Patents

Literature

31results about How to "Strong standardization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

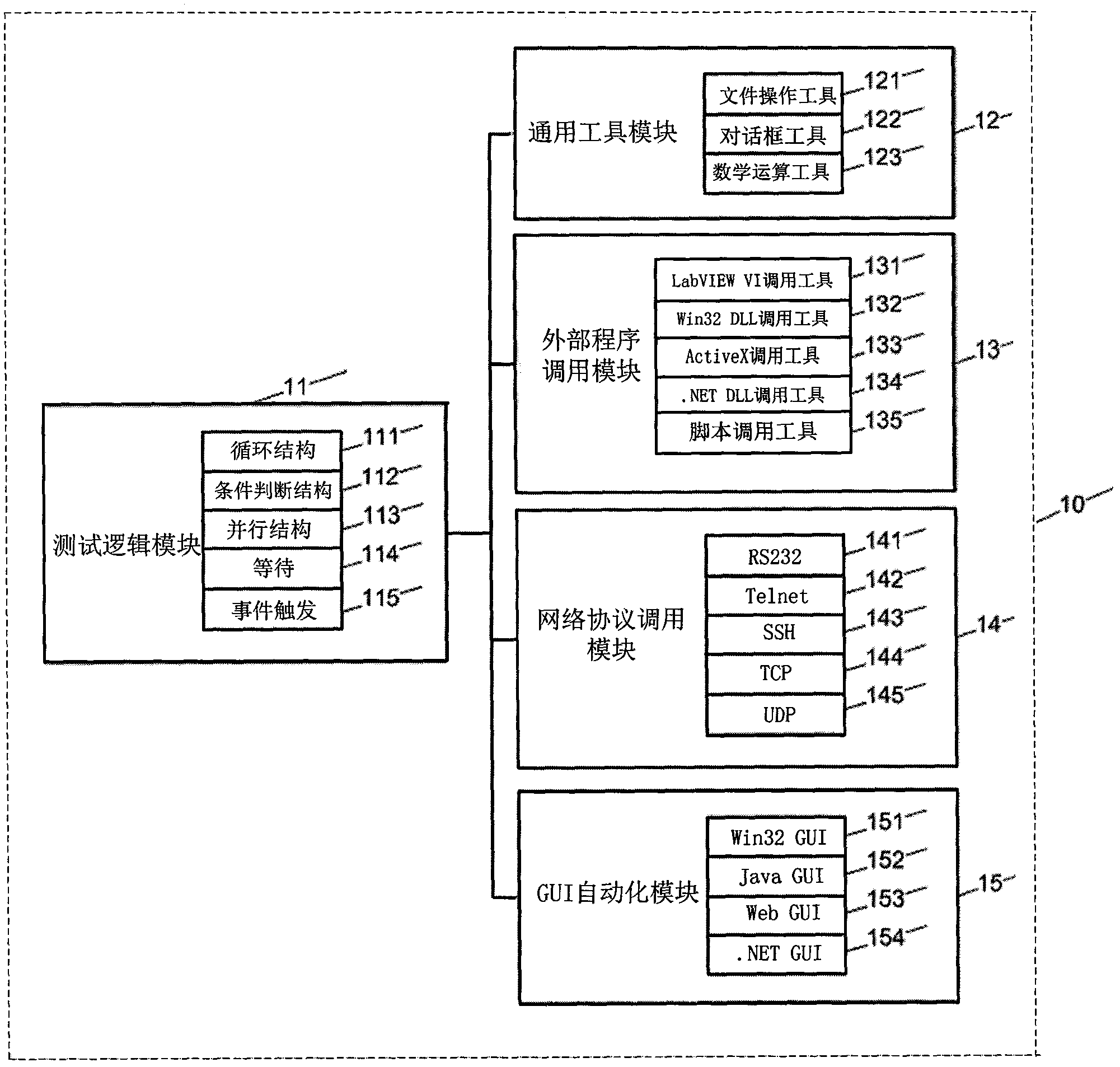

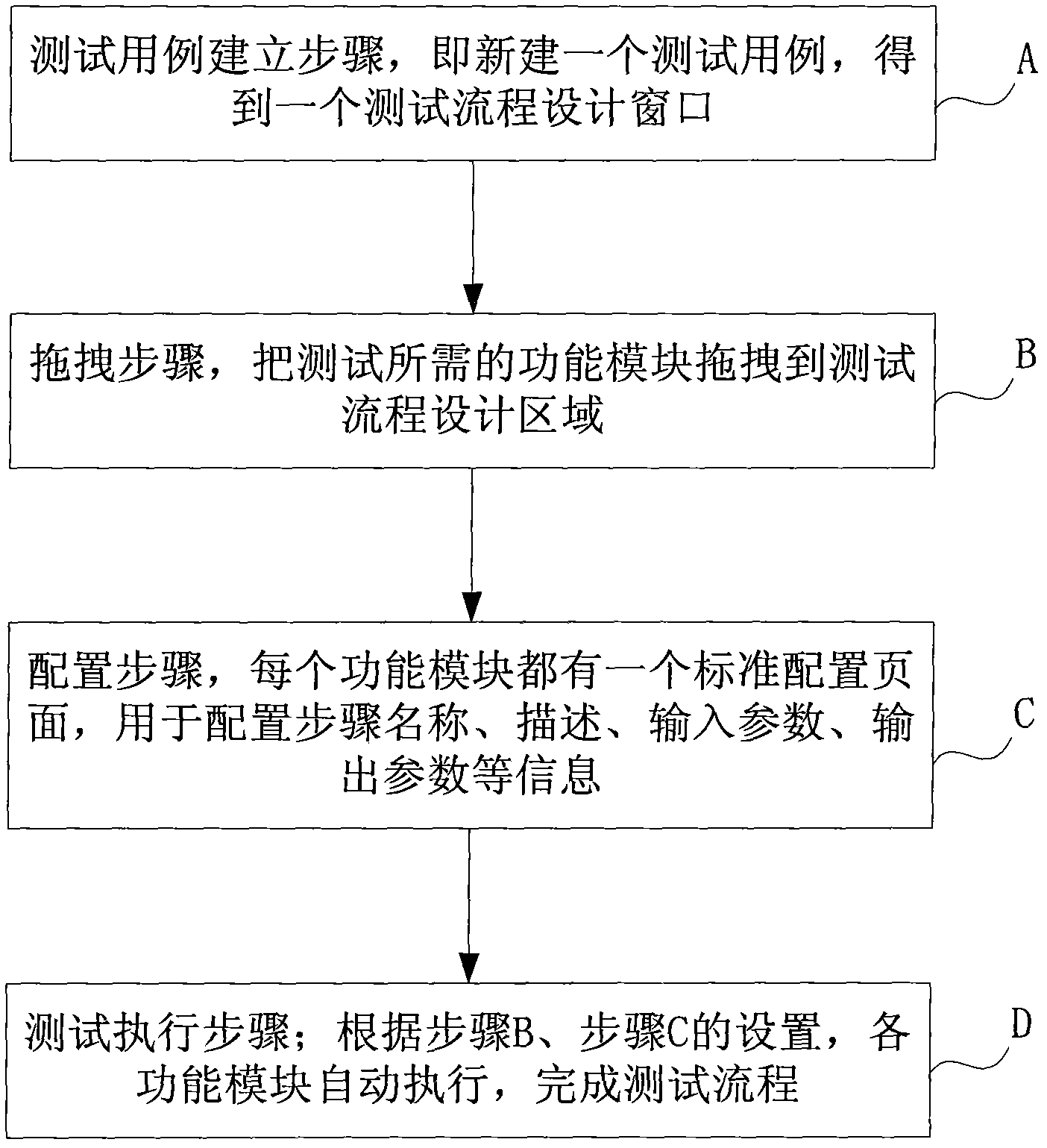

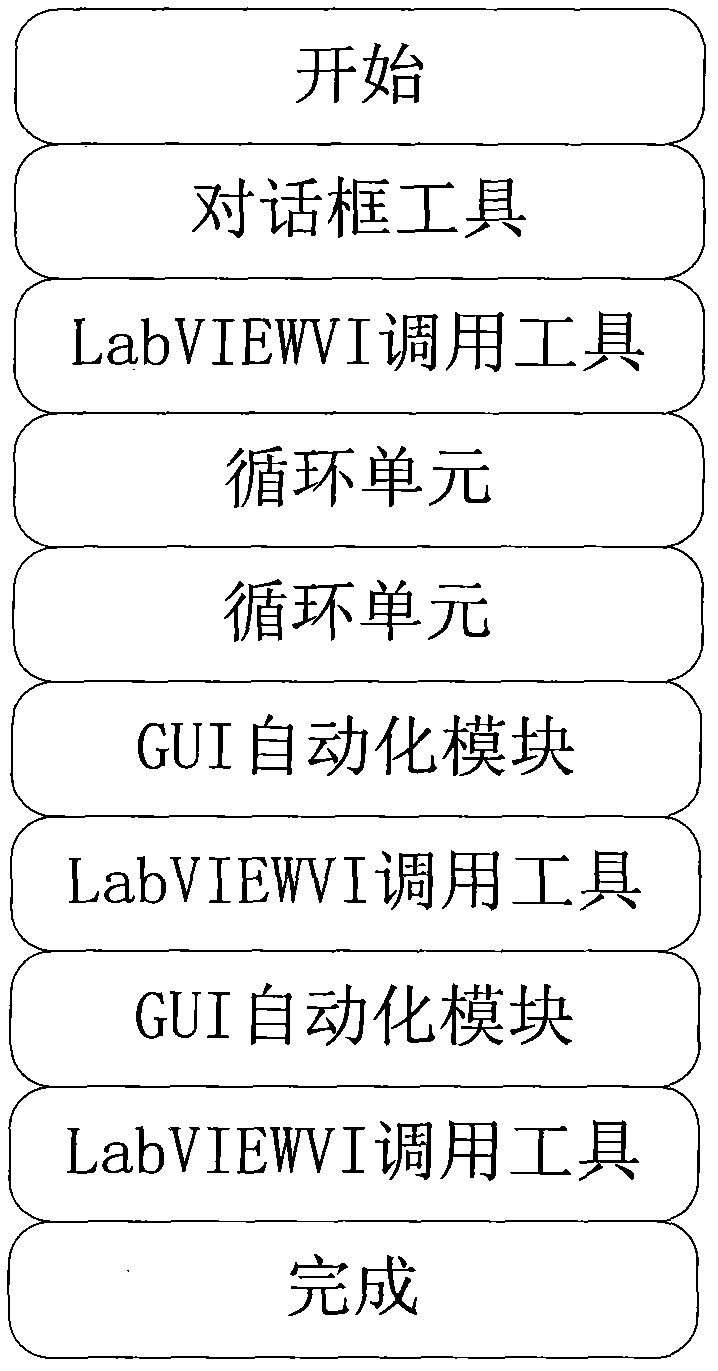

Hardware equipment automation testing system and testing method thereof

InactiveCN102609341AFully automatedStrong standardizationDetecting faulty computer hardwareGraphical user interfaceAutomatic testing

The invention discloses a hardware equipment automation testing system and a testing method thereof. The hardware equipment automation testing system comprises a test logic module, a general utility module, an external program calling module, a network protocol module and a GUI (graphical user interface) automation module. The test logic module comprises tools for realizing various test logics and combining tools in other modules into the complete test flow. The general utility module comprises general tools for implementing test steps during testing. The external program calling module comprises an external program used for calling compiling of various languages. The network protocol module is used for realizing automation in writing and reading of various network protocols. The GUI automation module is utilized for realizing automation of operations of various graphical user interfaces. According to the hardware equipment automation testing system and the testing method thereof, different modules / tools for realizing automation of testing steps are provided, different software and hardware resources can be combined in the same system, and accordingly automation of the test flow is realized.

Owner:李康 +2

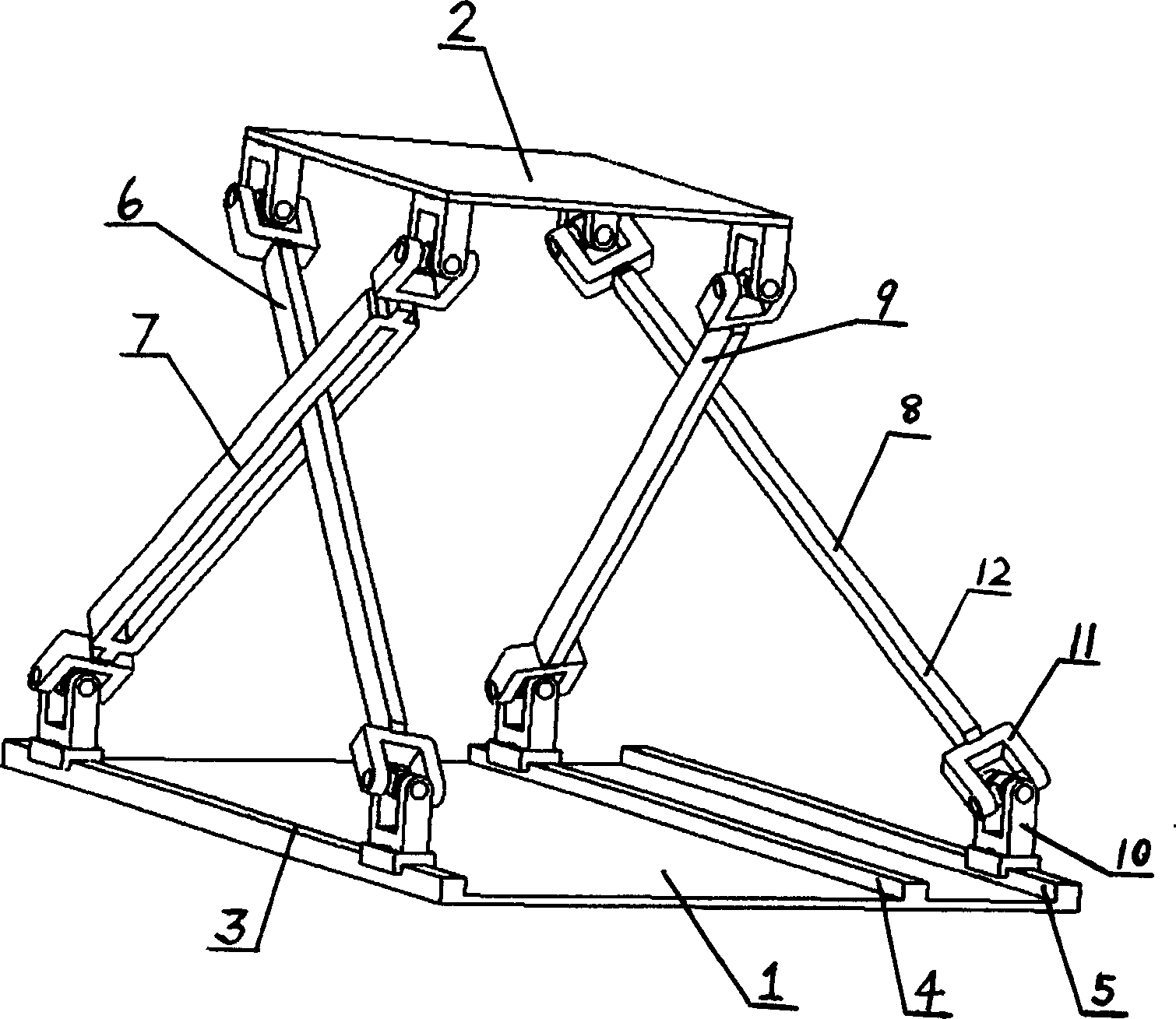

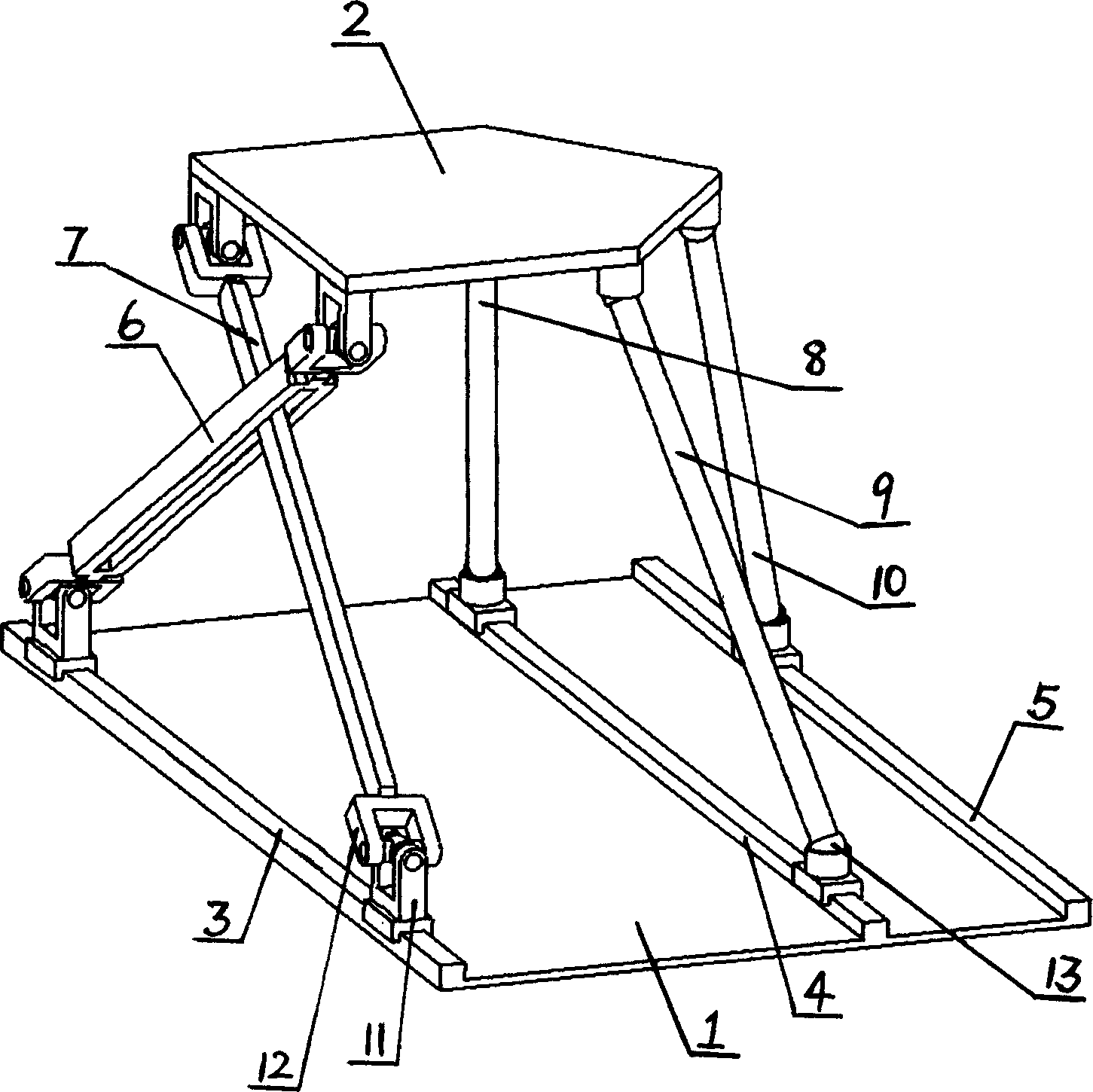

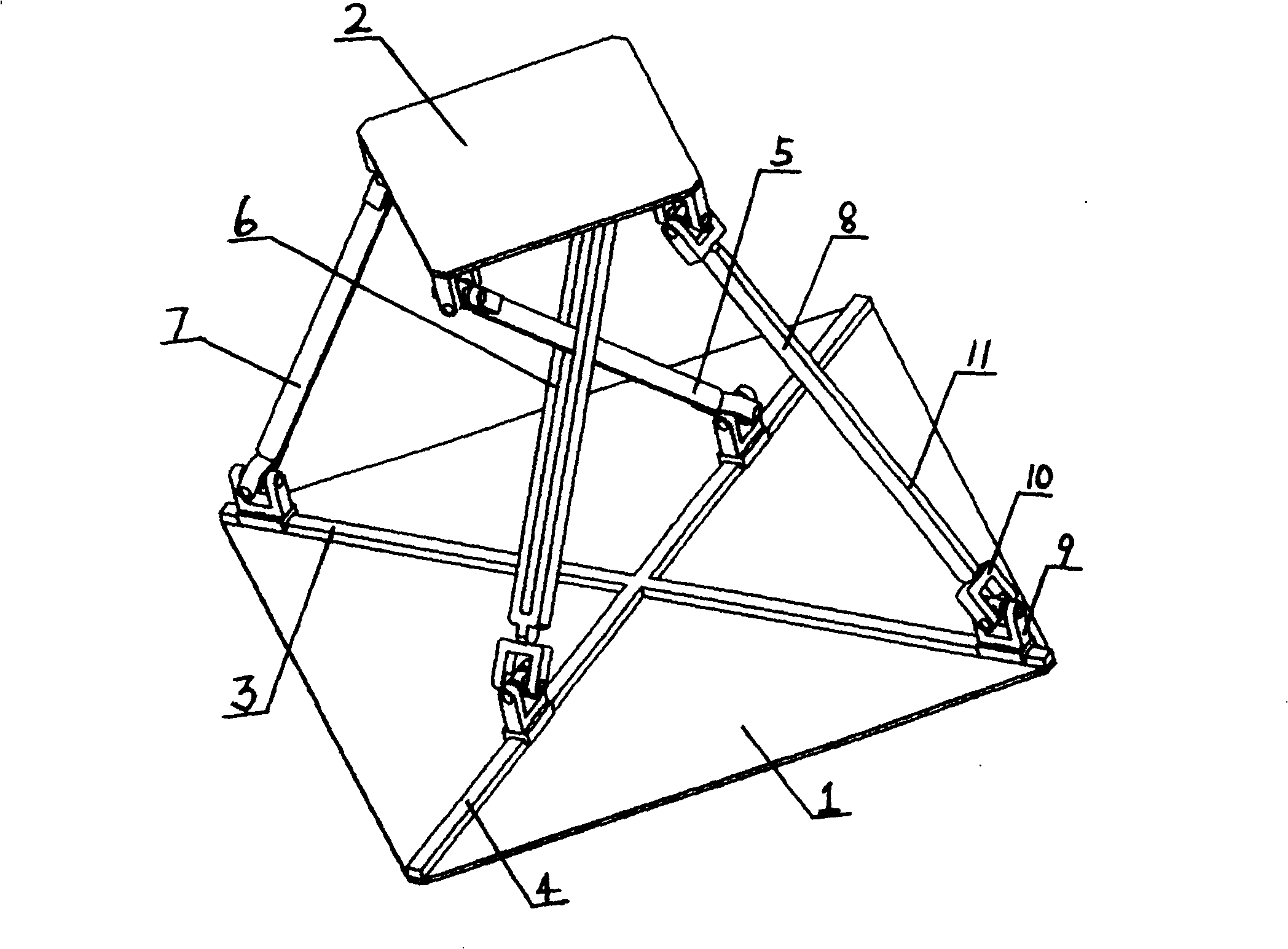

Four-freedom parallel robot mechanism with three translational dimensions and one rotational dimension

InactiveCN1772442AHigh precisionIncrease stiffnessProgramme-controlled manipulatorLarge fixed membersEngineeringDegrees of freedom

The present invention discloses one kind of four-freedom parallel robot mechanism with three translational dimensions and one rotational dimension and including static platform, dynamic platform and branches connecting the static platform and the dynamic platform. The dynamic platform is connected to the static platform through four branches, the static platform has three parallel tracks, two crossed branches, branch I and branch II, are connected to the identical track while other two, branch III and branch IV, are connected separately to one of the other two tracks. Each of the branches includes one shift pair, two Hookes and one branch rod, which has one end connected to the dynamic platform via a Hooke and the other end to the static platform via the composite motion pair comprising a shift pair and a Hooke. The present invention can realize four-freedom platform motion, has enhanced integral rigidity and may be used in operation needing four special motions.

