Patents

Literature

74results about How to "Reduce the number of molds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

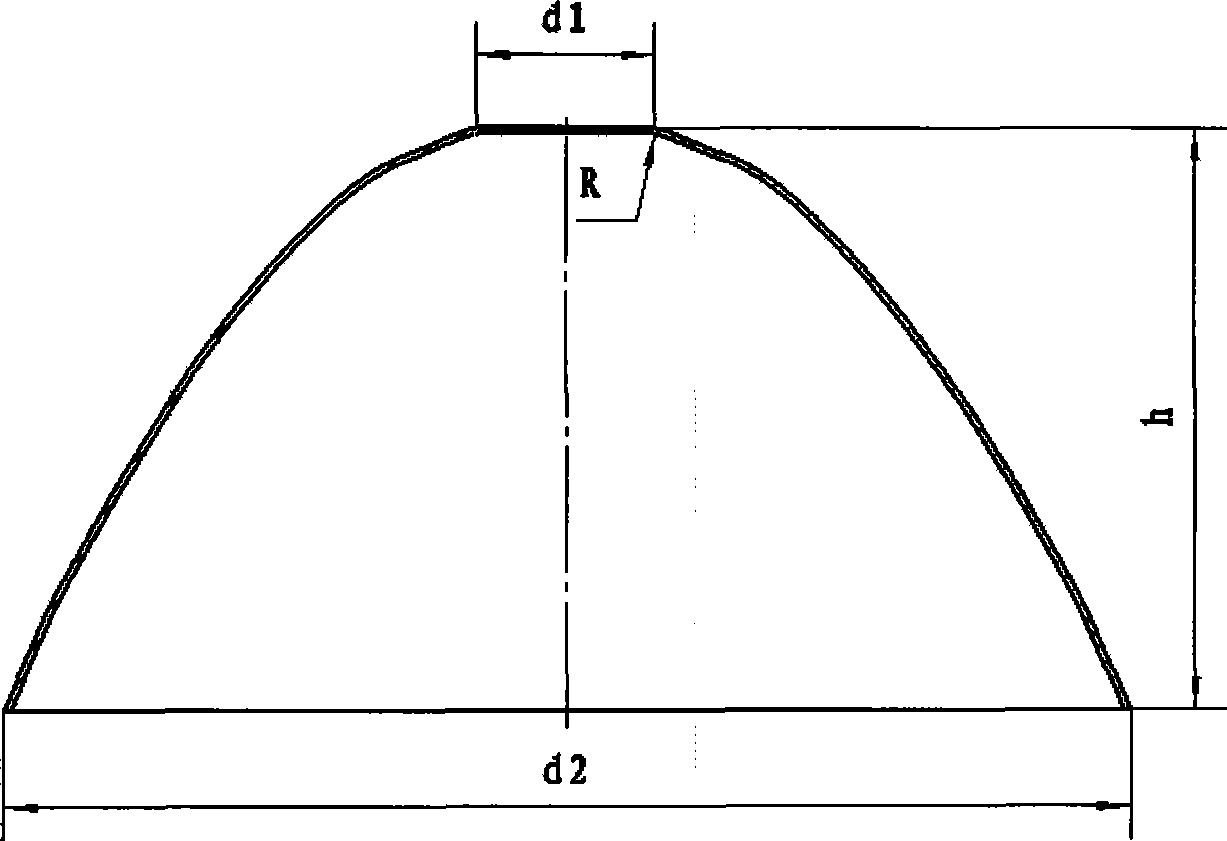

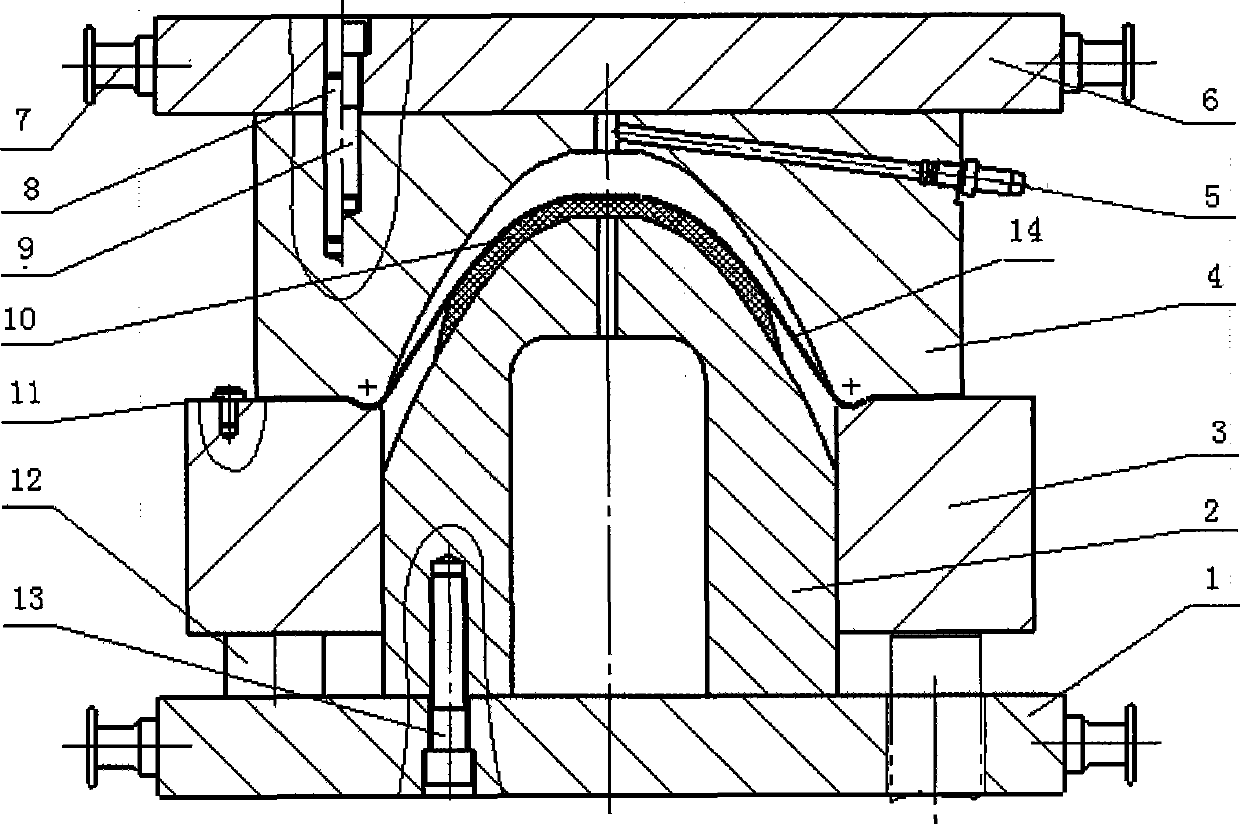

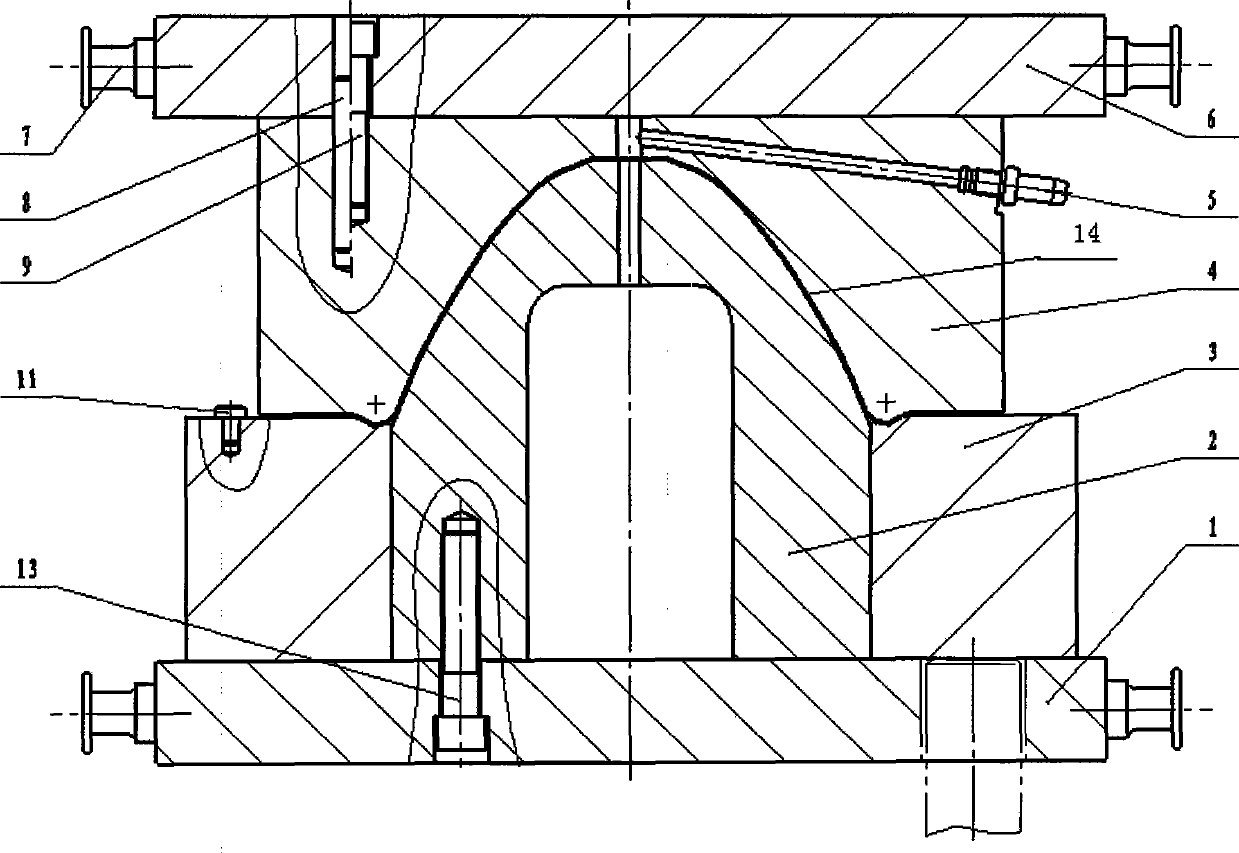

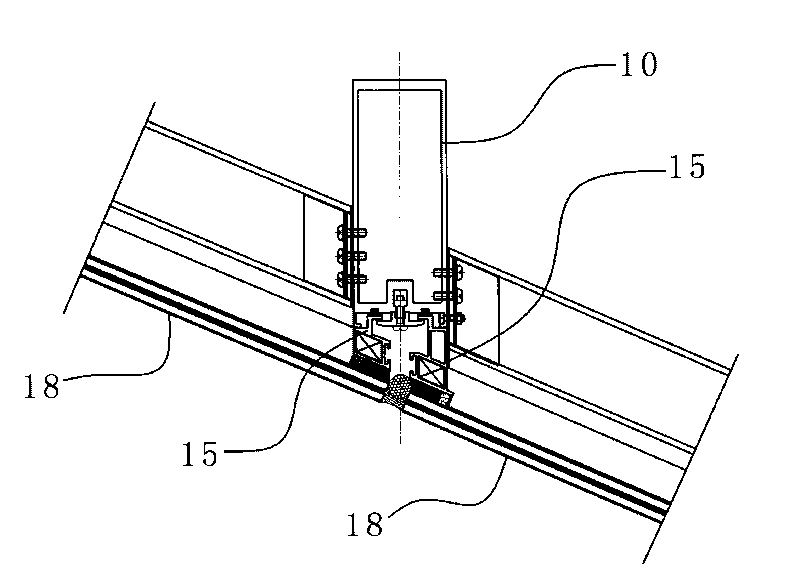

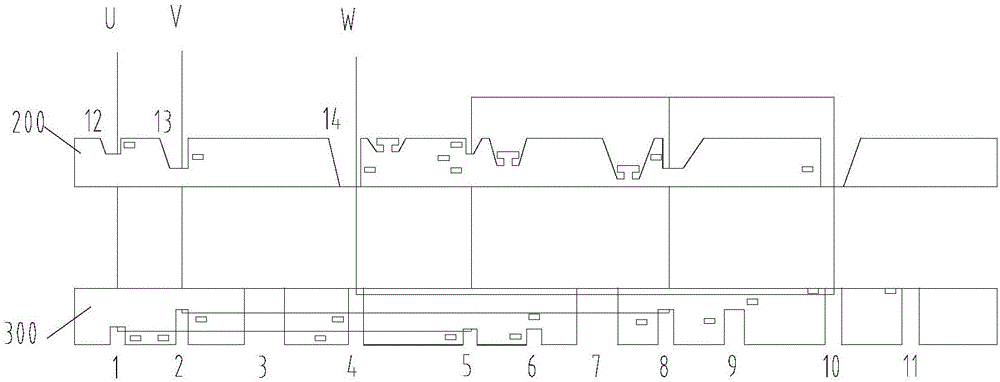

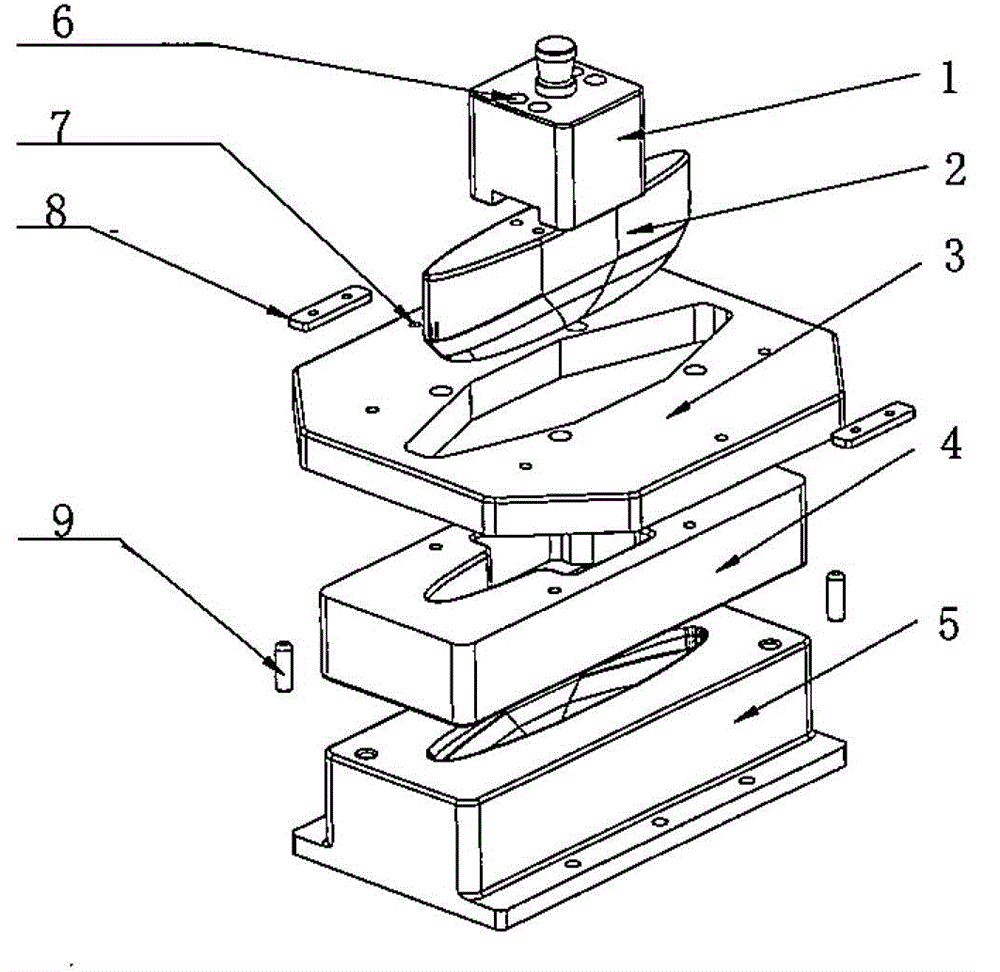

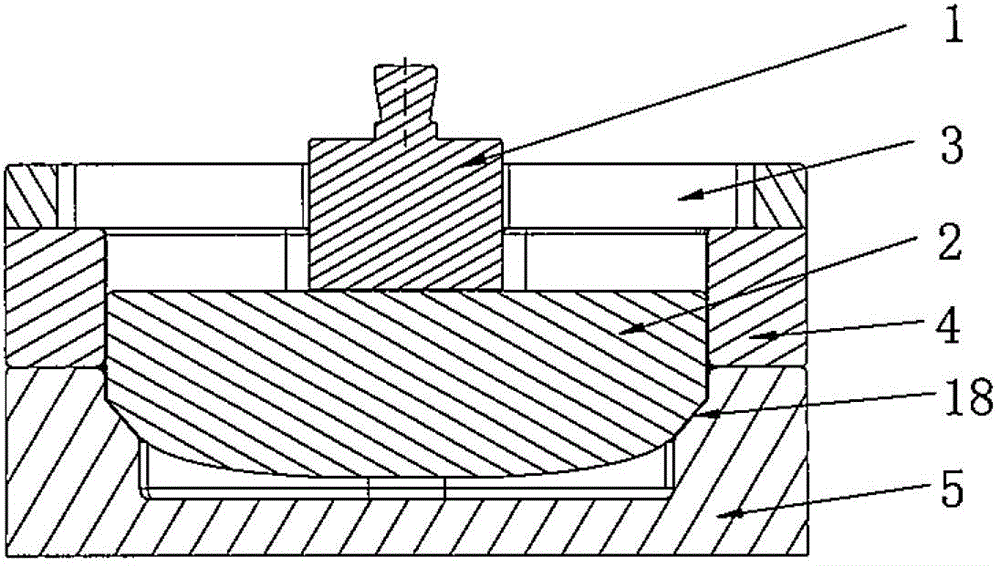

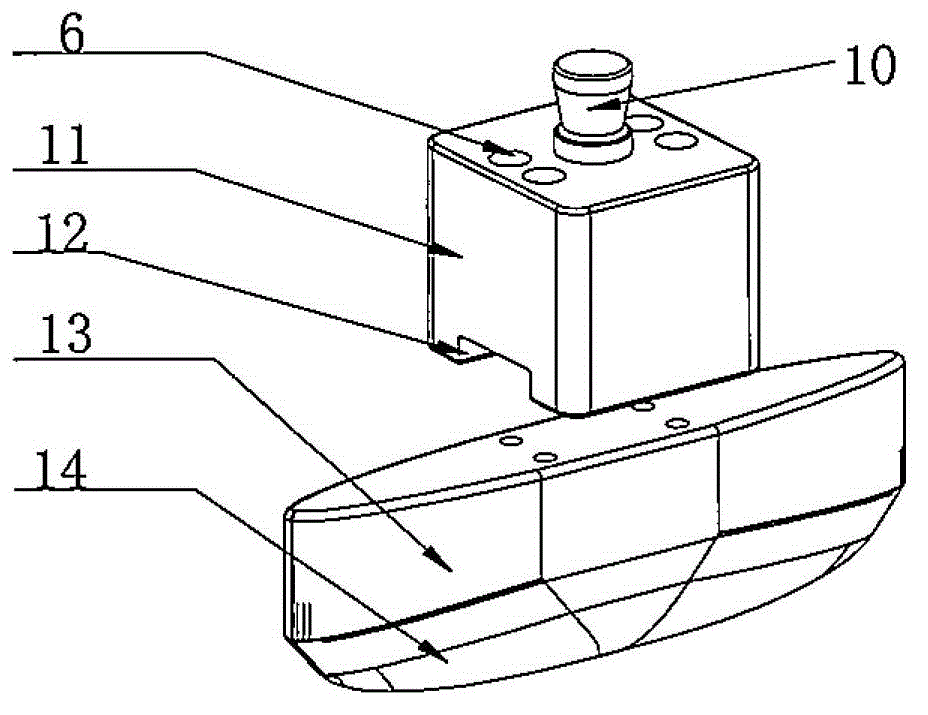

Method for drawing and forming parabola revolution body

The invention relates to a method for drawing shaped parabola revolving body, belonging to the technical field of the plastic forming of material processing engineering. The method comprises the following steps: (1) a set of mould is designed according to the final shape of revolving body parts; (2) the first drawing: when being drawn, a movable soft punch cushion block is arranged on a mould punch; the inner shape of the movable soft punch cushion block is similar to the shape of the punch; a movable rigidity limit cushion block is arranged below a blank holder with a belt drawbead; (3) the annealing heat treatment, the annealing heat treatment is carried out on the parts after the first drawing is carried out on the parts; (4) the second drawing, the same set of module is used; when in drawing, the movable soft punch cushion block and the movable rigidity limit cushion block are removed. In the invention, the movable soft punch cushion block is added on a drawing mould rigidity punch for enlarging the plastic forming of the materials in the first drawing; only one set of drawing module is used on an ordinary hydraulic press, therefore, the parahola revolving body parts which are usually formed with 3-4 sets of moulds by the common drawing processing are successfully formed by twice drawing.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

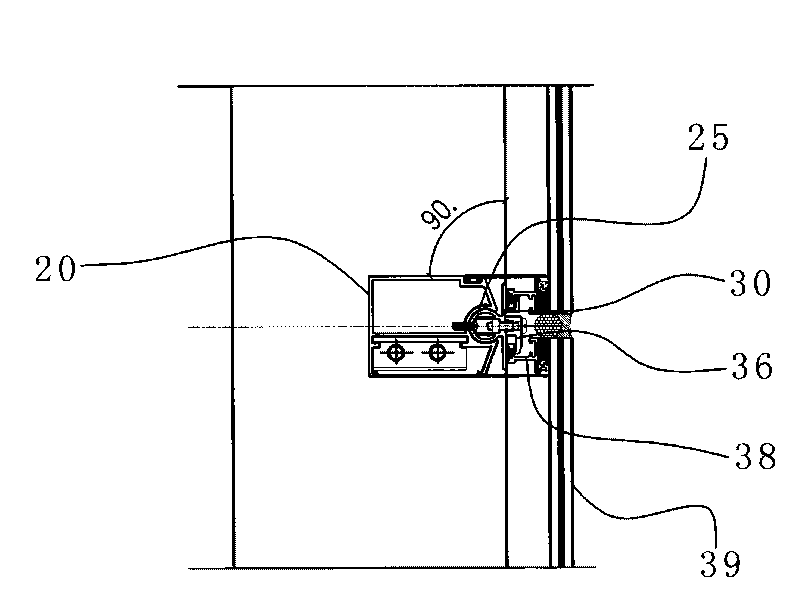

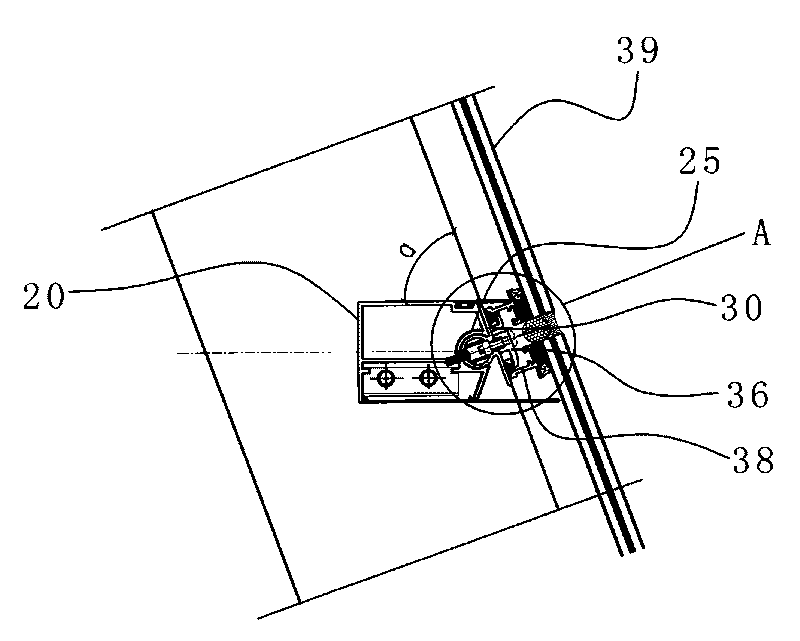

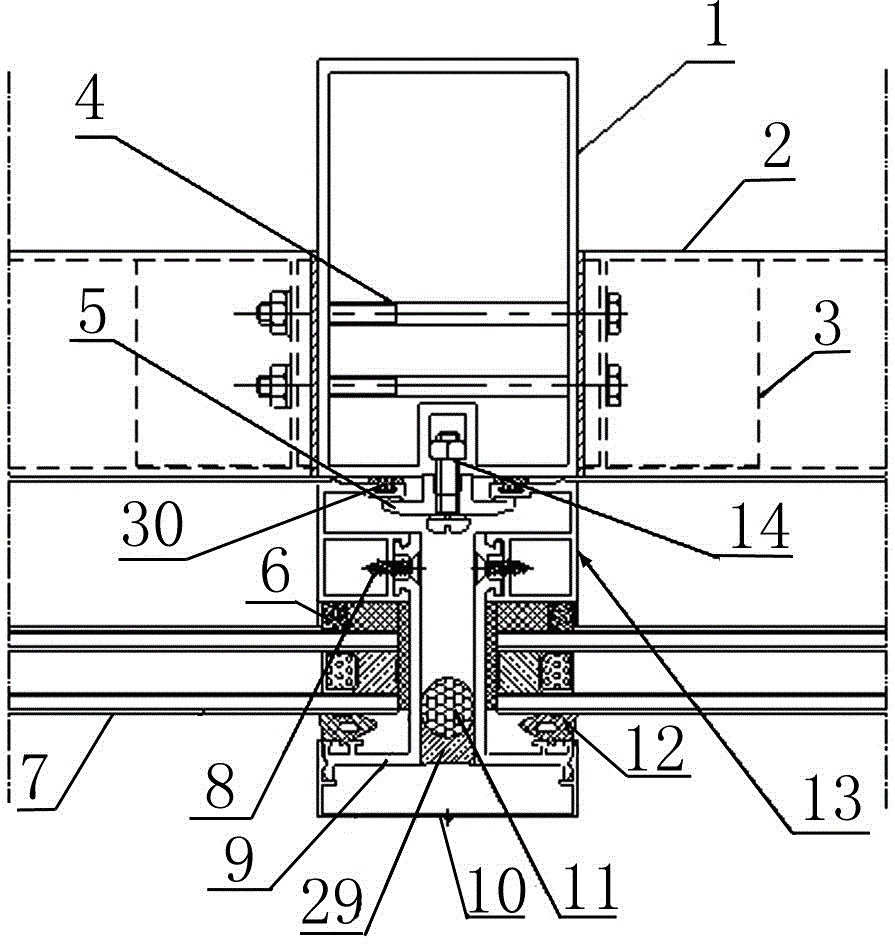

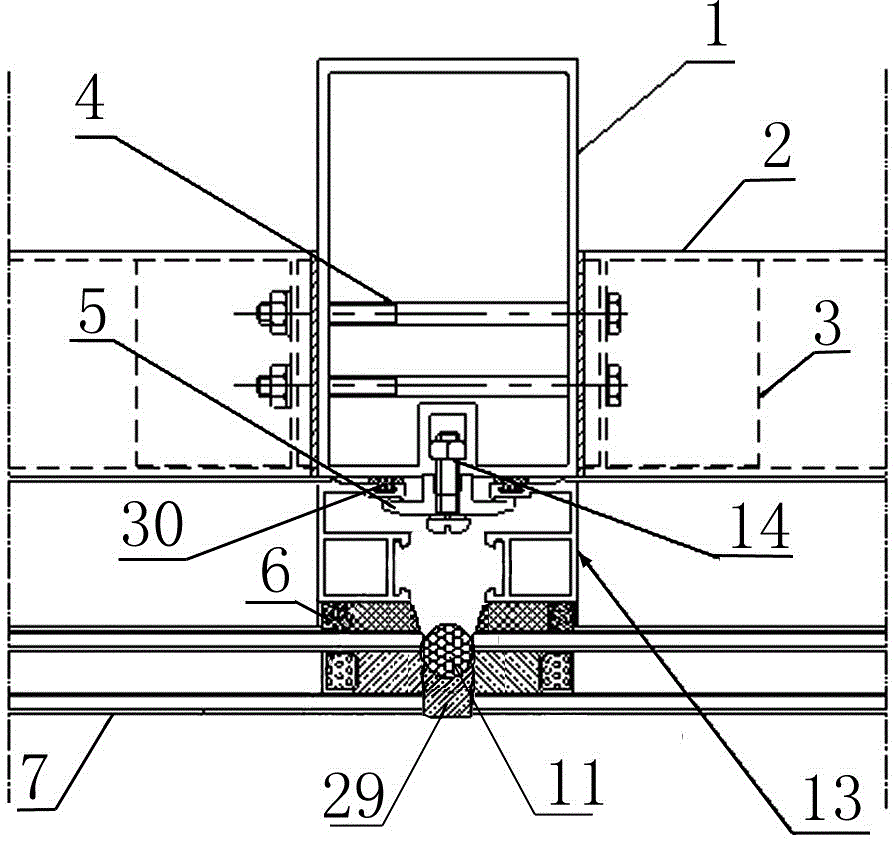

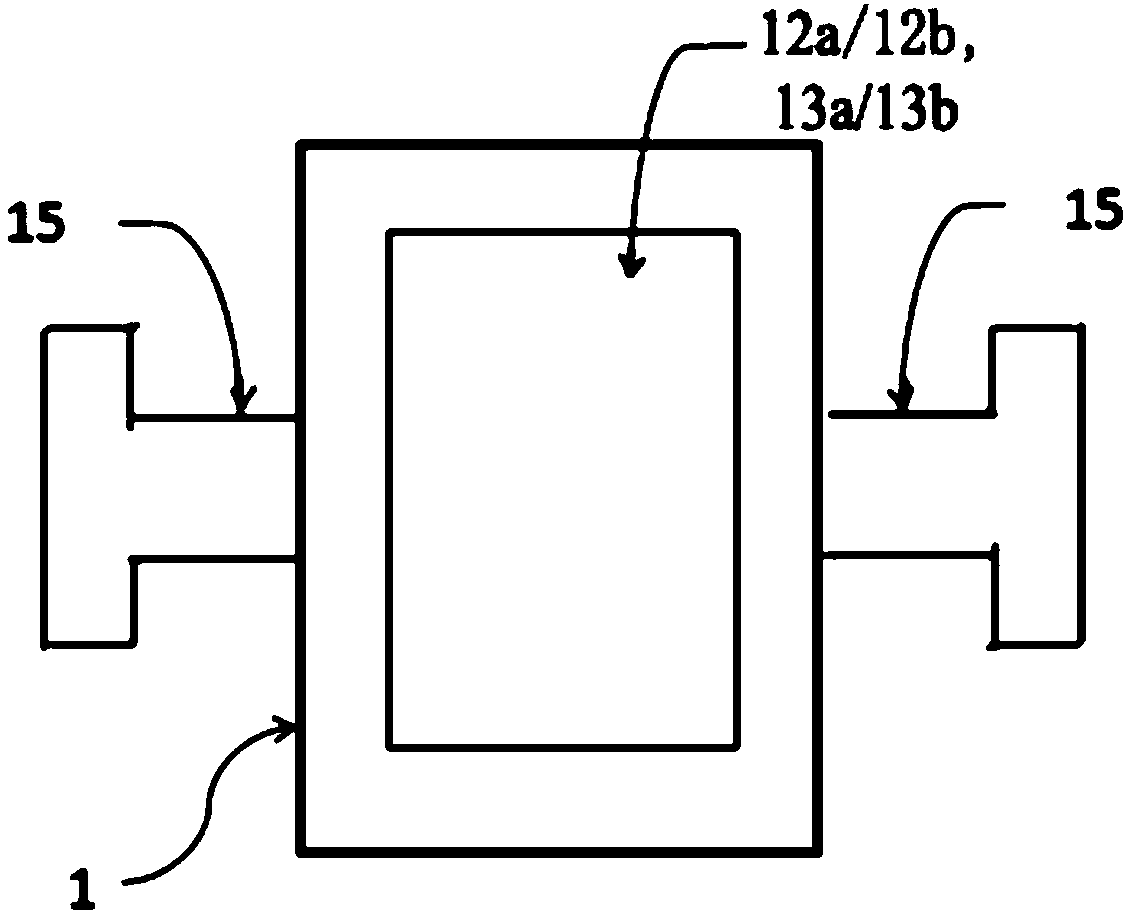

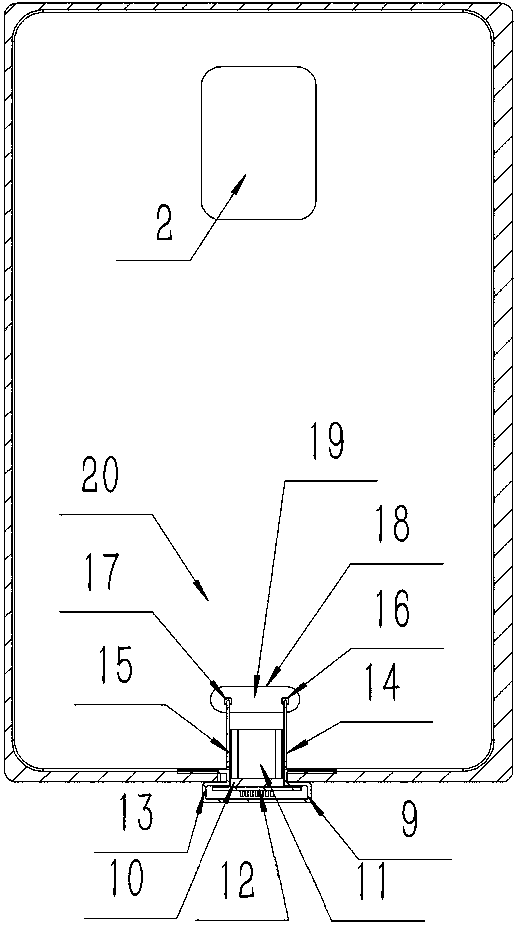

Glass curtain wall hidden frame

ActiveCN101736837AReduce specification requirementsSave manufacturing costWallsKeelBuilding construction

The invention discloses a glass curtain wall hidden frame which comprises a keel assembly, an auxiliary frame and a pressure plate, wherein the keel assembly comprises a main keel and a keel accessory, the main keel and the keel accessory are hinged, the pressure plate is installed on the keel accessory, and the auxiliary frame is compressed on the keel accessory. When the glass curtain wall hidden frame is used, the installation angle can be adjusted as required, thereby easily realizing the installation of a frame type glass curtain wall between a glass plate block and a building upright post (building crossbeam) in different angles, easily realizing the effect of a slope glass curtain wall in different angles, reducing the specification requirements for installing the main keel or the auxiliary frame on the curtain wall, saving the manufacturing cost and the production period of a mould, simultaneously improving the installation accuracy of the slope glass curtain wall, improving the universality of the frame installed on the curtain wall, greatly reducing the opening mould quantity of an aluminum shaped material, having no need of predefining and manufacturing frame fittings with different specifications, shortening the construction period of curtain wall installation and providing a technical guarantee for the standardization of a curtain wall frame.

