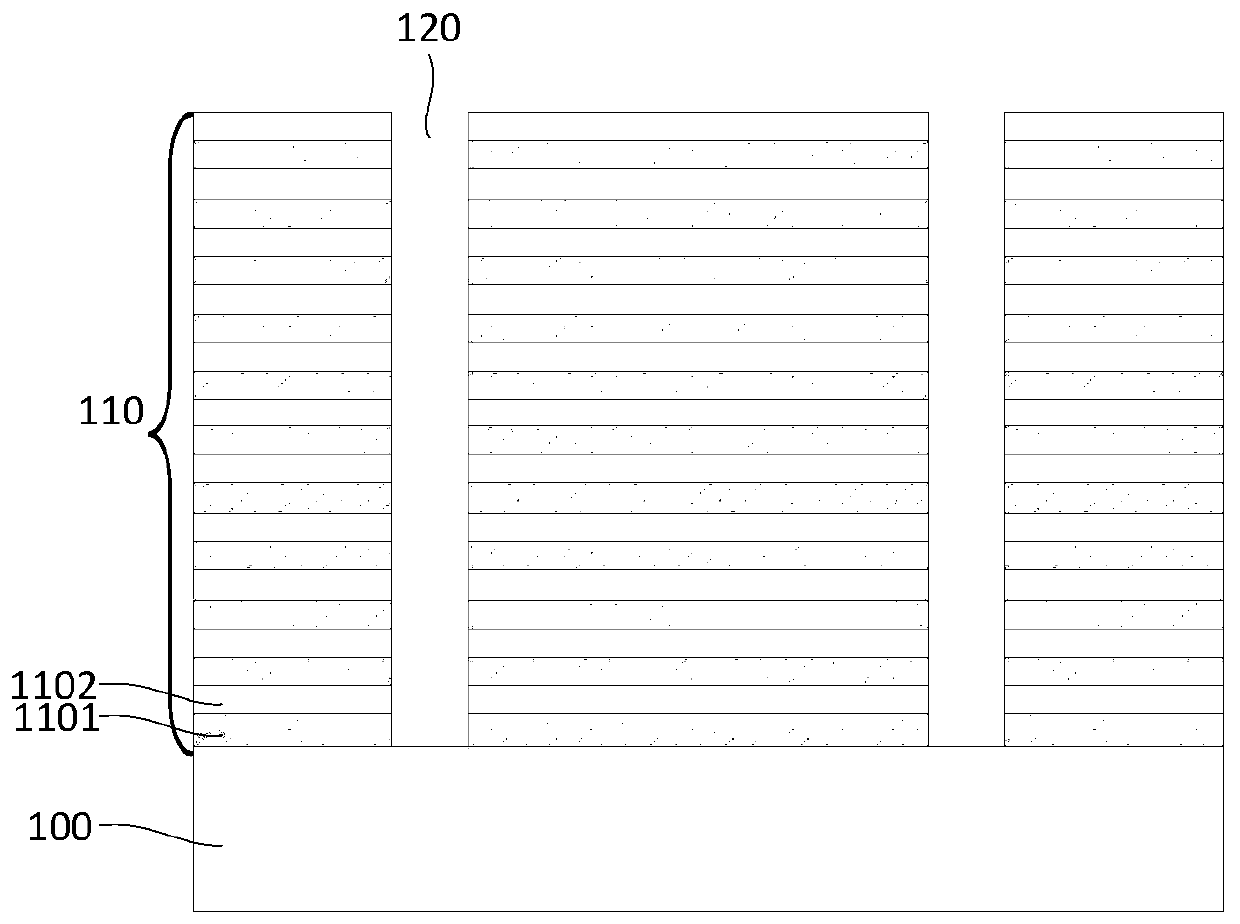

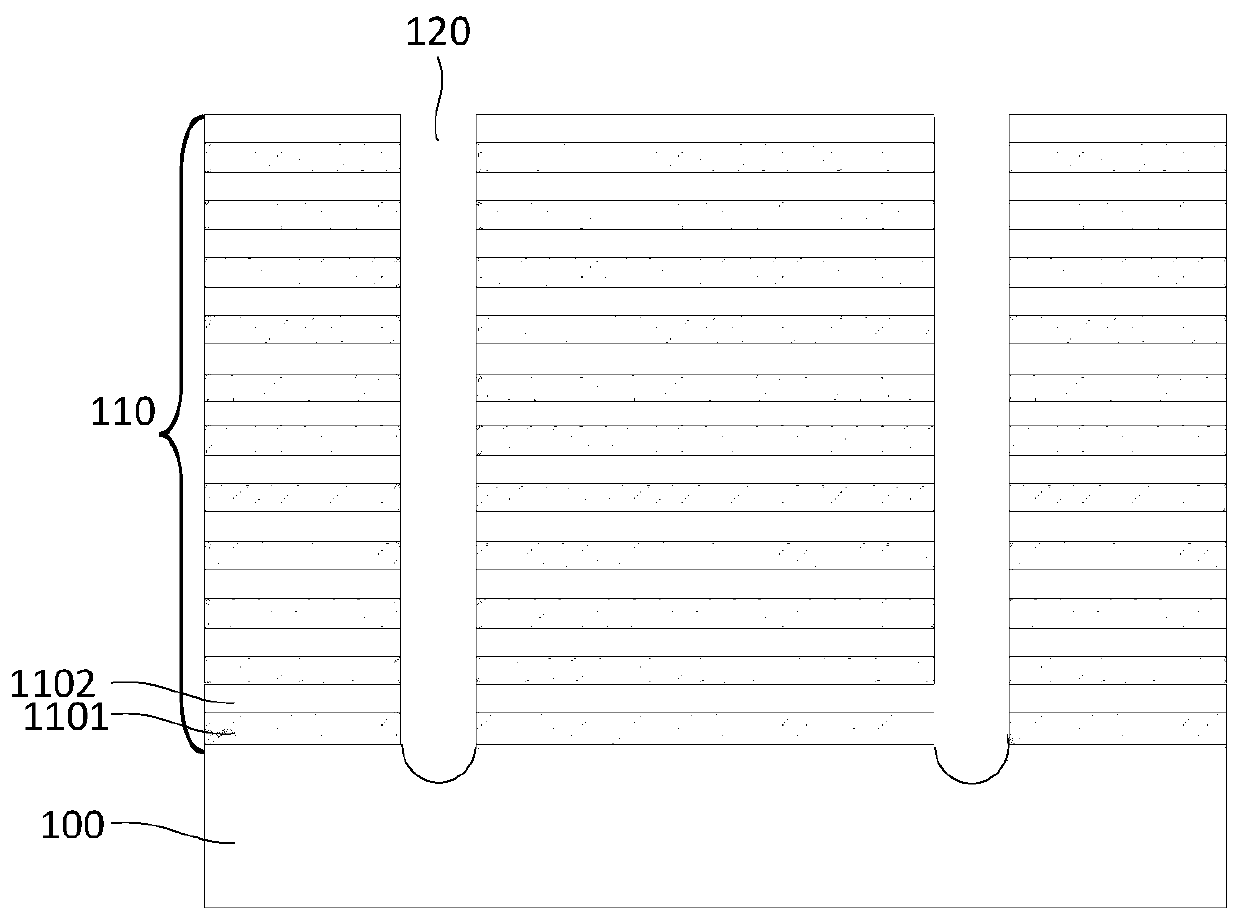

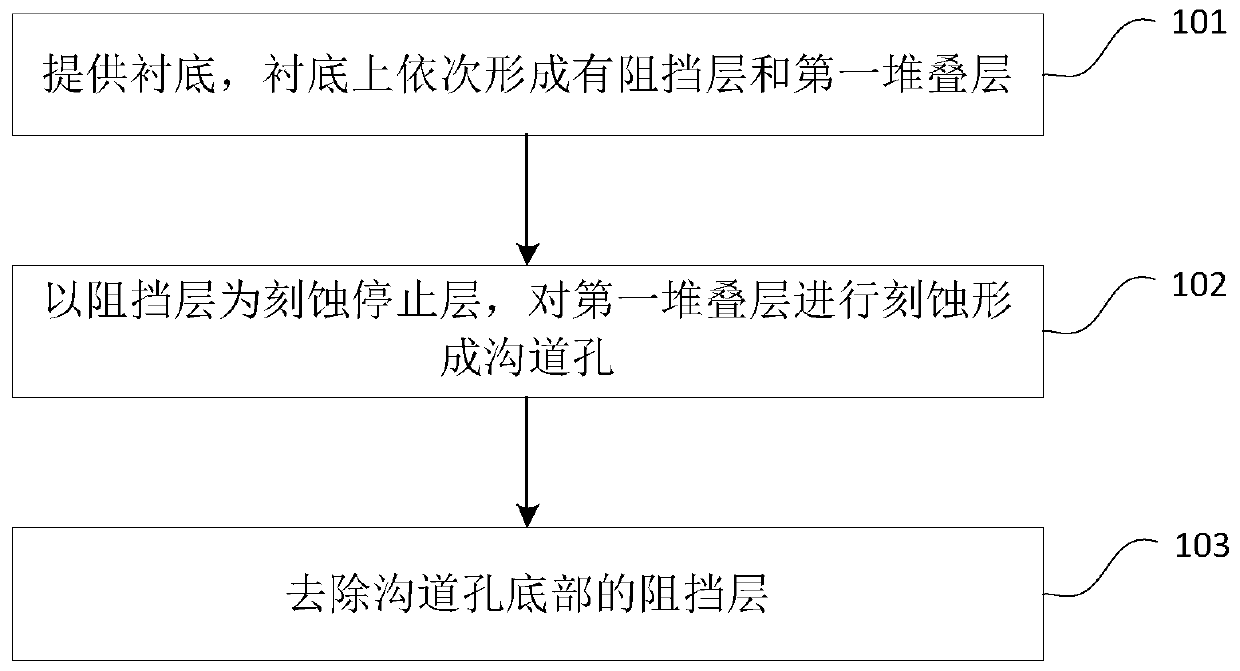

3D NAND memory device and manufacturing method thereof

InactiveCN110034124AImprove performanceSubstrate damageSolid-state devicesSemiconductor devicesEngineering

The invention provides a 3D NAND memory device and a manufacturing method thereof. A substrate is provided firstly; a barrier layer and a first stacking layer are sequentially formed on the substrate,wherein the first stacking layer is formed by alternately laminating an insulating layer and a sacrificial layer; the barrier layer is used as an etching stop layer; the first stacking layer is etched to form a channel hole; and the barrier layer at the bottom of the channel hole is removed, and etching of the channel hole is completed. In the embodiments of the invention, during the etching process of the first stacking layer, the barrier layer protects the substrate, so that after the barrier layer is removed, the substrate is not damaged, and therefore the subsequent processes are reduced,and the performance of the device is improved.

Owner:YANGTZE MEMORY TECH CO LTD

High-precision high-speed glass rotary disc visual inspection machine

InactiveCN110538805AOptimize working proceduresEfficient and high speedSortingVisual inspectionEngineering

The invention relates to the technical field of visual inspection, in particular to a high-precision high-speed glass rotary disc visual inspection machine. An industrial personal computer is installed in a machine cabinet, and a sensor, first to sixth visual inspection cameras and a discharging mechanism are all in signal connection with the industrial personal computer; and an arraying and feeding mechanism automatically arrays materials and evenly feeds the materials, a rotary disc rotates at the uniform speed, the sensor is triggered when each material passes through the sensor, the sensortransmits signals to the industrial personal computer, the industrial personal computer starts to calculate time nodes when the materials pass through all inspection cameras and time nodes when the materials reach the discharging mechanism and issues instructions to make all inspection cameras to shoot the materials at the corresponding time nodes, each inspection camera feeds back image data tothe industrial personal computer after shooting, the industrial personal computer counts the material states, the materials are blown into corresponding material boxes when reaching the discharging device according to the different states, and the efficiency is improved.

Owner:广东西尼科技有限公司

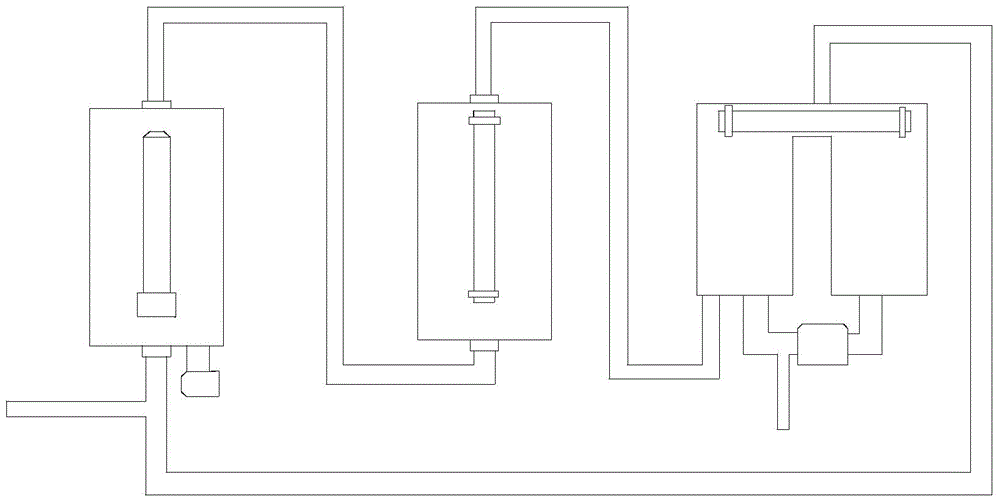

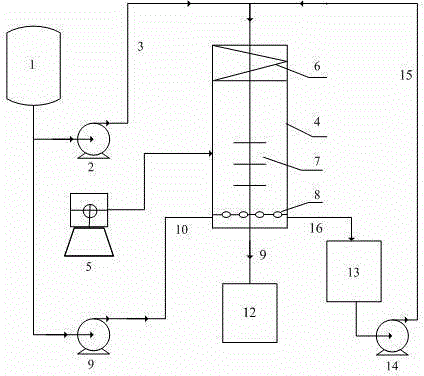

Process and device for circulating multi-dimensional catalyzing advanced oxidation treatment of oily wastewater

InactiveCN105366836AReduce usageThoroughly oxidizedMultistage water/sewage treatmentWater/sewage treatment by oxidationPtru catalystAdvanced oxidation process

The invention relates to the field of wastewater treatment, in particular to a process and device for circulating multi-dimensional catalyzing advanced oxidation treatment of oily wastewater, and particularly discloses a process for treating the oily wastewater. The process comprises the following steps that the oily wastewater is treated through ultrasonic waves and an oxidizing agent, and most of degradation-resistant micromolecules and easily- degradable long-chain and endless chain macromolecule matter in the wastewater are removed; treatment time ranges from 5 min to 10 min; the treated oily wastewater is treated through ultraviolet light and ozone, and part of easily degradable organic matter and a small part of degradation-resistant micromolecules in the oily wastewater are removed; treatment time ranges from 6 min to 8 min; the treated oily wastewater is treated through ultraviolet light, ozone and a catalyst, and a large amount of organic matter is degraded; treatment time ranges from 9 min to 12 min. The device for circulating treatment of the oily wastewater is further provided. Three advanced oxidation processes are combined, the micromolecule matter influencing hydroxyl radical in the oily wastewater is oxidized and removed, a large amount of hydroxyl radical is generated, and high-concentration organic matter can be thoroughly oxidized.