Owner:SOUTH CHINA UNIV OF TECH

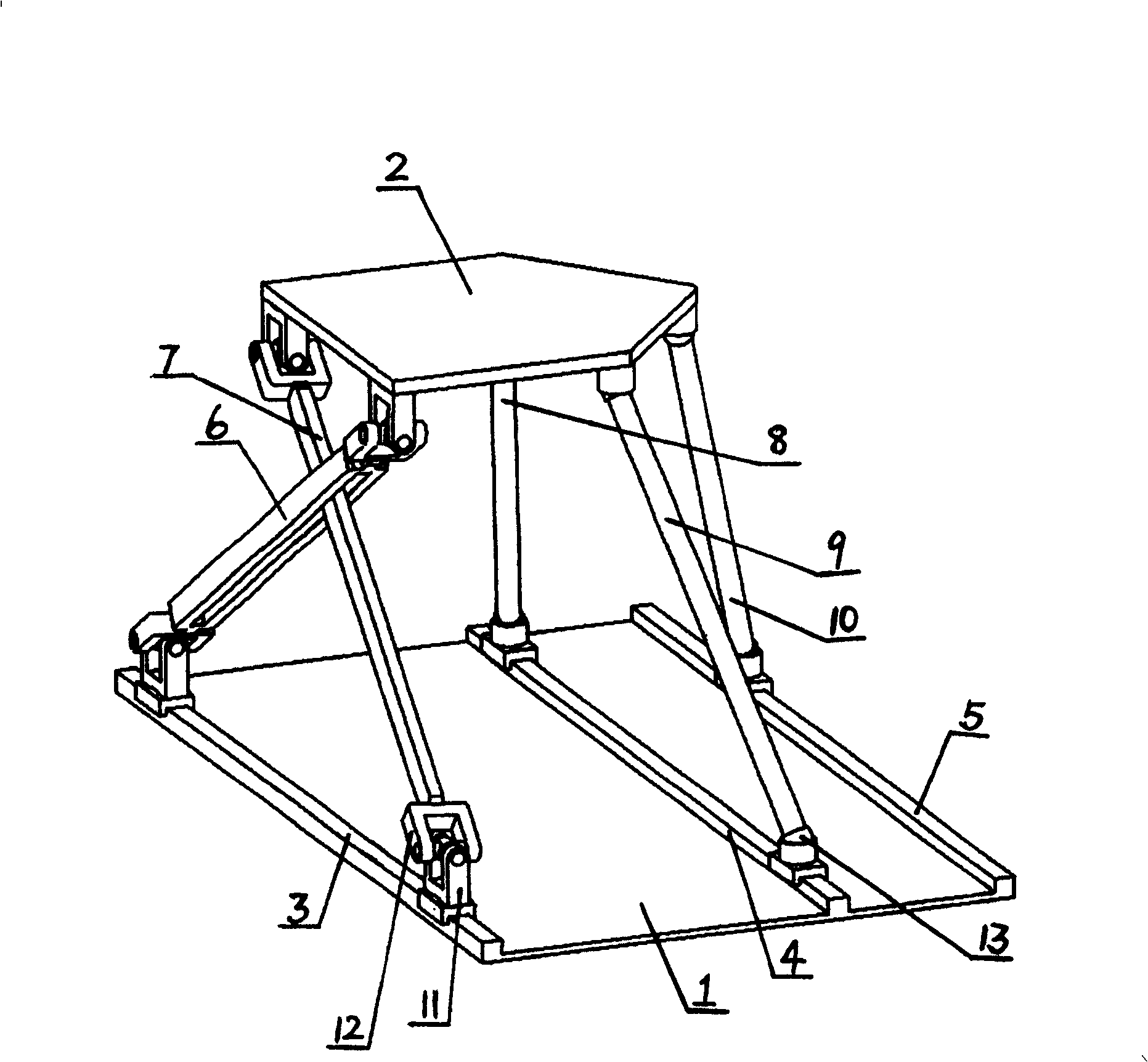

Five-freedom parallel robot mechanism with three translational dimensions and two rotational dimensions

InactiveCN1772443AHigh precisionIncrease stiffnessProgramme-controlled manipulatorLarge fixed membersDegrees of freedomEngineering

The present invention discloses one kind of five-freedom parallel robot mechanism with three translational dimensions and two rotational dimension and including static platform, dynamic platform and branches connecting the static platform and the dynamic platform. The dynamic platform is connected to the static platform through five branches, the static platform has three parallel tracks, two crossed branches, branch I and branch II, are connected to the first track, two other uncrossed branches, branch III and branch IV, are connected to the second track, and the branch V is connected to the third track. The present invention can realize four-freedom platform motion by means of the shifts of the shift pairs of the branches in separated tracks, has enhanced integral rigidity and may be used in operation needing five special motions.

Owner:SOUTH CHINA UNIV OF TECH

Five-freedom parallel robot mechanism with three translational dimensions and two rotational dimensions

InactiveCN100427276CHigh precisionIncrease stiffnessProgramme-controlled manipulatorLarge fixed membersDegrees of freedomEngineering

The present invention discloses one kind of five-freedom parallel robot mechanism with three translational dimensions and two rotational dimension and including static platform, dynamic platform and branches connecting the static platform and the dynamic platform. The dynamic platform is connected to the static platform through five branches, the static platform has three parallel tracks, two crossed branches, branch I and branch II, are connected to the first track, two other uncrossed branches, branch III and branch IV, are connected to the second track, and the branch V is connected to the third track. The present invention can realize four-freedom platform motion by means of the shifts of the shift pairs of the branches in separated tracks, has enhanced integral rigidity and may be used in operation needing five special motions.

Owner:SOUTH CHINA UNIV OF TECH

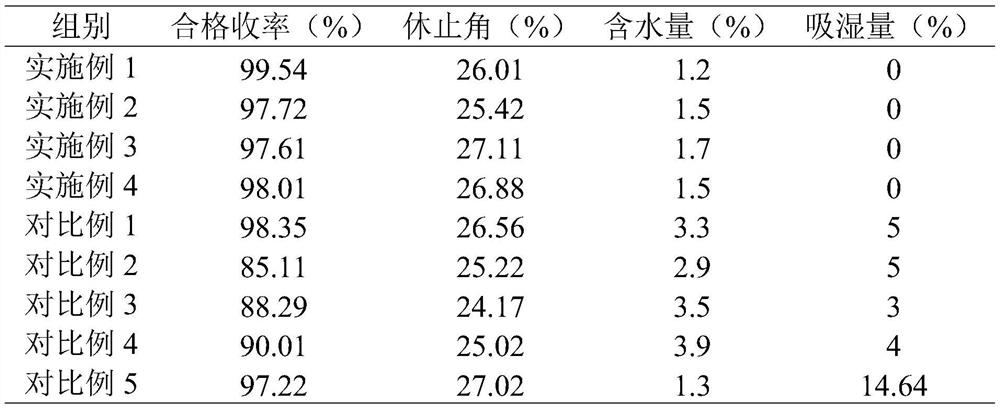

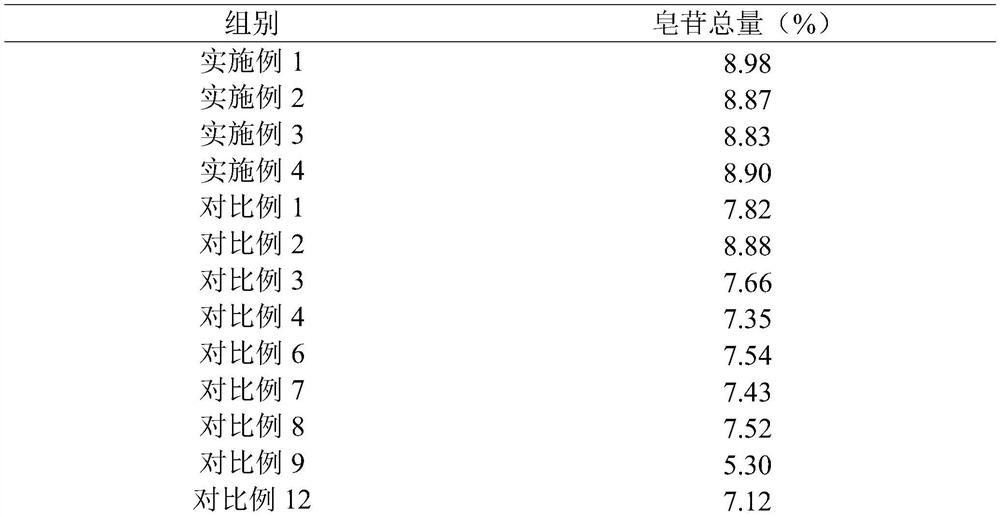

Pseudo-ginseng vacuum freeze-drying method and application thereof

InactiveCN112229148APrevent local melting and disintegrationAvoid affecting product qualityDrying solid materials without heatDaily livingFreeze-drying

The invention relates to a pseudo-ginseng vacuum freeze-drying method and application thereof, and relates to the technical field of traditional Chinese medicine processing. According to the vacuum freeze-drying method, pseudo-ginseng homogenate is subjected to pre-freezing and vacuum drying treatment, in the pre-freezing step, pre-freezing is carried out in stages at the temperature of minus 20-minus 75 DEG C, and in the vacuum drying treatment step, vacuum drying is carried out at the temperature of minus 20-30 DEG C. The vacuum freeze-drying method is applied to preparation of pseudo-ginseng processed products, and the obtained pseudo-ginseng processed products are high in cleanliness, fine and smooth in taste, stable in quality, accurate in dosage, convenient to apply and carry, high in dissolution and absorption speed, higher in product standardization, higher in production efficiency and suitable for daily life of normal people.

Owner:湖北金贵中药饮片有限公司

Four-freedom parallel robot mechanism with two translational dimensions and two rotational dimensions

InactiveCN100411826CHigh precisionIncrease stiffnessProgramme-controlled manipulatorLarge fixed membersEngineeringDegrees of freedom

Owner:SOUTH CHINA UNIV OF TECH

Traceable batch preparation method of dried tangerine peel

ActiveCN106387739AGuaranteed cleanlinessGuarantee product qualityFood dryingFood ingredient functionsTangerine PeelChemistry

The invention discloses a traceable batch preparation method of dried tangerine peel. The traceable batch preparation method of the dried tangerine peel comprises the following steps: S1, preliminary choosing tangerine fruits, checking the chosen tangerine fruits, boxing up the checked tangerine fruits, and then, sealing and labeling the boxes for the first time; S2, performing batch cleaning and sorting on the tangerine fruits on cleaning and sorting line equipment; S3, peeling the sorted tangerine fruits; S4, drying the tangerine peel in a drying device; S5, sealing and labeling the boxes of tangerine peel for the second time, and transferring the tangerine peel into a storage warehouse so as to prepare for aging. The step S5 comprises the following steps: S51, storing the tangerine peel in a standard warehouse for 2-5 months; S52, transferring the tangerine peel into a humidifying chamber so as to carry out first humidifying; S53, transferring the humidified tangerine peel into a wet-pumping and air-drying chamber so as to carry out first wet-pumping and air-drying; S54, transferring the wet-pumped and air-dried tangerine peel into the standard warehouse again, and storing the tangerine peel for 1 year; S55, performing second humidifying on the tangerine peel; and S56, performing second wet-pumping and air-drying on the humidified tangerine peel, so that the dried tangerine peel is prepared. The method disclosed by the invention realizes batch preparation of the dried tangerine pee; moreover, information of the tangerine fruits, including place of origin, householder, grade and so on, is traceable.

Owner:江门市新会陈皮村市场股份有限公司

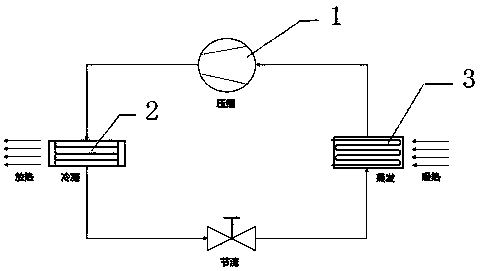

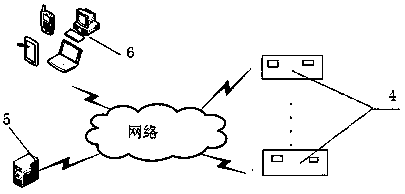

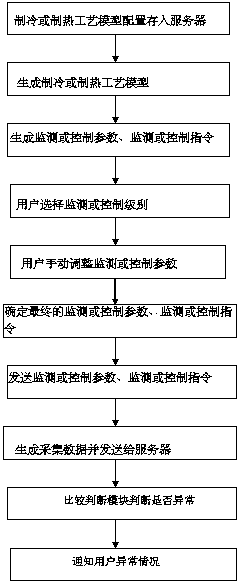

Refrigerating or heating equipment management system and method based on internet of things

InactiveCN107388659ARich varietyWill not cause lossOther databases retrievalRefrigeration safety arrangementPersonalizationInternet of Things

The invention discloses a refrigerating or heating equipment management system and method based on internet of things. The refrigerating or heating equipment management system based on the internet of things comprises a data collecting terminal and a server; and the refrigerating or heating equipment management system based on the internet of things is characterized in that the server comprises a model generating module, a monitoring or controlling parameter generating module, a data receiving and sending module and a database; and after the model generating module generates a refrigerating or heating module, the monitoring or controlling parameter generating module generates a monitoring or controlling parameter or a monitoring or controlling parameter instruction and sends the monitoring or controlling parameter or the monitoring or controlling parameter instruction to the data collecting terminal, the data collecting terminal collects data and feeds back the collected data to the server after collecting is conducted. According to the refrigerating or heating equipment management system and method based on the internet of things, monitoring or controlling management can be conducted on various kinds of refrigerating or heating, the universality is high, a user can choose according to the actual condition of equipment needing to be monitored and managed by the user, individuation management of the specific equipment is achieved, and moreover, the purpose that one set of system conducts monitoring or controlling management on multiple refrigerating or heating equipment is achieved.

