Patents

Literature

388 results about "Hydraulic hybrid vehicle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

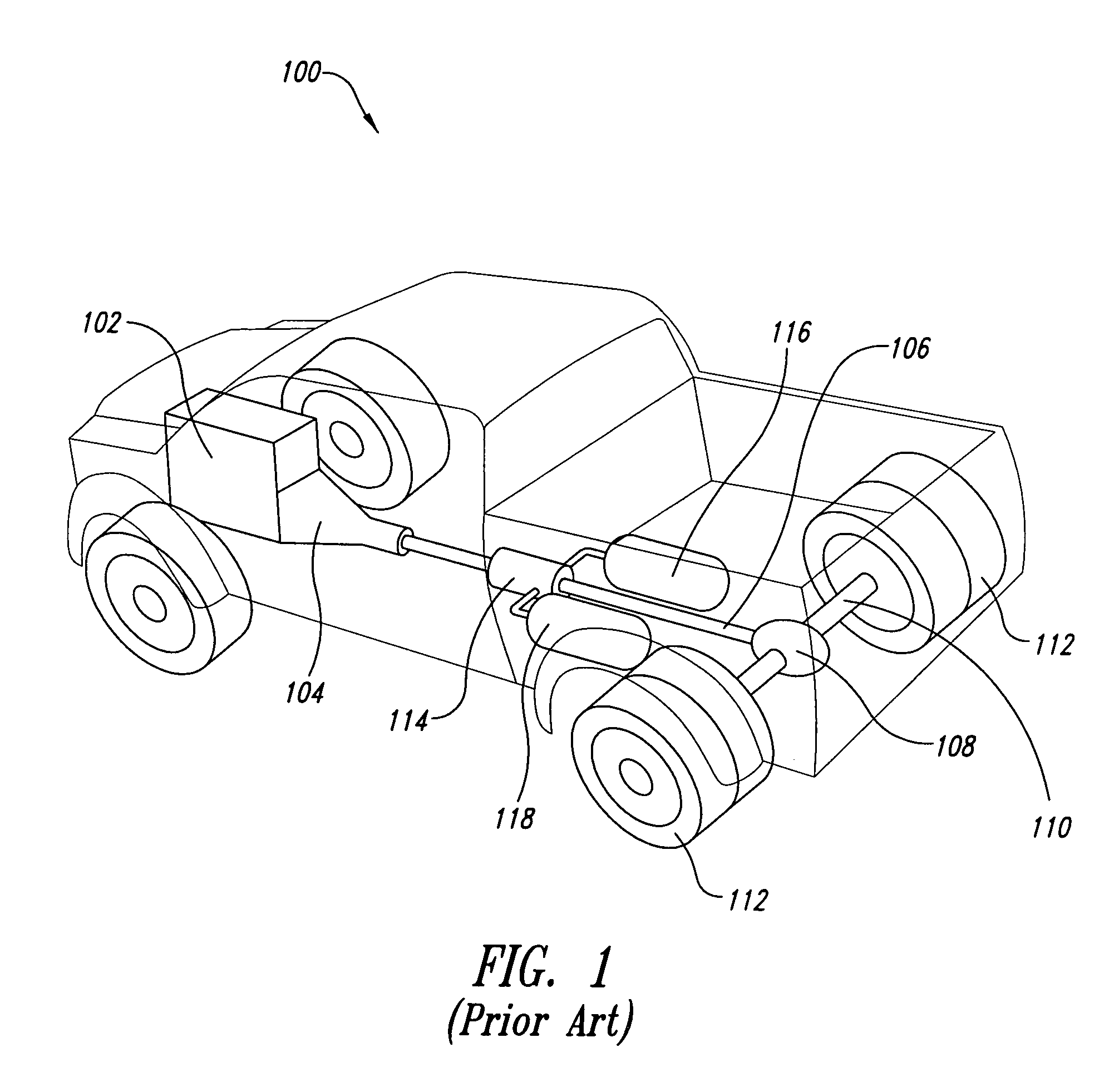

Hydraulic hybrid vehicles, or HHVs use a pressurized fluid power source, along with a conventional internal combustion engine (ICE), to achieve better fuel economy and reductions in harmful emissions. They capture and reuse 70% - 80% of the vehicle's braking/decelerating energy compared to 55% for electric hybrids. For trucks and buses, this can also be less expensive than electric systems, due to the price of batteries required for the latter. Hydraulic hybrid vehicle systems can also weigh less than electric systems, due to the high weight of the batteries. This can lead to a lower impact on payload capacity, especially for heavy vehicle classes.

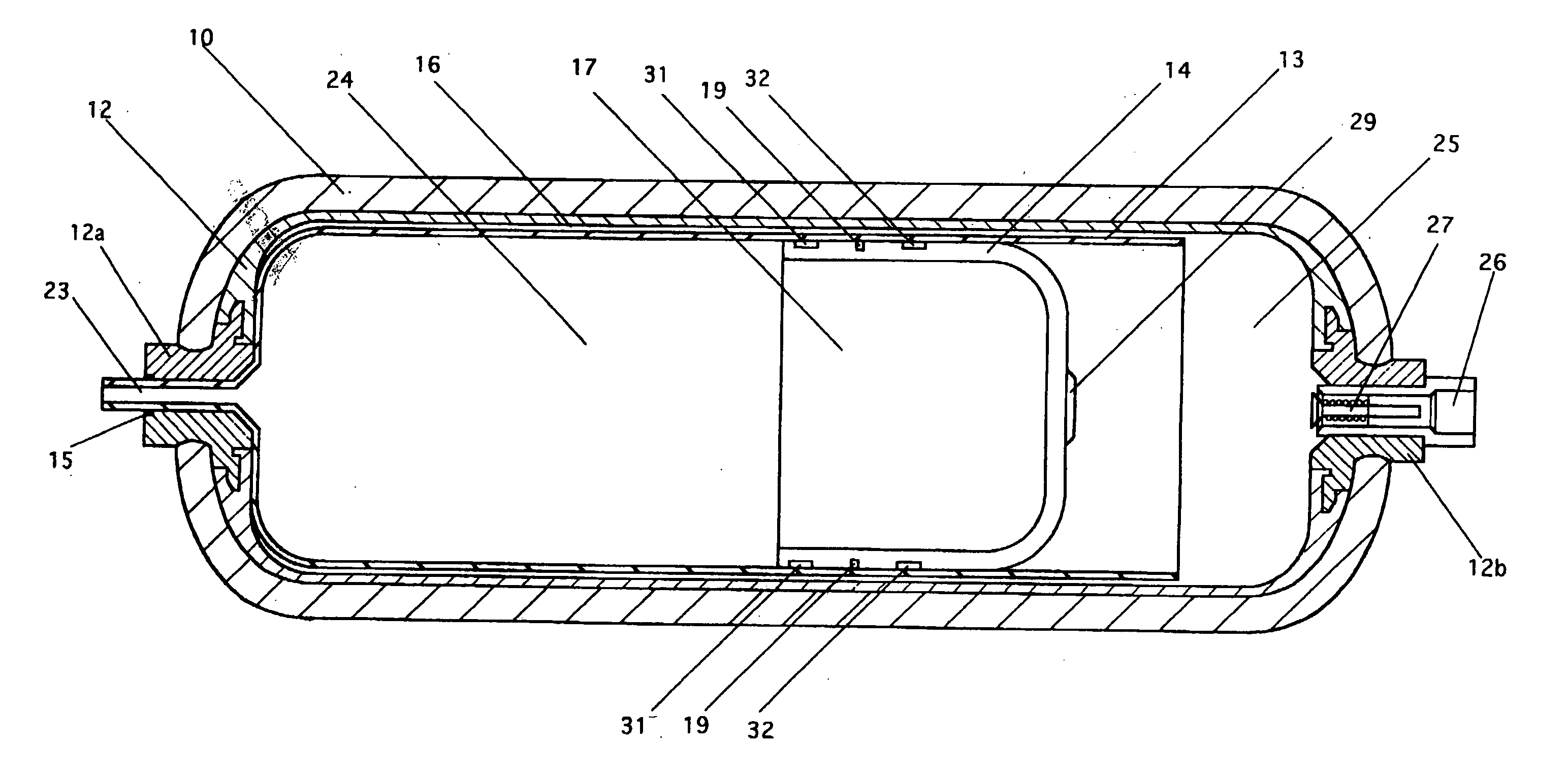

Compact hydraulic accumulator

InactiveUS20080308168A1Light weightEasy maintenanceFluid couplingsCheck valvesWorking fluidGas cylinder

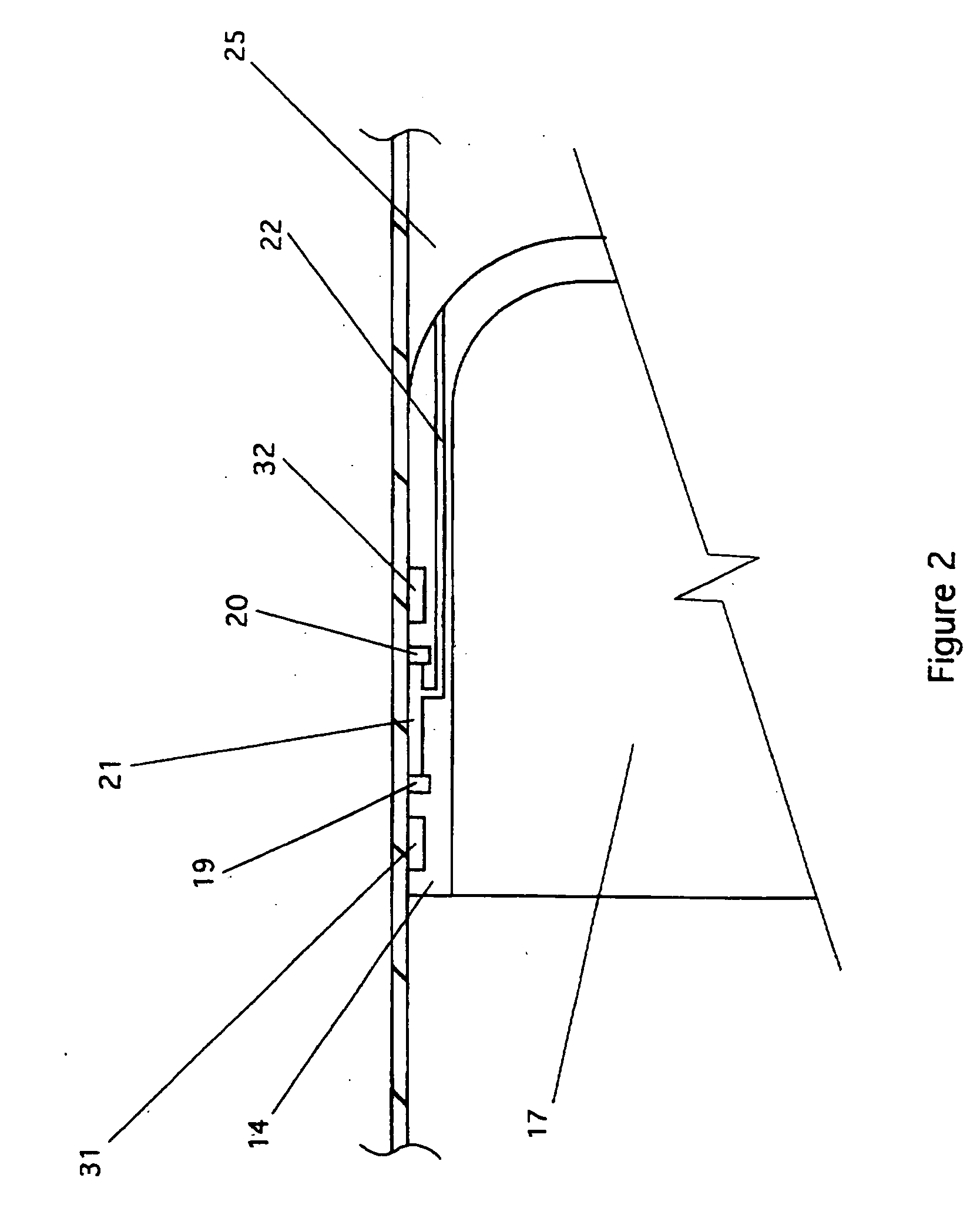

A lightweight, optimally efficient, easily serviced, piston-in-sleeve high pressure accumulator is provided. The accumulator includes one or more cylindrical composite pressure vessel separate end cap manifolds. A piston slidably disposed in a thin impermeable internal sleeve in the accumulator separates two chambers, one adapted for containing a working fluid and the other adapted for containing gas under pressure. Gas is provided in a volume between the impermeable internal sleeve and the composite pressure vessel wall. Additional gas is optionally provided in gas cylinders. Further components are provided for withstanding harmful effects of radial flexing of the composite vessel wall under high pressures, and from stresses present in use in mobile applications such as with a hydraulic power system for a hydraulic hybrid motor vehicle.

Owner:NRG ENTERPRISES

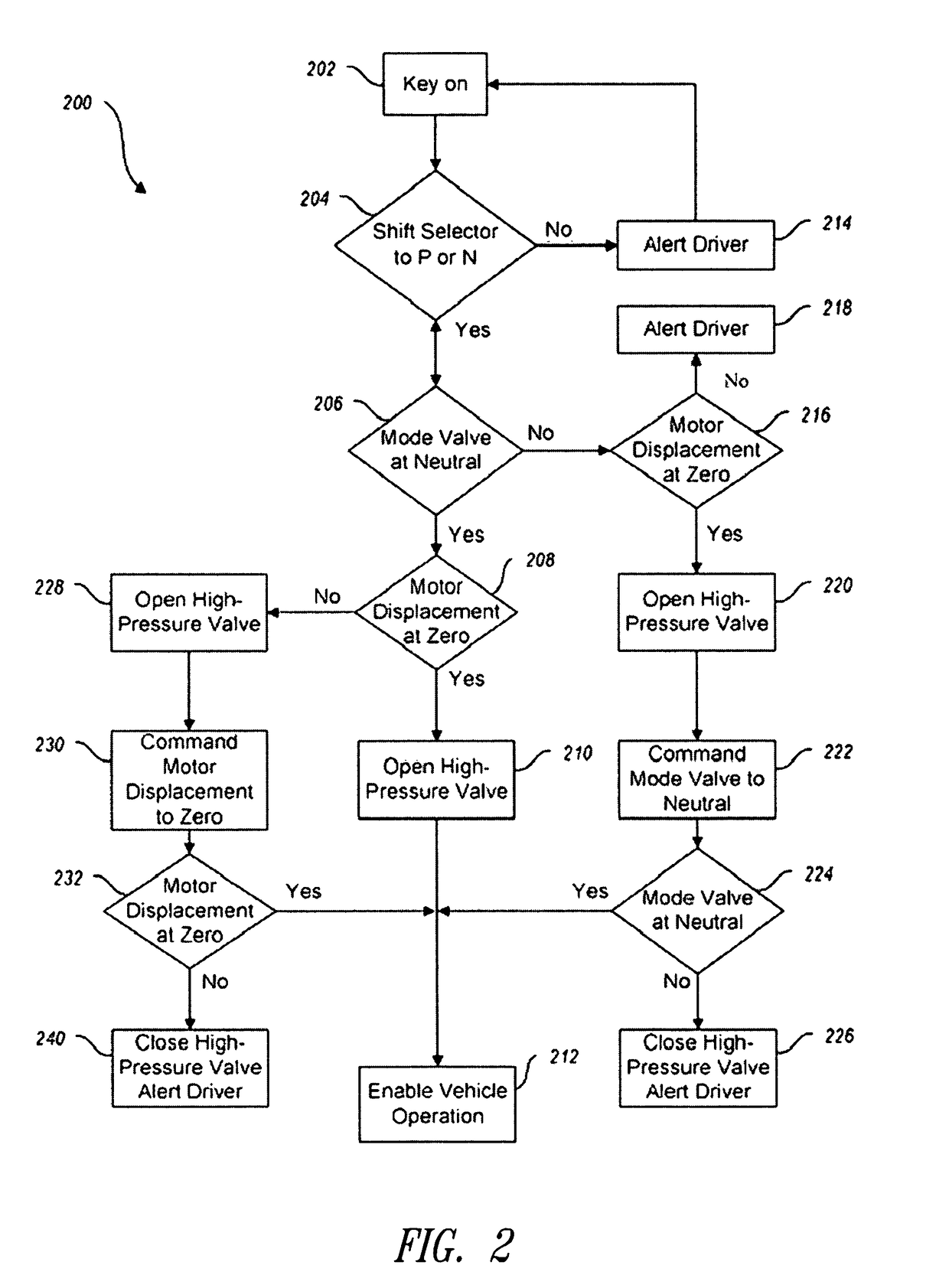

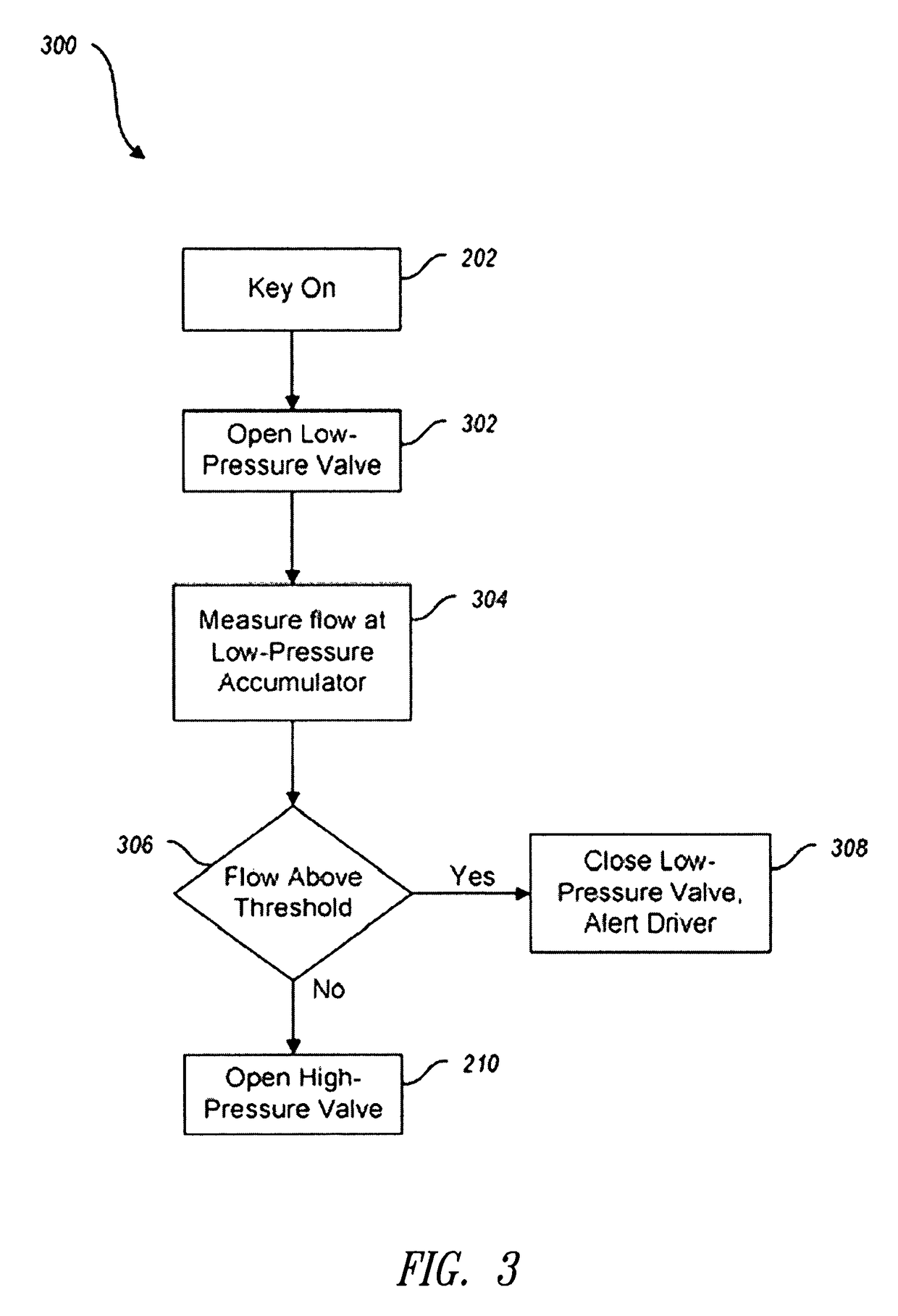

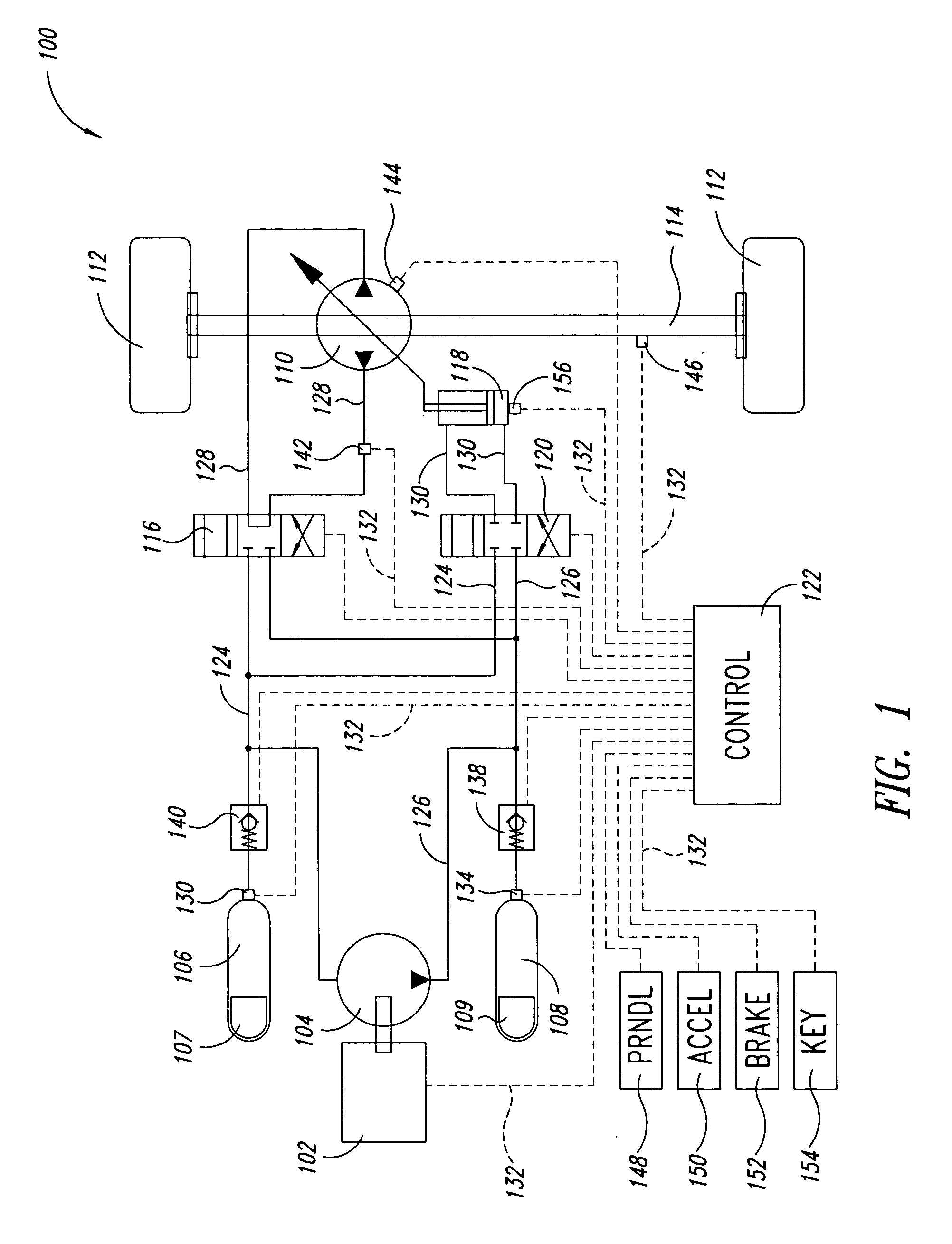

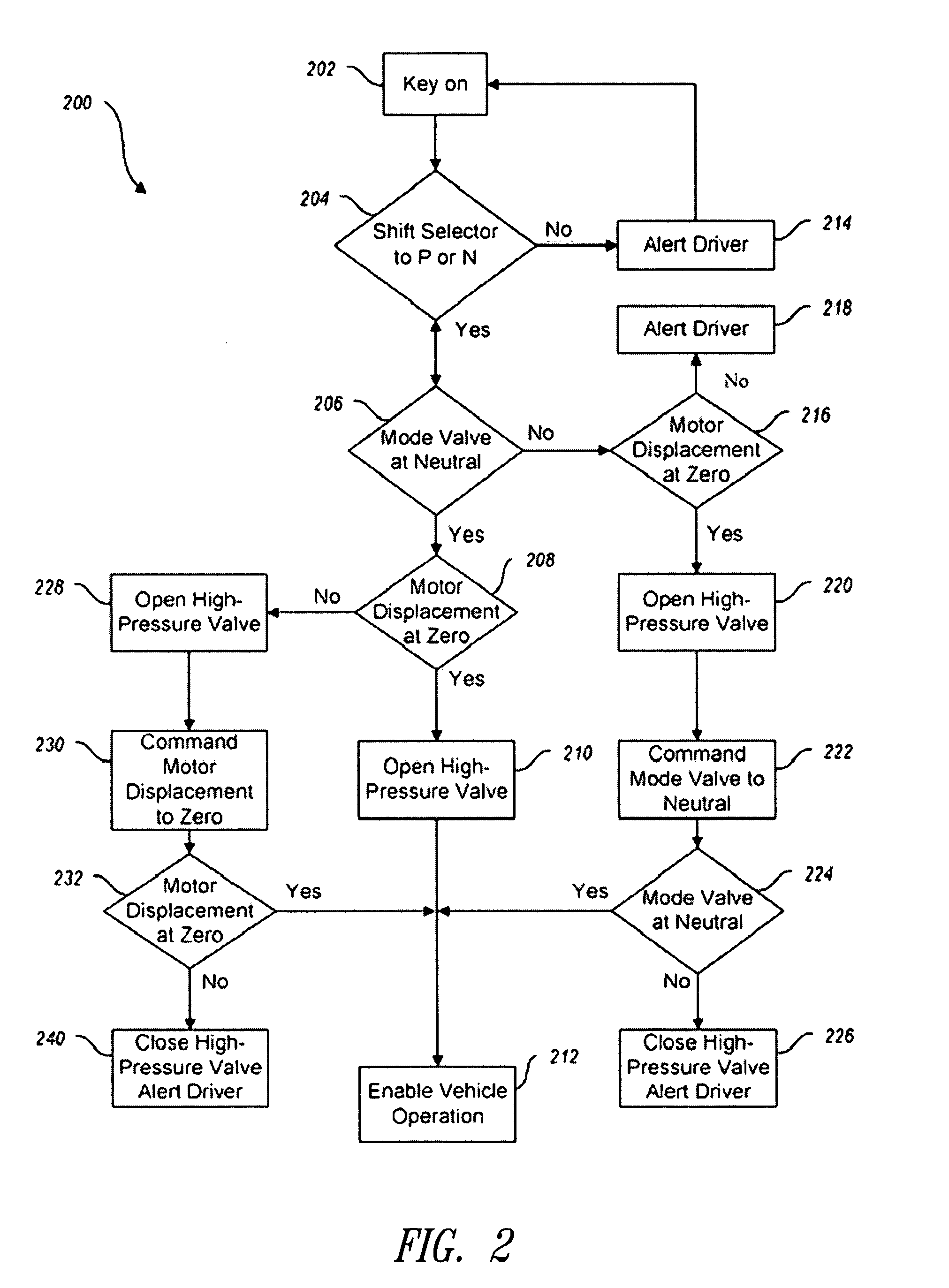

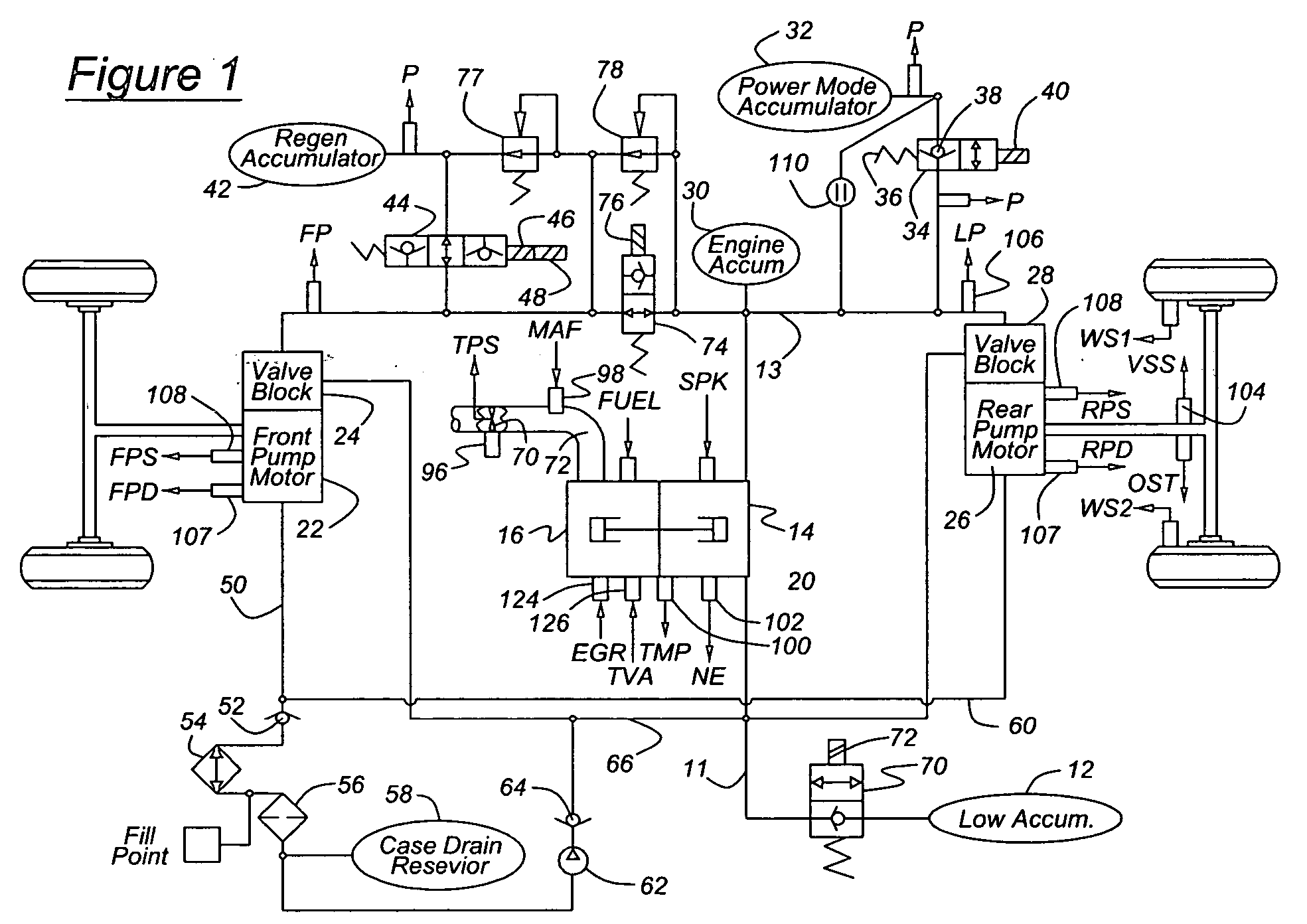

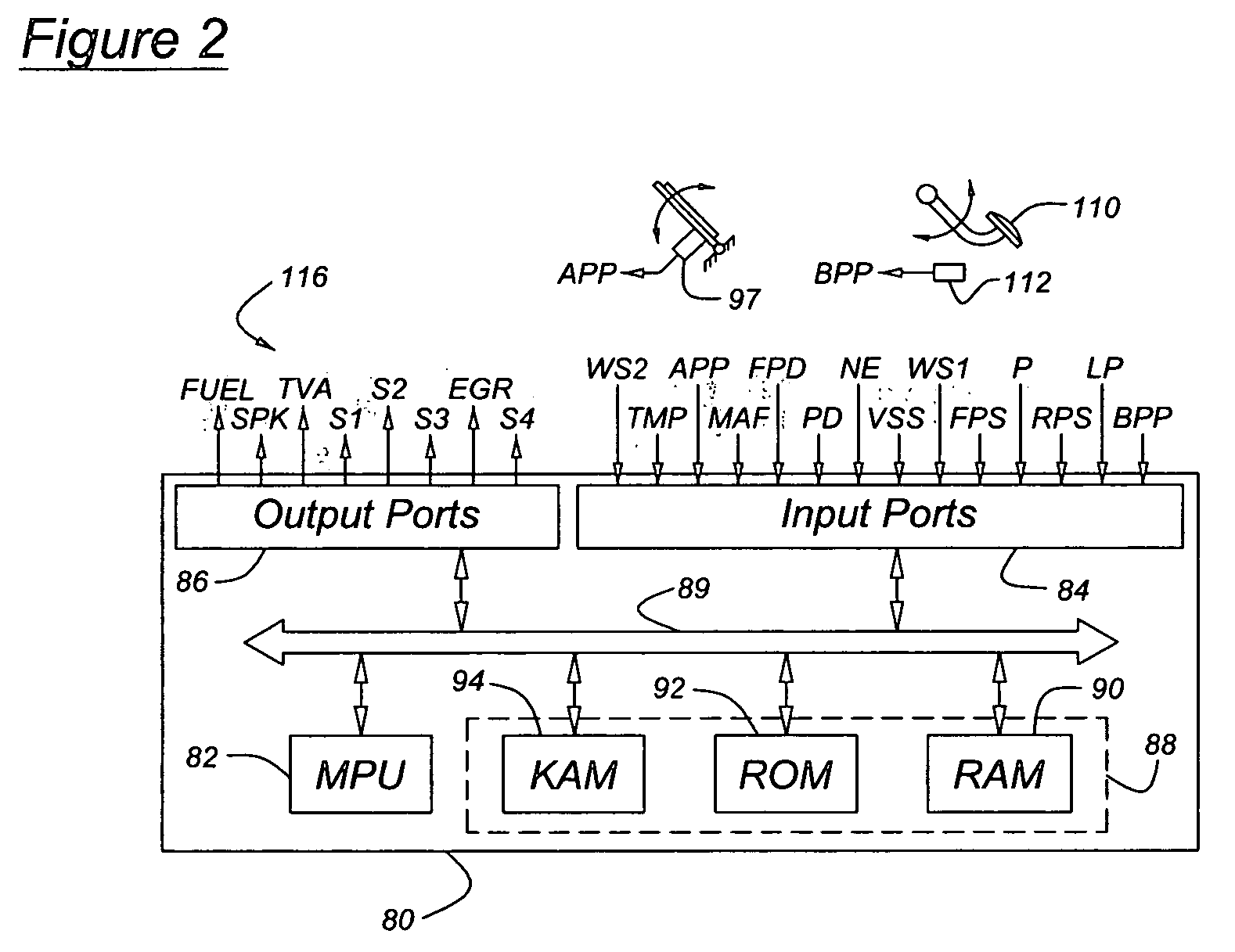

Hydraulic hybrid vehicle method of safe operation

InactiveUS8118132B2Gearing controlPlural diverse prime-mover propulsion mountingExternal combustion engineMode control

