Industrial preparation method of theaflavin

A technology for theaflavin and theaflavin ester, applied in the directions of organic chemistry, fermentation, etc., can solve the problems of restricting the large-scale production of theaflavin, complicated and expensive separation and purification procedures, etc., and achieves convenient industrial production, stable and controllable process, and reduced The effect of theabrownin production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

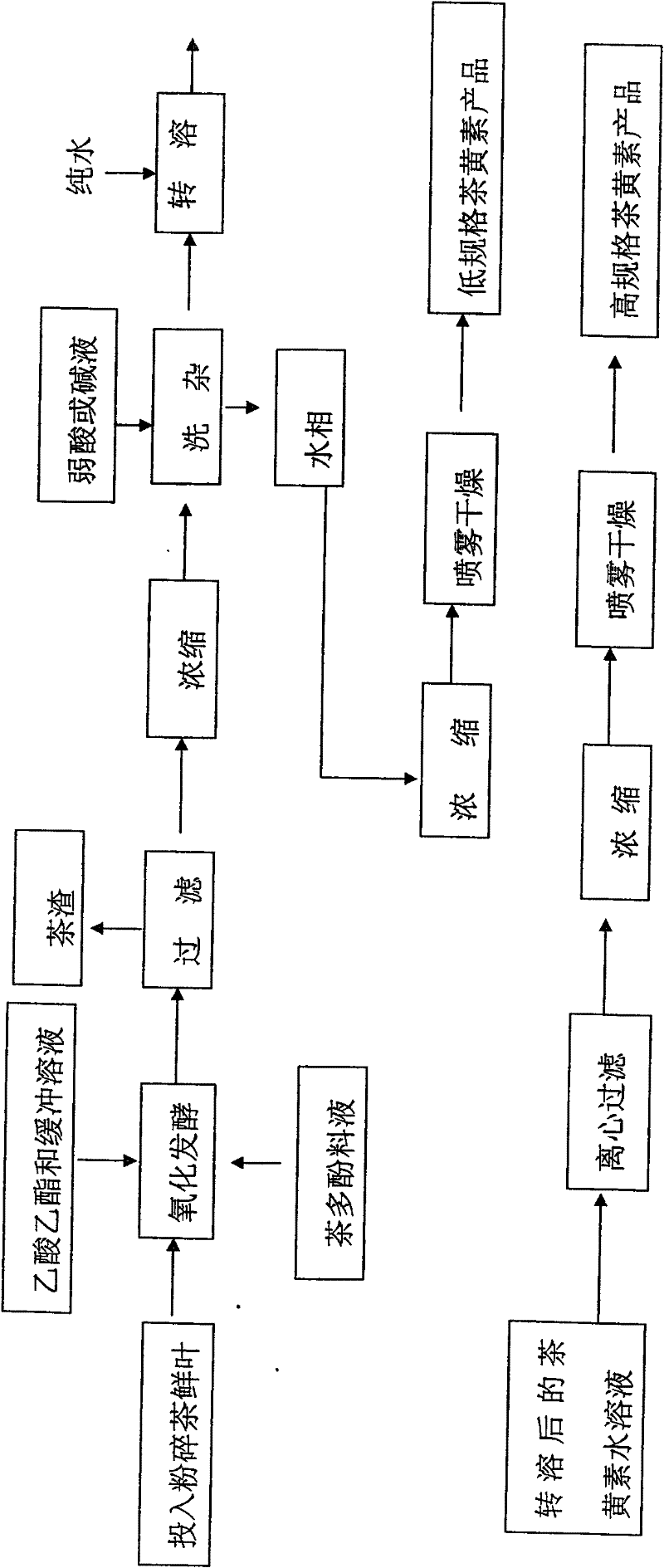

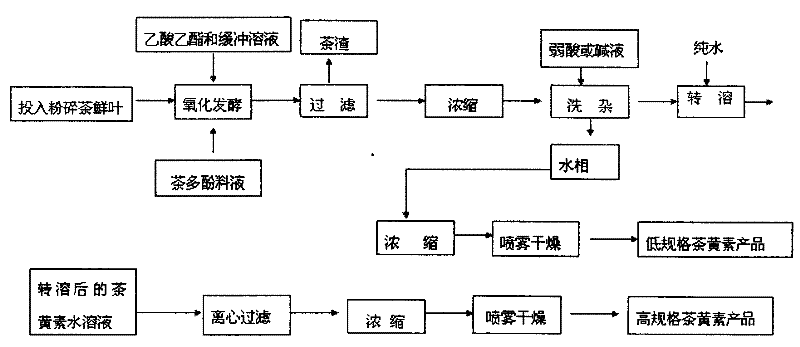

Image

Examples

Embodiment 1

[0029] (1) Prepare 700kg of ethyl acetate solution rich in 80mg / ml tea polyphenols by the process of extracting tea polyphenols;

[0030] (2) 700kg of ethyl acetate solution rich in tea polyphenols and 800kg of pulverized fresh tea leaves are dropped into an oxidation fermenter, followed by adding 20L of ethyl acetate and 1.5L of citric acid-disodium hydrogen phosphate buffer, at room temperature Under the state, the air is passed through to stir and oxidize and ferment for 30-40 minutes to obtain the theaflavin ester phase solution;

[0031] (3) The theaflavin ester phase solution is first filtered to remove the tea dregs, then concentrated and washed with sodium bicarbonate solution to obtain an aqueous phase solution and an ester phase solution; the tea dregs are dried and stored for later use.

[0032] (4) Spray-dry after the aqueous phase solution of step (3) is concentrated, obtain the theaflavin dry powder of low specification;

[0033] (5) the ester phase solution of ...

Embodiment 2

[0038] (1) Prepare 800kg of ethyl acetate solution rich in 80mg / ml tea polyphenols by the process of extracting tea polyphenols;

[0039] (2) 800kg of ethyl acetate solution rich in tea polyphenols and 800kg of pulverized fresh tea leaves are dropped into an oxidation fermenter, and 24L of ethyl acetate and 1.8L of citric acid-disodium hydrogen phosphate buffer are added successively. Under the state, the air is passed through to stir and oxidize and ferment for 30-40 minutes to obtain the theaflavin ester phase solution;

[0040] (3) The theaflavin ester phase solution is firstly filtered to remove tea dregs, then concentrated and washed with citric acid solution to obtain an aqueous phase solution and an ester phase solution; the tea dregs are dried and stored for later use.

[0041] (4) Spray-dry after the aqueous phase solution of step (3) is concentrated, obtain the theaflavin dry powder of low specification;

[0042] (5) the ester phase solution of step (3) is concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com