Owner:JIUPEI SUZHOU ENVIRONMENTAL PROTECTION TECH CO LTD

Method for growing bismuth silicate (BSO) scintillation crystal by shaping and lifting

InactiveCN102002754AReduce subsequent processesReduce manufacturing costPolycrystalline material growthBy pulling from meltSeed crystalSingle crystal growth

The invention discloses a method for growing a bismuth silicate (BSO short for Bi4Si3O12) scintillation crystal by shaping and lifting, belonging to the field of single crystal growth. The invention is characterized in that a mold in a specific shape is designed and installed in a crucible, and a shaping and lifting furnace is used for growing the BSO scintillation crystal. The method comprises the following steps: pre-burning Bi2O3 and SiO2 at high temperature to obtain a BSO polycrystalline raw material; putting the BSO polycrystalline raw material into the crucible with the mold in the specific shape, and putting the crucible into the shaping and lifting furnace; continuously heating to 1100-1200 DEG C, and keeping the constant temperature for 3-5h; and then, putting and quickly lifting a seed crystal, and growing to obtain a platy BSO crystal. By using the method of the invention, the purposes of quickly growing a high-quality platy BSO scintillation crystal, shortening the crystal growth cycle, simultaneously reducing the subsequent crystal manufacturing processes, improving the crystal utilization ratio, and effectively saving the production cost can be achieved.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

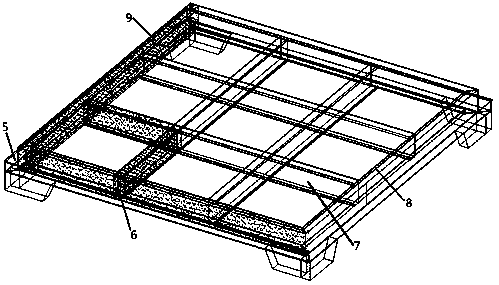

Cold-pressing pallet production process of chromium fine ore

InactiveCN103468943AReduce moisture contentReduce subsequent processesMaterial distributionFerrochrome

The invention discloses a cold-pressing pallet production process of a chromium fine ore. The production process includes the following steps that 1) raw materials are pre-homogenized, and by weight, 75-95 parts of chromium fine ore with the grain size less than or equal to 5mm, 1-5 parts of quicklime and 10-14 parts of dedusting powder are mixed uniformly to be processed; 2) by weight, 90-99 parts of the raw materials, 1-5 parts of agglomerant and 0.5-5 parts of solid additive in the raw materials after being pre-homogenized are sufficiently mixed to form mixtures; 3) cold-pressing palletizing is carried out on the mixtures to form pallets; 4) the pallets are taken out and naturally aired to form finished product pallets, or the pallets are conveyed into drying equipment to become the finished product pallets. The chromium fine ore, layered material distribution and pre-homogenization are carried out on the quicklime and the dedusting powder which are needed in high carbon ferrochrome production through a loader, the quicklime absorbs moisture in the chromium fine ore, so the moisture content of the fine ore is reduced, and a needed moisture content range for the finished product pallets is obtained.

Owner:CITIC DAMENG QINZHOU NEW MATERIALS

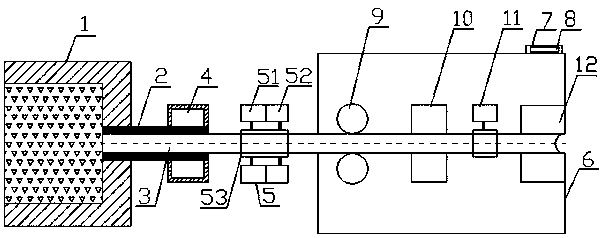

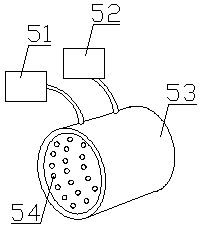

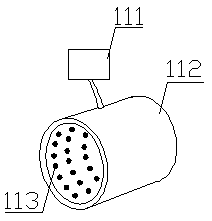

Novel copper bar drawing casting process and equipment

The invention discloses a novel copper bar drawing casting process and equipment. The technical method specifically comprises the following steps: (a) smelting: extruding molten liquid in a heat preservation furnace by an extruder into a graphite sleeve for forming; (b) condensation: condensing a copper bar initially formed in the step a through a water-cooled crystallizer; and (c) cooling: cooling the copper bar condensed in the step b through a cooling device, blowing out cold air by a cold air machine, uniformly spraying the cold air onto the copper bar through spraying holes in the inner wall of an annular sleeve, then blowing out air at normal temperature through a fan, and uniformly spraying the air onto the copper bar through the spraying holes in the inner wall of the annular sleeve to gradually cool the copper bar. The cooling effect is good, and the product quality is high. By procedures of smelting, twice cooling, drawing, drawing for stripping, cleaning and discharging, thenumber of subsequence procedures can be reduced, and the labor cost is reduced; furthermore, an all-in-one machine is controlled by a PLC (Programmable Logic Controller), so that the automation degree is high; and the produced copper bar product is stable in quality, clean, attractive and relatively high in quality.

Owner:三花股份(江西)自控元器件有限公司

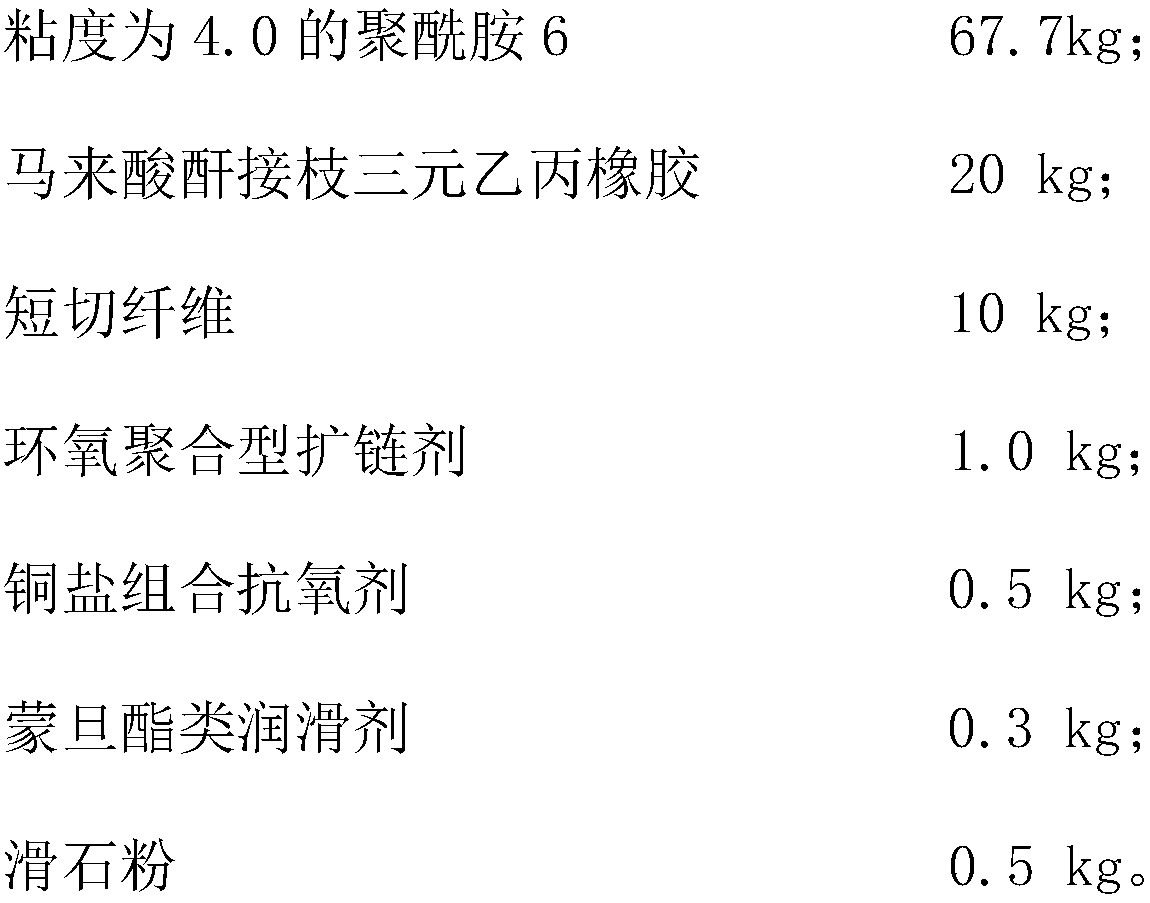

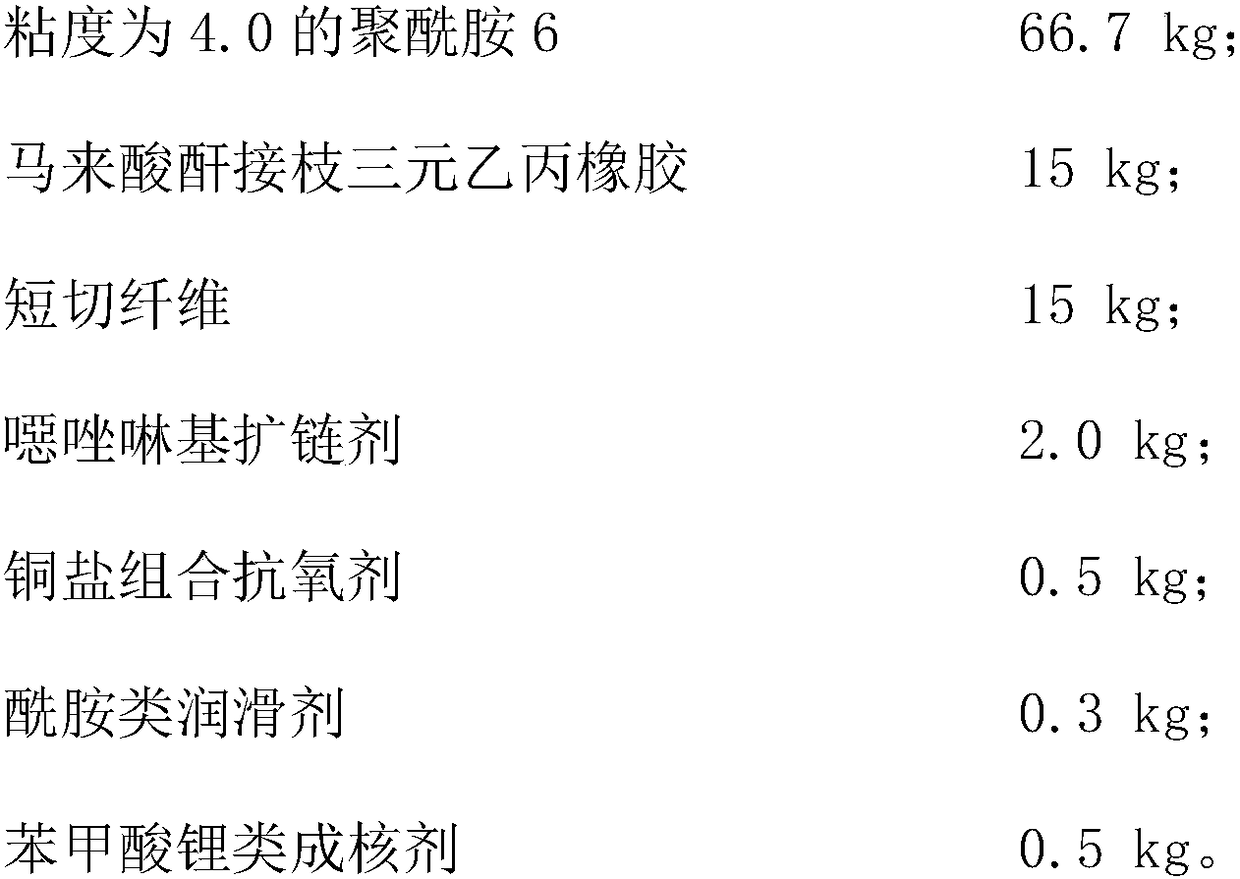

Automotive pipeline three-dimensional blow molding glass fiber reinforced polyamide 6 composition and preparation method thereof

The invention provides an automotive pipeline three-dimensional blow molding glass fiber reinforced polyamide 6 composition and a preparation method thereof. The automotive pipeline three-dimensionalblow molding glass fiber reinforced polyamide 6 composition comprises the following components in parts by weight: 25-83 parts of high-viscosity polyamide 6, 5-20 parts of an impact modifier, 10-40 parts of chopped glass fibers, 1-10 parts of a chain extender and 1-5 parts of other promoters. The relative viscosity of the high-viscosity polyamide 6 in 98wt% of concentrated sulfuric acid at the temperature of 25 DEG C is 3.4-4.0. The automotive pipeline three-dimensional blow molding glass fiber reinforced polyamide 6 composition has high melt strength, high mechanical property, excellent ageing resistance and good three-dimensional blow molding performance.