Owner:GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE ADMINISTATOR OF THE U S ENIVERONMENTAL PROTECTION AGENCY

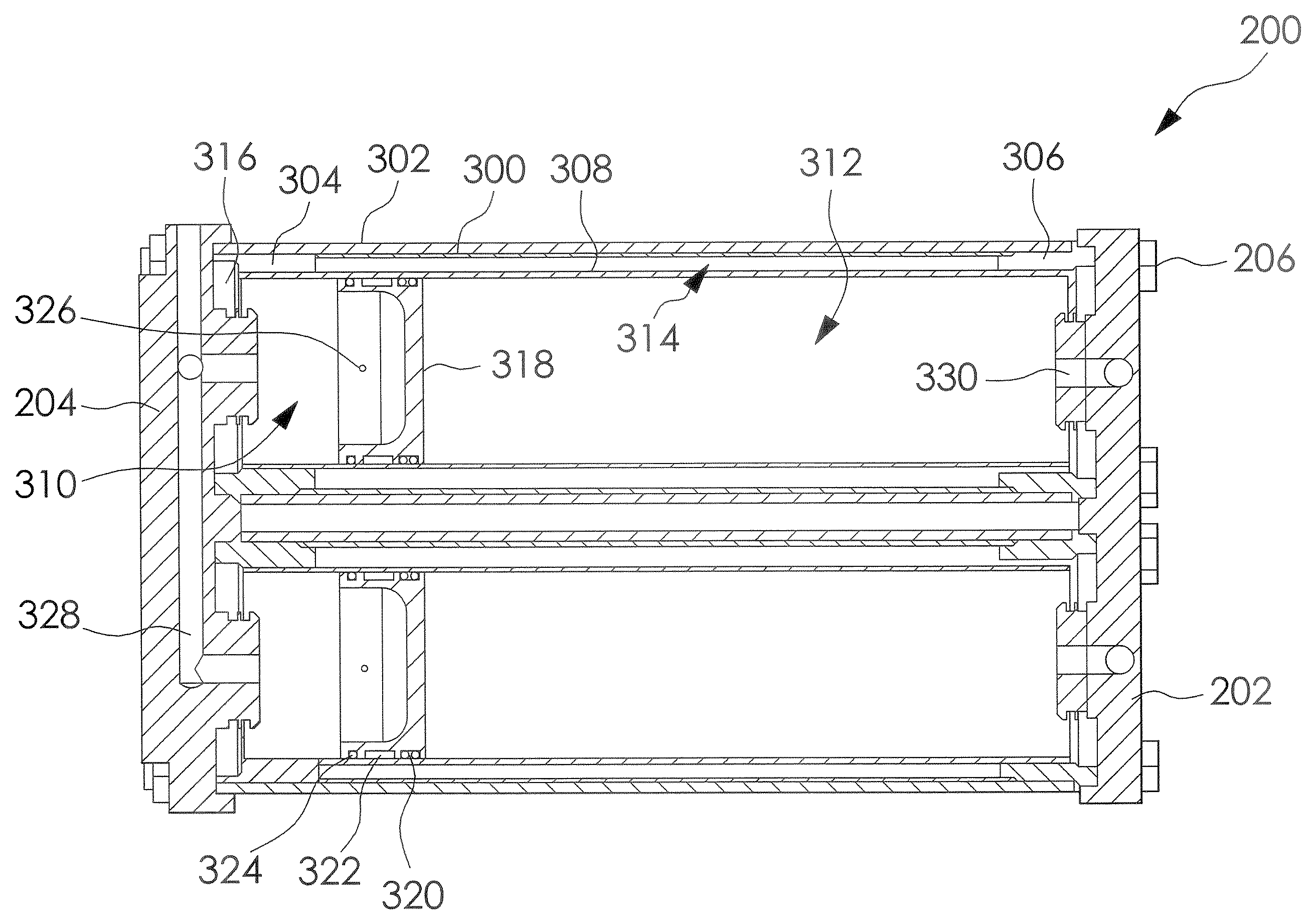

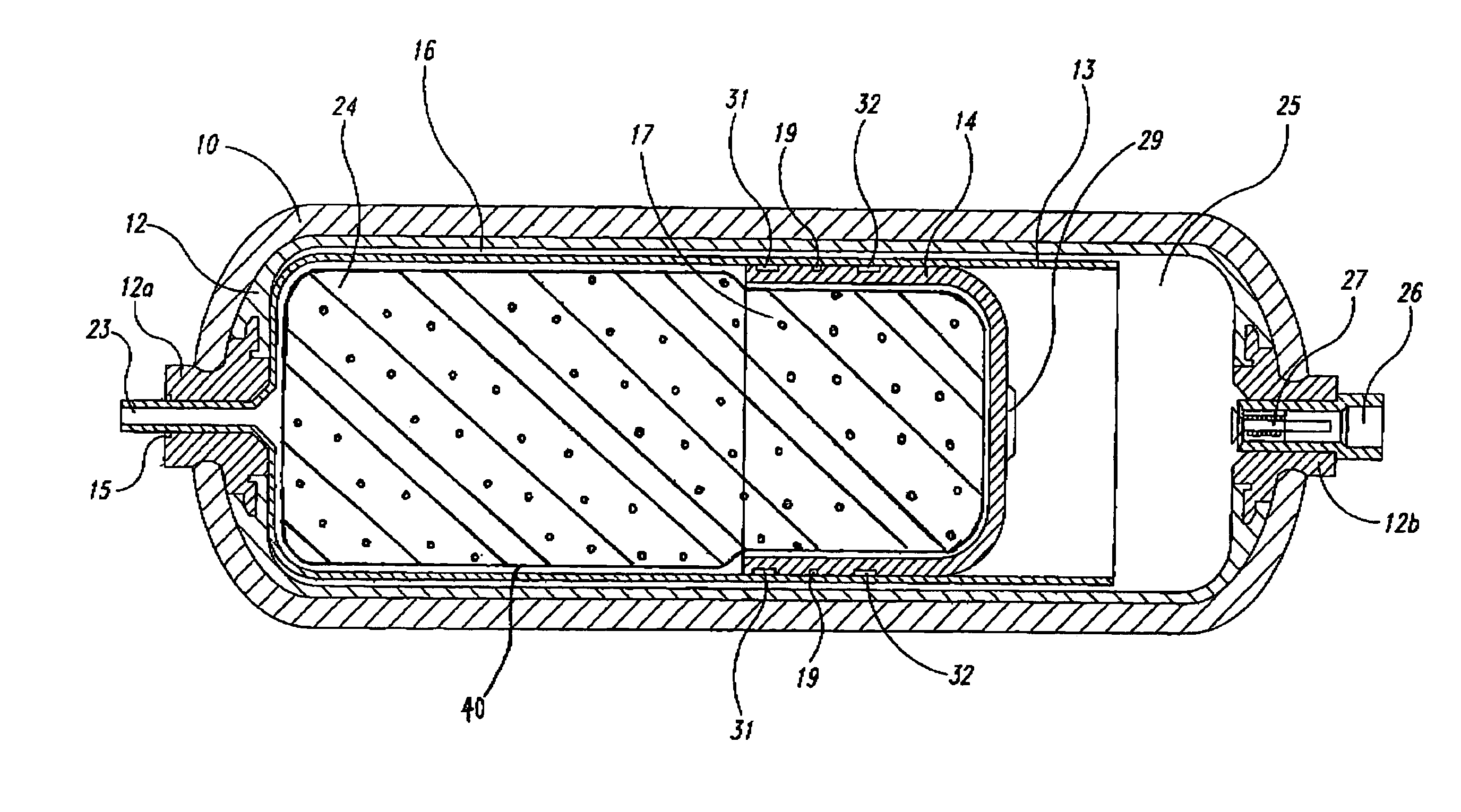

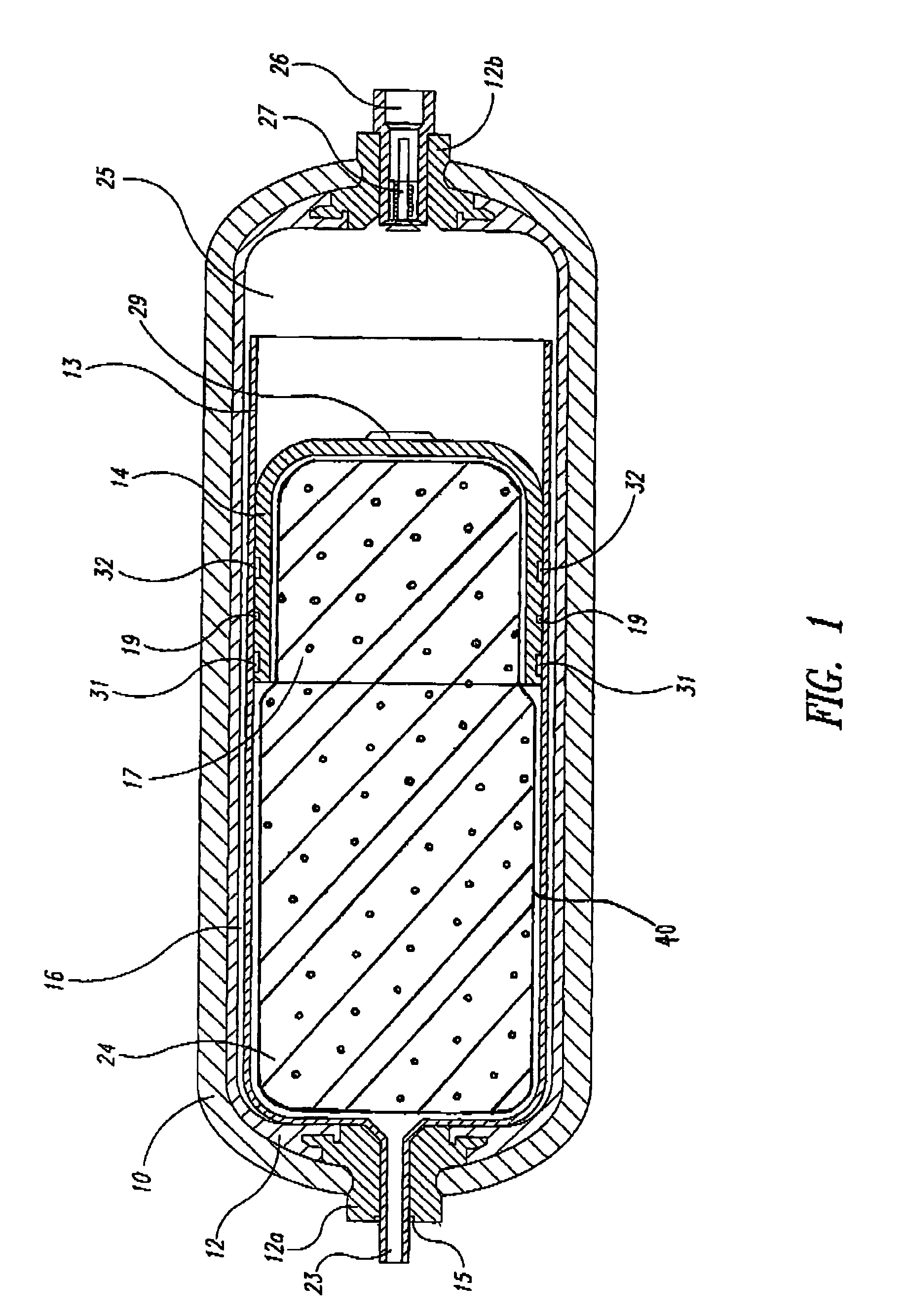

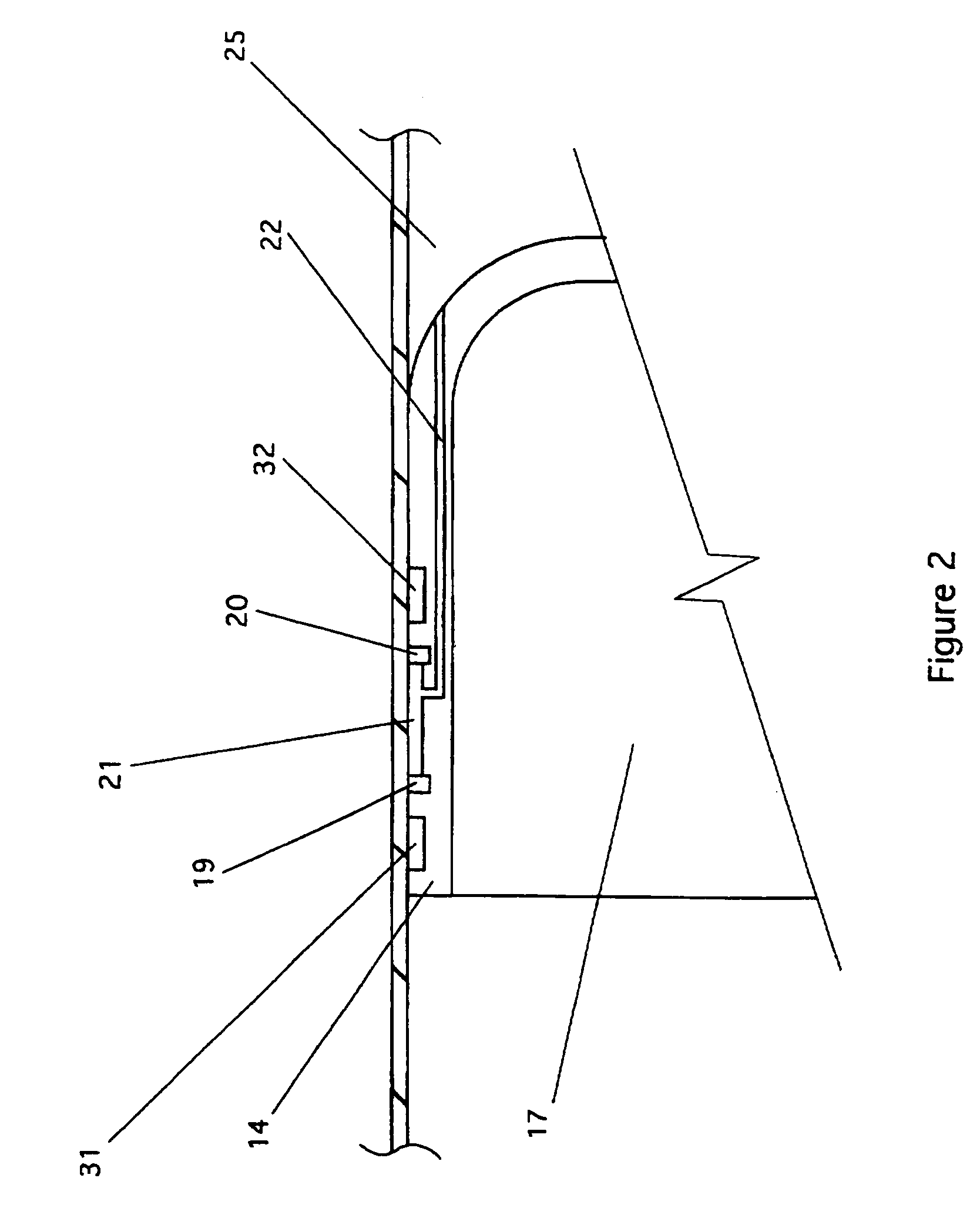

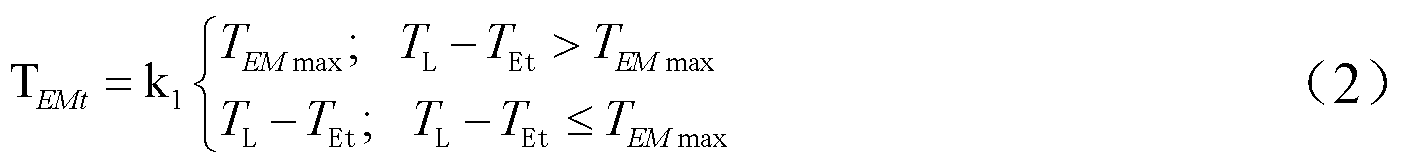

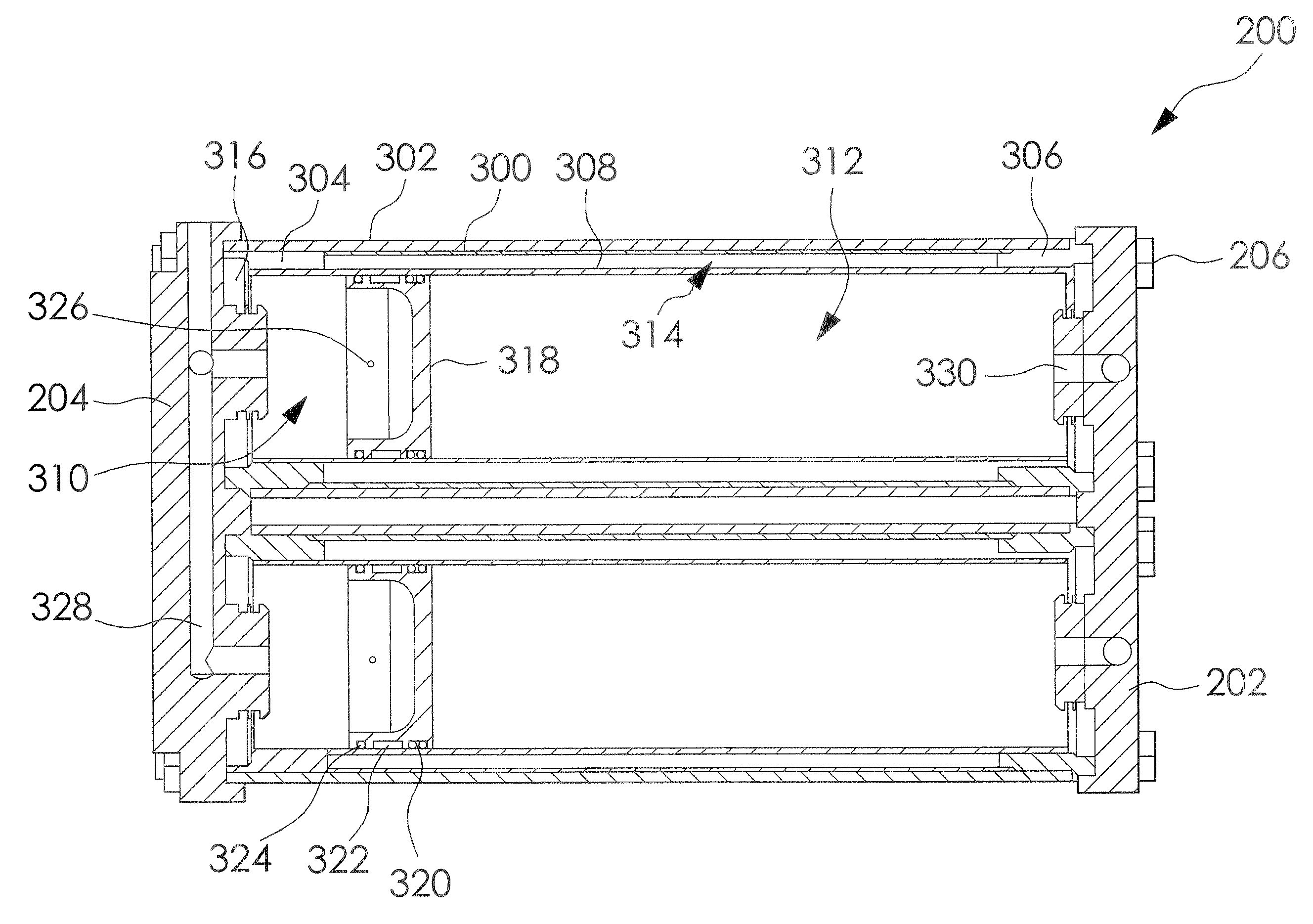

Lightweight low permeation piston-in-sleeve accumulator

Owner:UNITED STATES OF AMERICA

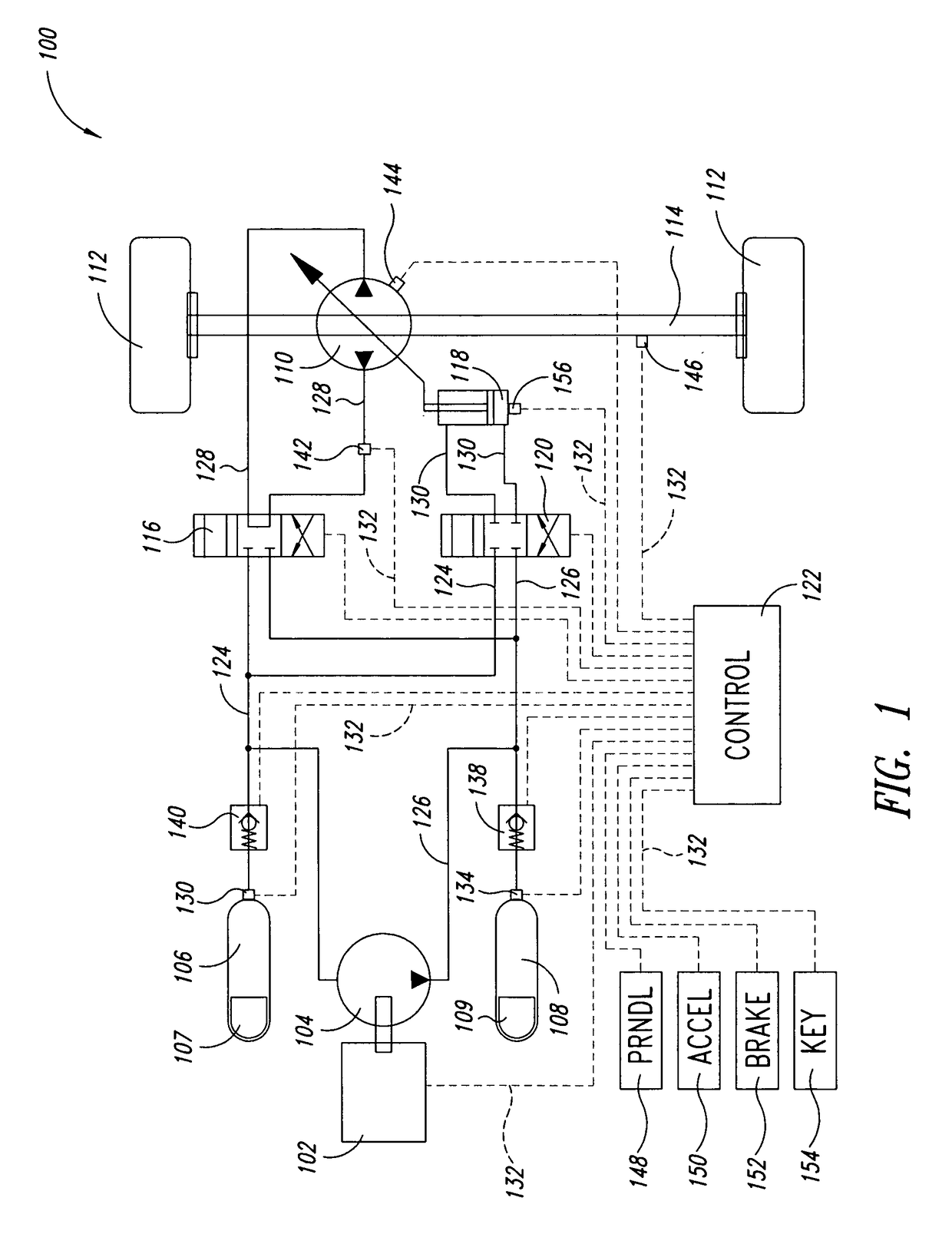

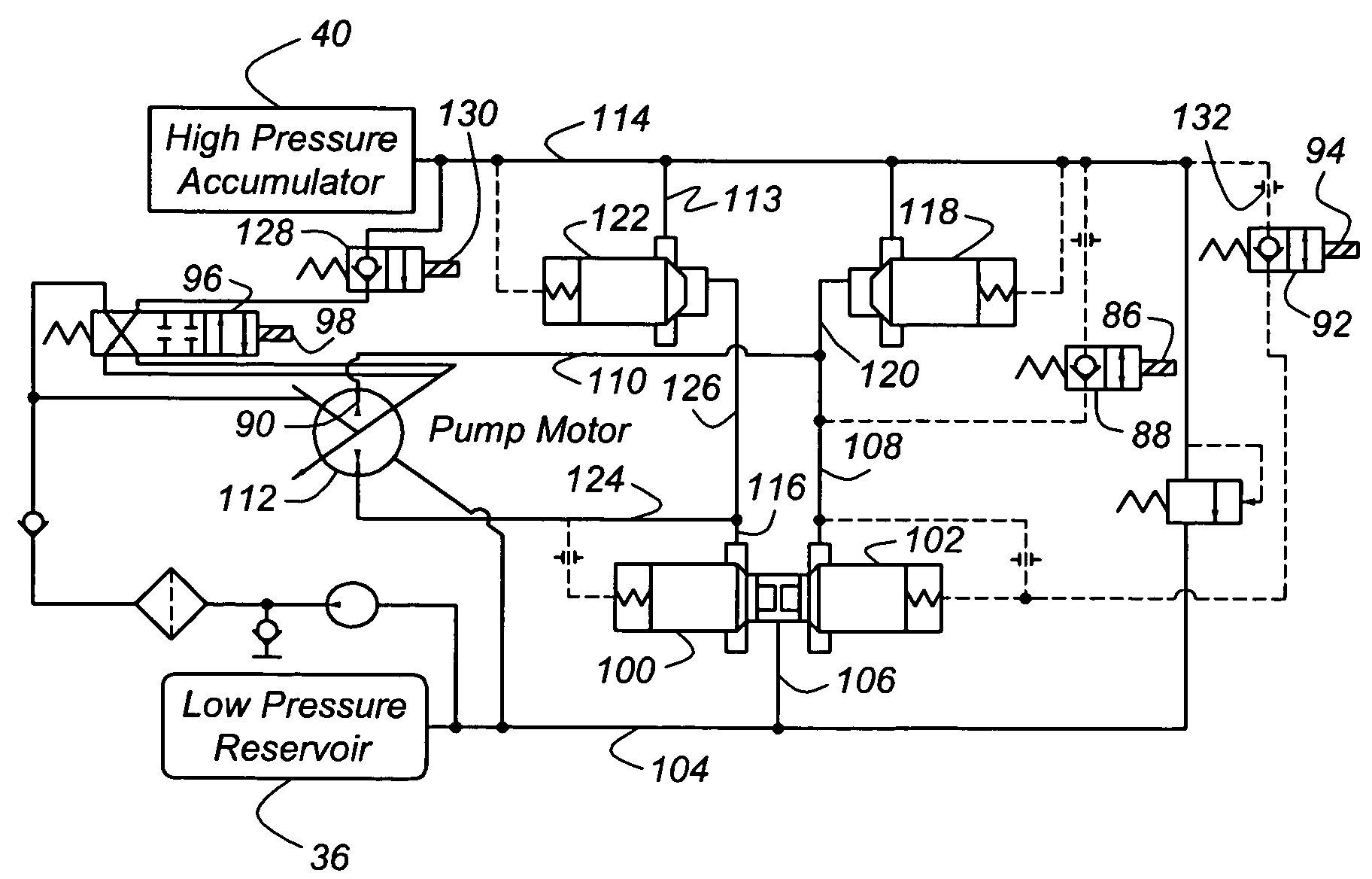

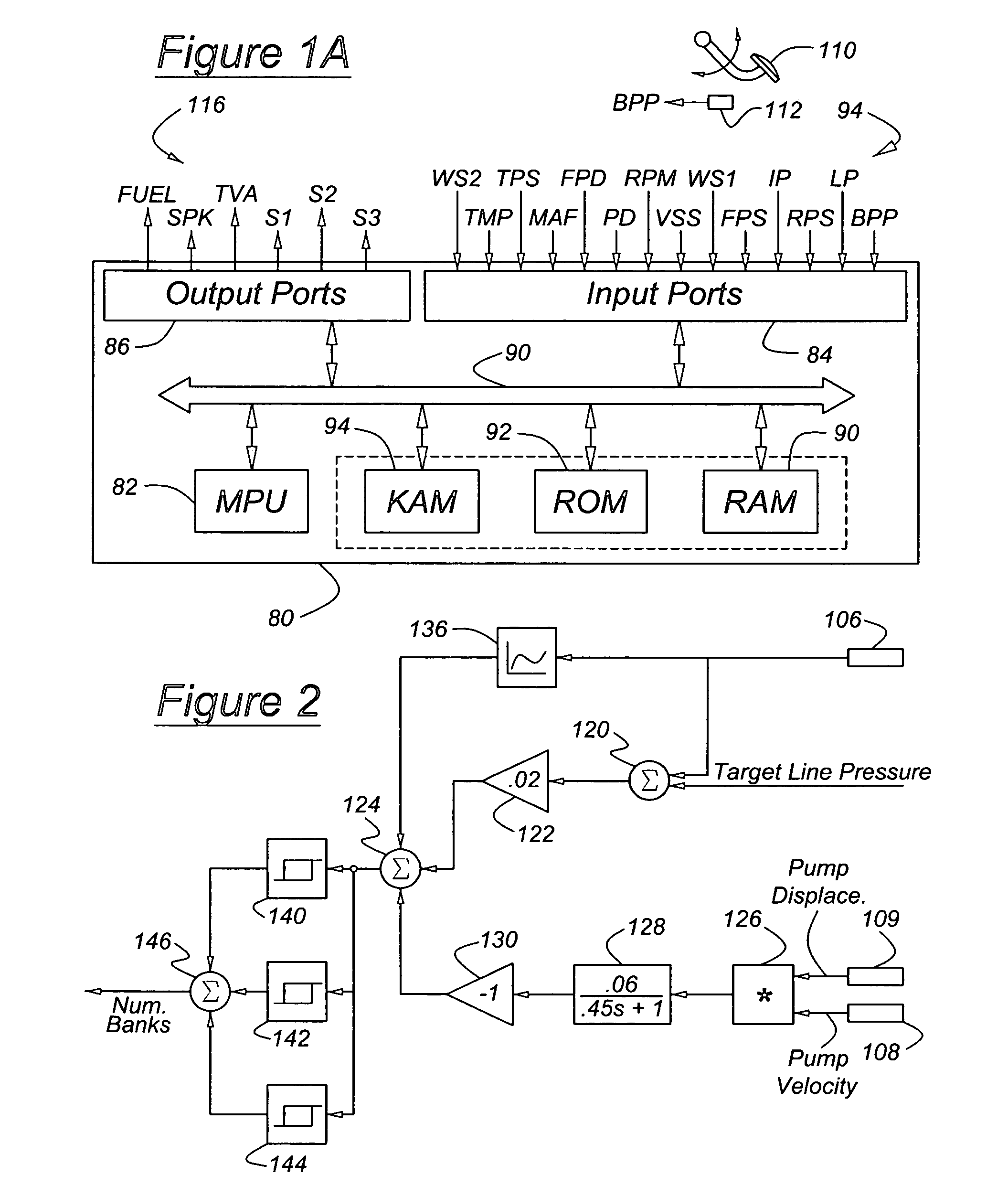

Pump/motor operating mode switching control for hydraulic hybrid vehicle

ActiveUS7082757B2Avoid vibration and noiseSlow pressureAuxillary drivesBraking element arrangementsMobile vehicleTransmitted power