Owner:成都冷云能源科技有限公司

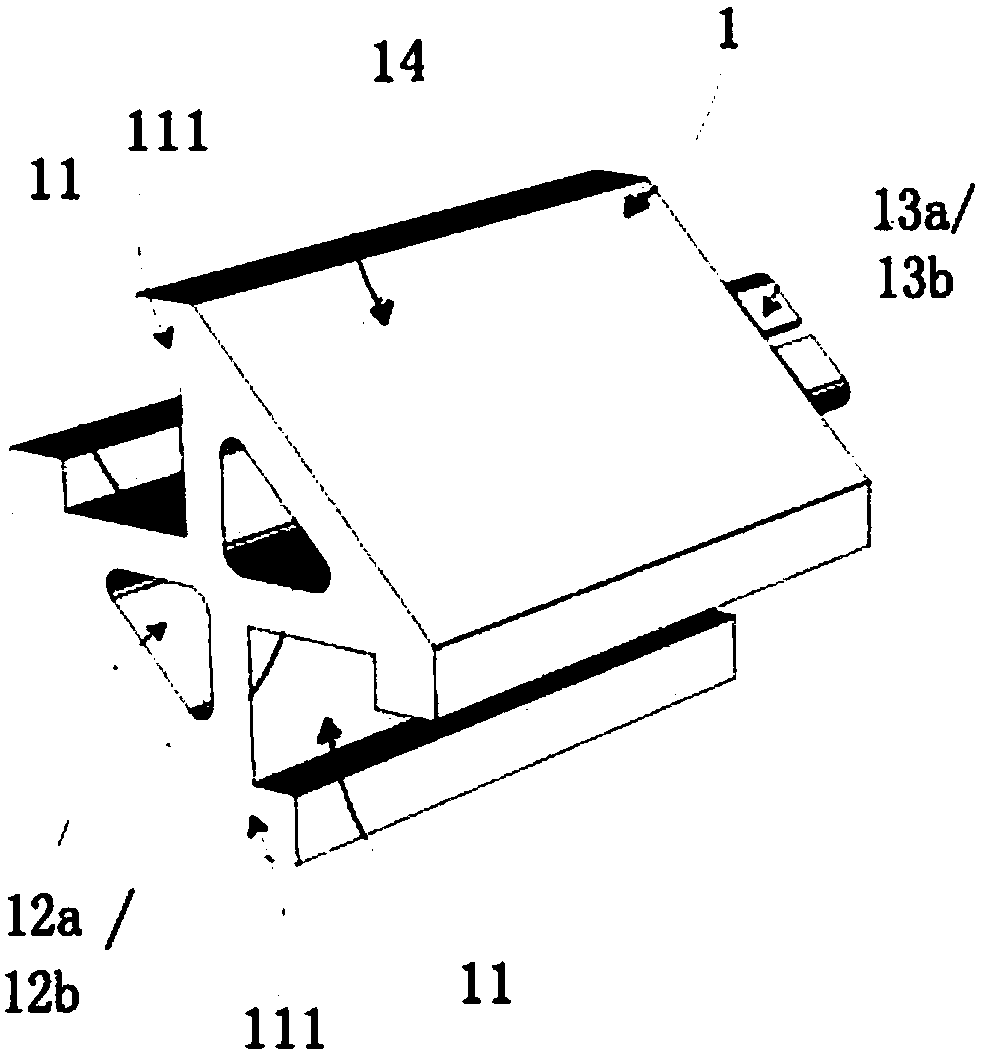

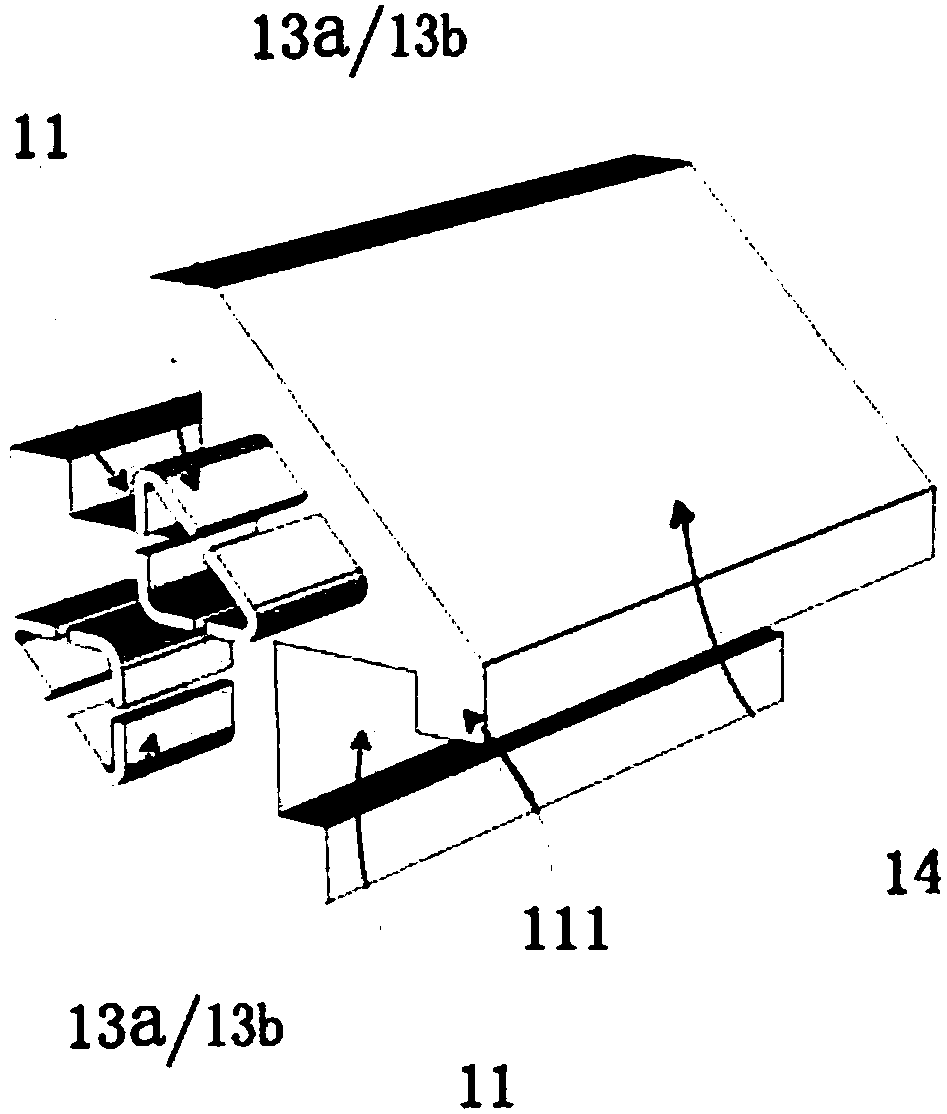

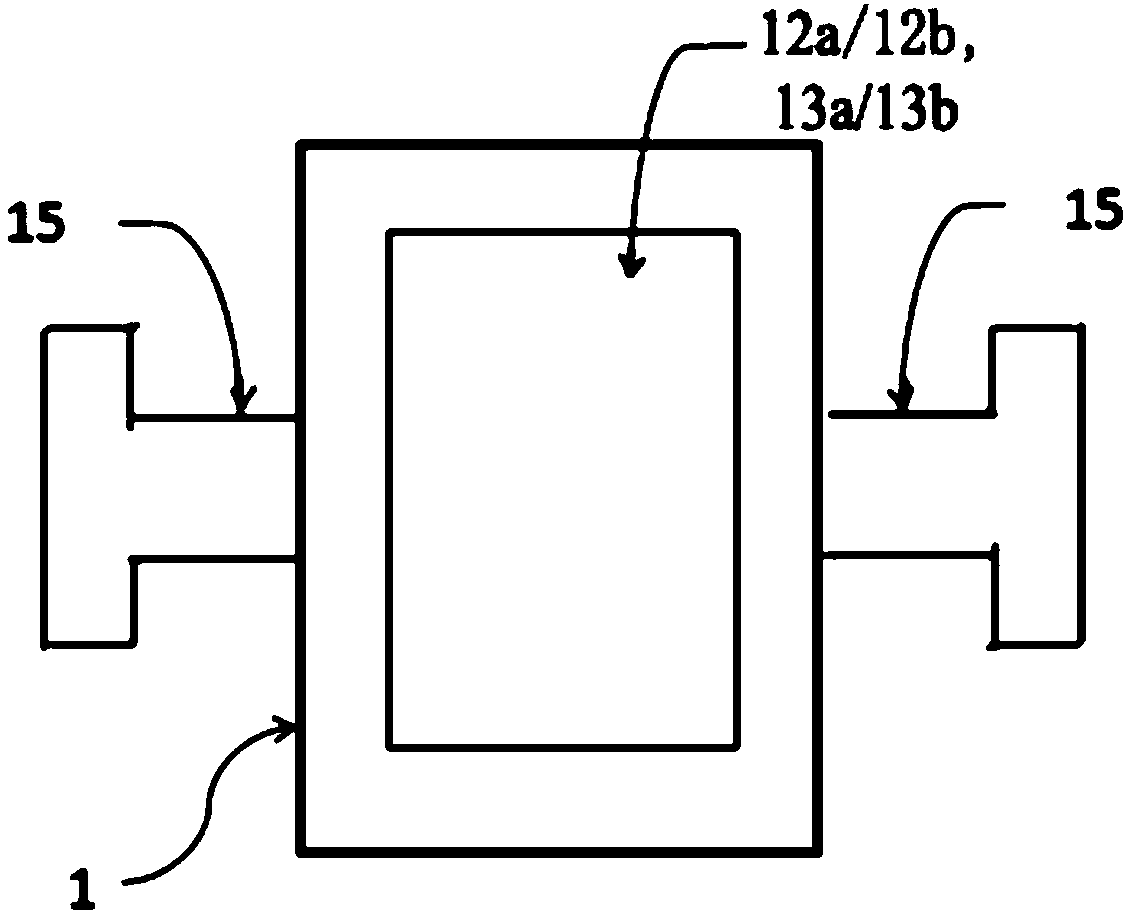

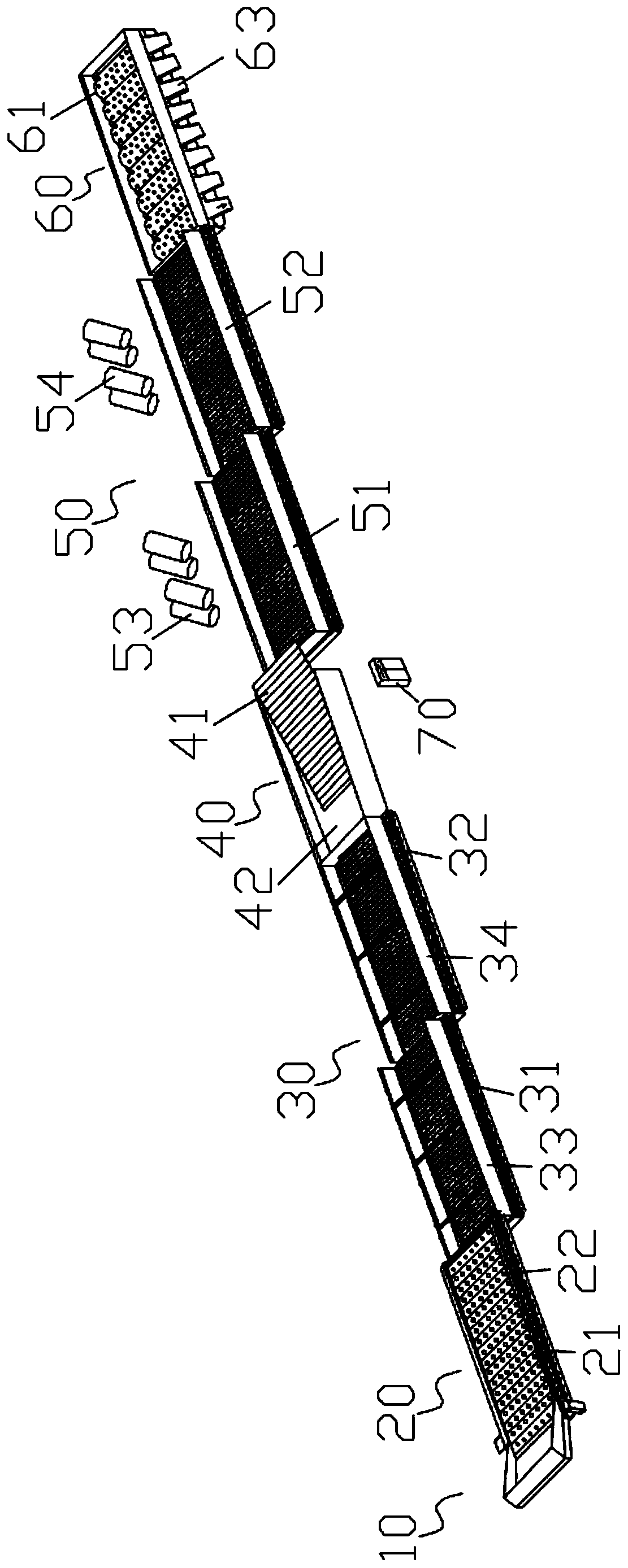

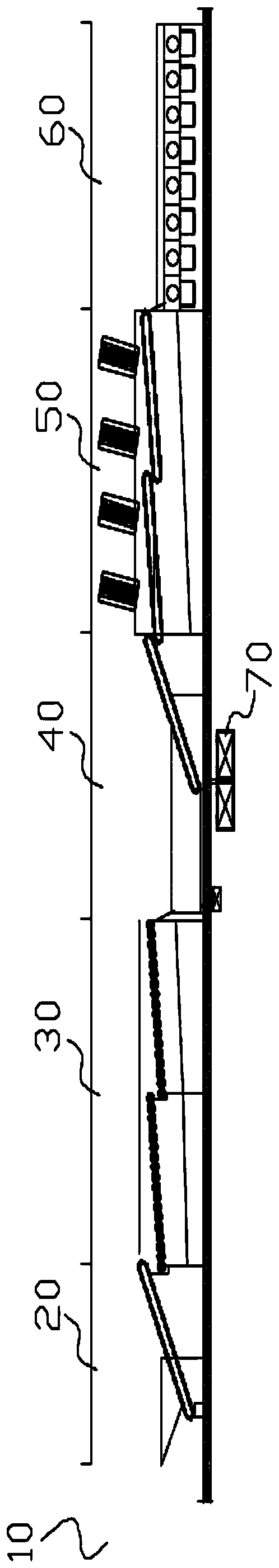

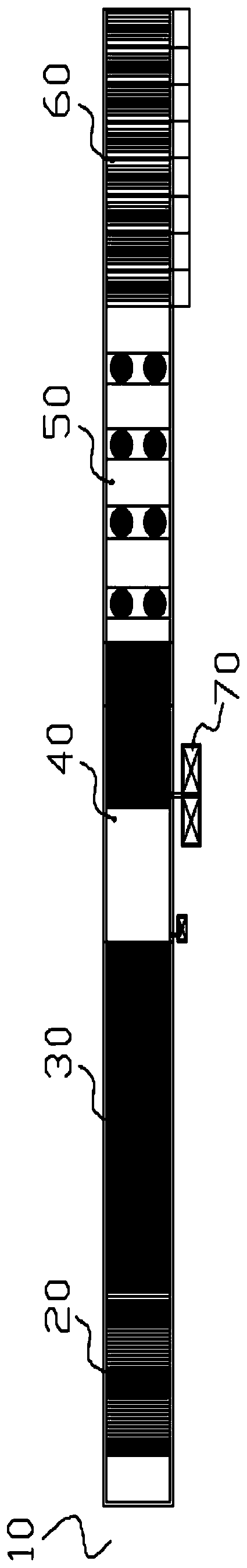

Connecting piece, assembling component and assembling method

PendingCN107781266AImprove machining accuracyStrong standardizationSheet joiningMechanical engineeringMortise and tenon

The invention discloses a connecting piece. The connecting piece is characterized in that a first end of the connecting piece is provided with first clamps and / or first clamp grooves, a second end ofthe connecting piece is provided with second clamp grooves and / or second clamps, and the second clamp grooves and / or the second clamps can be detachably matched with the first end; the connecting piece further comprises clamp portions, the clamp portions extend between the first end and the second end of the connecting piece along the axis of the connecting piece and are fixedly clamped on the connecting piece. The invention further discloses an assembling component and an assembling method. The connecting piece, the assembling component and the assembling method have the advantages that the problem of difficulty in processing technologies for splicing and forming plates in furniture and toy and during indoor decoration mainly can be solved by the aid of the connecting piece, the assembling component and the assembling method, the traditional mortise and tenon structure can be replaced with the designed simple connecting piece easy to use, the connecting piece and the assembling component are easy to machine, high in precision and standardization, products are convenient to assemble and disassemble, and the like.

Owner:孙绍顺

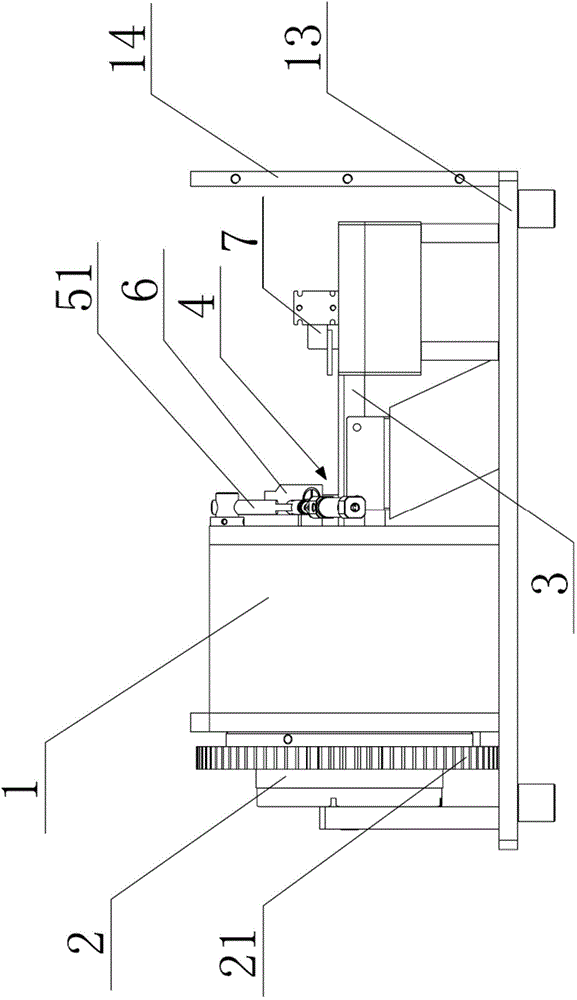

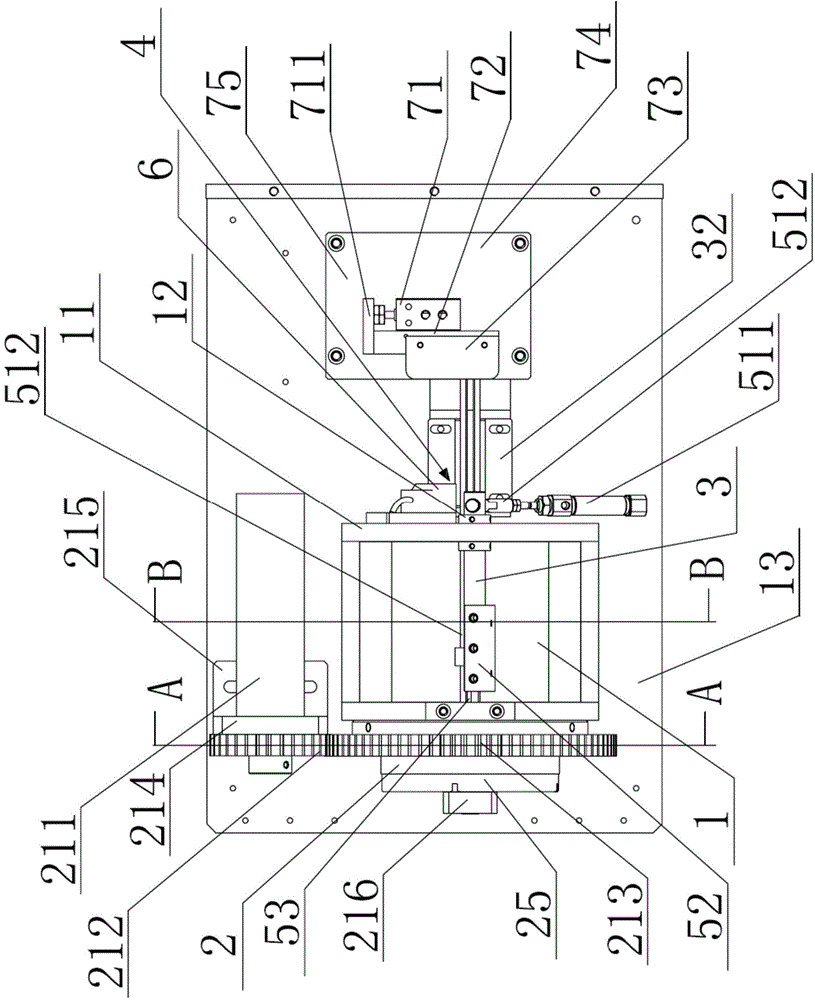

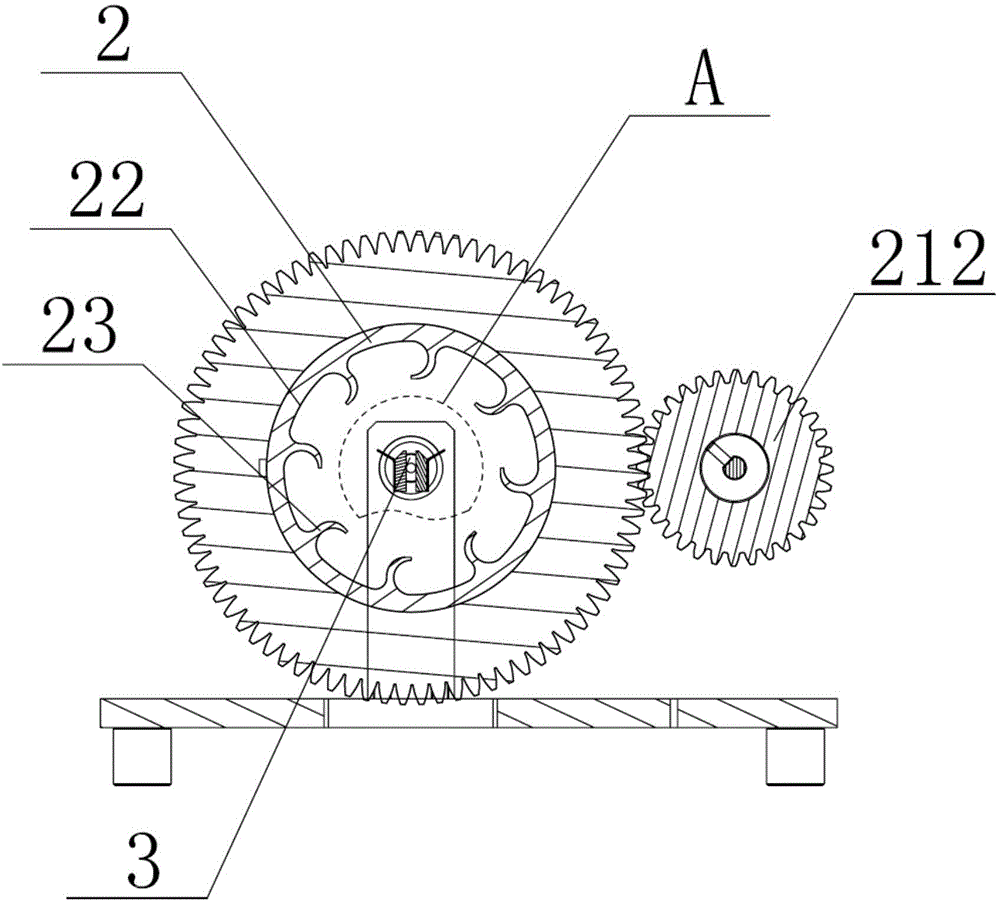

Novel feeding device

InactiveCN104440015AReduce institutional settingsSimple structureMetal working apparatusEngineeringMechanical engineering

Owner:YIHE PRECISION IND SUZHOU

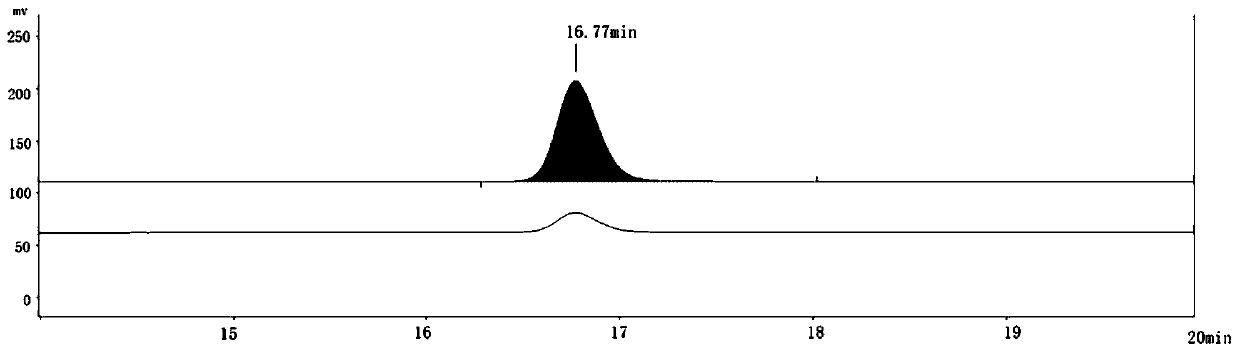

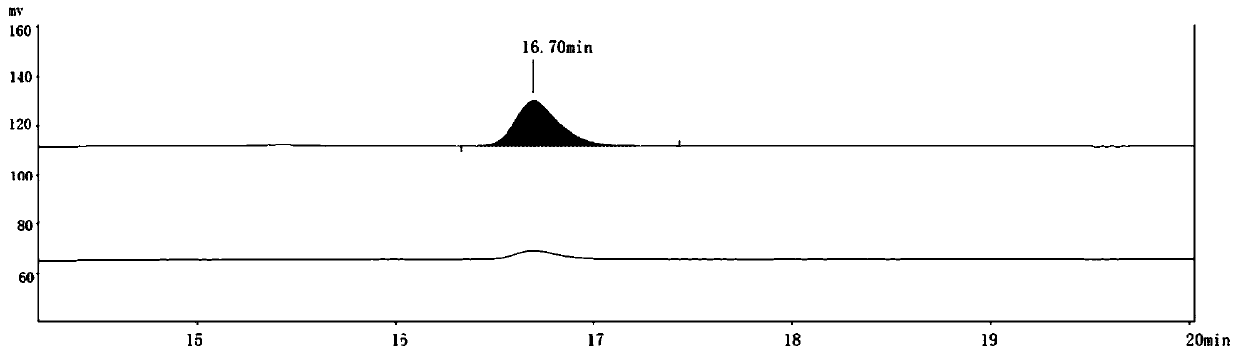

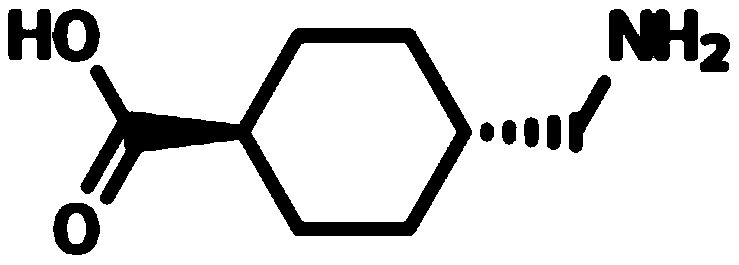

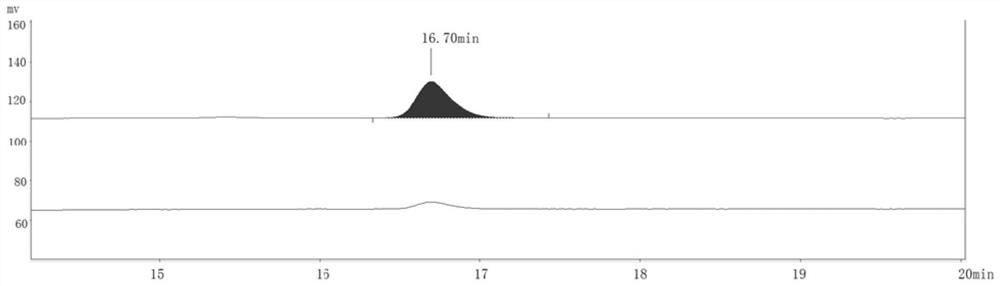

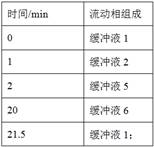

Method for using amino acid analyzer to determine tranexamic acid content

ActiveCN109959736AHigh measurement sensitivityHigh degree of automationComponent separationInjection volumeIon exchange

The invention provides a method for using an amino acid analyzer to determine the tranexamic acid content. The method for determining the tranexamic acid content through ion exchange chromatography and a standard curve method is used. The chromatographic conditions are a 4-micron prewash column and an 8-micron analytical column. Ion exchange resin is resin dedicated to the Biochrom30+ high efficiency amino acid automatic analyzer. The detection wavelength is 570nm. The pump flow rate is 35ml / h. A gradient elution procedure comprises a 0 to 1min buffer 1, a 1 to 2min buffer 2, a 2 to 20min buffer 5, a 20 to 21.5min buffer 6 and a 21.5 to 23.5min buffer 1. The column temperature is 44 DEG C. The reaction temperature is 135 DEG C. The injection volume is 20 mu l. The amino acid analyzer usedfor determining the tranexamic acid content has the characteristics of high commercialization and automation. The method for determining the tranexamic acid content by using the amino acid analyzer has the advantages of simple operation, strong standardization, high sensitivity, being fast and efficient and the like.