Owner:GUANGZHOU JANGHO CURTAIN WALL SYST ENG +2

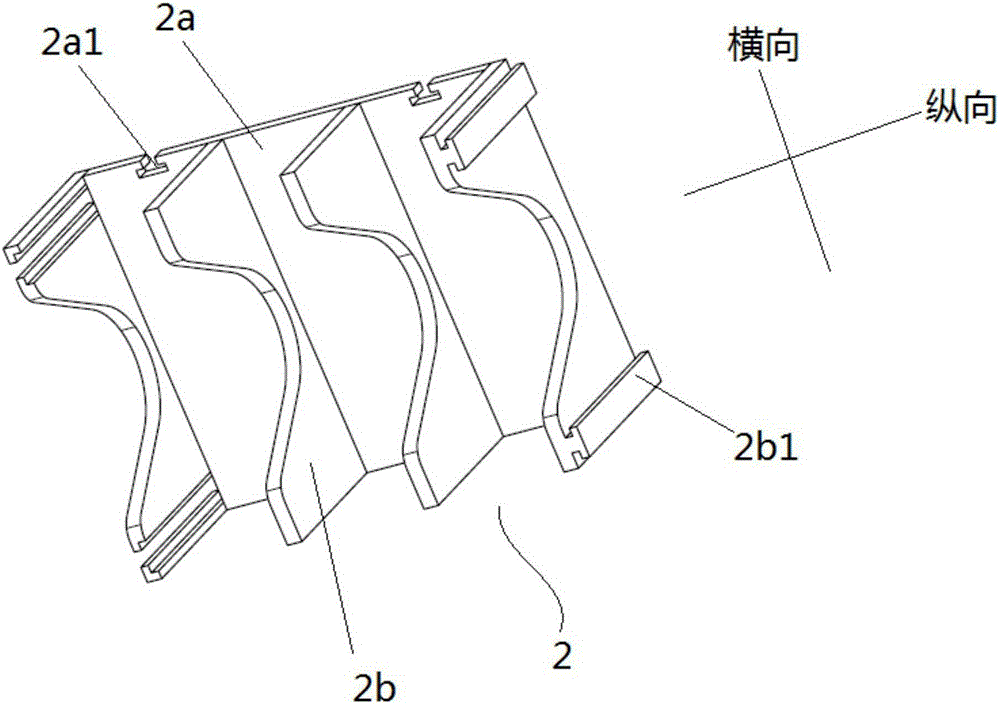

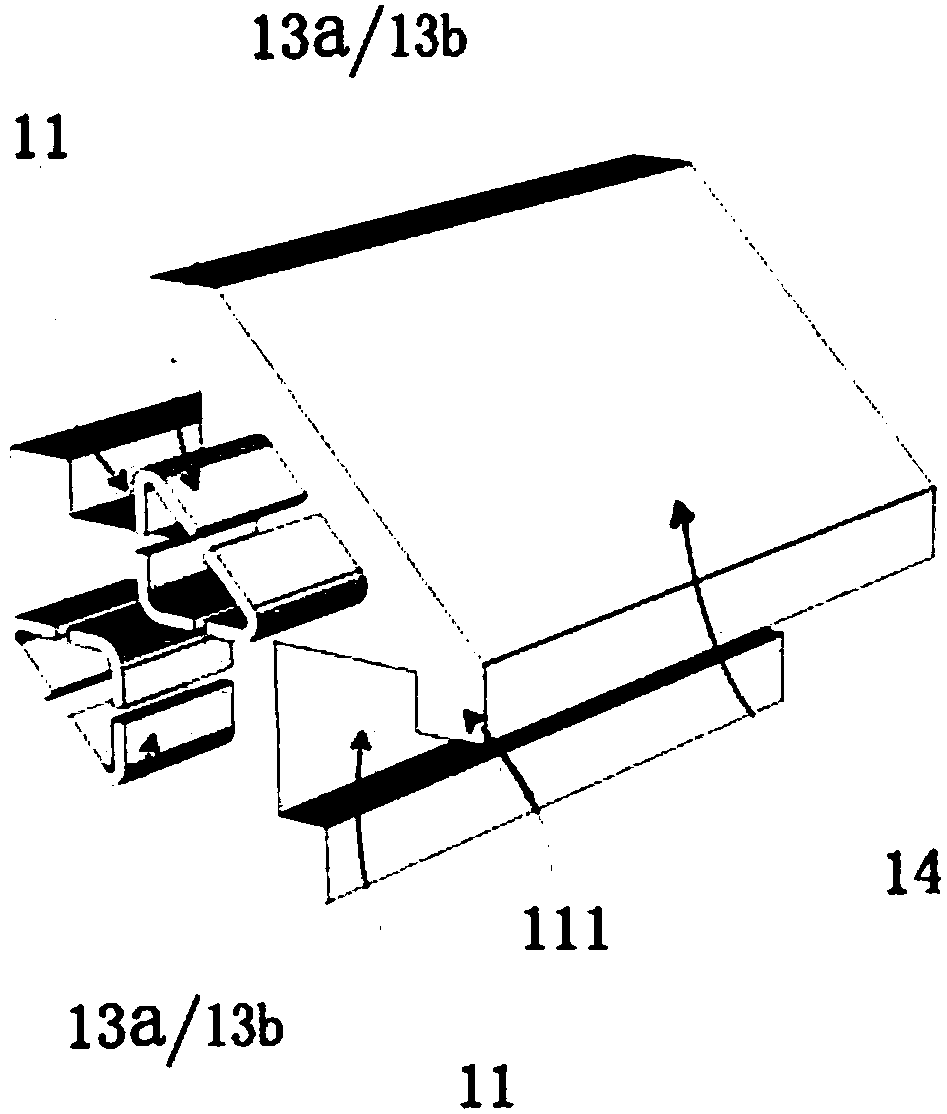

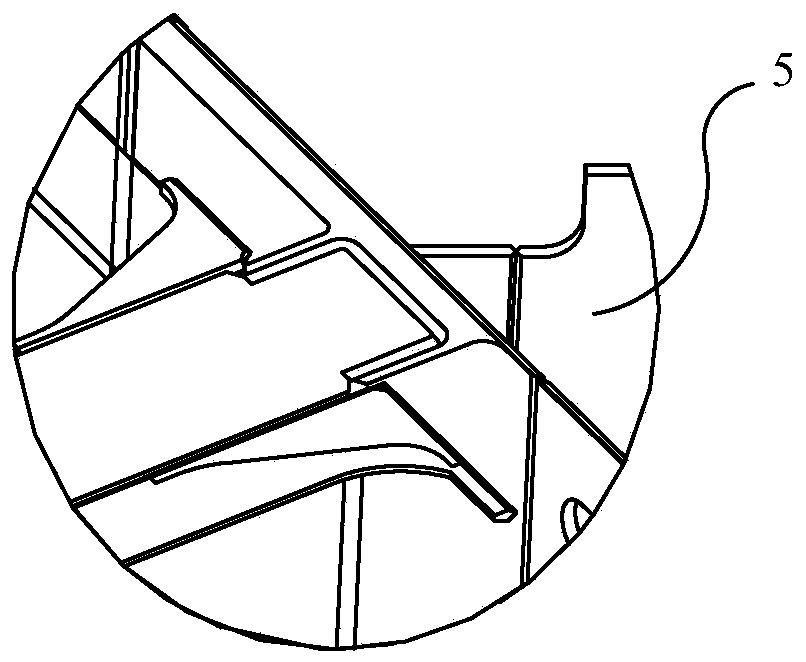

Disassembled and assembled type fire hose protecting bridge

The invention relates to a disassembled and assembled type fire hose protecting bridge. The disassembled and assembled type fire hose protecting bridge comprises lateral protecting bridge units and a middle protecting bridge unit. Each lateral protecting bridge unit comprises a lateral pressure bearing plate, at least two lateral rib plates and a lateral assembling plate, wherein the lateral rib plates are transversely arranged at the lower portion of the lateral pressure bearing plate and vertically connected with the lower portion of the lateral pressure bearing plate, the lateral assembling plate is longitudinally arranged and simultaneously connected with the lateral pressure bearing plate and the lateral rib plates, and arc-shaped holes allowing fire hoses to penetrate are formed in the lateral rib plates; the lateral assembling plates include the lateral assembling plates with convex sliding rails and the lateral assembling plates with concave sliding rails; the middle protecting bridge unit comprises a middle pressure bearing plate and at least two middle rib plates, wherein clamping grooves and clamping ribs are arranged along the two transverse ends of the middle pressure bearing plate respectively and used for being connected with the adjacent middle protecting bridge unit or the lateral protecting bridge units; and the middle rib plates are transversely arranged, arc-shaped holes allowing water supply belts to penetrate are formed in the lower portions of the middle rib plates, and the convex sliding rails and the concave sliding rails are arranged on the middle rib plates along the two longitudinal sides respectively and used for being connected with the longitudinally-extending middle protecting bridge unit.

Owner:SHANGHAI FIRE RES INST OF THE MIN OF PUBLIC SECURITY

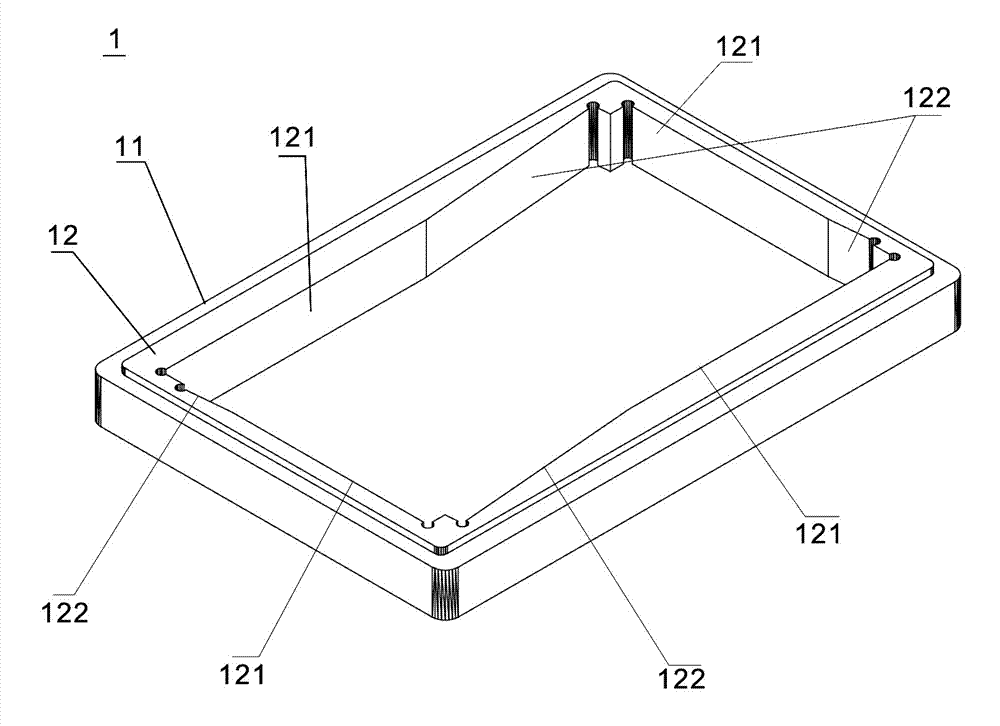

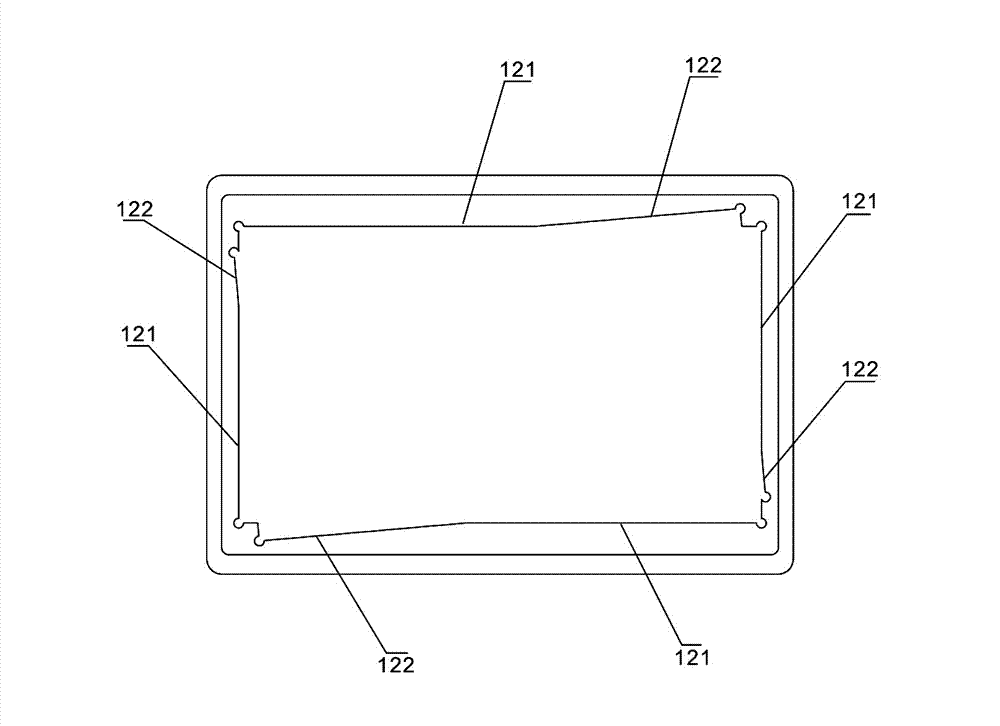

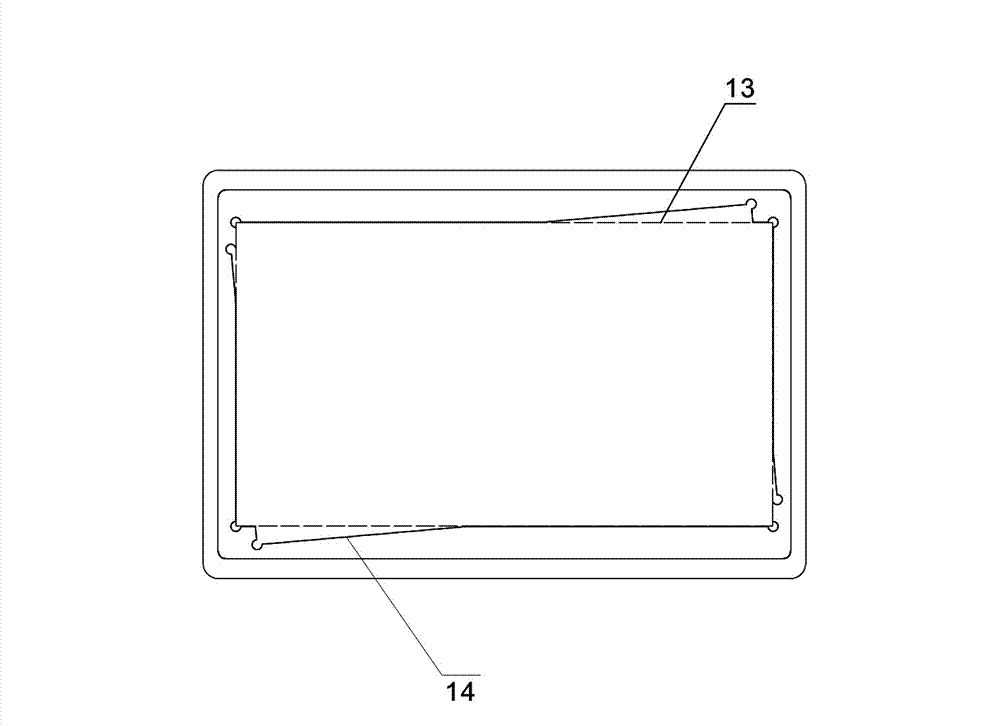

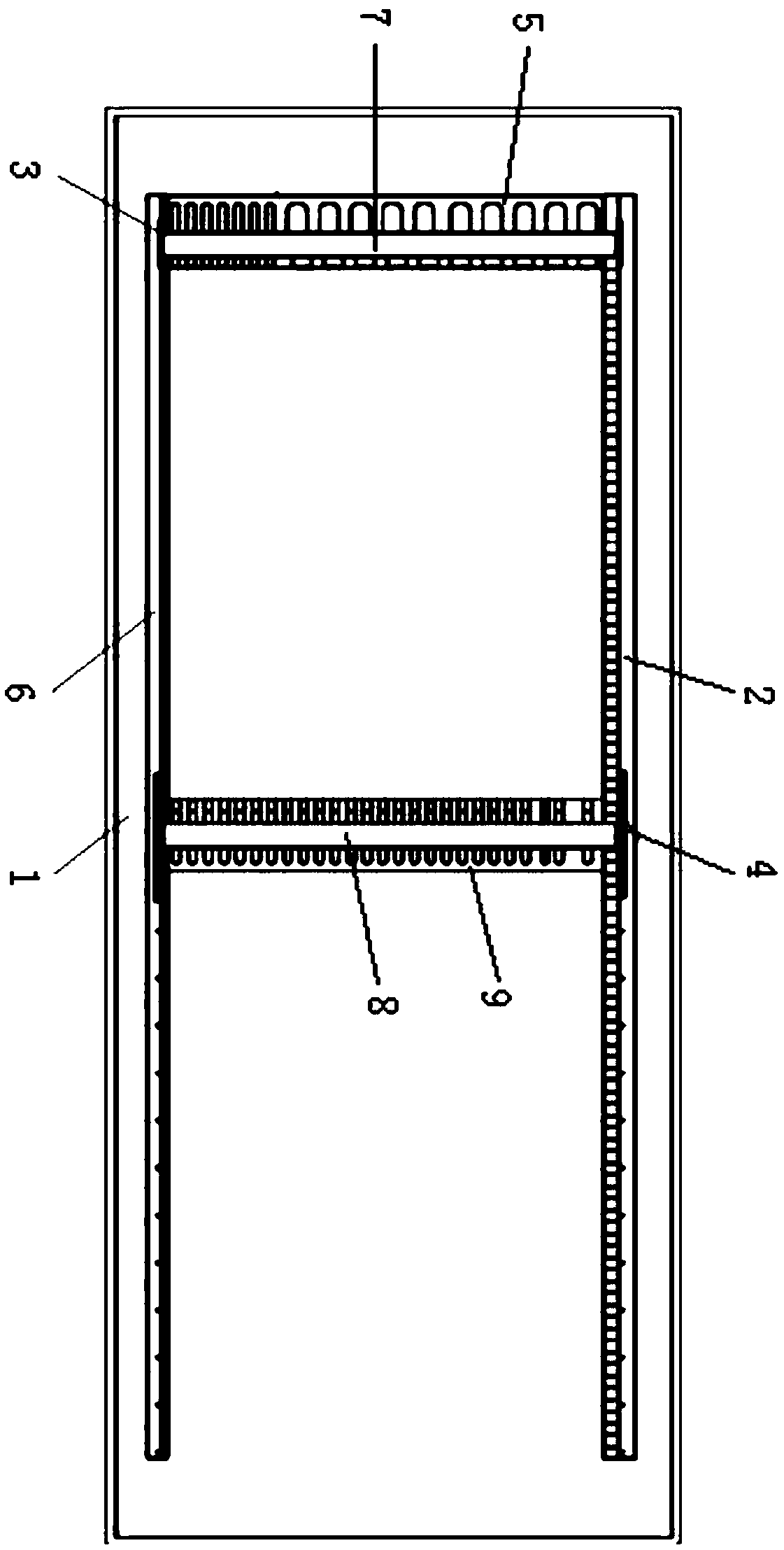

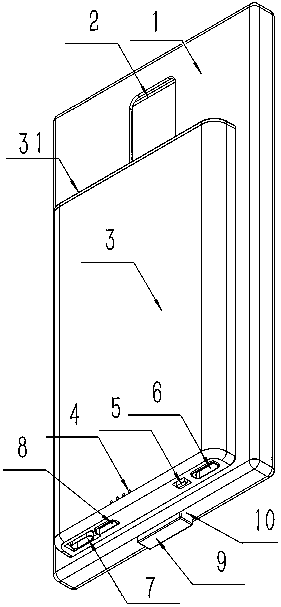

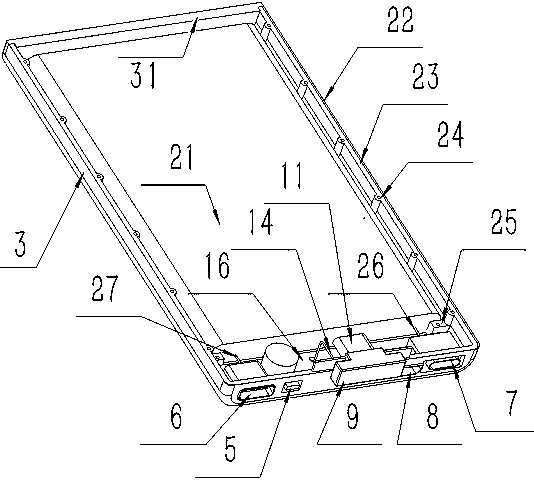

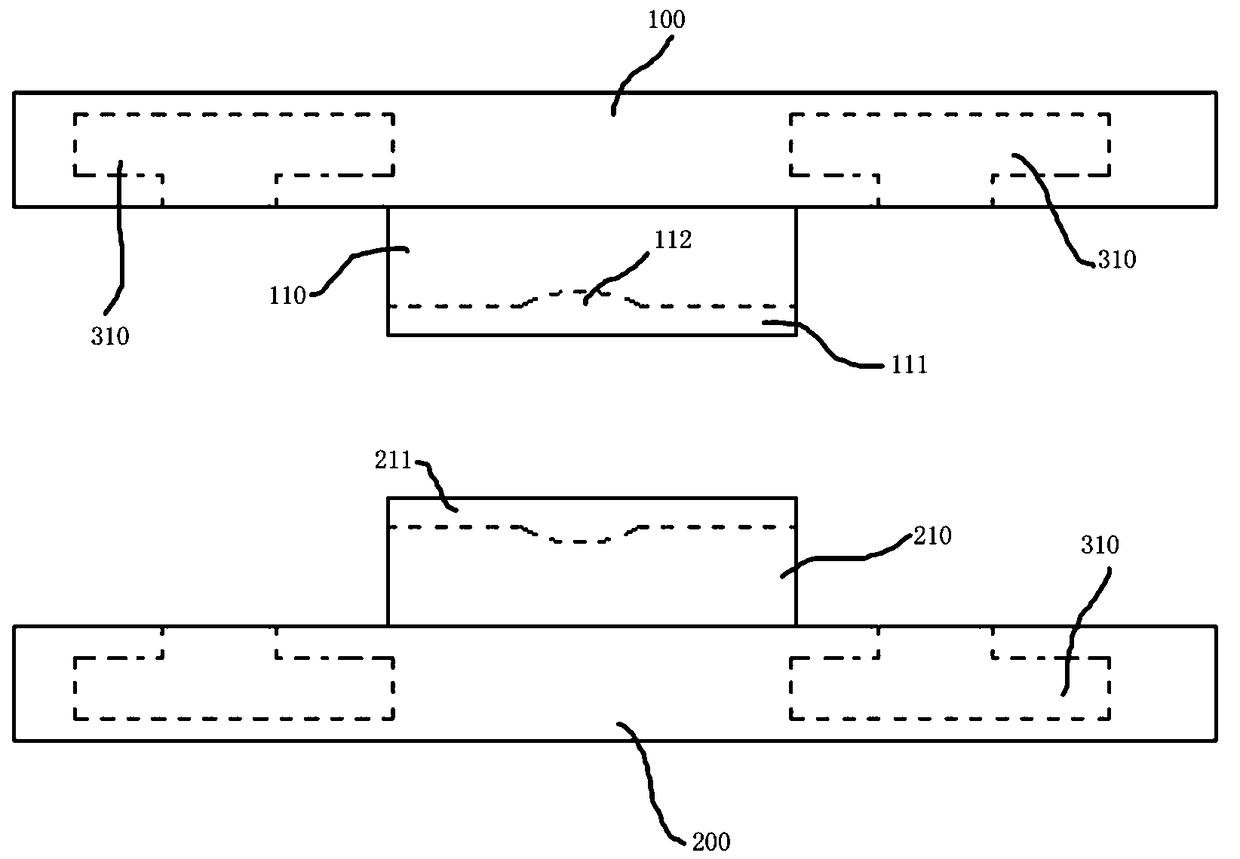

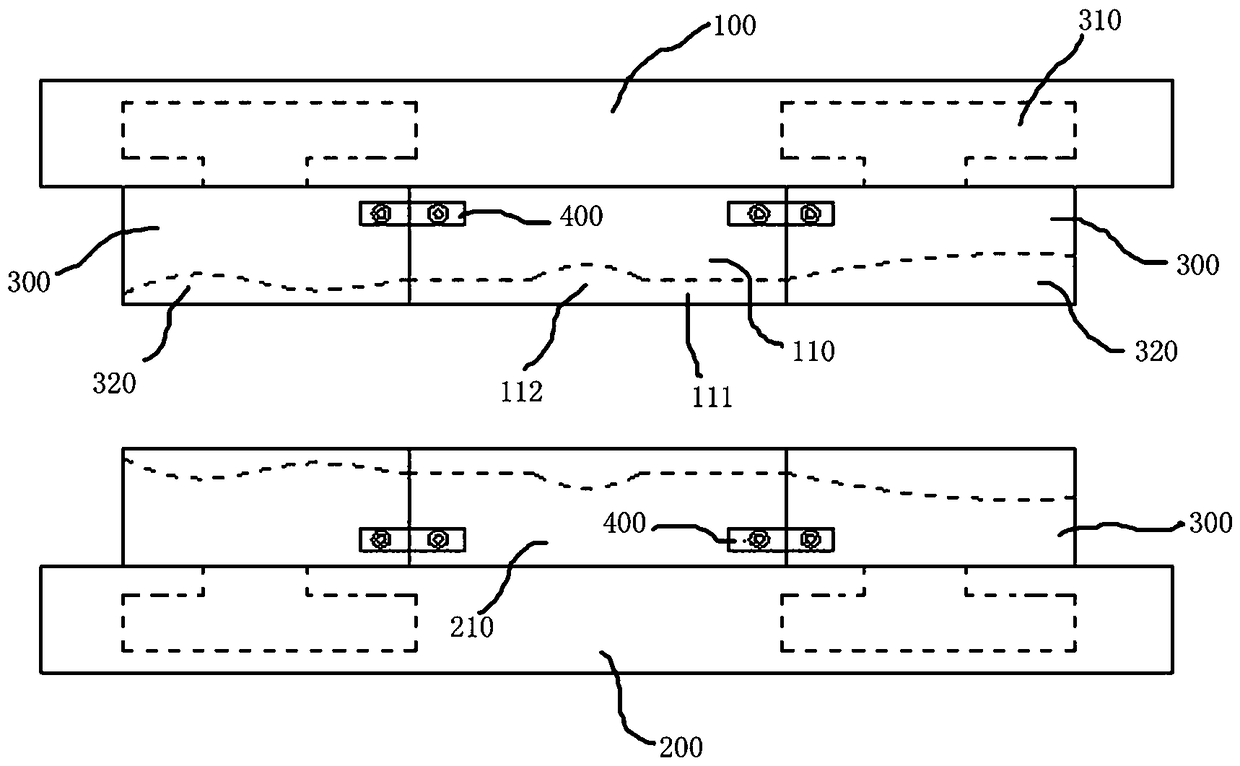

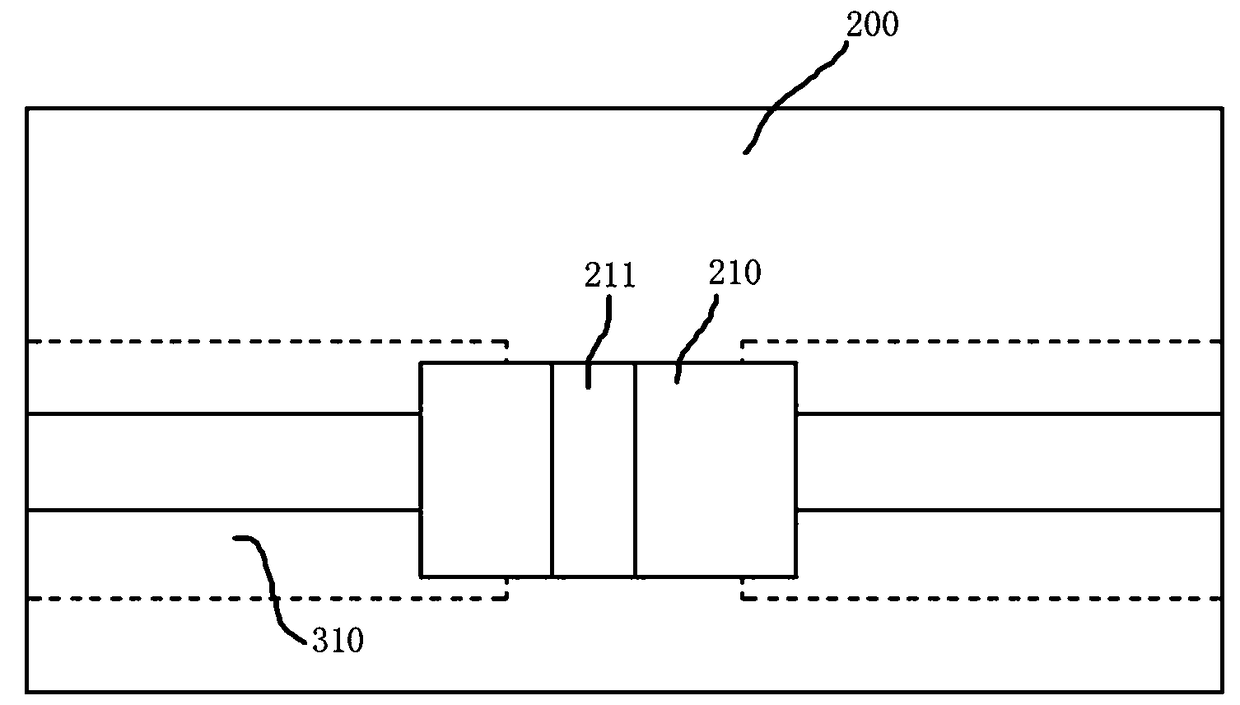

Liquid crystal glass packaging device

InactiveCN102815465AMeet in full bloomReduce the number of moldsContainers to prevent mechanical damageNon-linear opticsEngineeringMechanical engineering