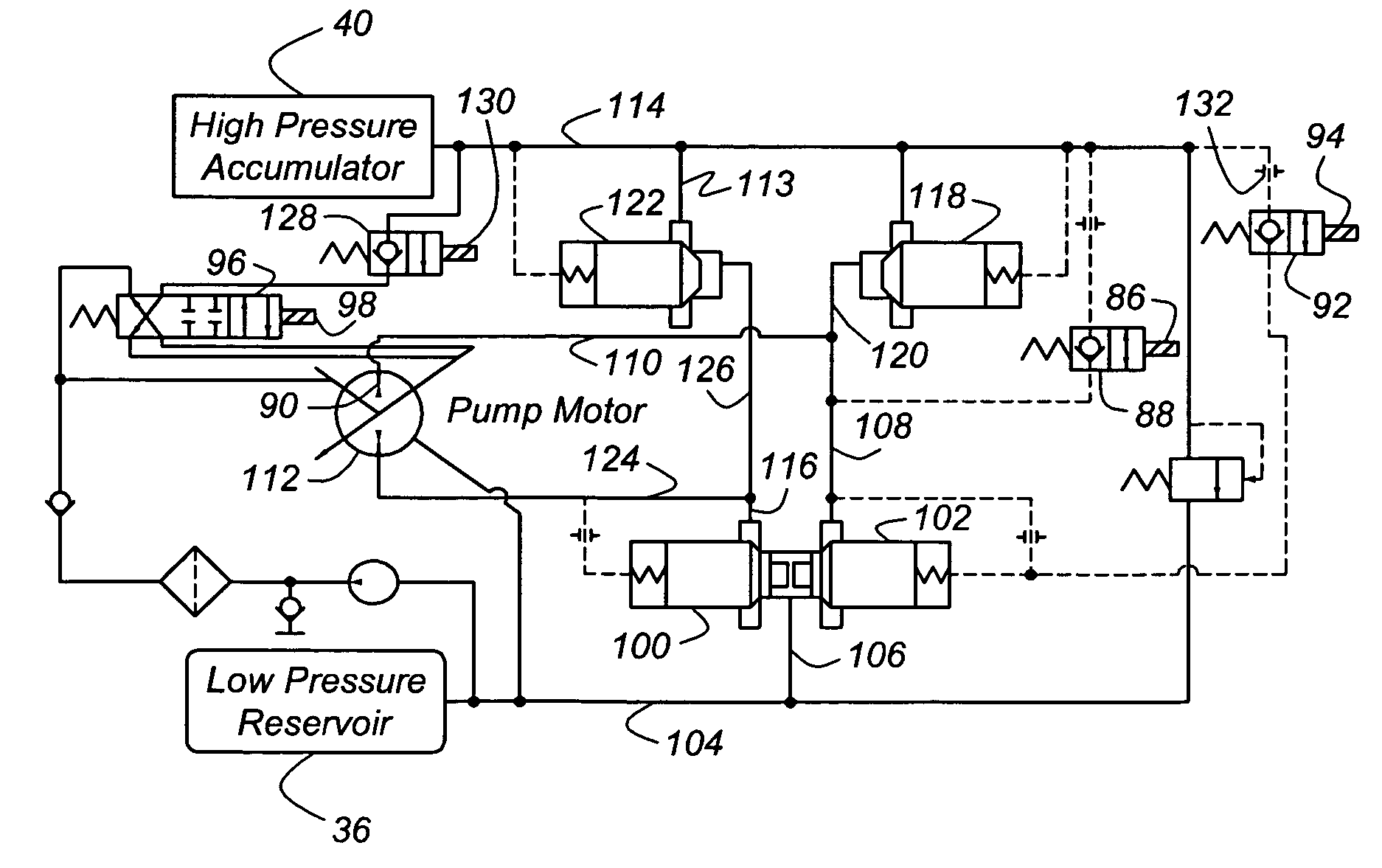

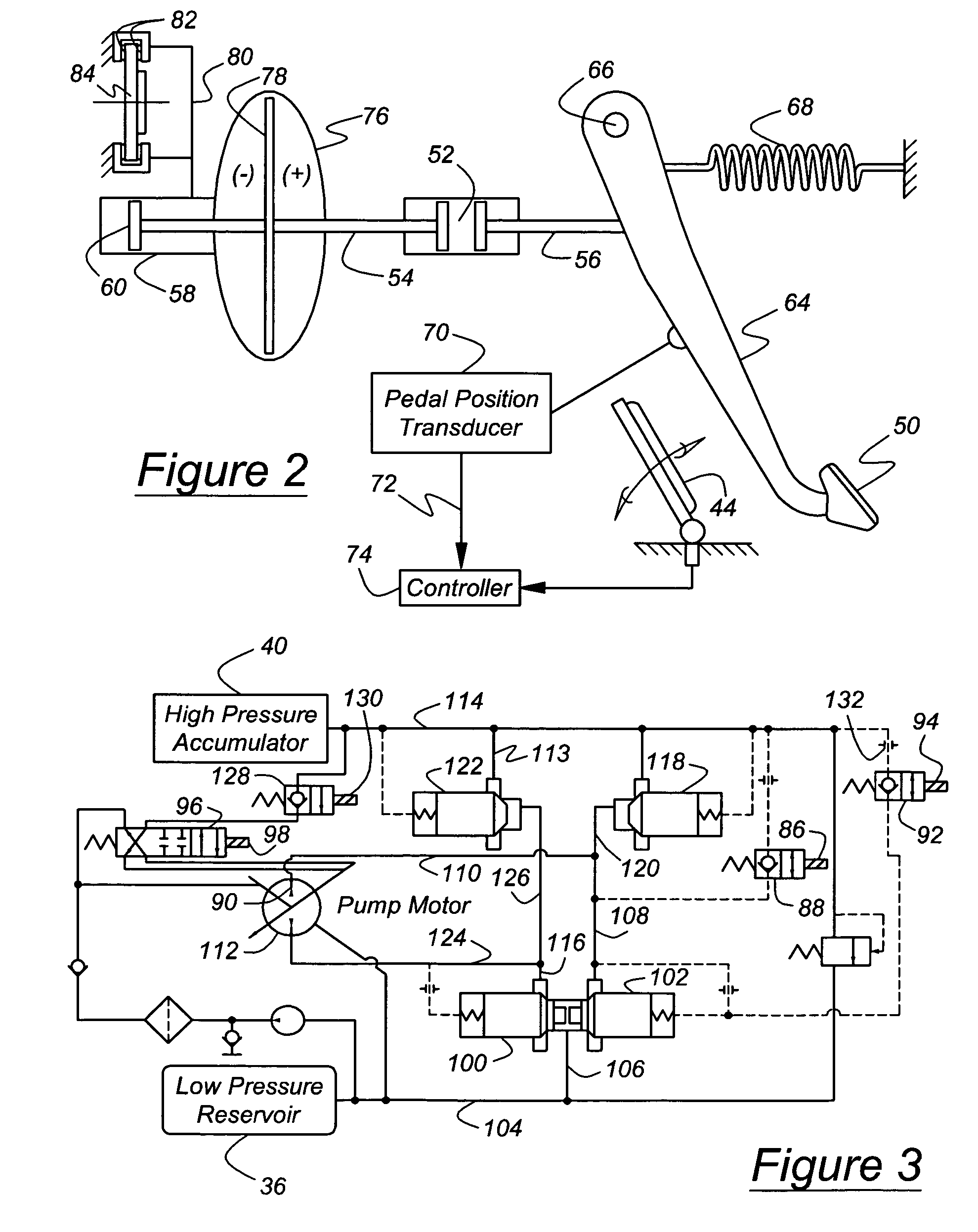

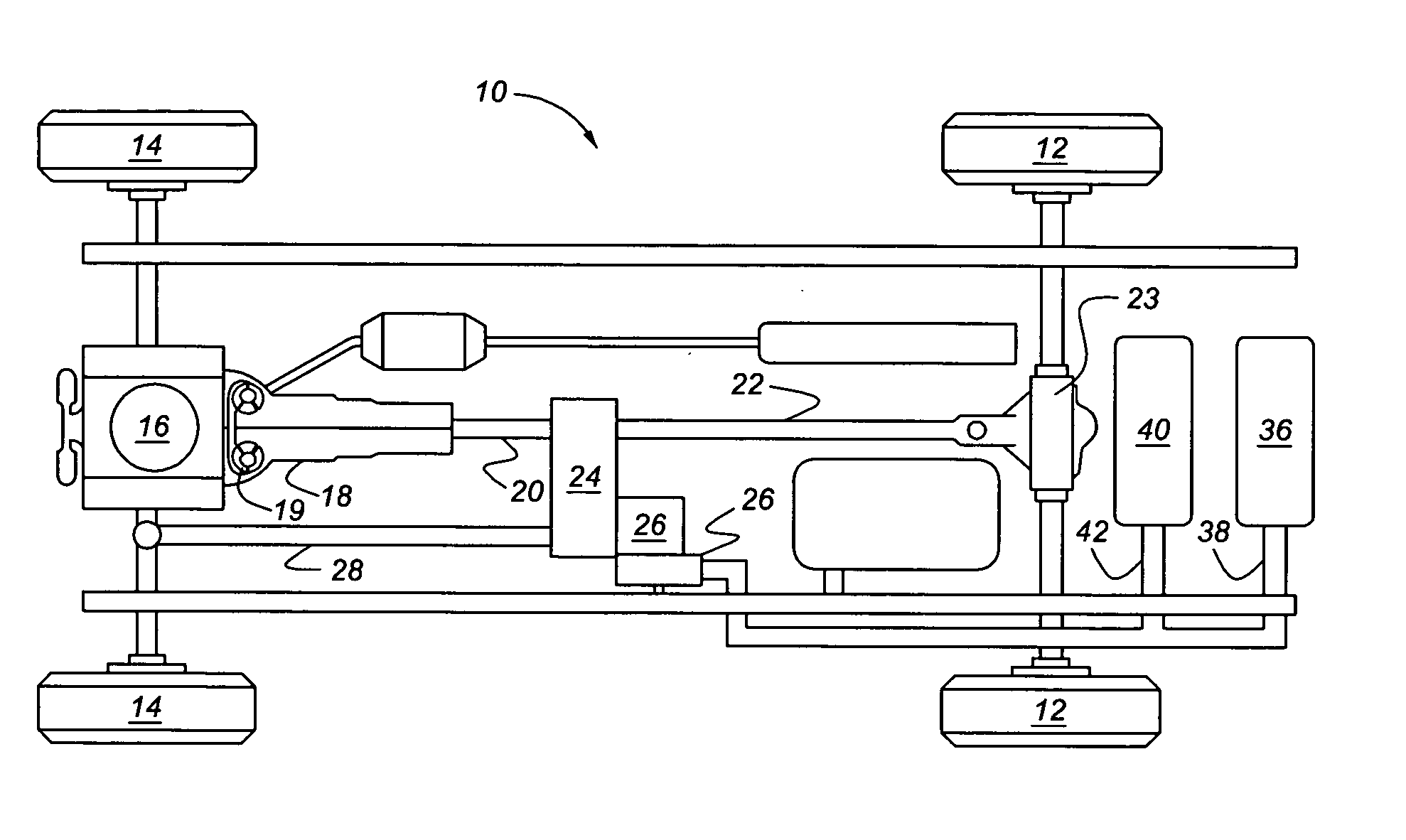

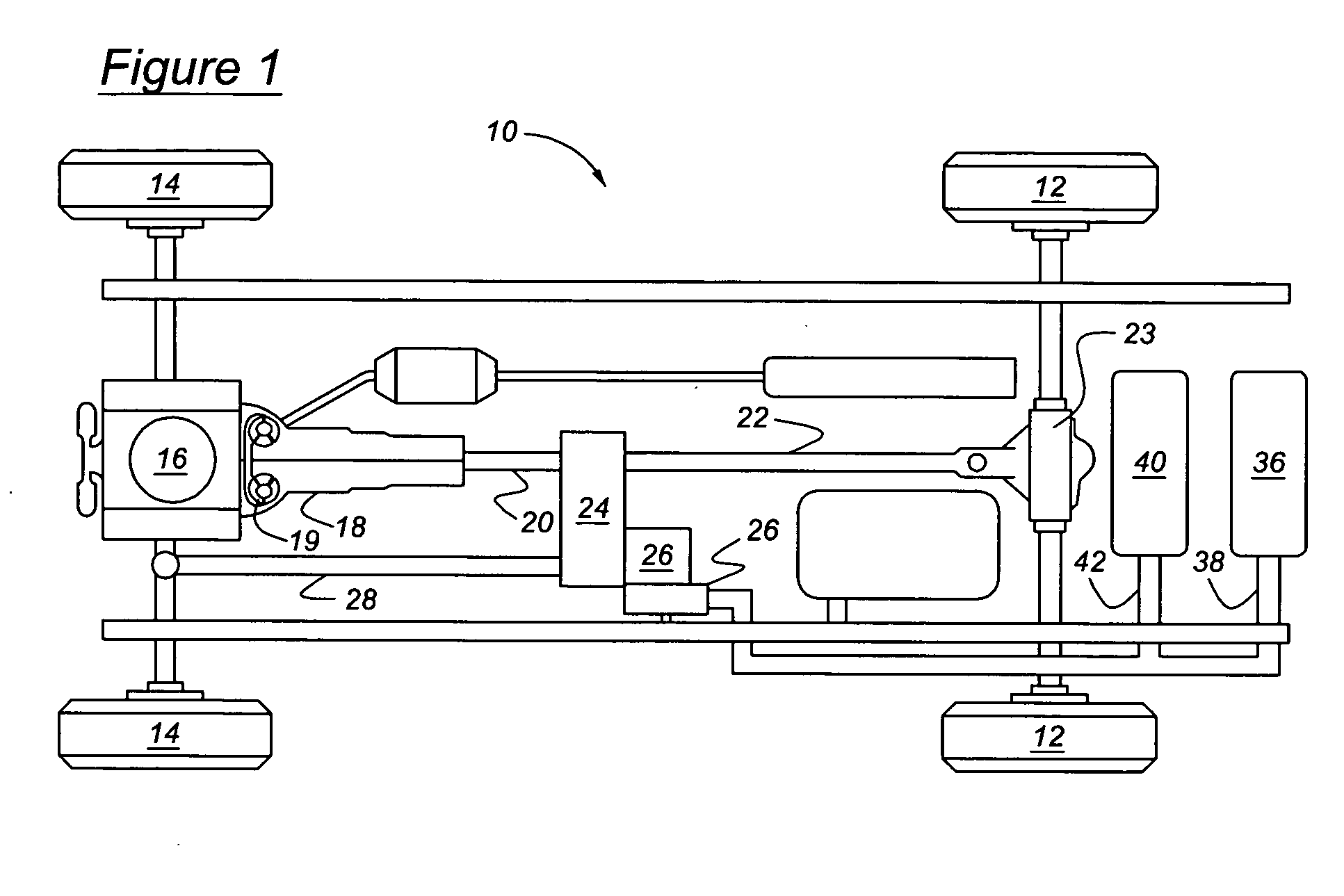

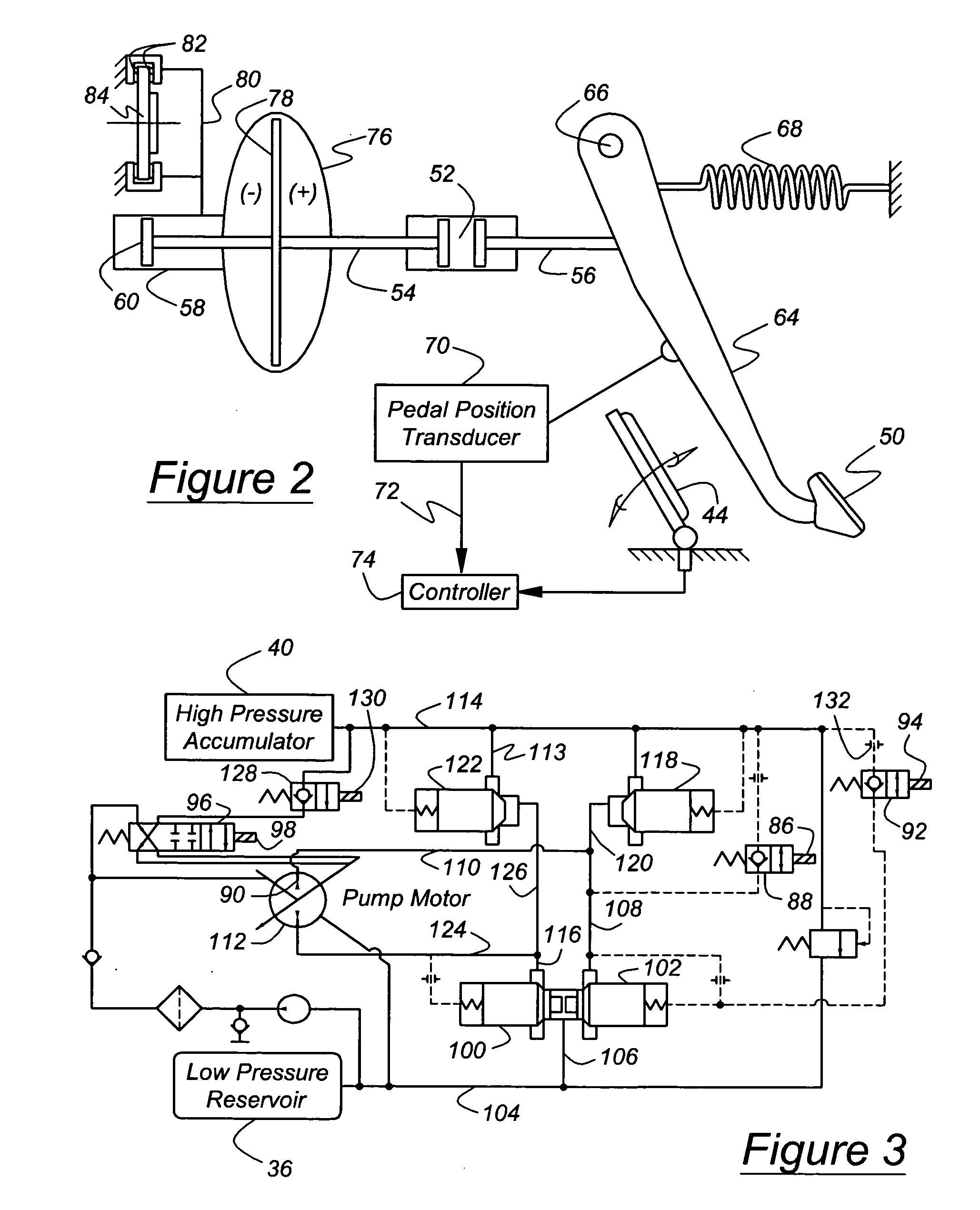

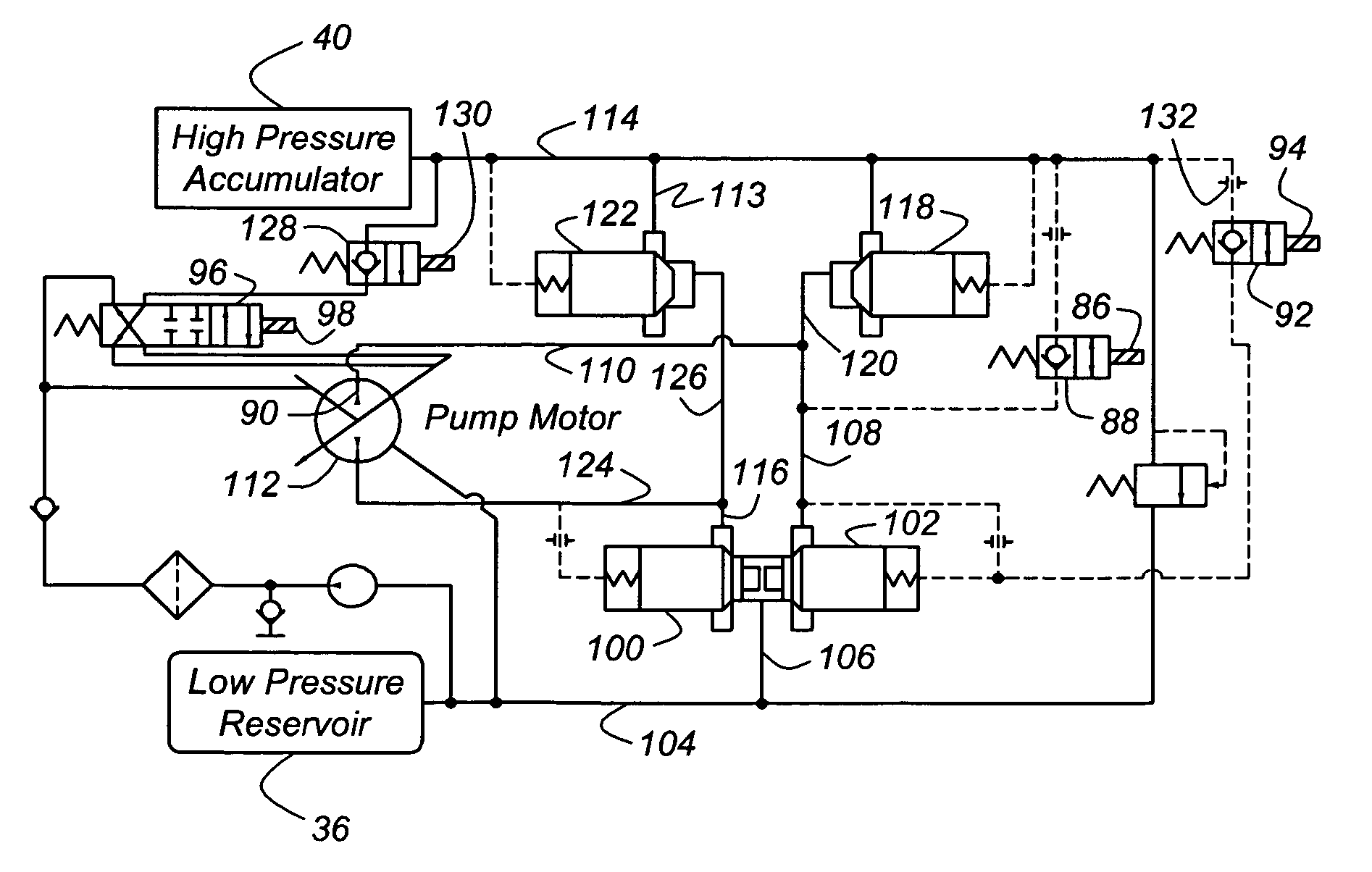

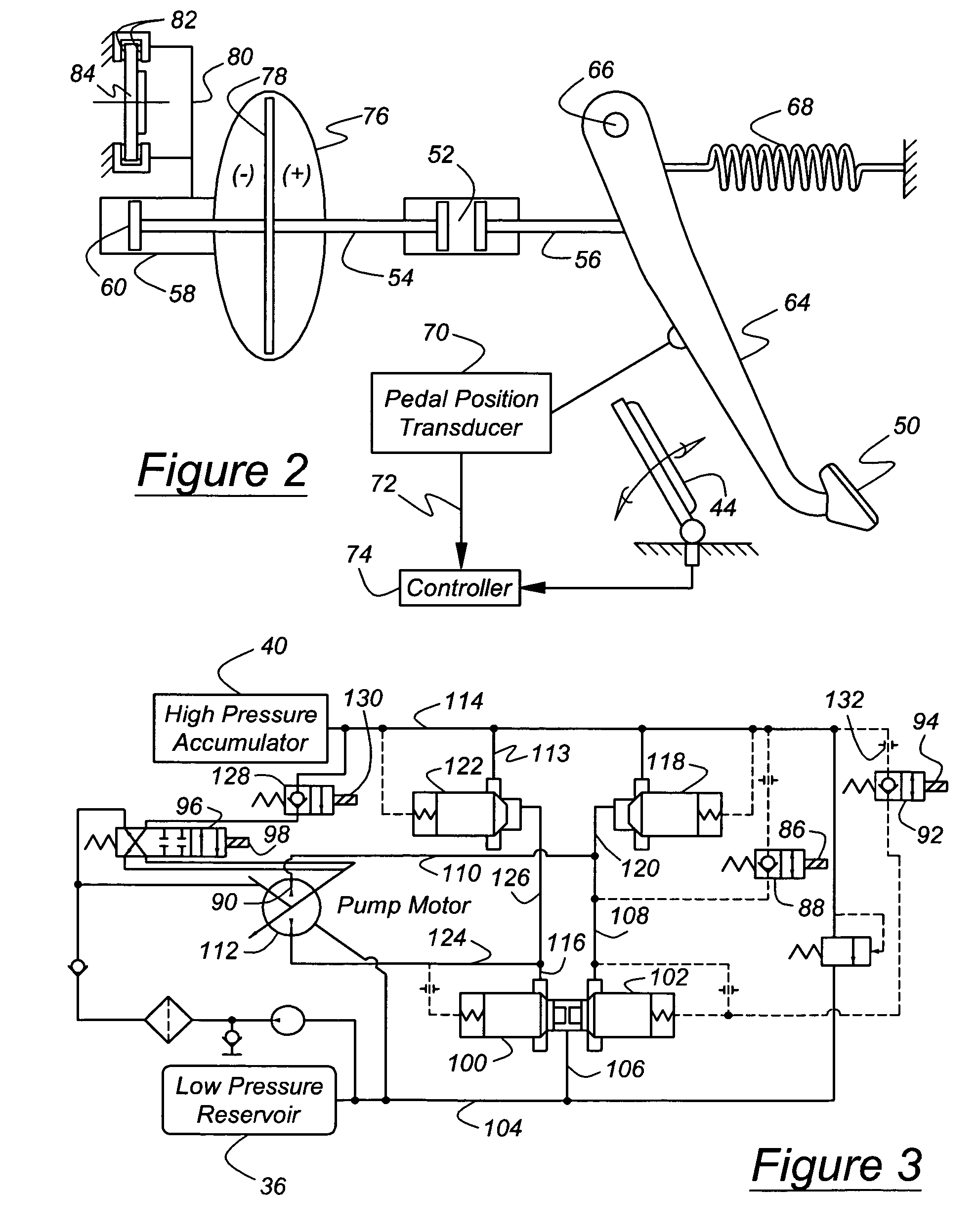

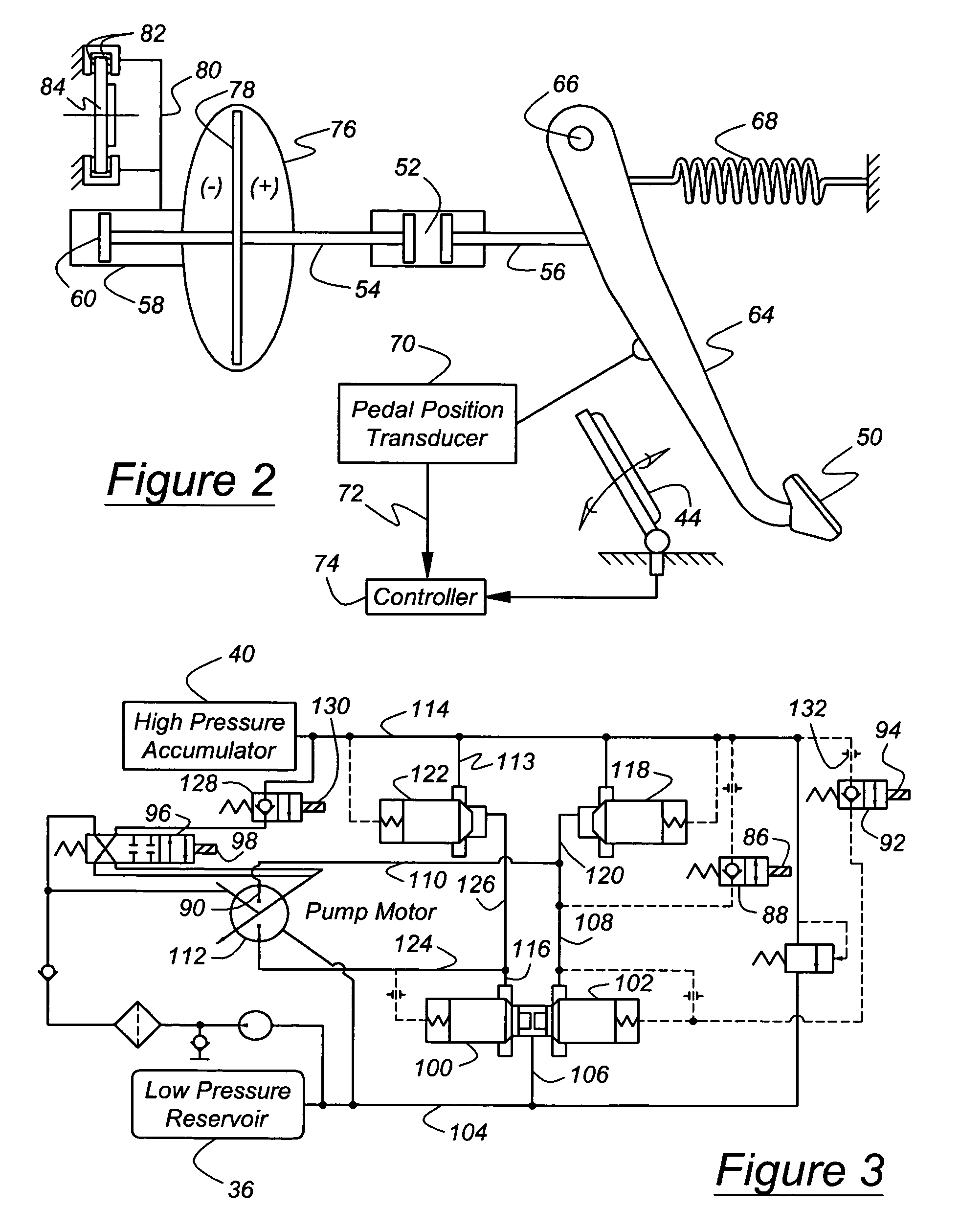

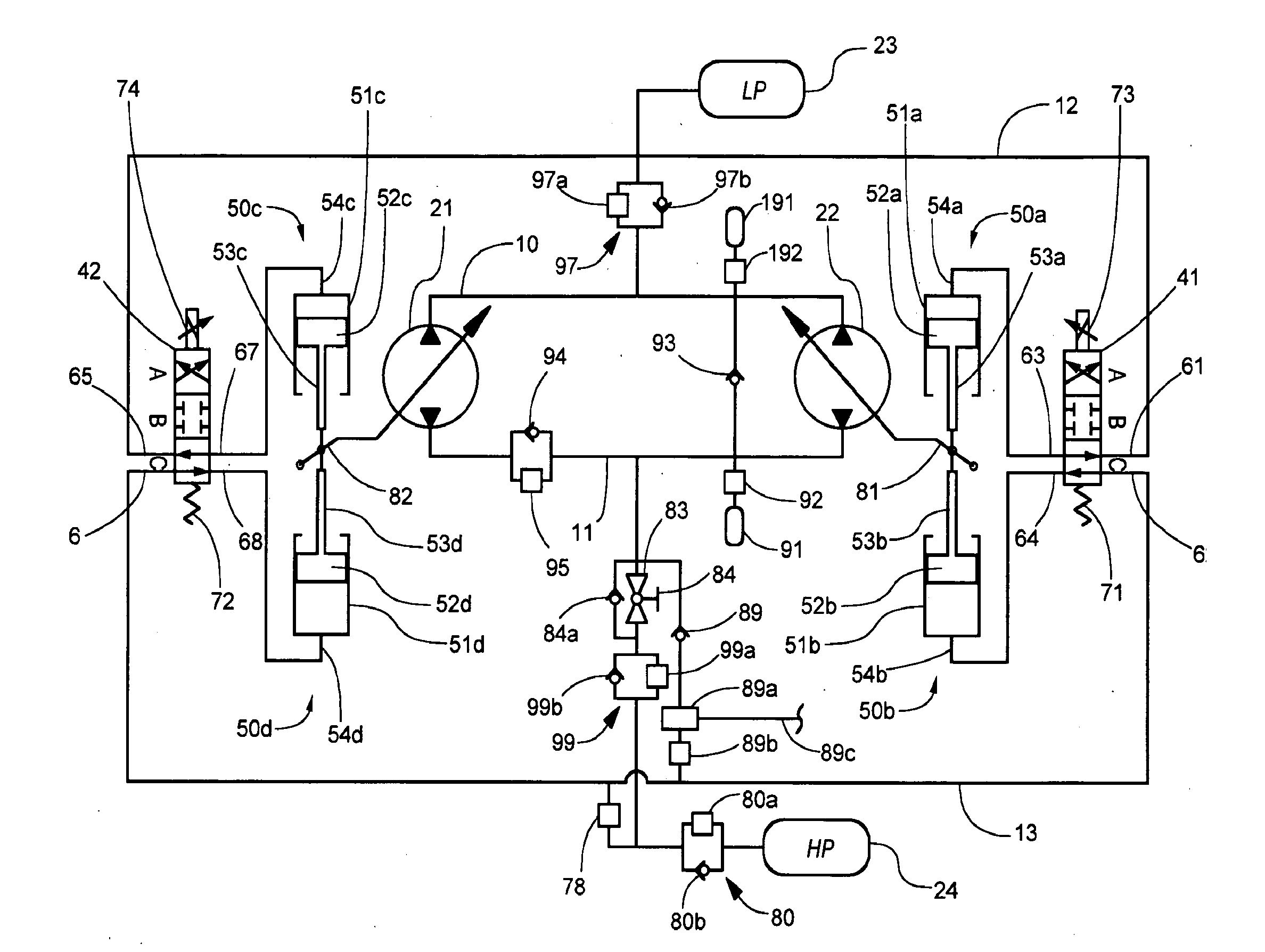

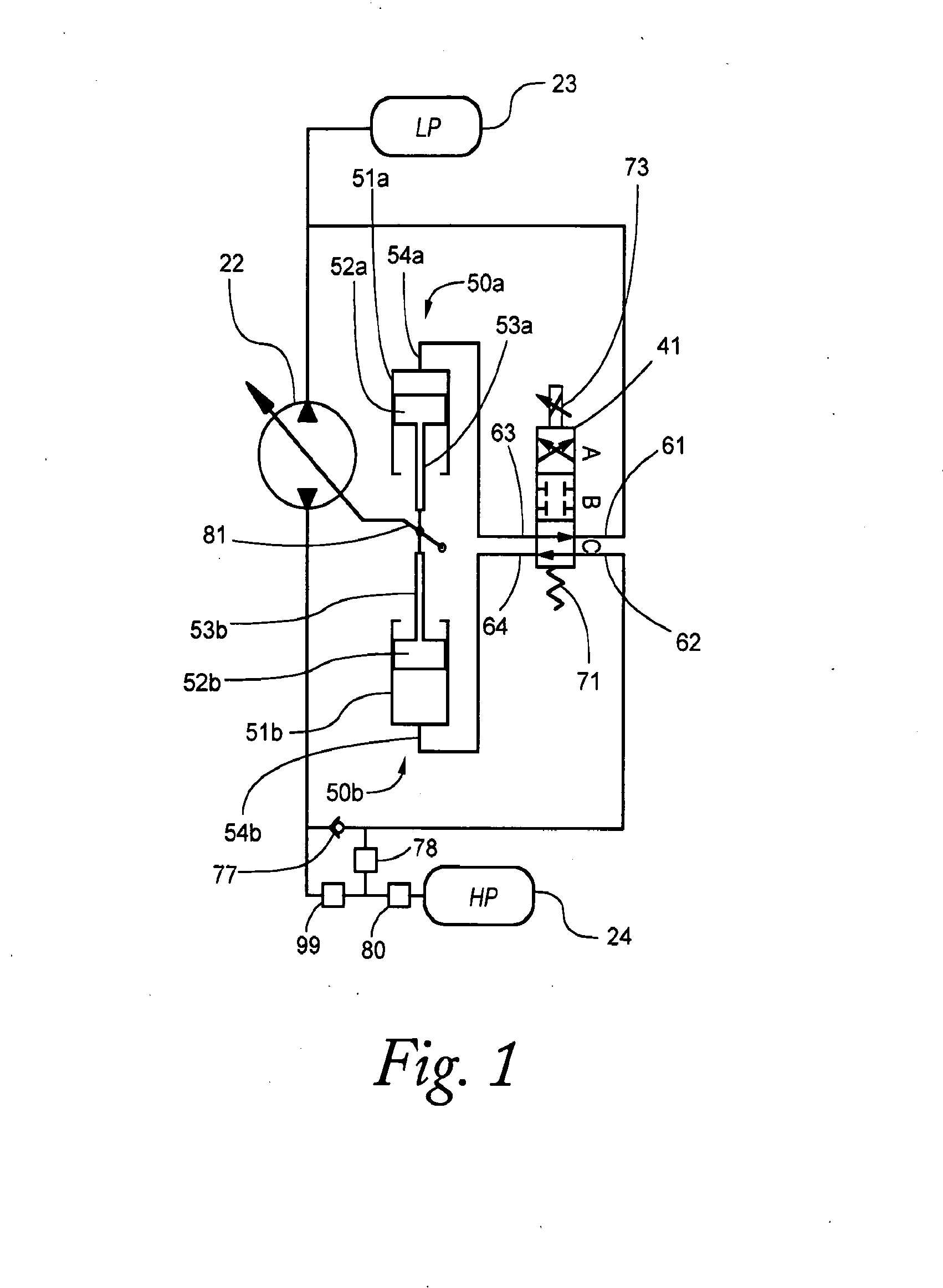

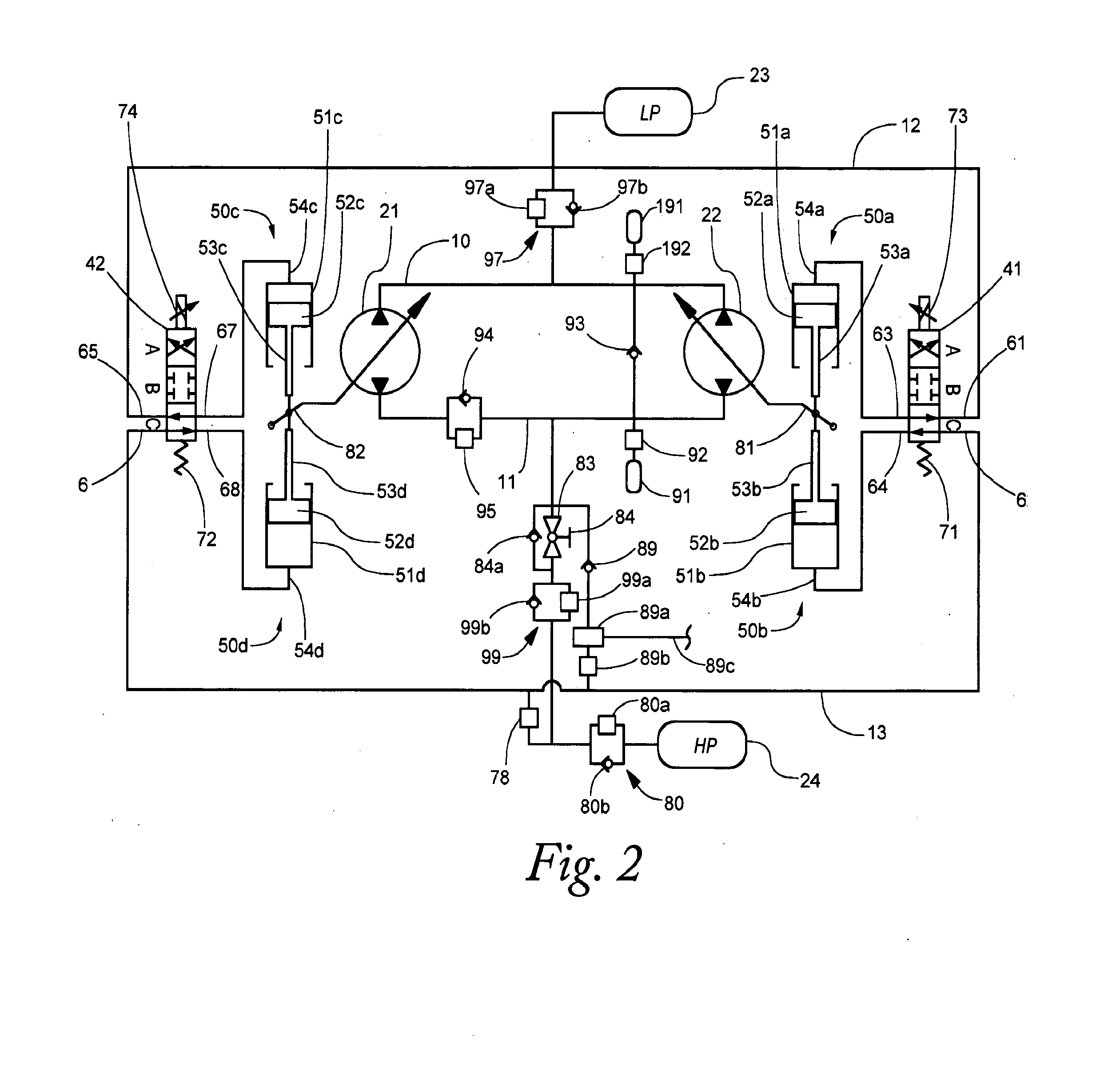

A system for transmitting power hydraulically to and from the wheels of a motor vehicle includes an accumulator containing fluid at relatively high pressure, a reservoir containing fluid at lower pressure, and a pump / motor driveably connected to the wheels and having a variable volumetric displacement for pumping fluid between the accumulator and the reservoir. A first circuit connects the inlet to the reservoir and the outlet to the accumulator. A second circuit includes a first path having a low flow rate capacity, a second path having a higher flow rate capacity. A controller switches between pumping operation and motoring operation, opens and closes the first path during motoring operation, and reduces the displacement before switching between pumping operation and motoring operation.

Owner:FORD GLOBAL TECH LLC

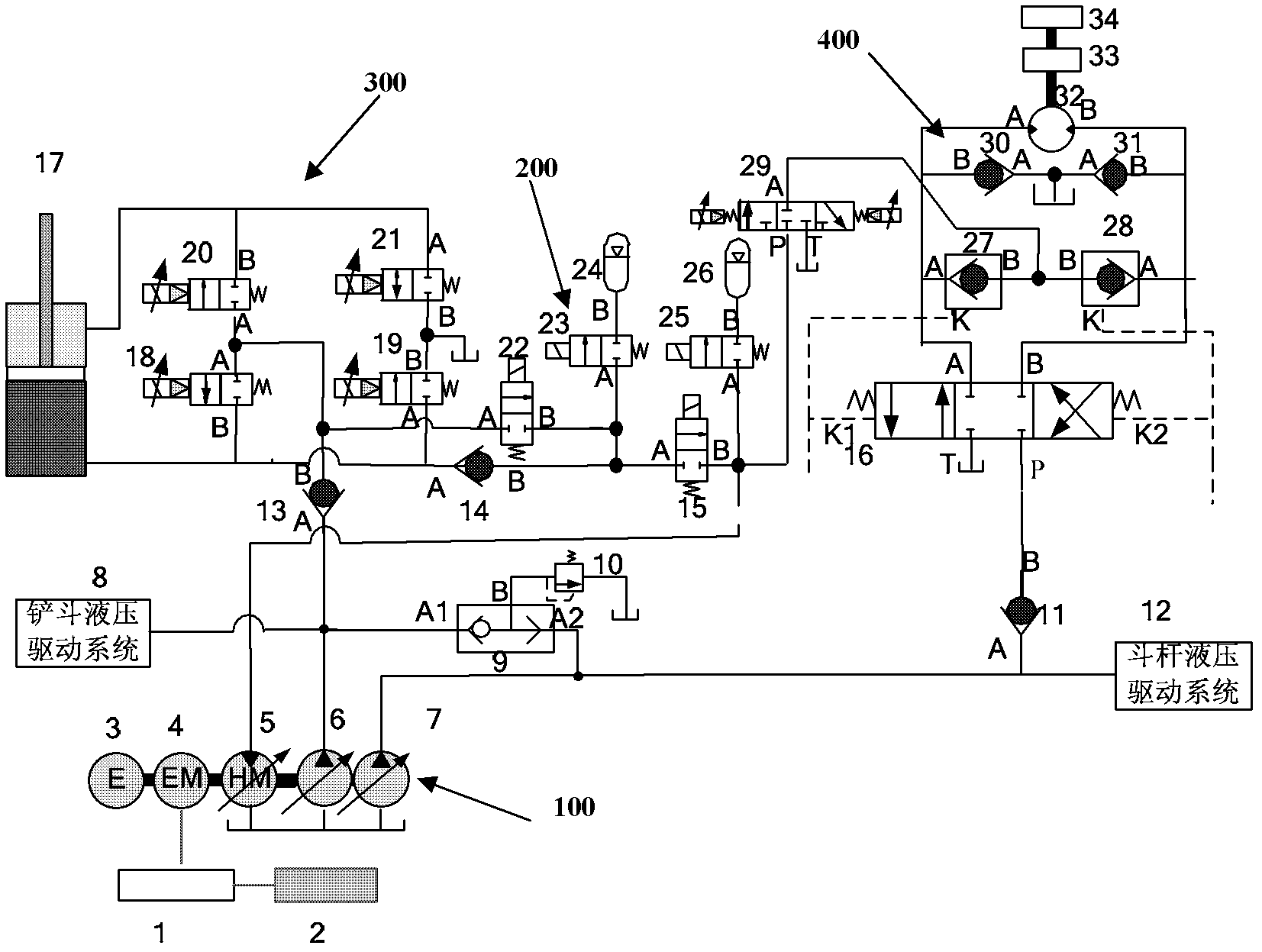

Hydraulic excavating energy saving system

ActiveCN102912821AIncrease energy densityReduce power levelMechanical machines/dredgersHydraulic hybrid vehicleHydraulic control unit

The invention discloses a hydraulic excavating energy saving system. The hydraulic excavating energy saving system comprises a movable arm driving oil cylinder, a loading mechanism, an oil-electricity-liquid hybrid driving system, a hydraulic accumulator control unit, a hydraulic control unit of the movable arm driving oil cylinder, a hydraulic control unit of the loading mechanism, a first one-way valve, a second one-way valve, a third one-way valve, a first hydraulic accumulator and a second hydraulic accumulator. The hydraulic excavating energy saving system combines the advantages of an oil-electricity hybrid power system and a hydraulic hybrid power system in the aspect of a power system, can meet the requirements of load on high power density and high energy density at the same time, and conforms to a principle of minimizing an energy transformation link in the aspect of energy recovery and recycle; and the hydraulic accumulators and a storage battery are shared by a power system and an energy recovering system. Therefore, the working efficiency of an engine can be improved, the energy consumption and loss of the energy recovery system can be reduced, and the work stability of the engine cannot be influenced.

Owner:HUAQIAO UNIVERSITY

Lightweight low permeation piston-in-sleeve accumulator

InactiveUS20050194054A1Increase pressureMass productionAccumulator installationsPipe elementsWorking fluidPre-charge

A lightweight, low permeation, piston-in-sleeve high pressure accumulator is provided. The accumulator includes a cylindrical composite pressure vessel with two integral rounded ends. A piston slidably disposed in a thin nonpermeable internal sleeve in the accumulator separates two chambers, one adapted for containing a working fluid and the other adapted for containing gas under pressure. Working fluid is provided in a volume between the nonpermeable internal sleeve and the composite pressure vessel wall. Further means are provided for withstanding harmful effects of radial flexing of the composite vessel wall under high pressures, and from stresses present in use in mobile applications such as with a hydraulic power system for a hydraulic hybrid motor vehicle. A method for pre-charging the device is also presented.

Owner:UNITED STATES OF AMERICA

Wheel creep control of hydraulic hybrid vehicle using regenerative braking

InactiveUS20060000659A1Increase displacementMinimal effortAuxillary drivesFluid couplingsRegenerative brakeControl system

A system according to this invention opposes creep in a hydraulic hybrid motor vehicle. An accumulator contains fluid at high pressure, and a reservoir contains fluid at lower pressure. An engine produces positive torque at the wheels during an engine idle condition, and a pump / motor, driveably connected to the wheels and the engine, has a variable volumetric displacement pumps fluid to the accumulator from the reservoir. A control system determines a magnitude of negative torque transmitted from the wheels to the pump / motor that would exceed the magnitude of positive torque, determines the volumetric displacement of the pump / motor corresponding to the magnitude of negative torque, changes the displacement of the pump / motor to the required displacement, and operates the pump / motor as a pump driven by negative torque from the wheels to pump fluid from the reservoir to the accumulator.