Owner:BEIJING INST FOR DRUG CONTROL

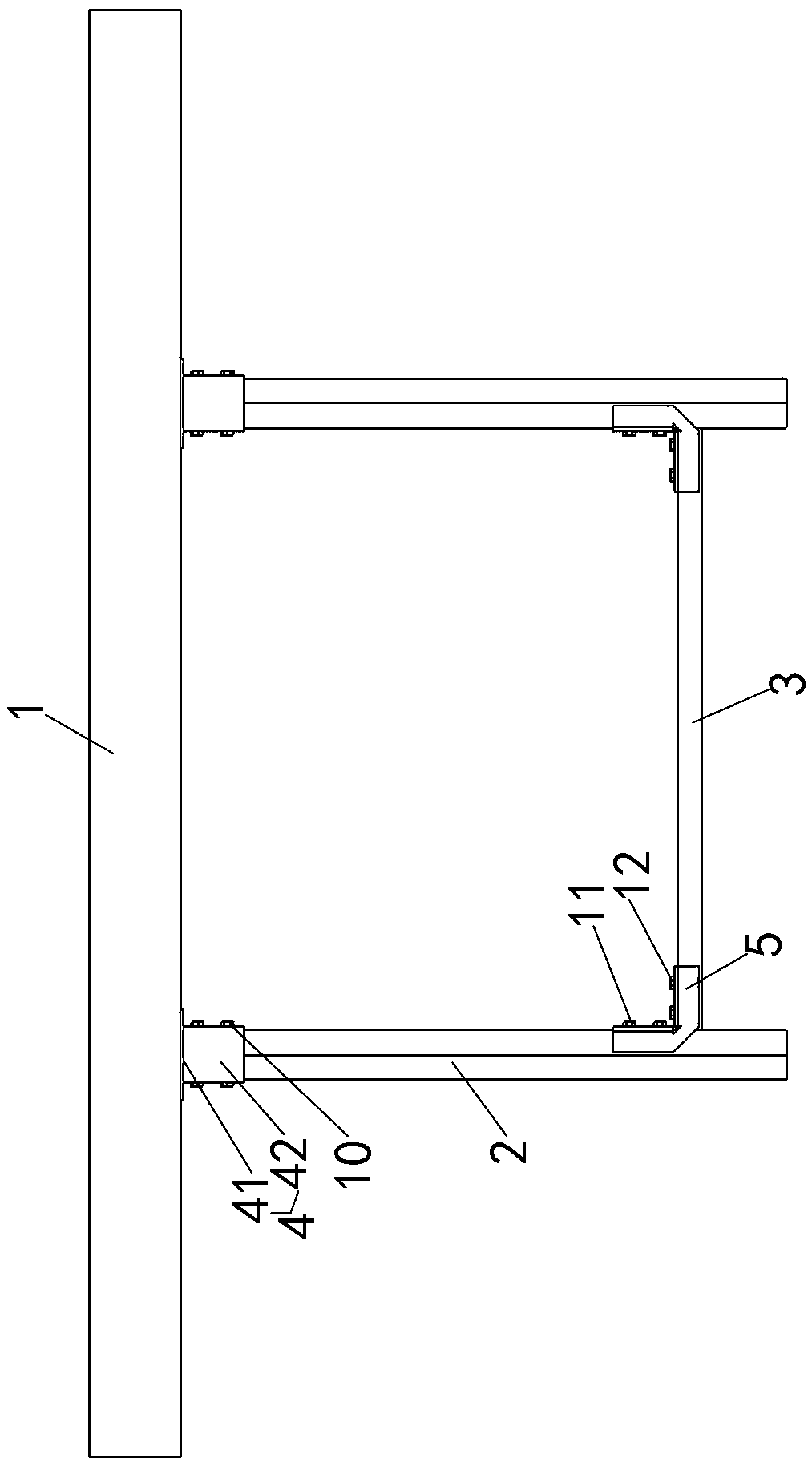

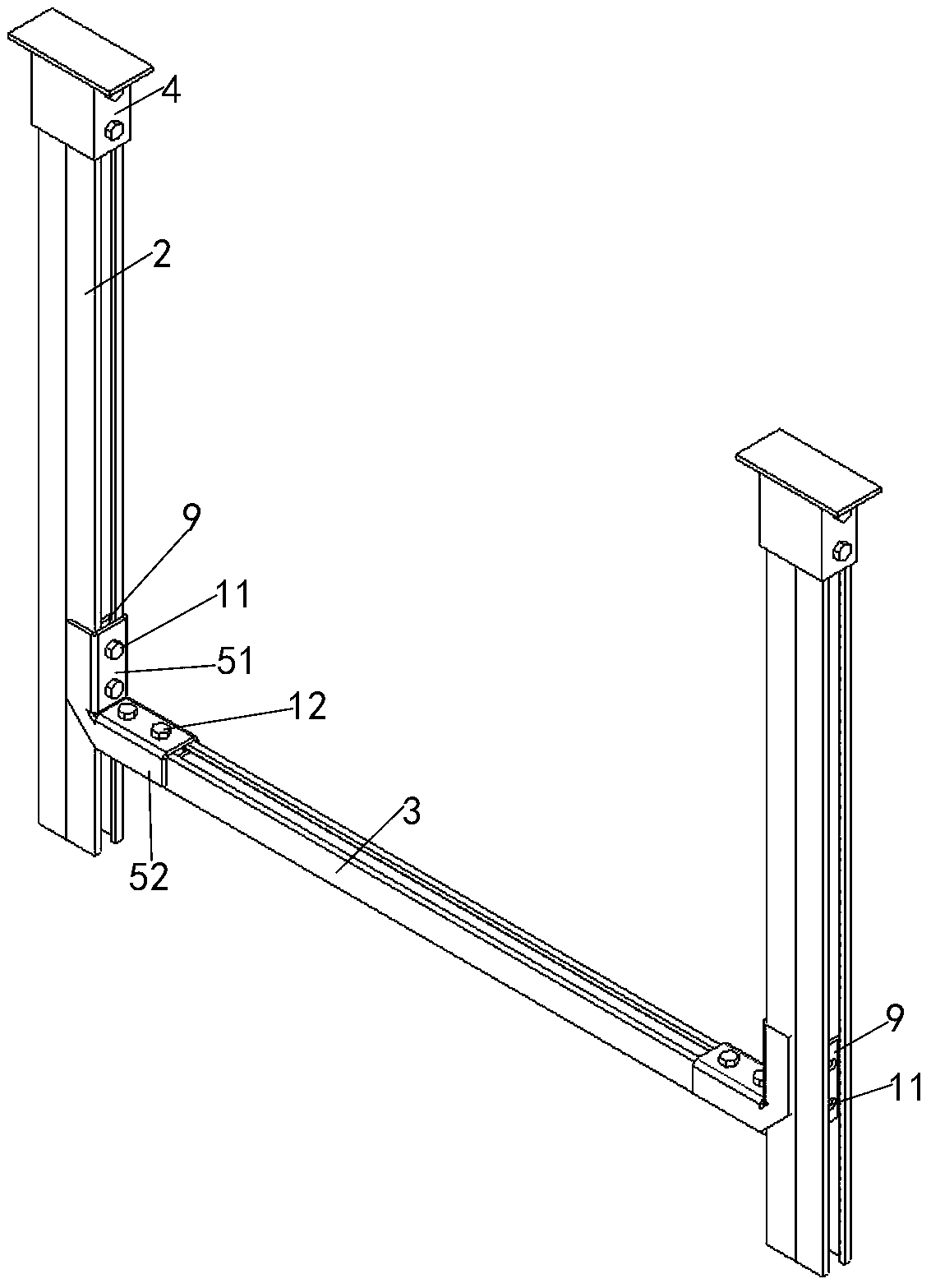

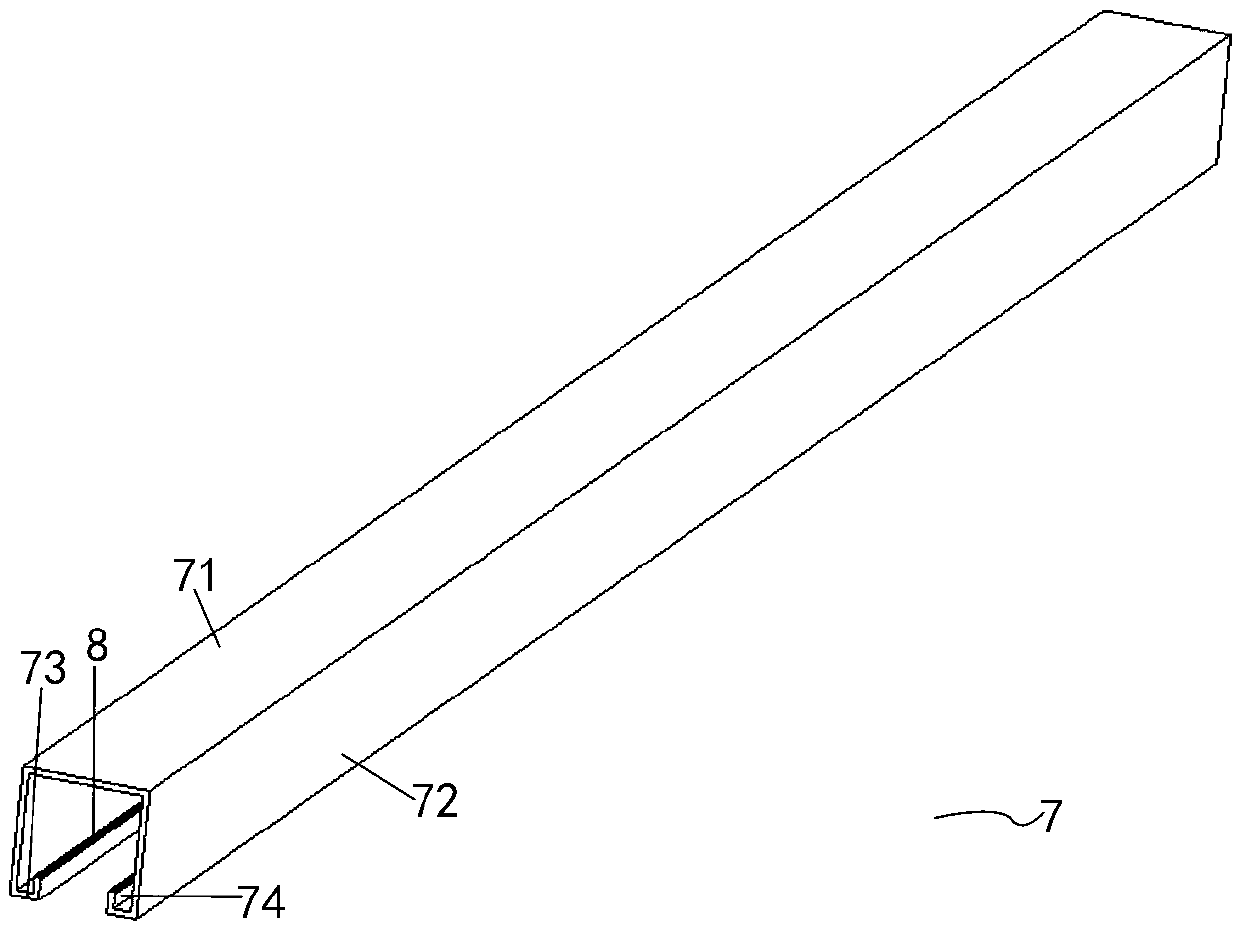

Standardized load-bearing support and hanger system and installation method thereof

InactiveCN111425667AMany optionsEasy to adjustPipe supportsElectrical apparatusEngineeringBolt connection

The invention provides a standardized load-bearing support and hanger system and an installation method thereof. The standardized load-bearing support and hanger system comprises a top transverse beamand a hanging bracket. The hanging bracket comprises vertical arms and a cross arm. The tops of the vertical arms are fixedly connected to the lower side of the hanging bracket through bases. The twoends of the transverse arm are fixedly connected with the vertical arms through angle connection assemblies. The vertical arms or the transverse arm is formed by a section of channel steel standard component or formed by two sections of channel steel standard components through a lengthening connection assembly in a lengthening manner. Each channel steel standard component comprises a channel bottom plate, channel side plates and channel side flanges. A channel steel tooth is arranged on the top end face of each parallel flange. Each base comprises a horizontal connection plate and an outer sleeve. A tooth plate is inserted in each vertical arm. The outer sides of the tooth plates abut against the channel side flanges. Tooth plate clamping teeth and the channel steel teeth are clamped andfixed. Tooth plate connection holes and outer sleeve connection holes are right opposite and connected through first connection bolts. According to the standardized load-bearing support and hanger system and the installation method, standardized design is conducted for the load-bearing support and hanger system, and connection of all the standardized components is achieved through biting of the tooth plates and the channel steel teeth and then through bolt and connection piece fastening.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

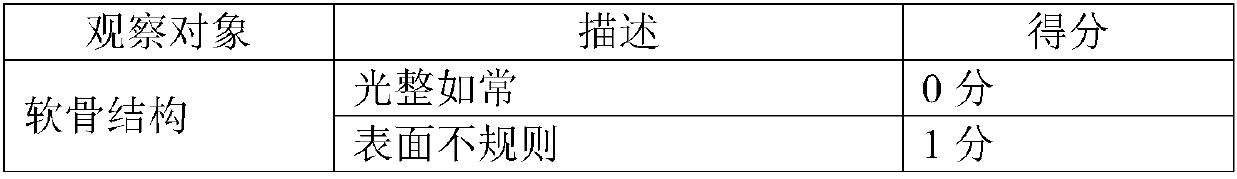

Nutritional composition for improving bone joint health as well as preparation method and application thereof

InactiveCN107669980AIncrease painReduce degradationSulfur/selenium/tellurium active ingredientsSkeletal disorderMyrrhAdditive ingredient

Owner:北京特食生物科技研究中心(有限合伙)

Wood fire-retarding treatment technology method

InactiveCN109176791AEasy maintenanceEasy loadingWood treatment detailsCoating impregnationEngineeringThreaded rod

The invention discloses a wood fire-retarding treatment technology method. A fire-retarding material coating device is applied to the wood fire-retarding treatment technology method and comprises a machine body and a coating cavity arranged in the machine body; the inner all of the top of the coating cavity is provided with a slide guiding groove in a communicating mode, and the left inner wall and the right inner wall of the first slide guiding groove are internally provided with symmetrical liquid storage cavities; the right end of the coating cavity is provided with a second slide guiding groove; the inner wall of the bottom of the coating cavity is slidably connected with a loading moving block in a matched mode, and the loading moving block is internally connected with a first threaded rod extending in the left-right direction through a thread in a matched mode; the tail of the right end of the first threaded rod stretches into the second slide guiding groove and is provided witha tooth rotation wheel; a third slide guiding groove provided with an upward opening is formed in the end surface of the top of the loading moving block and internally and slidably connected with a bilaterally-symmetrical clamping blocks in a matched mode; a second threaded rod extending in the left-right direction is connected into the clamping blocks through threads in a matched mode; and the tail of the right end of the second threaded rod stretches out of the end surface of the right end of the loading moving block and is fixedly connected with a second tooth rotation wheel.

Owner:竺妙飞

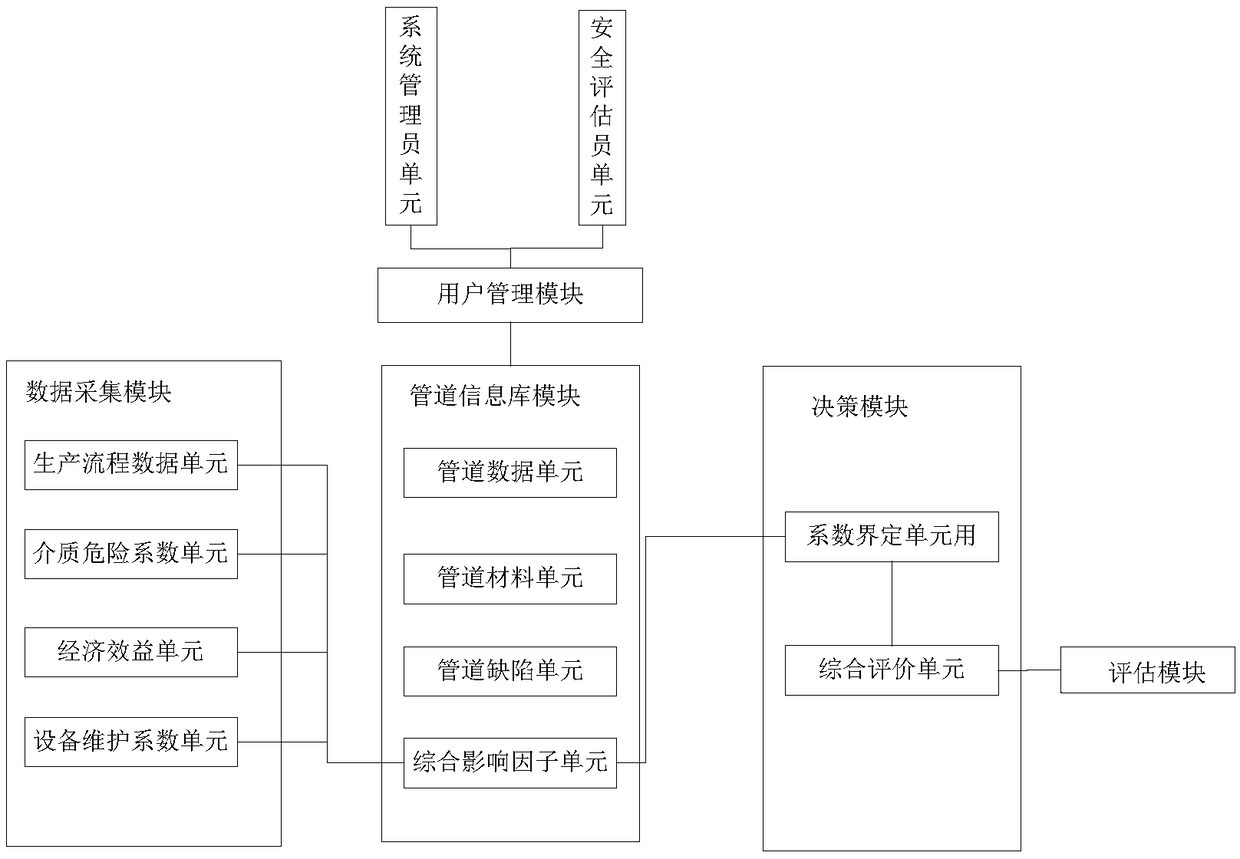

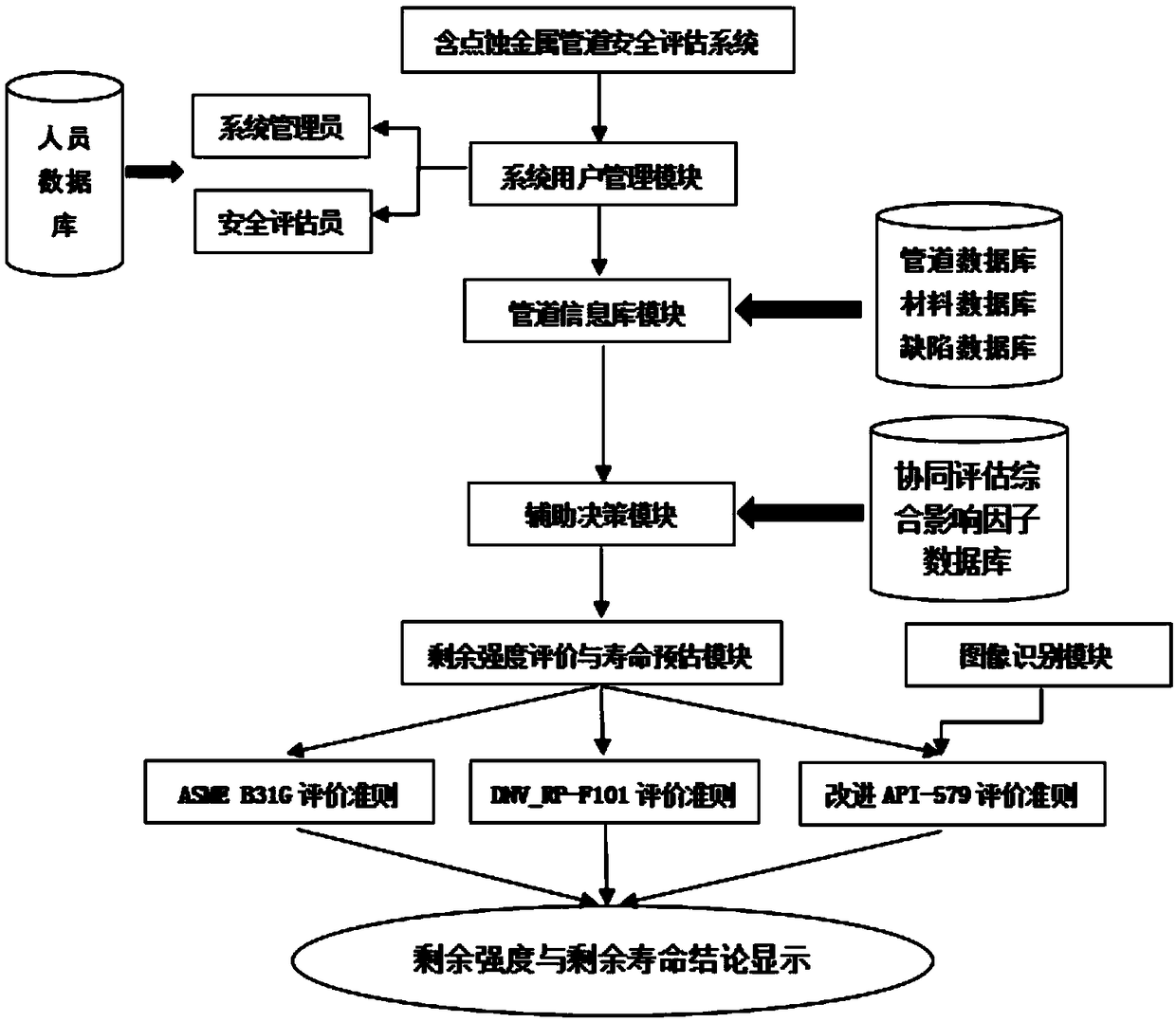

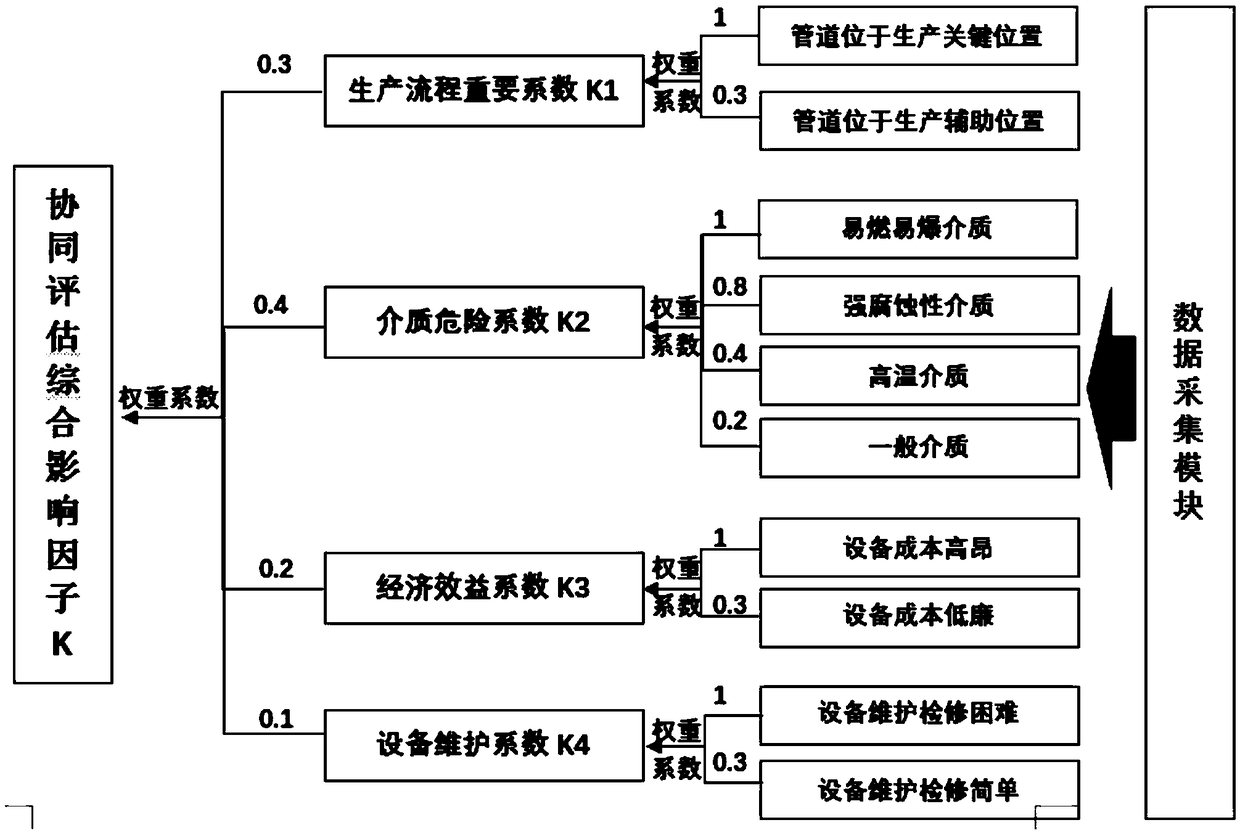

Oil and gas transport pipeline safety margin and residual life online monitoring platform

The invention provides an oil and gas transport pipeline safety margin and residual life online monitoring platform featured by comprising the following parts: a data acquisition module used for acquiring oil and gas transport pipeline related data information for assisting a decision module to make decisions; the decision module used for determining evaluation rules according to the data providedby the data acquisition module, wherein the evaluation rules comprise ASME B31G evaluation rules, DNV_RP-F101 evaluation rules, and API-579 evaluation rules; an evaluation module used for estimatingthe oil and gas transport pipeline residual strength and life according to the evaluation rules determined by the decision module. The online monitoring platform can realize synergy evaluation of various evaluation rules, can provide reliable data support for safety evaluation personnel to make correct evaluations, and comprises database technology, safety evaluation technology and assistance decision technology; the platform is stable, safe, practical, and expandable.

Owner:SICHUAN UNIV

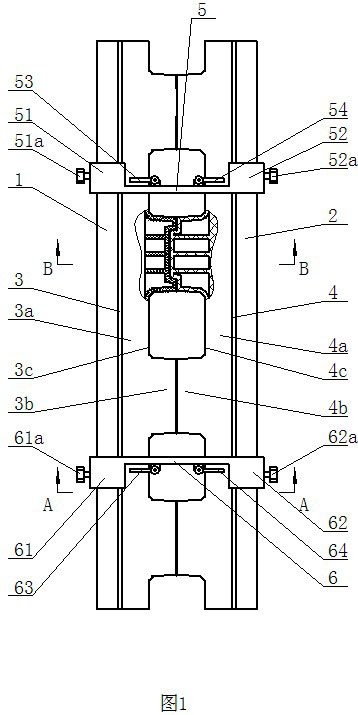

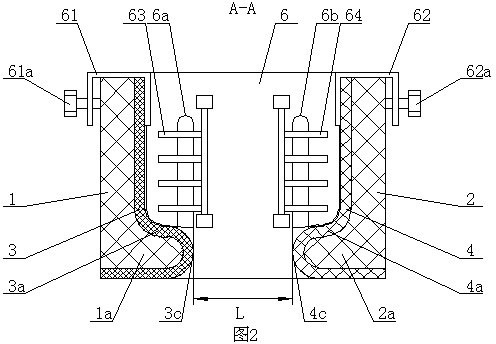

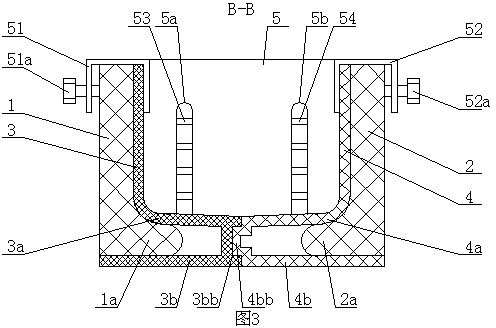

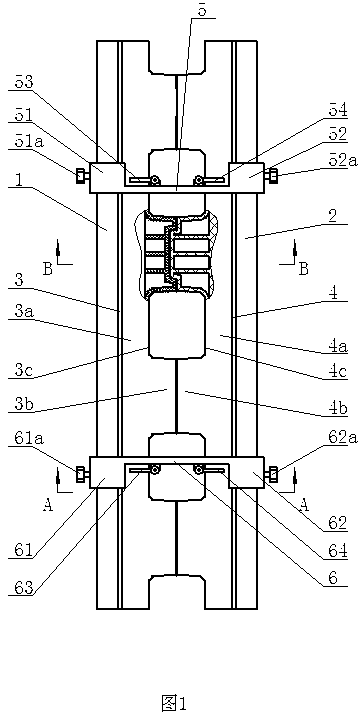

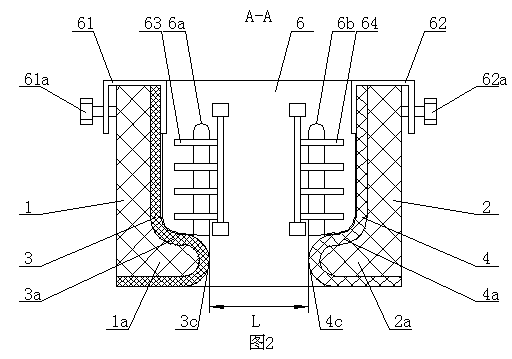

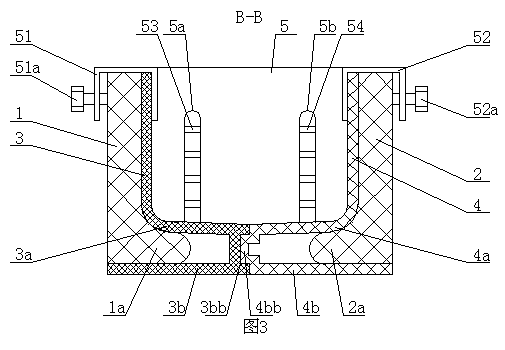

Reinforcing rib making die for ribbed superposed concrete prefabricated member

ActiveCN102303364AEasy to disengageSave manpower, material resources and working hoursMouldsEngineeringMechanical engineering

The invention discloses a reinforcing rib making die for a ribbed superposed concrete prefabricated member. The die comprises a first template and a second template which are arranged corresponding to each other; the sections of the first template and the second template respectively consist of a vertical plate body and a horizontal plate body positioned at the lower part of the vertical plate body and are L-shaped; a first elastic lining film and a second elastic lining film are respectively arranged on the inside walls of the first template and the second template; the mutually corresponding edges of the first lower lining film and the second lower lining film are respectively concave-convex; a first baffle plate and a second baffle plate are respectively arranged between the first template and the second template and are respectively in contact with the first elastic lining film and the second elastic lining film; the first baffle plate is provided with a first steel bar hole and asecond steel bar hole; and the second baffle plate is provided with a third steel bar hole and a fourth steel bar hole. The die has the remarkable characteristics of standardization, strong interchangeability, simplicity and convenience in disassembly and assembly, no need of die release treatment and capability of meeting industrialized production of concrete prefabricated members.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

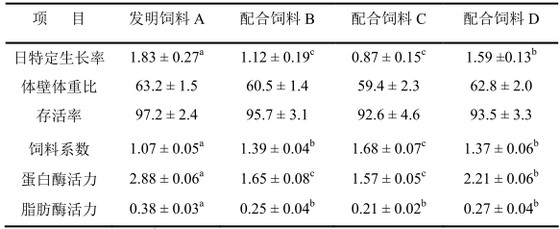

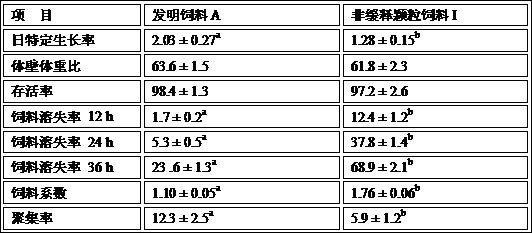

Slow-release pellet feed used in rapid growth period of south-moving stichopus japonicus and preparation method thereof

PendingCN111972544AGood sustained release effectGood slow releaseFood processingAnimal feeding stuffBioadhesiveMultivitamin

The invention discloses a slow-release pellet feed used in a rapid growth period of south-moving stichopus japonicus. The slow-release pellet feed is characterized by being prepared by mixing the following components in percentage by mass: 40-50% of a protein component composition, 6-8% of a grease component composition, 15-25% of a starch component composition, 0.5-0.6% of compound vitamins, 0.7-0.8% of compound mineral salt, 20-25% of a functional component composition and 1.0-1.5% of a biological adhesive.

