High-strength high-conductivity copper chromium zirconium alloy and low-temperature deforming preparing method thereof

A high-conductivity, high-strength technology, applied in the manufacture of high-strength and high-conductivity copper-chromium-zirconium alloys that are characterized by low-temperature deformation, can solve the problem of decreased conductivity, increased scattering cross-section, and alloys that cannot continue to reduce grain size Strength and other issues, to achieve the effect of relaxing the treatment conditions, improving the strength of the alloy, and eliminating the need for artificial aging treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

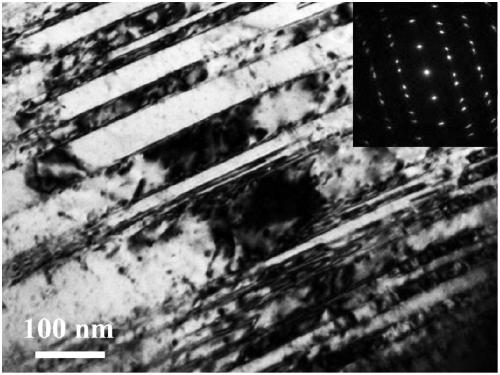

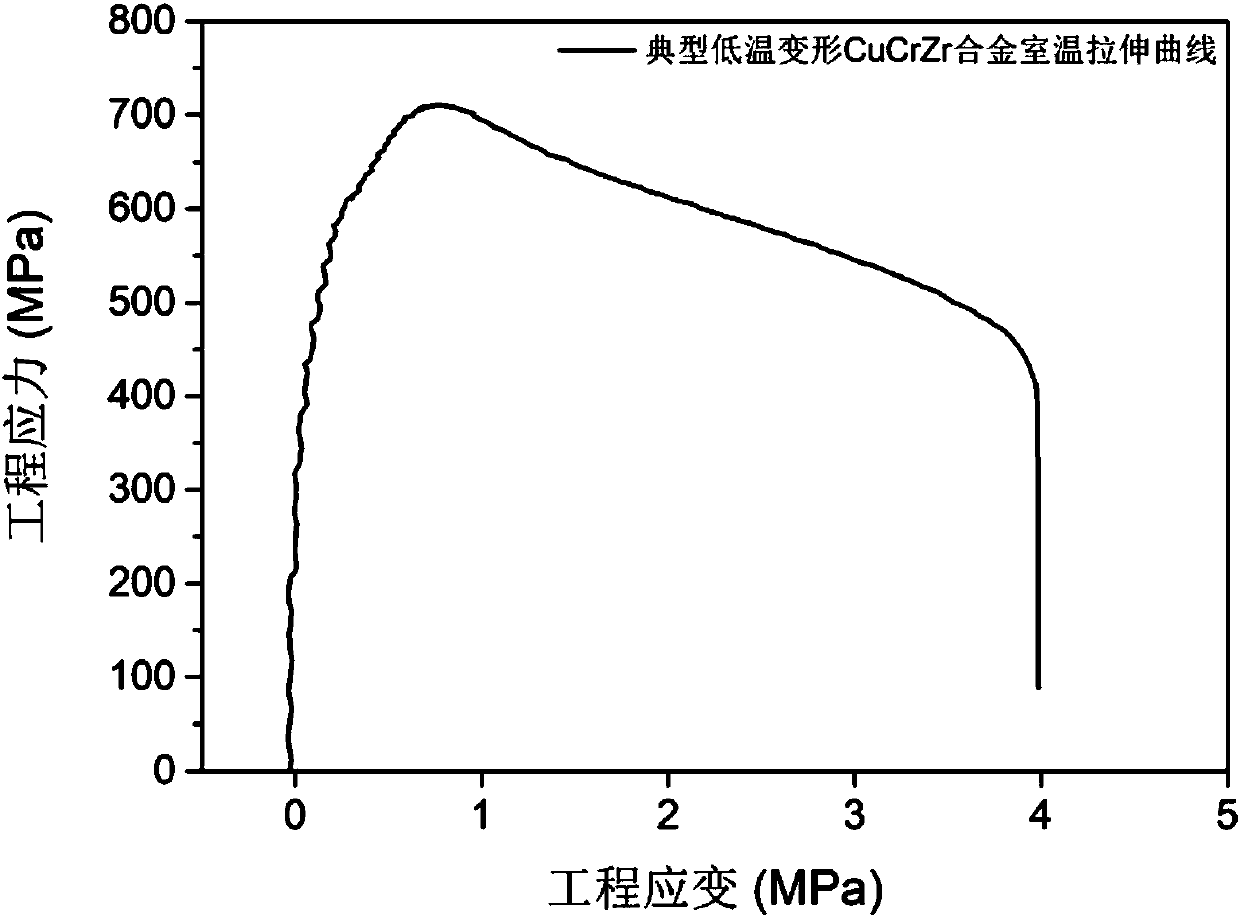

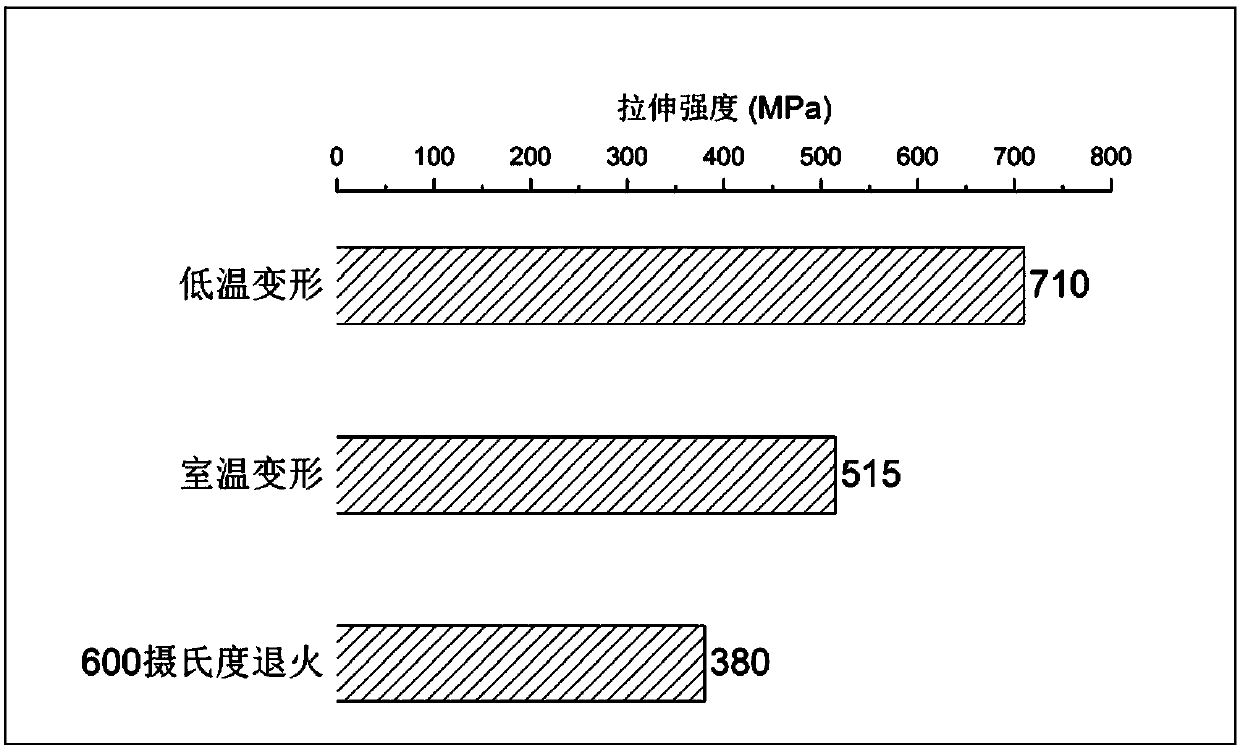

[0035] In terms of mass percentage, the composition of copper-chromium alloy is: 98.6% copper, 1.0% chromium, 0.1% zirconium, and the rest are unavoidable impurities. After vacuum casting, the alloy is hot-extruded at 1000°C and kept at 600°C for 0.5 hours. After hot extrusion, the alloy is soaked in liquid nitrogen and then cold forged in a liquid nitrogen environment, with an equivalent variable of 2.0. The typical microstructure of the alloy after deformation is a mixed structure of nano-sized twin bundles and nano-crystals, the average thickness of the nano-twins is 30nm, and the average grain size of the nano-crystals is 50nm. The tensile strength of the alloy at room temperature is 700 MPa, and the electrical conductivity is 78% IACS.

Embodiment 2