Owner:FORD GLOBAL TECH LLC

Pump/motor operating mode switching control for hydraulic hybrid vehicle

ActiveUS20060000208A1Slow pressureAvoid cavitationAuxillary drivesBraking element arrangementsTransmitted powerEngineering

A system according to this invention for transmitting power hydraulically to and from the wheels of a motor vehicle includes an accumulator containing fluid at relatively high pressure, a reservoir containing fluid at lower pressure, and a pump / motor driveably connected to the wheels and having an inlet, an outlet, and a variable volumetric displacement for pumping fluid between the accumulator and the reservoir. A first circuit connects the inlet to the reservoir and the outlet to the accumulator. A second circuit, which connects the inlet to the accumulator and the outlet to the reservoir, includes a first path having a low flow rate capacity, a second path having a higher flow rate capacity. A controller switches between pumping operation and motoring operation, opens and closes the first path during motoring operation, and reduces the displacement before switching between pumping operation and motoring operation. The first path includes a first valve responsive to the controller for opening and closing a connection between the accumulator and the inlet, and a first orifice arranged in series with the first valve having a relatively low flow rate capacity. The second path, arranged in parallel with the first path between the accumulator and the inlet, includes a second valve responsive to the controller for opening and closing a connection between the accumulator and the inlet, and a second orifice arranged in series with the second valve having a higher flow rate capacity than that of the first orifice.

Owner:FORD GLOBAL TECH LLC

Hydraulic hybrid vehicle method of safe operation

InactiveUS20080093152A1Gearing controlPlural diverse prime-mover propulsion mountingMode controlExternal combustion engine

A hydraulic hybrid vehicle includes elements such as a hydraulic pump driven by an internal combustion engine and arranged to draw in low pressure fluid and pump the fluid at high pressure to an accumulator. A hydraulic motor is powered by the pressurized fluid. Safety processes are provided for detecting and addressing a number of conditions that may arise in the operation of the hydraulic hybrid vehicle, including an initialization procedure for start-up of the vehicle, a shut-down procedure, and procedures for detecting and responding to failure of the pump or motor, internal and external fluid leaks, and non-responsive actuation and mode control systems.

Owner:GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE ADMINISTATOR OF THE U S ENIVERONMENTAL PROTECTION AGENCY

Wheel creep control of hydraulic hybrid vehicle using regenerative braking

InactiveUS7147239B2Prevent vehicle creepSlow acceleration of the vehicleAuxillary drivesFluid couplingsMobile vehicleRegenerative brake

Owner:FORD GLOBAL TECH LLC

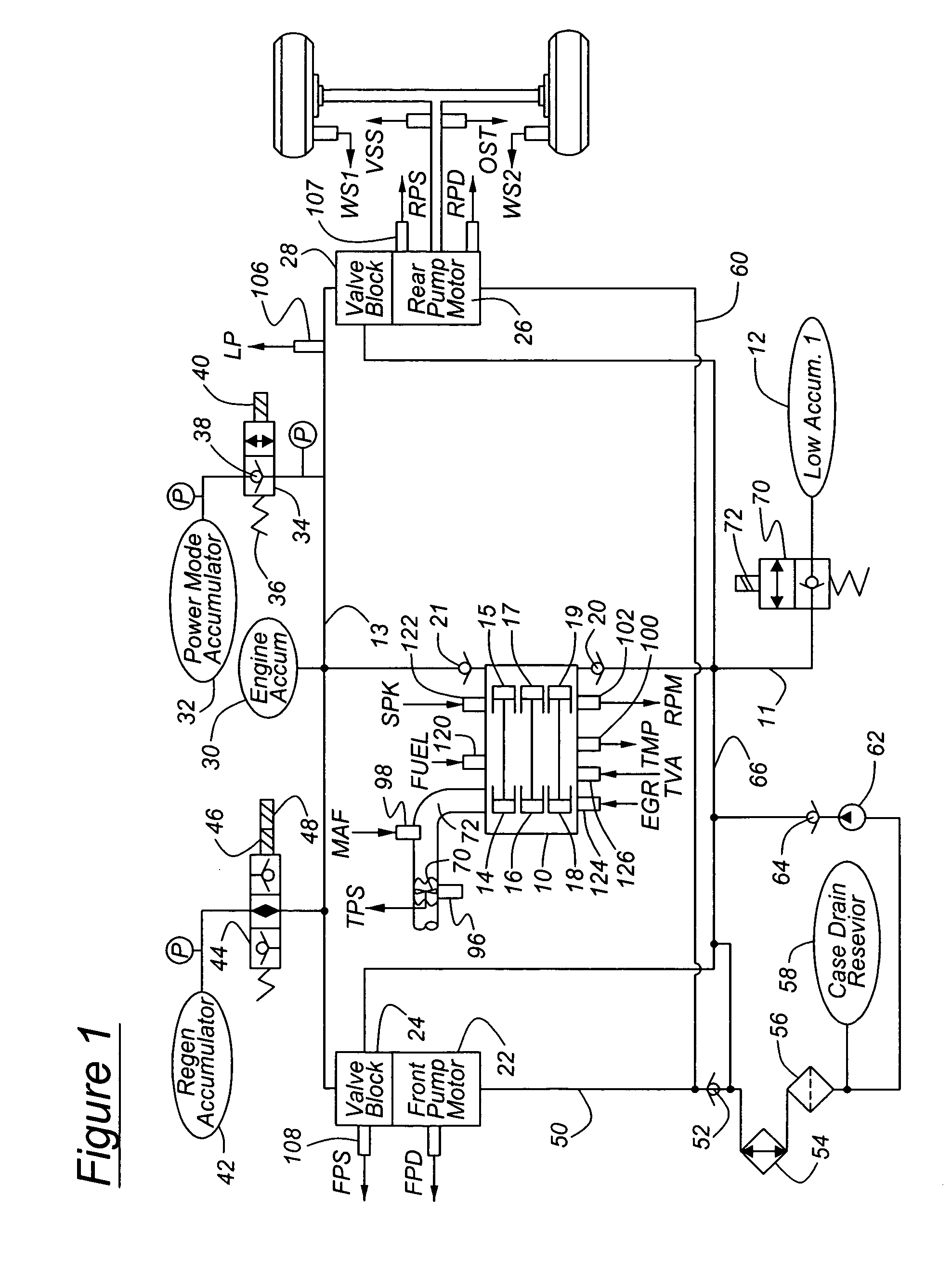

Multiple pressure mode operation for hydraulic hybrid vehicle powertrain

ActiveUS7100723B2Quick transitionWithout adverse performance effectAuxillary drivesGas pressure propulsion mountingMotor speedRail pressure

A system for a hydraulically driven vehicle includes a pump producing fluid flow at an outlet, pump-motors having variable flow rates for driving the wheels, a hydraulic rail having a pressure and connecting the pump and the pump-motors, sensors producing signals representing rail pressure, pump-motor speed, pump-motor displacement, and a controller for determining a target hydraulic system parameter, determining, based at least in part on the flow rate of the pump-motor, rail pressure, and a flow rate produced by the engine-pump, a flow rate produced by the engine-pump that is required to produce the target system parameter, and adjusting an engine operating parameter of a cylinder-pump bank such that the demanded magnitude of the system parameter is produced.