Owner:YANCHENG TEACHERS UNIV

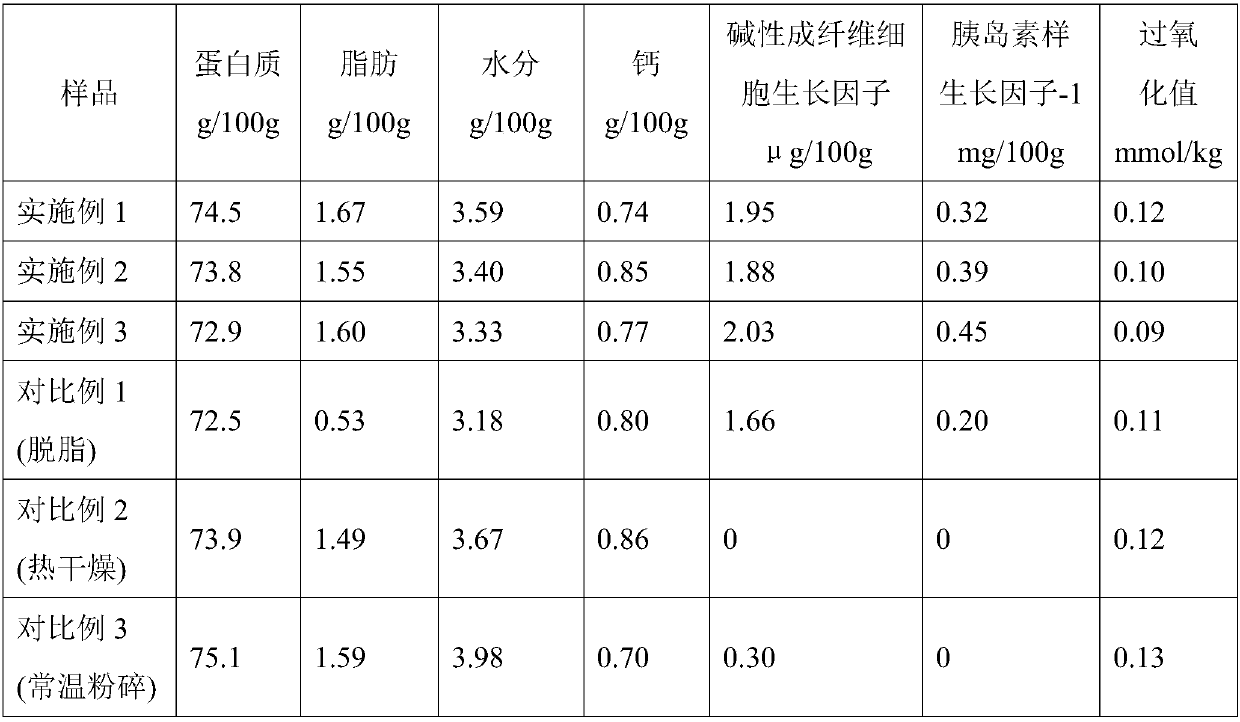

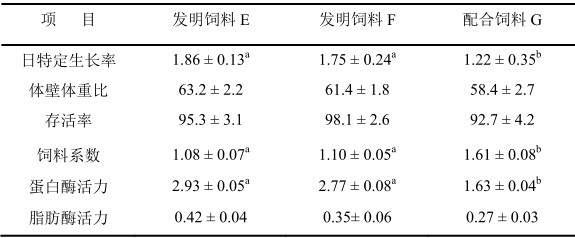

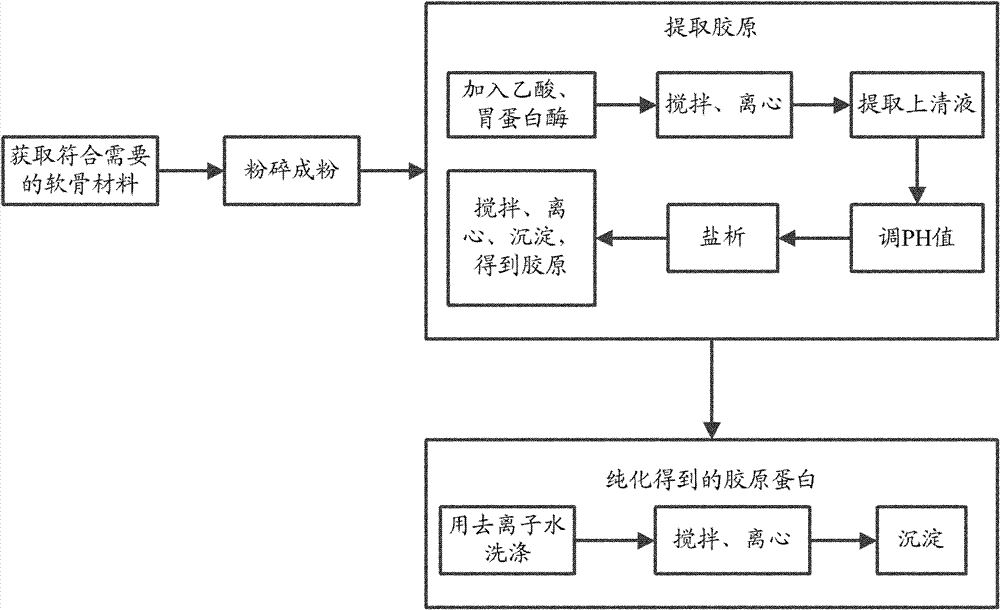

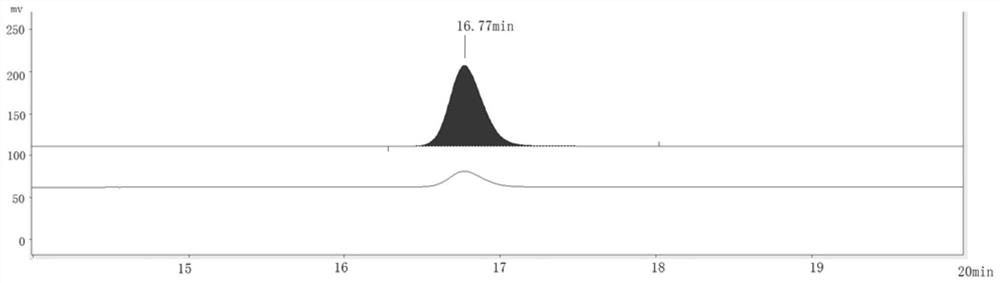

Production method of non-denatured II-type collagen

ActiveCN102154425BImprove consistencyReduce labor costsPeptide preparation methodsFermentationLaboratory scaleCollagen VI

The invention discloses a production method of non-denatured II-type collagen, which comprises the steps of: during removal of impurities, stirring and hydrolyzing 1:16w / w pepsase for 24h in the temperature of 26-28 DEG C respective under pH 6.5 and pH2.5 conditions, obtaining cartilage material and then grinding the obtained cartilage material into powder; and extracting collagen, and obtaining the non-denatured II-type collagen. The production method leads the extraction of the non-denatured collagen to be expanded into production scale from laboratory scale, thus basically meeting the production requirements; the technical scheme of the invention is simple and convenient to do, strong in standardization, less in human factors, cost-saving and high in yield; and the extraction process of the collagen is simpler and more convenient, so that the large-scale production can be more smoothly carried out.

Owner:北京华达杰瑞生物技术有限公司

Method for Determination of Tranexamic Acid Content Using Amino Acid Analyzer

ActiveCN109959736BHigh measurement sensitivityHigh degree of automationComponent separationPhysical chemistryIon exchange

Disclosed is a method for determining the content of tranexamic acid using an amino acid analyzer, and a method for determining the content of tranexamic acid by using ion-exchange chromatographic separation and a standard curve method. The chromatographic conditions are 4μm prewash column and 8μm analysis column, and the ion exchange resin is Biochrom30+ special resin for high-efficiency amino acid automatic analyzer; detection wavelength is 570nm; pump flow rate is 35ml / h; gradient elution program: 0~1min buffer 1, 1~ 2min buffer 2, 2-20min buffer 5, 20-21.5min buffer 6, 21.5-23.5min buffer 1; column temperature 44°C; reaction temperature 135°C; injection volume 20μl. The amino acid analyzer used in the determination of tranexamic acid content has the characteristics of commercialization and high degree of automation. The method for determining the content of tranexamic acid with an amino acid analyzer has the advantages of simple operation, strong standardization, high sensitivity, rapidity and high efficiency.

Owner:BEIJING INST FOR DRUG CONTROL

Reinforcing rib making die for ribbed superposed concrete prefabricated member

ActiveCN102303364BEasy to disengageArbitrarily determine the size lengthMouldsBody positionsSteel bar

The invention discloses a reinforcing rib making die for a ribbed superposed concrete prefabricated member. The die comprises a first template and a second template which are arranged corresponding to each other; the sections of the first template and the second template respectively consist of a vertical plate body and a horizontal plate body positioned at the lower part of the vertical plate body and are L-shaped; a first elastic lining film and a second elastic lining film are respectively arranged on the inside walls of the first template and the second template; the mutually corresponding edges of the first lower lining film and the second lower lining film are respectively concave-convex; a first baffle plate and a second baffle plate are respectively arranged between the first template and the second template and are respectively in contact with the first elastic lining film and the second elastic lining film; the first baffle plate is provided with a first steel bar hole and asecond steel bar hole; and the second baffle plate is provided with a third steel bar hole and a fourth steel bar hole. The die has the remarkable characteristics of standardization, strong interchangeability, simplicity and convenience in disassembly and assembly, no need of die release treatment and capability of meeting industrialized production of concrete prefabricated members.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

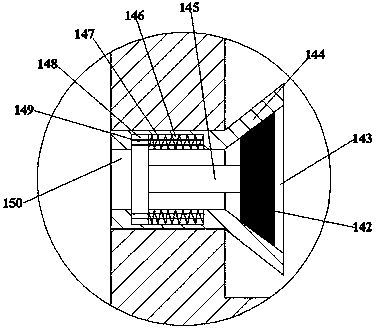

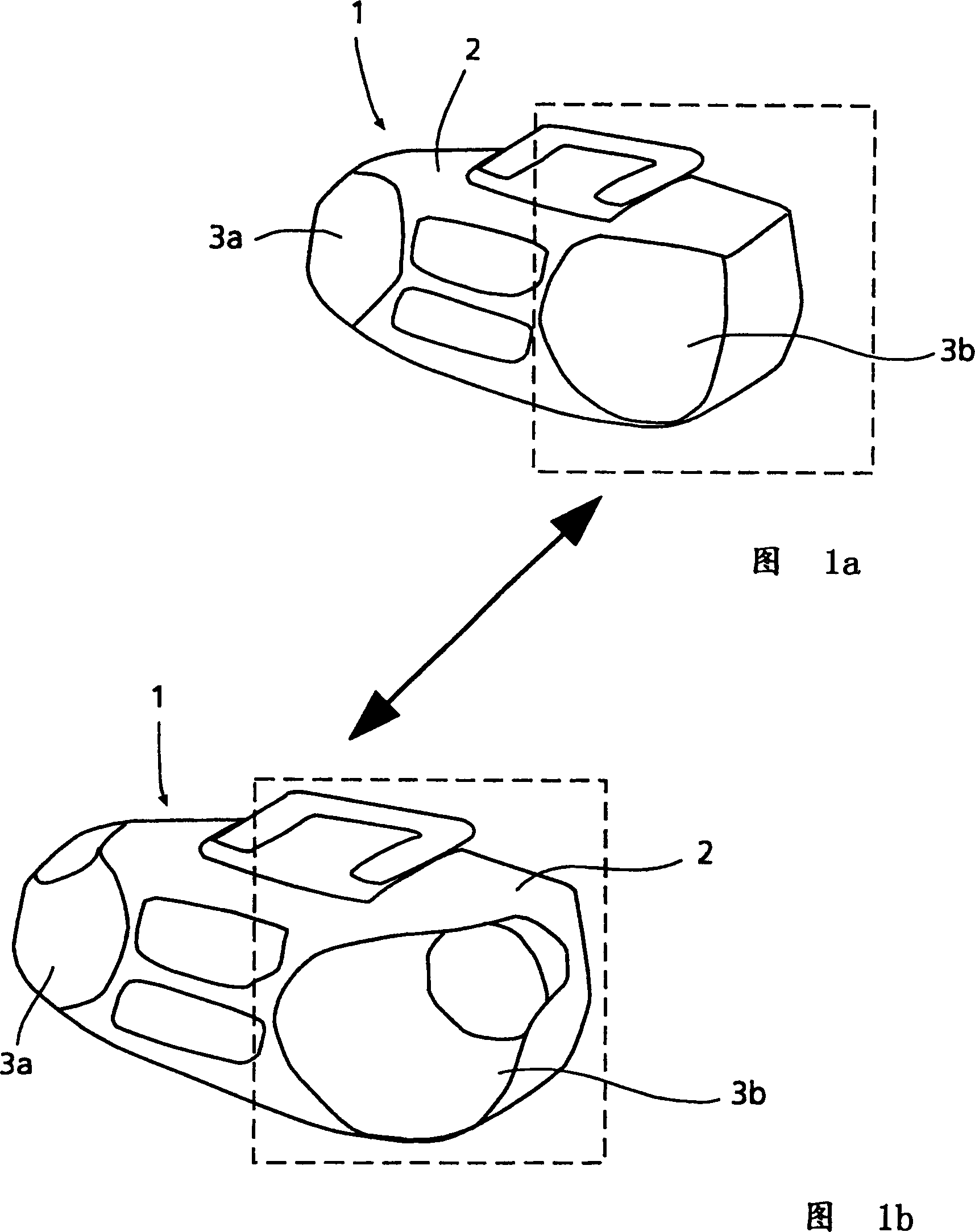

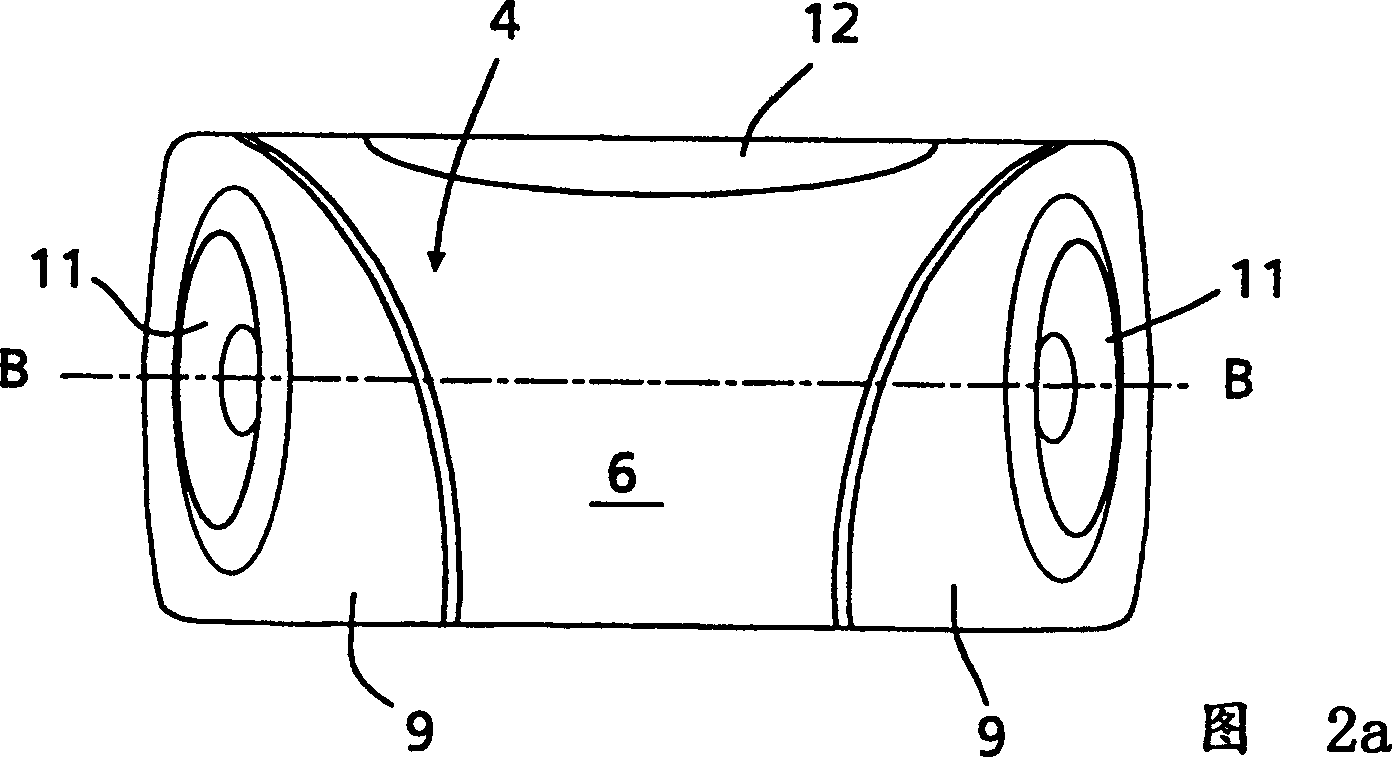

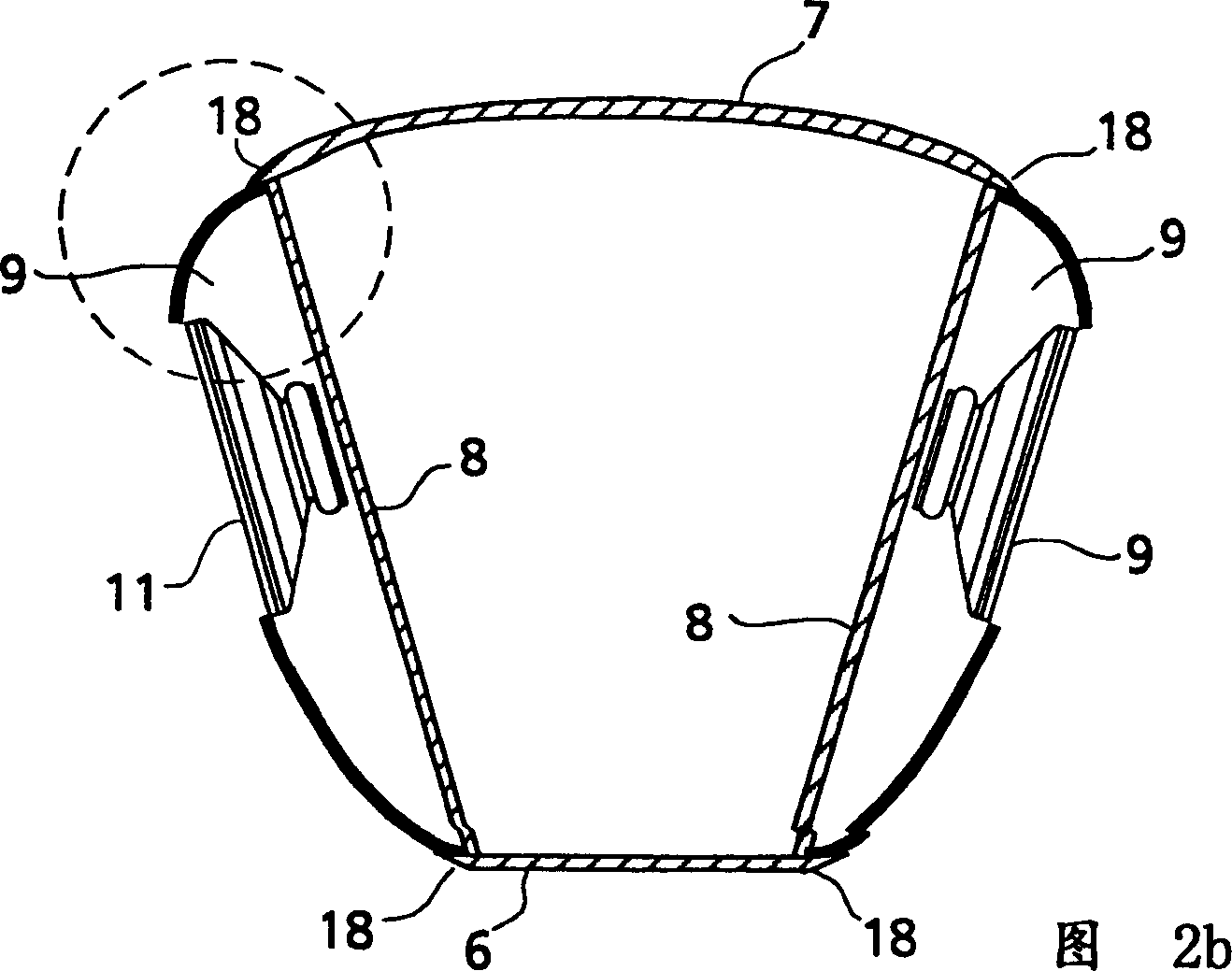

Casing of audio device

InactiveCN1179491CEasy to manufactureQuality improvementTransmissionLoudspeaker spatial/constructional arrangementsEngineeringLoudspeaker

The invention relates to a cabinet for household electronic devices with loudspeaker, which is comprised by a main cabinet for the accommodation of electronic devices and mechanical element, and a separate loudspeaker cabinet which can be fixed to the external side of the main cabinet in undetachable wise. In this wise, different electronic devices can be designed based on the same main cabinet, therefore, the production cost can be greatly reduced.

