Manufacturing method of propeller blade

A manufacturing method and propeller technology, which are applied to other household appliances, household appliances, household components, etc., can solve the problems of difficulty in controlling the foaming density of polyurethane foam, great influence on product quality, low strength of polyurethane foam, etc., so as to solve production defects. , shorten the production cycle, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

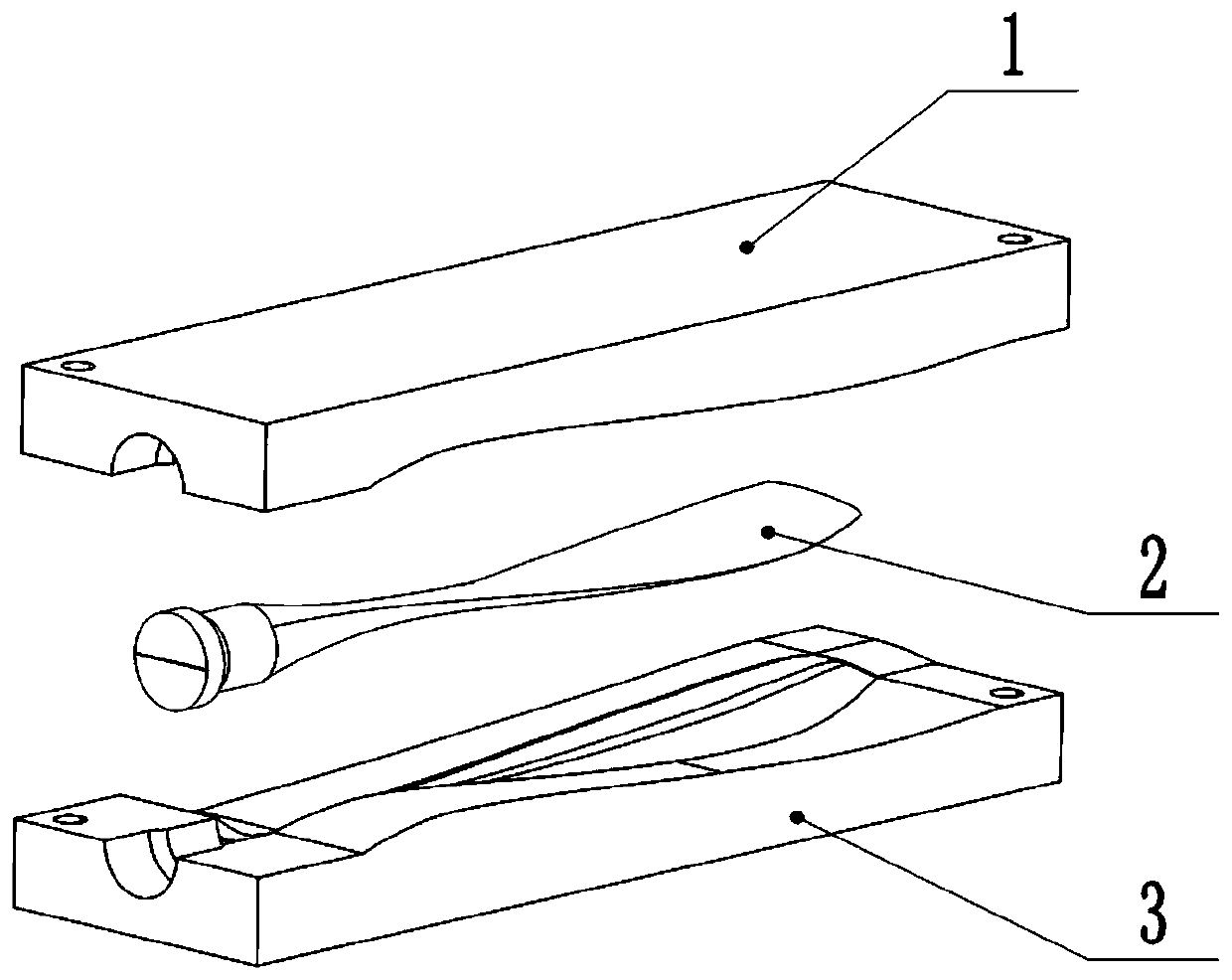

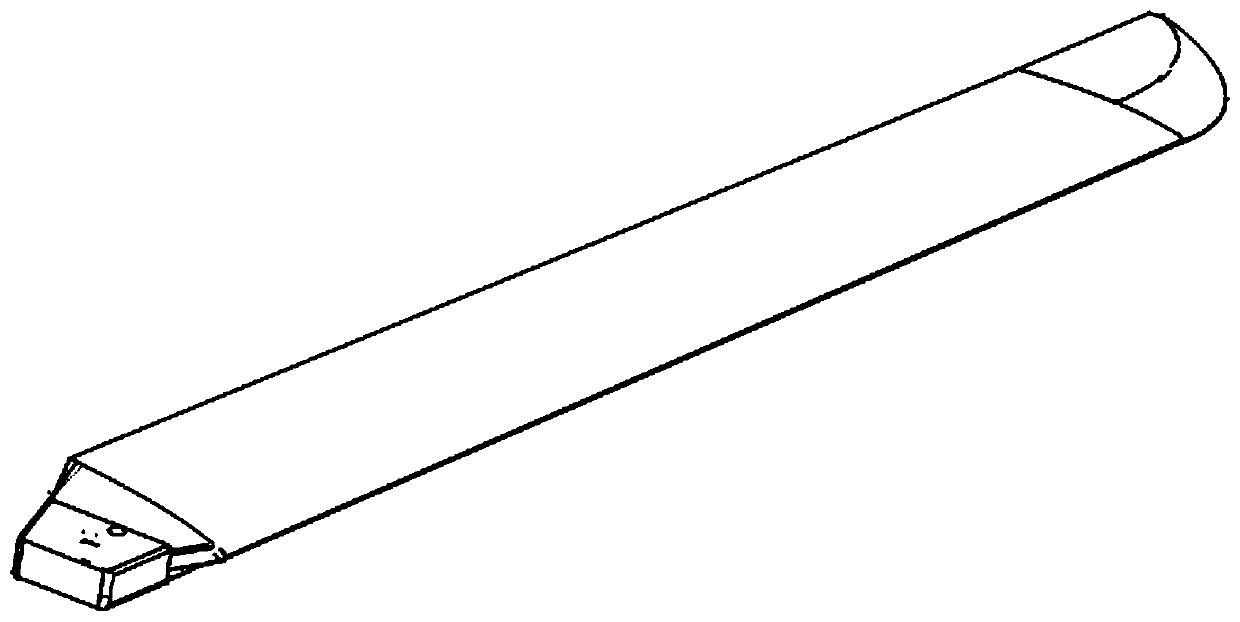

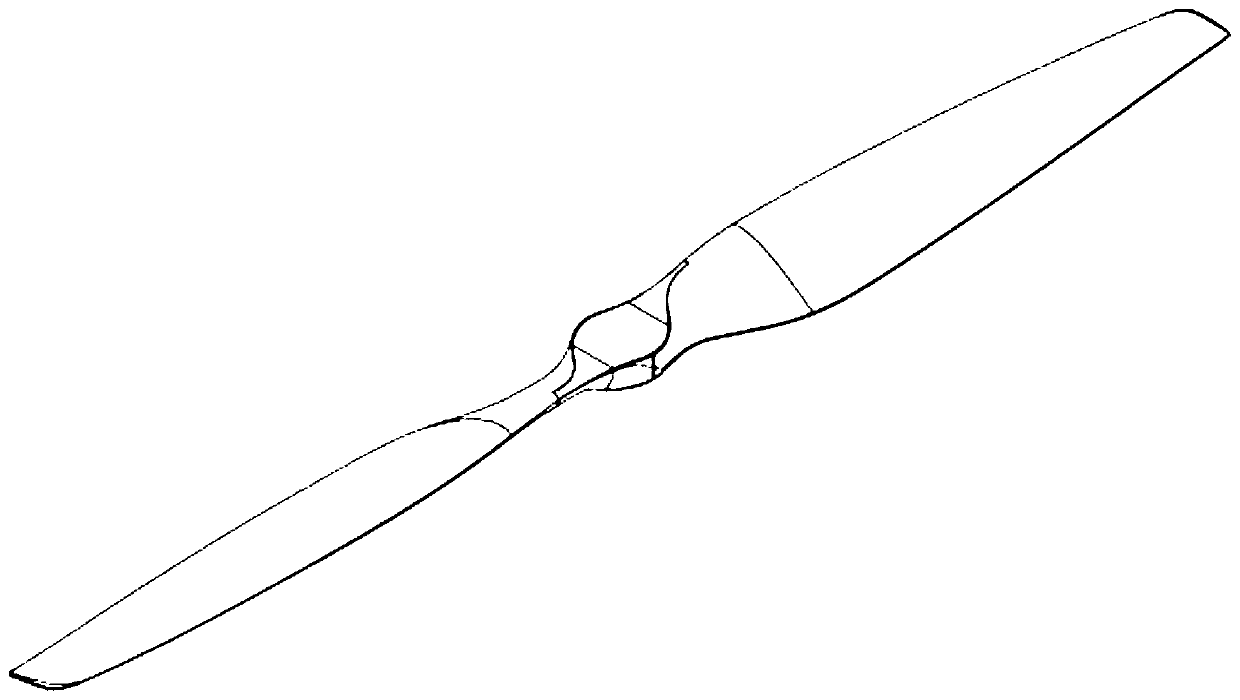

[0071] The size of the propeller blade that present embodiment manufactures is: rotation diameter (that is, when the propeller rotates, the diameter of its blade tip track circle) 1.5 meters, length 705 millimeters, width 147 millimeters, thickness 91 millimeters.

[0072] The manufacturing method of this embodiment is:

[0073] (1) According to the three-dimensional dimensions of the propeller, by calculating the thickness of the layer, the three-dimensional drawing of the sandwich foam inside the propeller is obtained, the numerical control processing program is customized, and the PMI foam blank of the