Method for growing bismuth silicate (BSO) scintillation crystal by shaping and lifting

A crystal growth and growth method technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of small light output, long light attenuation time, slow crystal growth rate, etc., to save production costs, reduce Subsequent process, the effect of fast growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

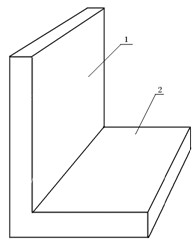

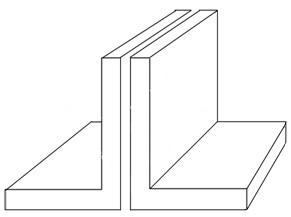

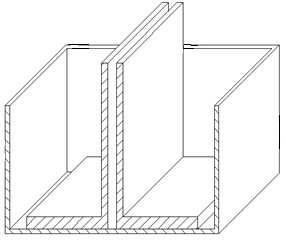

[0037] High-purity Bi 2 o 3 , SiO 2 As the initial raw material, the molar ratio is 2: 3 for batching, the raw materials are fully mixed, and pre-calcined at 650 ° C for 6 hours. Then the raw materials were ground to a particle size of 400nm, and then calcined at 850° C. for 12 hours to obtain the BSO polycrystalline material. The BSO crystal with orientation was used as the seed crystal, and the BSO polycrystalline material was placed in a crucible with a shaping mold (the width of the mold was 50 mm, and the width of the slit was 8 mm), and placed in a shaping and pulling furnace in an air atmosphere. Continue to raise the temperature to 1100°C, and keep the temperature constant for 5 hours until the polycrystalline material is completely melted. The seed crystal is slowly lowered to make it contact with the melt at the top of the slit, the top of the seed crystal is partially melted, and the melt spreads on the top of the mold. The schematic diagram of its crystal growt...

Embodiment 2

[0039] High-purity Bi 2 o 3 , SiO 2As the initial raw material, the molar ratio is 2: 3 for batching, the raw materials are fully mixed, and pre-calcined at 700 ° C for 8 hours. Then the raw materials were ground to a particle size of 550nm, and pre-calcined at 800°C for 8 hours to obtain the BSO polycrystalline material. The BSO crystal is used as the seed crystal, and the BSO polycrystalline material is placed in a crucible with a shaping mold (the width of the mold is 40mm, and the width of the slit is 5mm), and it is placed in a shaping and pulling furnace in an oxygen atmosphere. Continue to raise the temperature to 1130°C, and keep the temperature constant for 3 hours until the polycrystalline material is completely melted. Slowly lower the seed crystal to make it contact with the melt at the top of the slit, the top of the seed crystal is partially melted, and the melt spreads on the top of the mold, and grows at a speed of 8mm / h, and the temperature gradient of the...

Embodiment 3

[0041] A transparent window for observation is set up on the side of the crystal growth furnace, so that the solid-liquid interface and crystal growth during crystal growth can be observed in real time to achieve real-time monitoring. High-purity Bi 2 o 3 , SiO 2 As the initial raw material, the molar ratio is 2:3 for batching, the raw materials are fully mixed, and pre-calcined at 750 ° C for 10 hours. Then the raw materials were ground to a particle size of 600nm, and pre-calcined at 850°C for 8h. BSO crystals with an orientation of were used as seed crystals, and the BSO polycrystalline material was placed in a crucible with a shaping mold (the width of the mold was 60mm, and the width of the slit was 2mm), and placed in a shaping and pulling furnace in an air atmosphere. Continue to raise the temperature to 1200°C, and keep the temperature constant for 3 hours until the polycrystalline material is completely melted. Slowly put down the seed crystal so that it is in co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com