Owner:THOMSON MULTIMEDIA SA

Traceable bulk orange peel preparation method

ActiveCN106387739BGuaranteed cleanlinessGuarantee product qualityFood dryingFood ingredient functionsTangerine PeelFood science

The invention discloses a traceable batch preparation method of dried tangerine peel. The traceable batch preparation method of the dried tangerine peel comprises the following steps: S1, preliminary choosing tangerine fruits, checking the chosen tangerine fruits, boxing up the checked tangerine fruits, and then, sealing and labeling the boxes for the first time; S2, performing batch cleaning and sorting on the tangerine fruits on cleaning and sorting line equipment; S3, peeling the sorted tangerine fruits; S4, drying the tangerine peel in a drying device; S5, sealing and labeling the boxes of tangerine peel for the second time, and transferring the tangerine peel into a storage warehouse so as to prepare for aging. The step S5 comprises the following steps: S51, storing the tangerine peel in a standard warehouse for 2-5 months; S52, transferring the tangerine peel into a humidifying chamber so as to carry out first humidifying; S53, transferring the humidified tangerine peel into a wet-pumping and air-drying chamber so as to carry out first wet-pumping and air-drying; S54, transferring the wet-pumped and air-dried tangerine peel into the standard warehouse again, and storing the tangerine peel for 1 year; S55, performing second humidifying on the tangerine peel; and S56, performing second wet-pumping and air-drying on the humidified tangerine peel, so that the dried tangerine peel is prepared. The method disclosed by the invention realizes batch preparation of the dried tangerine pee; moreover, information of the tangerine fruits, including place of origin, householder, grade and so on, is traceable.

Owner:江门市新会陈皮村市场股份有限公司

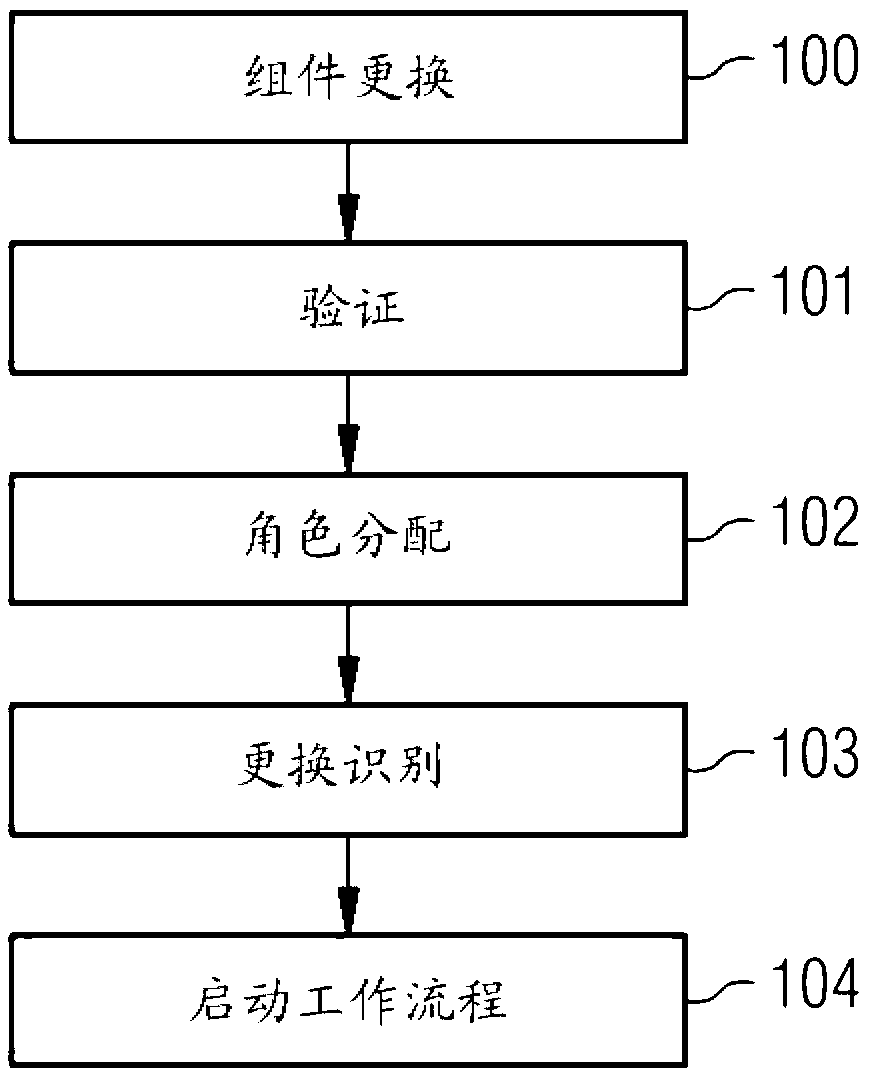

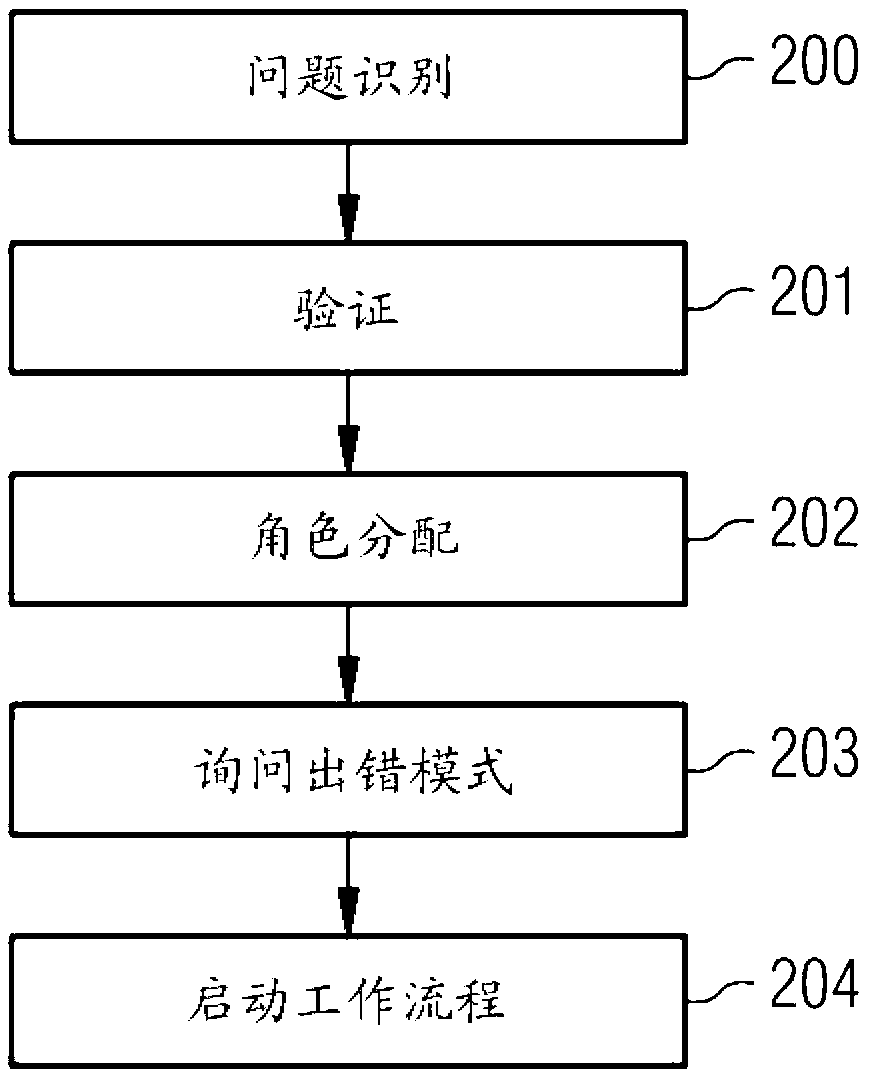

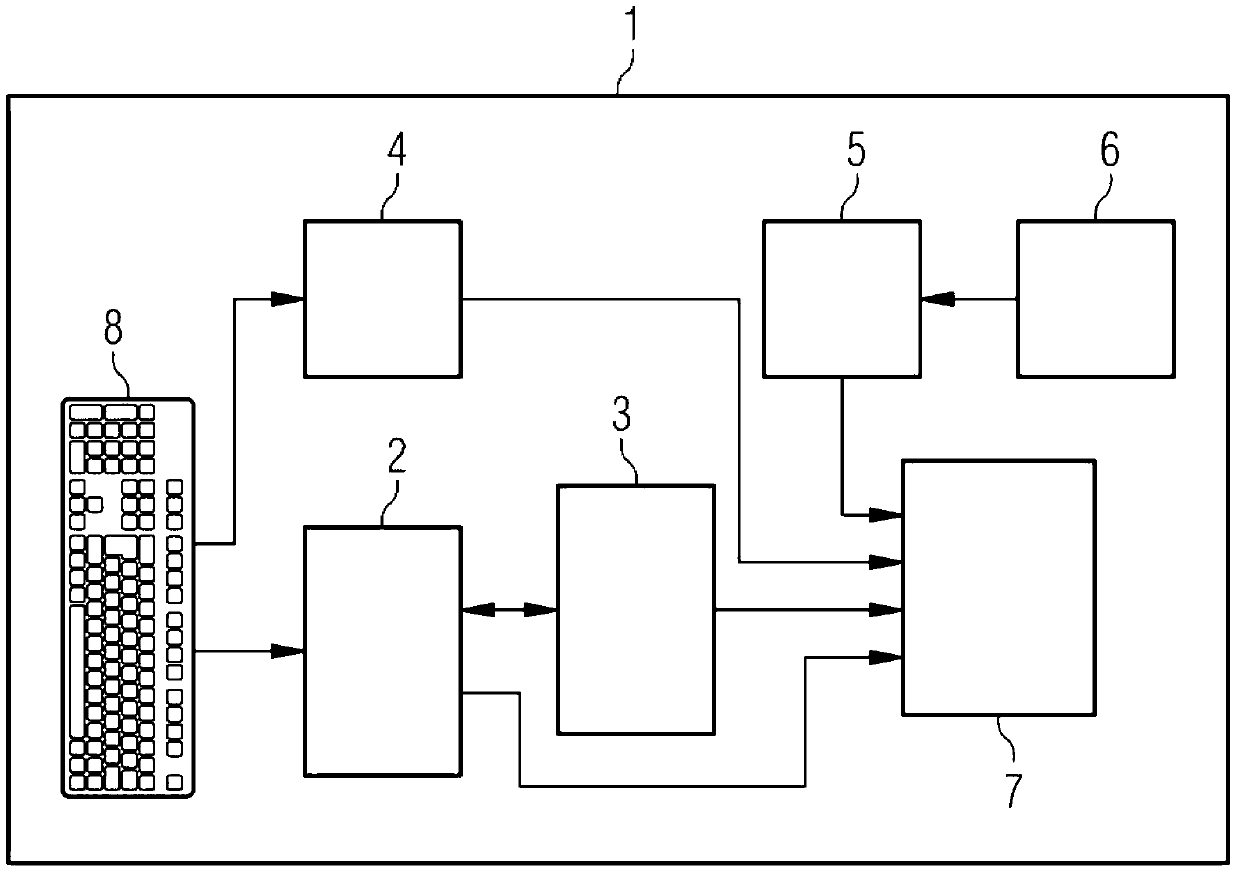

Computer-implemented method and medical-technical system automatically Starting a Medical Workflow

ActiveCN103300920AImprove satisfactionStrong standardizationData processing applicationsSurgeryService provisionElectronic serial number

The present invention provides a computer-implemented method for starting a role-specific workflow in a medical-technical system (1). The computer-implemented method comprising: authenticating (101) a user of the medical-technical system; assigning (102) a role to the user; identifying (103) a replacement component (6) using an electronic serial number stored in the component; and starting (104) the role-specific workflow when the replacement component is identified. The invention also provides a medical-technical system (1) for starting a role-specific workflow. A service delivery may be more heavily standardized and optimized by automatically assigning the workflow. As a result, service results may improve and customer satisfaction may increase.

Owner:SIEMENS HEALTHCARE GMBH

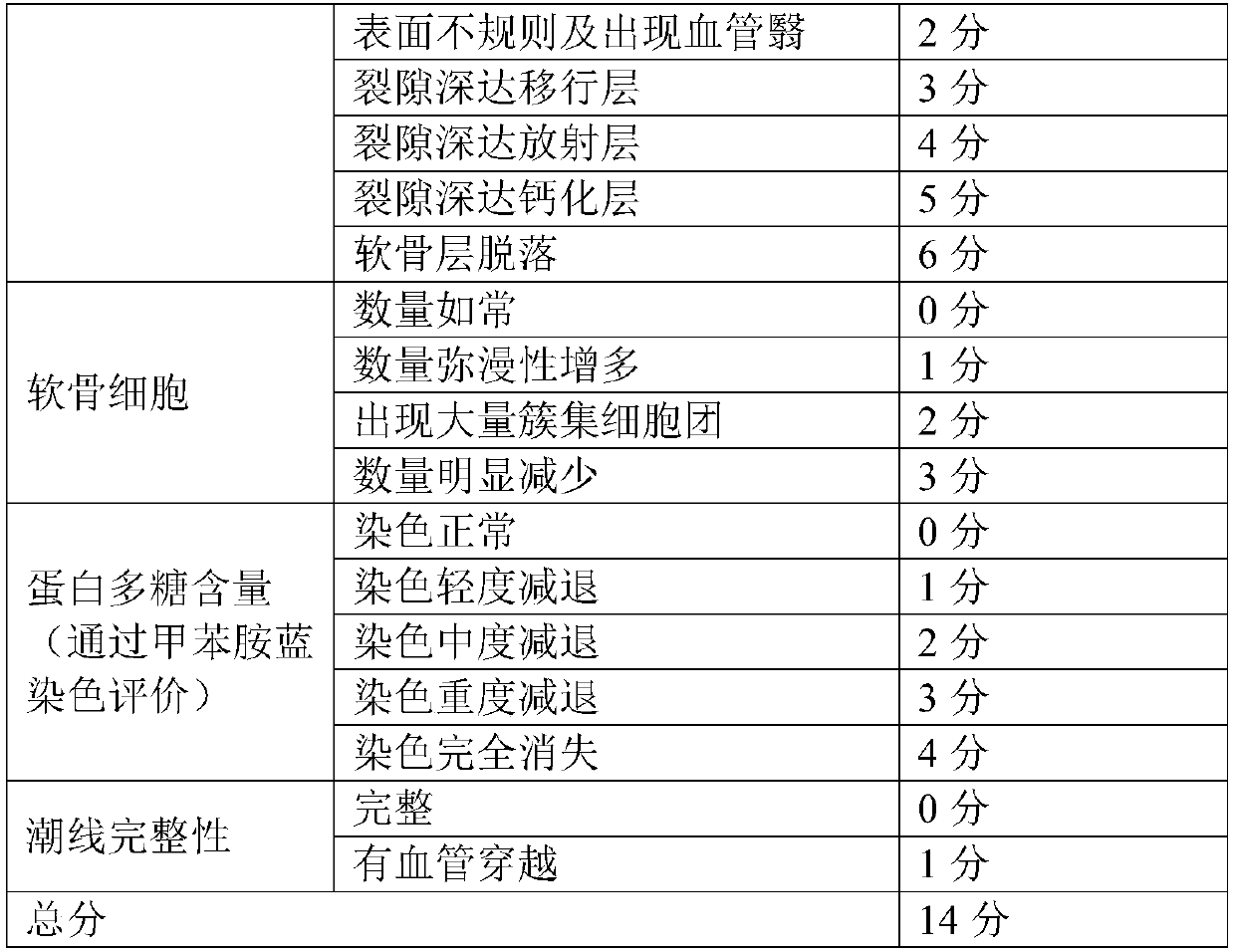

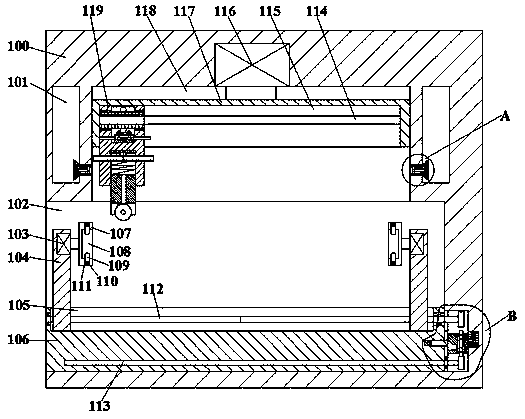

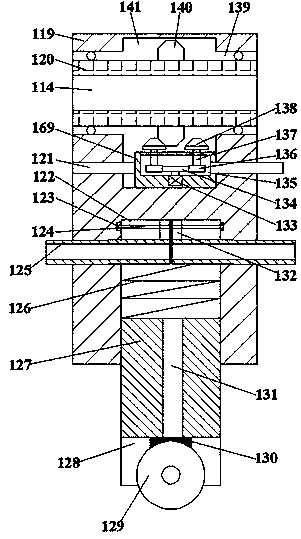

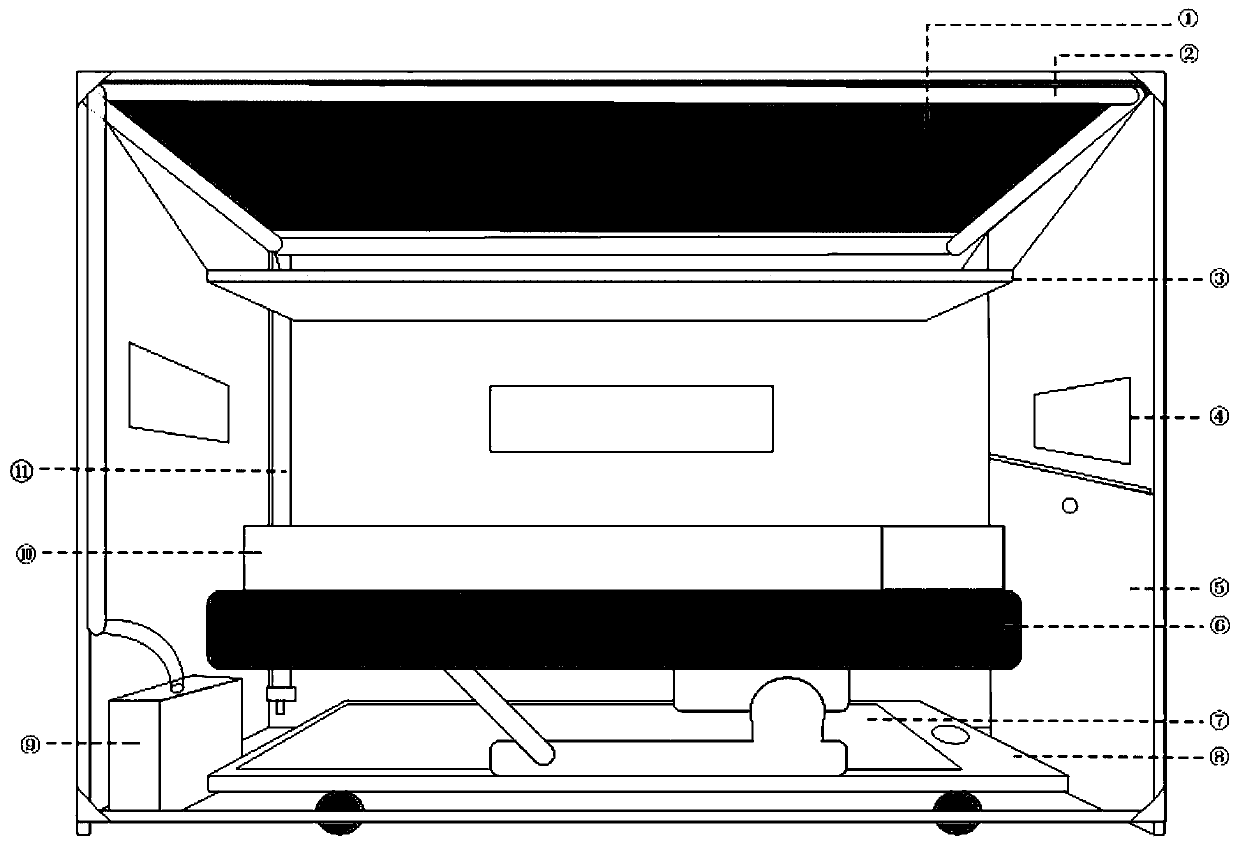

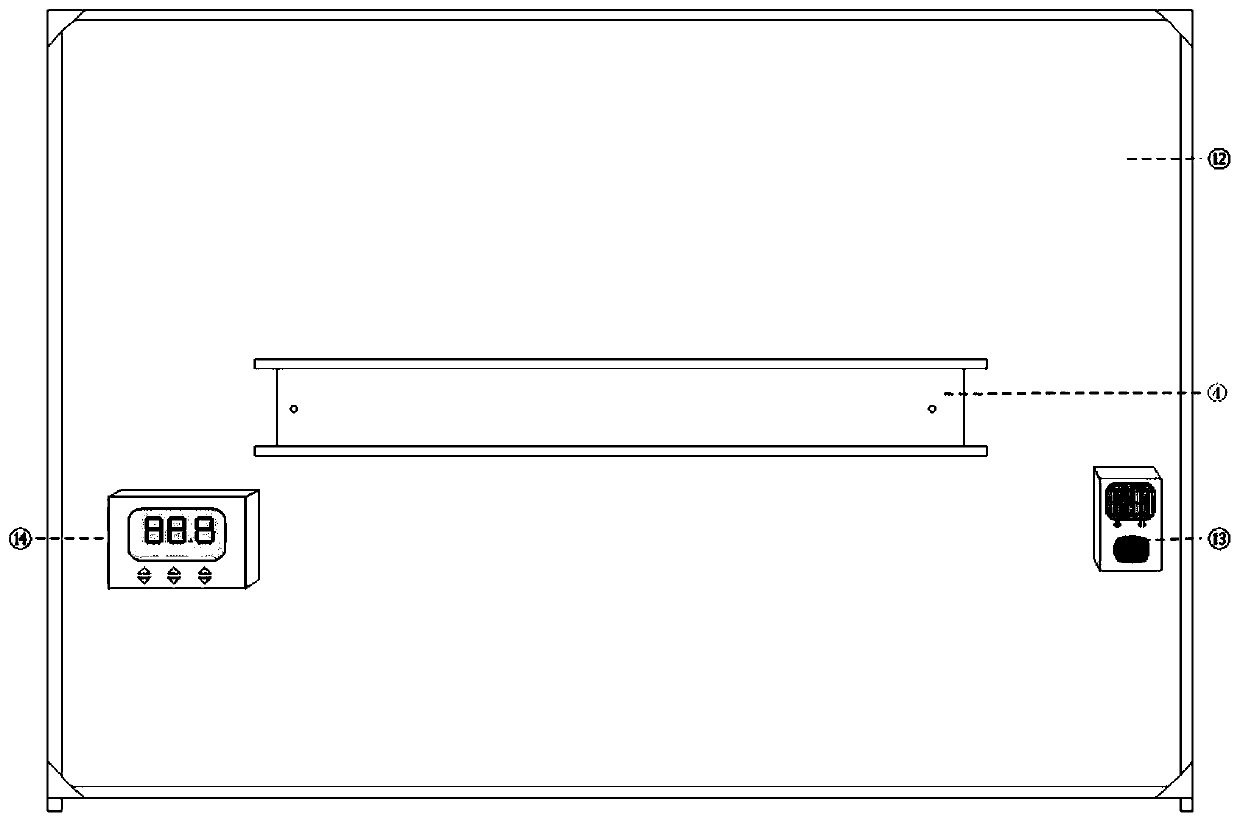

Animal experiment platform

PendingCN111328724AImprove practicalityImprove standardizationAnimal housingTaming and training devicesAnimal scienceElectronic temperature

The invention provides an animal experiment platform. The animal experiment platform is composed of a top wall, four side walls (12) and a cabin bottom, and further comprises a reflective heat insulation film (1), a humidifying pipe (2), an upper heating plate (3), a transfer window (4), a cabin door (5), an animal running platform (6), a lower heating plate (7), a flat car (8) and a humidifier water tank (9), an inner cabin (10), a drain pipe (11), a temperature controller (13) and an electronic temperature and humidity meter (14). The animal experiment platform can simulate a high-temperature and high-humidity environment, can provide a certain strength of labor training for experimental animals (rats and mice), can successfully replicate an experimental animal model of exertional heatstroke (EHS), is convenient to operate, strong in practicability, accurate, stable, high in standardization, simple, universal and good in repeatability.