The invention discloses a liquid crystal glass packaging device, which is used for receiving liquid crystal glass of multiple different sizes. The liquid crystal glass packaging device comprises a box body and a box cover correspondingly covering on the box body, wherein the box body comprises an outer box and an inner box arranged in the outer box; a plurality of assembly chambers capable of accommodating liquid crystal glass of multiple different sizes are formed in the inner box, and at least include a first assembly chamber and a second assembly chamber; the first assembly chamber is formed by encircling a plurality of first inner box walls on the inner box; the second assembly chamber is formed by encircling a plurality of second inner box walls on the inner box; and the first assembly chamber and the second assembly chamber are formed one above the other in a staggered way. Due to the adoption of the liquid crystal glass packaging device disclosed by the invention, liquid crystal glass of multiple different sizes can be accommodated under the situation of not adding any insertion block component, the structural design is exquisite, the die sinking amount of the packaging device can be reduced, and the production cost is further reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

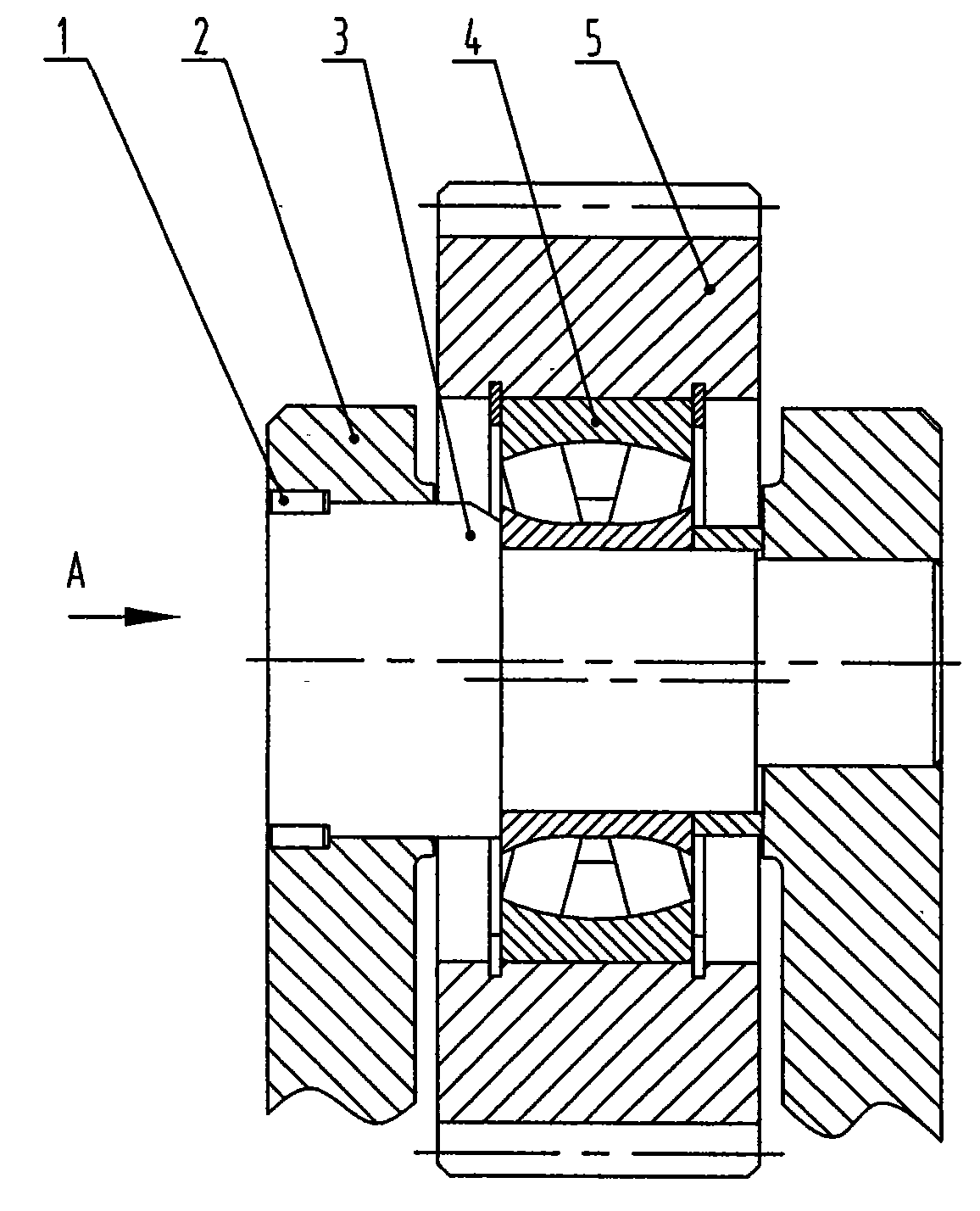

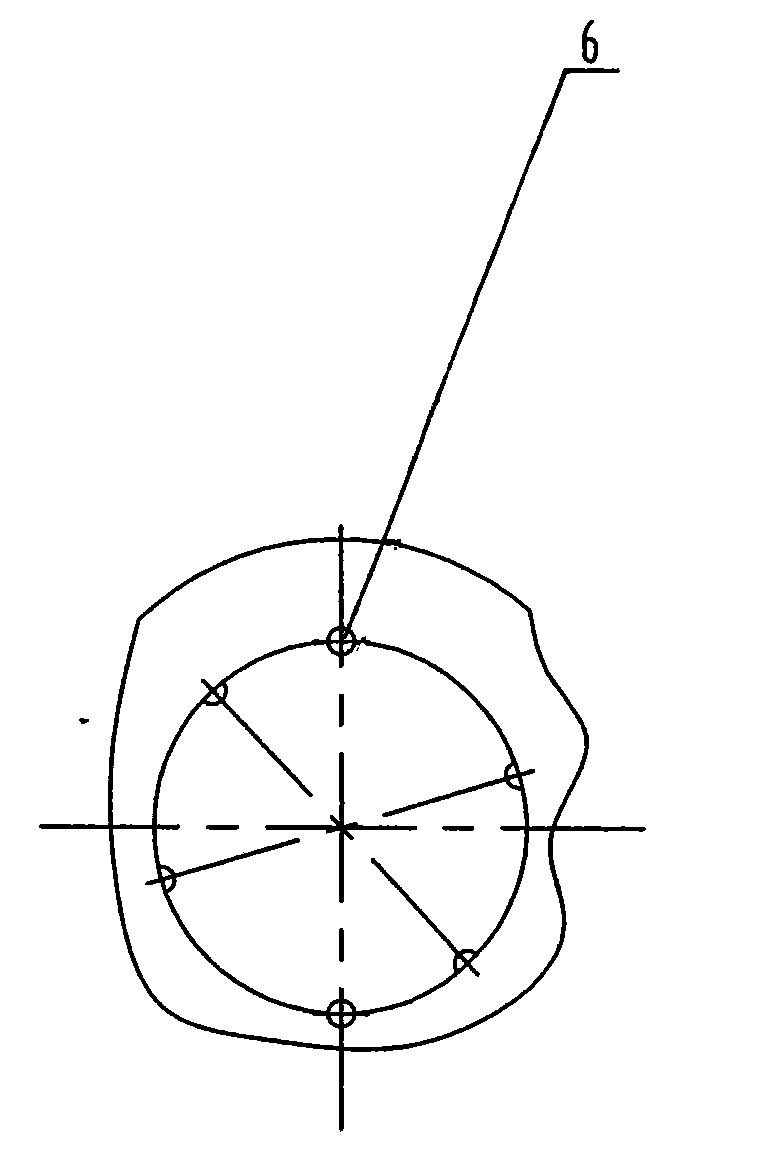

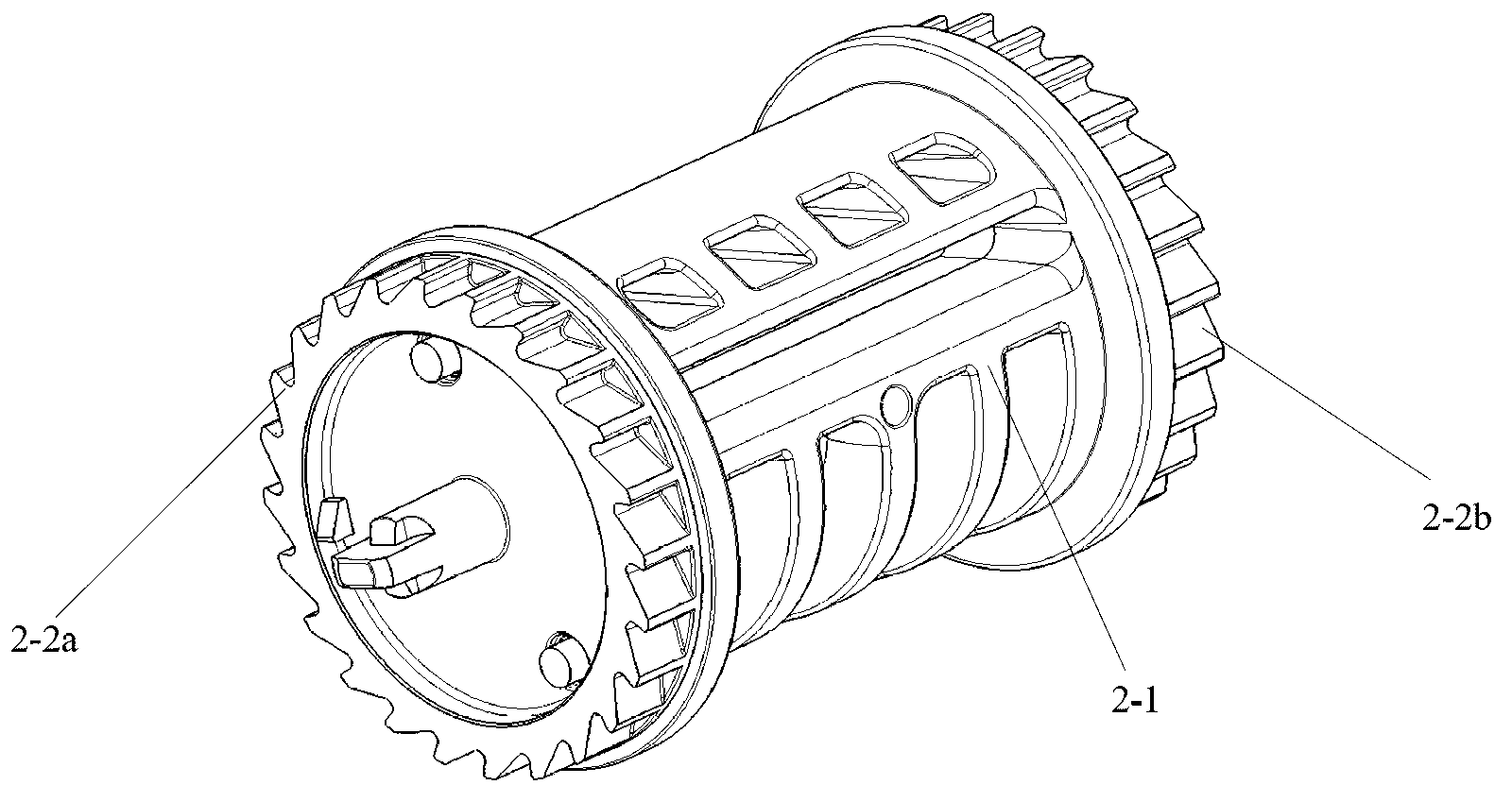

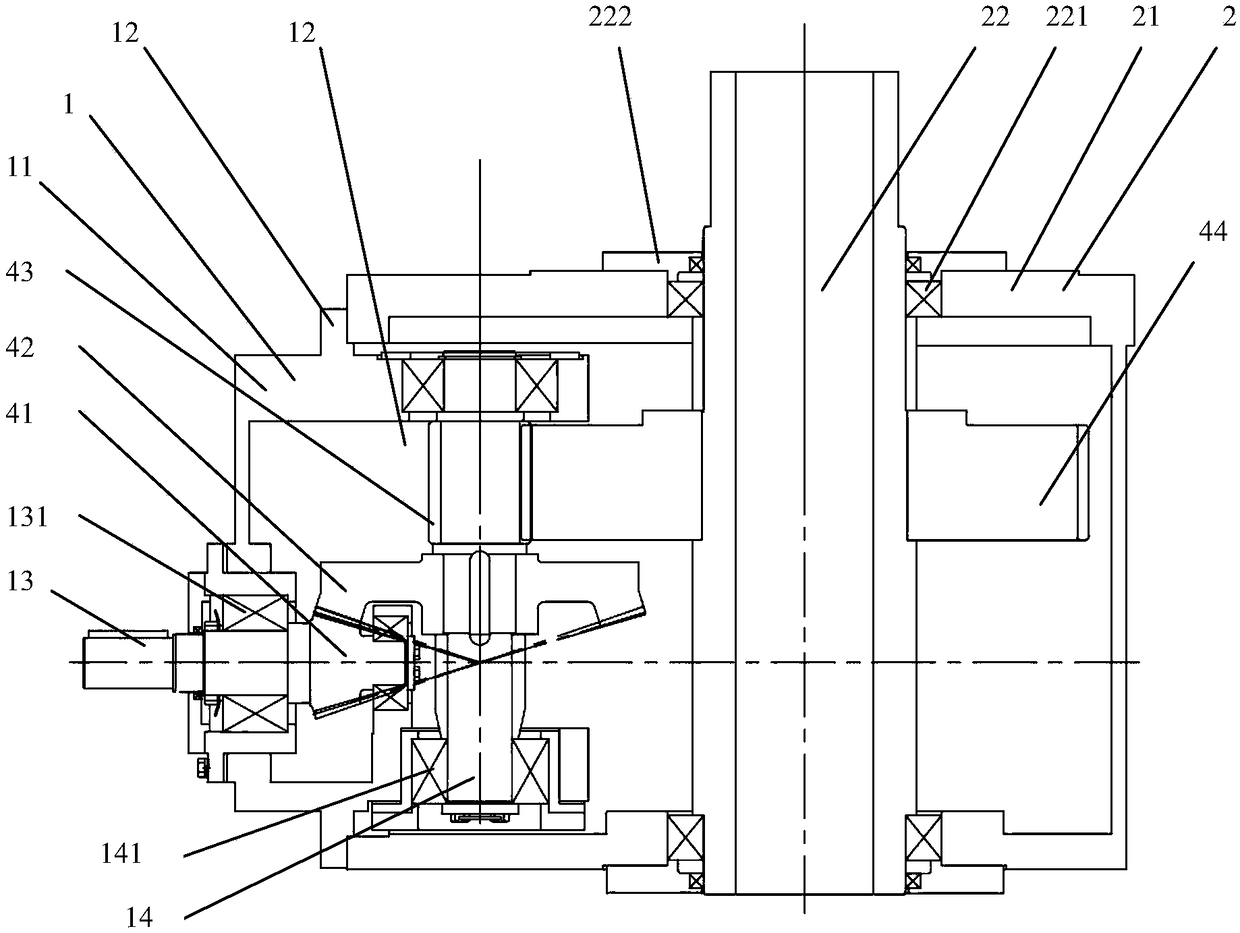

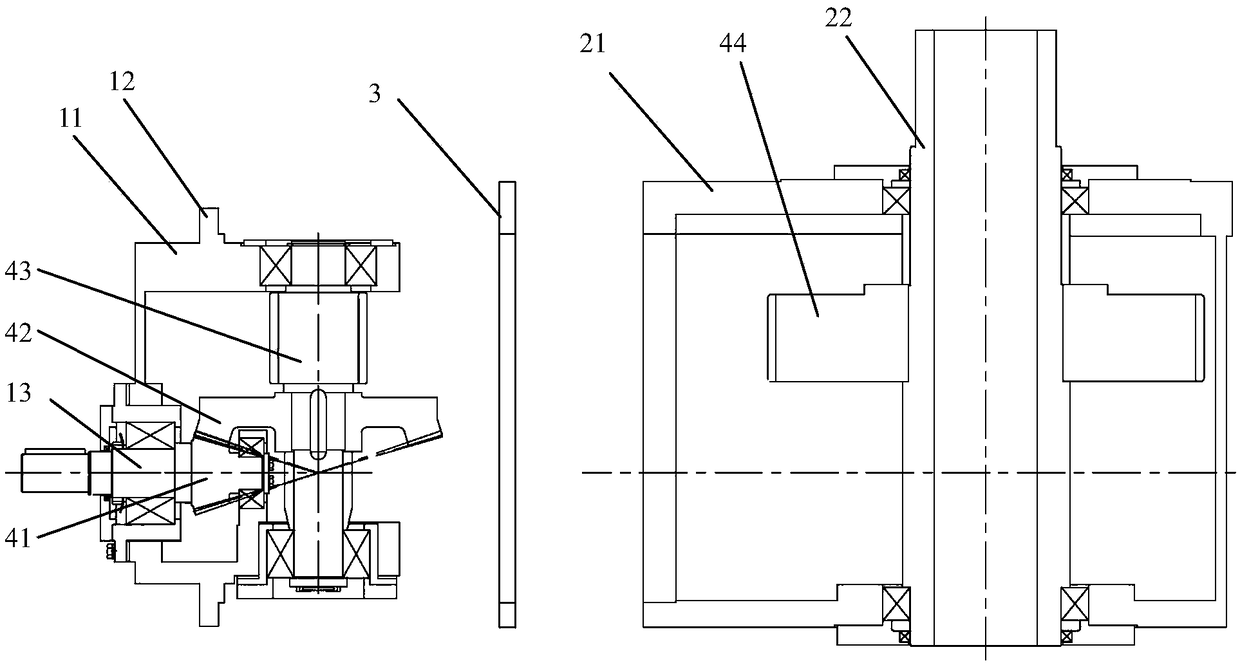

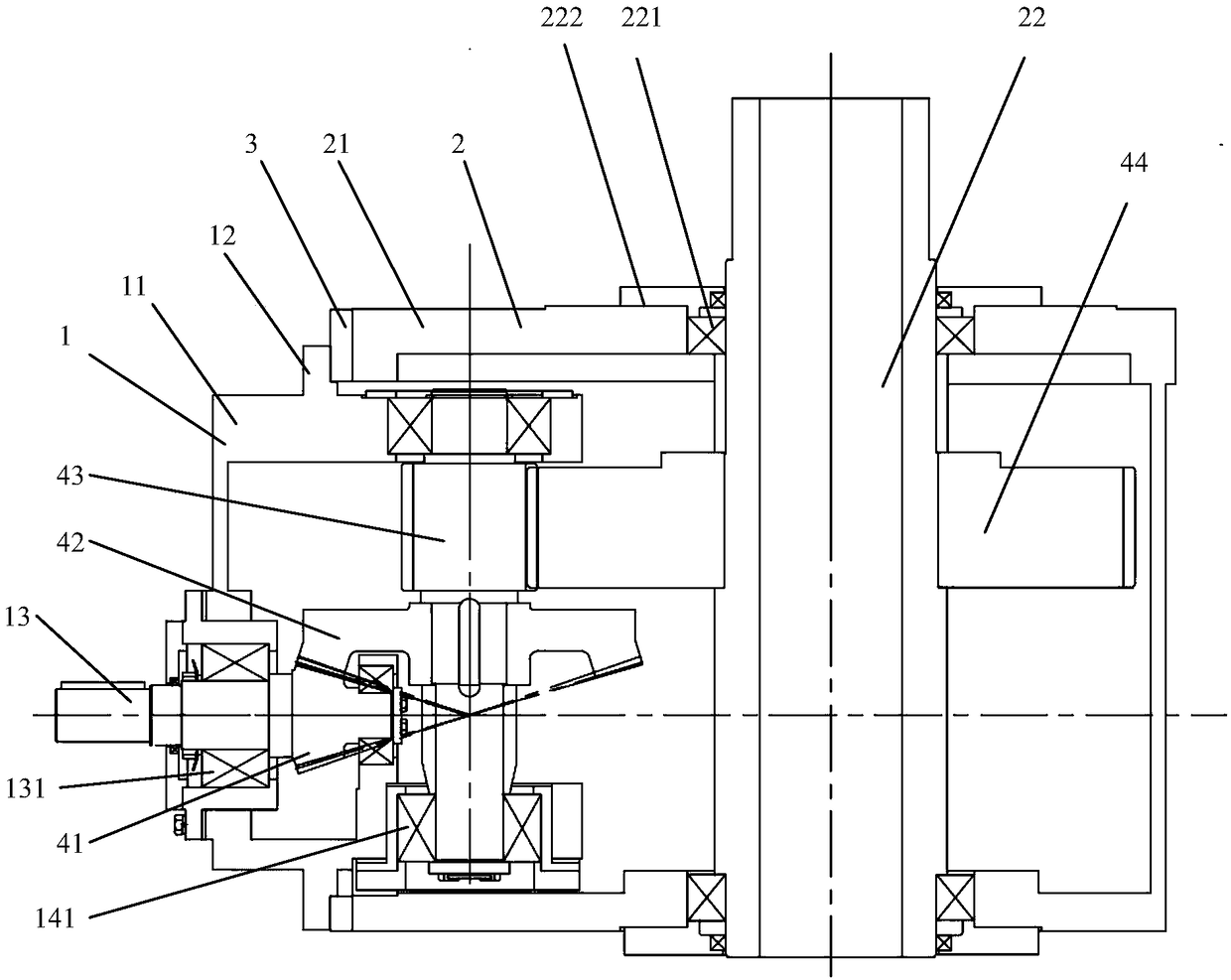

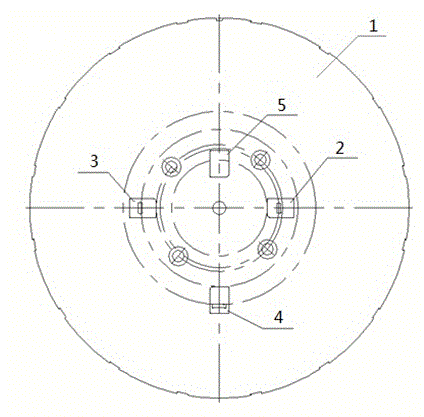

An eccentric planet axis mechanism with tunable centre-to-centre distance and its regulation means

ActiveCN101550990AReduce storageReduce the number of moldsToothed gearingsGearing detailsSEMI-CIRCLEEngineering

The invention relates to an eccentric planet axis mechanism with tunable centre-to-centre distance and its regulation means. The eccentric planet axis mechanism includes a planet frame, an eccentric planet axis, a bearing, a planet wheel and pins. Concentric axis are provided at both dies of the eccentric planet axis, and an eccentric spindle is provided in center; a pair of semi-circle pin holes are provided at the peak and lowest point of inner ring at any one end of the planet frame; at least a pair of symmetrical semi-circle pin holes are provided at the outer ring of the planet axis; the two semi-circle pin holes align the rear formed pin holes; the pins are mounted in the pin holes, and the planet frame is in positioning fixation with the eccentric planet axis. The invention is beneficial for generalization, large-scale and standardization of the production of the eccentric planet axis mechanism.

