Connecting piece, assembling component and assembling method

An assembly method and technology for connecting parts, which are applied in the direction of connecting components, thin plate connections, mechanical equipment, etc., can solve the problems of insufficient standardization of precision, easy loosening of time, and difficult processing, and achieve variability and diversity, good protection. Rounded edge processing, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

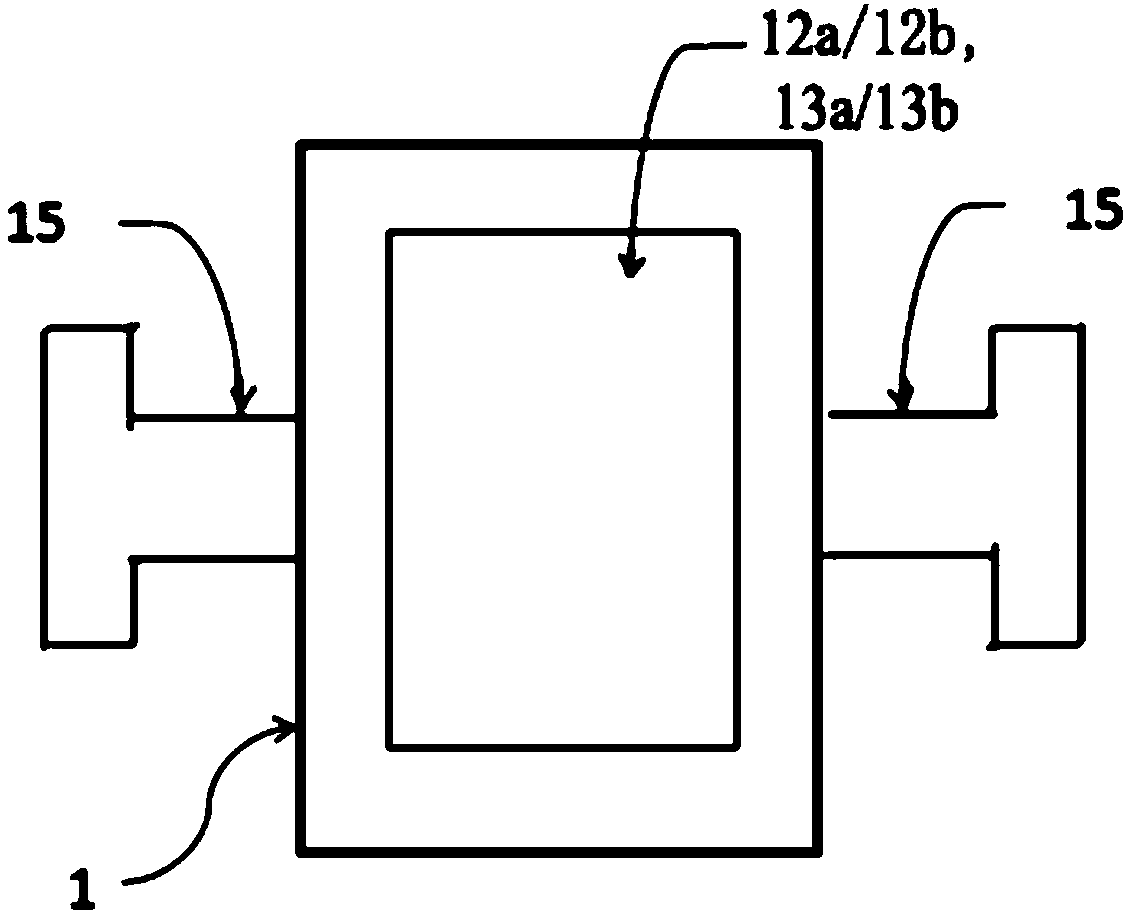

[0063] The connector 1 in this embodiment includes a first chuck 13a and / or a second chuck 13b, a first slot 12a and / or a second slot 12b, and a snap-in portion 15; the first end of the connector 1 There is a first card head 13a and / or a first card slot 12a, and the second end of the connector 1 has a second card slot 12b and / or a second card head 13b, the shape of the card slot is set to match the card head, so that the connectors 1 can be detachably plugged in through the cooperation of the chuck head and the slot; At the end, the clamping part 15 is set to match the groove 3 on the connected part 2 so that the clamping part 15 can be detachably clamped and fixed with the connected part 2 . image 3 A schematic cross-sectional view of the connecting piece 1 is shown. It should be understood that the shape and number of the snap-in portion 15 are not limited to the situation shown in the figure, as long as the shape of the snap-in portion 15 can match with the groove 3 on th...