Owner:GENERAL HOSPITAL OF PLA

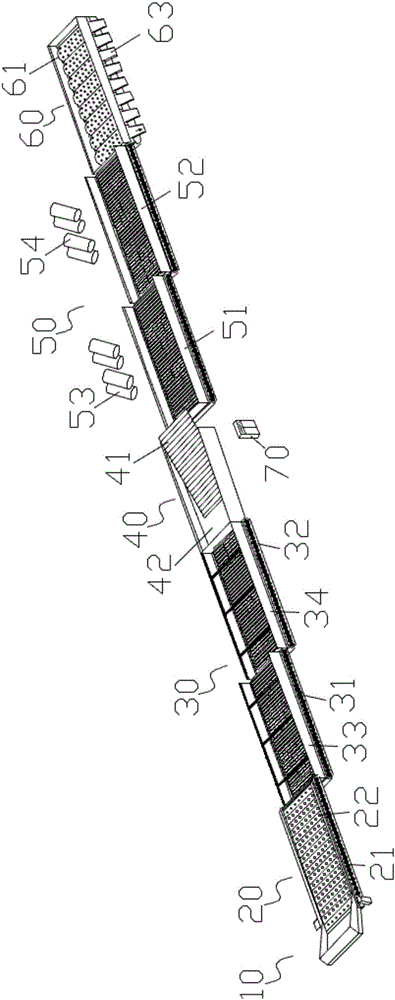

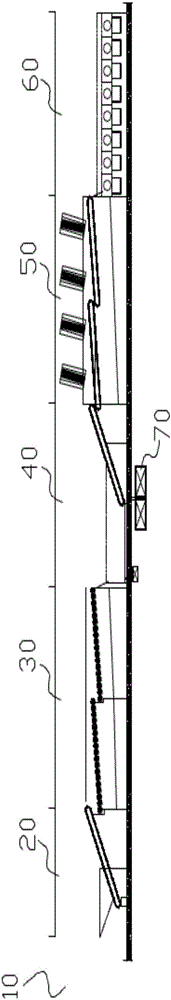

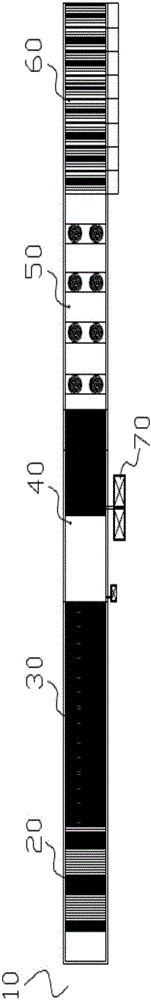

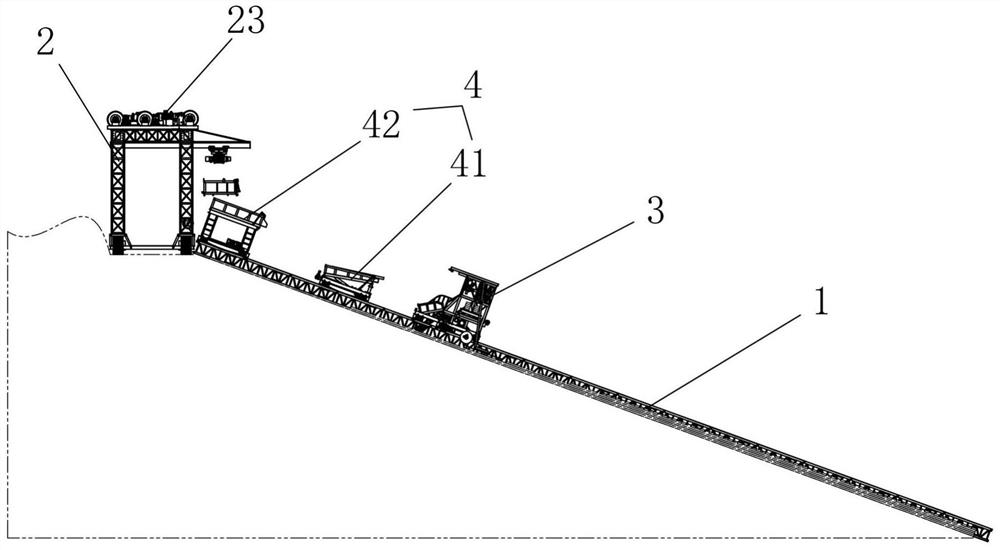

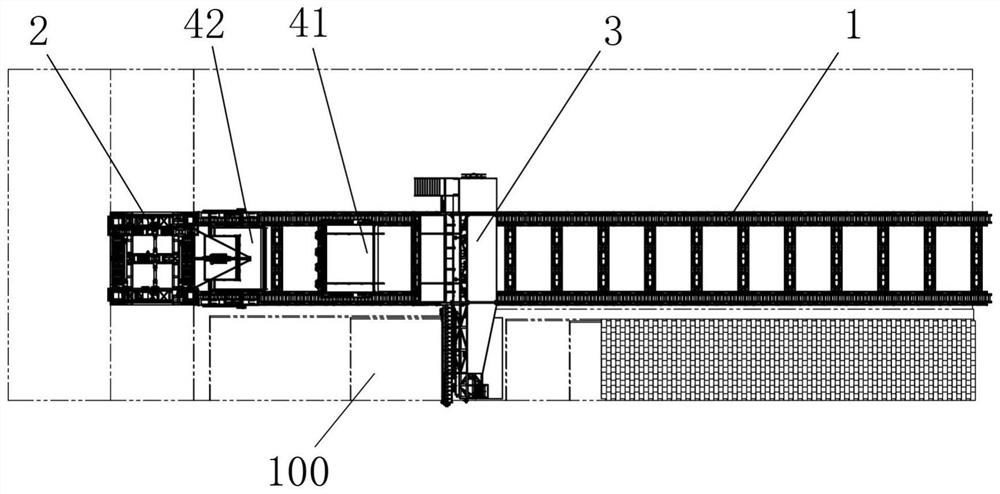

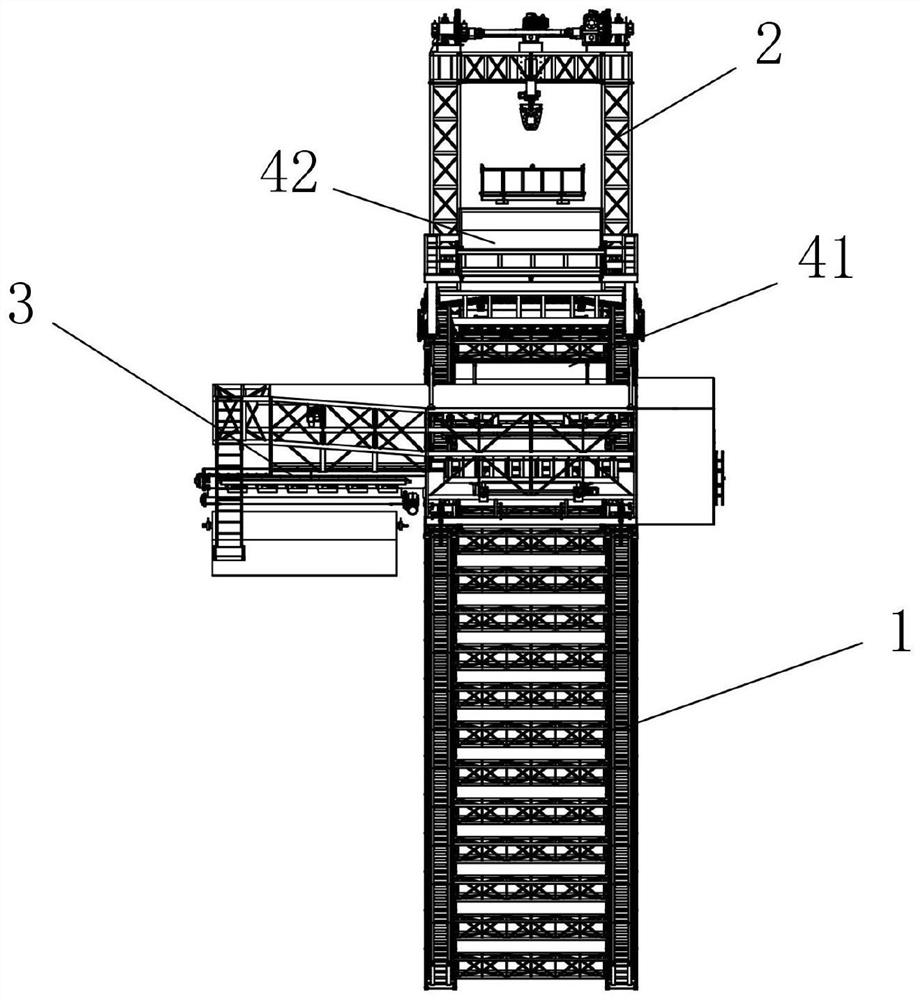

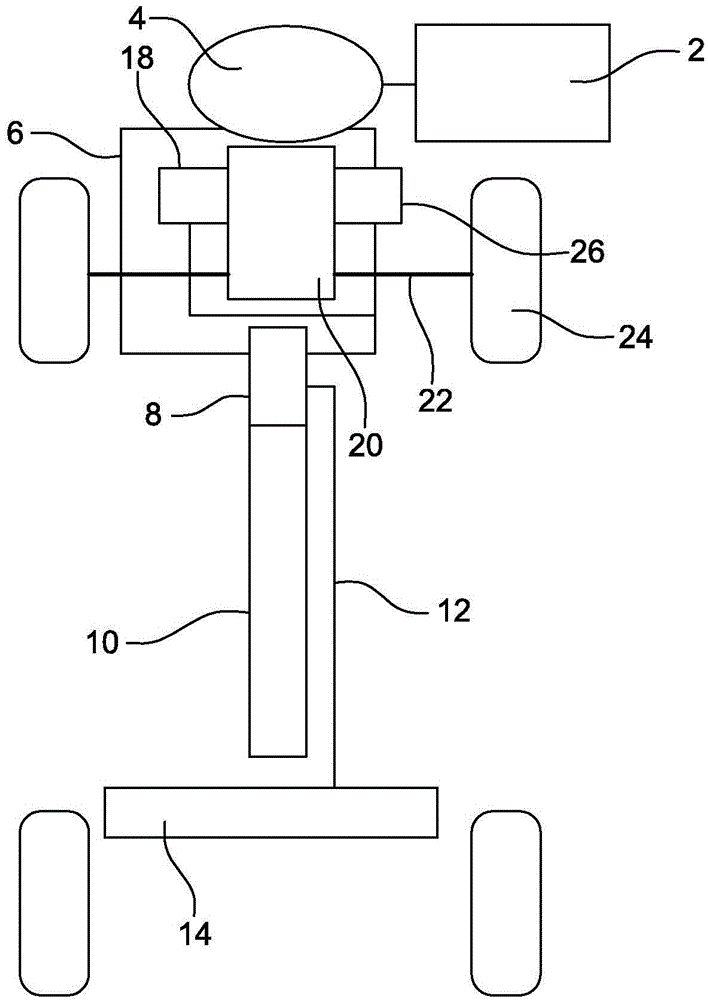

Geomembrane laying system and laying method

PendingCN113293736AReduce labor inputReduce construction costsCoastlines protectionGeomembraneArchitectural engineering

The invention discloses a geomembrane laying system and a laying method. The geomembrane laying system comprises a transportation track, a gantry feeding work vehicle, a construction laying work vehicle and a feeding vehicle, wherein the transportation track is arranged above a to-be-laid working face; the gantry feeding work vehicle is arranged on one end of the transportation track; the construction laying work vehicle is arranged on the transportation track in a sliding mode so as to lay a support layer, a geomembrane and a protective layer on the to-be-laid working face; and the feeding vehicle is arranged on the transportation track in a sliding mode so as to convey to-be-laid materials from the gantry feeding work vehicle to the construction laying work vehicle. According to the geomembrane laying system, the labor input of geomembrane laying operation can be reduced, the construction cost is reduced, and the construction quality and the construction efficiency are improved.

Owner:红河哈尼族彝族自治州水利水电工程地质勘察咨询规划研究院 +1

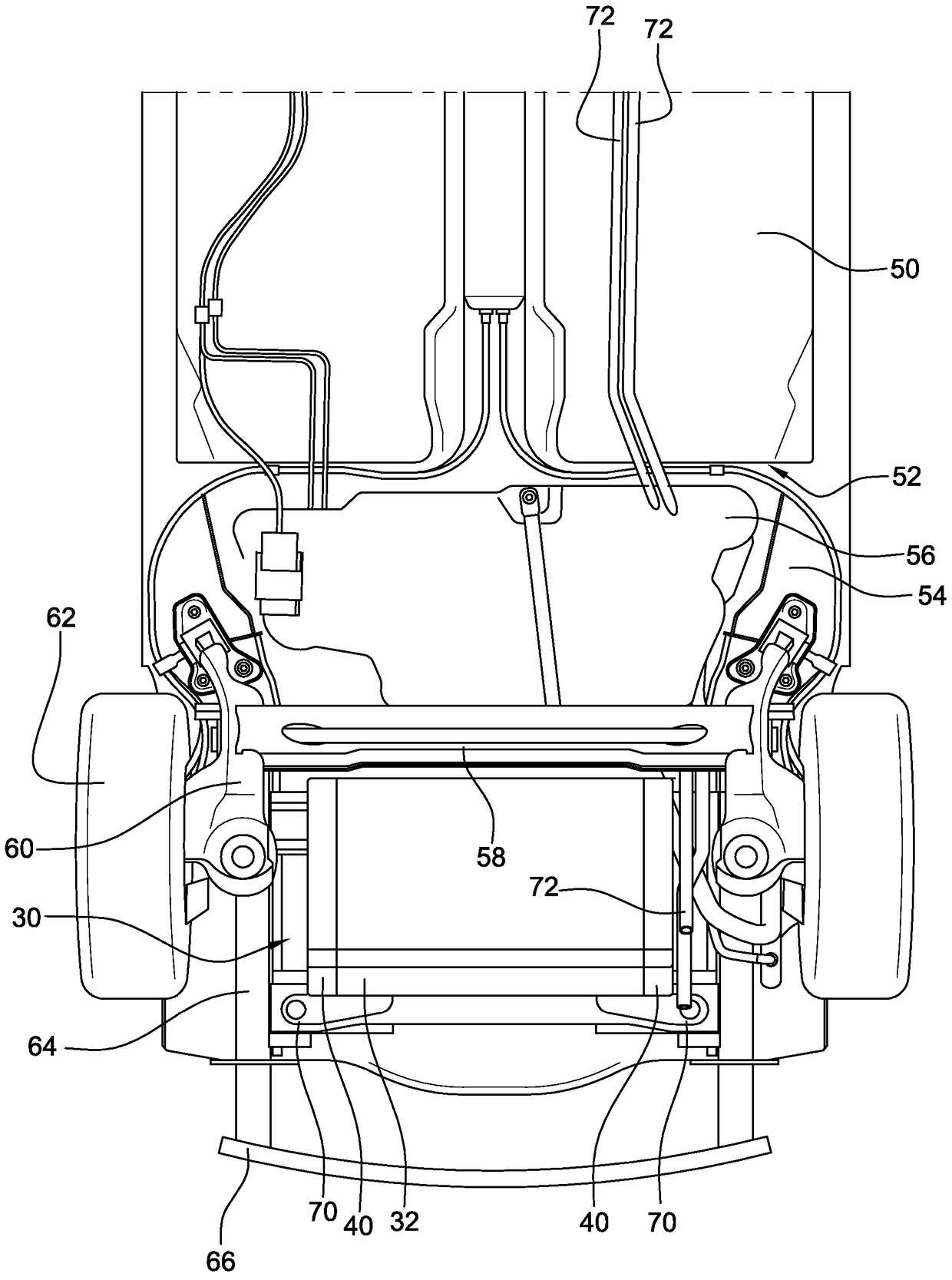

Hydraulic module comprising high- and low-pressure accumulators, for a hybrid vehicle

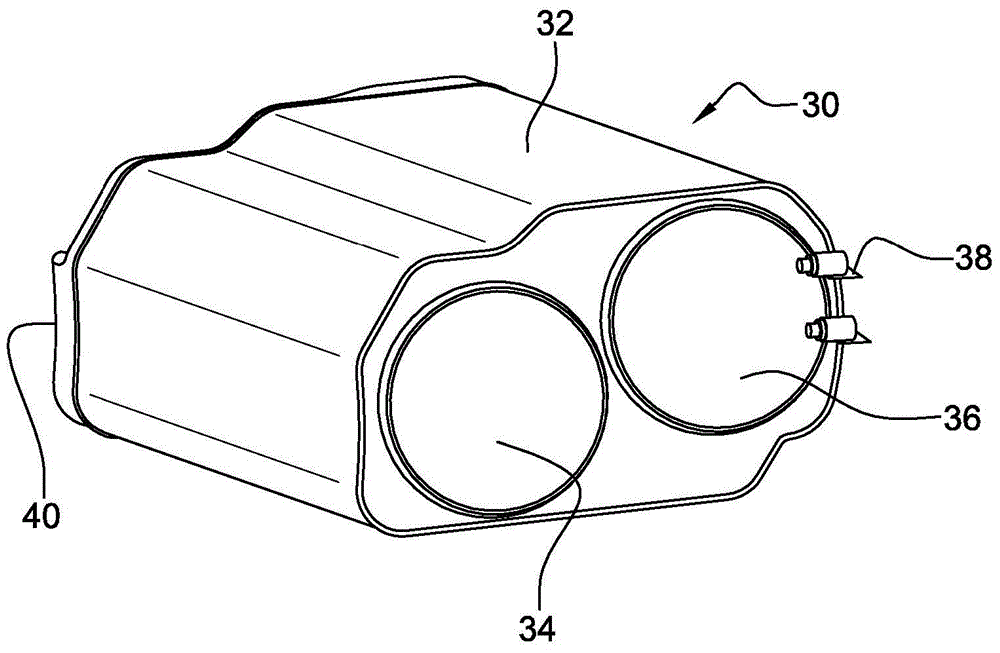

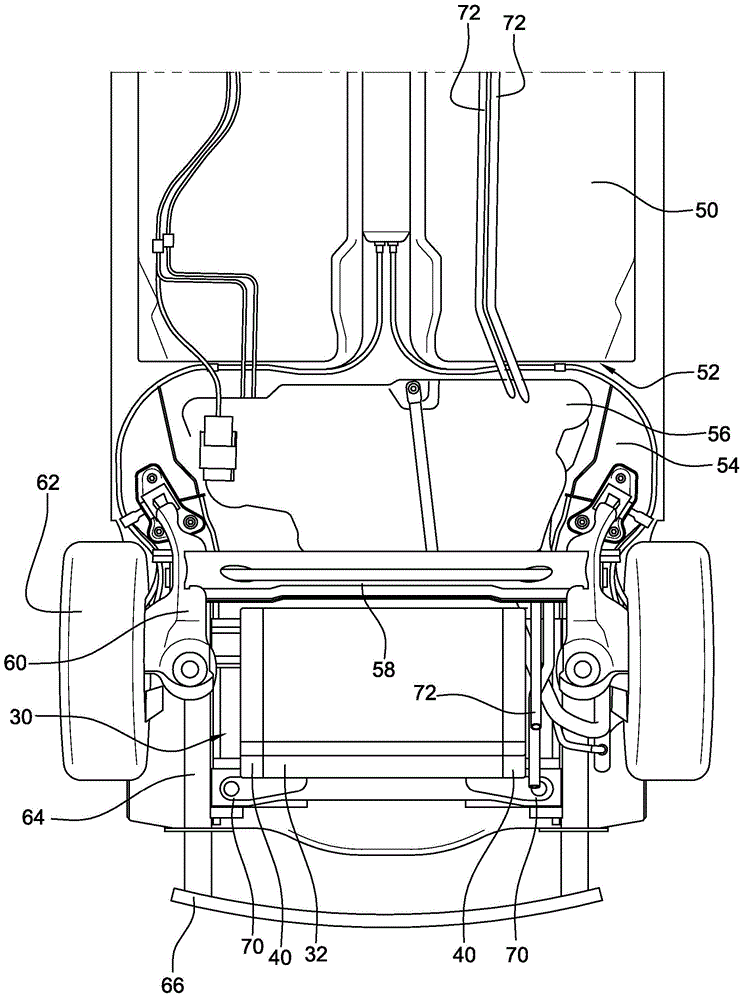

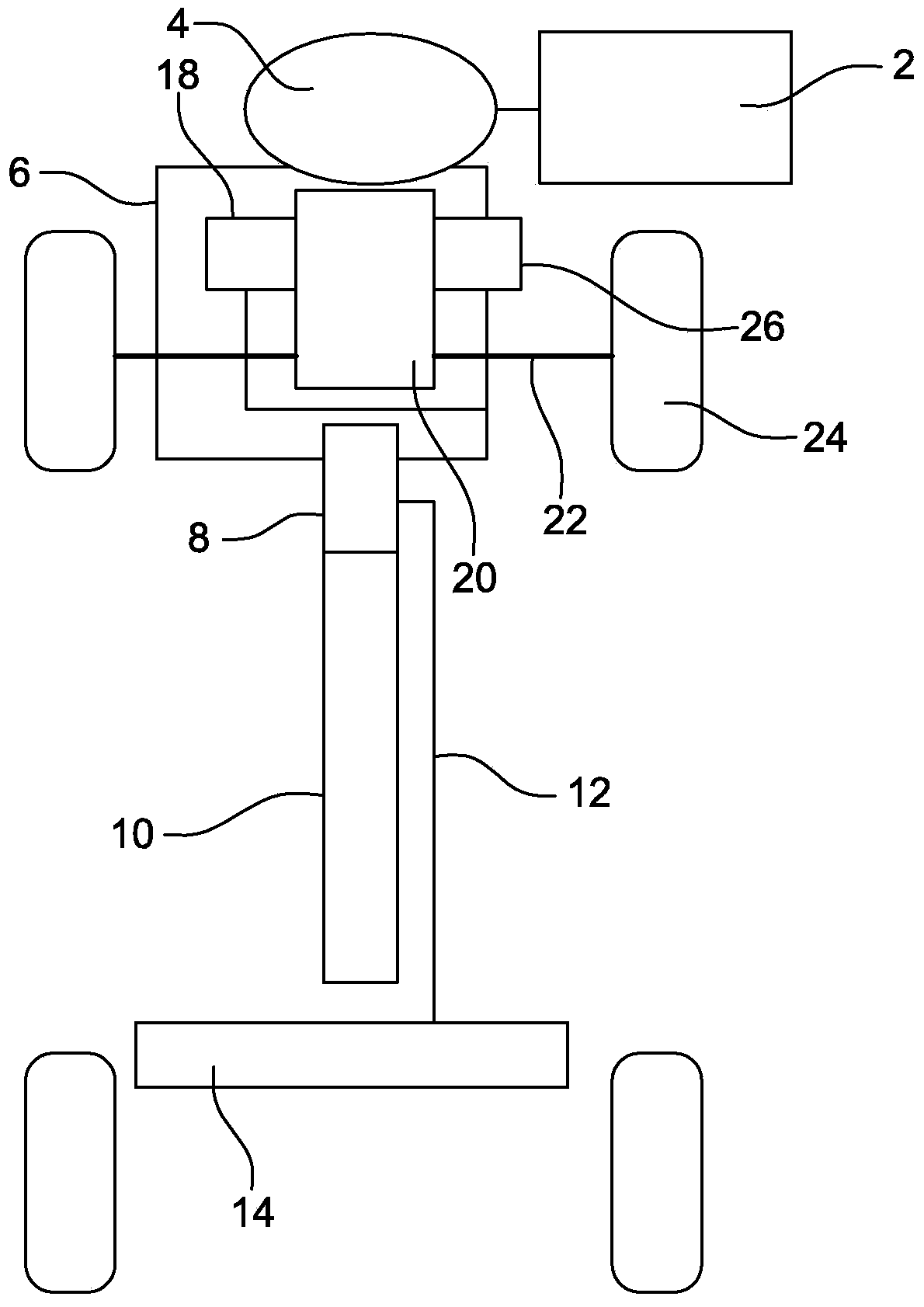

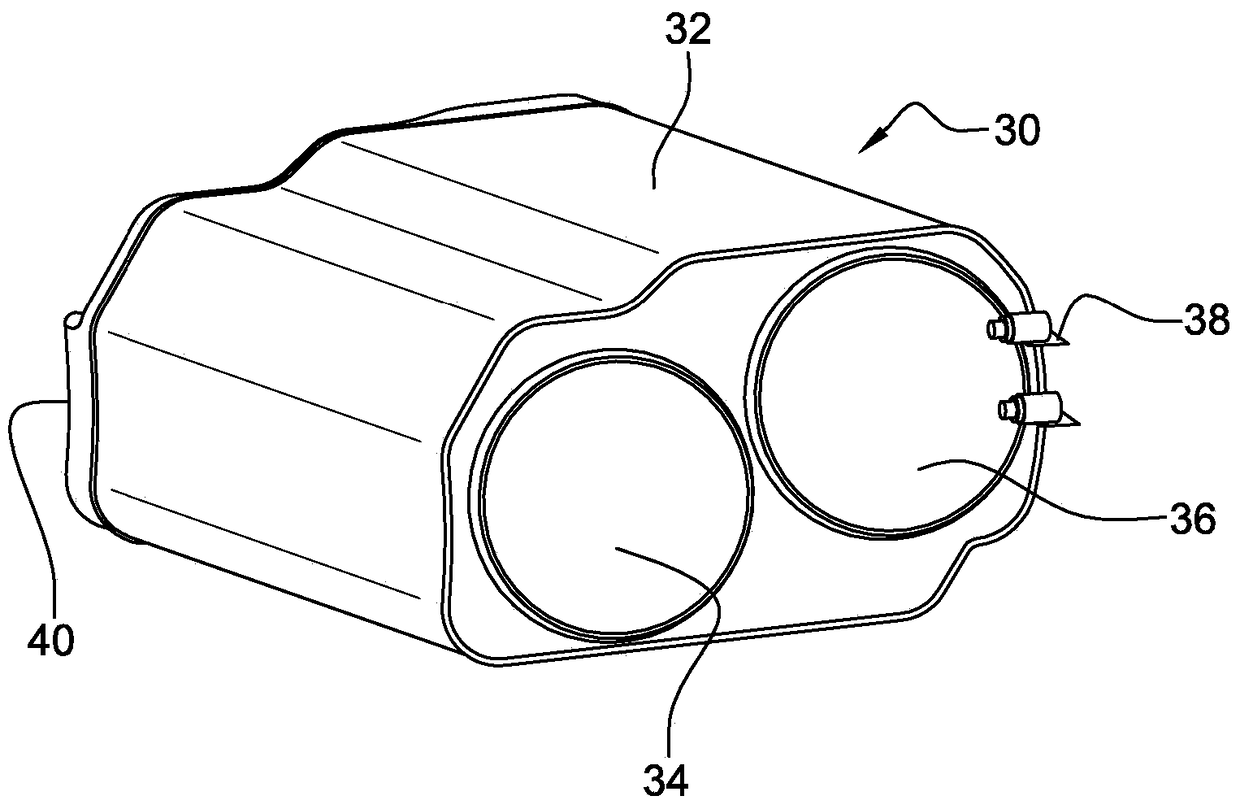

ActiveCN104903131AFlat installationStrong standardizationGas pressure propulsion mountingVehicle sub-unit featuresComputer moduleHigh pressure

A hydraulic module designed to be mounted on a hydraulic hybrid vehicle, characterised in that it forms a rigid and compact assembly comprising a body (32) receiving the high- and low-pressure accumulators intended to supply traction motors of the vehicle, comprising a generally parallelepipedal shape, and having attachment means designed to be fixed under a floor at the rear of the vehicle.