Owner:TIANJIN KINGFA NEW MATERIAL

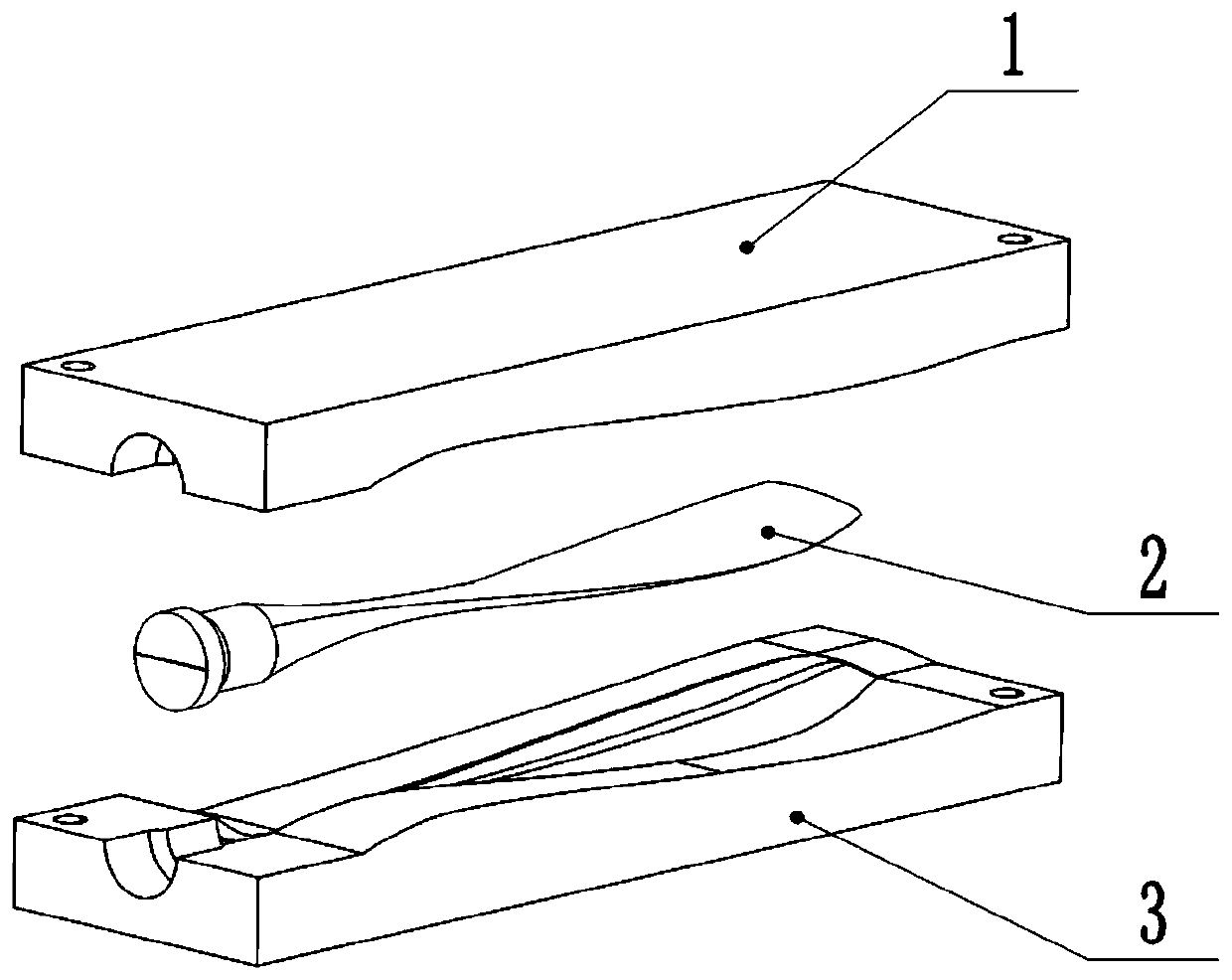

Manufacturing method of propeller blade

InactiveCN109849365AIncreased compressive and tensile strengthHigh strengthDomestic articlesNumerical controlFiber

The invention provides a manufacturing method of a propeller blade. The manufacturing method comprises the following steps of preparing a clamp core of the propeller blade by a numerical control machining method; wrapping the clamp core with fiber cloth impregnated with resin; vacuumizing and pressurizing the resin to cure the resin; and heating and curing to obtain the propeller blade. The preparation method is simple in process and low in cost, the obtained product is high in quality.

Owner:保定国奥新能源工程材料科技有限责任公司

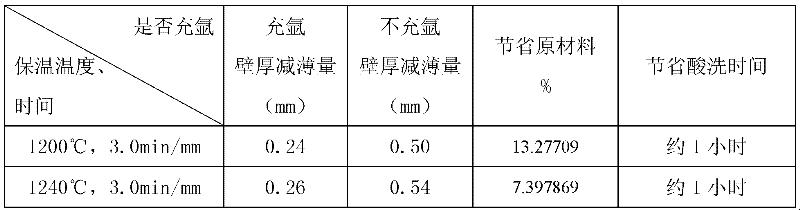

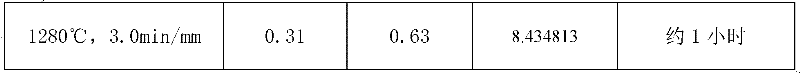

High-temperature solutionizing softening process for fine crystalline stainless steel pipe

InactiveCN102230064AReduce oxidationReduce wear and tearFurnace typesHeat treatment furnacesPower stationMetallurgy

The invention relates to a high-temperature softening process for fine crystalline stainless steel pipe for a supercritical power station unit. In the process, protective gas is filled into an inner cavity of the steel pipe in the high-temperature solutionizing process and the heat-preserving temperature and heat-preserving time are controlled; therefore, the oxidization of the internal surface of the steel pipe is reduced, the loss of materials is reduced, a subsequent process is reduced, and the work efficiency and yield rate are improved.