Owner:宁波东力股份有限公司

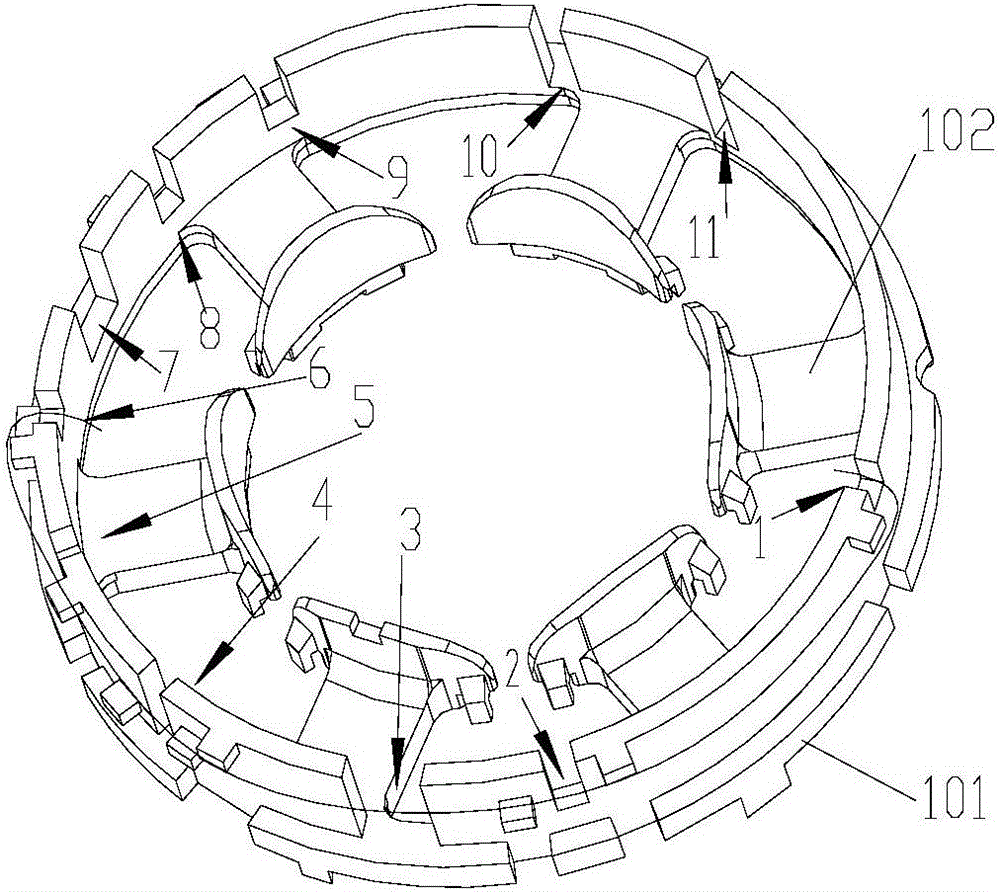

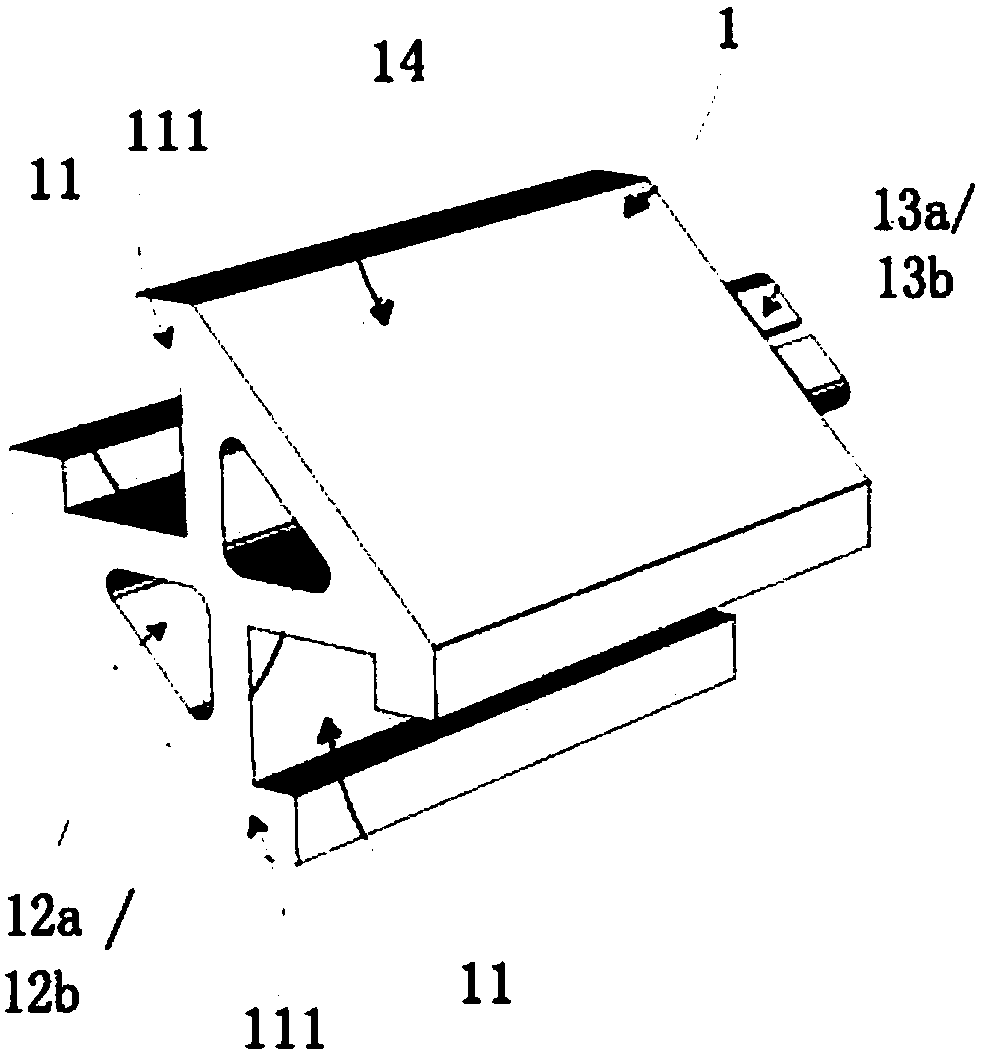

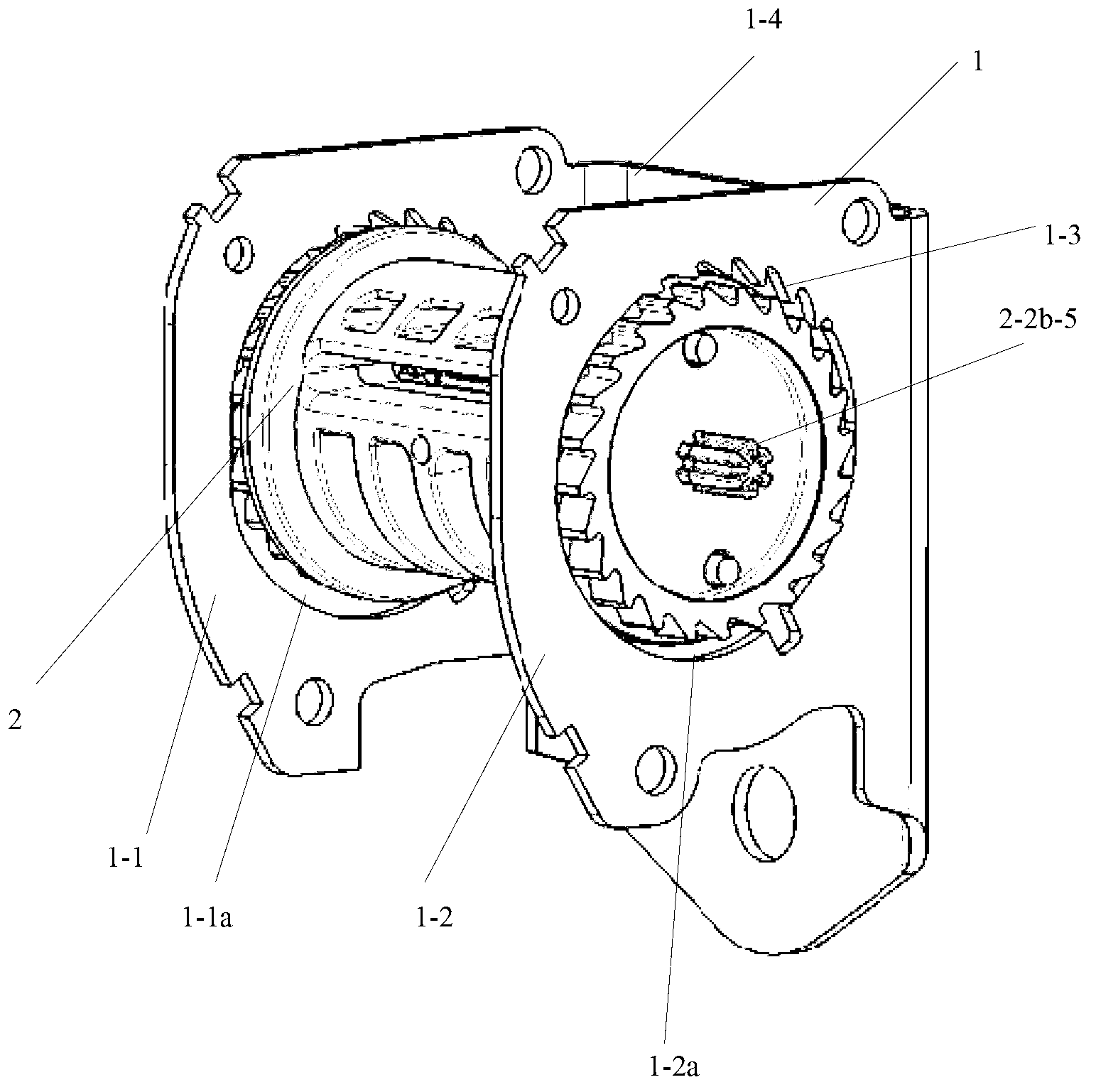

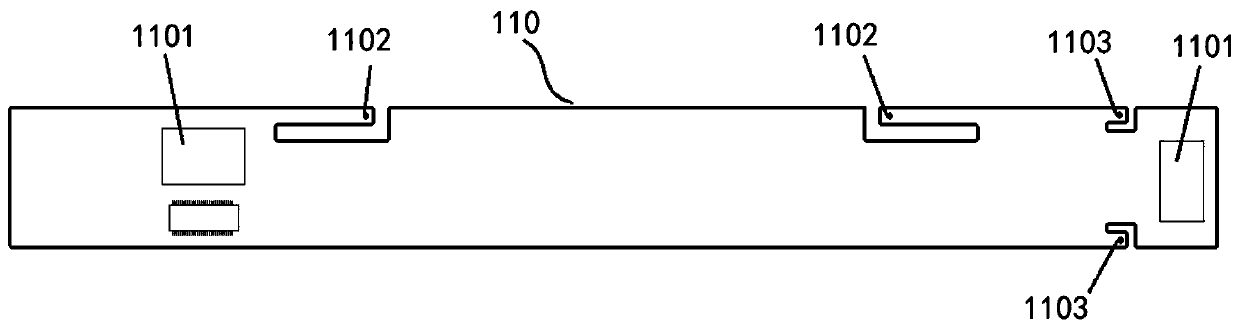

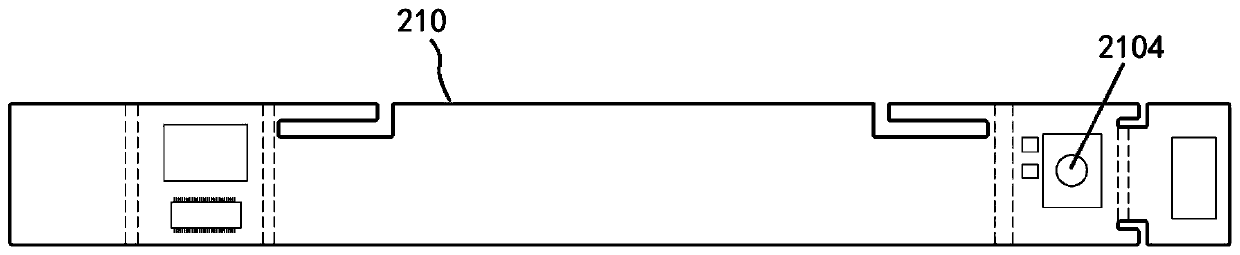

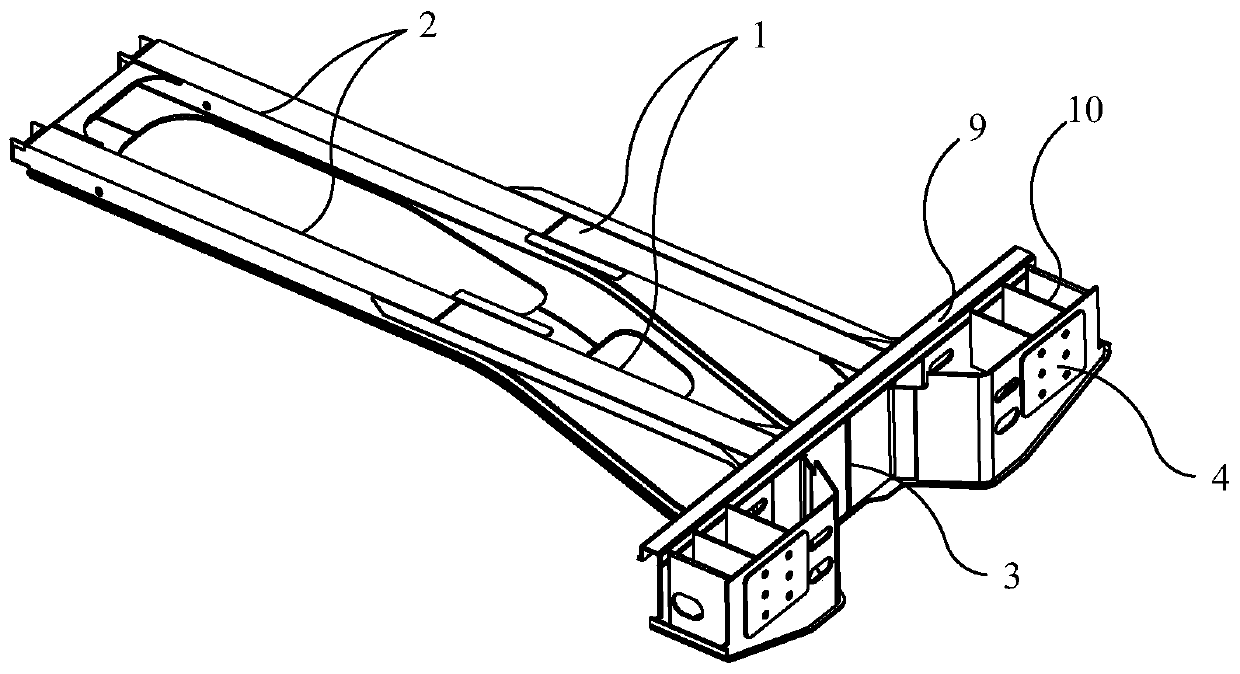

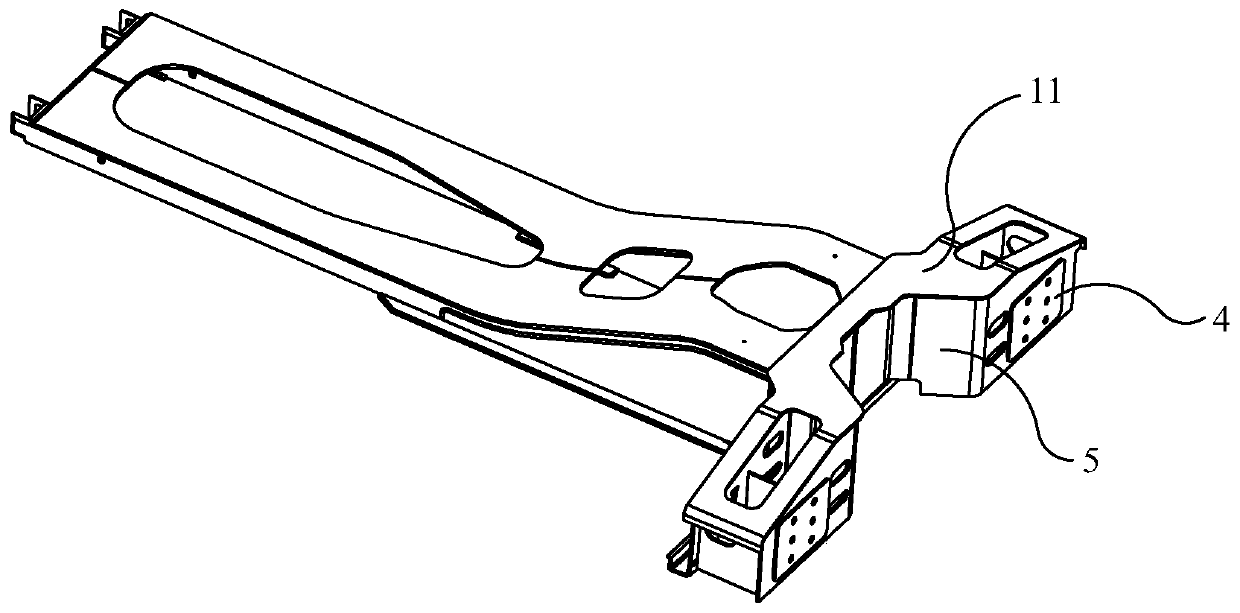

Insulated framework, motor stator and motor

ActiveCN106253535AAchieve normal functionAchieve effectWindingsMagnetic circuit stationary partsElectric machineEngineering

The invention provides an insulated framework, a motor stator and a motor. The insulated framework comprises an annular portion (101) and a plurality of tooth portions (102) projecting from the inner wall of the annular portion (101), wherein opening grooves are formed in the annular portion (101) on both sides of a joint position of at least one of the plurality of tooth portions (102) and the annular portion (101) in the circumferential direction; opening grooves are further formed on one side of joint positions of the rest of tooth portions (102) and the annular portion (101) in the circumferential direction; and the opening grooves on both sides in the circumferential direction of the at least one tooth portion (102) having the opening grooves on both sides in the circumferential direction are of the same structure. By adopting the insulated framework, the motor stator and the motor, one of the two opening grooves is used when in need of serial wire winding, and the other is used when in need of parallel wire winding, so that the single insulated framework can achieve the functions and effects of serial wire winding and parallel wire winding of the stator simultaneously, and the applicability is effectively improved.

Owner:GREE ELECTRIC APPLIANCES INC +1

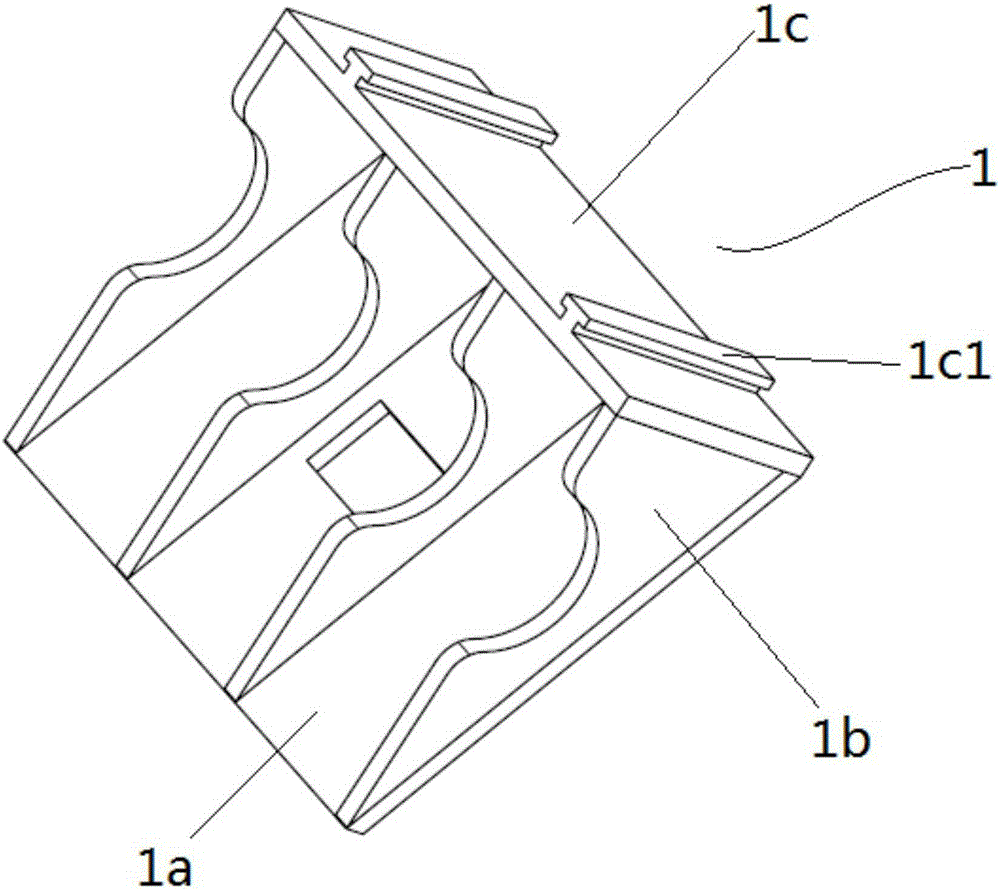

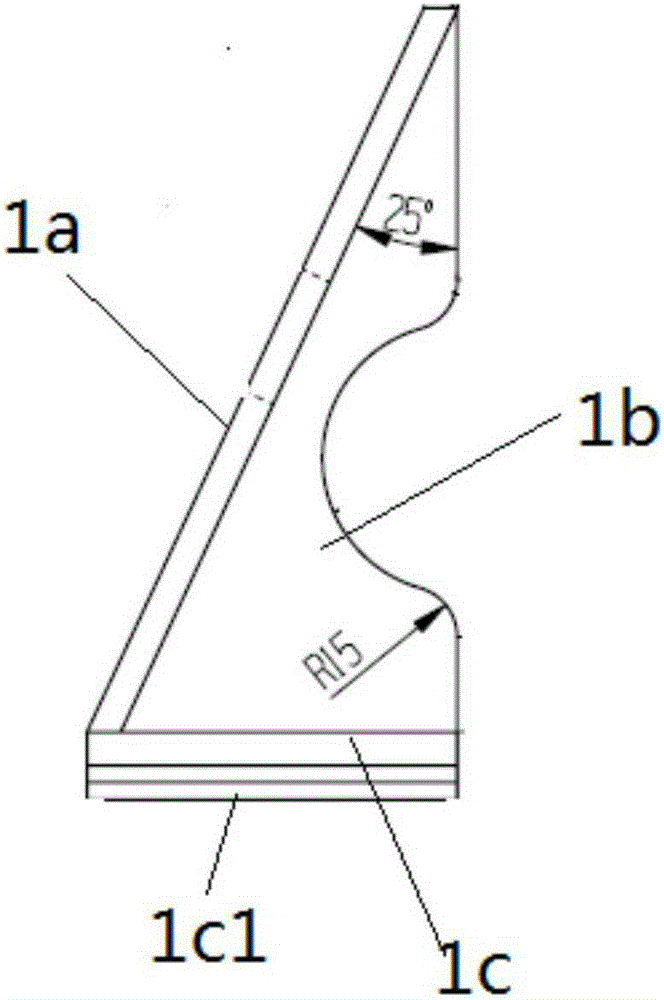

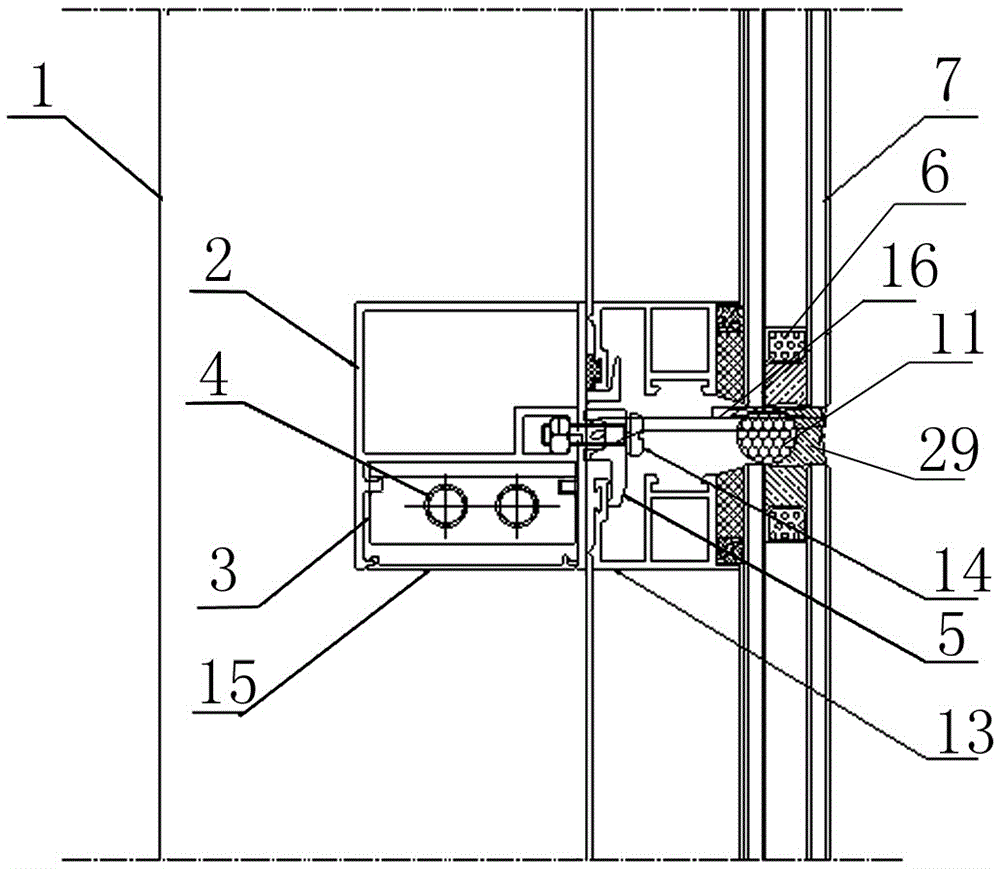

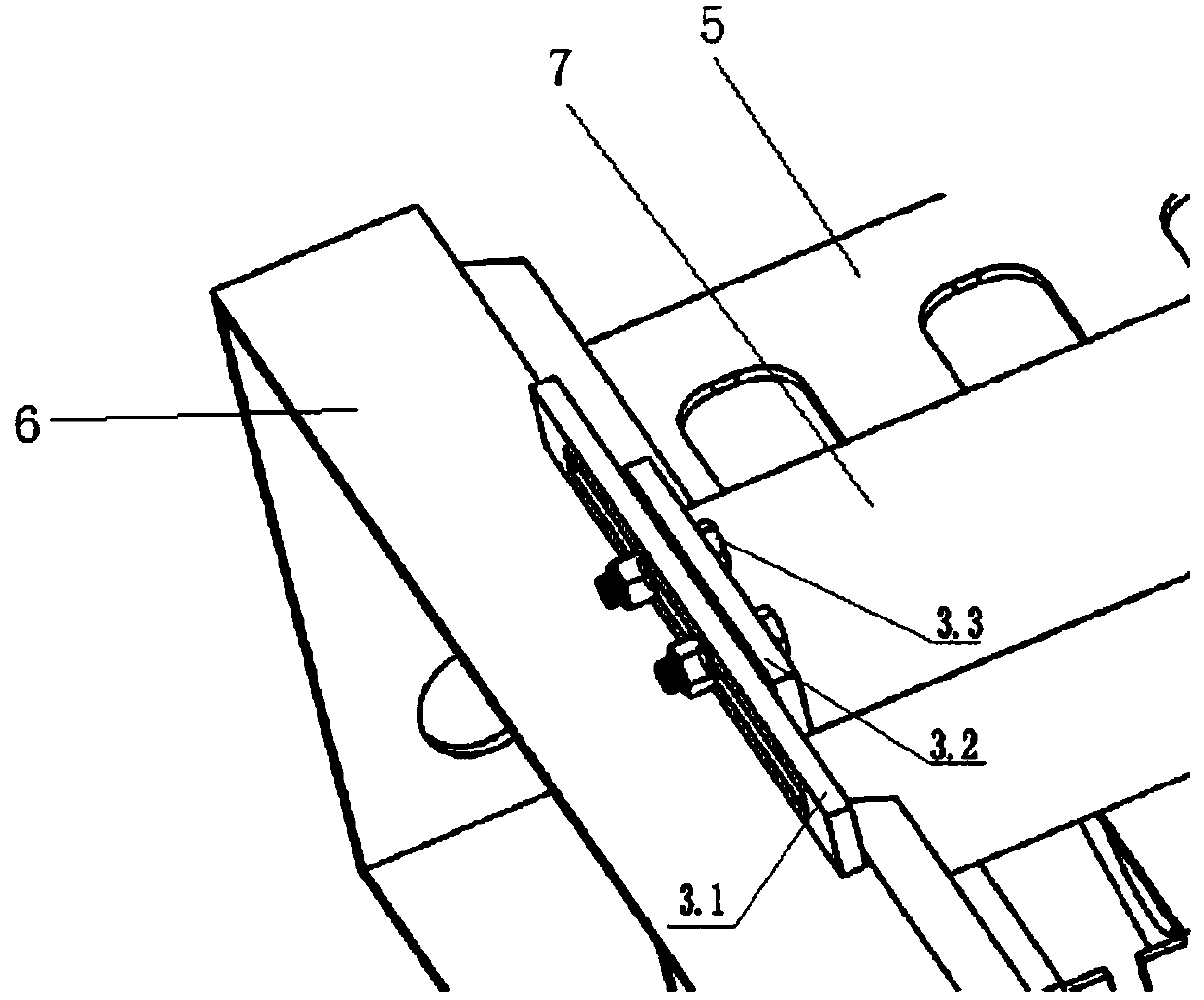

Curtain wall exposed and hidden frame connecting auxiliary frame, curtain wall system and construction method thereof

InactiveCN106284779ASimple structureReasonable designWallsMutual transformationStructural engineering

The invention relates to a curtain wall exposed and hidden frame connecting auxiliary frame, a curtain wall system and a construction method thereof. The connecting auxiliary frame comprises two strip-shaped auxiliary frame units of mirror symmetry and a transforming auxiliary frame detachably connected with the auxiliary frame units; the transforming auxiliary frame comprises two strip-shaped exposed frame press plate units and strip-shaped decorative buckling covers, wherein the strip-shaped exposed frame press plate units are arranged in a mirror symmetry and correspondingly connected with the auxiliary frame units. The cross section of the exposed frame press plate units is in a J shape and comprises a vertical plate and a transverse plate, wherein a clamping strip connected with a connecting slide groove in a matched mode is arranged at the upper end of the vertical plate, a second through clamping groove is formed in the outer end of the upper surface of the transverse plate in the length direction, and a third through clamping groove is formed in the side face of the outer end of the transverse plate in the length direction, and the decorative buckling covers are connected with the third through clamping grooves in the two exposed frame pressing plate units through convex strips on the two side walls. The connecting auxiliary frame is simple in structure and reasonable in design and is combined with the exposed frame press plate units to achieve mutual transformation between an exposed frame glass curtain wall and a hidden frame glass curtain wall.

Owner:中标建设集团股份有限公司

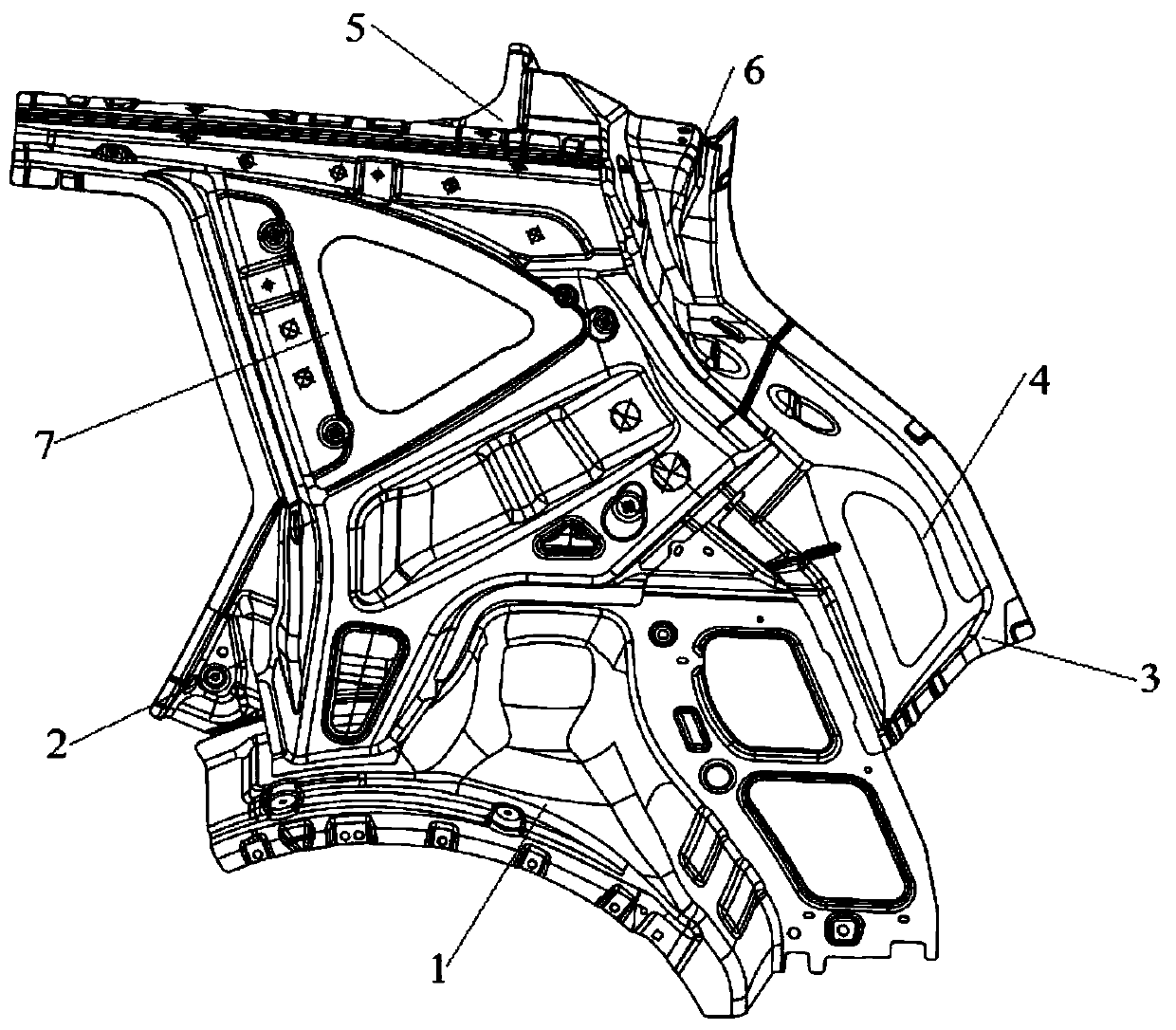

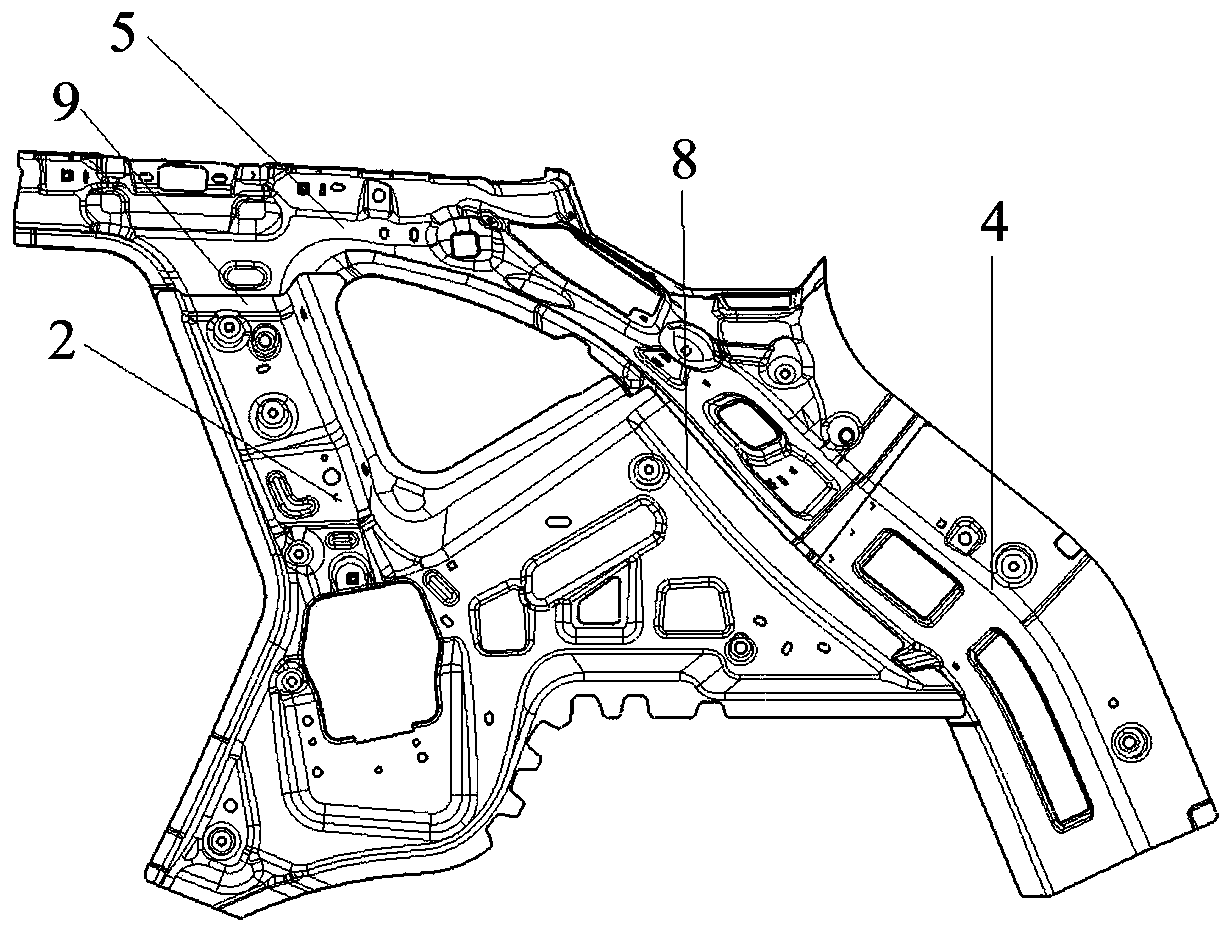

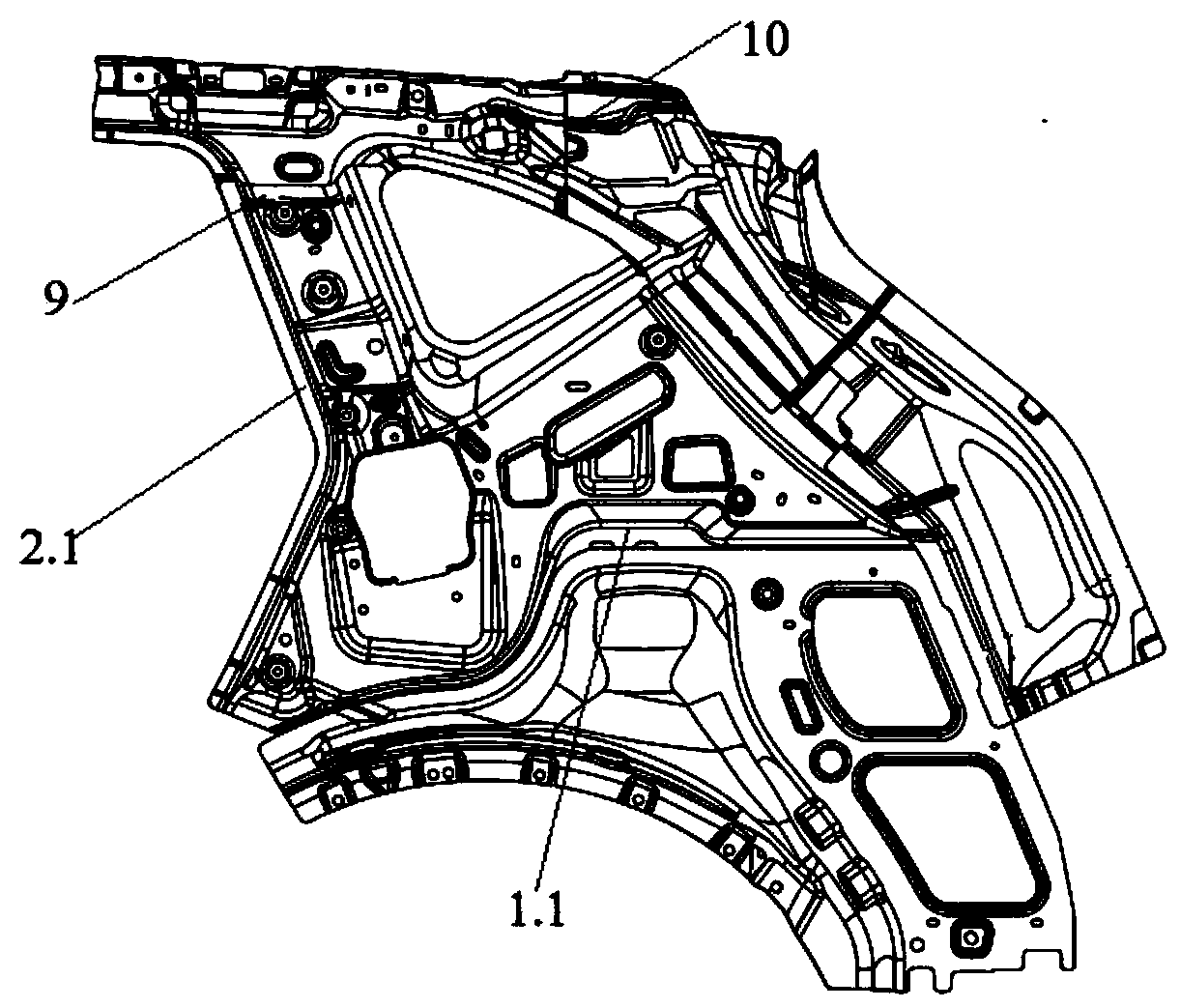

Vehicle body side wall C-column inner plate reinforced structure and vehicle

PendingCN110104072AReduce the number of moldsReduce stressSuperstructure subunitsTorsional rigidityEngineering

The invention discloses a vehicle body side wall C-column inner plate reinforced structure, and relates to the technical field of vehicle structure design. The vehicle body side wall C-column inner plate reinforced structure includes a rear wheel cover outer plate, a C-column front segment inner plate body, a C-column rear segment inner plate body, a C-column top cover rear beam connecting plate,a C-column rear segment reinforced upper plate, a C-column rear segment reinforced lower plate, and a C-column front segment reinforced plate body, wherein the C-column rear segment reinforced upper plate and the C-column rear segment reinforced lower plate are lap-jointed on the outer sides of the C-column top cover rear beam connecting plate and the C-column rear segment inner plate body to forma first cavity structure of a tail door frame structure; and the periphery of the C-column front segment reinforced plate body is lap-jointed on the outer sides of the rear wheel cover outer plate, the C-column front segment inner plate body, the C-column front segment inner plate body and the tail door frame structure to form a second cavity structure communicating with the first cavity structure. According to the vehicle body side wall C-column inner plate reinforced structure, the C-column front segment reinforced plate body is arranged to be of an integrated structure, and integral rigidity of a C-column upper reinforced zone and torsional rigidity of the door frame structure are improved.