Embodiment 2

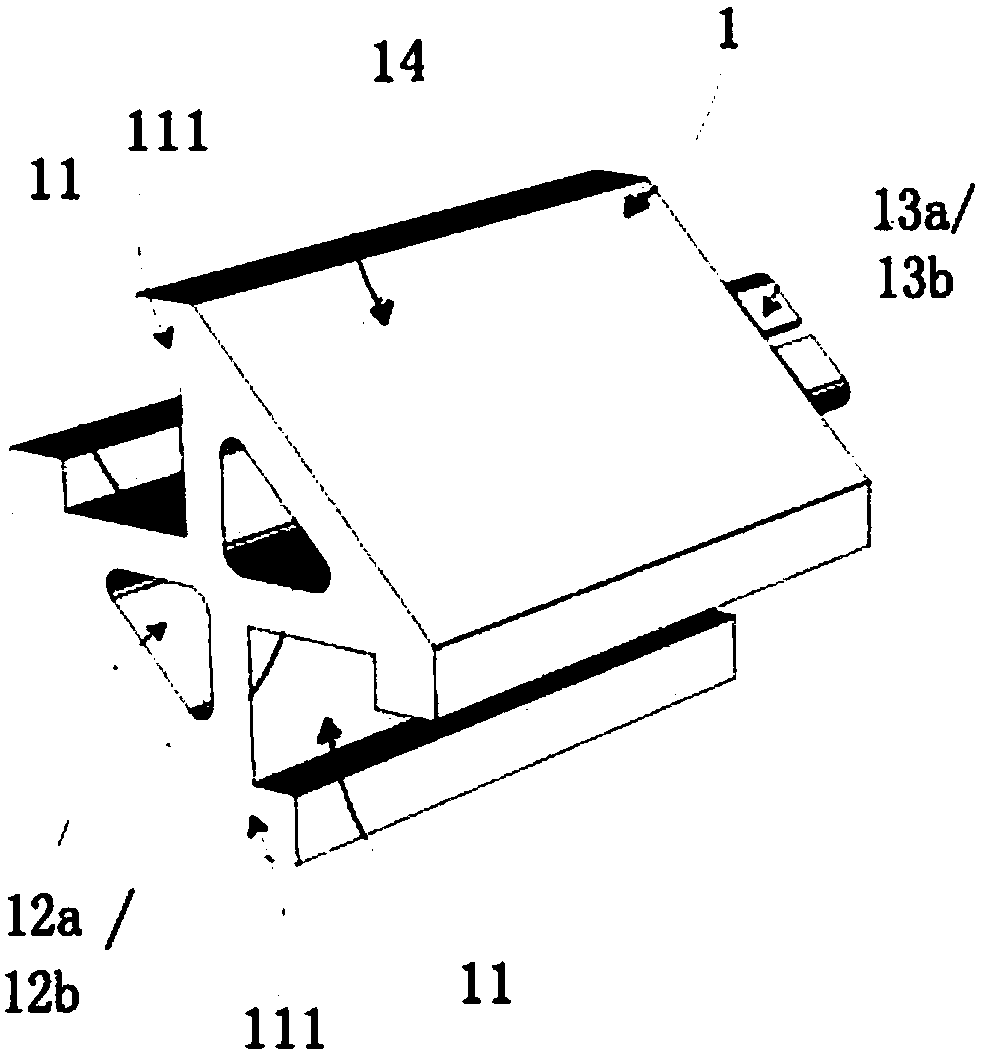

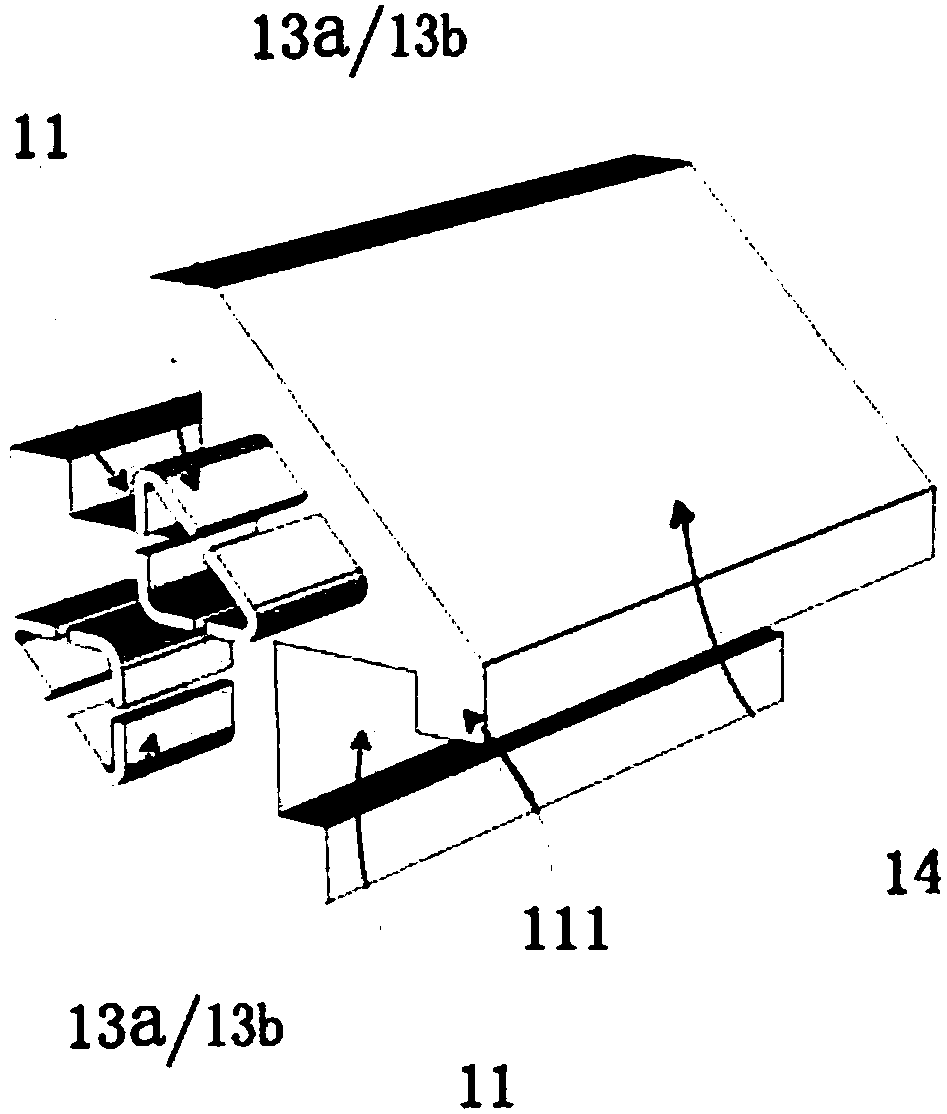

[0065] see figure 1 , which shows a schematic diagram of a three-dimensional structure of a connecting piece in the present invention, the connecting piece 1 includes a fixing groove 11, a first clamping groove 12a and a second clamping head 13b (or the second clamping groove 12b and the first clamping head 13a ); the fixed groove 11 is provided with a raised portion 111, and the raised portion 111 is set to cooperate with the groove 3 on the connected piece 2 so that the fixed groove 11 and the connected piece 2 are detachably clamped and fixed, the first The card slot 12a is configured to cooperate with the second card head 13b, so that the connectors 1 can be detachably inserted end-to-end through the card slot and the card head. figure 1 shows a schematic diagram of the three-dimensional structure viewed from the side of the card slot, figure 2 A schematic diagram of the three-dimensional structure viewed from the chuck head side is shown. In this embodiment, there are ...

Embodiment 3

[0067] see Figure 5 , which shows a schematic three-dimensional structural diagram of an assembly in the present invention, the assembly includes a connecting piece 1 and a connected piece 2; There is a groove 3, and a protrusion 111 is arranged in the fixing groove 11, and the protrusion 111 is set to cooperate with the groove 3 on the connected part 2 so that the fixing groove 11 and the connected part 2 are detachably clamped and fixed , the card slot is set to cooperate with the card head, so that the connectors 1 can be detachably plugged end-to-tail with the card head through the card slot. In this embodiment, each connecting piece 1 has two fixing grooves 11 , each of which is clamped and fixed with one connected piece 2 . It should be understood that the number of fixing slots 11 is not limited to two, Figure 7 to Figure 12 A schematic cross-sectional view of the assembly is shown. As shown in the figure, several fixing grooves 11 may be provided on the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com