Owner:JIANGSU WUJIN STAINLESS STEEL PIPE GRP

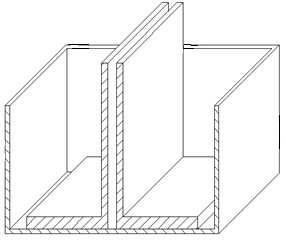

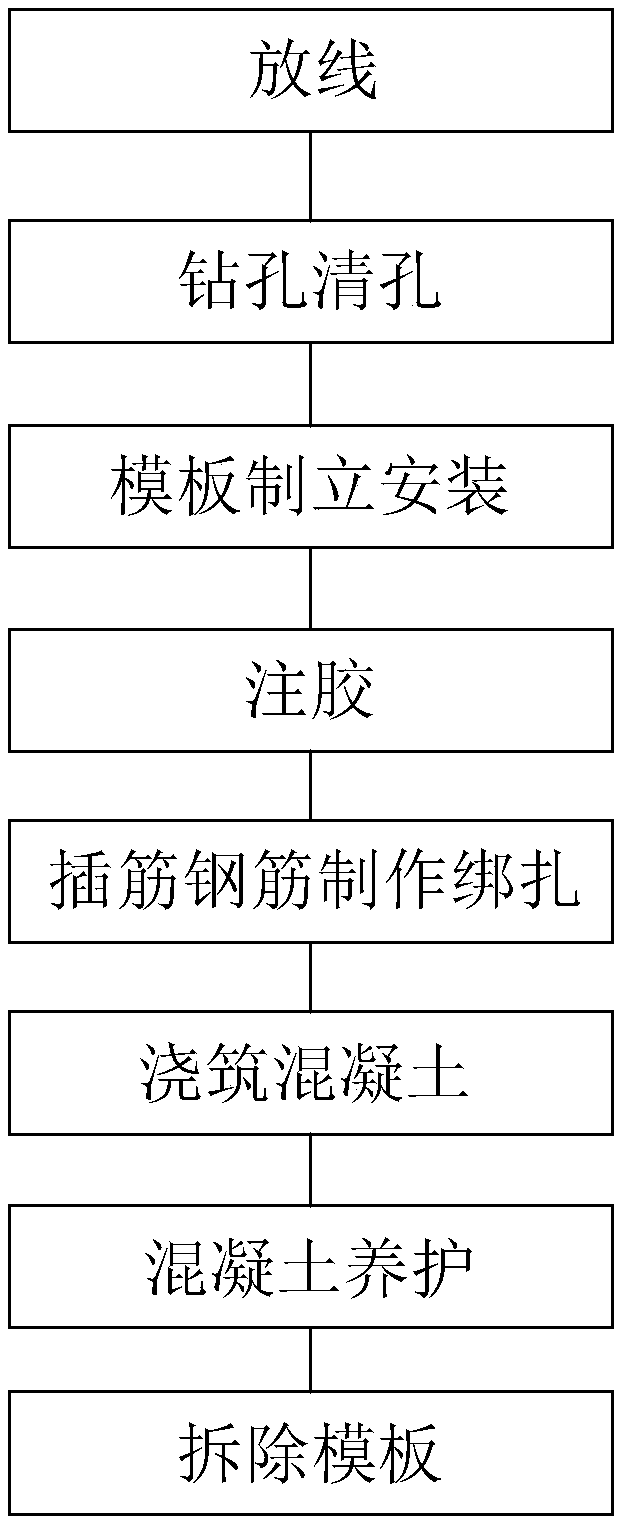

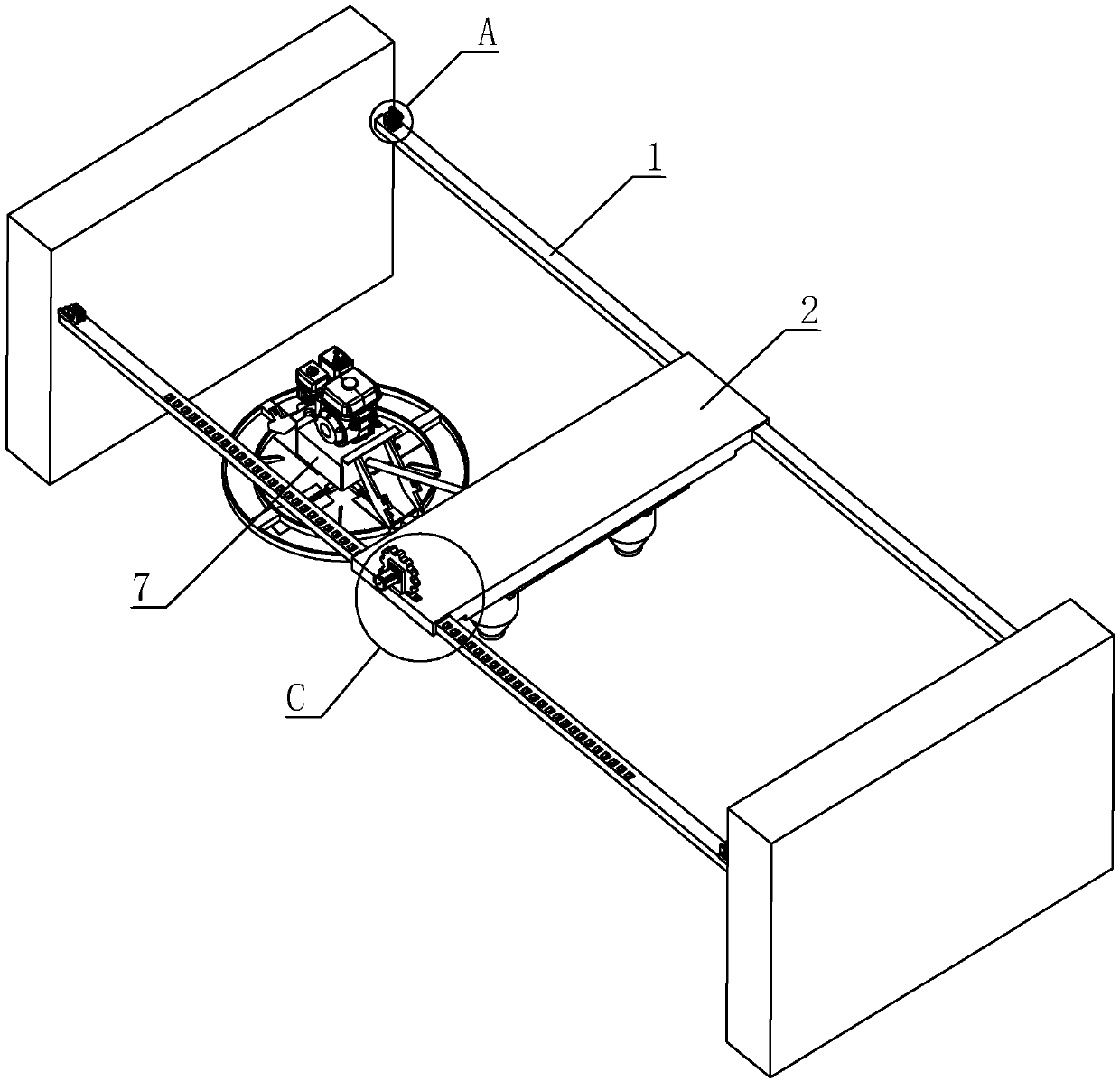

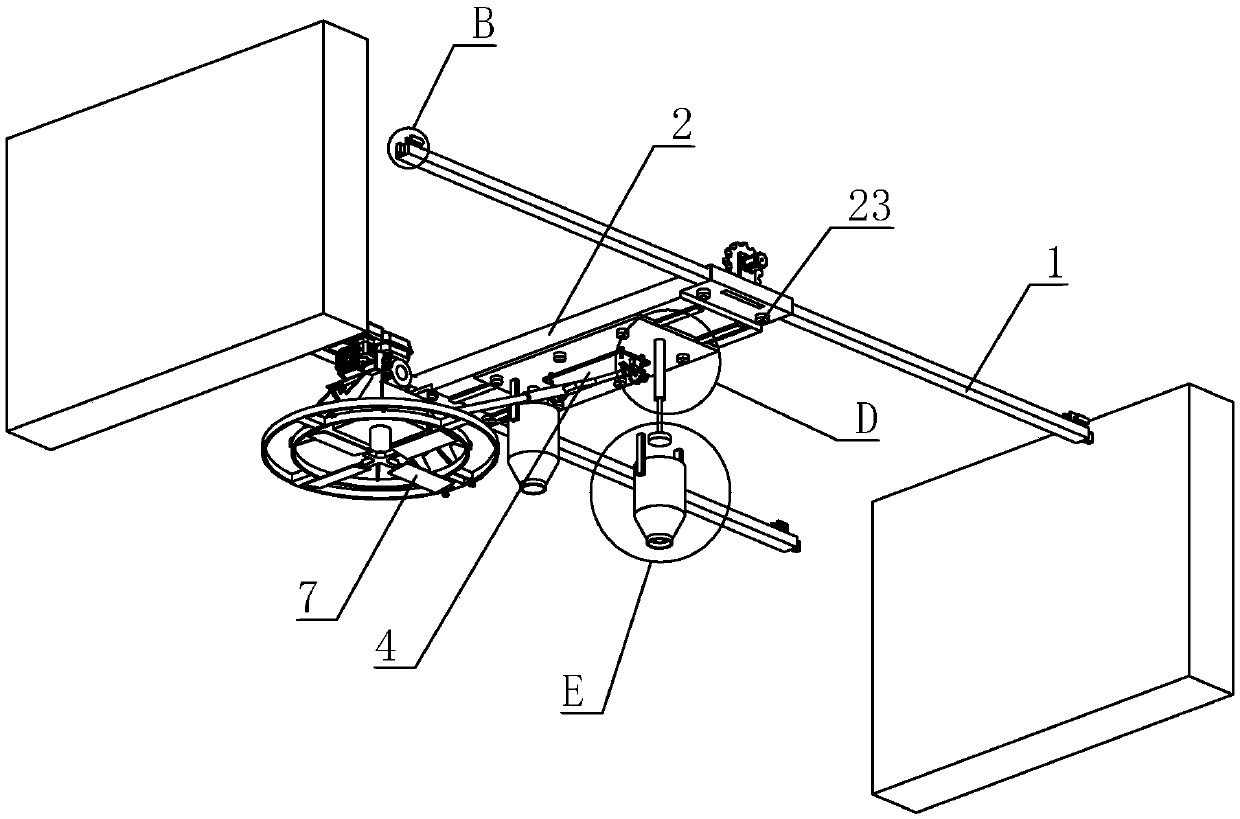

Building method for case-in-place floor

ActiveCN109653421AReduce the thickness is not enoughImprove flatnessFloorsForms/shuttering/falseworksFloor slabEngineering

The invention relates to a building method for a case-in-place floor, and relates to the technical field of the building construction. The method comprises the following steps: Sp1: paying off; Sp2: drilling and hole-cleaning; Sp3: erecting and installing a template; Sp4: injecting glue; Sp5: manufacturing and bundling a reinforced steel bar; Sp6: pouring concrete; Sp7: curing the concrete; and Sp8: detaching the template, wherein a troweling device is used in troweling operation in the Sp6. The troweling device comprises a support rod supported on a wall surface, a moving frame slidably installed on the support rod, a driving component installed on the moving frame, an installing frame slidably installed on the lower surface of the moving frame, a power component installed on the installing frame, a clamping component installed on the installing frame, and a troweling machine connected with the clamping component. The method is capable of, through controlling the driving component andthe power component, controlling operation of the troweling machine, avoiding a person from stepping on concrete, reducing a situation that a thickness of a protecting layer is not enough, improvingflatness of the floor, and improving quality of the floor.