Owner:FORD GLOBAL TECH LLC

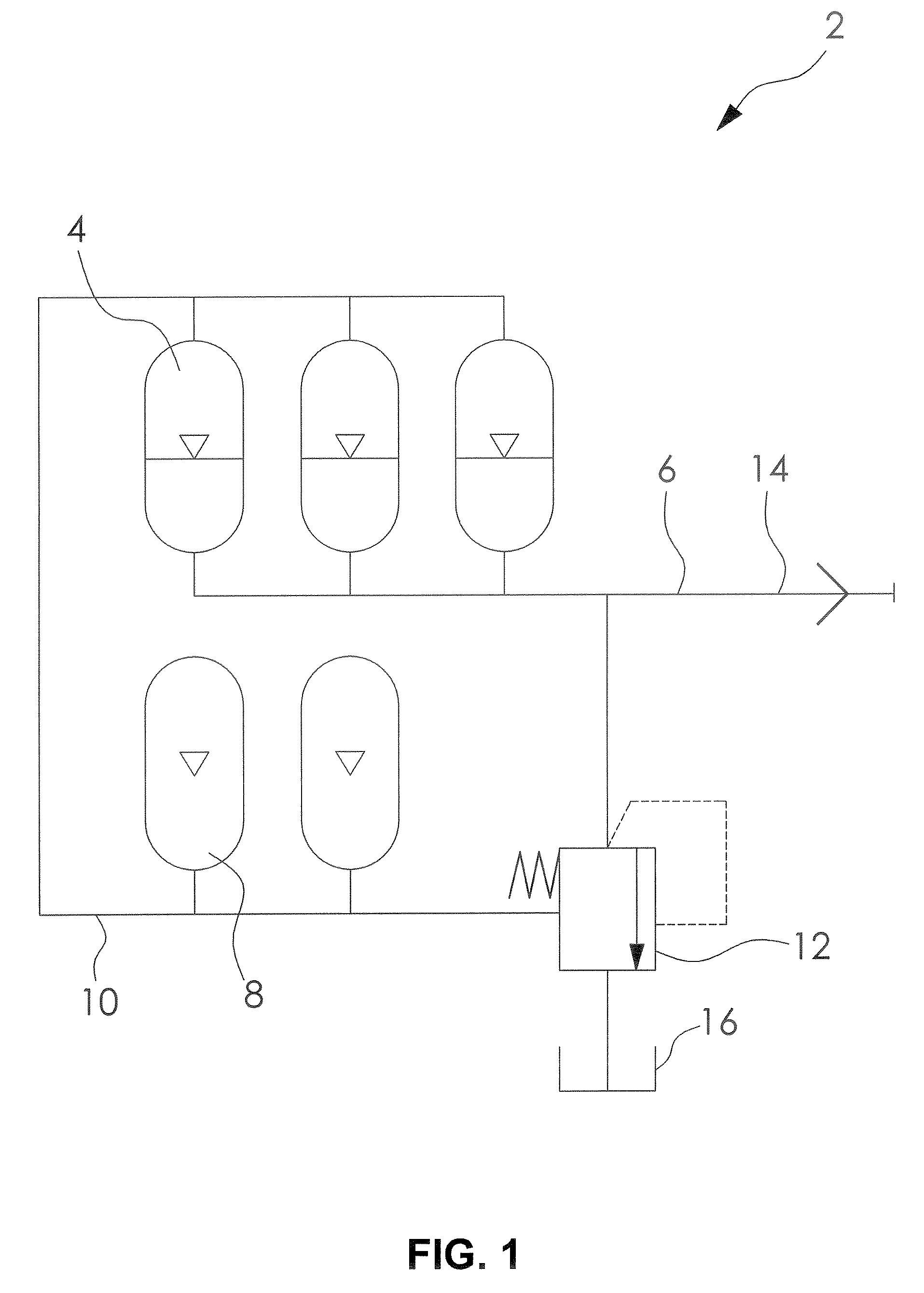

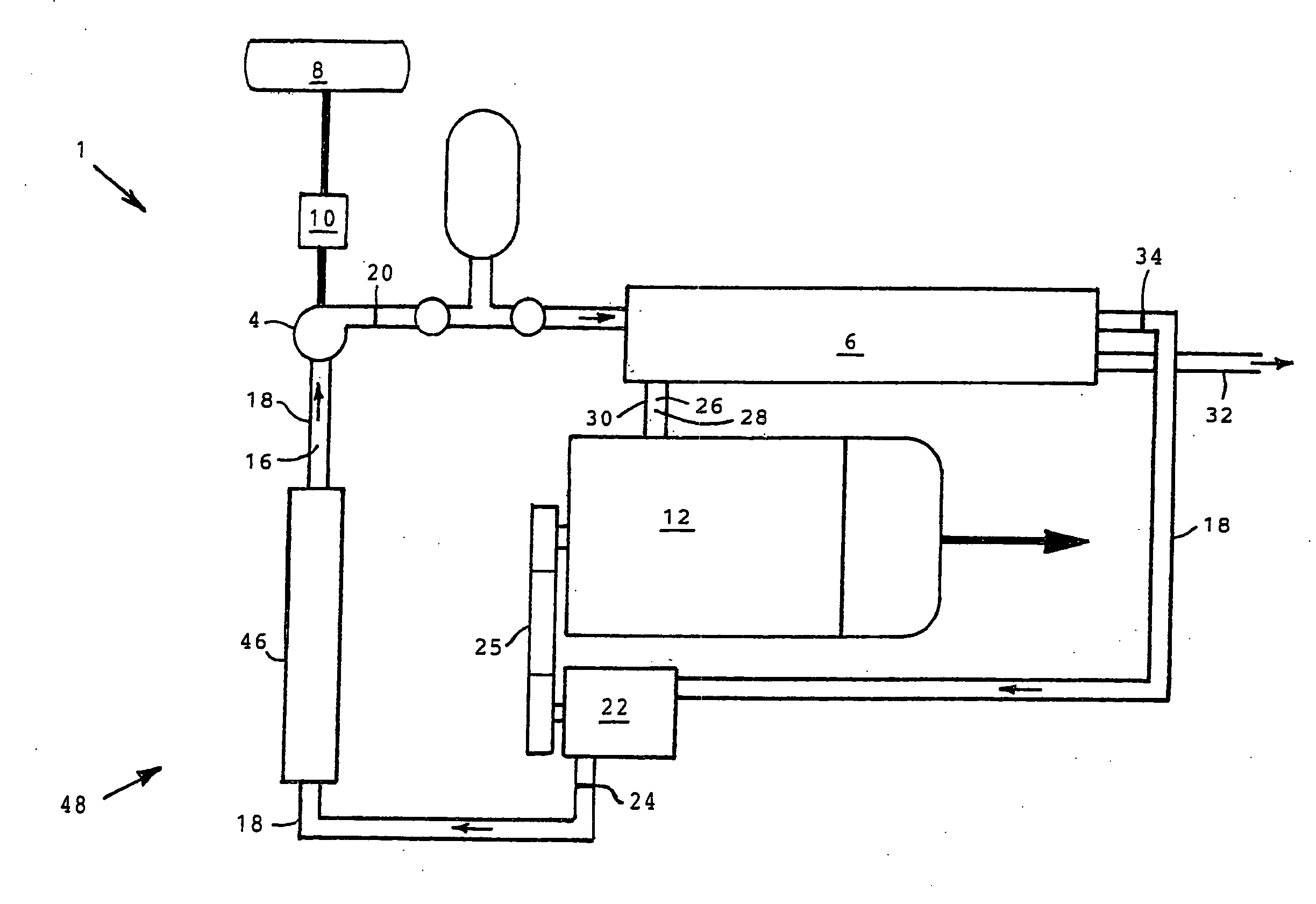

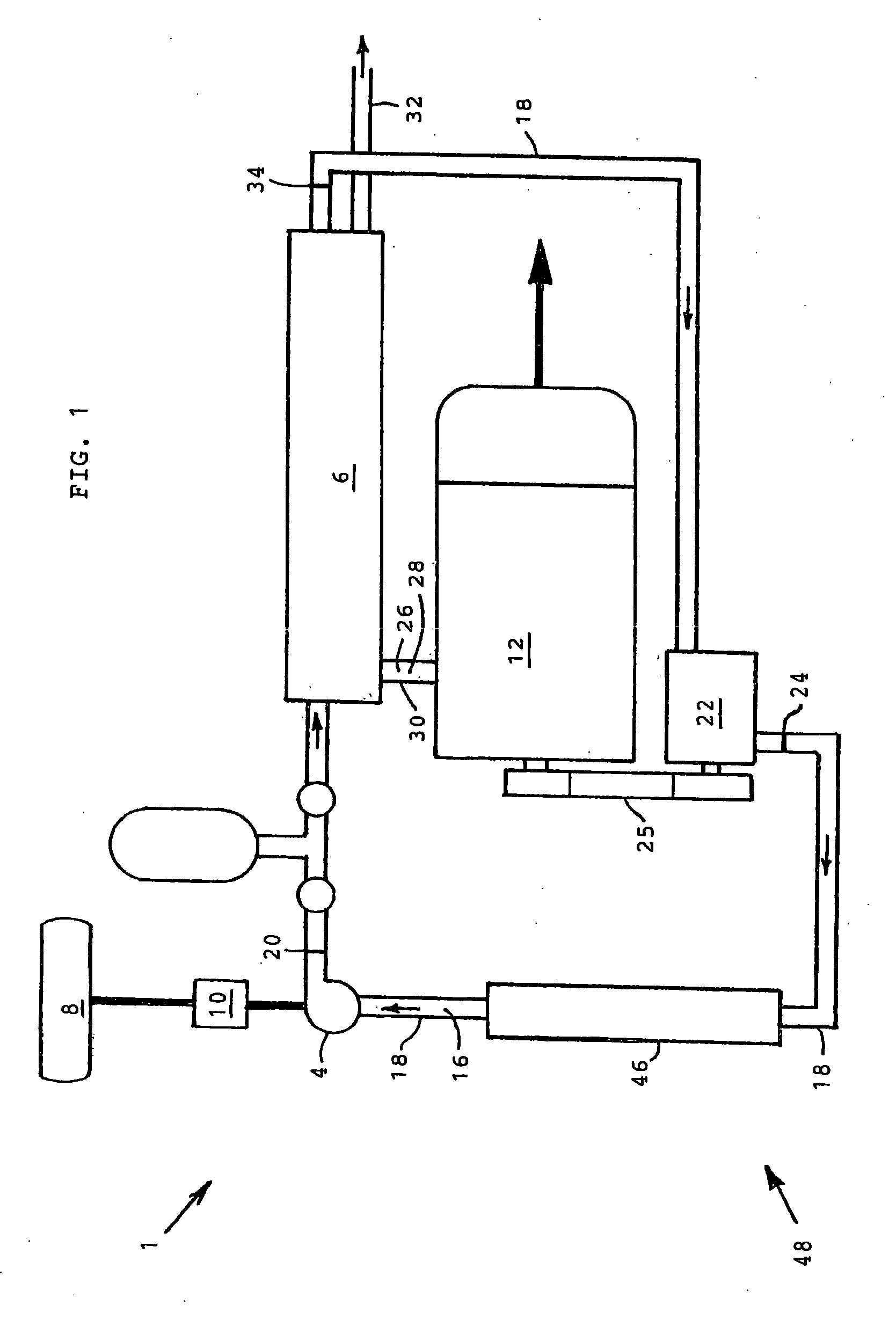

Hydraulic hybrid power system

InactiveUS20100133031A1Big economyLow costAuxillary drivesElectrodynamic brake systemsHigh pressureHydraulic pressure

According to the present invention a pump is driven by one or more wheels of a hydraulic hybrid vehicle during braking. The inertial energy of the vehicle powers the pump during braking of the vehicle, and the pump pumps a hydraulic liquid into an hydraulic accumulator that stores the fluid at its elevated pressure. When additional power is required by the vehicle, the liquid is released into a heat exchanger that transfers heat from the exhaust gas of the engine to the liquid causing at least a portion of the liquid to become gaseous. The heated fluid is then fed into an expander that generates shaft power by expanding the pressurized and heated gaseous and / or liquid fluid mixture. The preferred embodiment of the present invention operates under the Rankine cycle or steam engine cycle where the liquid compression function is performed using power from regenerative braking, and the liquid heating and vaporization function is performed using exhaust gas waste heat. The present invention shows potential for more than tripling the regenerative braking power of hydraulic hybrid vehicles, thereby providing a large improvement in vehicle fuel economy.

Owner:MENDLER EDWARD CHARLES

Engine control based on flow rate and pressure for hydraulic hybrid vehicle

InactiveUS6959545B2Improve fuel economyHigh activityFluid couplingsGas pressure propulsion mountingMotor speedEngineering

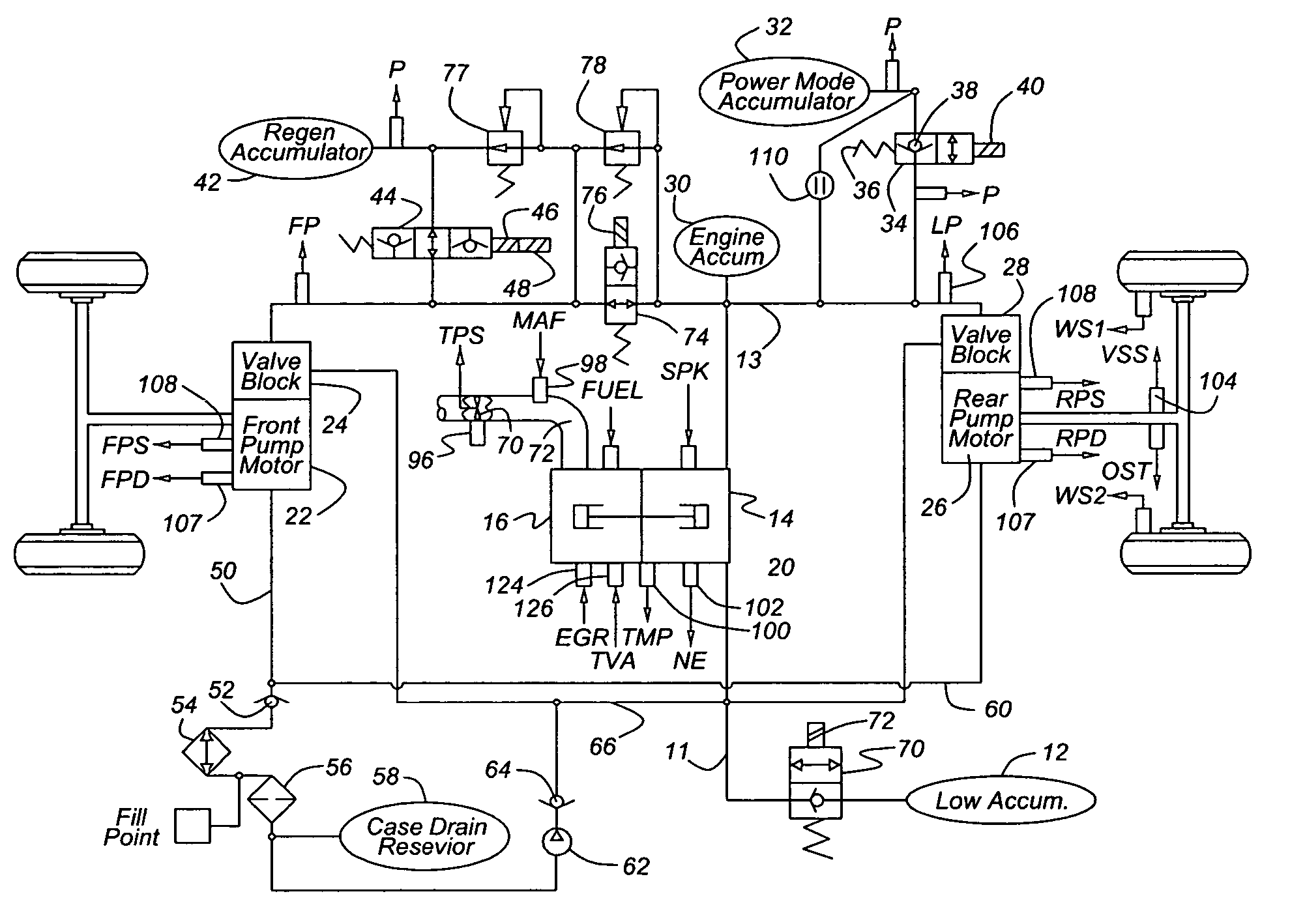

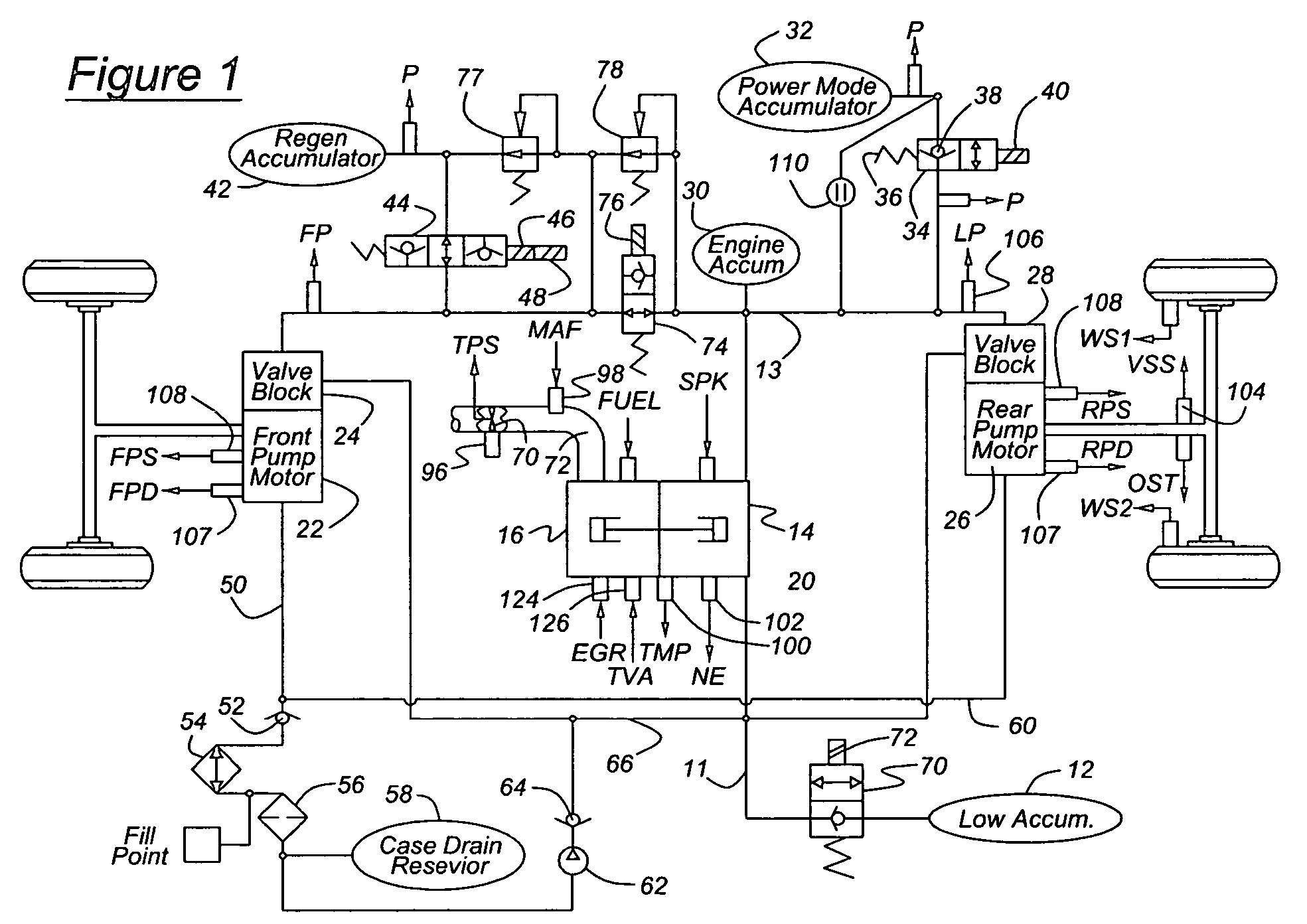

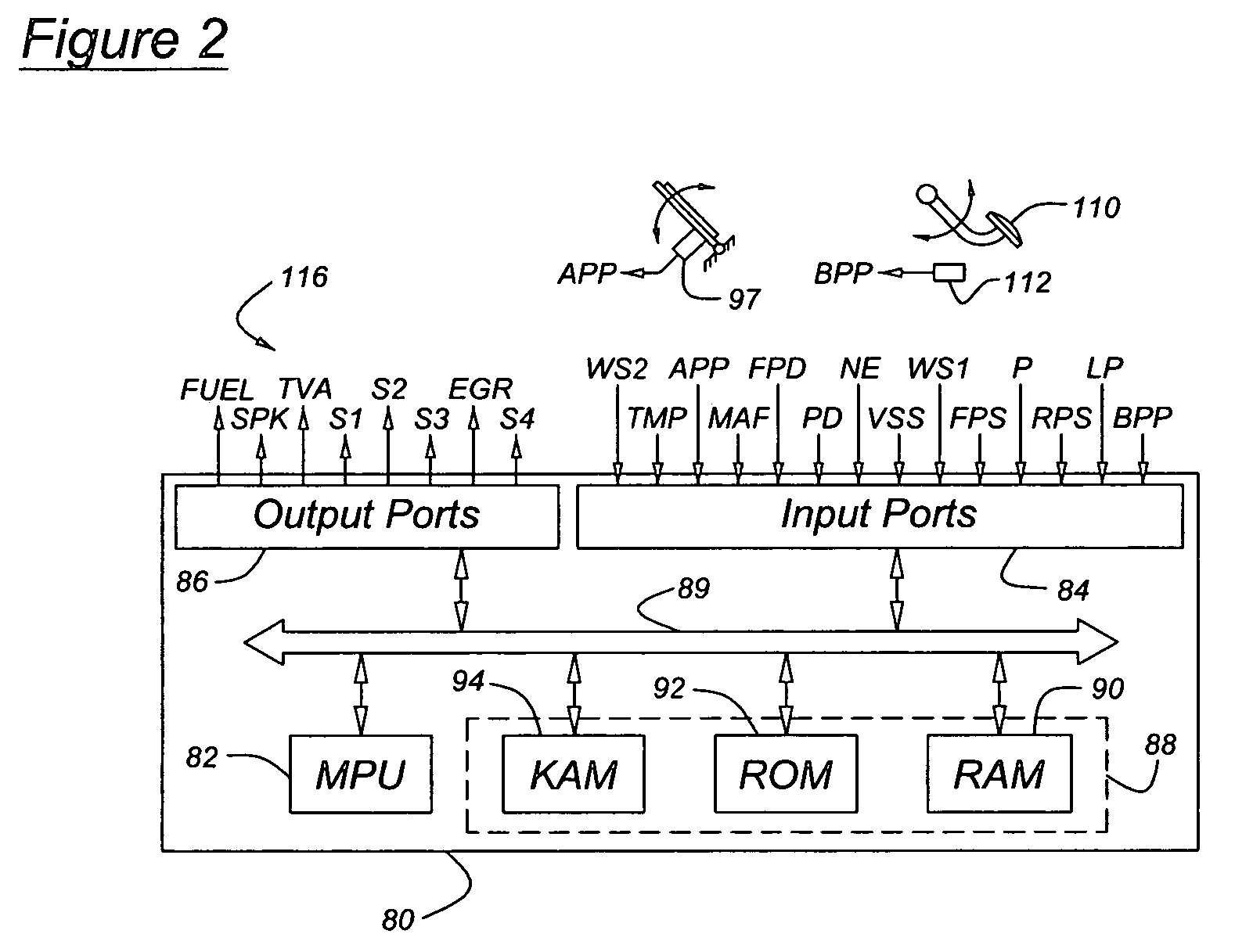

A system for a hydraulically driven vehicle includes an engine having multiple, selectively operating cylinder-pump banks producing fluid flow at an outlet, a pump / motor having a variable flow rate including an inlet for driving the wheels, a hydraulic line having a line pressure and connecting the outlet and the inlet, sensors producing signal representing line pressure, pump / motor speed, pump / motor displacement, and a controller for determining a target hydraulic system parameter, determining, based at least in part on the flow rate of the pump / motor and a flow rate produced by each engine cylinder bank, a number of operating cylinder-pump banks that is required to produce the target hydraulic system parameter, and in response to determining the required number of operating cylinder-pump banks, adjusting an engine operating parameter of a cylinder-pump bank such that the required number of cylinder-pump banks operate.

