Thermoplastic polymer matrix heat conduction composite material, and preparation method and application thereof

A technology of thermoplastic polymers and heat-conducting composite materials, which is applied in the field of polymer-based heat-conducting composite materials, can solve the problems of high heat-conducting functional fillers, high dosage ratio, and high price, so as to improve heat resistance, working temperature, and high-efficiency heat-conducting network , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

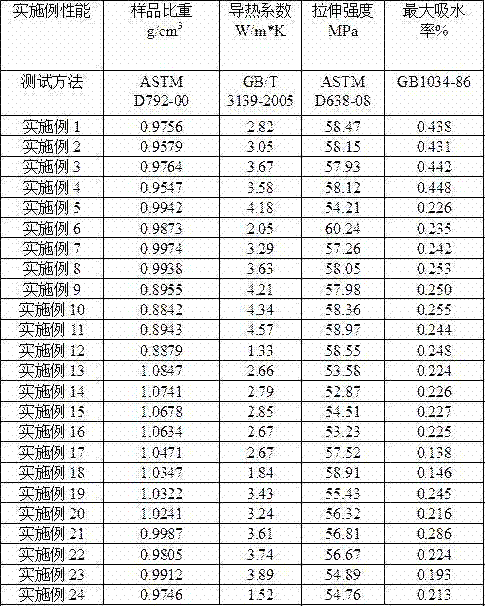

Examples

Embodiment 1

[0043] A thermoplastic polymer-based thermally conductive composite material of this embodiment, the preparation method thereof comprises the following steps:

[0044] step 1.

[0045] Pretreatment of thermally conductive powder for surface modification of hollow glass microspheres: micron-sized nitrides, micron-sized carbides, micron-sized thermally conductive metal oxides, micron-sized thermally conductive carbon powders and micron-sized thermally conductive graphite The powders were irradiated and activated by a plasma activator in the normal plasma treatment mode (1.01MPa, 30°C) for more than 1h, and then mixed to form a mixture, which was dispersed uniformly by acetone ultrasonically to obtain a mixed solution; the components in the mixture Concrete description, and the consumption (parts by weight) of this component in the mixture are as follows:

[0046] The micron-scale nitride is aluminum nitride with a particle size of 1 μm to 2 μm, and the dosage is 30 parts;

[0...

Embodiment 2

[0060] A thermoplastic polymer-based thermally conductive composite material of this embodiment, the preparation method thereof comprises the following steps:

[0061] step 1.

[0062] Pretreatment of thermally conductive powder for surface modification of hollow glass microspheres: micron-sized nitrides, micron-sized carbides, micron-sized thermally conductive metal oxides, micron-sized thermally conductive carbon powders and micron-sized thermally conductive graphite The powders were irradiated and activated by a plasma activator in the normal plasma treatment mode (1.01MPa, 30°C) for more than 1h, and then mixed to form a mixture, which was dispersed uniformly by acetone ultrasonically to obtain a mixed solution; the components in the mixture Concrete description, and the consumption (parts by weight) of this component in the mixture are as follows:

[0063] The micron-scale nitride is aluminum nitride with a particle size of 1 μm to 2 μm, and the dosage is 30 parts;

[0...

Embodiment 3

[0077] A thermoplastic polymer-based thermally conductive composite material of this embodiment, the preparation method thereof comprises the following steps:

[0078] step 1.

[0079] Pretreatment of thermally conductive powder for surface modification of hollow glass microspheres: micron-sized nitrides, micron-sized carbides, micron-sized thermally conductive metal oxides, micron-sized thermally conductive carbon powders and micron-sized thermally conductive graphite The powders were irradiated and activated by a plasma activator in the normal plasma treatment mode (1.01MPa, 30°C) for more than 1h, and then mixed to form a mixture, which was dispersed uniformly by acetone ultrasonically to obtain a mixed solution; the components in the mixture Concrete description, and the consumption (parts by weight) of this component in the mixture are as follows:

[0080] The micron-scale nitride is aluminum nitride with a particle size of 1 μm to 2 μm, and the dosage is 30 parts;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com