Owner:广州市黄埔建筑工程总公司

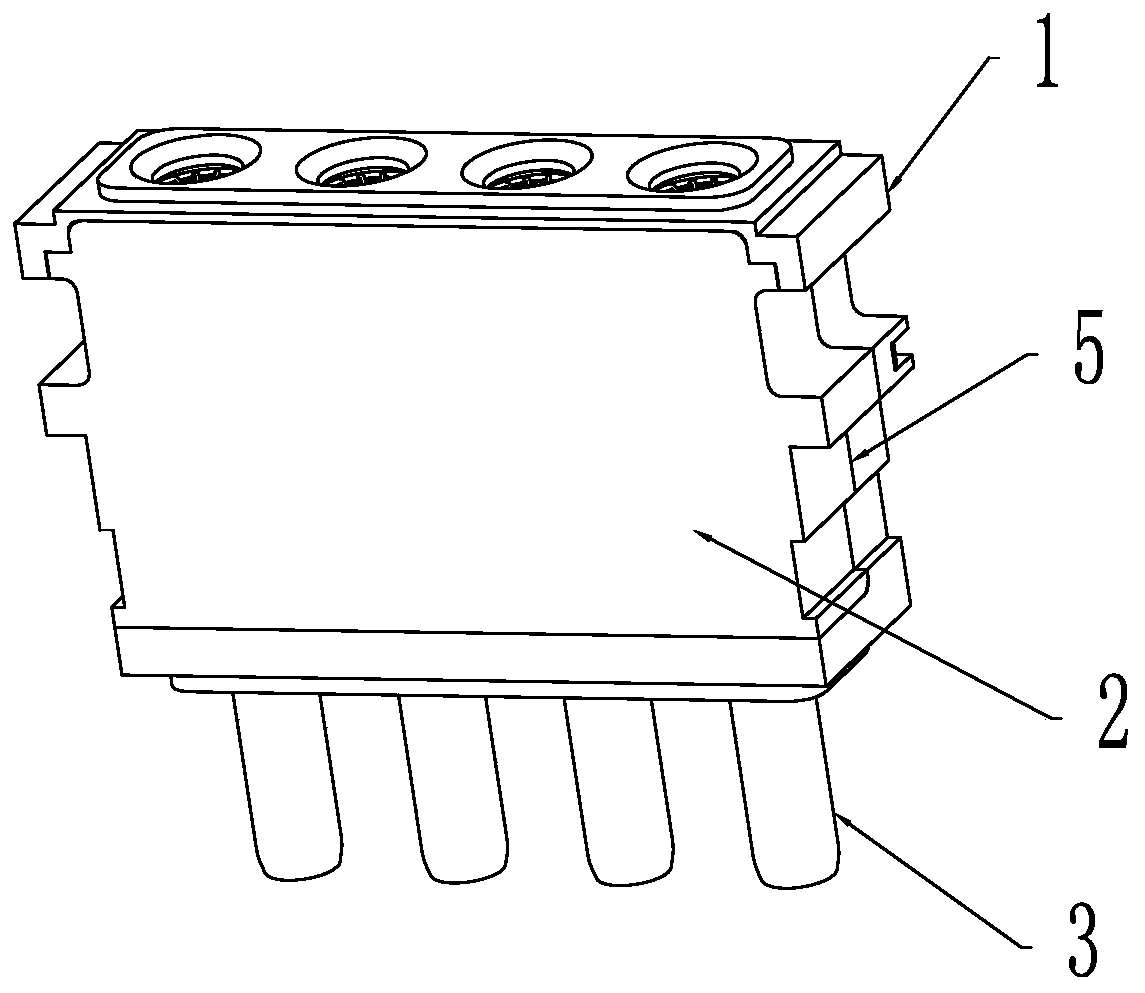

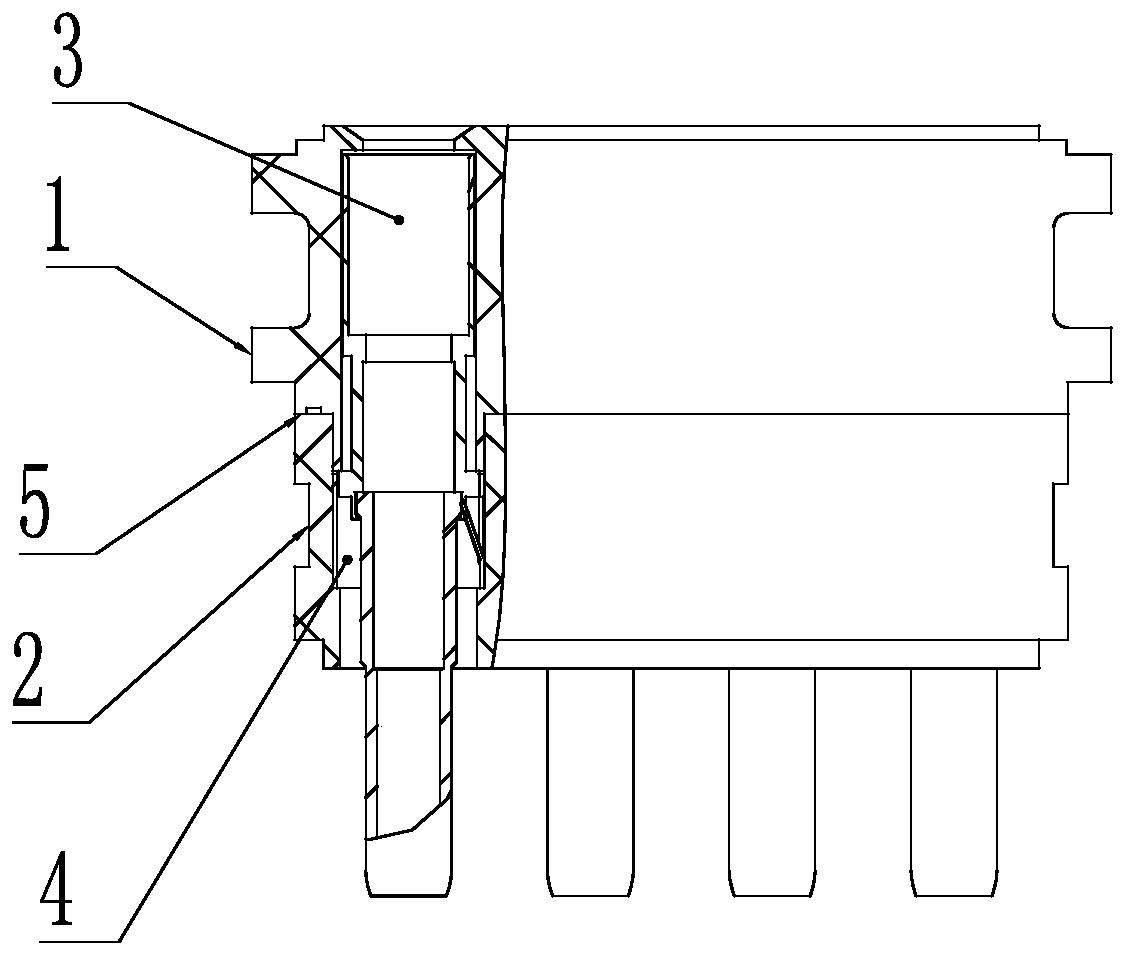

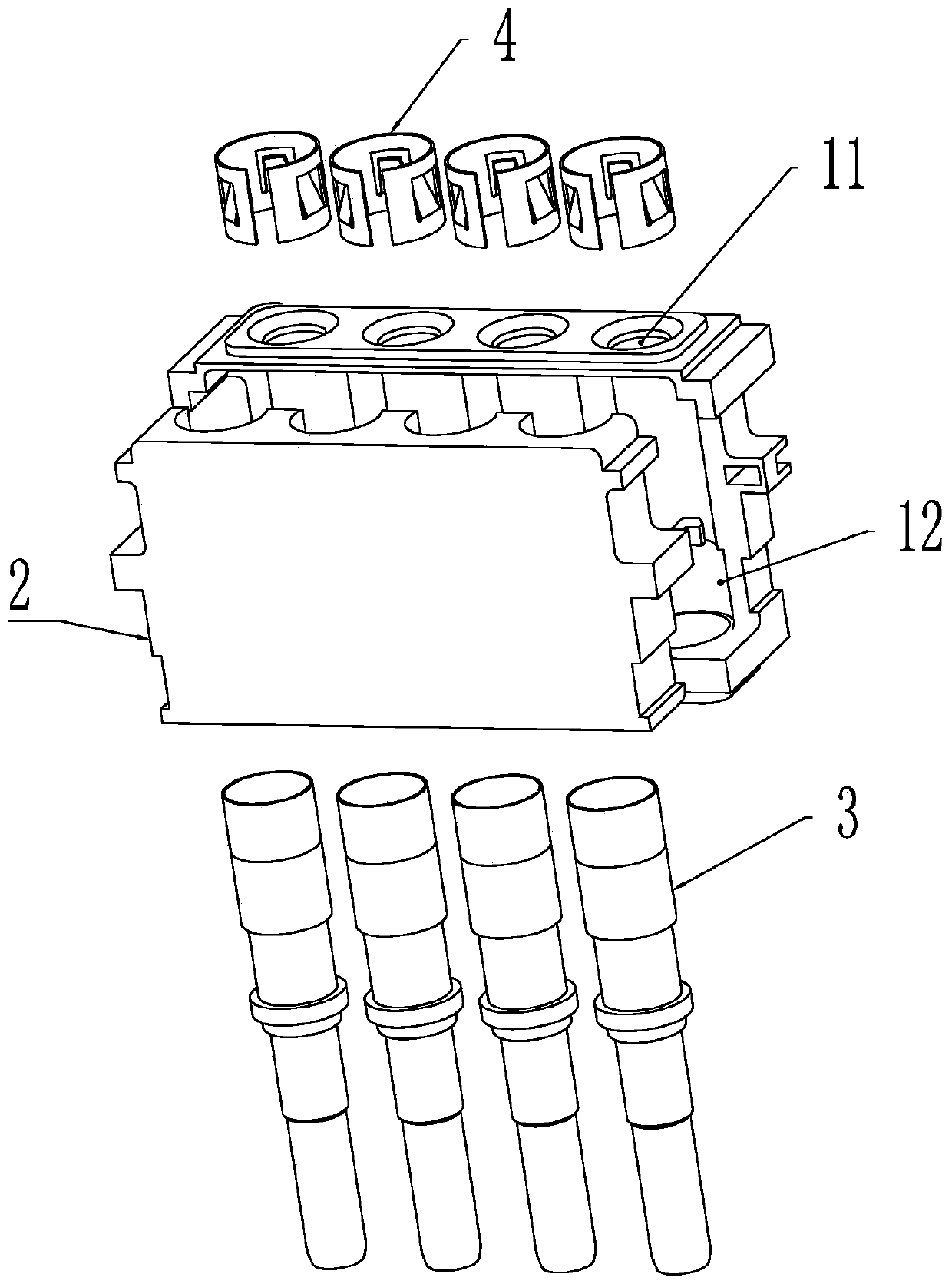

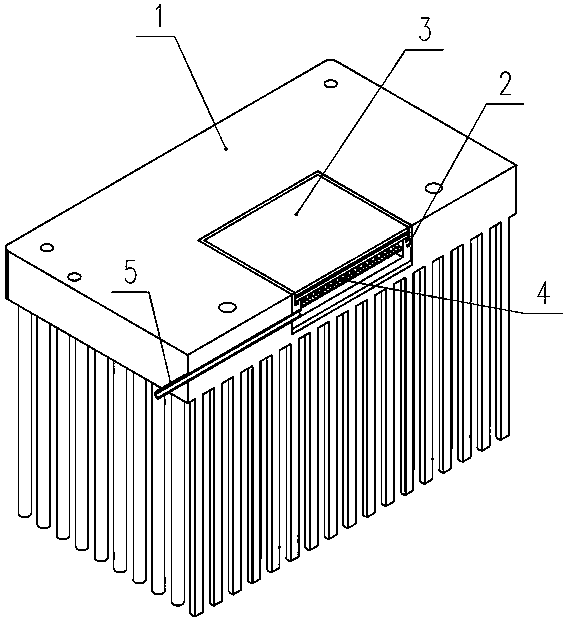

Side buckled modular connector

ActiveCN110247240AImprove Assembly ConsistencyIncrease productivityCoupling device detailsEngineeringModular connector

The invention relates to a side buckled modular connector. The side buckled modular connector includes an insulator (1), an insulation pressing plate (2) and a contact member (3) assembled in the insulator, wherein the insulation pressing plate (2) is buckled with a side surface of the insulator (1) to form a combination surface (5), and the combination surface (5) and an insertion direction of the contact member (3) are in non-perpendicular setting. The connector is advantaged in that the insulator and the insulation pressing plate are in side surface buckling matching mode, the combination surface (5) and the insertion direction of the contact member (3) are in a non-perpendicular setting mode, during operation, the combination surface bears no force, a force bearing point is on the insulator, product quality consistency and reliability of the modular connector are guaranteed, and problems of difficulty in detecting connector quality and lower production efficiency are solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

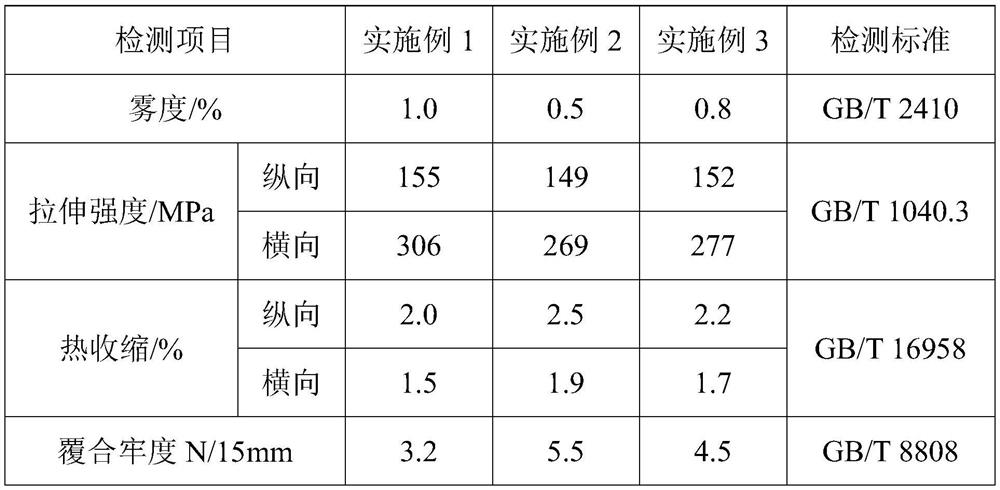

BOPP film capable of being directly used for paper-plastic compounding and preparation method thereof

PendingCN112123902AQuality assuranceAvoid pollutionSynthetic resin layered productsLow-density polyethylenePolymer science

The invention discloses a BOPP film capable of being directly used for paper-plastic compounding and a preparation method thereof, and relates to the technical field of films. The BOPP film comprisesan upper surface layer, a core layer and a lower surface layer. The upper surface layer is made of homo-polypropylene and anti-sticking master batch, and the anti-sticking master batch is composed ofhollow ceramic microbeads and homo-polypropylene; the core layer is made of homo-polypropylene; and the lower surface layer is made of an ethylene-ethyl acrylate copolymer and low-density polyethylene. The BOPP film prepared by the method is good in brightness, and can be directly compounded with paper under a hot pressing condition, so that a procedure and a tool for applying a hot melt adhesiveare omitted, and the pollution of a primer to the environment is avoided; and besides, in the preparation process, the core layer melt is distributed into a plurality of die heads, and a multi-layer co-extrusion structure is adopted, so that the requirements of production equipment for different film thicknesses can be flexibly met, and the burden of the equipment is reduced.

Owner:ANHUI GUOFENG PLASTIC

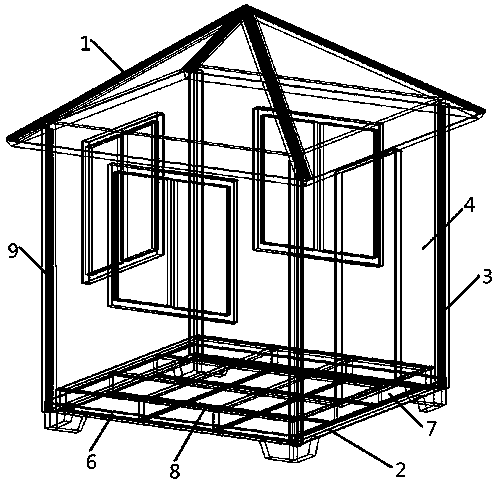

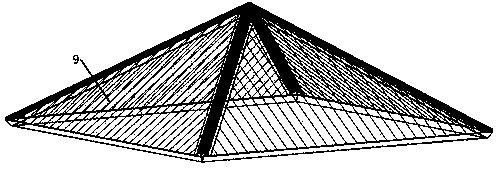

Lightweight assembled house

The invention discloses a lightweight assembled house, which comprises a roof, a base and a house body, wherein the house body is formed by combining four wallboards, and wallboard sockets for installing the wallboards are arranged on the base; the roof is integrally formed at one step; the base comprises a main keel and a secondary keel which are fixedly connected together, and the wallboard sockets are located on the main keel; floor is paved on the main keel and the secondary keel, reinforcing heat insulation layers are sprayed on the inner surfaces of the roof and the wallboard and the bottom surface of the floor, and the reinforcing heat insulation layers are filled in the main keel and the secondary keel. According to the invention, the roof is integrally formed in one step, and subsequent procedures caused by splicing are reduced; the main keel and the secondary keel are made of C-shaped steels, and the main keel and the secondary keel are connected through splicing operation, so that the processing procedures are simplified, the manufacturing materials are saved, the integral strength of the house is increased through the arrangement of reinforcing heat insulation layers inthe house, and compared with a traditional assembled house, the roof is lighter in weight and convenient to carry.

Owner:SUIZHOU ZHUFENG STEEL STRUCTURE ENG

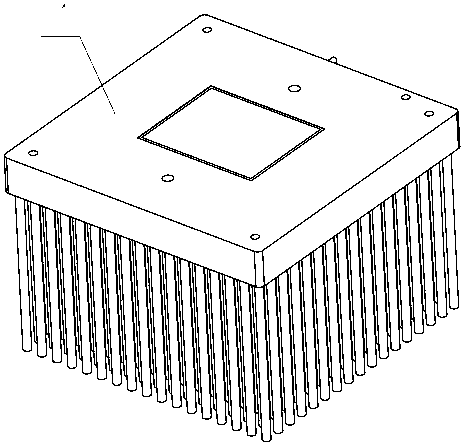

Copper-aluminum composite radiator and machining method thereof

PendingCN110849190AImprove thermal conductivityImprove cooling effectIndirect heat exchangersHeat exchanger casingsSilicone greaseAluminum composites

The invention discloses a copper-aluminum composite radiator. The radiator comprises an aluminum alloy radiator body and further comprises a copper substrate fixed to a heat conduction surface of thealuminum alloy radiator body in an embedded mode and in a clamping groove shape. An opening is formed in the upper portion of a clamping groove of the copper substrate. A capillary plate is paved in the clamping groove. The opening of the clamping groove is closed by soldering a DBC plate. The composite radiator fully utilizes characteristics of two types of materials, namely, the characteristicsthat the copper is quick in heat conductivity while the aluminum is high in heat sinking capability, easy to machine, low in cost and the like; by means of the better heat conductivity of the copper,heat transfer is quickened, and the heat sinking performance is improved; the capillary plate is arranged inside the copper substrate, namely the clamping groove, and can transfer heat more quickly; and the copper substrate and the DBC substrate can be directly welded in the opening of the groove, the integrated radiator is formed directly, the number of subsequent procedures is decreased, and nointermediate medium heat-conducting silicone grease is needed.

Owner:浙江天毅半导体科技有限公司

Method for preparing vanadium-nitrogen alloy through stone coal vanadium extraction vanadium-rich liquid

The invention relates to a method for preparing vanadium-nitrogen alloy through stone coal vanadium extraction vanadium-rich liquid. According to the technical scheme, a carbonaceous reducing agent is added into the vanadium-rich liquid, stirring and drying are conducted, and a precursor is obtained; the vanadium-rich liquid is an intermediate product of stone coal vanadium extraction; the molar weight of the carbonaceous reducing agent is 1.5-4 times the total molar weight of positive ions in the vanadium-rich liquid, the precursor is mechanically pressed into a block shape, at the ordinary pressure and a nitrogen atmosphere, the blocky precursor is subjected to heat preservation for 1-5 h under the condition of 1000-1400 DEG C, then cooled with a furnace and levigated, and a second intermediate product is obtained; a hydrochloric acid solution is added into the second intermediate product, stirring and solid-liquid separation are conducted, and solid slag is obtained; the molar weight of HCl in the hydrochloric acid solution is 3-5 times the total molar weight of positive ions except vanadium positive ions in the vanadium-rich liquid; and the solid slag is dried and briquetted, and the vanadium-nitrogen alloy is obtained. The method has the characteristics that the stone coal vanadium extraction vanadium-rich liquid is used as a vanadium source, the production cost is low, the raw material consumption is low, and the reaction time is short.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method of rare earth transition alloy rotary target for film coating of magneto-optical recording medium and prepared target of rare earth transition alloy rotary target

ActiveCN105803406AImprove qualityOvercome the shortcomings of component segregation and brittlenessVacuum evaporation coatingSputtering coatingPorosityIndium

The invention discloses a preparation method of a rare earth-transition alloy rotary target for film coating of a magneto-optical recording medium and a prepared target of the rare earth transition alloy rotary target. The method comprises the steps that rare earth transition metal alloy is prepared; rare earth transition metal alloy hollow target tubes are formed through vacuum pouring; the poured rare earth transition metal alloy target tubes are subjected to hot isostatic pressing; machining is conducted; and indium binding is conducted. The rare earth transition alloy rotary target prepared through the method is even in composition, the relative density can reach 99.9%, the purity can reach 99.99%, the length is not limited, the defects of rotary target composition segregation, high fragility and the like are overcome, the porosity of the target is lowered, and the target is made to stably discharge in the application process, so that the quality of a magneto-optical recording medium thin film is improved. In addition, the method is simple in process and convenient to operate, conventional sheaths and argon arc welding are not needed during hot isostatic pressing, subsequent procedures are reduced, and the target tubes can be directly subjected to hot isostatic pressing, so that the production cost is reduced.