[0037] In terms of mass percentage, the composition of copper-chromium alloy is: 98.6% copper, 1.0% chromium, 0.1% zirconium, and the rest are unavoidable impurities. After the alloy is vacuum melted and cast, it is hot extruded at 1000°C and cooled through water. The hot extruded material is naturally cooled after being kept at 600 degrees Celsius for 2 hours, and then cold forged at -50 degrees Celsius after soaking in liquid nitrogen. After the alloy goes through the above process, the typical microstructure is a mixed structure of nano-sized twin beams and nano-crystals, the average layer thickness of nano-twins is 30nm, and the average grain size of nano-crystals is 100nm. The tensile strength of the alloy at room temperature is 650 MPa, and the electrical conductivity is 80% IACS.

Embodiment 3

[0039] In terms of mass percentage, the composition of copper-chromium alloy is: 98.6% copper, 1.0% chromium, 0.1% zirconium, and the rest are unavoidable impurities. After the alloy is vacuum melted and cast, it is hot extruded at 1000°C and water cooled. After hot extrusion, the alloy is soaked in liquid nitrogen after heat preservation at 600°C for 2 hours, and rolled at -100°C, with a total rolling reduction of 85%. After the alloy goes through the above process, the typical microstructure is a mixed structure of nano-sized twin beams and nano-crystals, the average layer thickness of nano-twins is 30nm, and the average grain size of nano-crystals is 50nm. The tensile strength of the alloy at room temperature is 680 MPa, and the electrical conductivity is 80% IACS.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com