Owner:TECHNOBOOST

Hydraulic modules including high and low pressure accumulators for hybrid vehicles

ActiveCN104903131BFlat installationStrong standardizationHybrid vehiclesGas pressure propulsion mountingHigh pressureHybrid vehicle

A hydraulic module designed to be mounted on a hydraulic hybrid vehicle, characterized in that the hydraulic module forms a rigid, compact assembly comprising a body (32) receiving high and low pressure accumulators, said high-pressure and low-pressure accumulators intended to supply the traction motor of the vehicle, said assembly comprising a substantially parallelepiped shape and having attachment means designed to be fixed at the rear of the vehicle to below the floor.

Owner:TECHNOBOOST

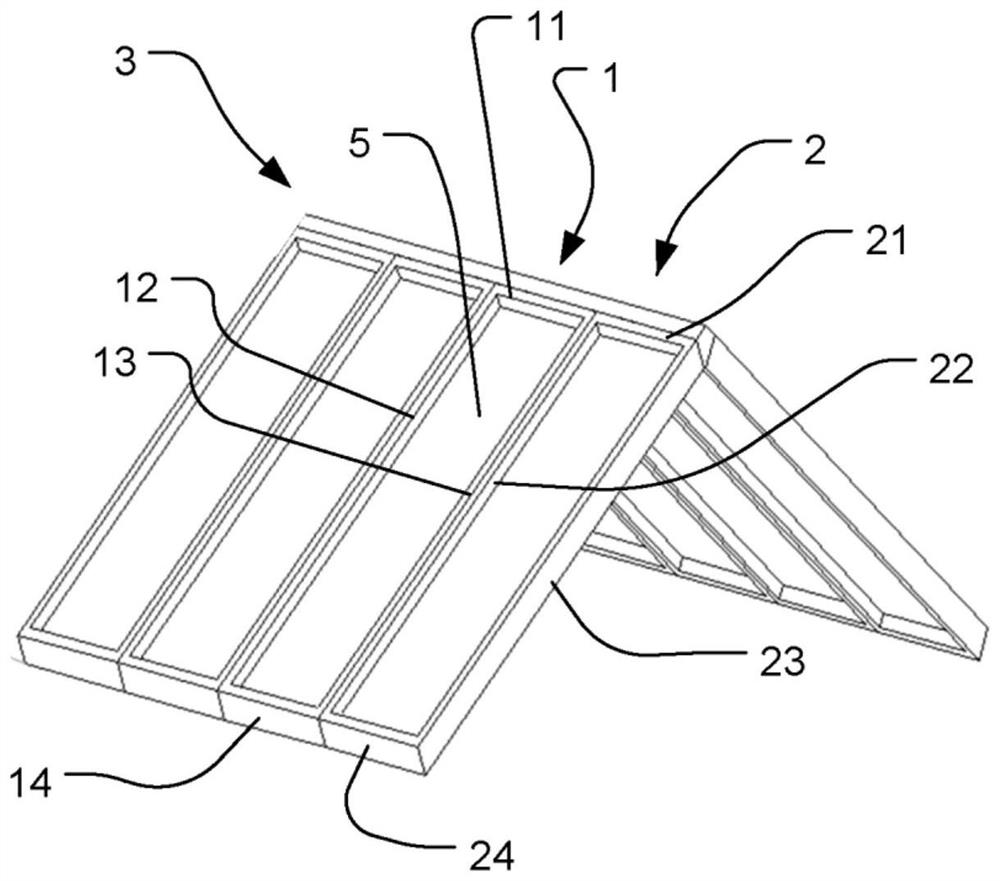

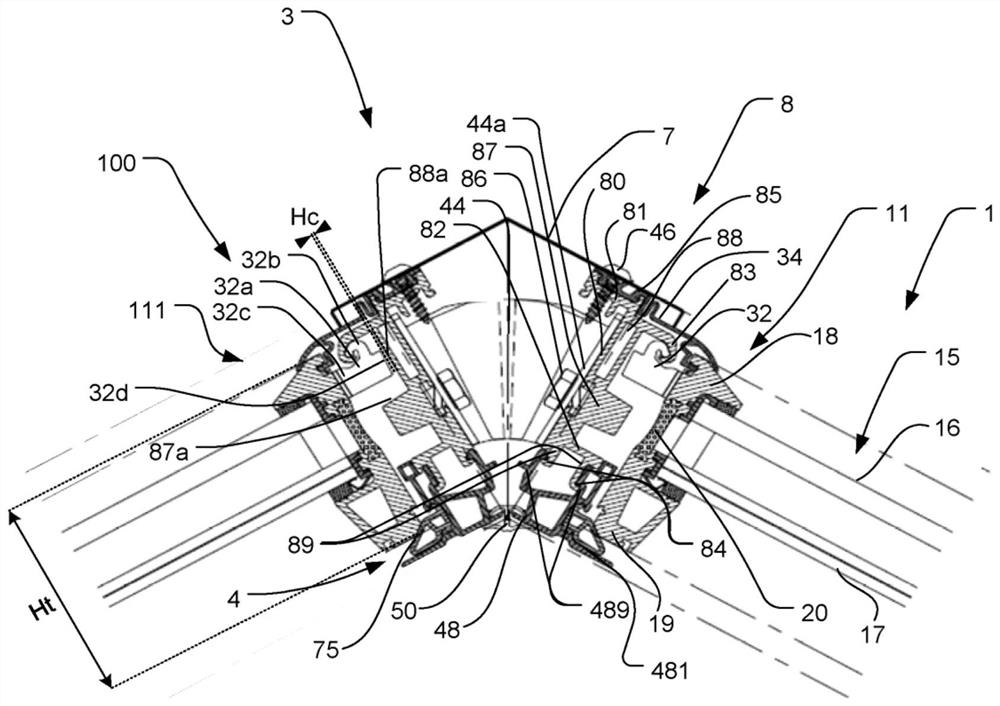

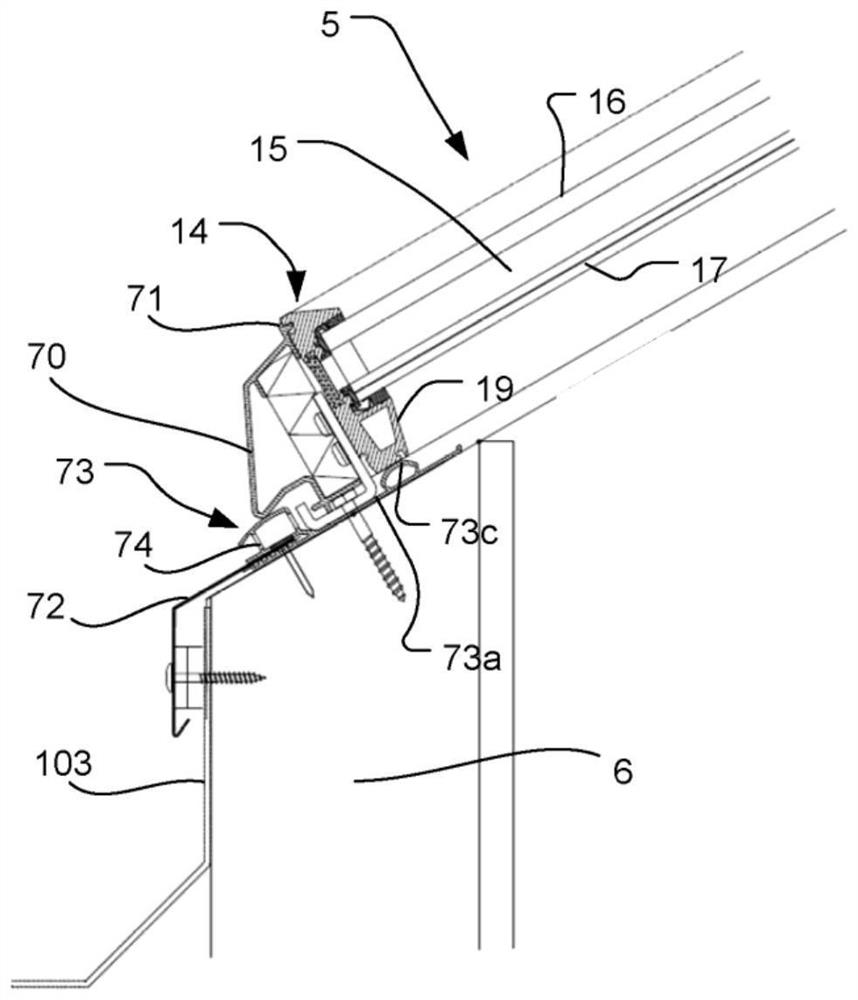

Panel system having mounting and hinge assembly with mounting profile and hinge

The invention relates to a panel system (3), comprising a plurality of fixed panels (1) and a plurality of openable panels (2). Each fixed panel (1) and each openable panel (2) comprise a frame structure consisting of a set of profile elements (11, 12, 13, 14, 21, 22, 23, 24) surrouding panel elements (5; 15; 15'), and said frame structure comprises a top profile element (11, 21) configured to be connected to a support structure by means of a mounting and hinge assembly. The mounting and hinge assembly comprises a mounting profile (9) and a hinge (25), and the hinge (25) is configured as a connecting element between the mounting profile (9) and the top profile elements (11, 21) of each fixed panel (1) and each openable panel (2).

Owner:VKR HLDG AS

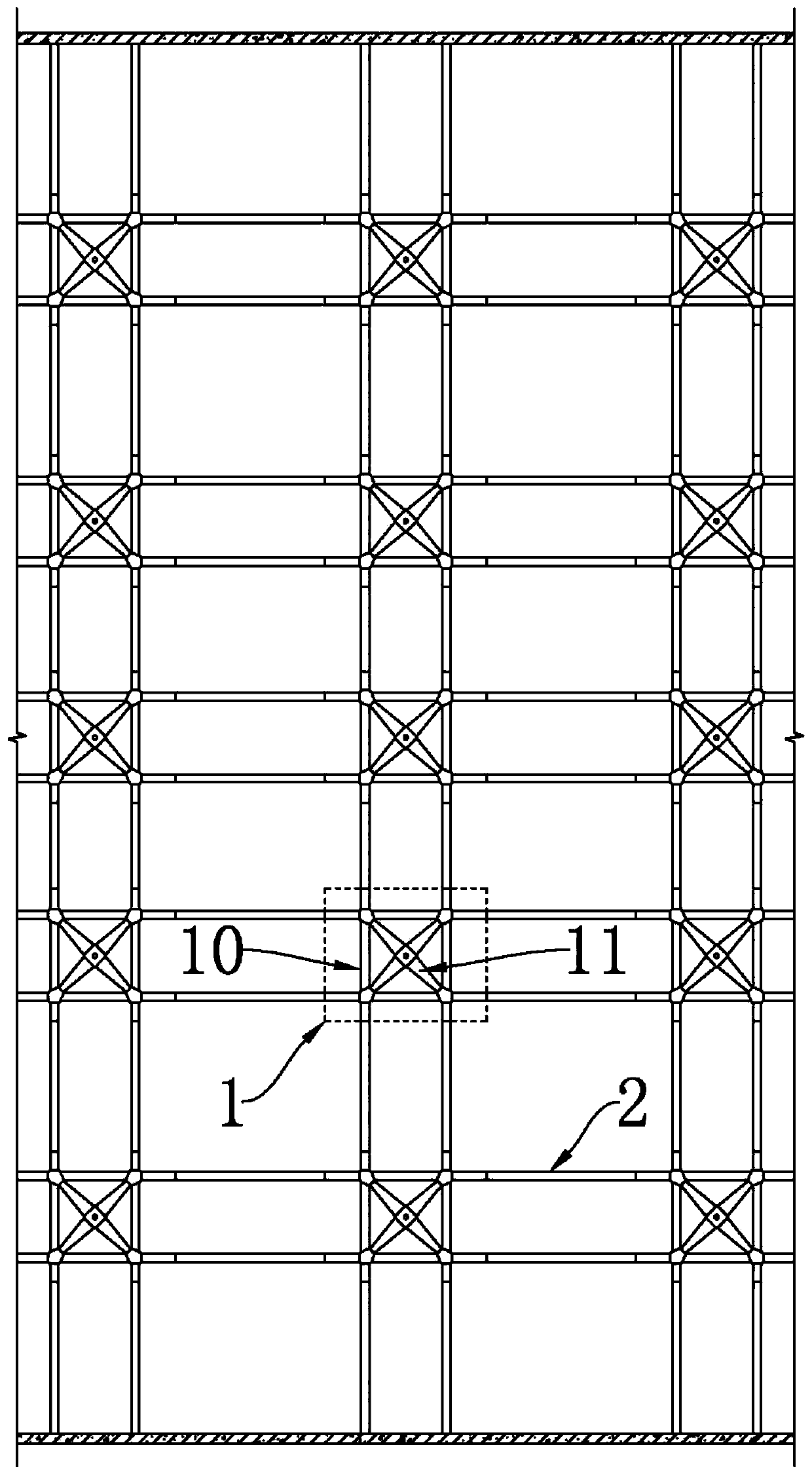

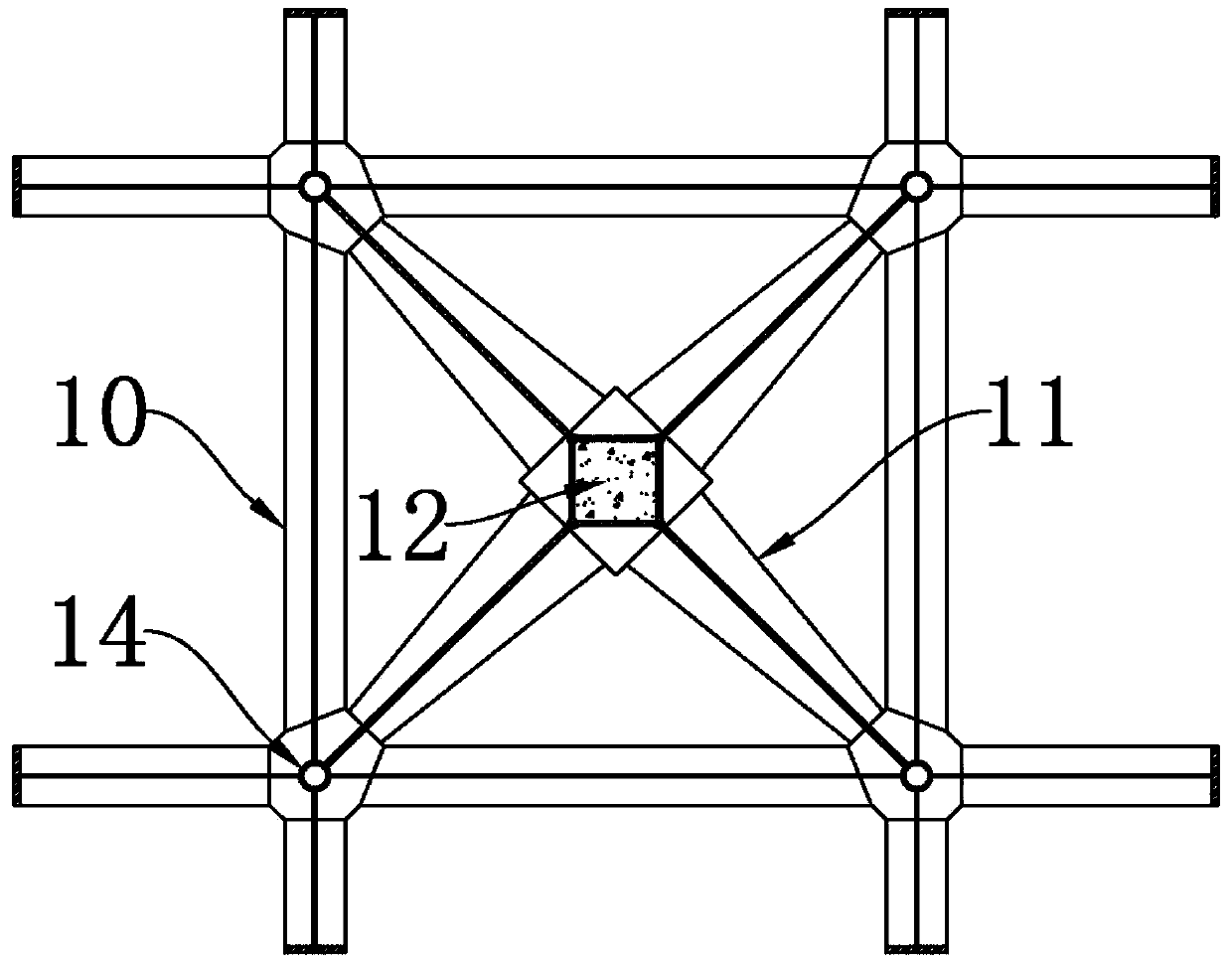

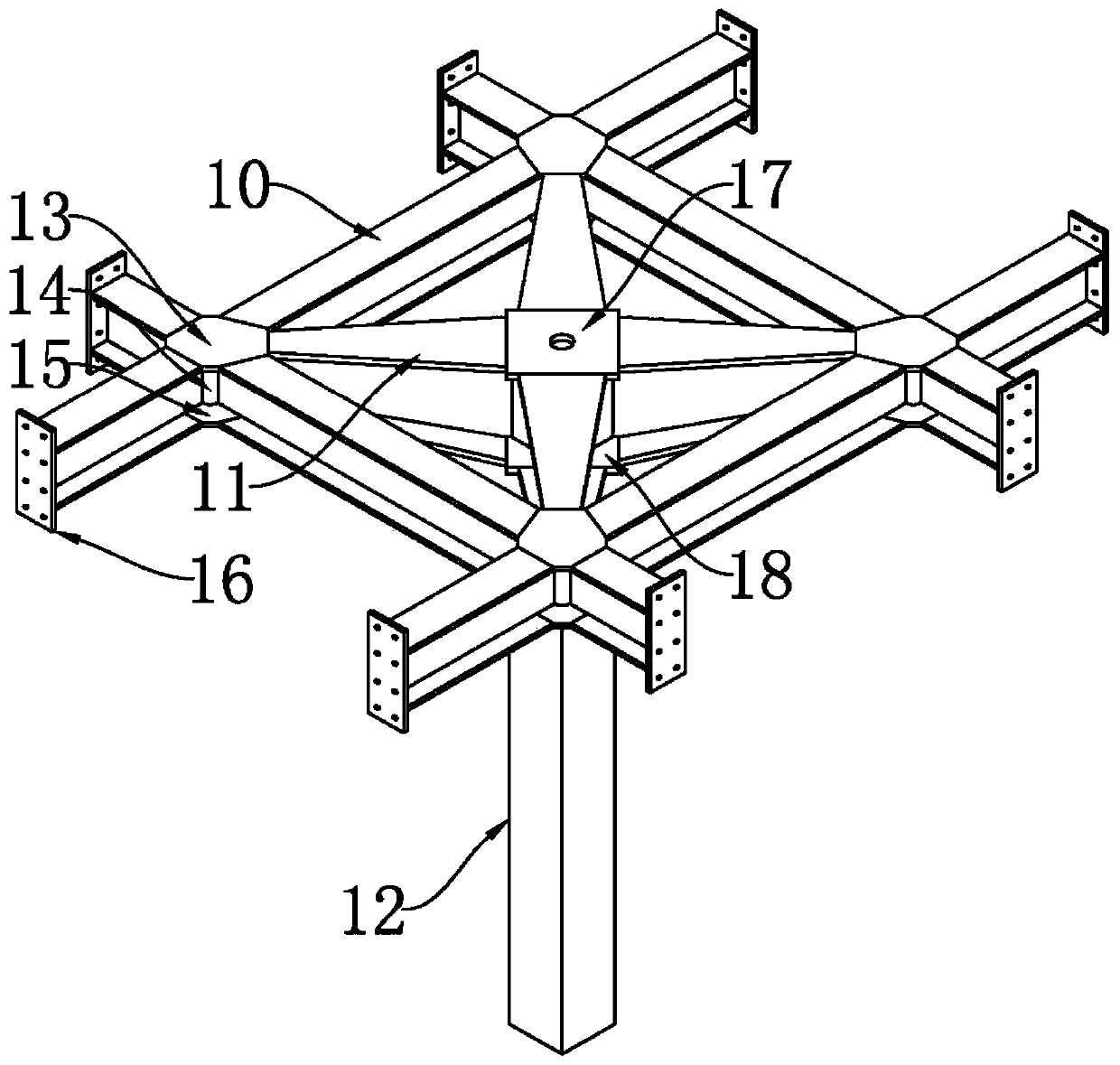

A double girder floor structure

Owner:杨大刚

Sika deer identifying primer and method and application

InactiveCN108148916AAccurate identificationSolve the bottleneck problemMicrobiological testing/measurementDNA/RNA fragmentationAgricultural scienceNucleic acid

The invention relates to a sika deer identifying primer and method and application, and belongs to the technical field of species identification. The identifying primer comprises an inner primer FIP:TGTCCTATACACCGATTTATGTGCTGCAAAACACGTGATATAACCT, an inner primer BIP: TGCCCCATGCTTATAAGCATGTGTACGATGAACAACATCATG, an outer primer F3: TCTATGTCCTACTAATTACAC, an outer primer B3: GACTGATTTGACTTAATGCAC, aloop primer LF: ACACGTGTGTCTTAATGTAC, and a loop primer LB: TCCTATCATTTATAGTACATAGT. By the primer, sika deer nucleic acid can be specifically amplified rapidly, and the bottleneck difficulty on identifying cartialgenous.

Owner:SHENZHEN INST FOR DRUG CONTROL SHENZHEN TESTING CENT OF MEDICAL DEVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com