Keyboard key full-pattern injection mold structure and system thereof

An injection mold and injection system technology, applied in the field of injection mold structure and its system, can solve the problems of occupying inventory space, increasing labor costs, reducing production efficiency, etc., and achieving the effect of reducing weight, reducing subsequent processes, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

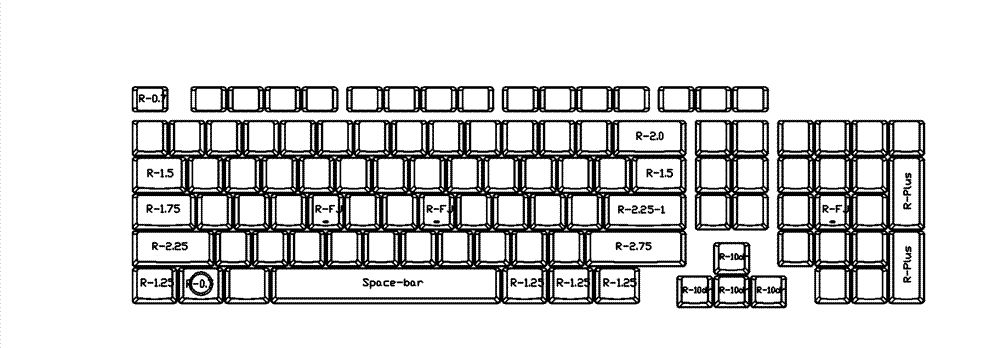

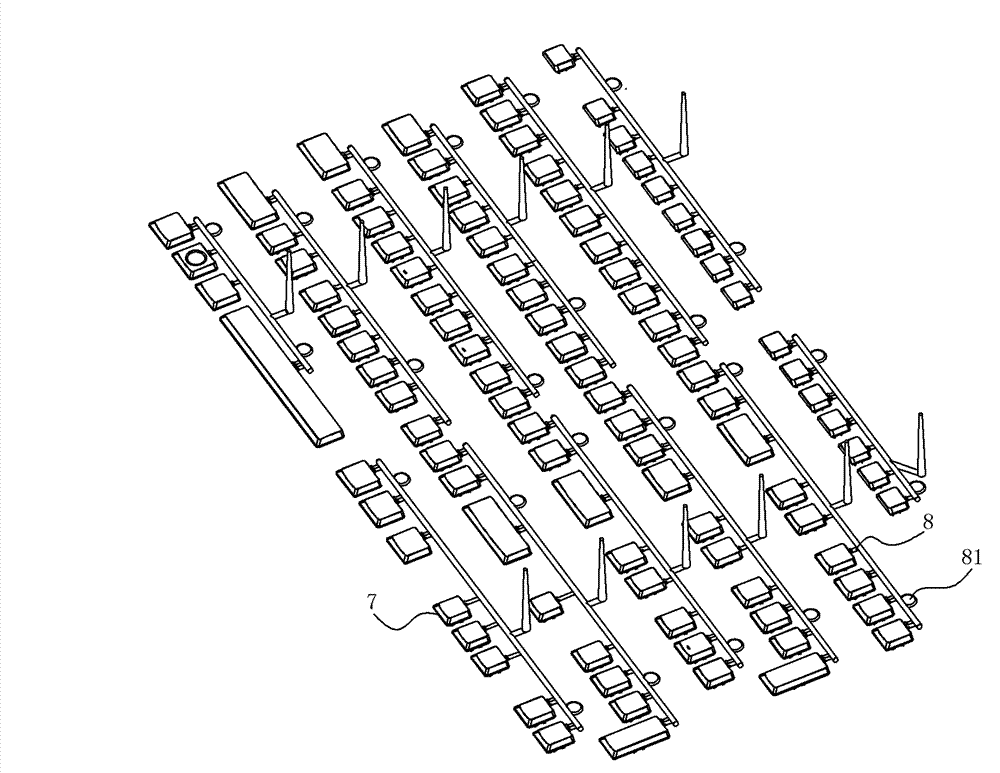

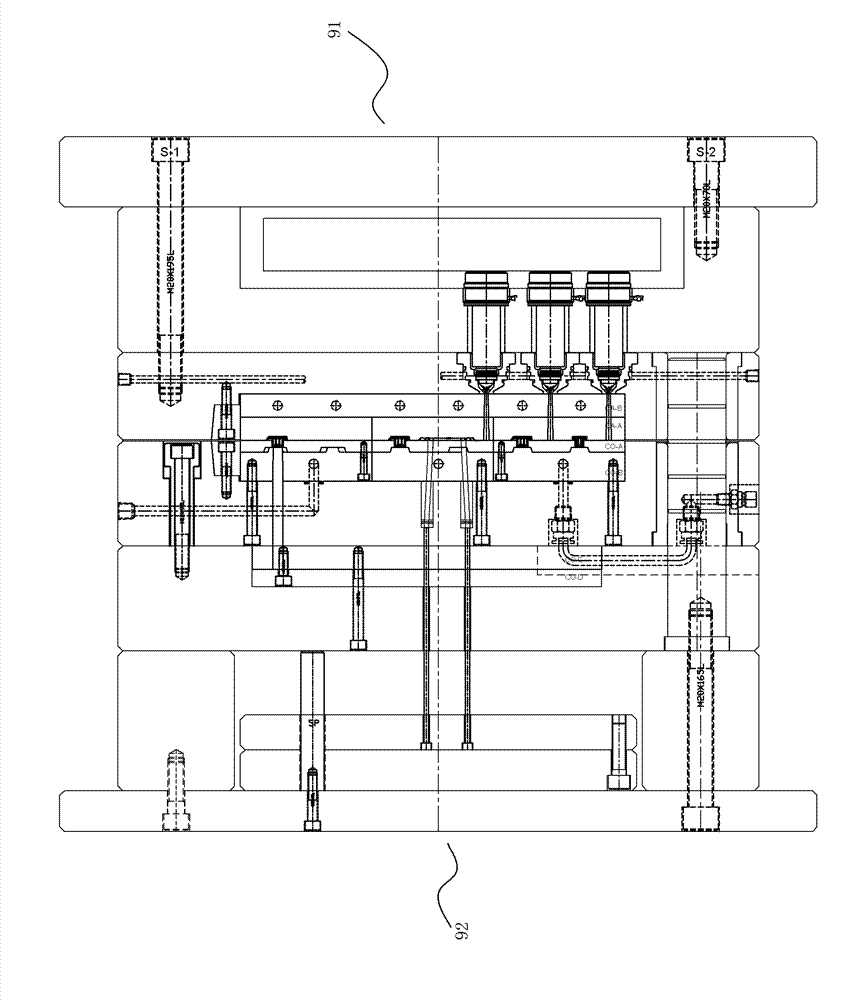

[0077] Such as Figure 3 to Figure 12 As shown, the whole-page injection mold structure of the keyboard button of the present invention includes a front mold base 91 and a rear mold base 92. Including the rear mold base 921 and the rear mold core 922 fixed on the rear mold base 921, between the front mold core 912 and the rear mold core 922 are provided with several molding cavities for forming the keys of the entire keyboard, and are connected to several The hot runner of the molding cavity, the hot runner communicates with the hot nozzle 913 located at the front mold base 911, the molding cavity is divided into several rows, and the row spacing between each row of molding cavities is greater than the row spacing of the keys on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com