Owner:FORD GLOBAL TECH LLC

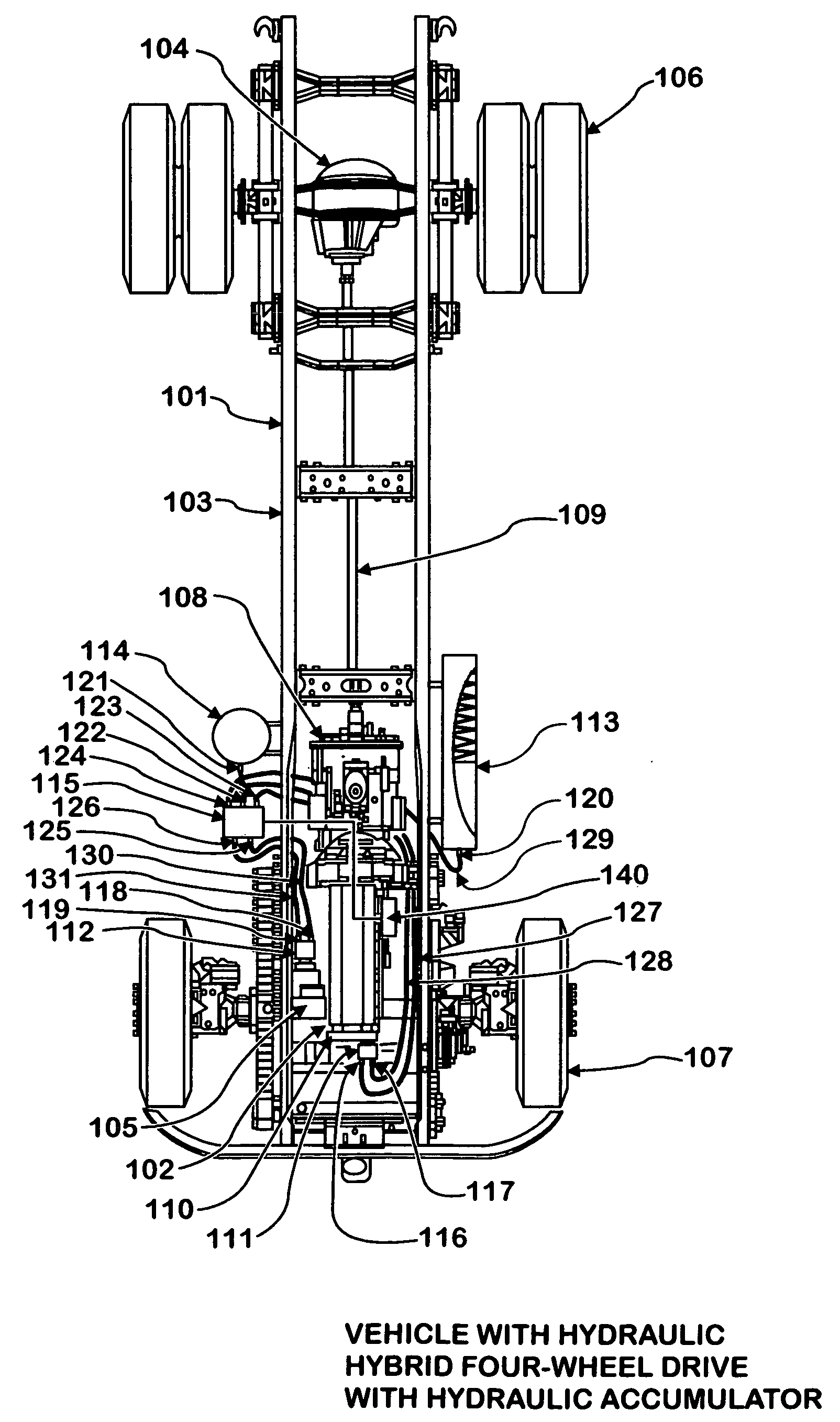

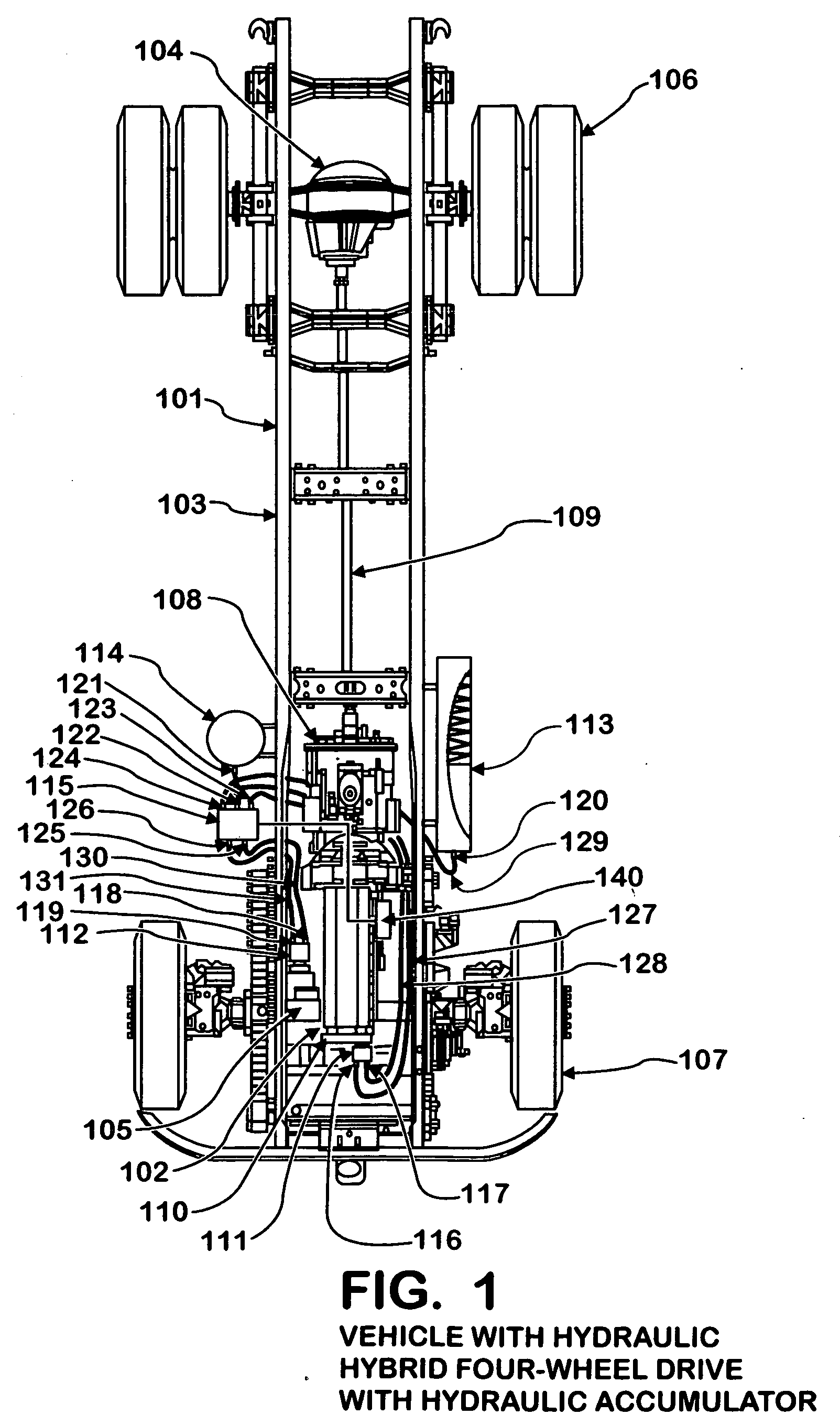

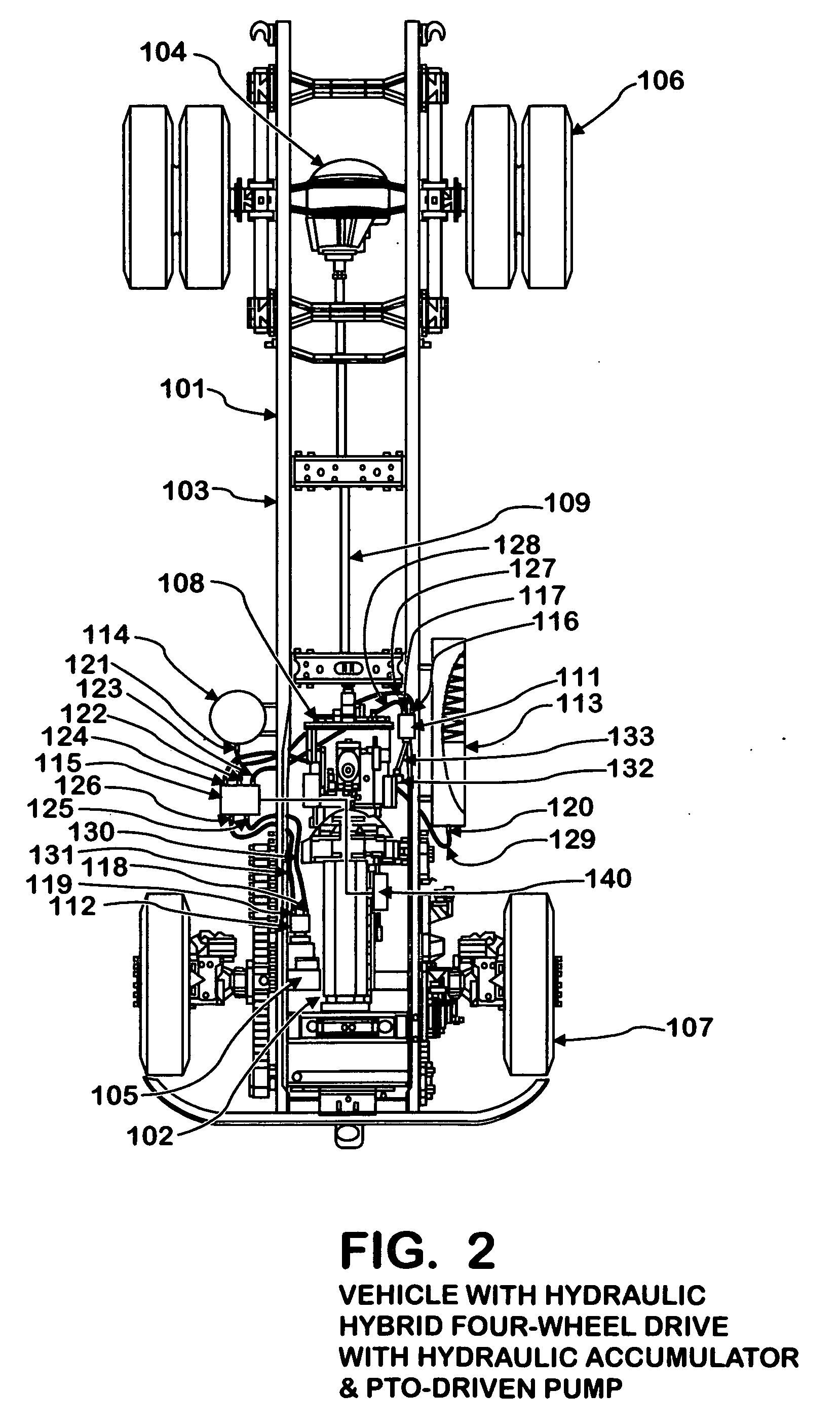

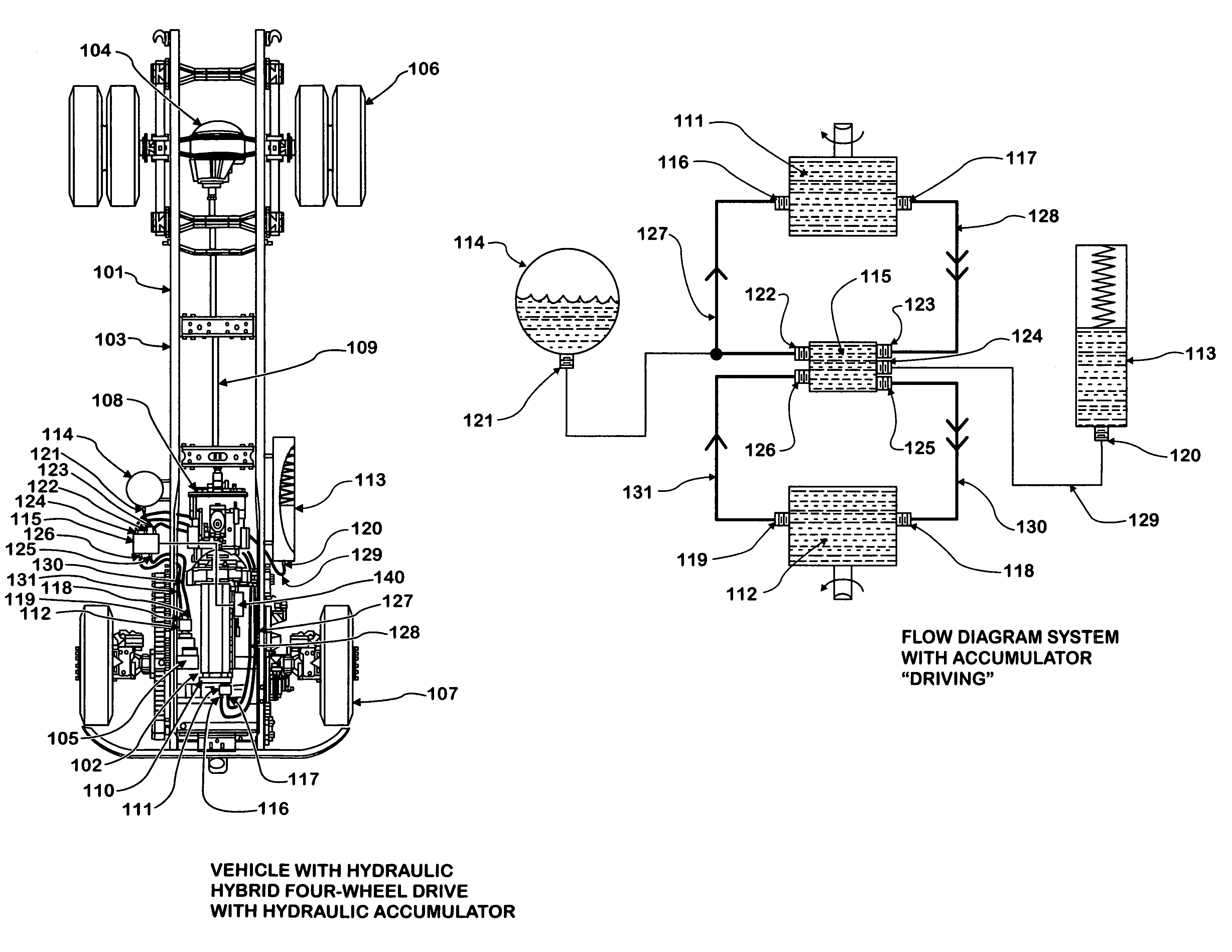

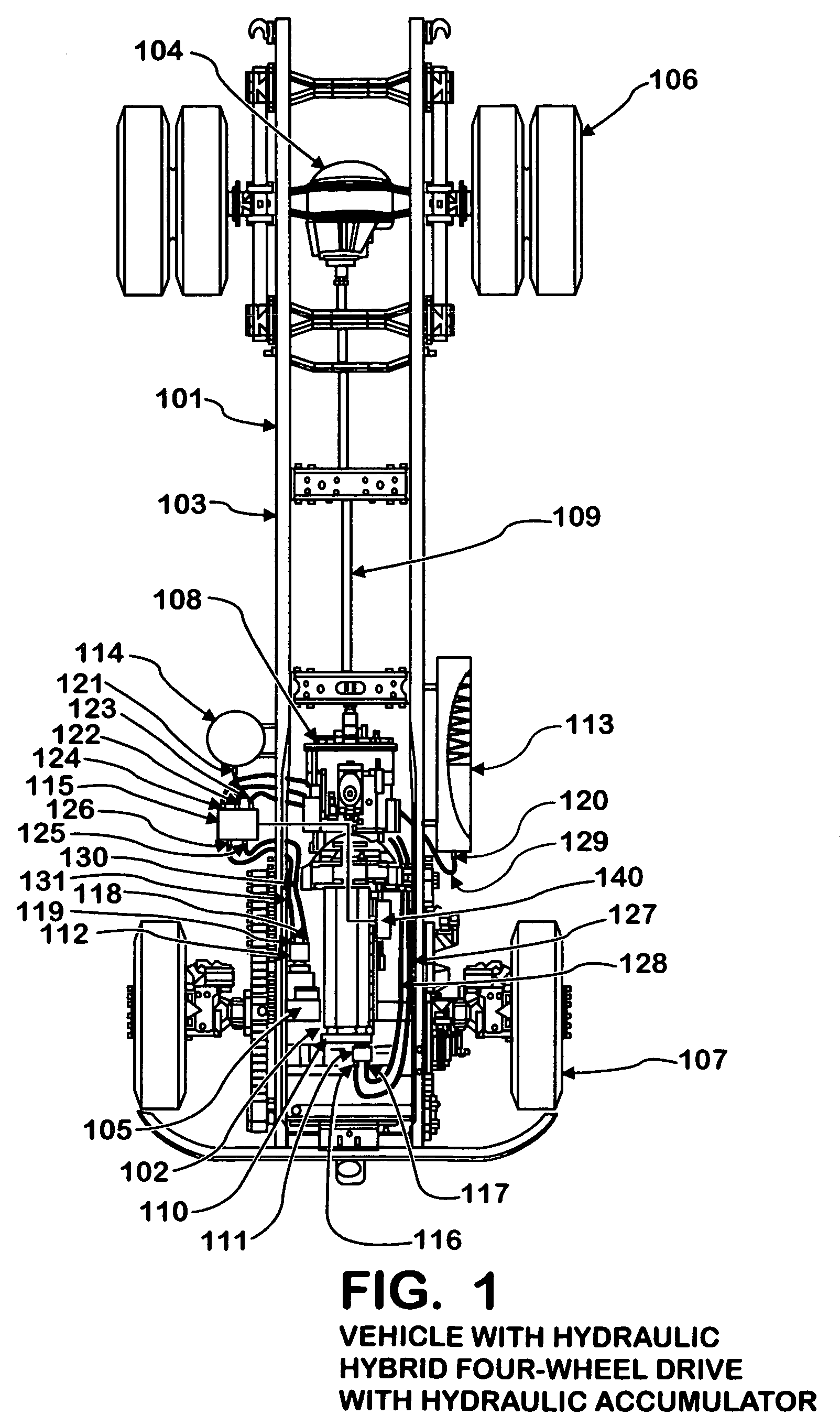

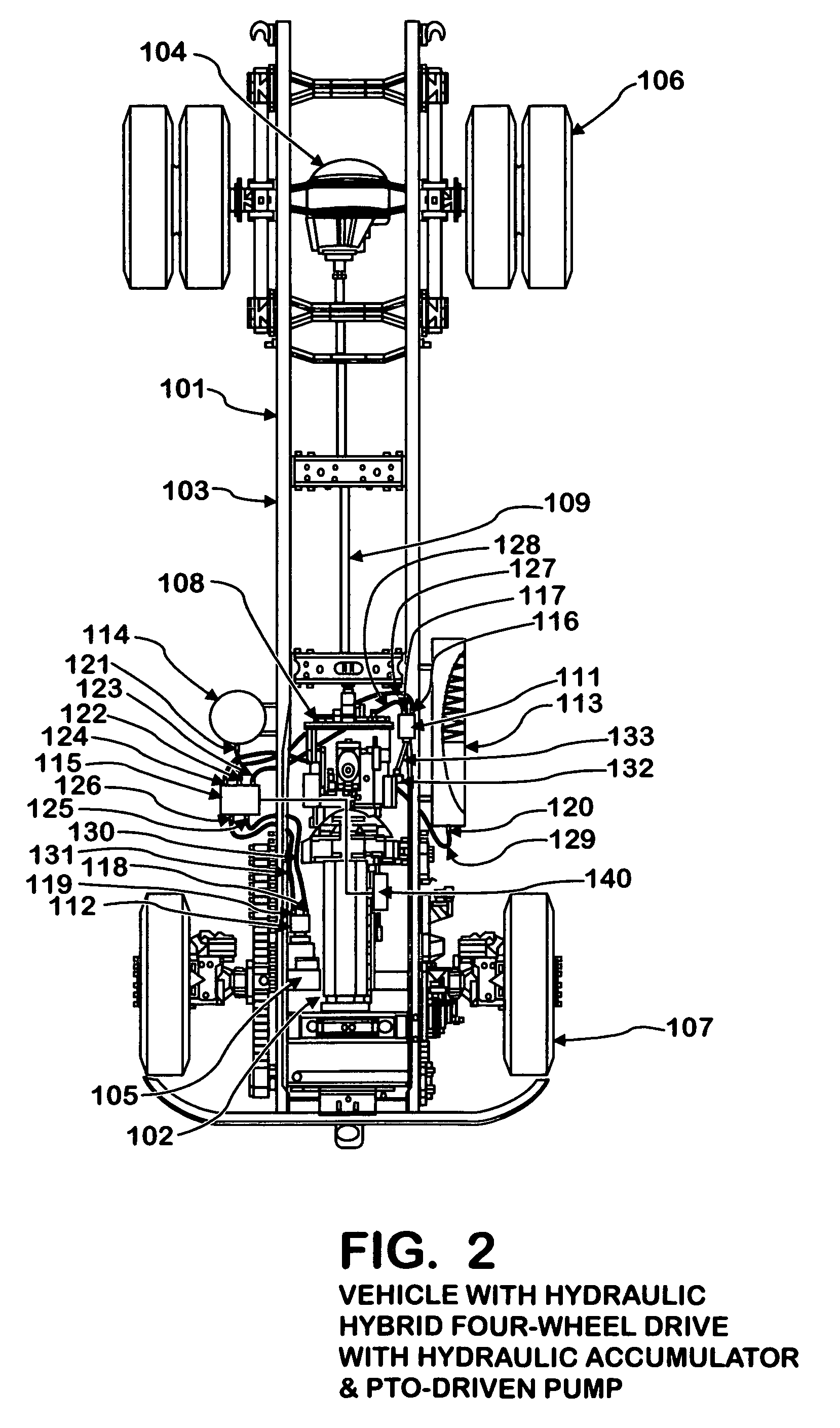

Hydraulic hybrid four wheel drive

InactiveUS20060197375A1Enhance engine brakingImprove fuel efficiencyBraking action transmissionPlural diverse prime-mover propulsion mountingHydraulic motorEngineering

Owner:INT TRUCK INTPROP LLC

Compact hydraulic accumulator

A lightweight, optimally efficient, easily serviced, piston-in-sleeve high pressure accumulator is provided. The accumulator includes one or more cylindrical composite pressure vessel separate end cap manifolds. A piston slidably disposed in a thin impermeable internal sleeve in the accumulator separates two chambers, one adapted for containing a working fluid and the other adapted for containing gas under pressure. Gas is provided in a volume between the impermeable internal sleeve and the composite pressure vessel wall. Additional gas is optionally provided in gas cylinders. Further components are provided for withstanding harmful effects of radial flexing of the composite vessel wall under high pressures, and from stresses present in use in mobile applications such as with a hydraulic power system for a hydraulic hybrid motor vehicle.

Owner:NRG ENTERPRISES

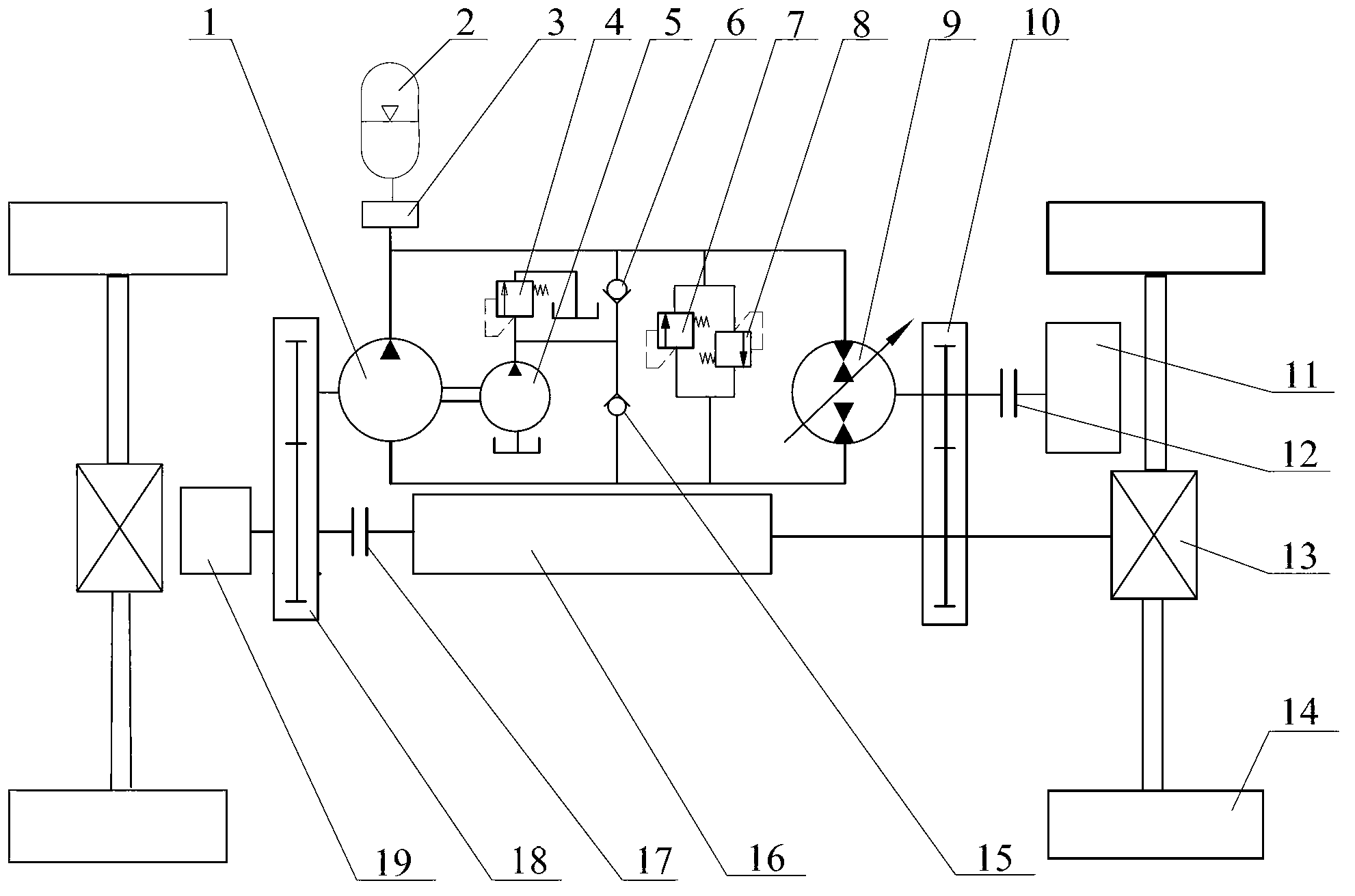

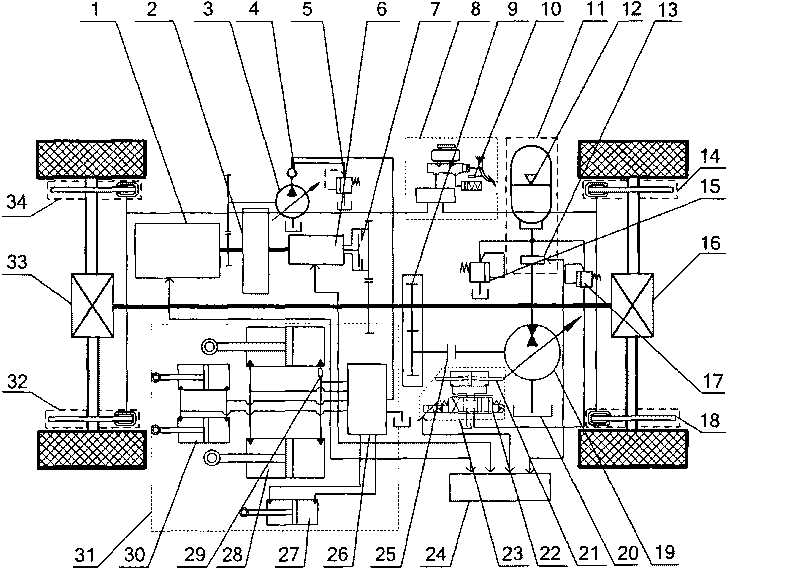

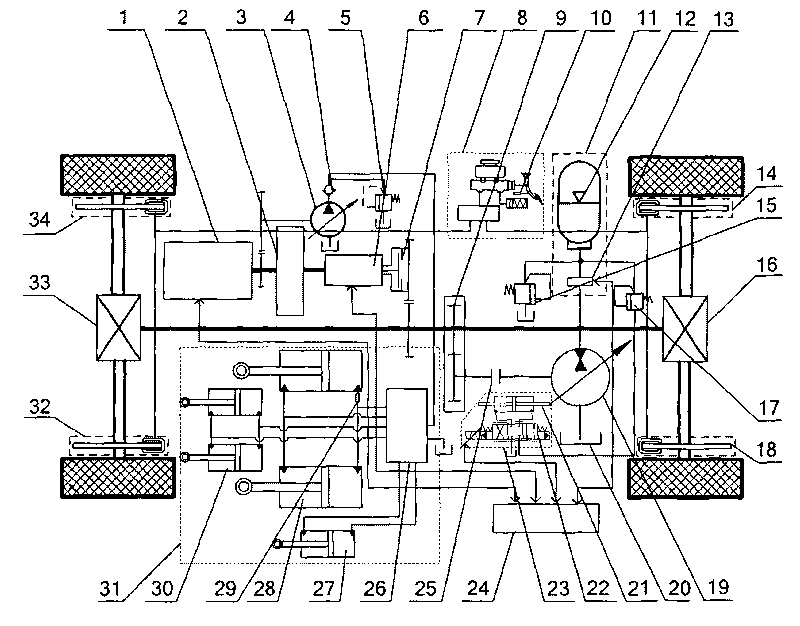

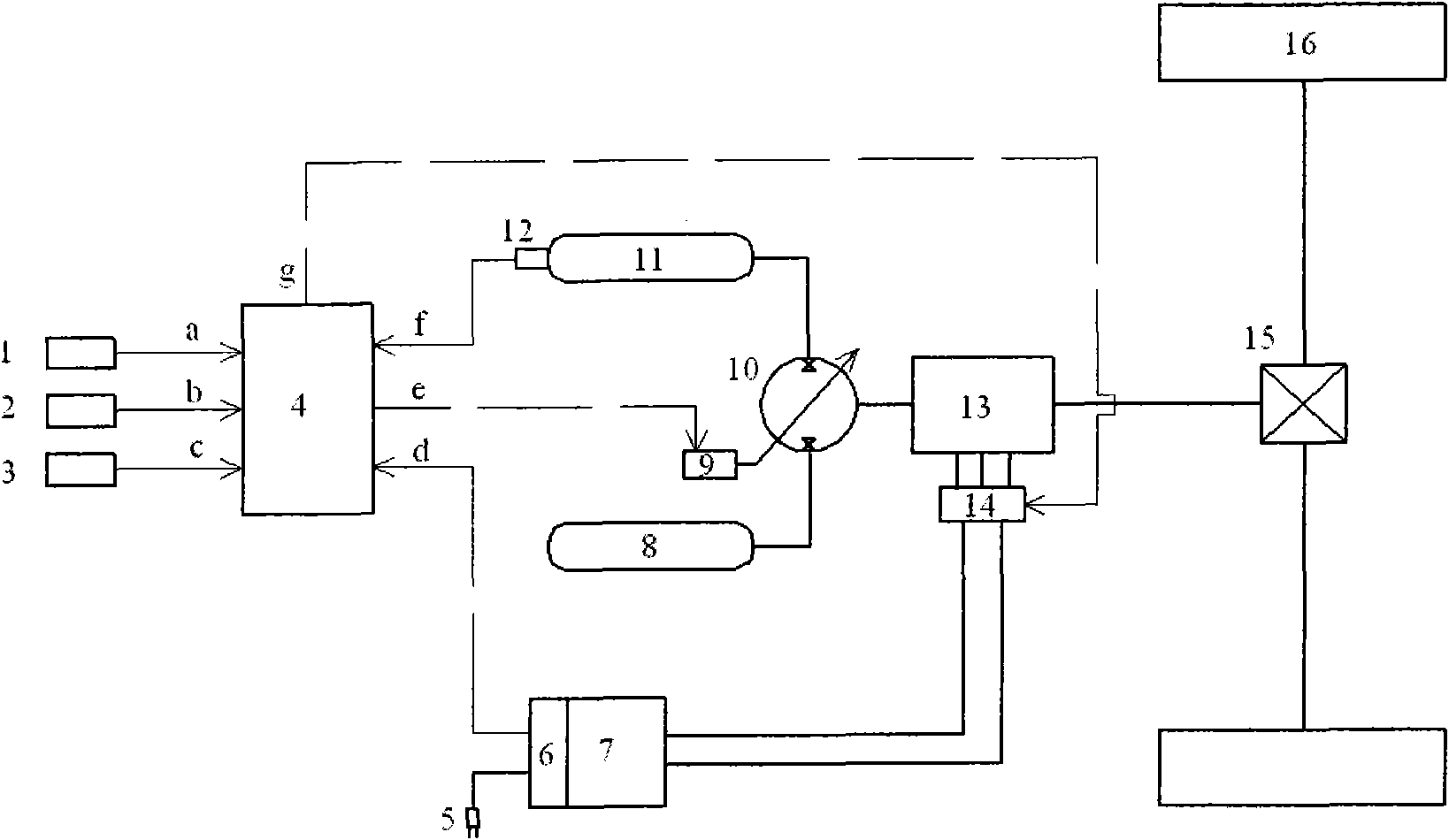

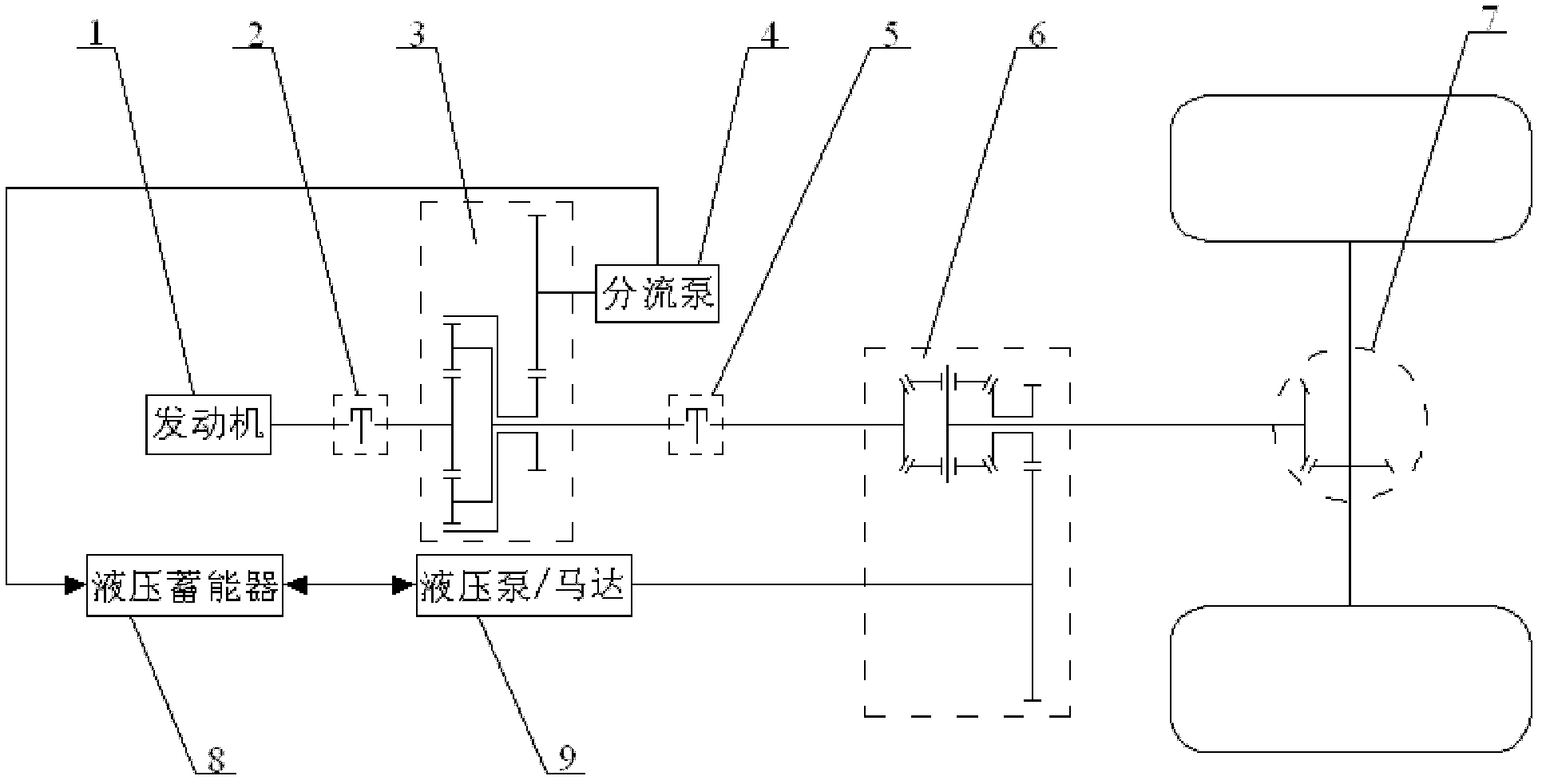

Power distribution hydraulic hybrid power drive device and vehicle

ActiveCN102795092AImprove transmission efficiencyImprove driving abilityGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingEngineeringPower take-off

The invention relates to a power distribution hydraulic hybrid power drive device and a vehicle. The power distribution hydraulic hybrid power drive device comprises a first drive unit and a second drive unit connected in parallel, and a central controller connected with the first drive unit and the second drive unit, wherein the first drive unit comprises an engine, a first clutch, a force takeoff device connected with the engine, a gearbox connected with the power takeoff device through the first clutch and a drive axle connected with the gearbox; the second drive unit comprises a hydraulic variable pump, a hydraulic energy storage device, a hydraulic pump motor and a torque coupler; the hydraulic variable pump is connected with the power takeoff device; and the torque coupler is also connected with the gearbox and the drive axle of the first drive unit. According to the power distribution hydraulic hybrid power drive device, hydrostatic transmission and / or mechanical transmission can be reasonably adopted by the central controller according to the running condition of the vehicle, so that the transmission efficiency of the whole vehicle is improved and the energy consumption is reduced.

Owner:XCMG CONSTR MACHINERY

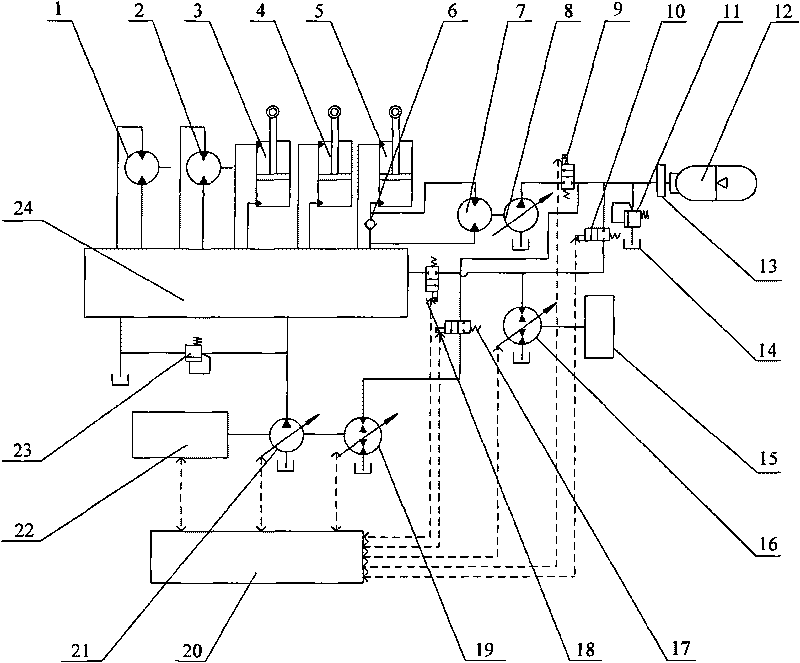

Hydraulic hybrid power system of excavator

ActiveCN101858094AEasy wiringEase of recyclingSoil-shifting machines/dredgersMechanical componentsEngineering

The invention discloses a hydraulic hybrid power system of an excavator, which is connected with a hydraulic rotary motor of the excavator and comprises a variable pump I, a variable pump II, a non-return valve, change valves, an accumulator and shuttle valves, wherein the variable pump I and the variable pump II are reversely connected; two ends of the shuttle valves are connected with the oil inlet and the oil outlet of the rotary motor; the variable pump I and the variable pump II are respectively connected with the two shuttle valves through the change valves; the accumulator is connected with one change valve; and the variable pump II is connected with the accumulator through the non-return valve. The hydraulic hybrid power system can effectively absorb the energy generated when the excavator carries out revolving breaking and release the energy when the excavator rotates reversely, thereby realizing the purpose of recycling the energy, simultaneously protecting hydraulic systems and elements, avoiding hydraulic impact and overflow heating, and prolonging the service lives of hydraulic elements and mechanical parts.

Owner:SINOTRUK QINGDAO HEAVY IND

Multiple pressure mode operation for hydraulic hybrid vehicle powertrain

ActiveUS20050167177A1Quick transitionWithout adverse performance effectAuxillary drivesGas pressure propulsion mountingMotor speedRail pressure

A system for a hydraulically driven vehicle includes a pump producing fluid flow at an outlet, pump-motors having variable flow rates for driving the wheels, a hydraulic rail having a pressure and connecting the pump and the pump-motors, sensors producing signals representing rail pressure, pump-motor speed, pump-motor displacement, and a controller for determining a target hydraulic system parameter, determining, based at least in part on the flow rate of the pump-motor, rail pressure, and a flow rate produced by the engine-pump, a flow rate produced by the engine-pump that is required to produce the target system parameter, and adjusting an engine operating parameter of a cylinder-pump bank such that the demanded magnitude of the system parameter is produced.