Owner:亚芯半导体材料(江苏)有限公司 +1

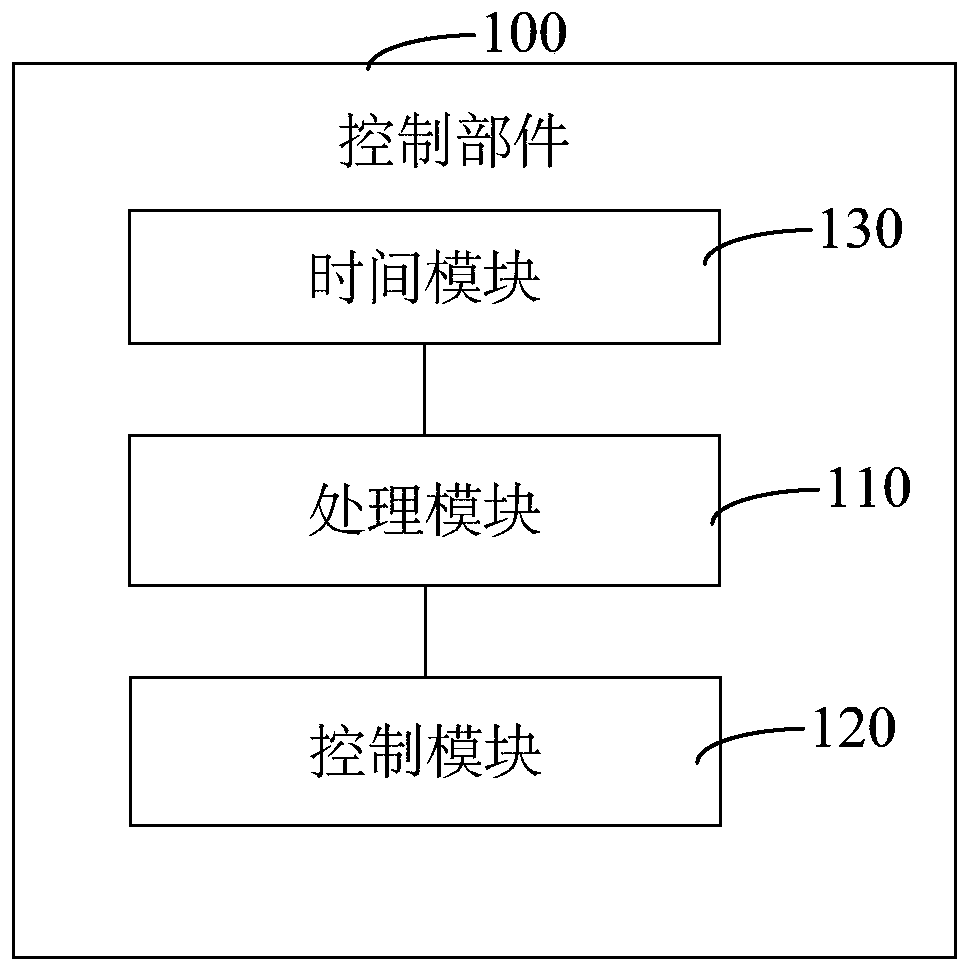

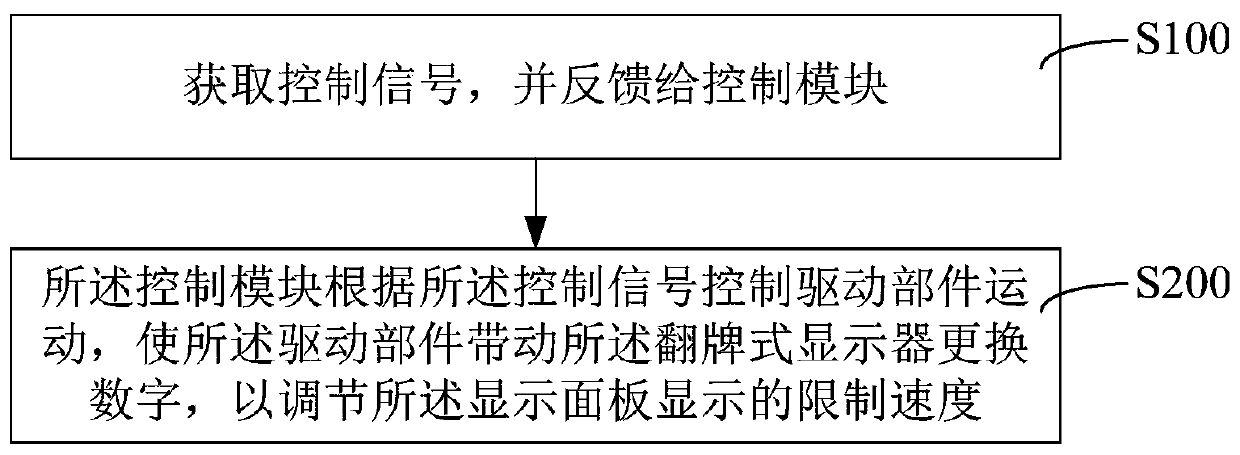

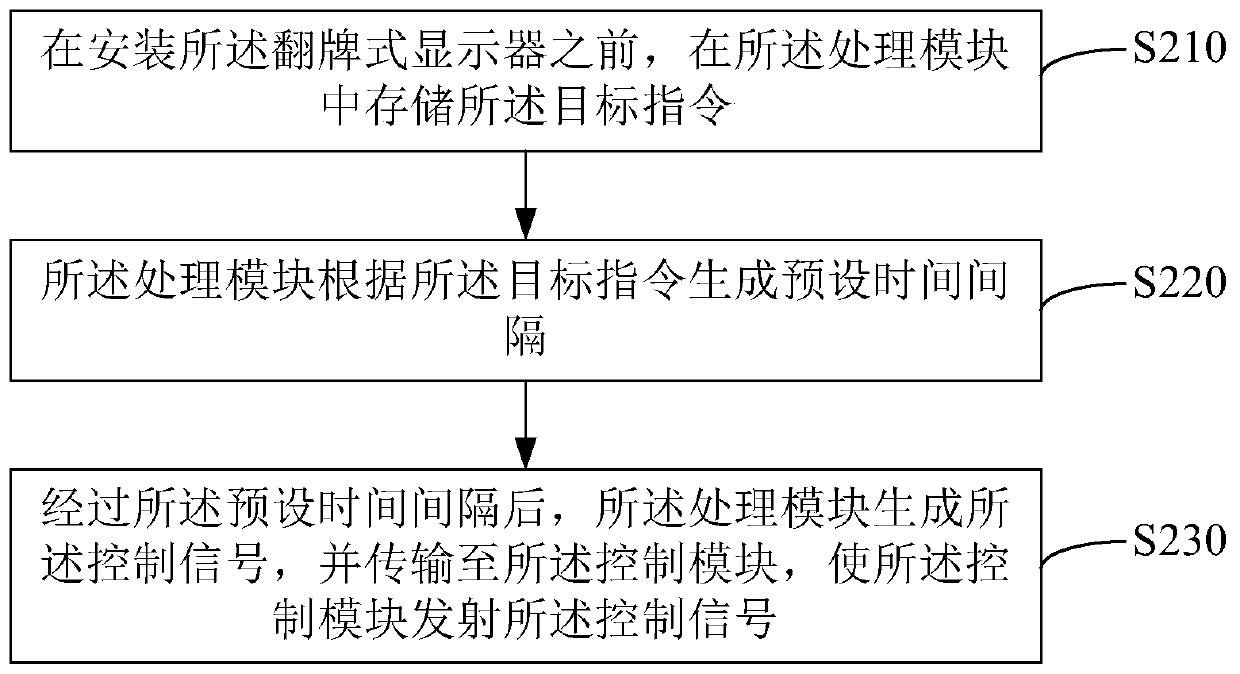

Railway deceleration signal board and control method thereof

InactiveCN110641520AEasy to operateSolve potential safety hazardsVisible signalsElectric energy managementDisplay deviceElectrical connection

The invention provides a railway deceleration signal board and a control method thereof. The railway deceleration signal board comprises a board overturning type display, a driving component and a control component, wherein the board overturning type display comprises a display panel, an adjusting component and at least two replaceable number boards; the adjusting component is arranged in the display panel, and is used for adjusting the number boards to enable the number boards to be positioned on the display panel and display a limited speed; the driving component is connected with the adjusting component, and is used for driving the adjusting component to move; and the control component is electrically connected with the driving component, and is used for controlling the driving component to move. A railway deceleration signal is displayed in such a way that the control component controls the driving component to drive the adjusting component to move, automatic adjustment and remotecontrol of limited speed display are realized, an engine driver is asked to control the operation speed below the limited speed, and the deceleration signal board does not need to be replaced on a scene by a constructor, so that the potential safety hazard of the constructor is reduced; and the railway deceleration signal board is simple to operate, and is used conveniently by the constructor, andthe follow-up process is reduced.

Owner:CHINA SHENHUA ENERGY CO LTD

Industrial preparation method of theaflavin

InactiveCN101691591BHigh purityReduce subsequent processesOrganic chemistryFermentationAcetic acidTheaflavin

The invention relates to an industrial preparation method of theaflavin, which comprises the following steps: (1) preparing an ethyl acetate solution containing rich tea polyphenol; (2) respectively adding pulverized fresh tea leaves and the ethyl acetate solution into a oxidation-fermentation tank, orderly adding ethyl acetate and a buffering solution, introducing air at normal temperature, and stirring, oxidizing and fermenting to obtain the theaflavin ester-phase solution; (3) filtering the theaflavin ester-phase solution, concentrating and washing to remove impurities; (4) concentrating the water-phase solution, and spray-drying to obtain low-specification dry theaflavin powder; (5) concentrating the ester-phase solution to recycle ethyl acetate, and adding water so that the theaflavin is dissolved in the water; (6) centrifugally filtering the theaflavin water solution to obtain a pure theaflavin solution; (7) and concentrating the theaflavin solution, and spray-drying to obtain the dry theaflavin powder. The method of the invention simultaneously enhances the yield and the quality of the theaflavin, saves the energy and the man hours and reduces the emission of waste water.