Owner:JIANGSU MINAN AUTOMOTIVE CO LTD

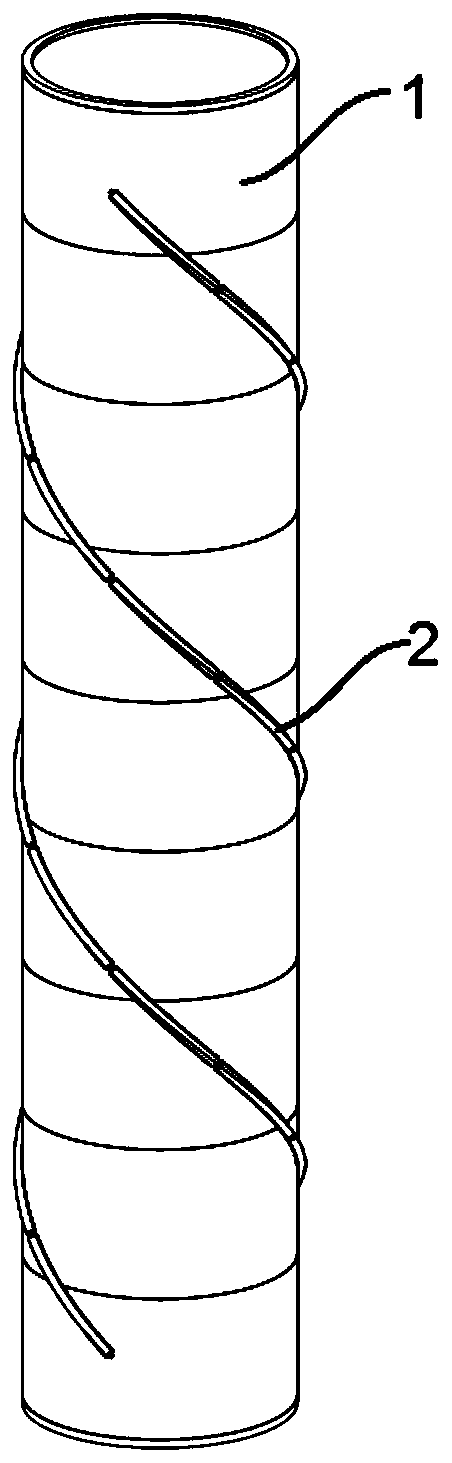

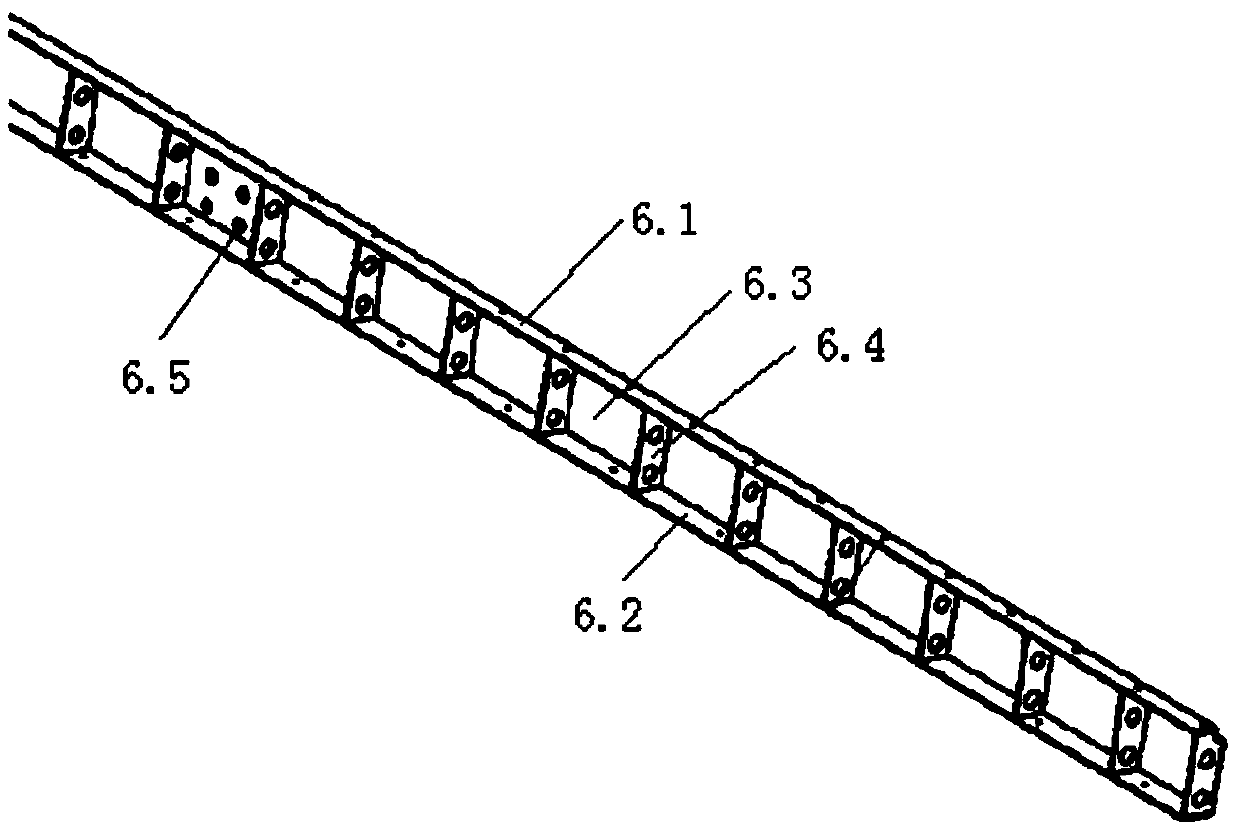

Wind electricity tower spoiler

PendingCN110925148APrevention of first-order vortex resonancePrevention of second-order vortex resonanceWind motor controlWind motor supports/mountsEngineeringTower

The invention discloses a wind electricity tower spoiler, which consists of a plurality of spoiler units, wherein the section of each spoiler unit is of a sealed three-edge solid structure or a three-edge thin-wall structure with an opening end; the plurality of spoiler units are connected in sequence to form one strand of continuous spiral line; in addition, the spiral line is fixed on the outerwall of the tower through the spoiler units positioned on the end parts; the bottom surface of each spoiler unit is fit to the outer wall of the tower; or the plurality of spoiler units form one strand of continuous spiral line, the continuous spiral line is arranged on the outer wall of the tower, i.e., each spoiler unit is fixed on the outer wall of the tower, and in addition, the bottom surfaceof each spoiler unit is fit to the outer wall of the tower; and two adjacent spoiler units are arranged at an interval. The spoiler can adapt to the shape follow-up technology of different external diameters of the whole tower, has a good spoiling effect and has a long service life.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

Connecting piece, assembling component and assembling method

PendingCN107781266AImprove machining accuracyStrong standardizationSheet joiningMechanical engineeringMortise and tenon

The invention discloses a connecting piece. The connecting piece is characterized in that a first end of the connecting piece is provided with first clamps and / or first clamp grooves, a second end ofthe connecting piece is provided with second clamp grooves and / or second clamps, and the second clamp grooves and / or the second clamps can be detachably matched with the first end; the connecting piece further comprises clamp portions, the clamp portions extend between the first end and the second end of the connecting piece along the axis of the connecting piece and are fixedly clamped on the connecting piece. The invention further discloses an assembling component and an assembling method. The connecting piece, the assembling component and the assembling method have the advantages that the problem of difficulty in processing technologies for splicing and forming plates in furniture and toy and during indoor decoration mainly can be solved by the aid of the connecting piece, the assembling component and the assembling method, the traditional mortise and tenon structure can be replaced with the designed simple connecting piece easy to use, the connecting piece and the assembling component are easy to machine, high in precision and standardization, products are convenient to assemble and disassemble, and the like.

Owner:孙绍顺

Universal prefabricated concrete wallboard mold

InactiveCN109648690AIncrease flexibility and versatilityReduce the number of moldsMouldsMould fastening meansPrecast concreteMaterials science

Owner:中建科技武汉有限公司

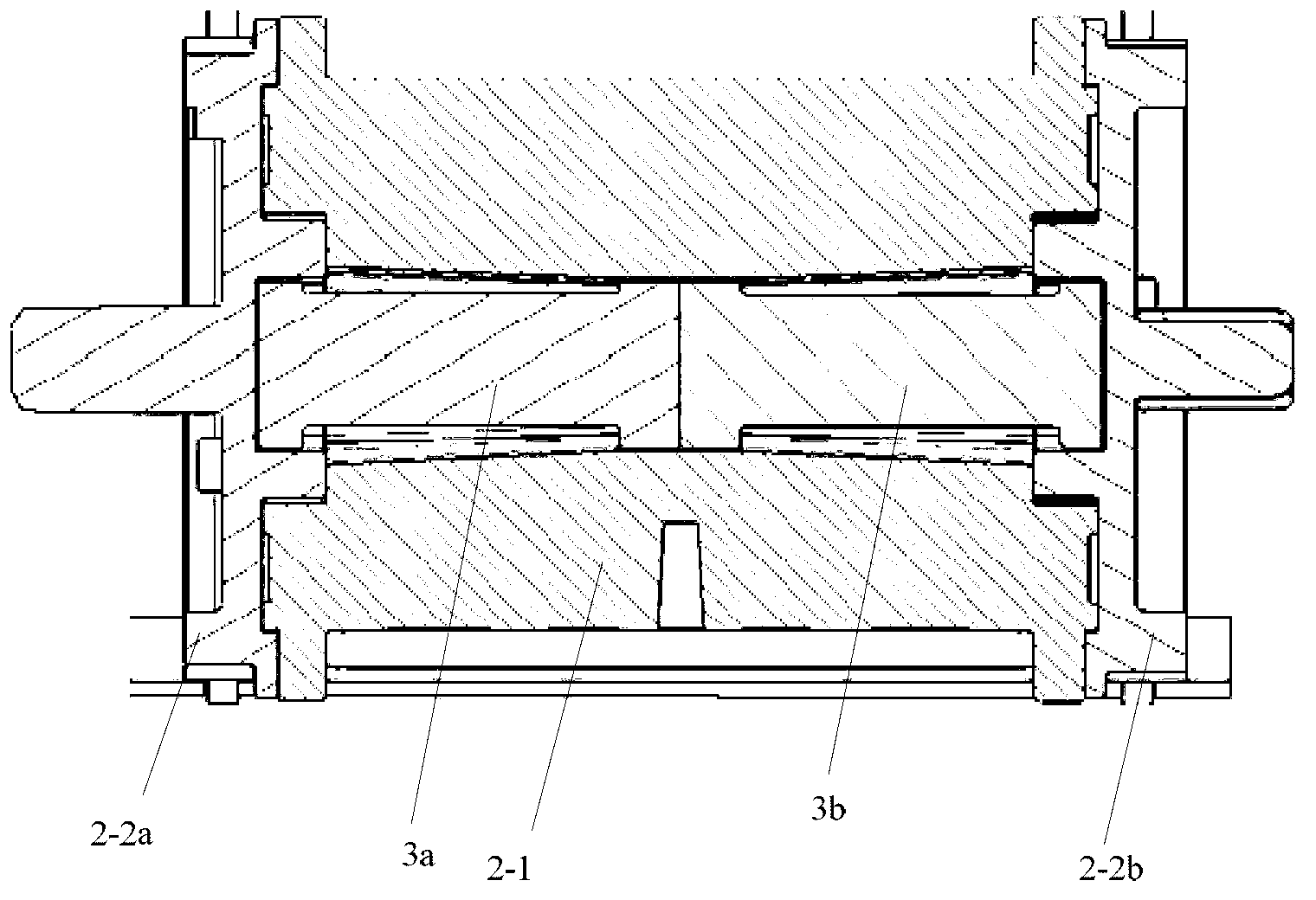

Torsion bar for safety belt coiling device as well as safety belt coiling device and safety belt assembly

InactiveCN102837663AShorten the lengthNot easy to bend and deformBelt retractorsEngineeringLimit value

The invention provides a torsion bar for a safety belt coiling device. The torsion bar is in a bar shape and the axial length of the torsion bar is not more than the axial length of a coiling shaft; peripheral outer teeth are arranged at two end parts and the middle part of the torsion bar and the outer teeth at the two end parts of the torsion bar are matched with inner teeth of central concave holes of end faces of the two end faces on the coiling device; the peripheral outer teeth at the middle part are matched with inner teeth arranged at the middle section of a through hole at a central axis position of a core shaft; the torsion bar is divided from the middle part of the axial direction to form a two-section type structure; and the peripheral outer teeth at the middle part are located at abutted end parts of two sections. Compared with the prior art, the torsion bar disclosed by the invention does not pass through an end cover and is shorter in length, so that the torsion bar is not easy to bend and deform and the use process is safer and more stable. The torsion bar is divided into the two sections, so that different safety belt force limiting value requirements can be met through the combination of different diameters or materials. The invention further provides the safety belt coiling device using the torsion bar and a safety belt assembly.

Owner:和励科技有限公司

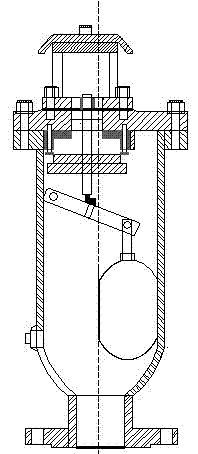

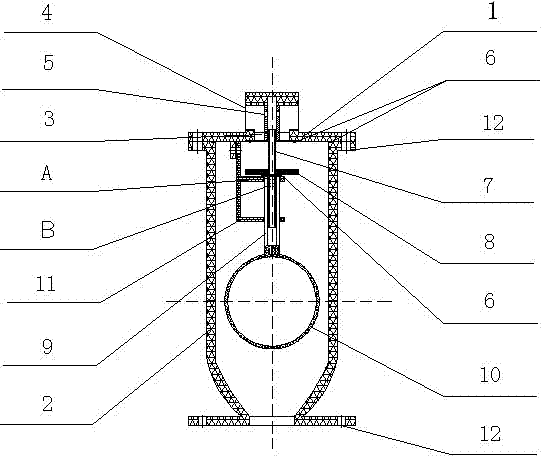

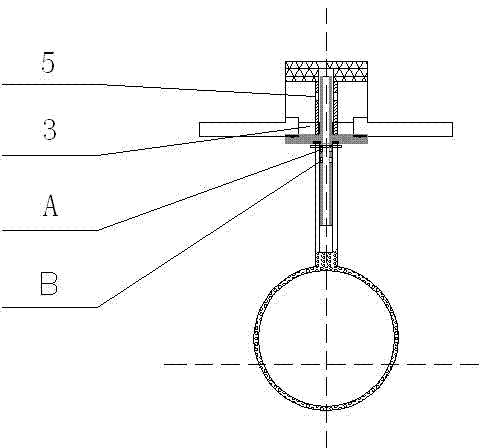

A kind of intake and exhaust valve for sewage with many impurities and large gas volume

InactiveCN102261513AIncrease sizePrevent cloggingOperating means/releasing devices for valvesSewageMechanical engineering

The invention relates to a sewage inlet / exhaust valve, specifically to an inlet / exhaust valve for sewage containing lots of impurities and gases. The exhaust valve is provided with a gas vent having an enlarged size, which is advantageous for the exhausting of a large quantity of gases in the sewage, and simultaneously capable of preventing blockage; the gas vent is under the protection of a guide rod on a floating ball without contacting with bubbles easily incrusted in the sewage gases, thereby reducing blockage and ensuring long-term operation; besides, the position of the floating ball is in the middle position, so that the diameter of the whole valve body is reduced; and a circular floating ball is employed so that the contact area thereof with the liquid level can be widened and the length of the valve body can be also reduced. The exhaust valve overcomes the defects of impurity blockage and low gas output caused by a small gas outlet of the existing sewage inlet / exhaust valve.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

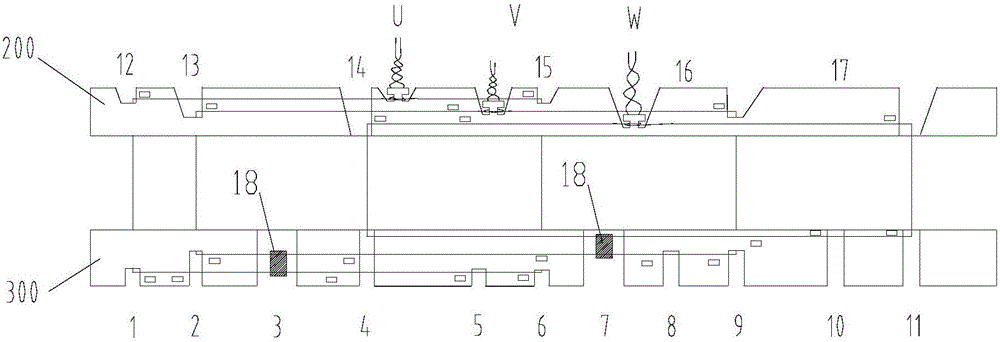

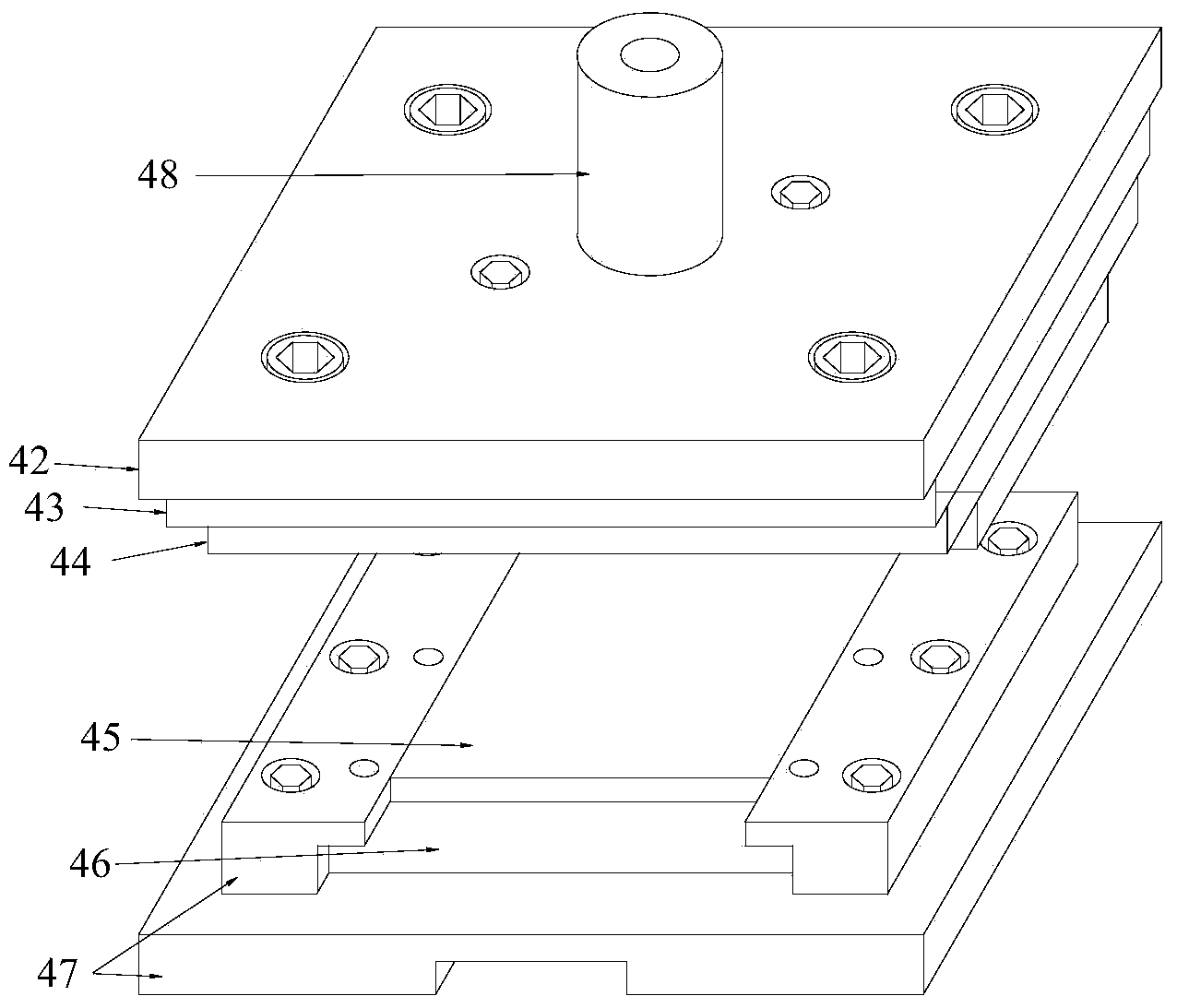

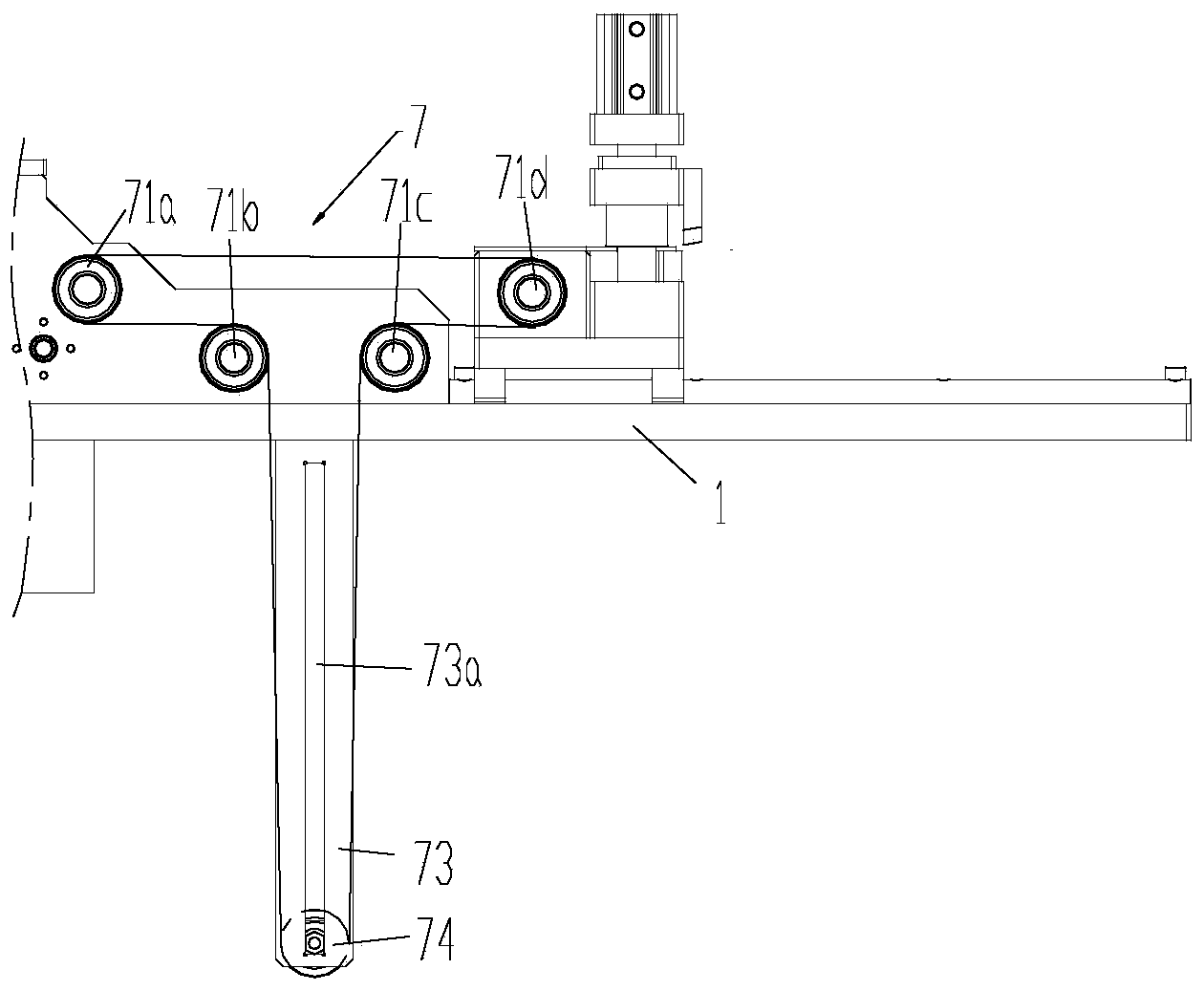

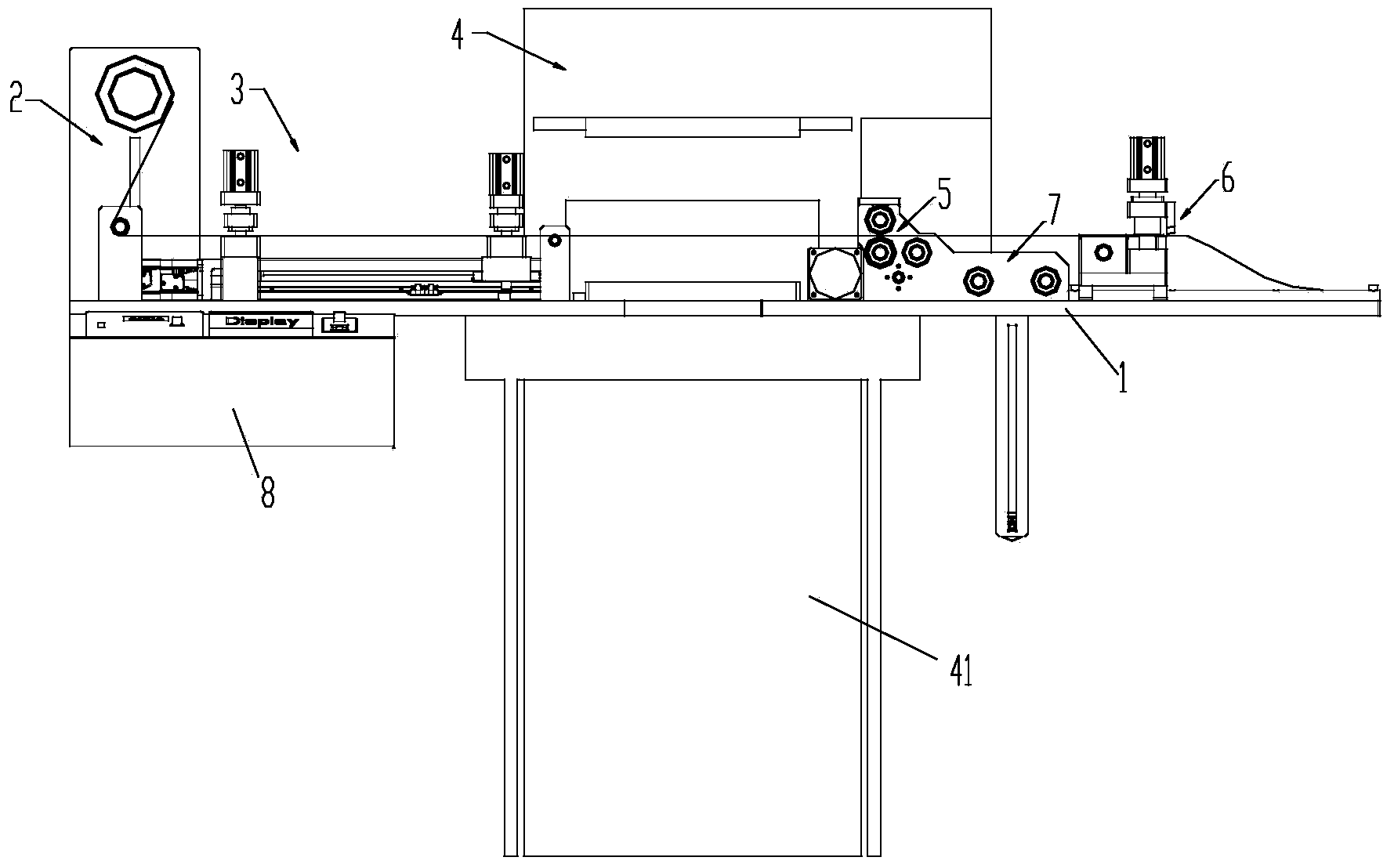

Method and device for universally and continuously die-stamping FPC (Flexible Printed Circuit) auxiliary material

InactiveCN104227780AFlexible size adjustmentFlexible adjustment of punching rangeMetal working apparatusPunchingDisplay device

The invention relates to a method and a device for universally and continuously die-stamping a FPC (Flexible Printed Circuit) auxiliary material. A punching mechanism in the device is divided into an upper mould and a lower mould, wherein the upper mould comprises an upper mould seat, an upper clamping plate and an upper template, and the upper mould seat, the upper clamping plate and the upper template are fixedly connected through bolts; the lower mould comprises a lower template, a lower mould seat and a clamping seat, and the lower template and the lower mould seat are respectively and fixedly arranged on the clamping seat through bolts. By effectively combining a feeding mechanism comprising a fixed clamping device and a movable clamping device with a universal die-punching mechanism and a cutting mechanism, inputting required dimension data into a controller display and controlling a punching machine at intervals to adjust the shape size of the stamped auxiliary material, not only is the transformation from original manual punching to continuous automatic punching realized, but also the die-cutting range and magnitude of a mould can be flexibly adjusted, the molding mould-opening quantity of the FPC auxiliary material and the machining working procedure of the auxiliary material are decreased, the production cost is lowered, and the production efficiency is improved.

