Diversified waterproof coating

A waterproof coating and pure water technology, applied in the field of coatings, can solve the problems of shortening the life of the coating, airtight walls, polluting the environment, etc., and achieve the effects of simple construction, long shelf life, and increased compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

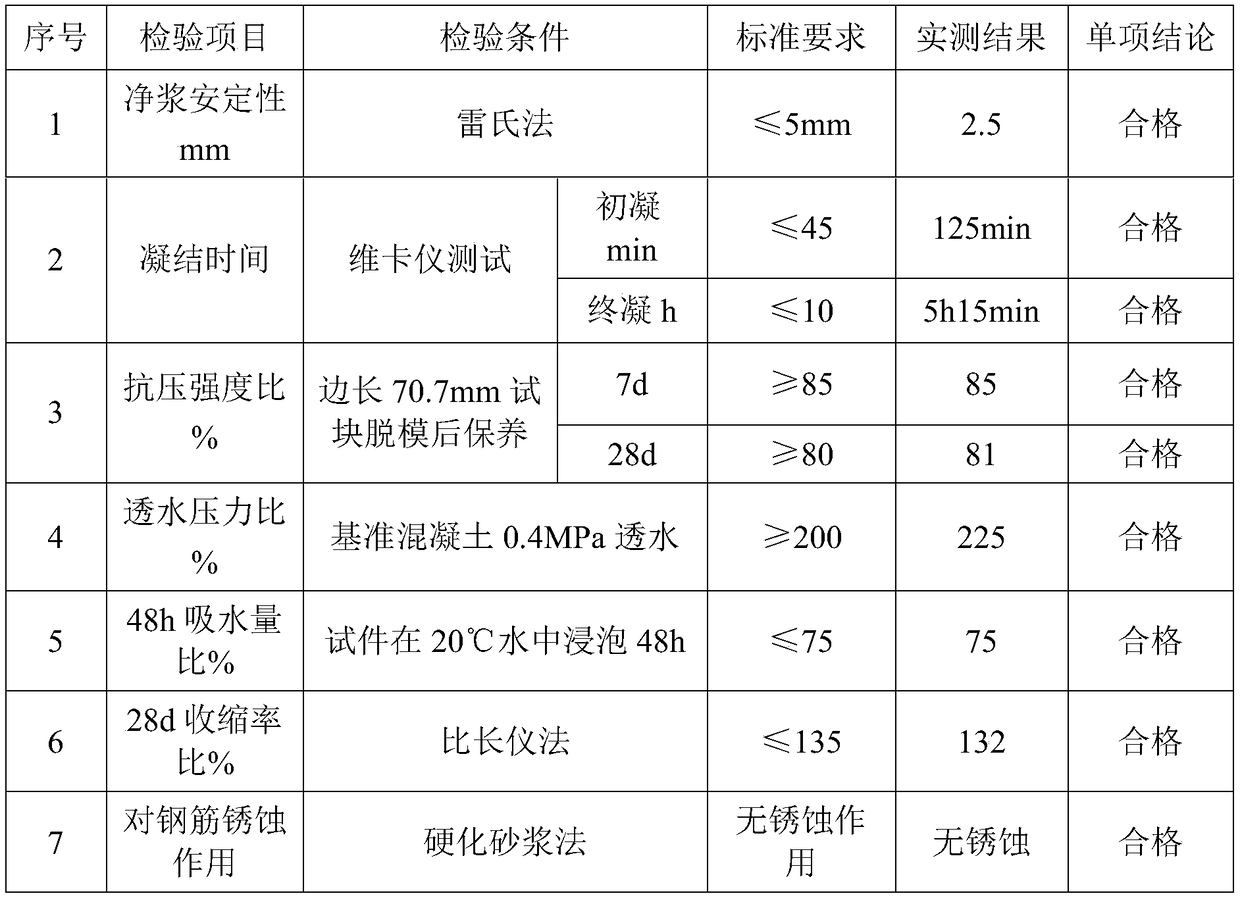

Image

Examples

Embodiment 1

[0033] The invention relates to a diversified waterproof paint. The composition and proportion of the diversified waterproof paint are 32-42% sodium methyl silicate, 2.5% aluminum sulfate and 55.5-65.5% water.

[0034] Prepare the production technology of sodium methyl silicate, the steps are as follows:

[0035] S1. Take methyltrichlorosilane and water in a ratio of 1:6 and heat it in a non-metallic reactor to 28-32°C to react CH 3 SiCl 3 +3H 2 O=CH 3 Si(OH) 3 +3HCl to obtain methyl silicic acid;

[0036] S2. Take methyl silicic acid, sodium hydroxide, and water in a ratio of 3:1:5, heat up to 90-95°C in a non-metallic reactor, and react fully until completely dissolved to obtain sodium methyl silicate, and then adjust the pH The value reaches 11-13.

[0037] The production method of diversified waterproof paint, the steps are as follows:

[0038] S1, aluminum sulfate 25kg, add in 100kg water, dissolve evenly, obtain aluminum sulfate solution;

[0039] S2. In a stainl...

Embodiment 2

[0047] The composition and ratio of the diversified waterproof coating are 320kg sodium methyl silicate, 25kg aluminum sulfate and 555kg water.

Embodiment 3

[0049] The composition and ratio of the diversified waterproof coating are 420kg sodium methyl silicate, 25kg aluminum sulfate and 655kg water.

[0050] Therefore, the present invention adopts the above-mentioned multiple waterproof coating, which is simple in construction, saves time and effort, and has good waterproof and air permeability. The outside water does not penetrate, and the inside moisture can be emitted outwards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com