appropriate size is customized. The material model is RP-D60, and the density is 60kg / cubic. Put the PMI blank into the three-axis CNC machining center. Because the foam material is soft, it cannot be clamped with a common fixture. Therefore, after adjusting the position, fix the material firmly with hot melt adhesive. Due to the large thickness of the blank material and the ...

Embodiment 2

[0078] The size of the propeller blade that present embodiment manufactures is: rotating diameter 5 meters, length 2350 millimeters, width 211 millimeters, thickness 45 millimeters.

[0079] The manufacturing method of this embodiment is:

[0080] (1) According to the three-dimensional dimensions of the propeller, by calculating the thickness of the layer, the three-dimensional drawing of the sandwich foam inside the propeller is obtained, the numerical control processing program is customized, and the PMI foam blank of the appropriate size is customized. The material model is RP-D60, and the density is 60kg / cubic. Put the PMI blank into the three-axis CNC machining center. Because the foam material is soft, it cannot be clamped with a common fixture. Therefore, after adjusting the position, fix the material firmly with hot melt adhesive. Due to the large thickness of the blank material and the softness of the foam material, a custom-made R4 double-edged flat end mill is used ...

Embodiment 3

[0085] The size of the propeller blade that present embodiment manufactures is: diameter of rotation: 720 millimeters, long 720 millimeters, wide 64 millimeters, thickness 25 millimeters.

[0086] The manufacturing method of this embodiment is:

[0087](1) According to the three-dimensional dimensions of the propeller, by calculating the thickness of the layer, the three-dimensional drawing of the sandwich foam inside the propeller is obtained, the numerical control processing program is customized, and the PMI foam blank of the appropriate size is customized. The material model is RP-D60, and the density is 60kg / cubic. Put the PMI blank into the three-axis CNC machining center. Because the foam material is soft, it cannot be clamped with a common fixture. Therefore, after adjusting the position, fix the material firmly with hot melt adhesive. Due to the large thickness of the blank material and the soft foam material, a custom-made R3 double-edged flat end mill is used with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com