Owner:SHENZHEN HUALIN CIRCUIT TECH

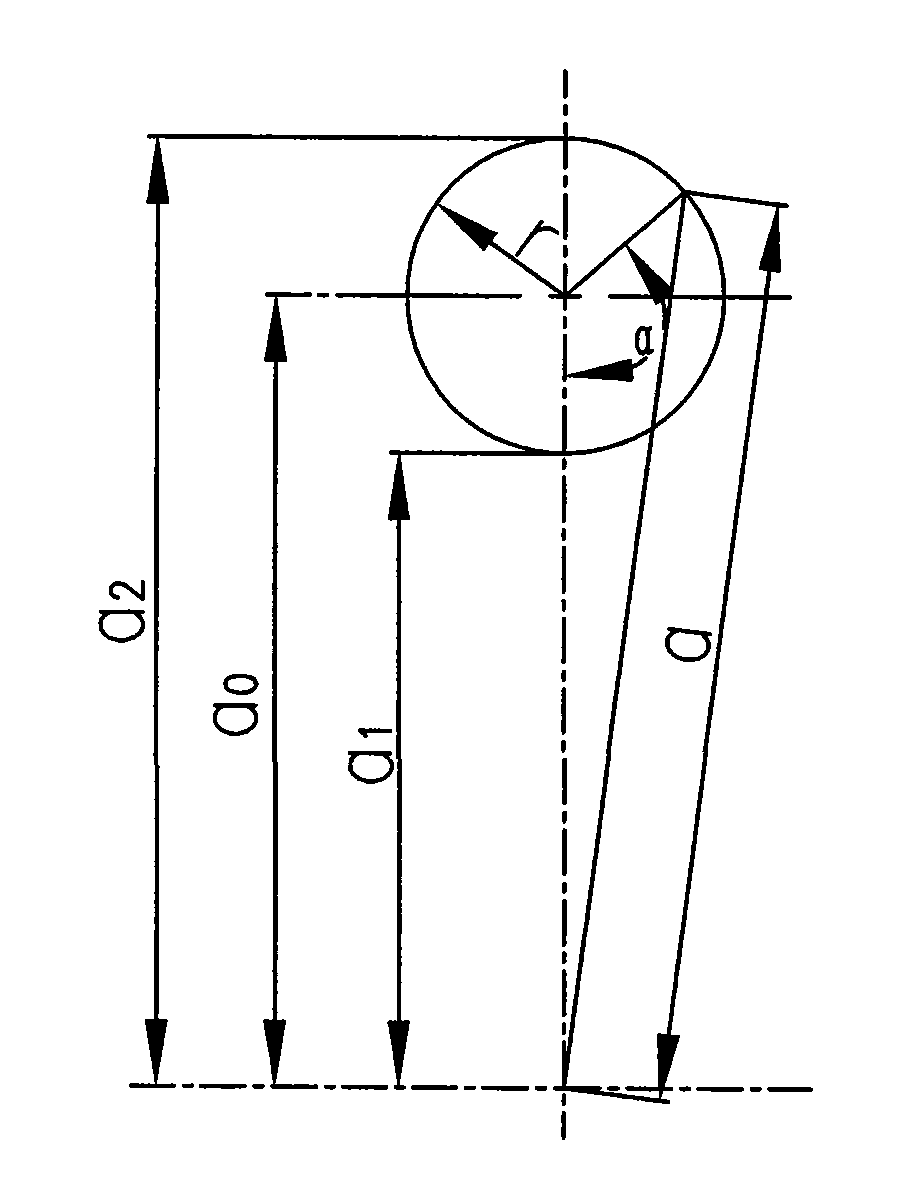

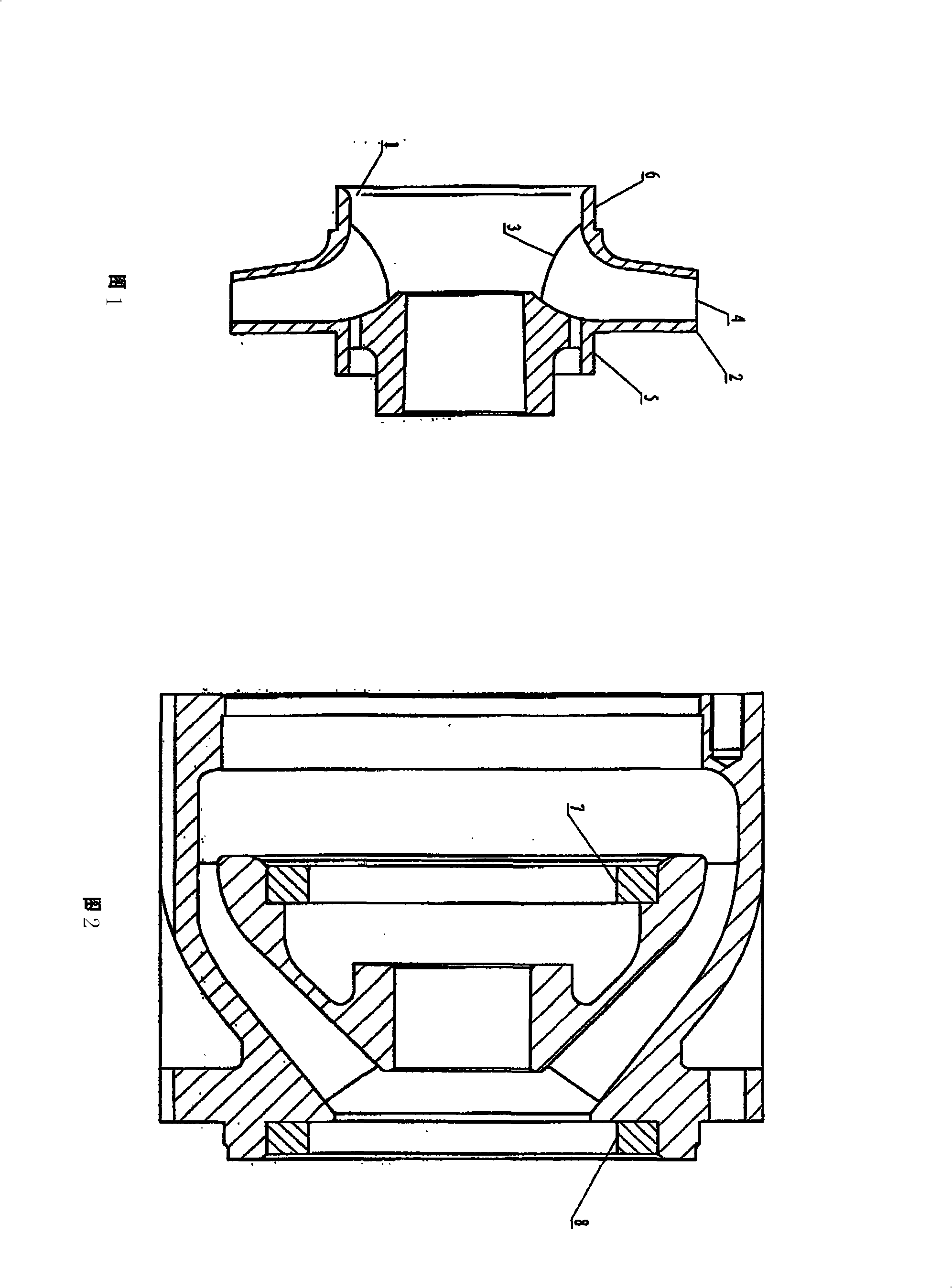

Method for producing single-pump body multi-flux submersible pump

InactiveCN101270754AExpand flow rangeReduce the number of moldsPump componentsPump installationsImpellerManufacturing technology

The invention belongs to the submersible pump manufacturing technology, in particular to the manufacturing technology of a centrifugal multi-grade submersible pump. With the same casing of the pump used, the submersible pumps with different flows are manufactured through the change of impellers. The impellers are designed according to the solution of the parameters of Euler equation. Then, a unary theory design method is adopted for the adjustment of the preliminary design. The casing of the pump is commonly used through the adjustment of the main sizes and angles of the impellers and the adjustment of the size of a sealing ring. With the generality of the casing of the pump improved, few pump casings can be used for manufacturing the submersible pumps with a plurality of specifications. The product cost is greatly lowered, the processing and the management are simplified, the resources are effectively saved, and the production cost is lowered.

Owner:TIANJIN GANQUAN GROUP

Gear box structure with variable center distance and method thereof

The invention discloses a gear box structure with a variable center distance and a method thereof. The gear box structure comprises a first main body module, a second main body module which is connected with the first main body module, and a transition flange which is connected with the first main body module and the second main body module, wherein the first main body module comprises a first outer shell, wherein the first outer shell is of a cylindrical structure which is horizontally arranged, the middle of the outer wall of the first outer shell extends outwards to form a ring-shaped firstflange; the second main body module comprises a second outer shell, the second outer shell is of a cylindrical structure which is horizontally arranged; one end of the first outer shell is inserted into the interior of the second outer shell; one end of the second outer shell is fixedly connected with the first flange; and the transition flange is arranged at one part which between one end part of the second outer shell and the first flange. According to the gear box structure with the variable center distance and the method thereof, the gear box can achieve the diversity of the center distance of the gearbox through the thickness of the transition flange, so that the advantages of the modular design are further embodied.

Owner:宁波东力股份有限公司

Stamping die with replaceable inserts

InactiveCN105436307AImprove versatilityReduce the number of moldsShaping toolsEngineeringElectrical and Electronics engineering

The invention relates to a stamping die with replaceable inserts. The stamping die comprises a female die plate, the male die inserts and the female die inserts. The stamping die is characterized in that under the condition that the diameters of outer circles of stamped steel products are identical, according to different shaft hole diameters and key groove shapes of the stamped steel products, the four female die inserts are mounted on the female die plate in the four positive directions according to different distributions of the shaft hole diameters; according to the key groove positions of the stamped steel products needing to be manufactured, the male die inserts corresponding to the female die inserts are mounted on the female die inserts. The stamping die has the advantages and the beneficial effects that the stamping die is suitable for machining various products with the identical outer circles and identical buckle slab grooves and with different shaft hole diameters and different key grooves; when one of the products is produced, the corresponding female die inserts can be all mounted in the female die plate, and different female die inserts can be mounted for production according to the different sizes of the key grooves of the products; the number of made dies is reduced, the universality of the die is improved, and manufacturing cost is lowered.

Owner:TIANJIN BINHAI TONGDA POWER TECH

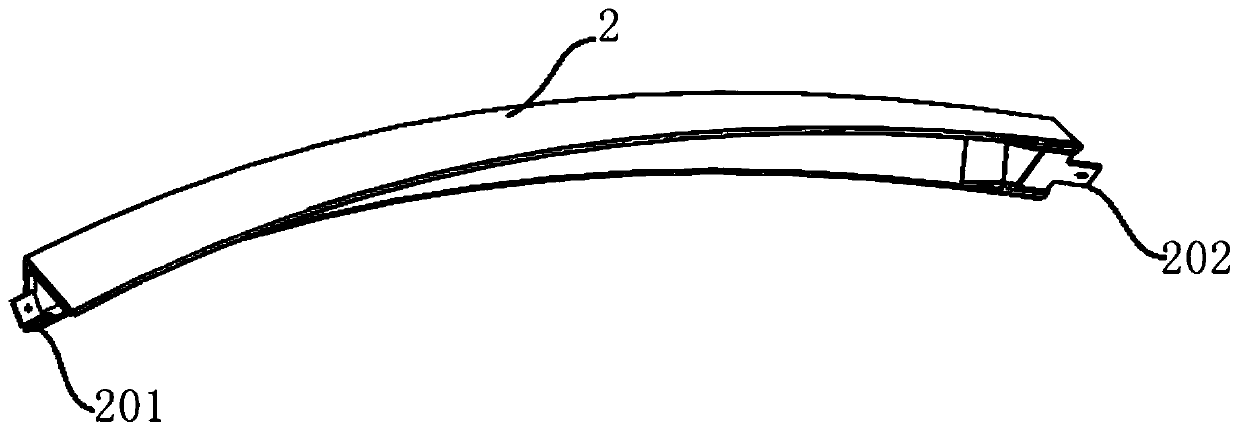

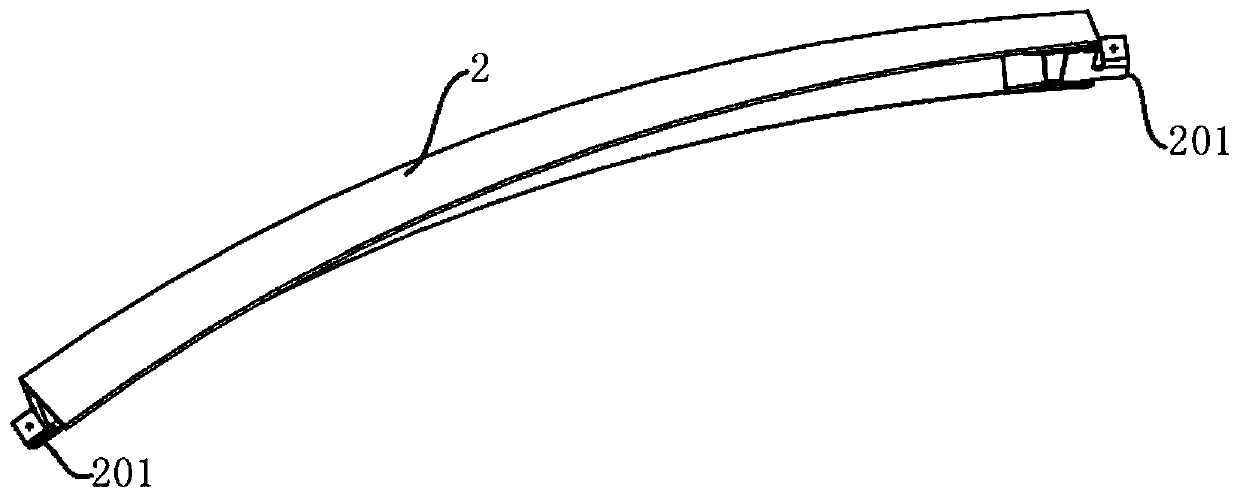

Arc-shaped tower pieces for tower tube sections and tower tube sections

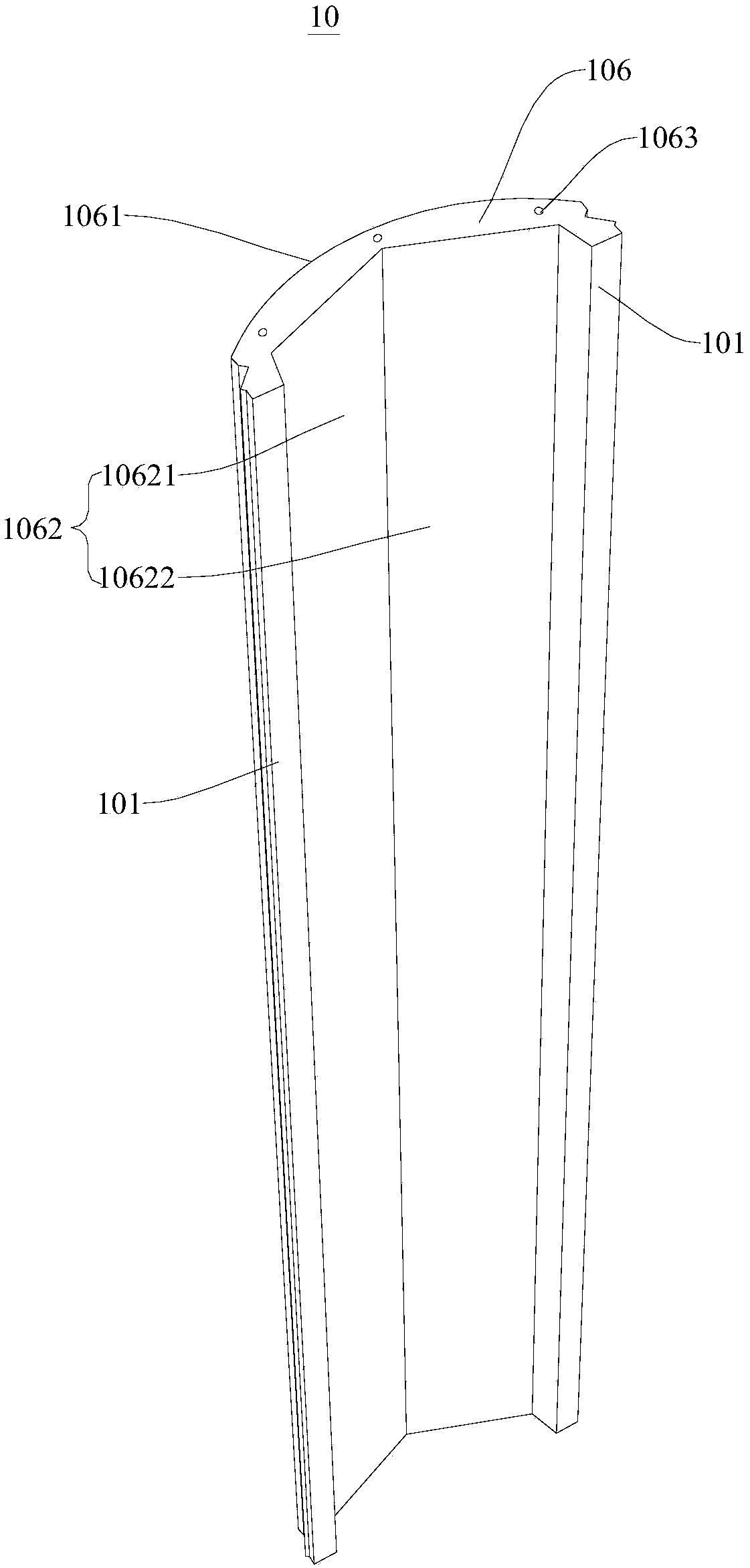

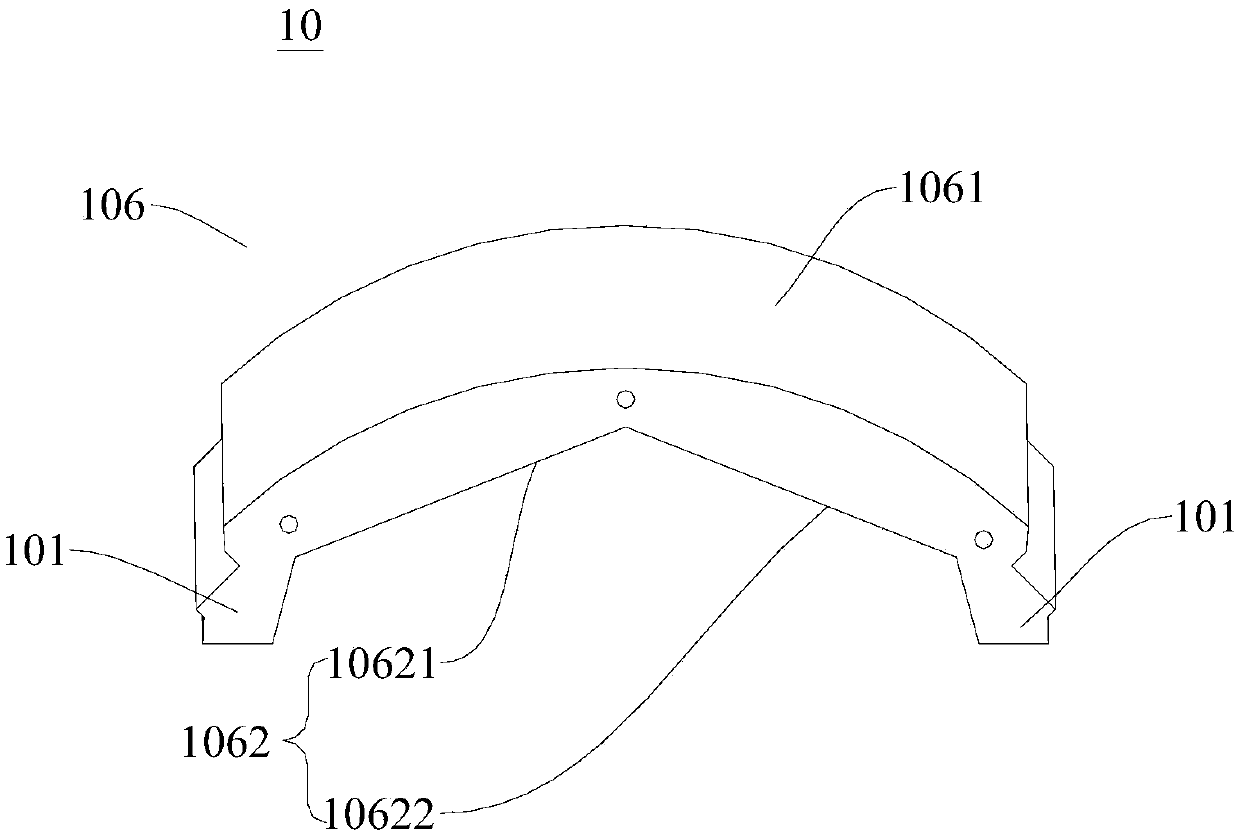

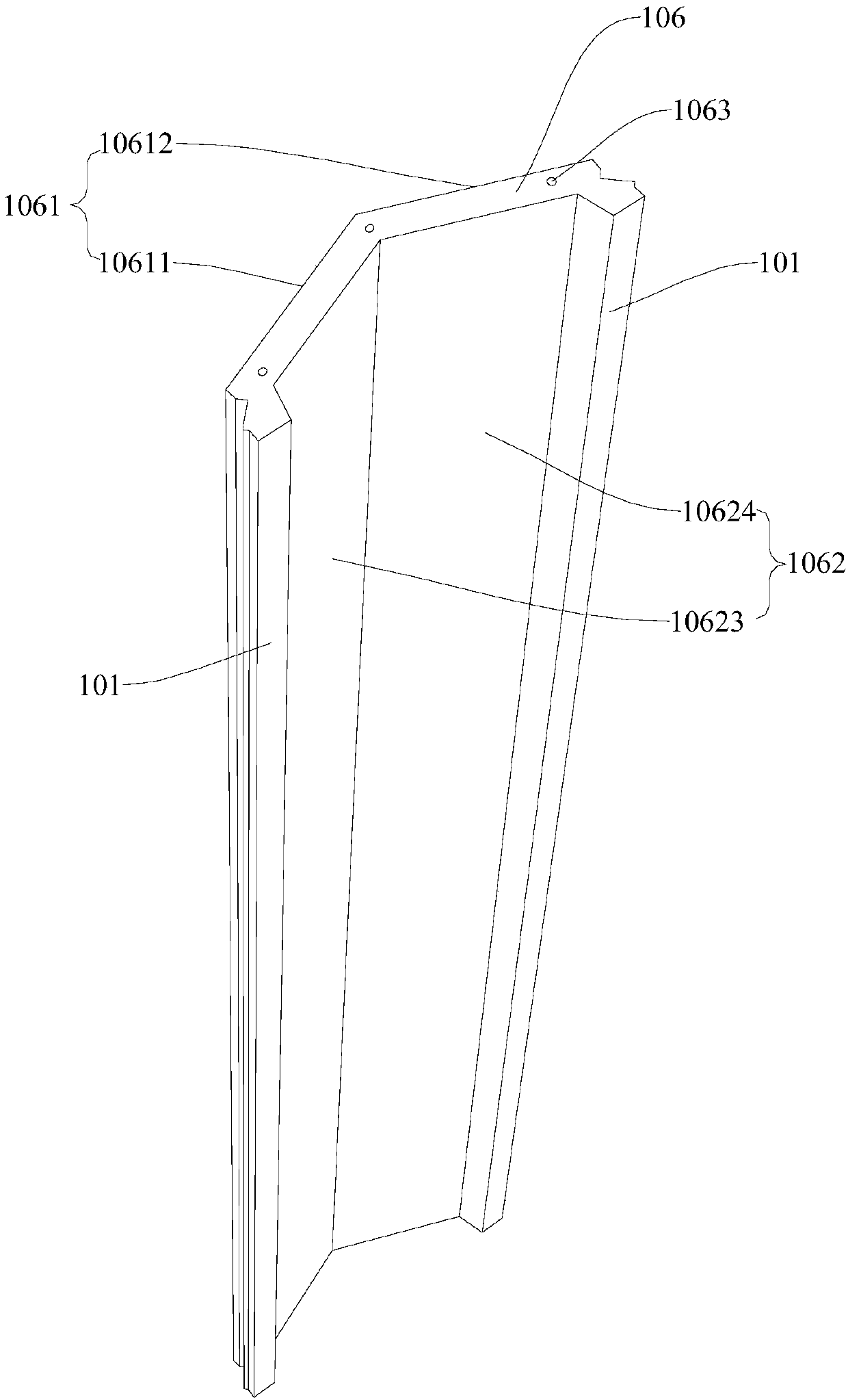

PendingCN111287537ASimplify the manufacturing processReduce the number of moldsWind motor supports/mountsTowersMechanical engineeringIndustrial engineering

The invention discloses arc-shaped tower pieces for tower tube sections and the tower tube sections. The arc-shaped tower pieces for the tower tube sections include main body sections and first lapping sections, the main body sections are provided with outer wall surfaces and inner wall surfaces, the outer wall surfaces are circular arc surfaces or folding surfaces, the inner wall surfaces are circular arc surfaces or folding surfaces, and the first lapping sections are arranged at two circumferential ends of the main body sections; and the multiple arc-shaped tower pieces are connected with aplurality of straight tower pieces end to end alternately through the first lapping sections to form the annular tower tube sections, the multiple tower tube sections are stacked in the up-down direction in sequence, for every two adjacent tower tube sections, the circumferential dimension of the straight tower pieces at the lower part is larger than that of the straight tower pieces at the upperpart at the same position, and the circumferential dimension of the arc-shaped tower pieces at the multiple tower tube sections is same. According to the arc-shaped tower pieces of the embodiment ofthe invention, the prefabrication is simple, the axial length of the arc-shaped tower pieces in the tower tube sections in the up-down direction is equal, and the number of molds is reduced, so that the difficulty of prefabrication is reduced.

Owner:上海风领新能源有限公司

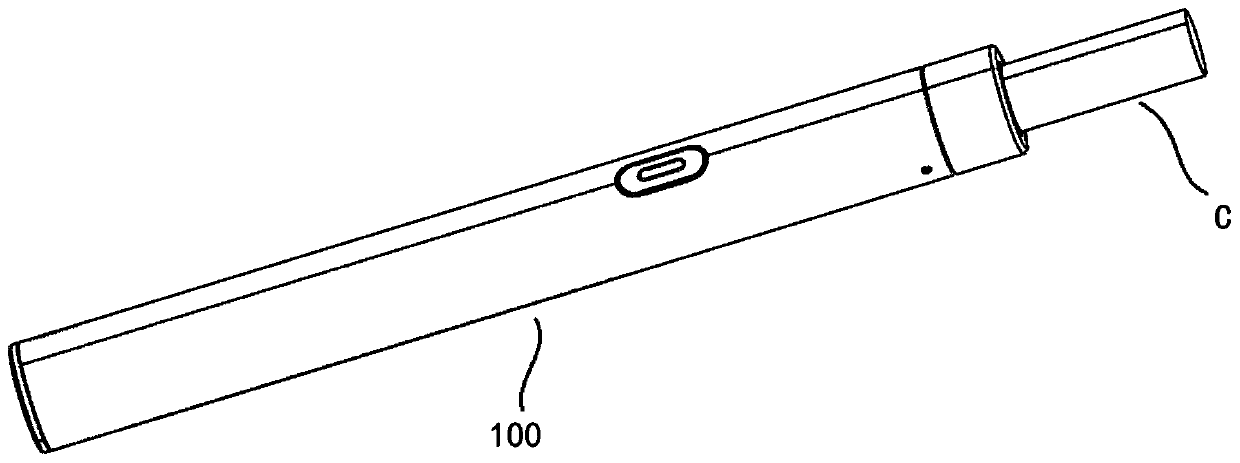

Heating non-combustion smoking set

PendingCN110384259AReduce connectivityReduce the number of moldsTobacco devicesCombustionEngineering

The invention relates to a heating non-combustion smoking set comprising a battery and a heating body and further comprising a circuit assembly; the circuit assembly comprises a flexible substrate, acontrol circuit, a battery welding spot and a heating body welding spot, wherein the control circuit, the battery welding spot and the heating body welding spot are formed on the flexible substrate; and the flexible substrate is connected with the battery and the heating body through the battery welding spot and the heating body welding spot. According to the heating non-combustion smoking set inthe invention, the connection of all components in the smoking set can be more compact to a certain extent, and the overall assembly process is simplified by improving the connection mode.

Owner:QINGDAO ETSONG TECH CO LTD

Manufacturing method of vehicle traction beam, vehicle traction beam and rail vehicle

ActiveCN110480266AReduce the difficulty of manufacturing processGuarantee the difficulty of manufacturing processVehicle componentsWelding apparatusButt weldingButt joint

The invention provides a manufacturing method of a vehicle traction beam, the vehicle traction beam and a rail vehicle. The manufacturing method of the vehicle traction beam comprises the steps: forming two traction beam webs by using a single sectional material; splicing the traction beam webs and a lower cover plate to form a V-shaped groove, and carrying out butt welding to form a vehicle traction beam body; enabling the vehicle traction beam body to be in butt joint with a vehicle coupler mounting seat to form a Y-shaped groove, and then carrying out butt welding; and welding a curved surface mounting plate between an anti-climbing energy absorption device mounting seat and the vehicle coupler mounting seat. According to the manufacturing method of the vehicle traction beam and the vehicle traction beam, the single sectional material is used for forming the two traction beam webs, so that the machining efficiency is improved; the V-shaped groove is formed in the spliced position ofthe traction beam webs and the lower cover plate; the Y-shaped groove is formed in the spliced position of the vehicle traction beam and the vehicle coupler mounting seat, so that the welding operation difficulty is reduced, and the welding quality is ensured; and the curved surface mounting plate is welded to the position between the anti-climbing energy absorption device mounting seat and the vehicle coupler mounting seat, so that a long enough gap is reserved between a vehicle coupler and the vehicle coupler mounting seat.