Owner:ZHEJIANG PAINUO BIO TECH

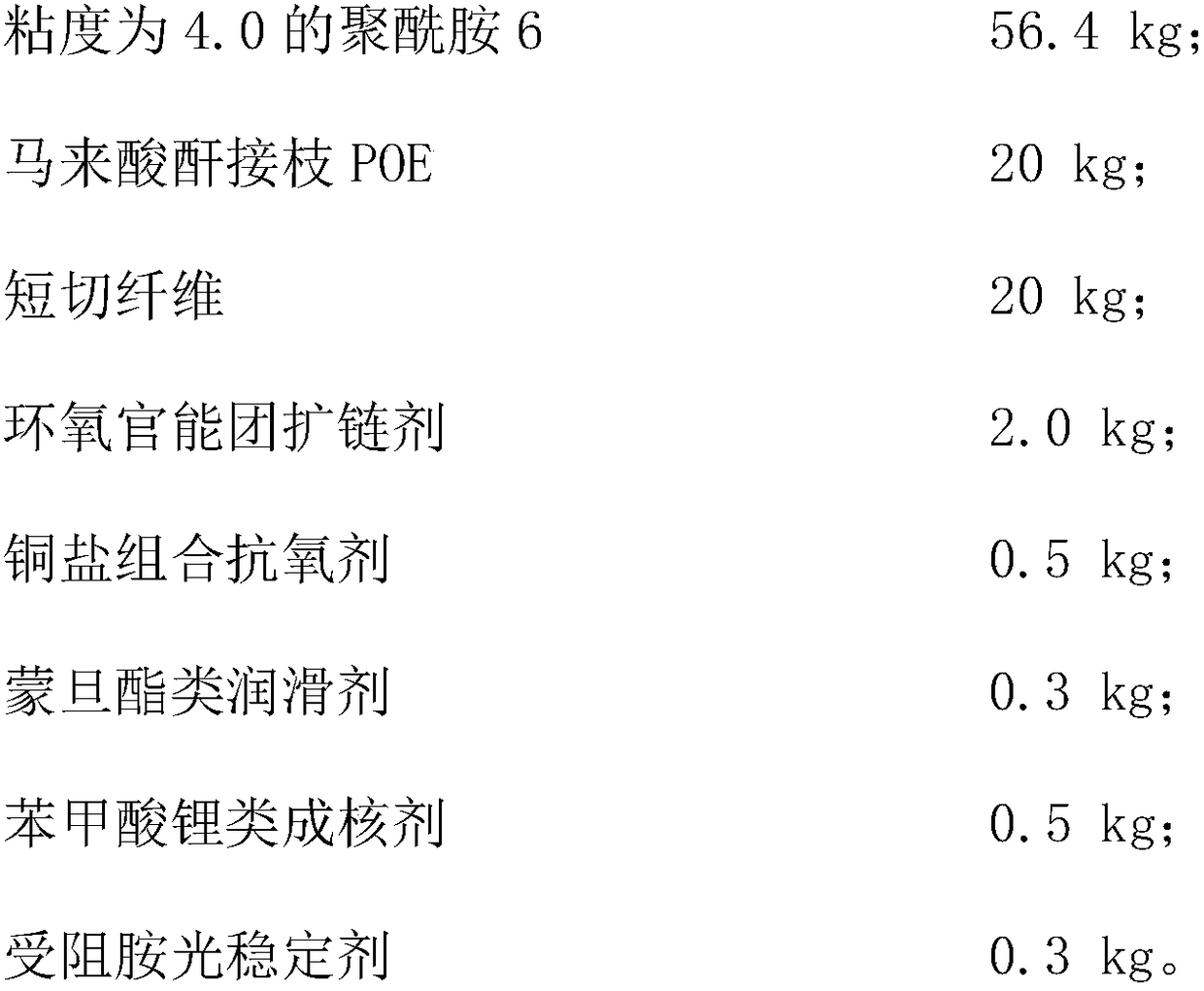

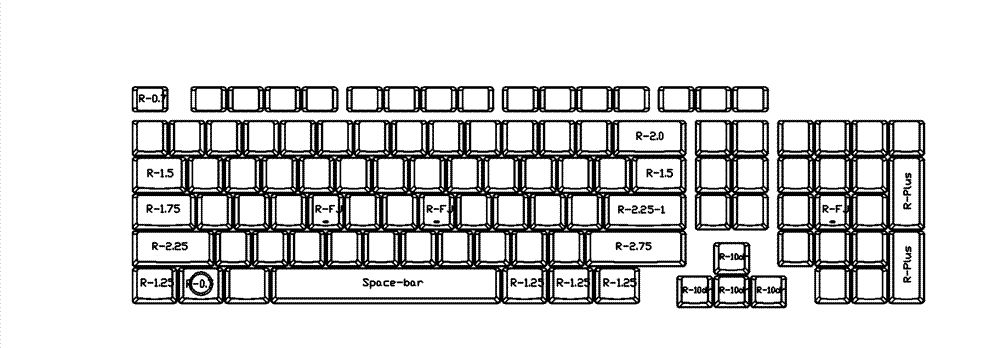

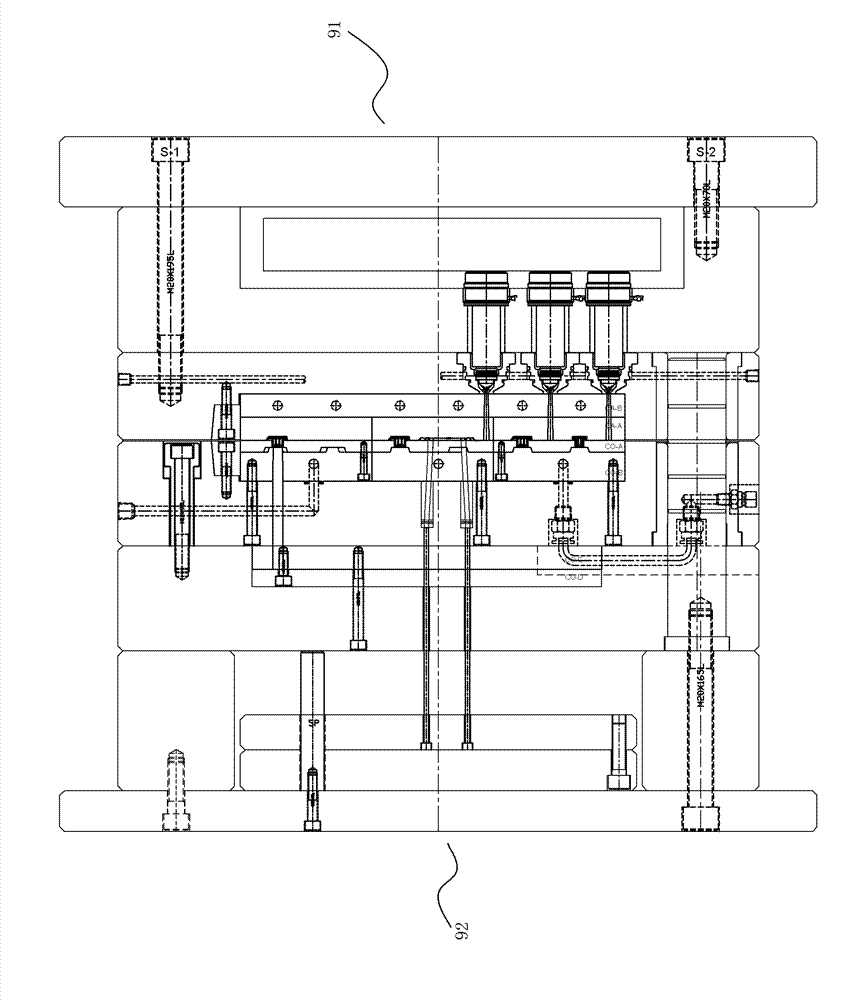

Keyboard key full-pattern injection mold structure and system thereof

InactiveCN102896741AReduce subsequent processesOptimizing the injection molding processHot runnerEngineering

The present invention discloses a keyboard key full-pattern injection mold structure and a system thereof. The keyboard key full-pattern injection mold structure comprises a front mold frame and a rear mold frame, wherein the front mold frame comprises a front mold holder and a front mold core fixed on the front mold holder, and the rear mold frame comprises a rear mold holder and a rear mold core fixed on the rear mold holder. A plurality of molding mold cavities for forming keys of the whole keyboard and a plurality of hot runners communicated between the plurality of the molding mold cavities are arranged between the front mold core and the rear mold core, wherein the hot runners and a hot sprue arranged on the front mold holder are communicated, the molding mold cavities are divided into a plurality of rows, the row distance of the molding mold cavity is greater than the row distance of the keys on the keyboard, and the interval of the molding mold cavity is further greater than the interval of the keys on the keyboard. According to the present invention, the key production of the whole keyboard can be solved by only requiring a set of the mold, and fully automated direct assembly of the followed segments is completely considered, such that all the key caps can be assembled without manual assembly so as to improve production efficiency; and transference stock of the keys is canceled, wherein the key caps are required to be subjected to warehousing after injection molding, and then are assembled by receiving the material through the assembly workshop.

Owner:SHENZHEN RAPOO TECH

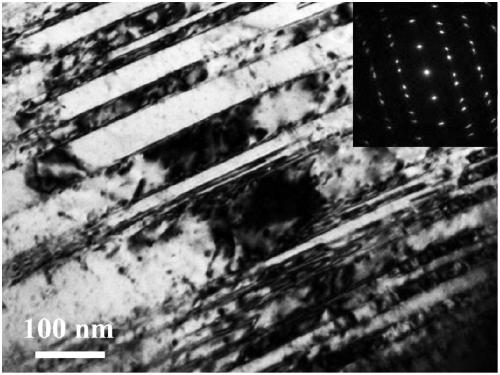

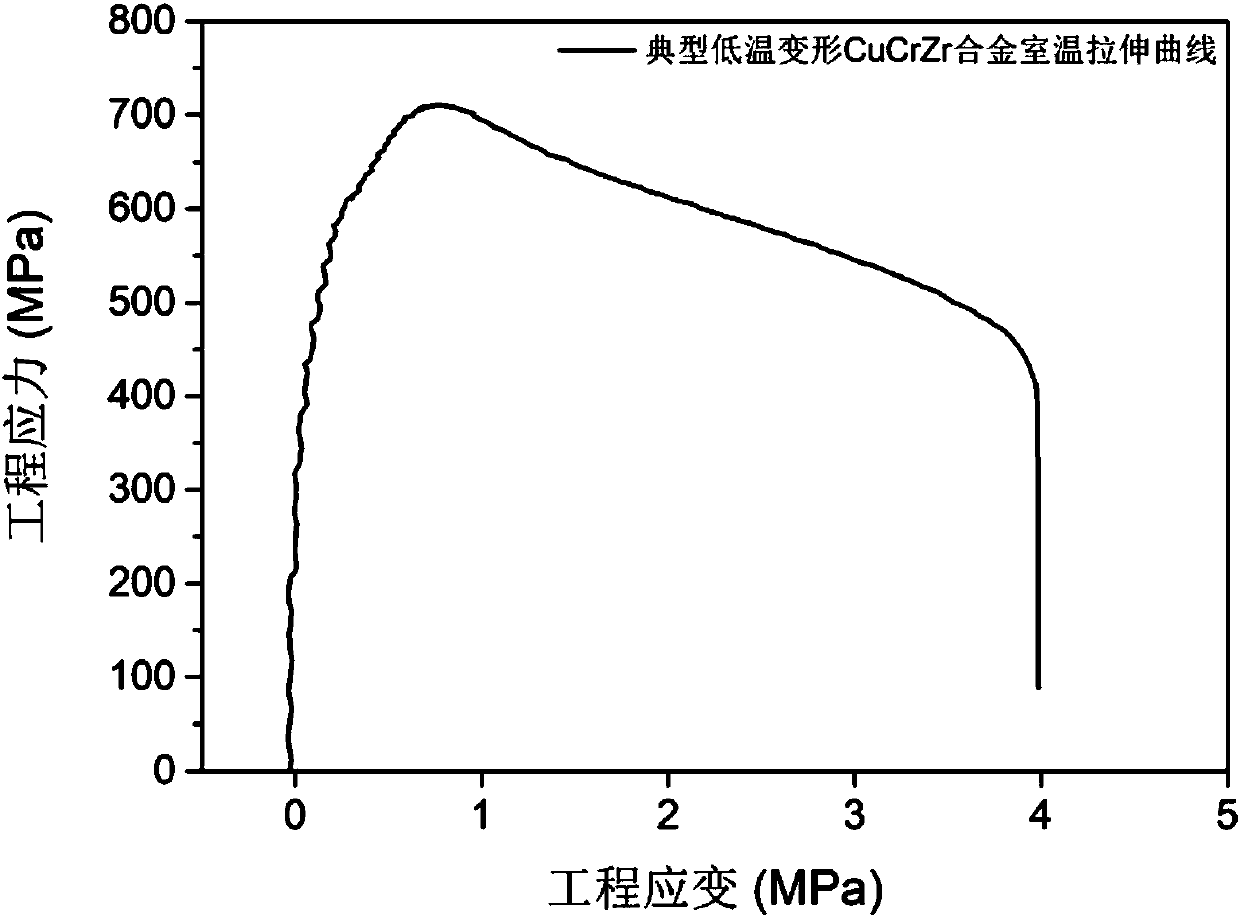

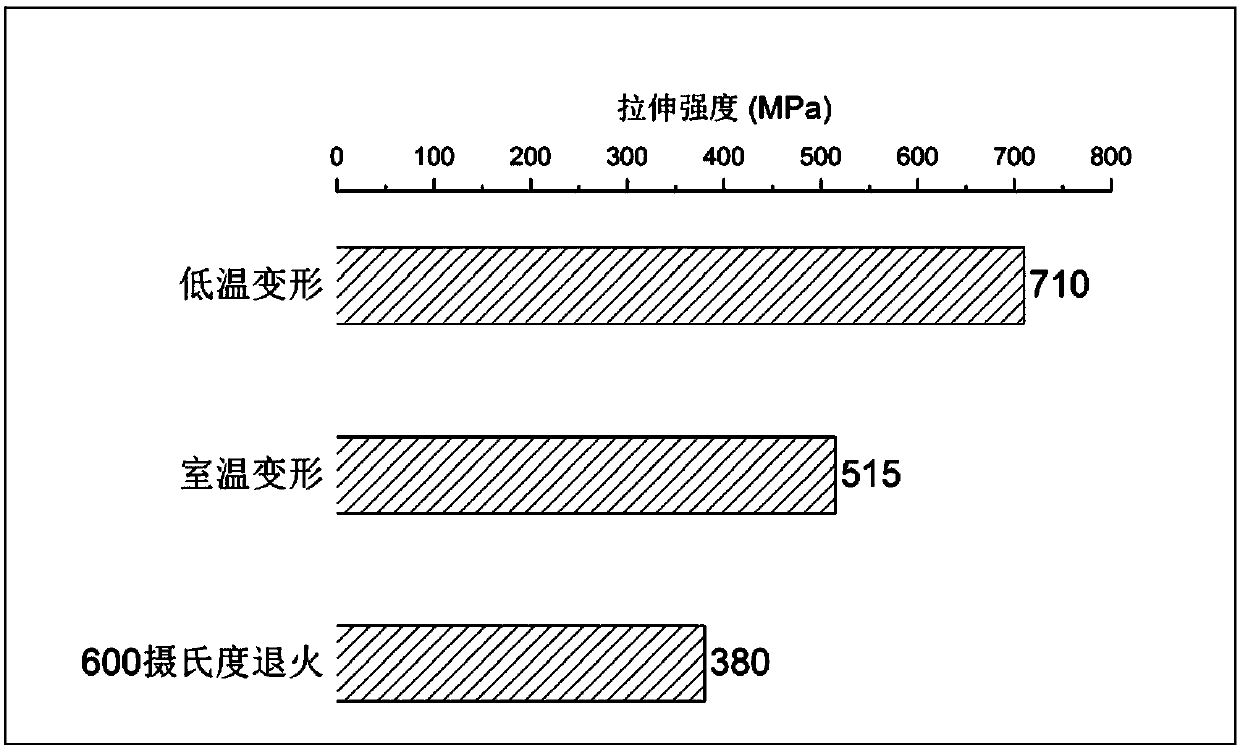

High-strength high-conductivity copper chromium zirconium alloy and low-temperature deforming preparing method thereof

ActiveCN110066939AHigh conductivity at room temperatureMany low temperature methods are availableNanoscopic scaleNanostructure

The invention relates to the field of copper alloy and application thereof, in particular to a high-strength high-conductivity copper chromium zirconium alloy and a low-temperature deforming preparingmethod thereof. The alloy comprises chemical components including, by mass percent, 0.2 to 1.5% of chromium, 0.05 to 0.2% of zirconium and the balance copper and inevitable impurities. The typical structure of the alloy comprises a copper matrix of a nanoscale deformation structure and dispersed distribution chromium particles, the typical nanostructure is a deformation twin crystal bundle, the twin crystal layer piece thickness ranges from 20 to 100 nanometers, the twin crystal bundle size ranges from several microns to several hundred microns, and the diameter of the dispersed distributionchromium particles ranges from 10 to 100 nanometers. The alloy has the 700 MPa stage strength, and meanwhile, the conductivity is within the 78 to 82% IACS range. The manufacturing method of the alloycomprises the steps of alloy blank casting heat machining and low-temperature deforming. The alloy has the advantages of being high in strength, high in conductivity, high in softening temperature, excellent in wear resisting and welding property and the like and can be suitable for the field of use of existing copper chromium zirconium alloy and the field with the higher requirement for strength-conductivity.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for dilute acid pretreatment of plant straws by microwave-cyclic compression percolation

ActiveCN103060481AImprove reaction efficiencyReduce concentrationBiofuelsGlucose productionPhysical chemistryEngineering