Owner:FORD GLOBAL TECH LLC

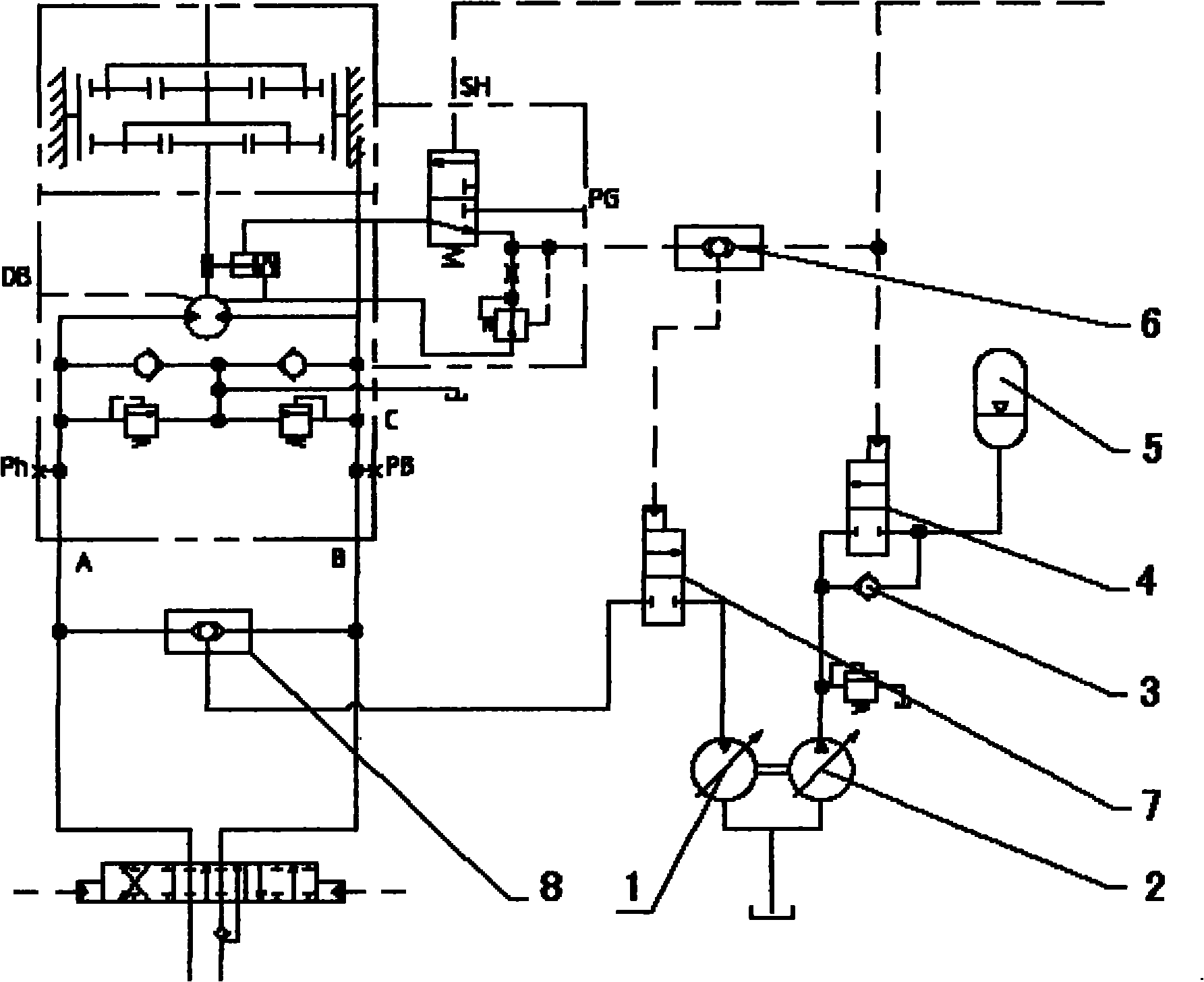

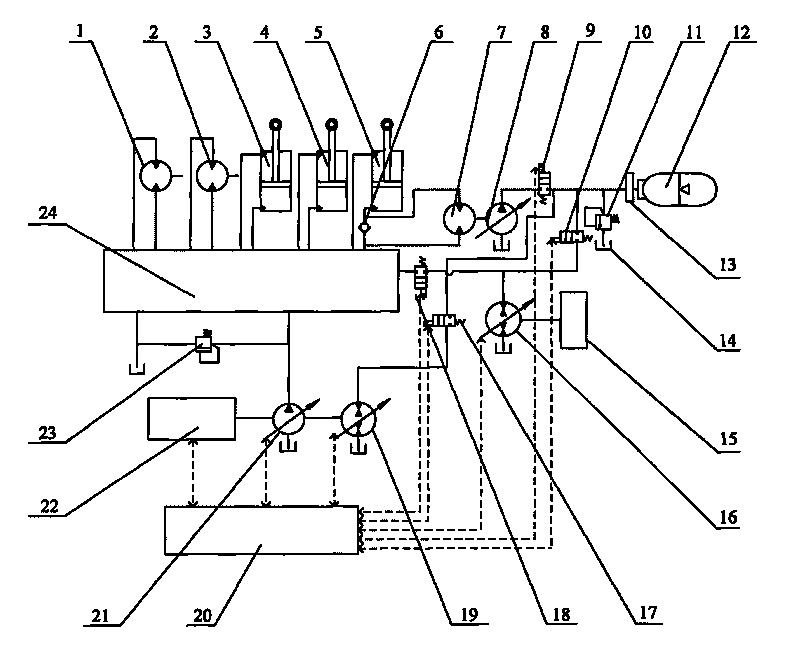

Energy-saving hydraulic hybrid power system of loader

ActiveCN101704336AReal-time control of output powerDriving to achieveGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingWork performanceElectromagnetic clutch

The invention relates to an energy-saving hydraulic hybrid power system of a loader and belongs to a power system of the loader. An engine of the hybrid power system is in mechanical connection with a hydraulic variable pump and a hydraulic torque converter; an oil outlet of the hydraulic variable pump is communicated with an oil inlet of a one-way valve; an oil inlet of a second overflow valve and a distribution valve are communicated with oil inlets or oil return ports of the one-way valve, an oil tank, a movable arm oil cylinder, a bucket oil cylinder and a steering oil cylinder respectively; an oil inlet of a hydraulic pump / motor control component is communicated with an oil outlet of a reducing valve; each oil return port is communicated with the oil tank; an oil outlet of a two-position two-way reversing valve is communicated with an oil inlet of the hydraulic pump / motor; the hydraulic pump / motor component and the hydraulic pump / motor are in mechanical connection; and an output shaft of the hydraulic pump / motor is in mechanical connection with the input ends of a front axle and a rear axle through an electromagnetic clutch and a torque coupler. The energy-saving hydraulic hybrid power system has the advantages that: the hydraulic hybrid power system can reclaim the braking kinetic energy of the whole machine, improves the working efficiency and working performance of thewhole machine and has long service life.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

Hydraulic hybrid electric vehicle transmission system and control method thereof

InactiveCN102019842AAchieving zero emissionsEfficient recyclingHybrid vehiclesGas pressure propulsion mountingDriver/operatorWork performance

The invention provides a hydraulic hybrid electric vehicle transmission system, which belongs to the technical field of vehicle energy conservation and emission reduction. The vehicle transmission system, without a clutch or a gear box, is directly connected with a main reducer and a differential to drive the vehicle according to the stepless speed regulation characteristics of an electromotor and a hydraulic pump / motor to reduce the operation strength of a driver. A storage battery-electromotor is used as the main power source of the vehicle; a hydraulic accumulator-variable pump / motor is only used for recycling and reusing the brake energy of the vehicle; during acceleration, the hydraulic pump / motor supplies extra power; particularly in start process, the hydraulic pump / motor alone drives the vehicle to start moving, and the electromotor can always run in stable conditions. The impact of variable conditions on the circuit system is reduced, the load of the storage battery is remarkably lowered, the work performance of the storage battery-electromotor is promoted, the service life of the storage battery-electromotor is prolonged, and the continuous mileage of the electric vehicle is prolonged.

Owner:BEIJING UNIV OF TECH

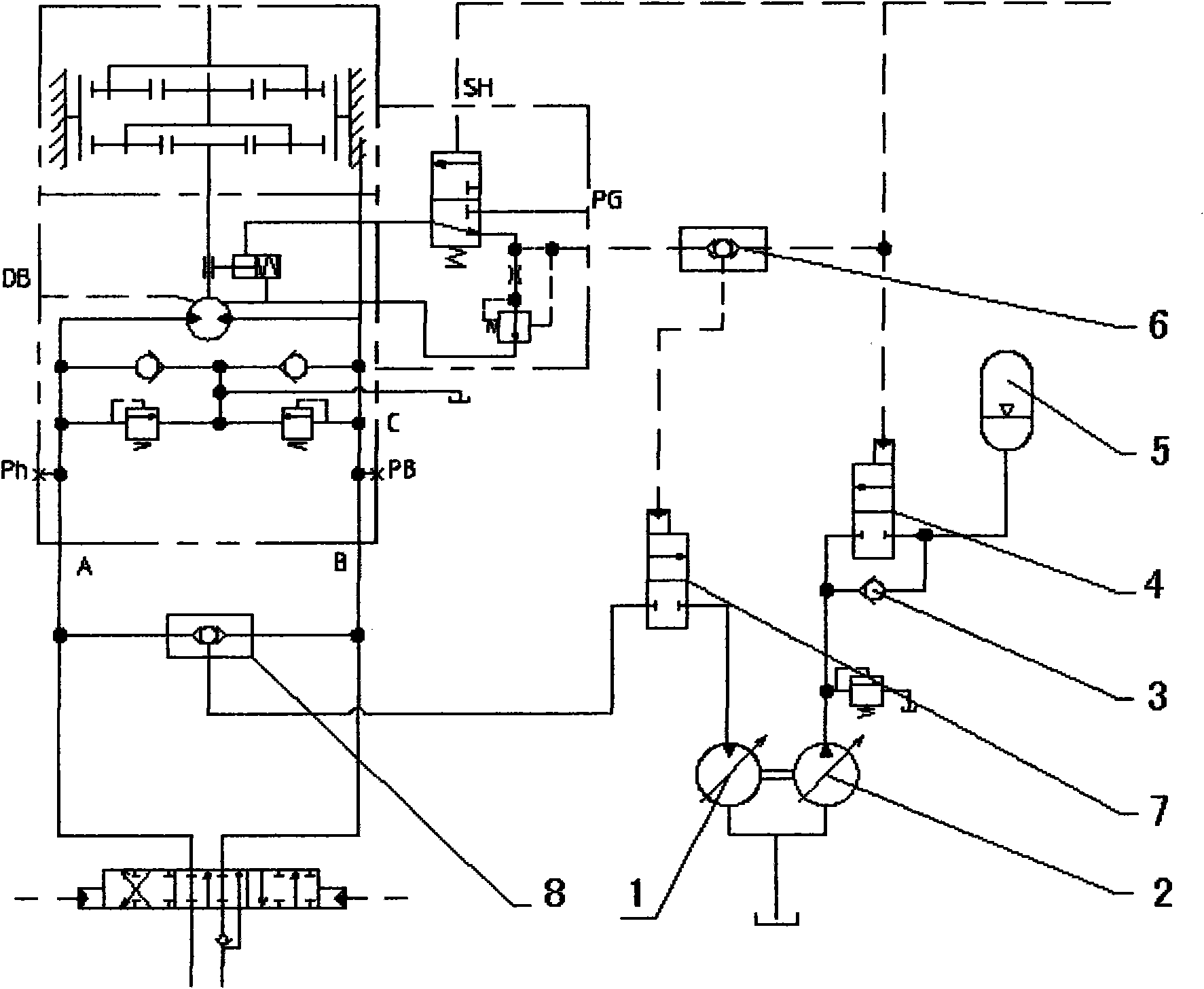

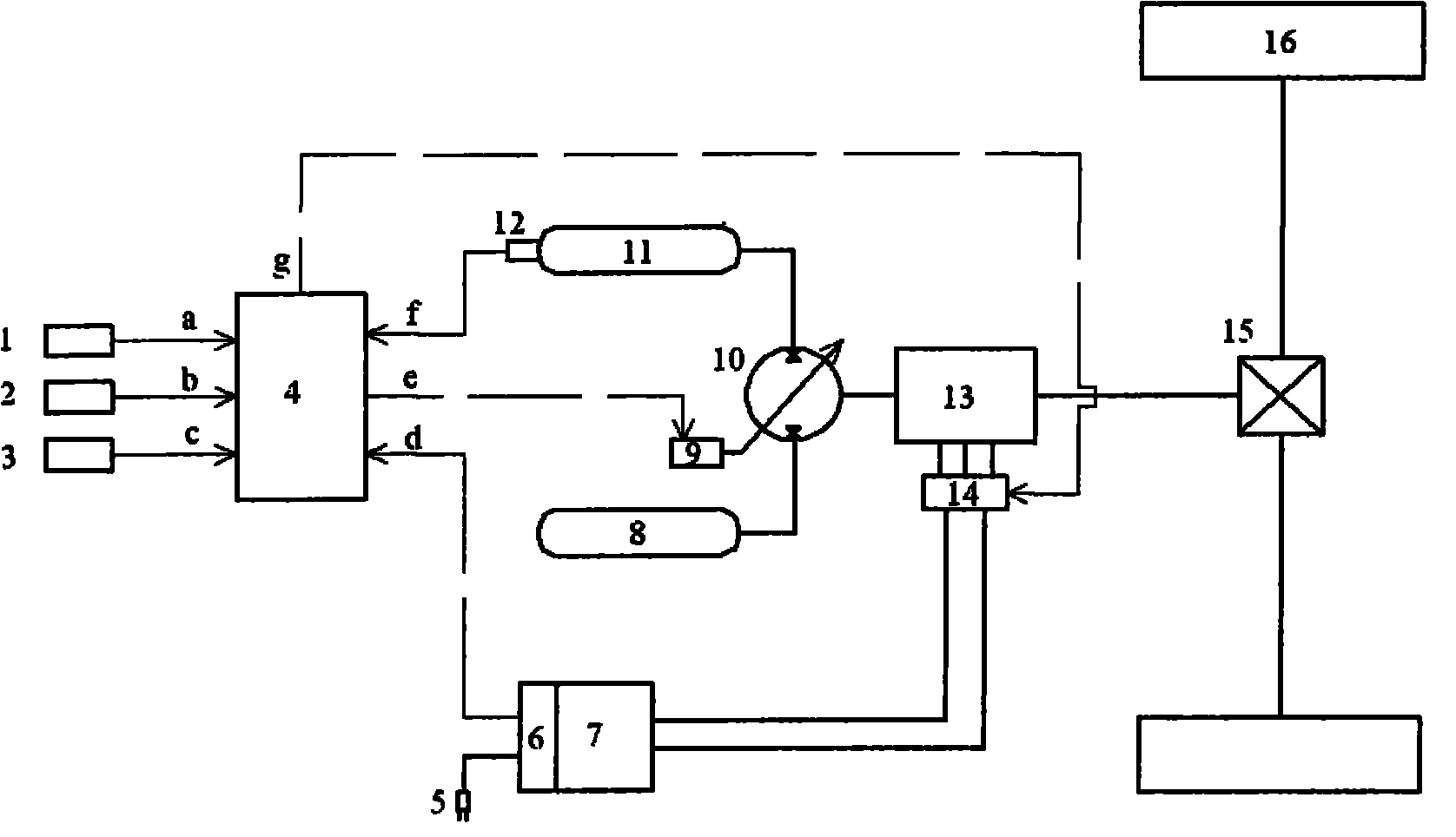

Parallel hydraulic hybrid driving system of vehicle

InactiveCN103223849ASimple structureReduce lossesGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingHigh pressureHydraulic pressure

The invention relates to a parallel hydraulic hybrid driving system of a vehicle, which comprises a mechanical transmission system and a hydraulic regenerative brake system, wherein the mechanical transmission system comprises an engine, a gearbox, a hydraulic control clutch, a power coupler, a two-way variable pump / motor, a transmission shaft and a rear driving axle; and the hydraulic regenerative brake system comprises a two-way variable pump / motor, a first stop valve, an oil tank, a variable mechanism of the two-way variable pump / motor, a plugin valve, a high pressure accumulator, a high pressure accumulator pressure gauge, a pressure sensor, a reducing valve, a two-position two-way reversing valve, an overflow valve and a filter. A charging / discharging major loop of the driving system adopts a controllable plugin valve, the plugin valve is controlled by controlling a pilot valve of the driving system, and the driving system responses rapidly. The driving system is convenient to operate and high in reliability, the power source switching is smooth, the power performances of the vehicle are improved, and the driving system has significant effects in recovering energy of the vehicle and improving fuel economy. The driving system meets the intermittent and high-power requirements and is used for the heavy vehicle requiring frequent start and parking operations.