Owner:CRRC QINGDAO SIFANG CO LTD

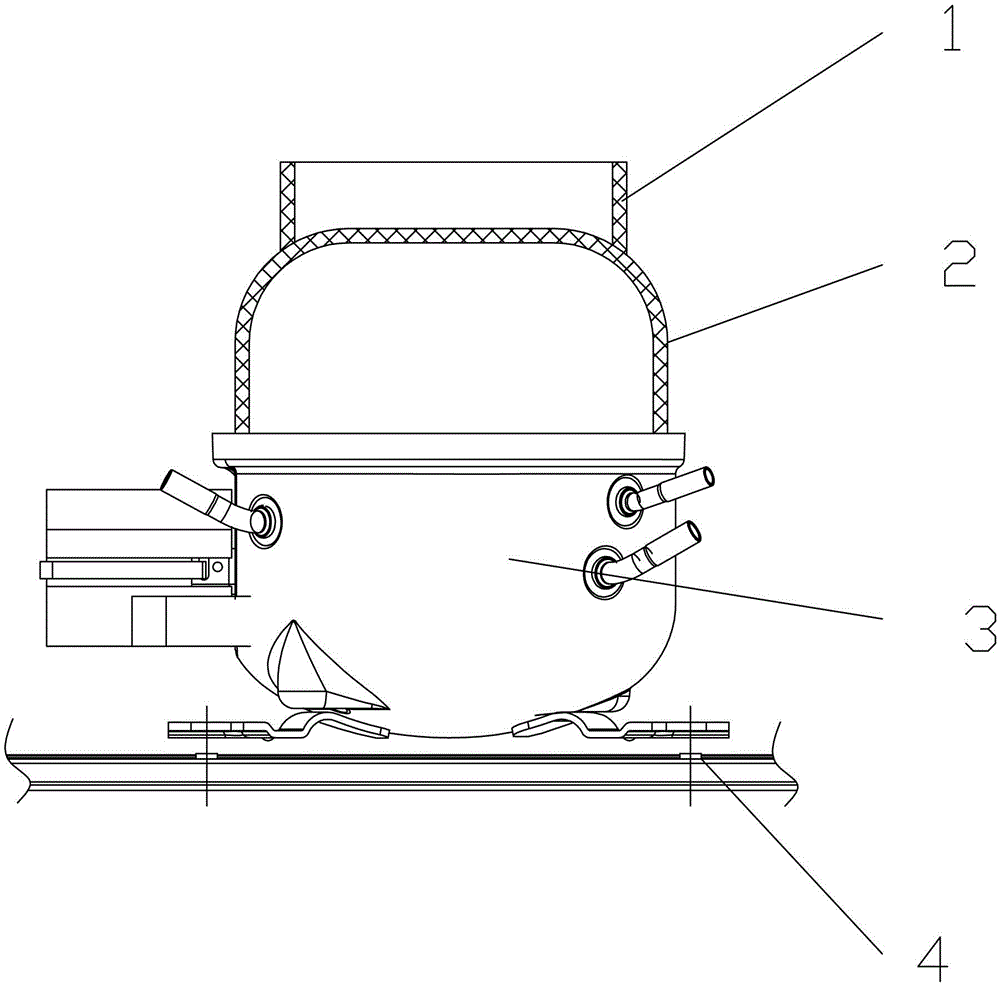

Compressor with water pan

InactiveCN105352245AReduce installation processImprove evaporation efficiencyLighting and heating apparatusRefrigeration devicesEvaporationEngineering

The invention discloses a compressor with a water pan. The compressor is arranged in a compressor bin of a refrigerator. An open container is integrally arranged on a top shell of the compressor and located below a condensate water outlet of a refrigerator body. The compressor and the water pan are combined into a whole, the water pan is arranged on the top shell of the compressor, heat radiation of the compressor is directly used for evaporating water, and evaporation efficiency is high; and abnormal noise is avoided, the mounting procedure of the water pan is omitted, and the number of opened molds is lowered.

Owner:GUANGDONG HOMA APPLIANCES

Modular back clamping battery

InactiveCN108565932ALower cost of capitalSave time and costBatteries circuit arrangementsElectric powerModularityEngineering

Intelligent mobile phones are different due to appearance, and therefore back clamping batteries are forced to be varied. The number of Android mobile phone manufacturers and the number of models arelarge, the scale of single mobile phones in the market is small, if a model is formed for the back clamp battery of each model of Android mobile phones, the investment cost is high, the time is long and the inventory pressure is large, and the back clamping batteries are not available for most Android mobile phones. Compared with the back clamping batteries, the application range of mobile phone protective shells is wider, the number of the manufacturers is large and the mobile phone protective shells are easier to obtain. The back clamping batteries are modular, the mobile phone protective shells sold in the market replace back clamping connecting covers, and charging back clamps can be provided for the large-screen intelligent mobile phones quickly at a low cost as long as the intelligent mobile phone protective shells are found.

Owner:深圳创新黑科技有限公司

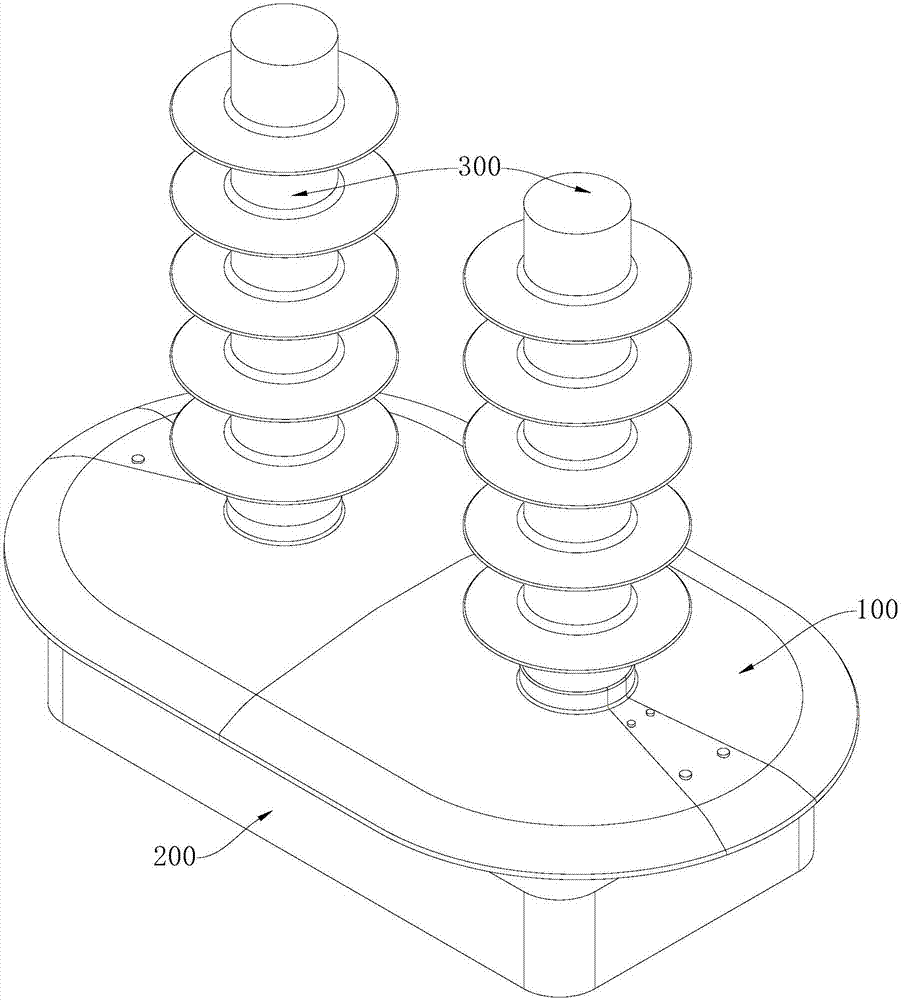

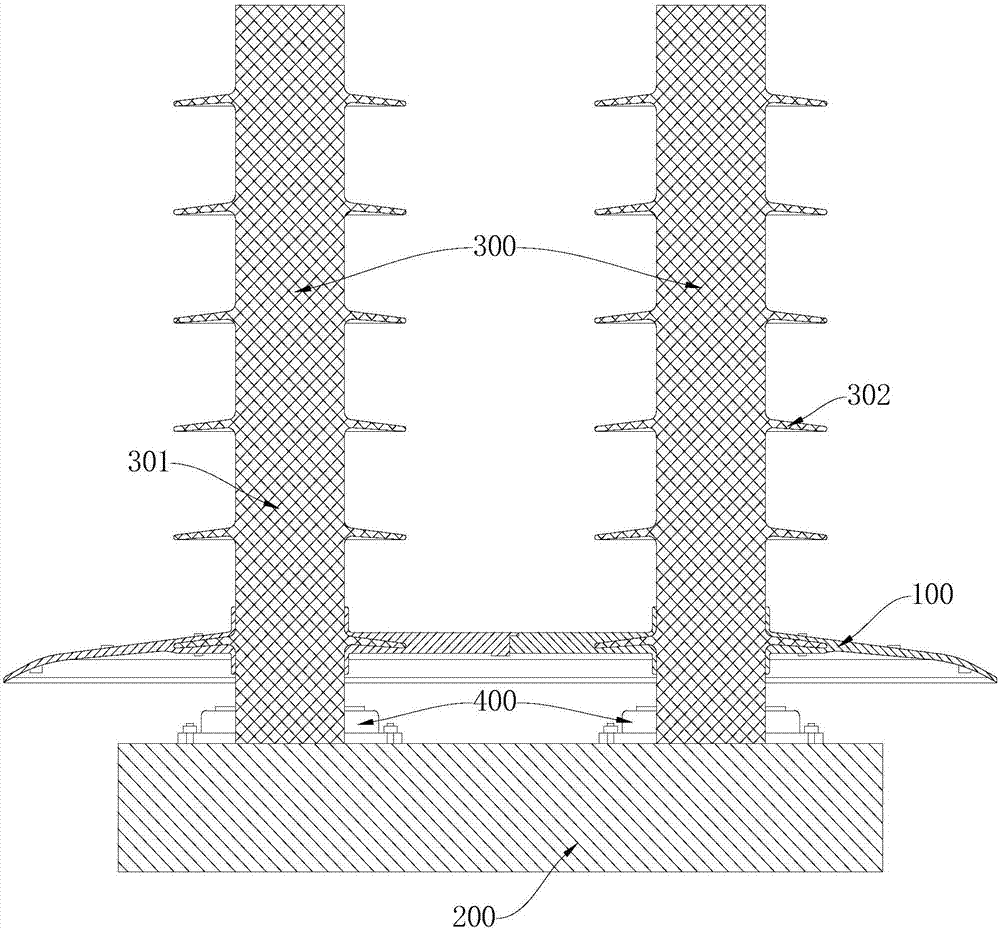

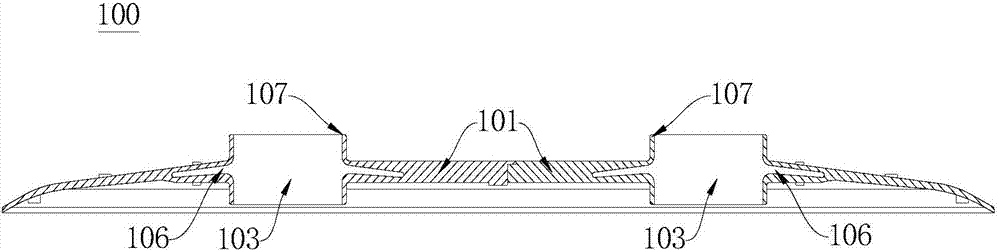

Umbrella cover and electrical device applying same

InactiveCN106898441AReduce manufacturing difficultyReduce manufacturing costInsulatorsSewageElectrical and Electronics engineering

The present invention provides an umbrella cover and an electrical device applying the same. The umbrella cover is arranged on an electrical device including at least two insulators; the umbrella cover is provided with at least two installation holes configured to allow the at least two insulators to pass through and openings corresponding to the installation holes, and the openings communicate the installation holes and the edge of the umbrella cover. In one embodiment, the electrical device also comprises a housing, the at least two insulators are connected with the housing through housing connection portions; and the umbrella cover at least shield the housing connection portions. The effect of creep distance increasing of the umbrella cover is remarkable, and snow and rain and sewage can be effectively blocked, and the umbrella cover and the electrical device applying same have a good anti-pollution flashover effect. In one embodiment, the umbrella cover can effectively prevent snow and rain and sewage from entering the connection position of the connection portions with the insulators and the housing so as to improve the safety of the electrical device. The diameter of the umbrella cover is big to cut off the conductive channel configured to form an umbrella curtain so as to avoid even put an end to rain flashover accidents to some extent.

Owner:JIANGSU SHENMA ELECTRIC CO LTD

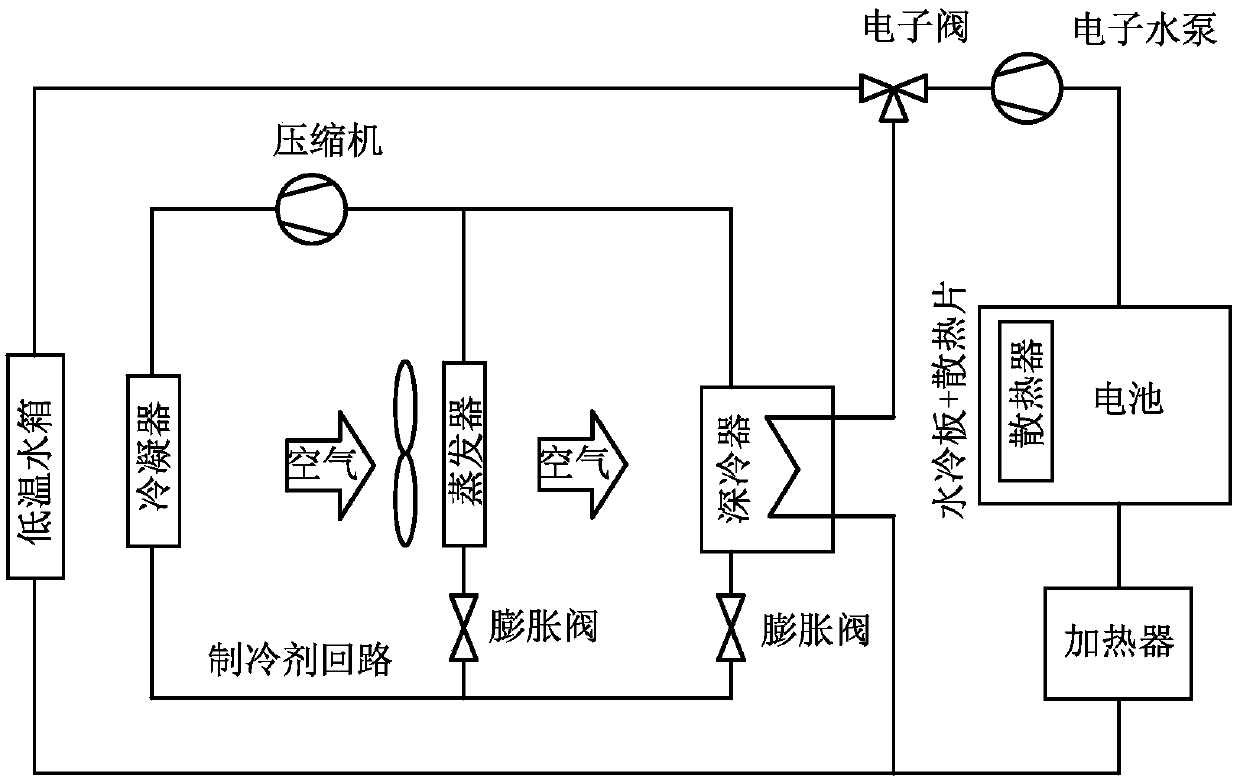

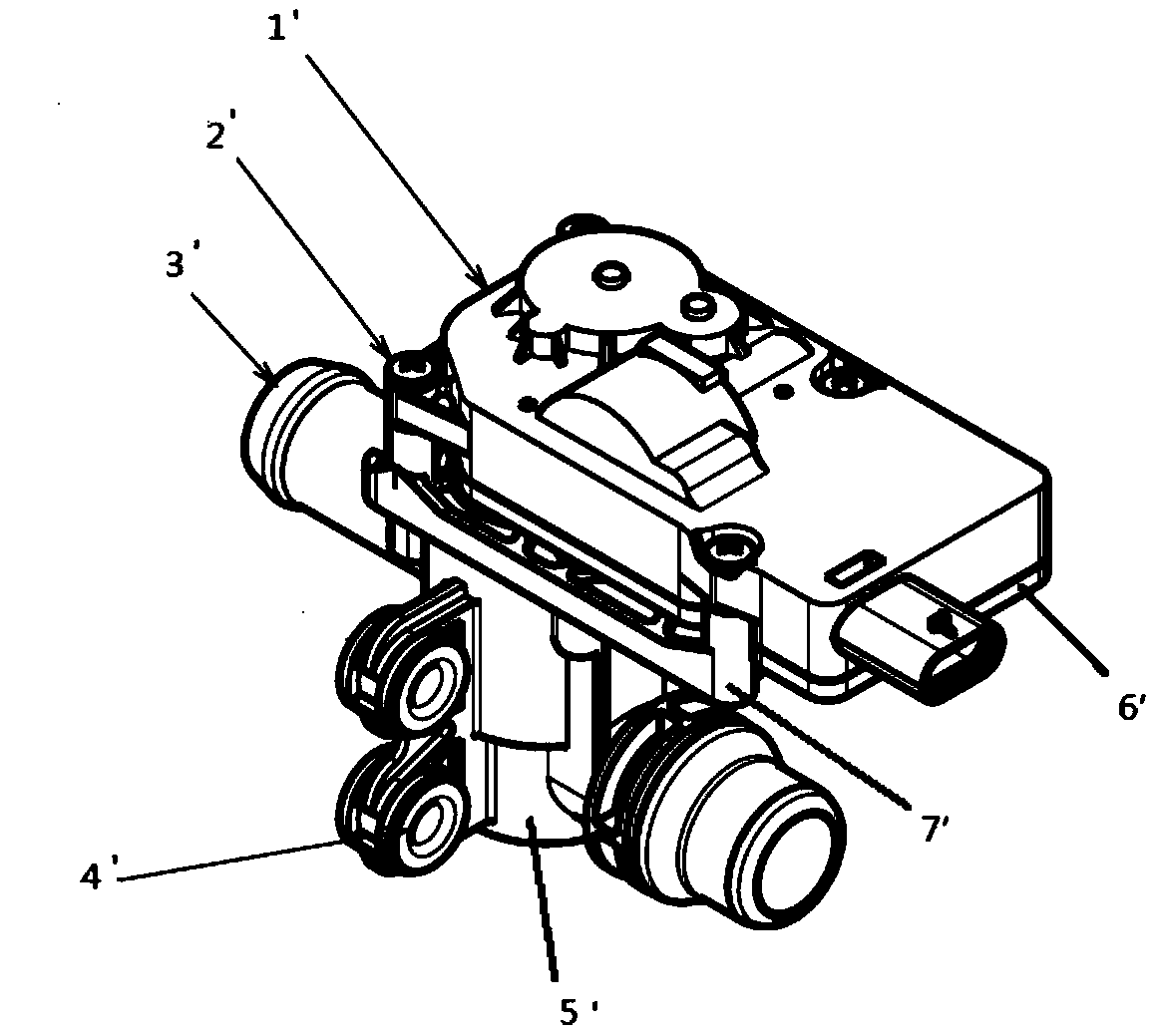

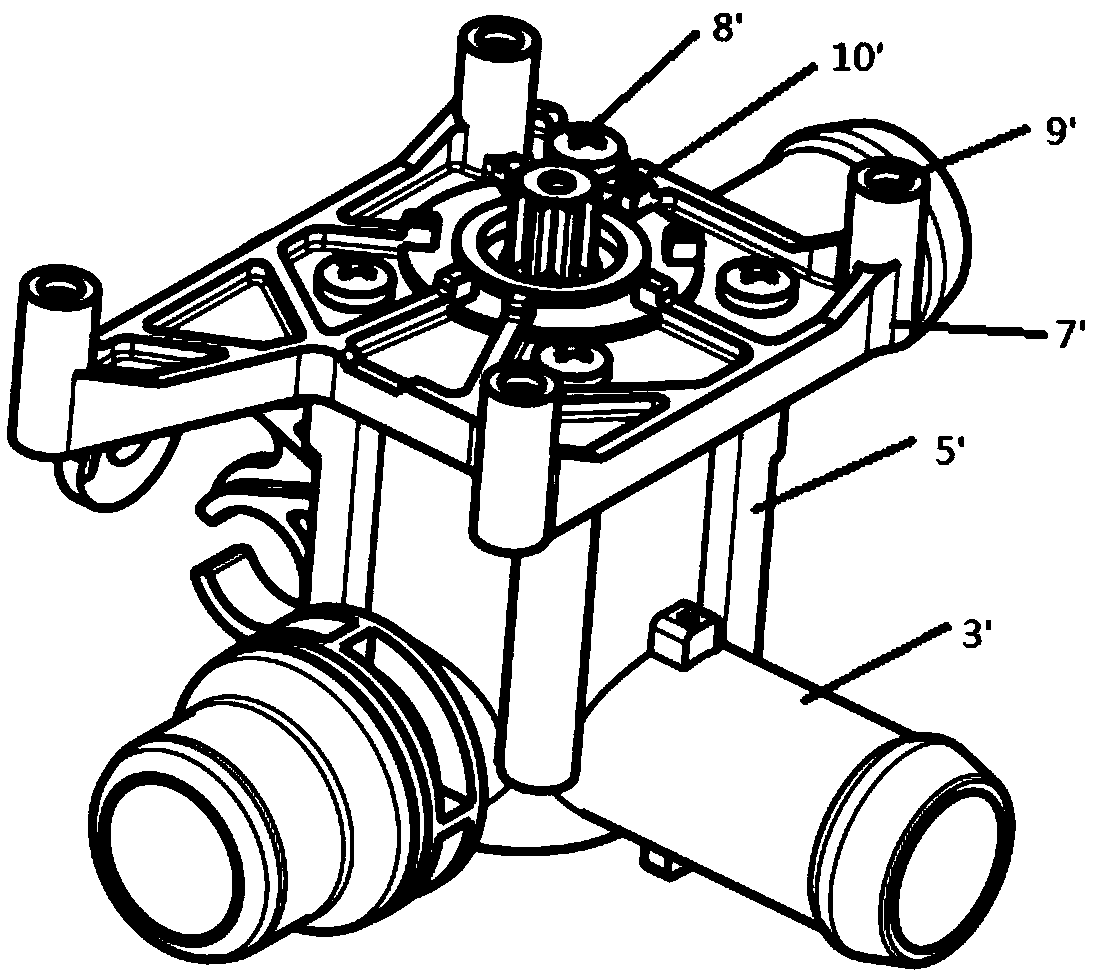

Electronic valve and valve body structure thereof

PendingCN111412321AReasonable structural designReduce in quantitySpindle sealingsValve housingsEngineeringPower apparatus

The invention discloses an electronic valve. The electronic valve includes a valve body assembly, a flow control device and a power device. The valve body assembly includes a valve body, the valve body includes a valve body upper part and a valve body lower part, an upper end cover is arranged on the valve body upper part, and a connecting pipe and a lower end cover are arranged on the valve bodylower part; the power device is arranged in a space formed by the upper end cover and the valve body upper part; and the flow control device is arranged in a space formed by the lower end cover and the valve body lower part. The electronic valve is characterized in that the valve body upper part and the valve body lower part are integrally molded by injection molding. According to the electronic valve, the structure design is reasonable; the valve body is integrally molded in an mold opening mode, the number of parts is reduced, the assembly processes of the valve body upper part and valve body lower part are reduced, and the number of open molds of product parts is reduced, and the development cycle and research and development cost are recued; and moreover, the size of the products is easy to ensure, the weight can further be reduced, and the lightweight and integrated purposes required by a main engine plant are easier to achieve.

Owner:ZHEJIANG YINLUN MACHINERY

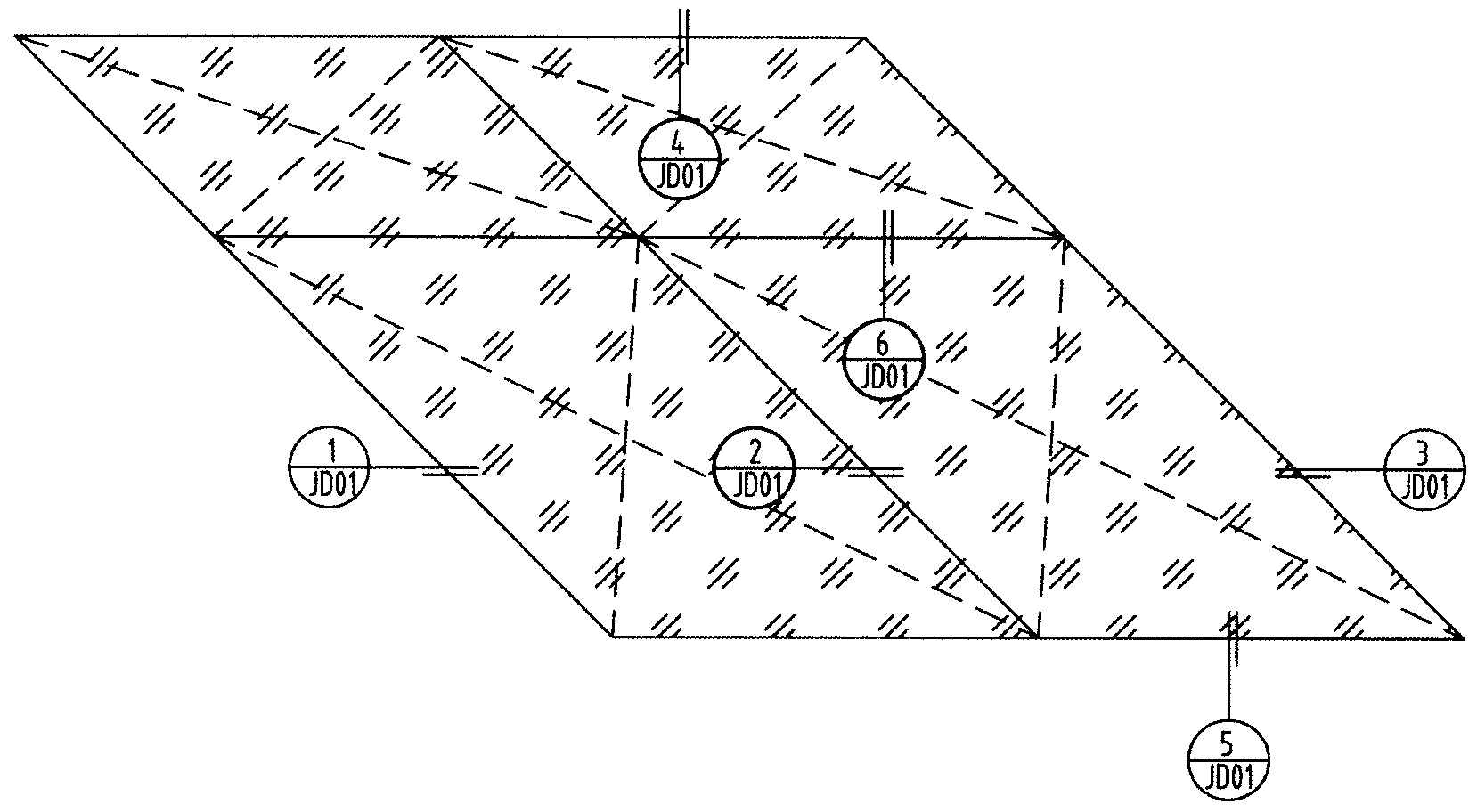

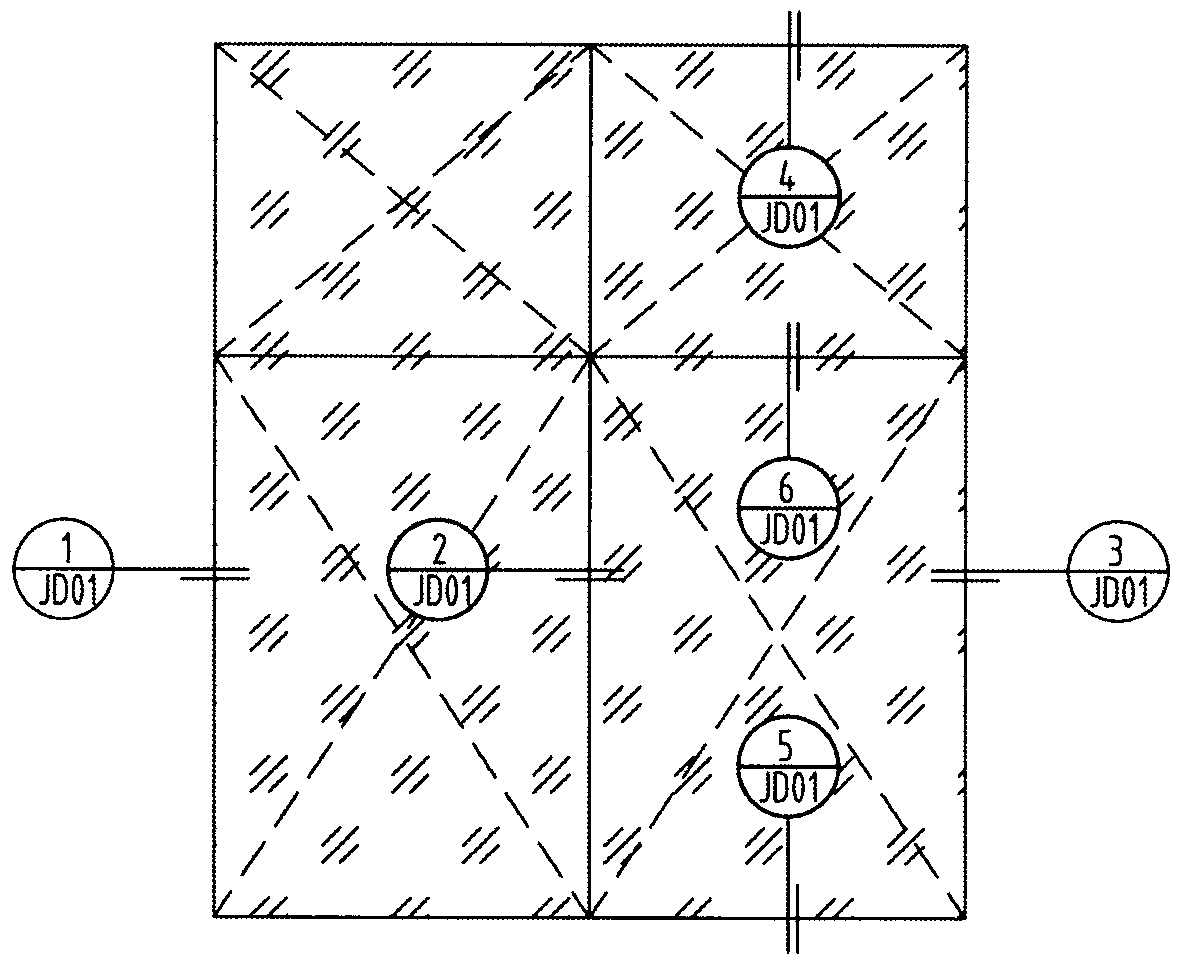

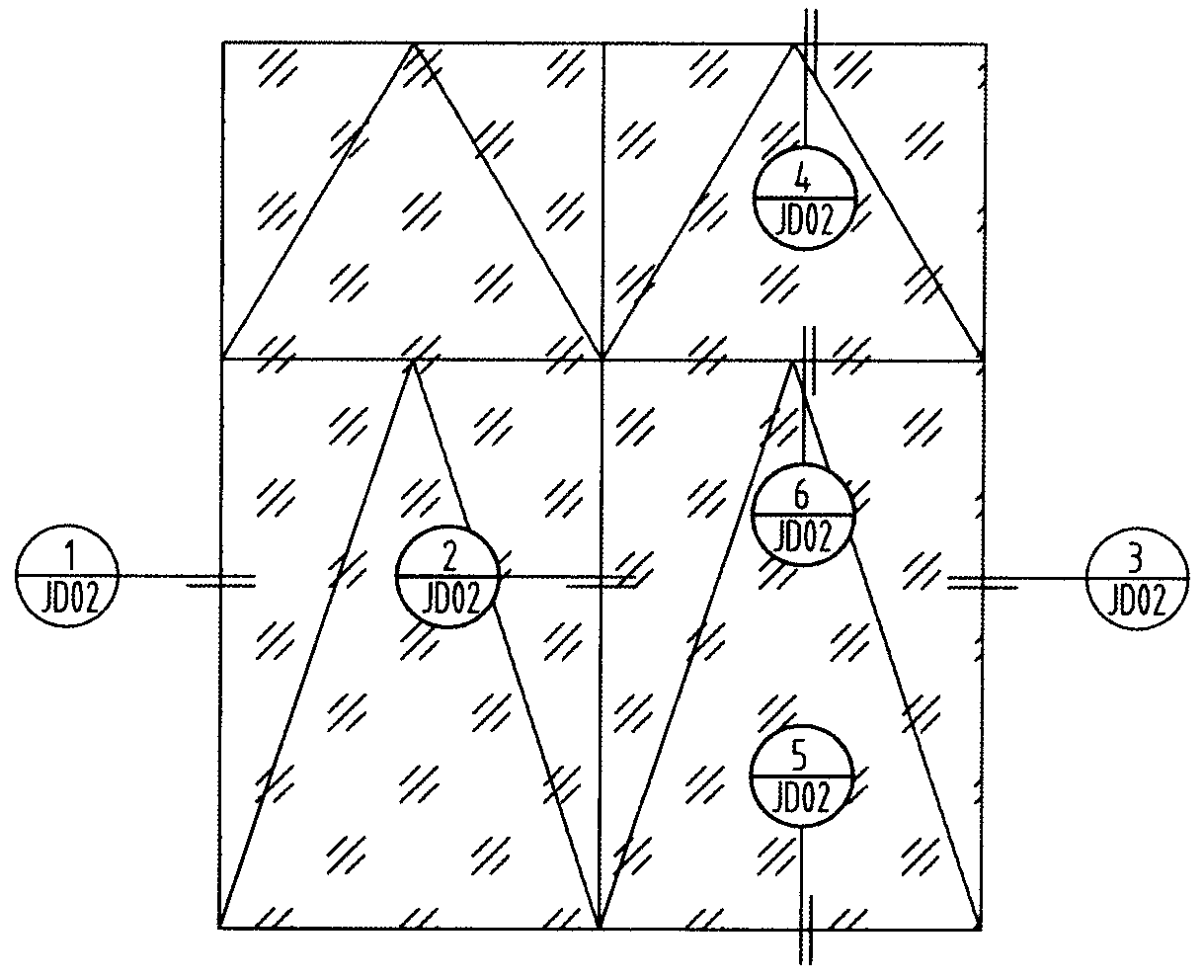

Forming mold for aircraft skin part

ActiveCN103464561BRaise the forming limitReduce the number of deep drawingShaping toolsMaterials scienceAirplane

The invention relates to a forming die of a skin part for an airplane. The forming die comprises a compression block, a male die, a female die, a binder ring and a pressing plate, wherein the male die comprises a straight wall part and a forming part; the female die is provided with a cavity for holding billets and liquid; the binder ring comprises an upper binder ring and a lower binder ring; the lower binder ring can be slidably located on the female die in the longitudinal direction, and is provided with a second penetrating hollow part adapt to a lower straight wall part; the upper binder ring can be detachably fixed on the lower binder ring, and is provided with a first up-and-down penetrating hollow part; the upper binder ring is detachably connected with a second pressurizing source, so that the compression block and the male die sequentially penetrate through the first hollow part and the second hollow part under the action of a first pressurizing source, and when the forming part of the male die is used for forming the billets in the cavity of the female die, the second pressurizing source presses the upper binder ring and the lower binder ring on the female die. According to the forming die of the skin part for the airplane, the resilience after a part is formed is effectively reduced, and the forming accuracy and the surface quality are improved.