The invention discloses a method for dilute acid pretreatment of plant straws by microwave-cyclic compression percolation. The method comprises: first conducting standing infiltration on straw particles with a dilute acid solution, then loading the straw particles into a cylindrical reactor, performing fed-batch of the dilute acid solution to the reactor, and at the same time, applying the action of microwave and compressing the straw particles, and discharging the liquid in the reactor; after solid-liquid separation, re-injecting the acid solution and dispersing the straw particles uniformly; carrying out fed-batch of the filtrate obtained from the separation to the reactor, and at the same time, applying the action of microwave and compressing the straw particles, and discharging the liquid in the reactor; and repeating the operations till the end of the reaction. By infiltrating the straw particles in the acid solution in advance and adopting a filtrate cyclic compression mode, the method provided in the invention reduces the concentration and dosage of the acid solution, increases the reaction product concentration, and enhances the reaction speed simultaneously.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hole helical milling device

ActiveCN102689040BImprove hole making efficiencyReduce processing costsMilling machinesNumerical controlMilling cutter

Owner:SHANGHAI AIRCRAFT MFG +1

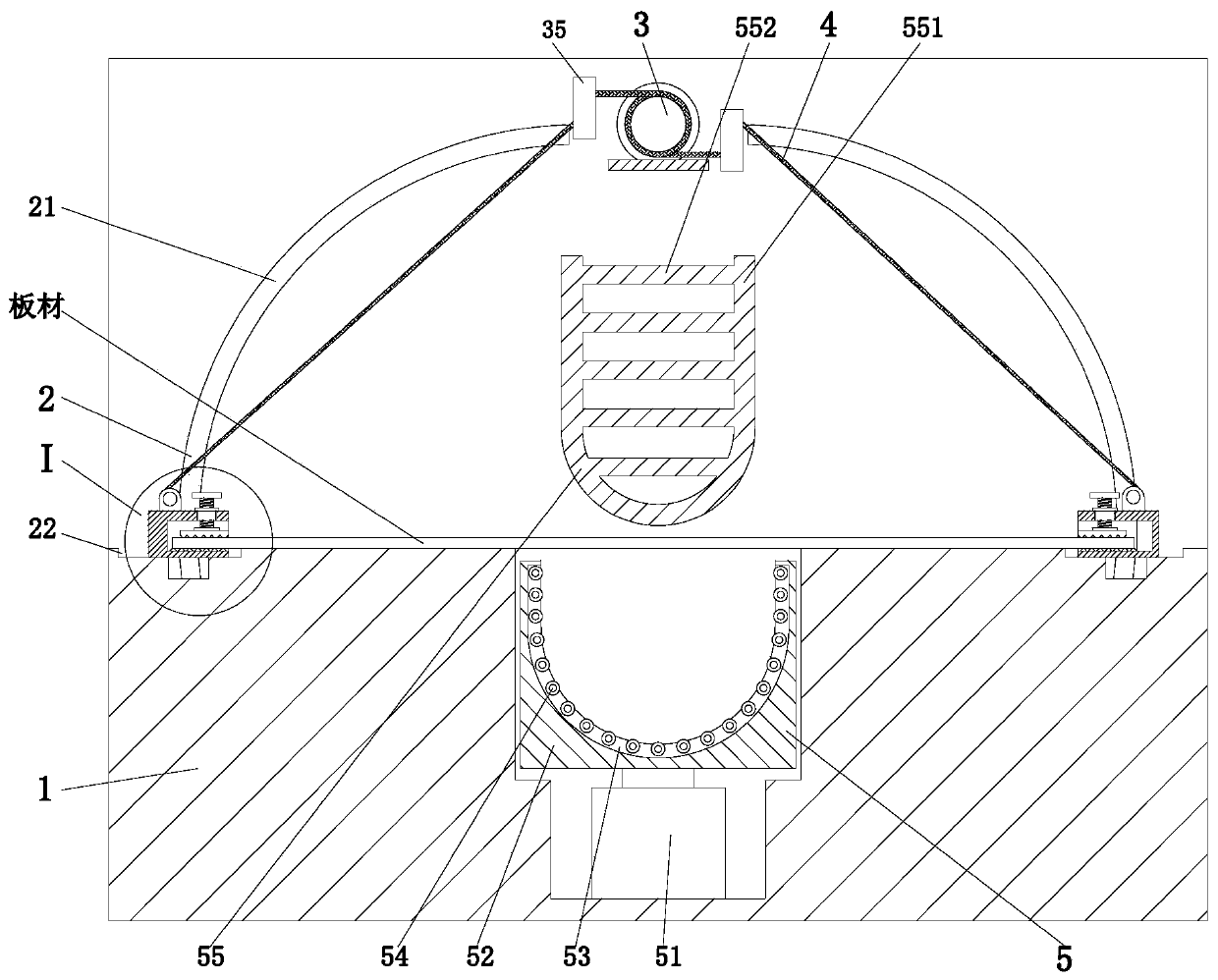

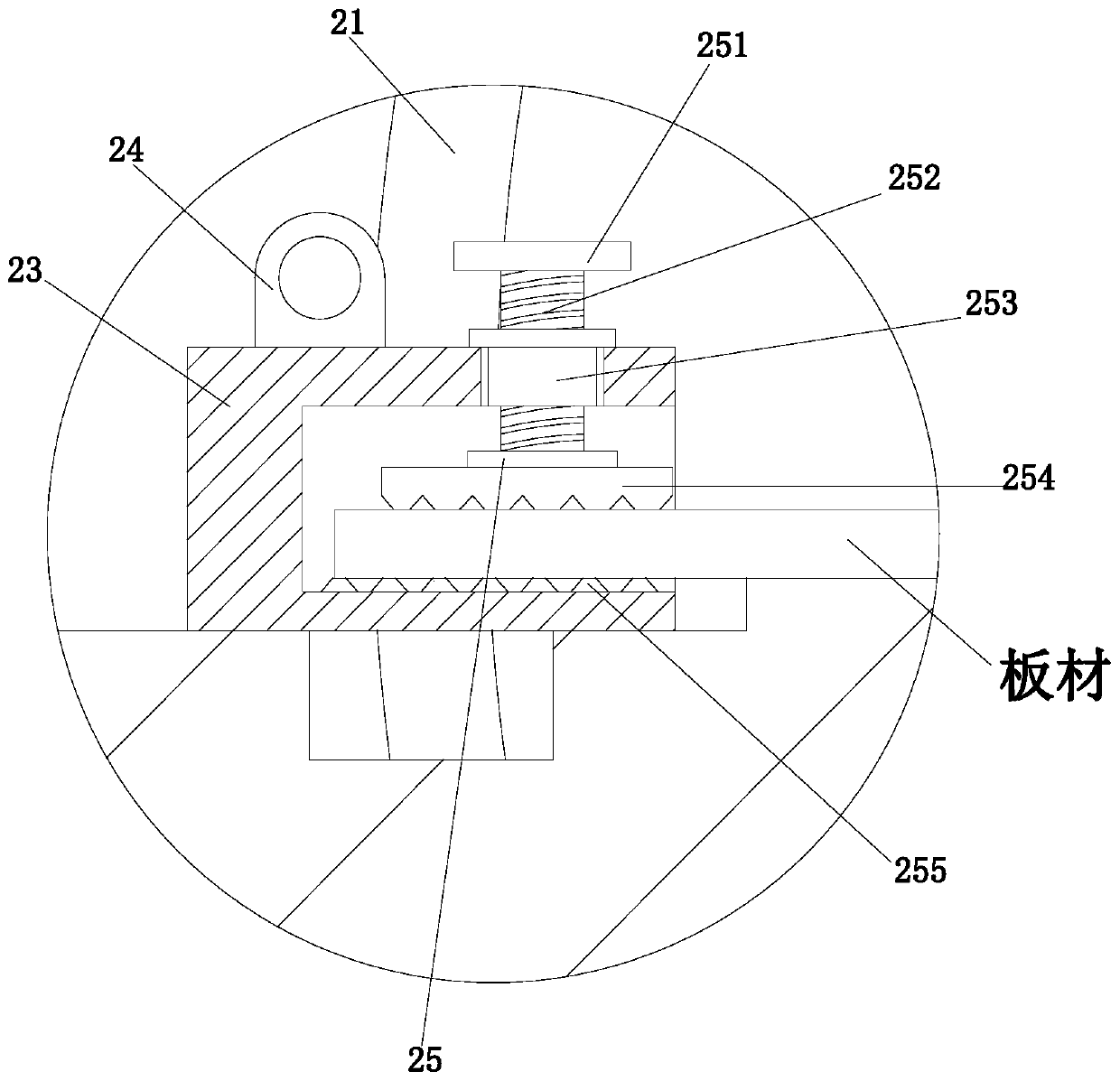

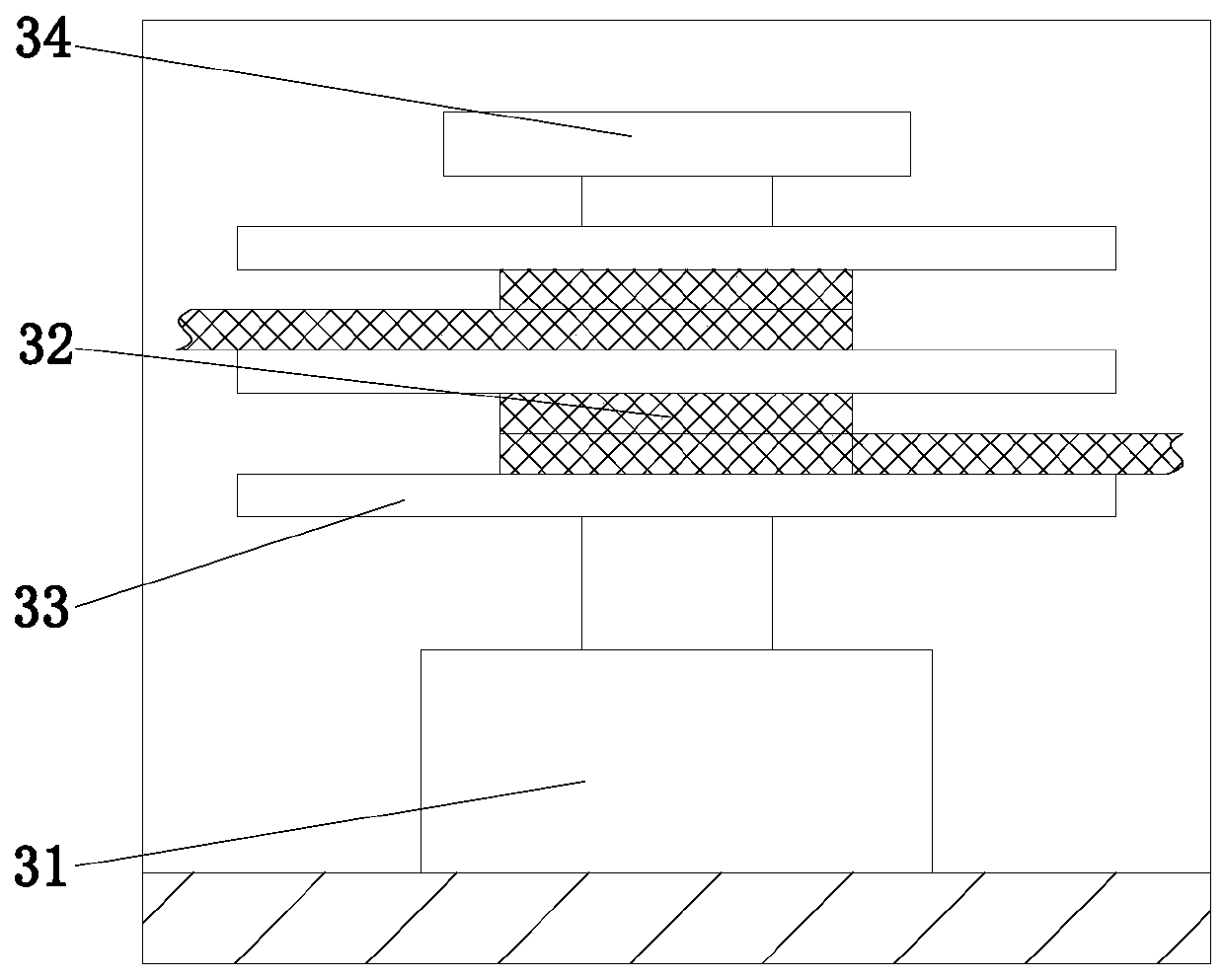

Mold for bending and forming sheet metal U-shaped parts

ActiveCN110508646AAvoid breakingAvoid deformation and other phenomenaMetal-working feeding devicesPositioning devicesDrive motorMetal

The invention relates to a mold for bending and forming sheet metal U-shaped parts. The mold comprises a platform, bending devices, a traction apparatus, steel ropes and an extrusion forming device, wherein the bending devices are arranged at the upper end of the platform in a left-right symmetrical manner; a mounting wall is arranged at the rear end of the platform; the traction apparatus is arranged at the front end of the mounting wall; the steel ropes are connected between the traction apparatus and the bending devices; the platform is internally provided with a cavity; and the extrusion forming device is arranged on the inner wall of the lower end of the platform. According to the mold, by adopting a method of two-step forming of bending and then extruding, the U-shaped sheet metal parts obtained by bending do not rebound, the molding is perfect, subsequent procedures are reduced and the production efficiency is improved. An arranged driving motor drives the steel ropes to simultaneously pull sheets from two ends; by using the U-shaped mold, the sheets are preliminarily formed; and extrusion rolls extrude the formed sheets by adopting a rolling mode, so that the sheets are thoroughly formed, and the rebounding of the sheets is prevented.

Owner:湖州卓域机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com