Owner:SHANGHAI AIRCRAFT MFG +1

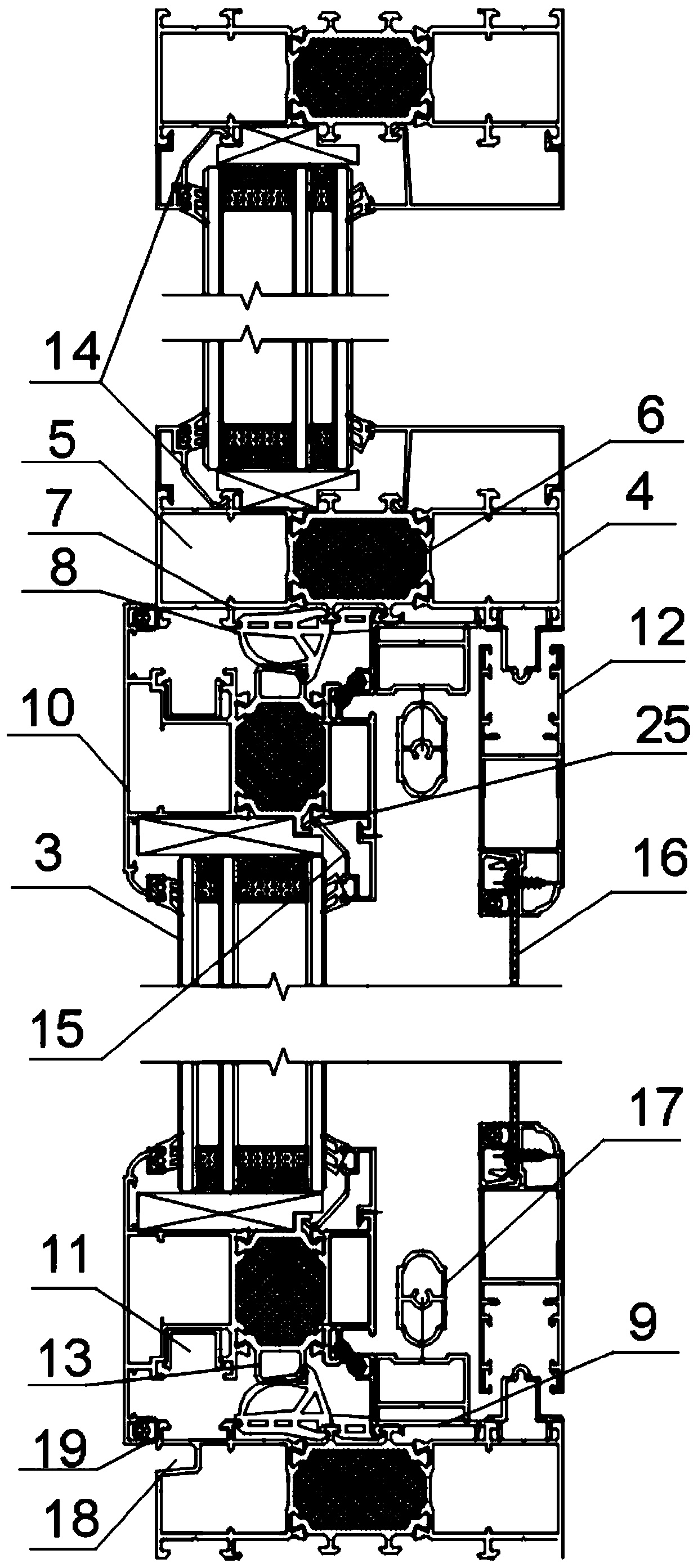

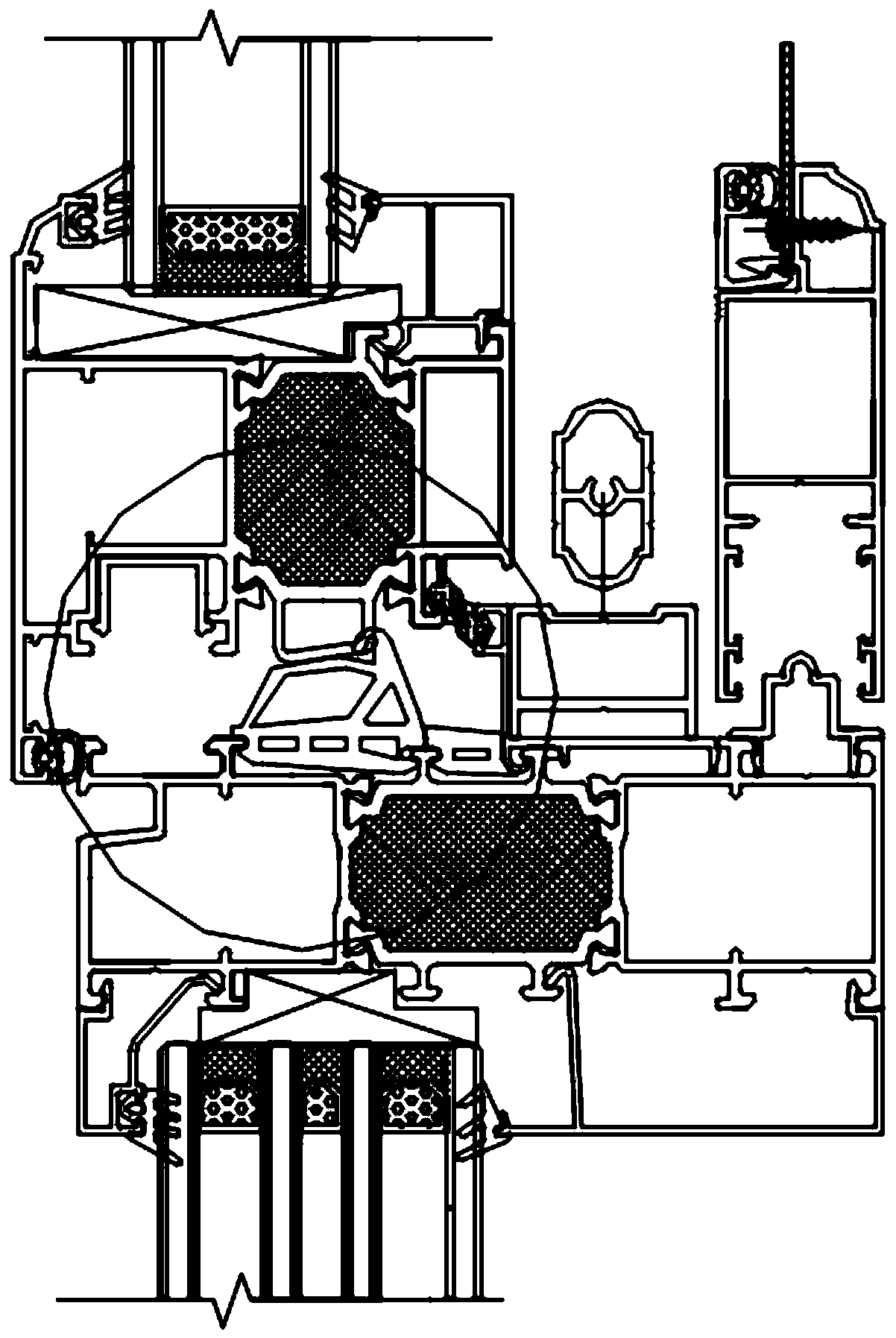

Multifunctional hidden frame window system

InactiveCN102865014AIncrease profitReduce the number of moldsSealing arrangementsWing arrangementsSash windowEngineering

The invention discloses a multifunctional hidden frame window system, comprising casements, and window frames / stiles, wherein the casements and the window frames / stiles are connected and encircled into at least one sealing cavity through sealing elements, and the space size of at least one of the sealing cavities is suitable for installing a connecting part which keeps the casements and the window frames / stiles in fixing or relative displacing. The system can meet the requirements for fixing the window and opening the window in a plurality of forms simultaneously by using one section bar, so that the design is more flexible, and the mould number of the aluminium alloy curtain wall window system is obviously reduced.

Owner:苏州苏明装饰股份有限公司

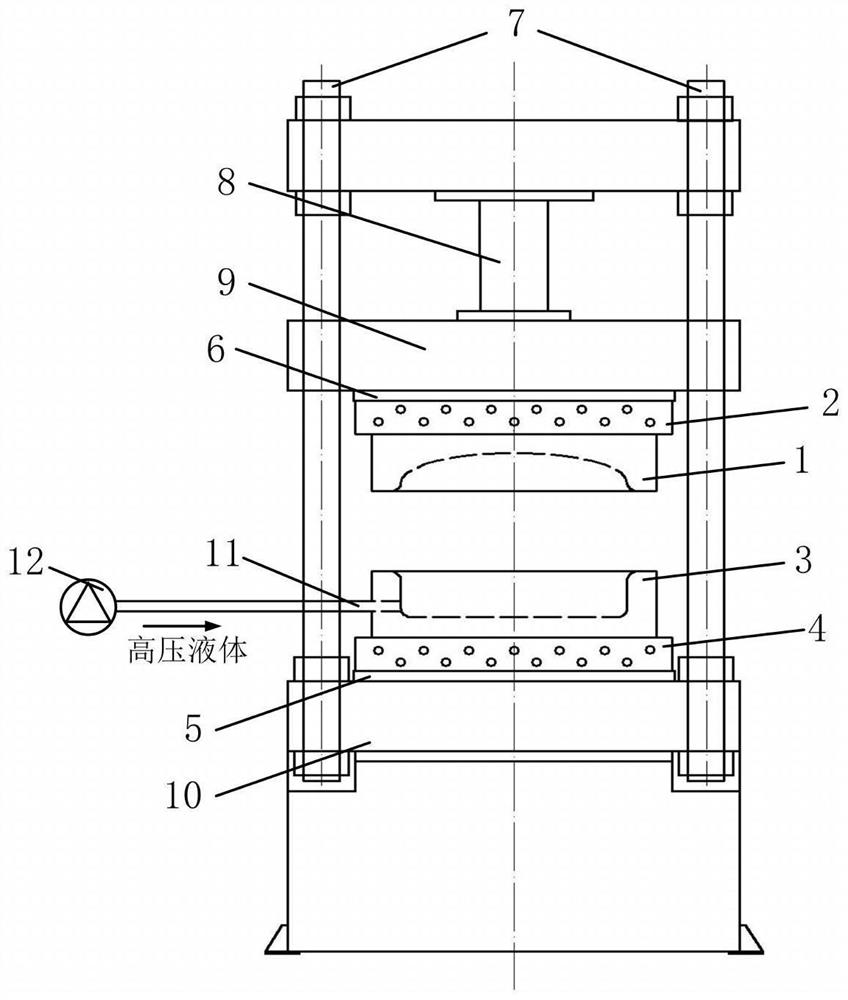

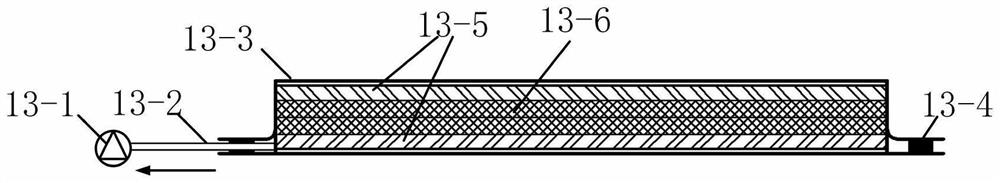

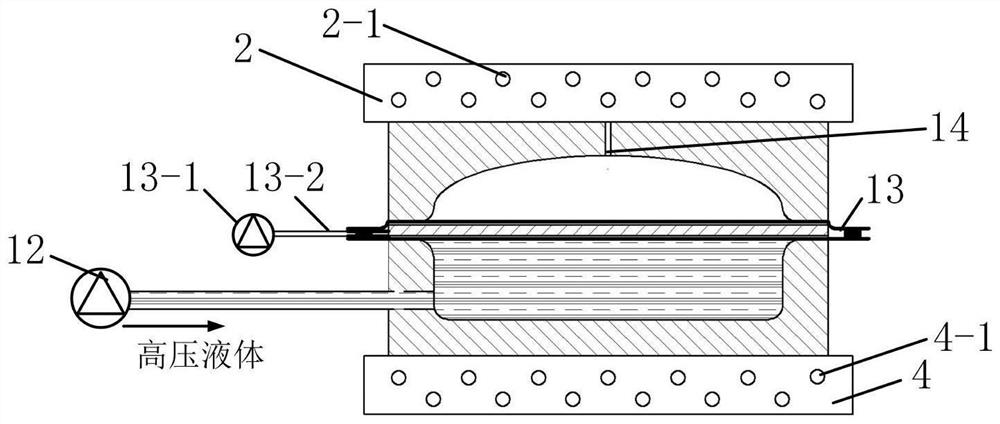

Vacuum-assisted fiber-reinforced metal laminate flexible medium hydroforming method and device

The invention discloses a vacuum-assisted fiber-reinforced metal laminate flexible medium hydroforming method, and relates to the technical field of composite material forming. The method mainly comprises the five process steps of fiber reinforced metal laminate blank preparation, vacuum treatment, vacuum bag assisted flexible medium hydroforming, fiber reinforced metal laminate composite material component curing treatment and process supplementary surface removal. The invention further discloses a vacuum-assisted fiber-reinforced metal laminate flexible medium hydroforming device. The prepared fiber-reinforced metal laminate component is high in dimensional precision and few in internal defect, layering, stripping and other defects are not prone to being generated, the mode that vacuum bag forming and flexible medium liquid filling forming and curing integrated technology is combined is adopted, the forming quality and forming efficiency of the fiber-reinforced metal complex component are improved, and the manufacturing cost is reduced. And the application field of the fiber-reinforced metal laminate composite material is greatly widened.

Owner:BEIHANG UNIV

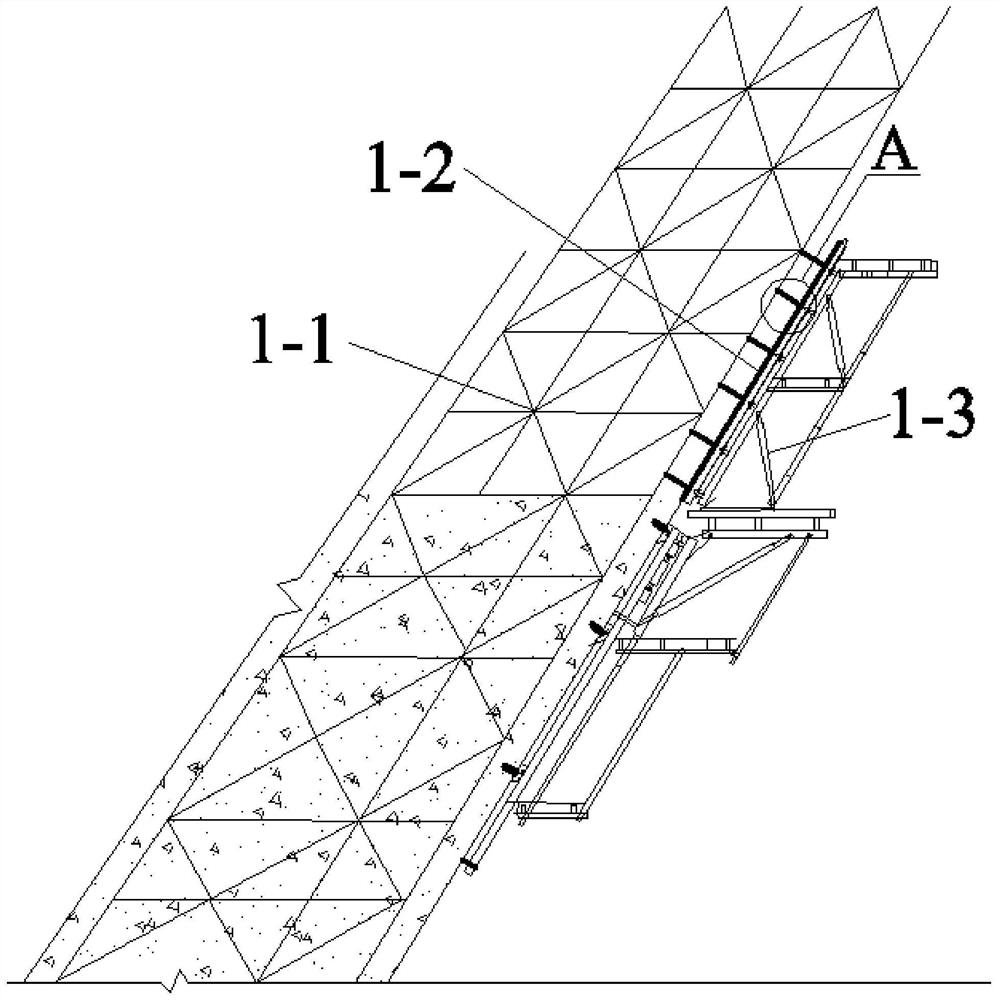

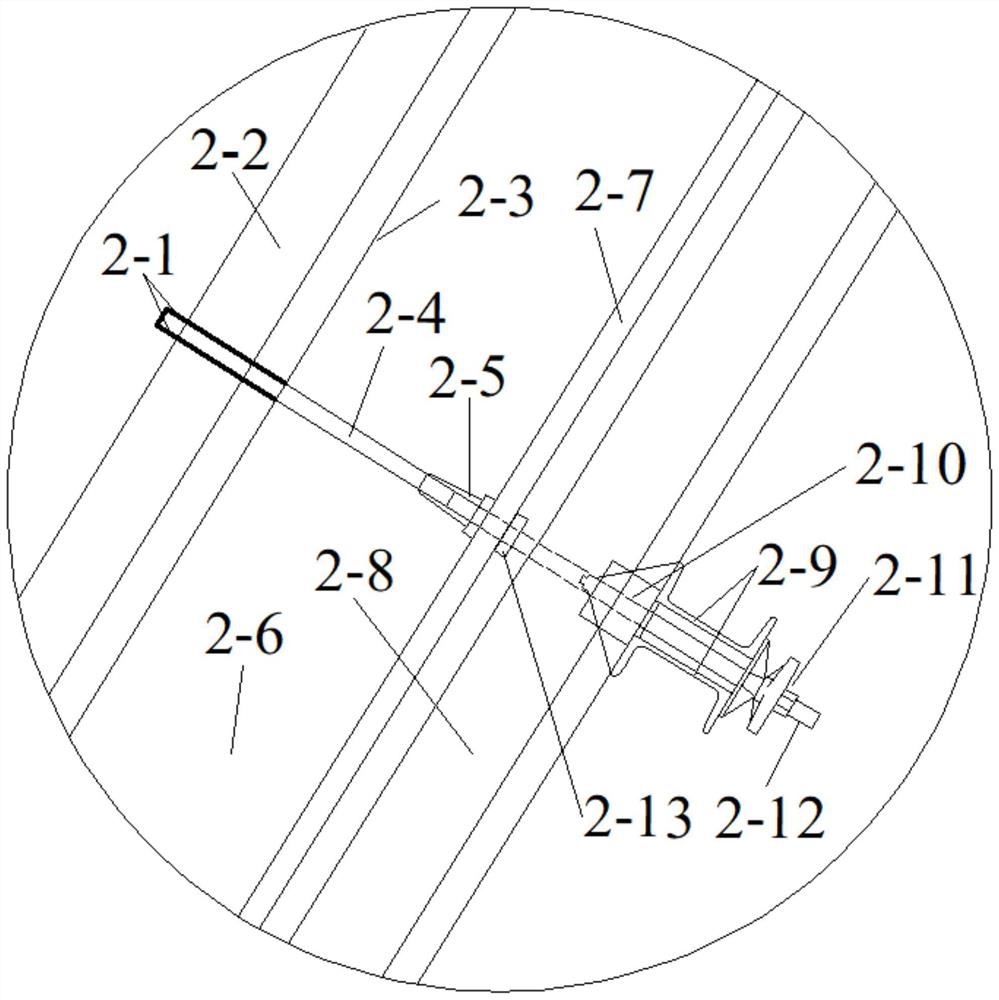

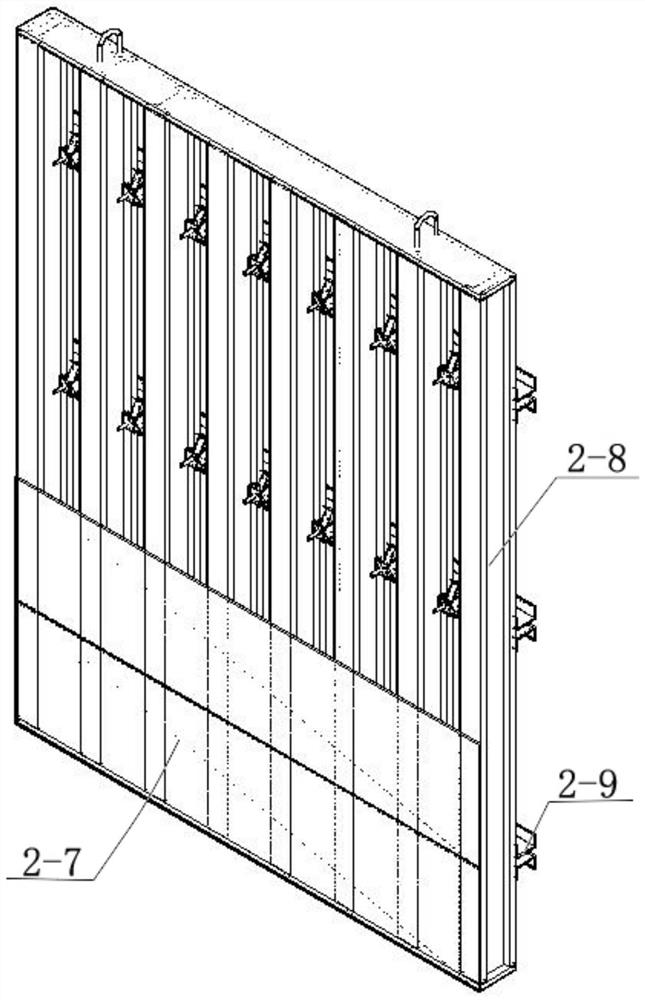

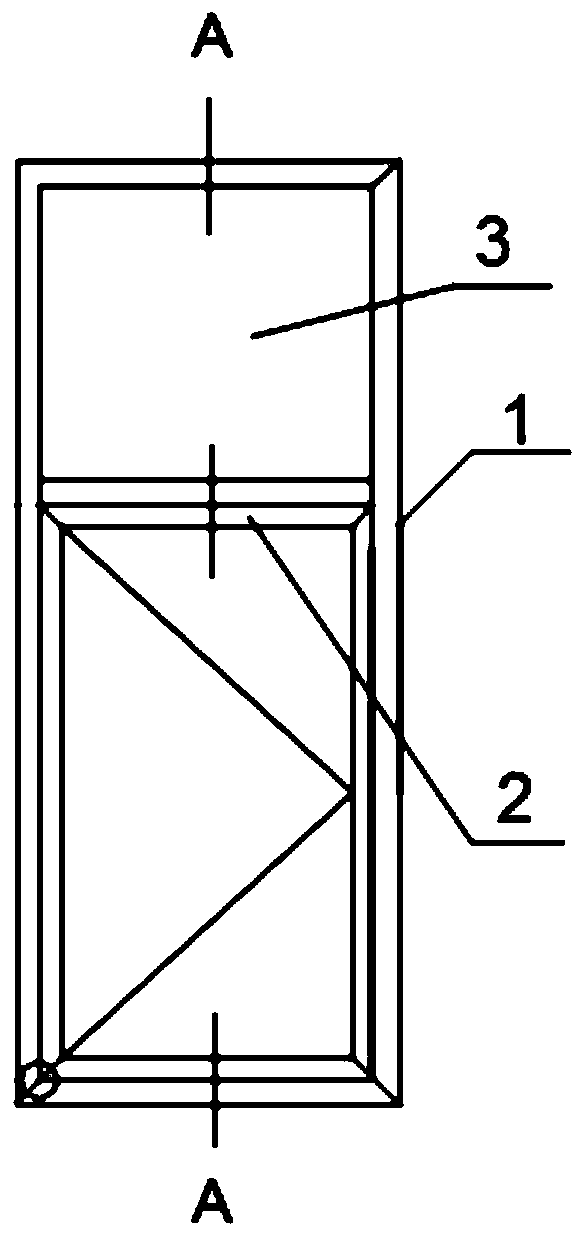

Construction method of formwork system for highly-deviated tower construction creeping formwork

PendingCN113338170ATo achieve the effect of load reductionSolve problems that cannot be used directlyBridge structural detailsForms/shuttering/falseworksArchitectural engineeringRebar

The invention discloses a construction method of a formwork system for a highly-deviated tower construction creeping formwork. The construction method comprises the following steps: A, building a formwork assembly; b, mounting a climbing frame system and a template; c, building a pull rod tying unit between the formwork assembly and the stiff framework, enabling a screw rod to penetrate into the formwork assembly, wherein one end of the screw rod extends out of the transverse back edge of the formwork assembly and is sleeved with a clamping nut, the clamping nut tightly presses the transverse back edge, the other end of the screw rod extends out of a panel of the formwork assembly and is sleeved with a conical connector, and the screw rod is sleeved with an adjusting nut, the adjusting nut is matched with the conical joint to tightly press the panel; the tie bar is inserted into the other end of the conical joint in a threaded fit manner; the other end of the lacing wire is welded with a stiff framework of the highly-deviated tower; d, pouring concrete; e, removing the mold; by installing the pull rod tying units, the distance between the panel and the binding steel bars on the outermost side of the stiff framework is adjusted, the stiff framework shares the concrete load, and the effect of reducing the load of the formwork is achieved.

Owner:ZHENGZHOU UNIV

Inner/outer opening heat insulation broken bridge window screen integrated window

PendingCN110905345AImprove performanceSave aluminumInsect protectionNoise insulation doors/windowsEngineeringWindow screen

The invention discloses an inner / outer opening heat insulation broken bridge window screen integrated window. The window comprises a frame and a mullion, wherein the frame is defined by an upper frame, a lower frame, a left frame and a right frame, the mullion divides the frame into panes, one or more of glass, a window sash or a screen sash are respectively installed in the panes, the frame and the mullion are formed by splicing an inner frame section bar, an outer frame section bar and middle heat insulation strips, and isobaric rubber strips and inner-outer opening conversion pieces are arranged between clamping grooves of the inner frame section bar, the outer frame section bar and the middle heat insulation strips. According to the window, the centers of the inner frame section bar, the outer frame section bar, heat insulation strips and the middle heat insulation strips are horizontally symmetrical and vertically symmetrical with one another, the inner frame section bar and the outer frame section bar adopt the same section bar, so that flexible splicing of window is realized, the screen sash adopts a casement screen sash or a push-pull screen sash, the requirements of different consumers for different opening modes of a screen window can be met, and various screen window installation modes are realized.

Owner:连云港双源窗业有限公司

Internal high pressure forming device for manufacturing special-shaped interface pipe for vehicle

PendingCN108356130AReduce the number of moldsLow installation costVehicle componentsInternal pressureHigh pressure

The invention discloses an internal high pressure forming device for manufacturing a special-shaped interface pipe for a vehicle. The internal high pressure forming device comprises an upper template,an upper main mold, a lower template and a lower main mold; the upper main mold is fixed on the upper template, the lower main mold is fixed on the lower template, an upper main mold cavity is formedin the upper main mold, and the lower main mold is provided with a lower main mold cavity; the upper template and the lower template are provided with detachable auxiliary molds respectively, the auxiliary molds are provided with auxiliary mold cavities, the auxiliary cavities are located at one ends of the auxiliary molds on the upper template and abut against the upper main mold, and the auxiliary mold cavities on the upper template and the upper main mold cavity form an upper mold cavity. The upper mold and the lower mold are divided into the upper main mold, the auxiliary molds, the lowermain mold and the auxiliary molds, and expansion deformation parts, namely the parts for plastic deformation, are arranged in the upper main mold cavity and the lower main mold cavity, and other material supplementing parts are arranged in the auxiliary mold cavities, so that when the shapes of the material supplementing parts of the pipe change, only the auxiliary molds need to be replaced, other parts in the device do not need to be replaced, the number of molds is reduced, and the cost of the device is reduced.

Owner:苏州柏仕非奥自动化设备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com