Owner:TONGJI UNIV +1

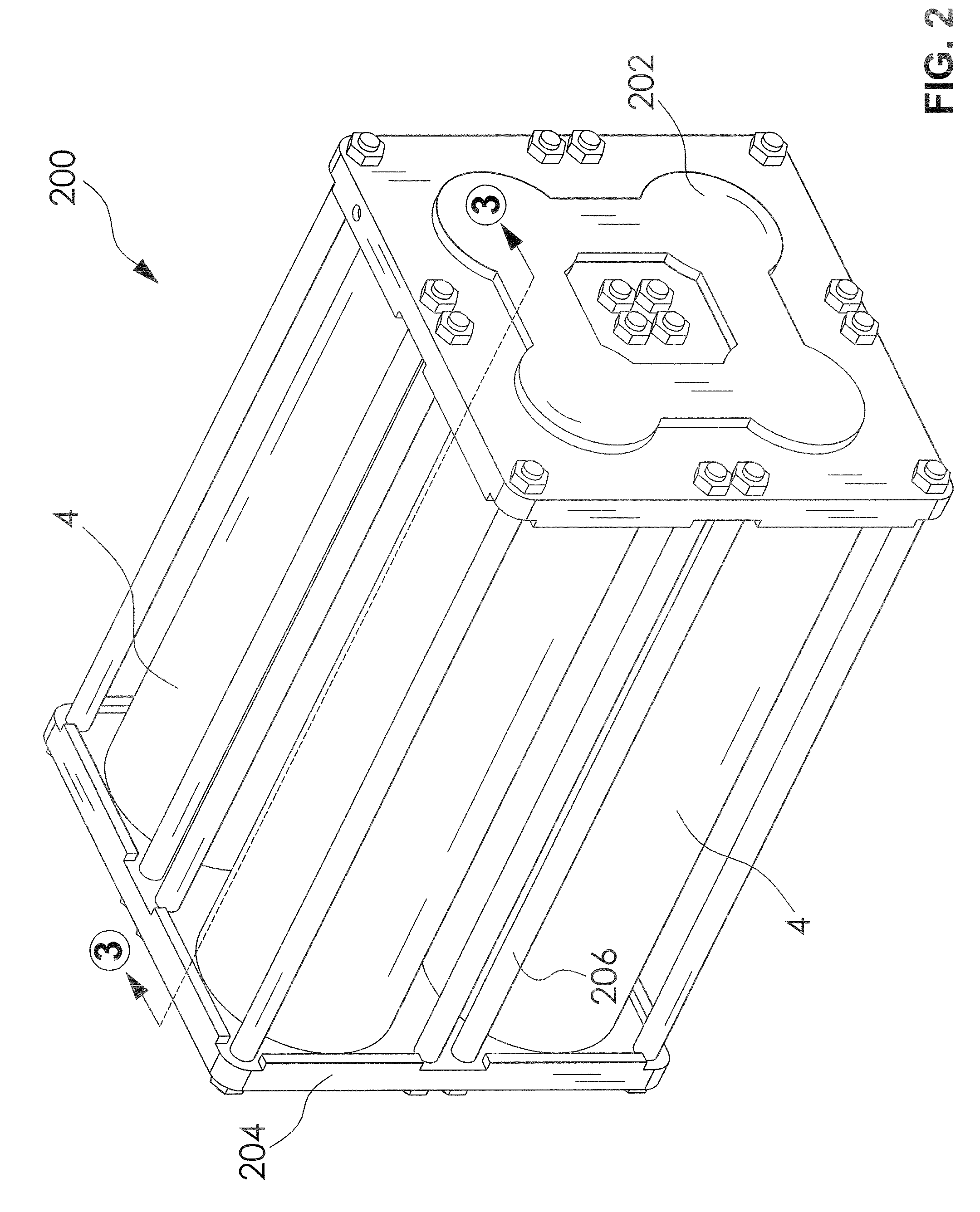

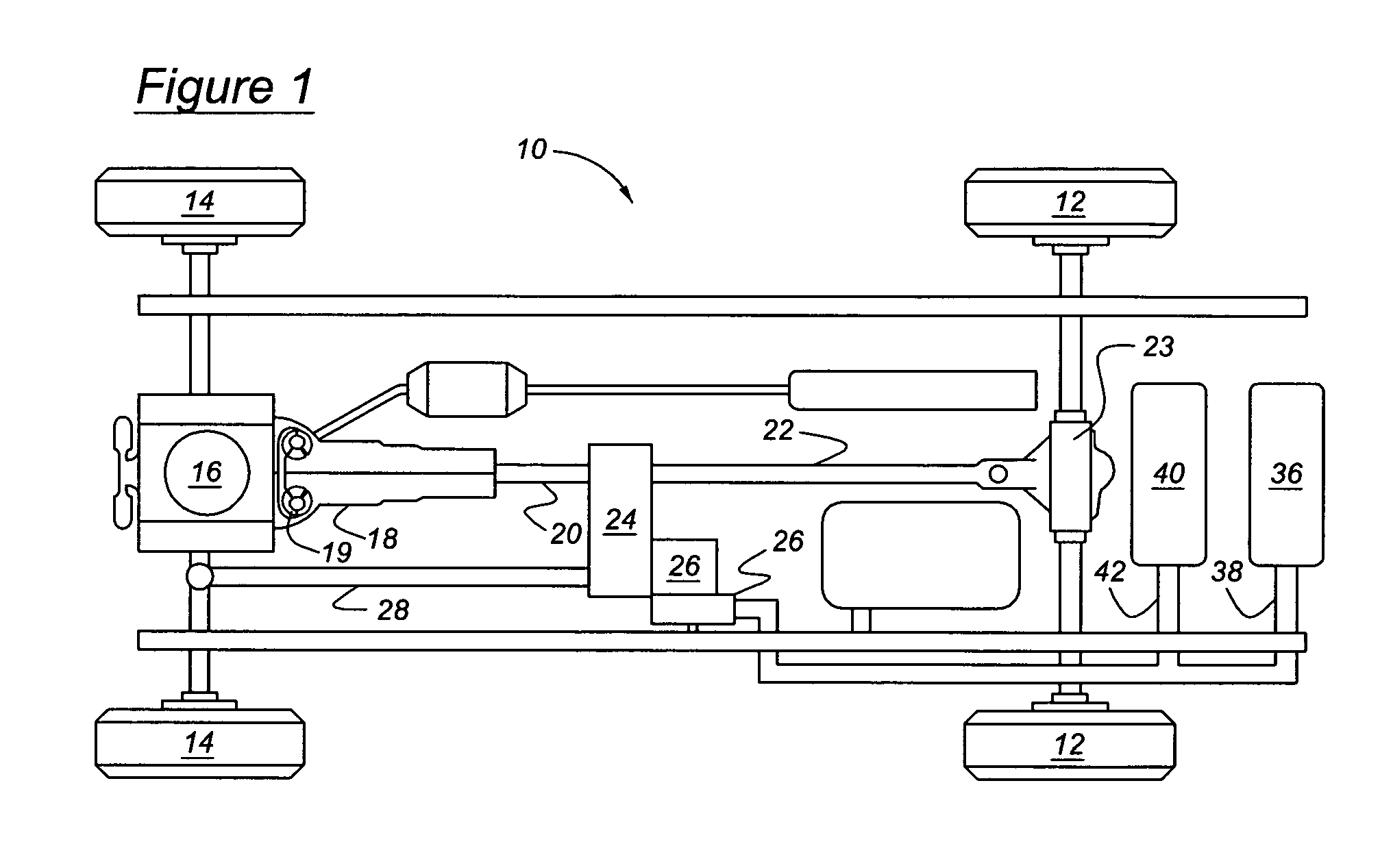

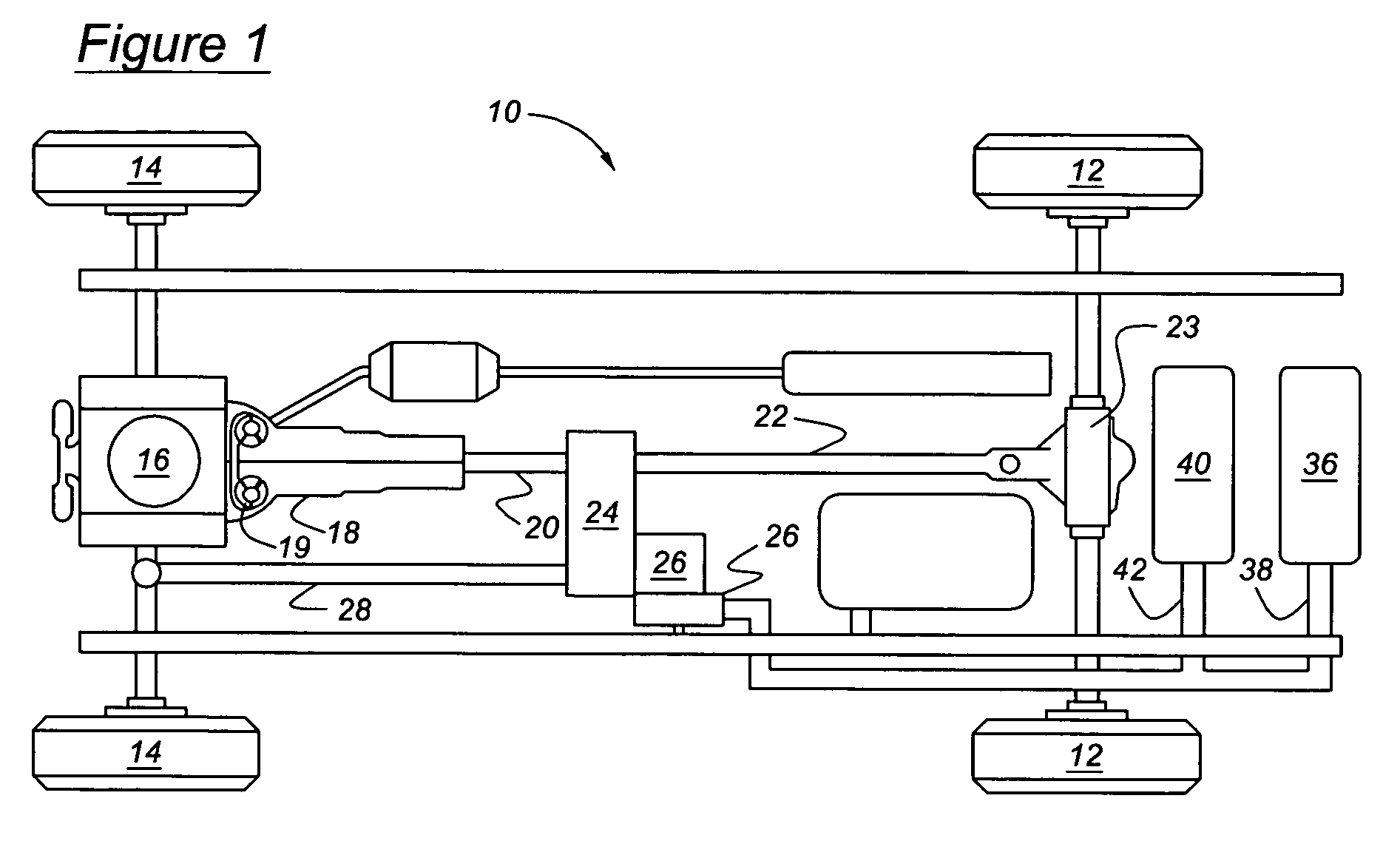

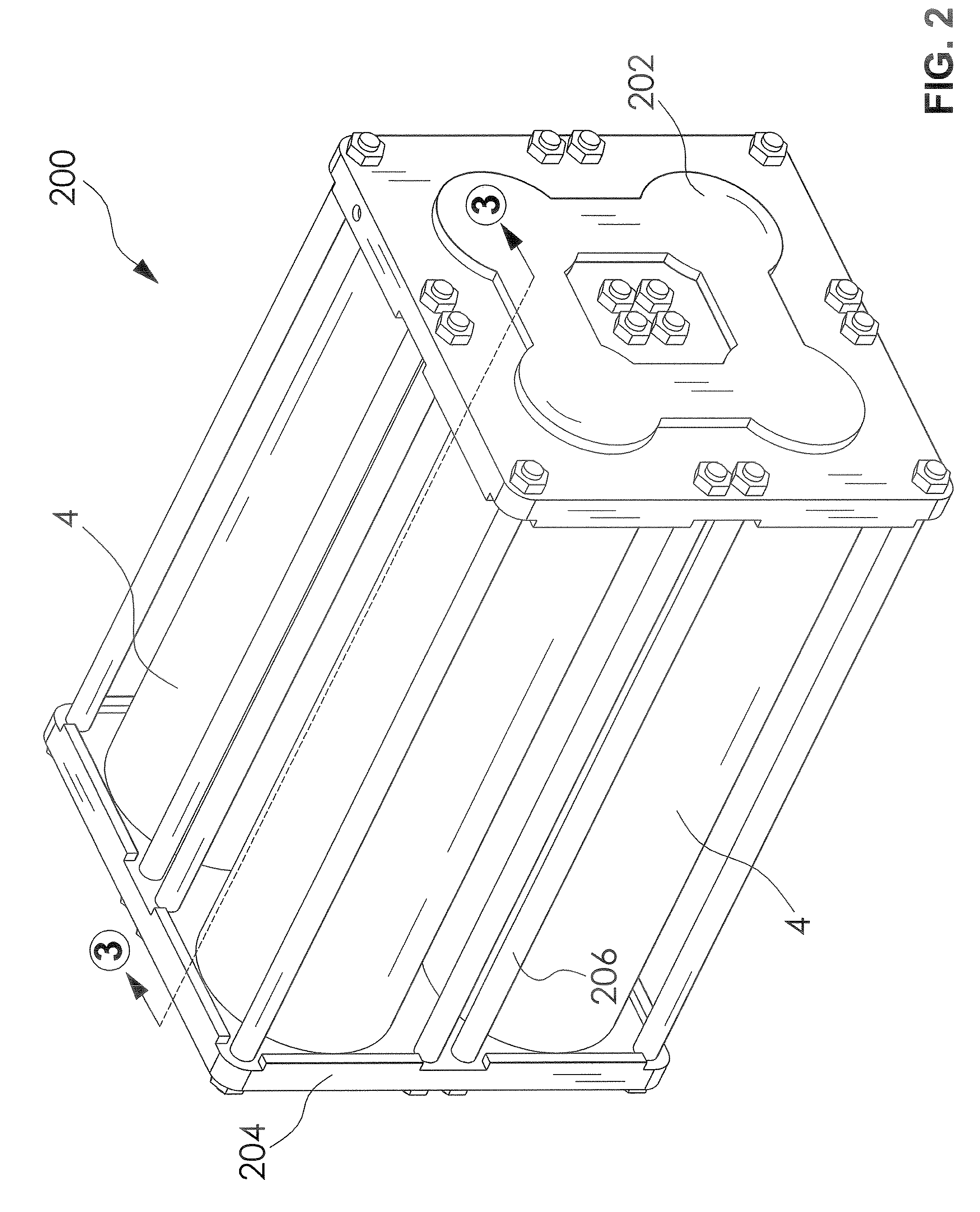

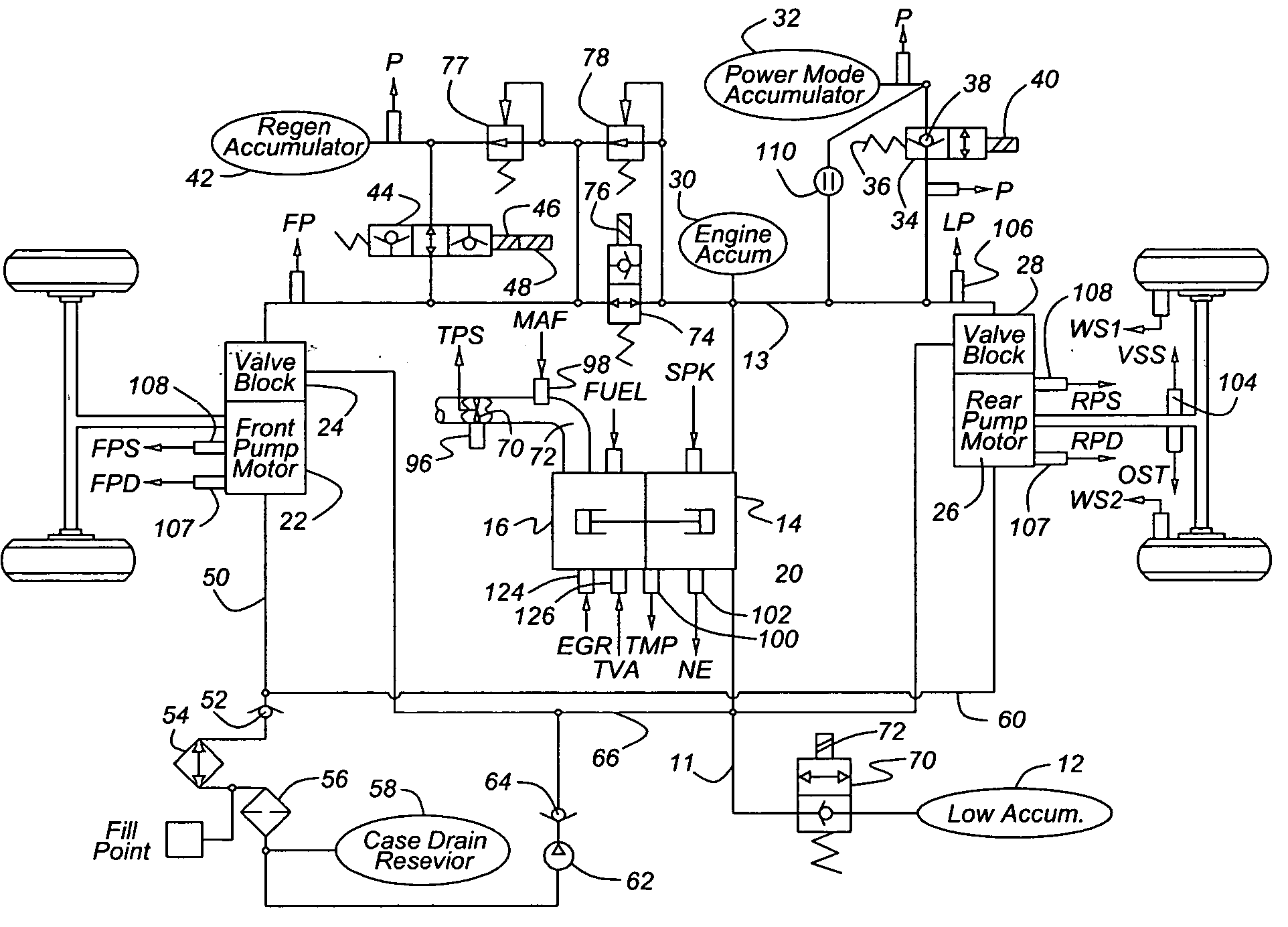

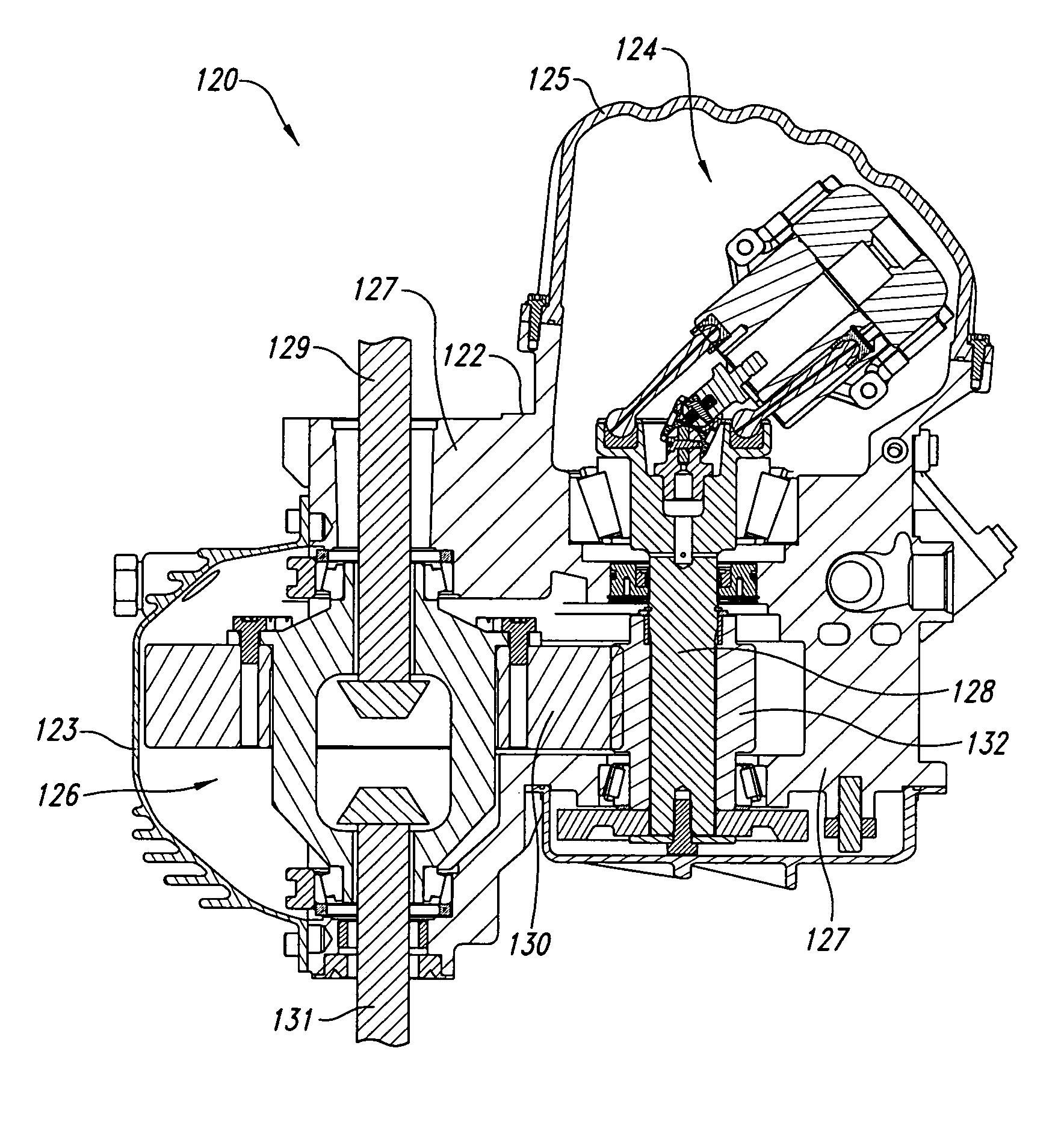

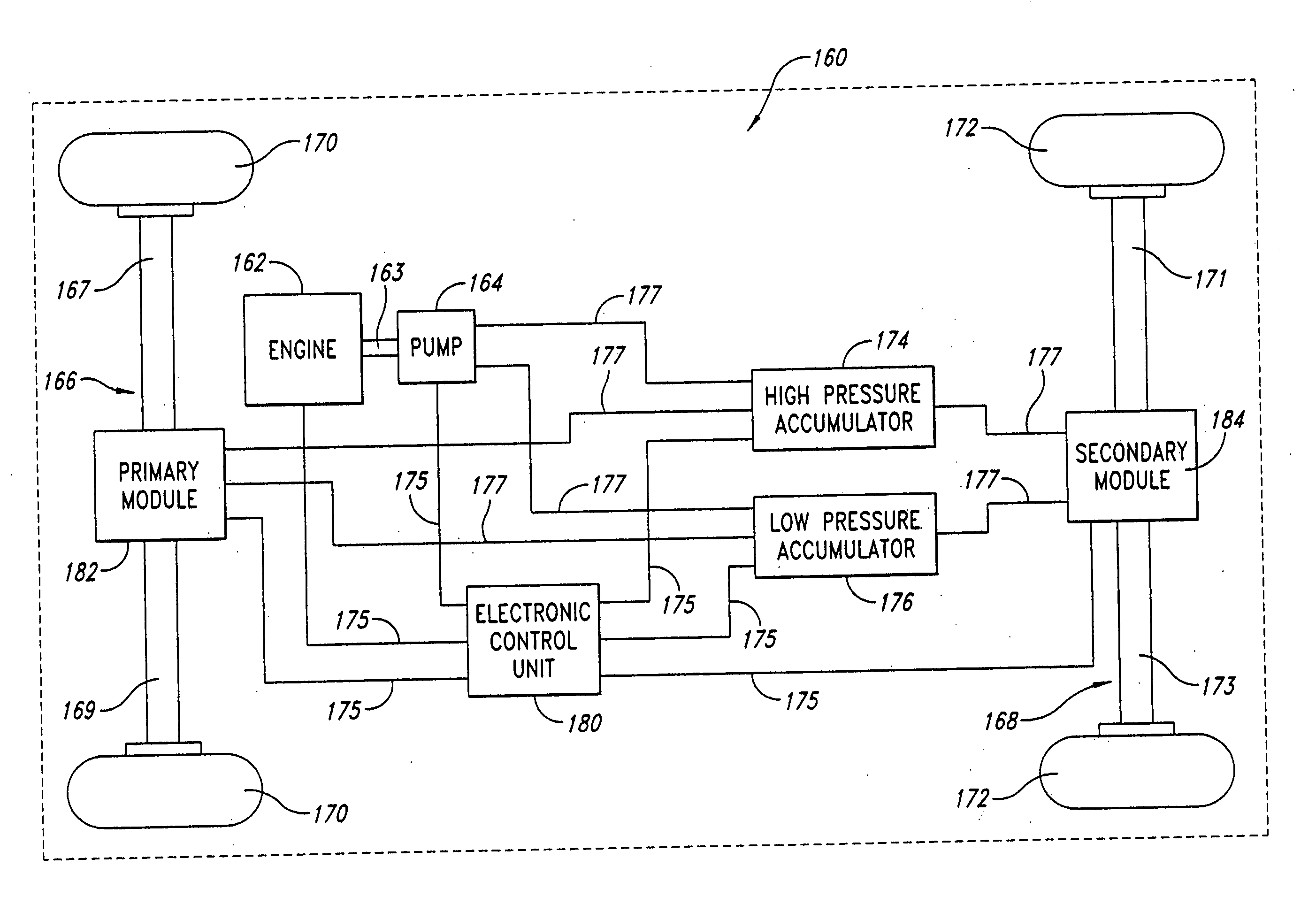

Hydraulic hybrid vehicle with integrated hydraulic drive module and four-wheel-drive, and method of operation thereof

InactiveUS7337869B2Small sizeReduce weightAuxillary drivesGearing controlHydraulic motorComputer module

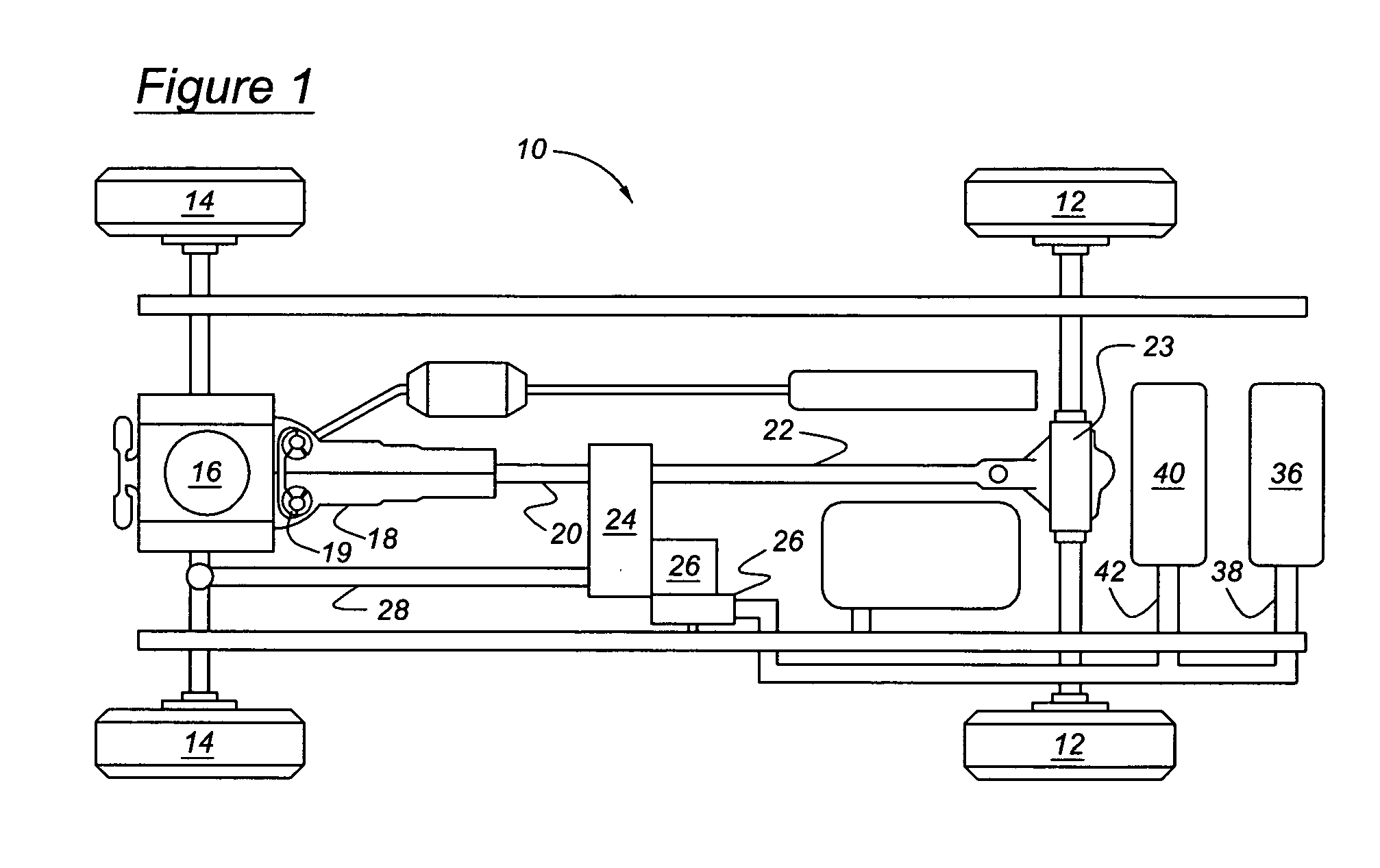

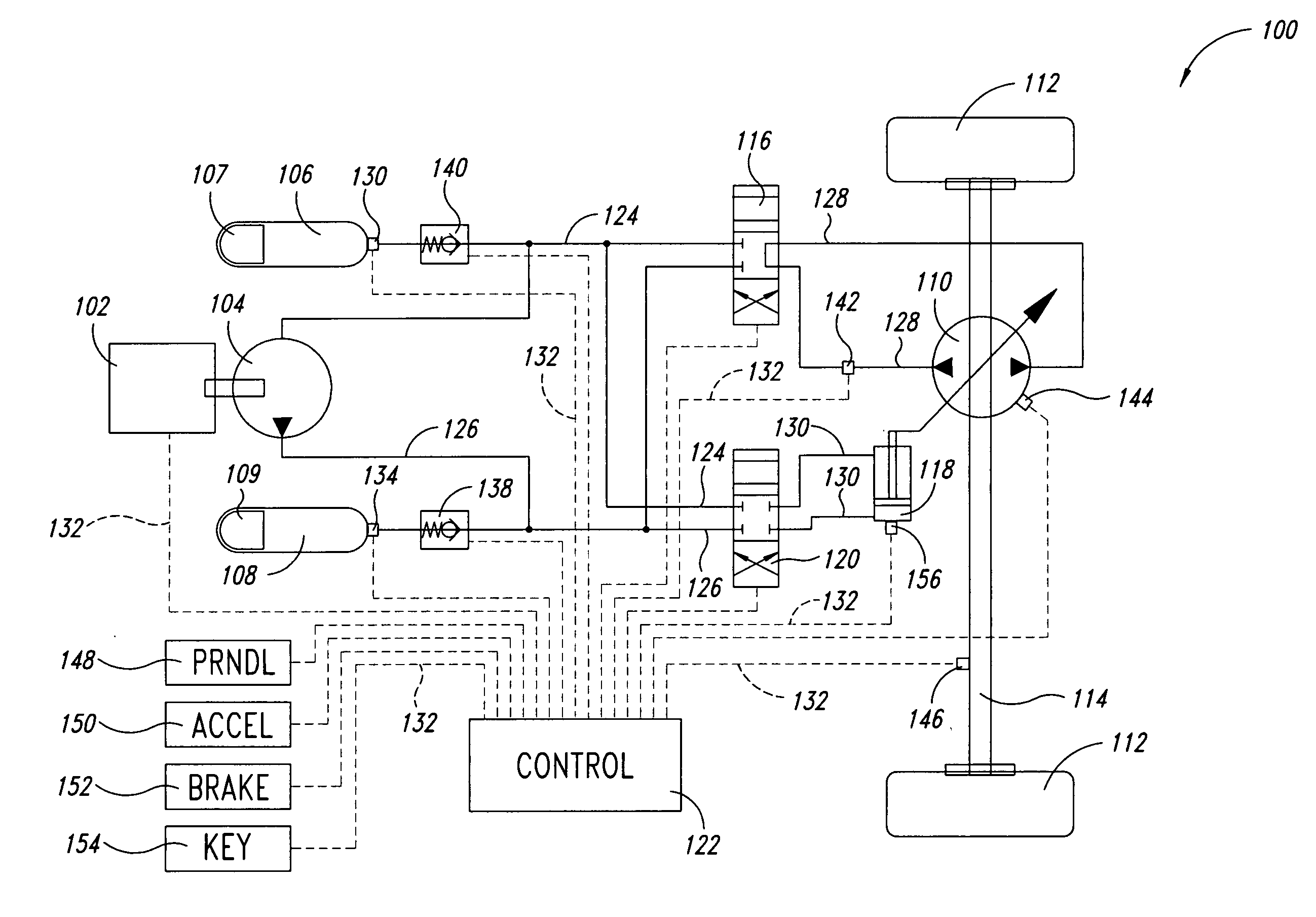

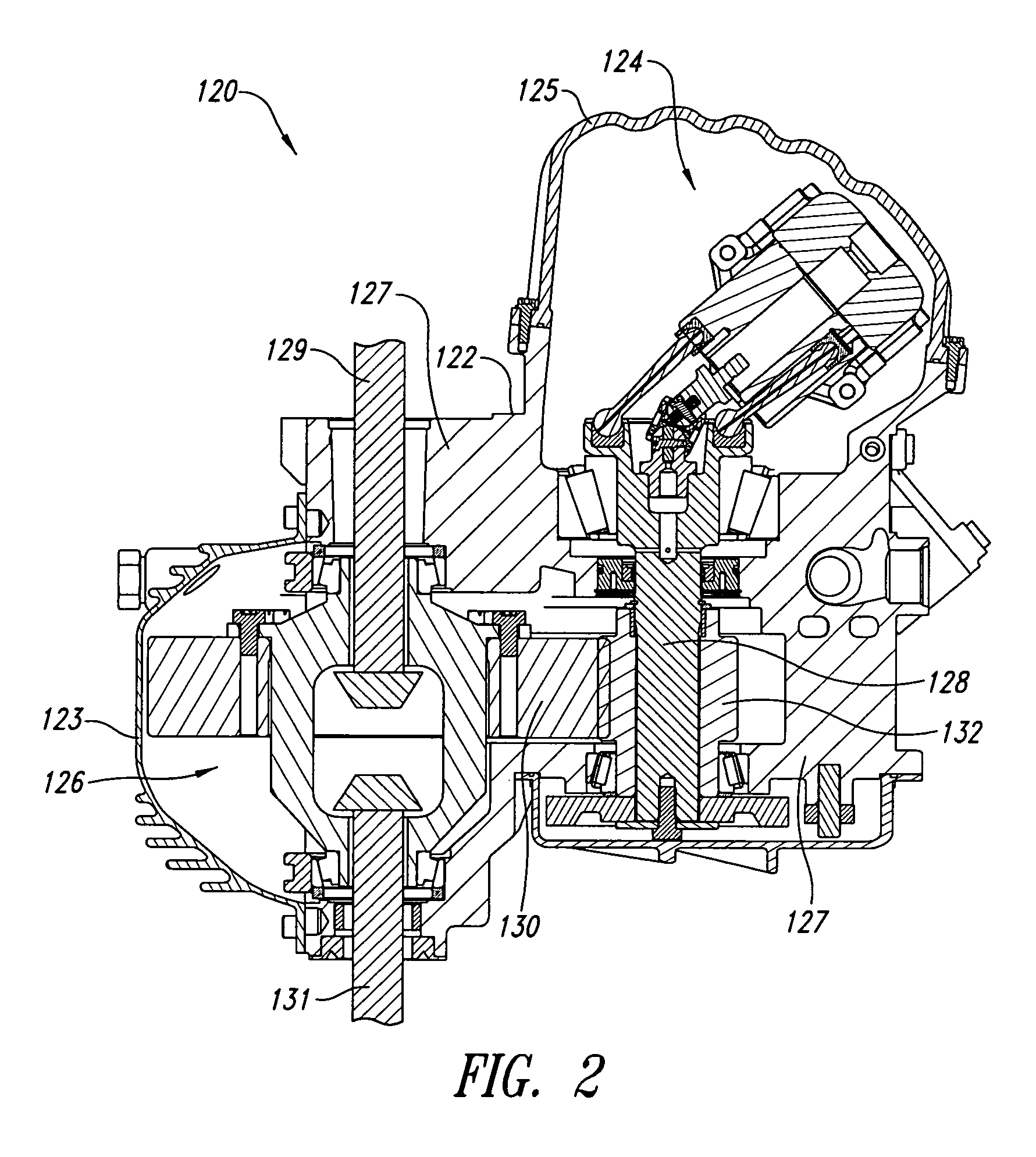

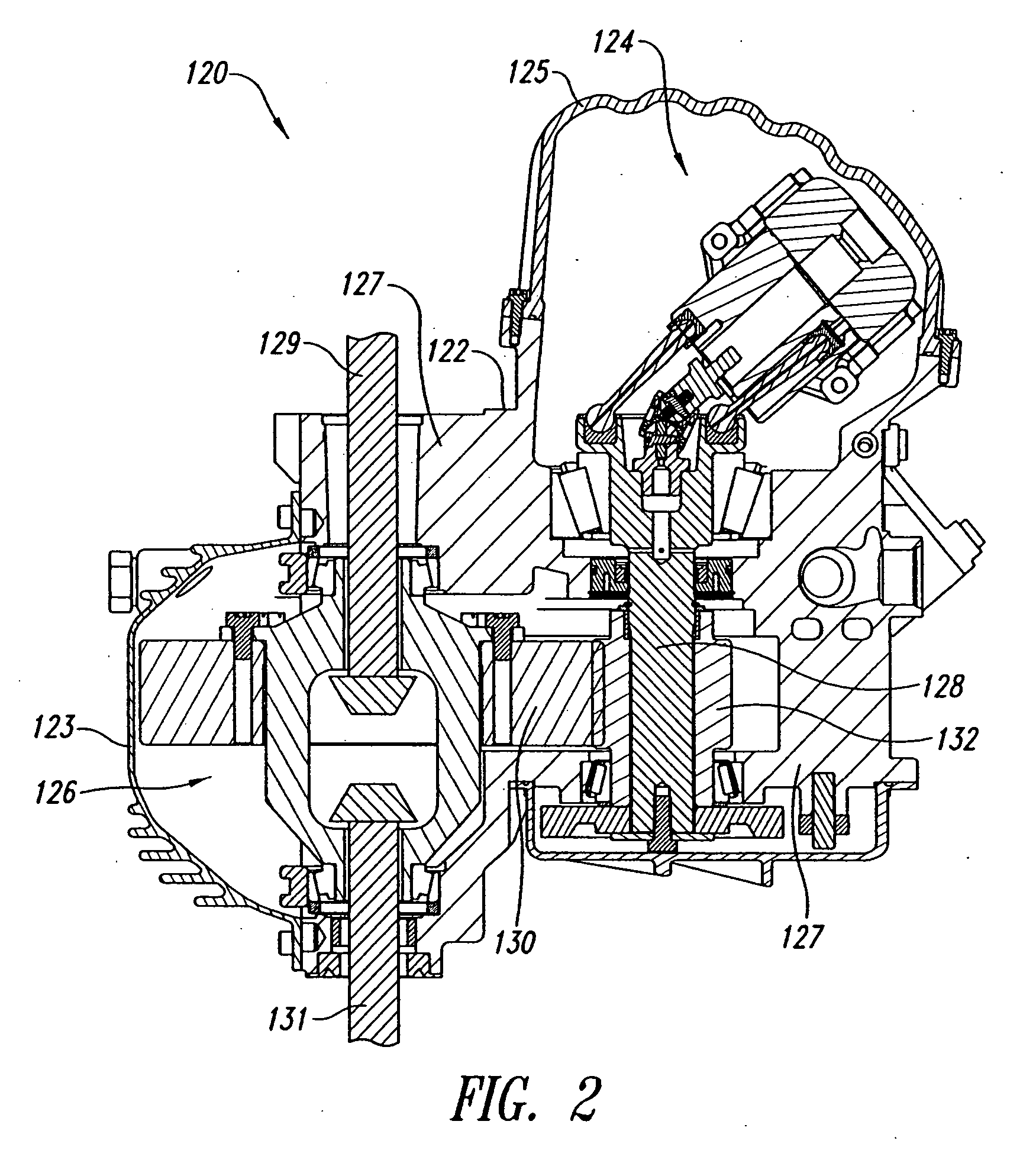

A vehicle includes an integrated drive module coupled to an axle thereof. The module includes a hydraulic motor configured to provide motive power at an output shaft, and a differential for distributing the motive power to right and left portions of the axle. The hydraulic motor and the differential are encased within a common housing. The vehicle may include a second integrated drive module having, within a housing, a second hydraulic motor (or multiple hydraulic motors), and a second differential coupled thereto and configured to distribute motive power to right and left portions of a second axle. The second module may also include a transmission within the same housing. The transmission may be a two speed or other multi-speed transmission. The second module is configured to operate in neutral while power demand is below a threshold, and to engage while the power demand exceeds the threshold. The second module may be configured to remain engaged for full-time four-wheel-drive operation.

Owner:GOVERNMENT OF THE US REPRESENTED BY THE ADMINISTRATOR OF THE U S ENVIRONMENTAL PROTECTION AGENCY

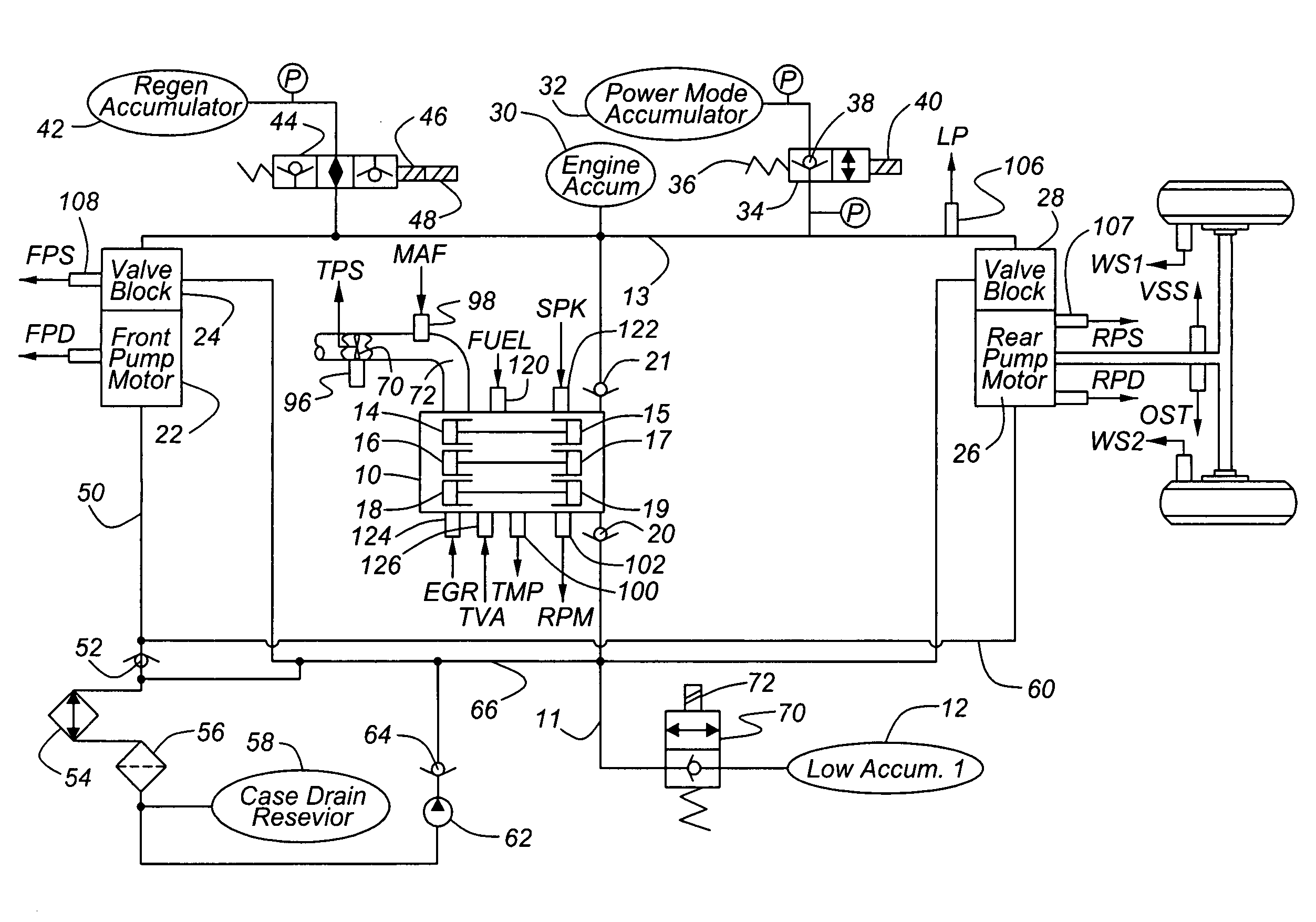

Methods for Safe Operation of Hydraulic Hybrid Vehicles with Over-Center Pump/Motors

InactiveUS20130014499A1Safe and stable mode of failurePrevents catastrophic over-pressurizationFluid-pressure actuator safetyRotary clutchesDisplacement controlDrive motor

Fail-safe methods for utilizing an over-center pump / motor in a hydraulic hybrid vehicle are disclosed. A high-pressure fluid shutoff valve and an optional electrically or manually operated valve are additionally provided as means to ensure disconnection of the high pressure source in the event of a failure. Displacement stroke position and pressure differentials across the pump / motor are continually monitored. On detection of various modes of failure or irregularity in control of displacement, actions are taken including any of: the high pressure and low pressure accumulators are shut off automatically or manually, a check valve between the high and low pressure ports of the pump / motor is activated, and a small amount of pressurized fluid is released from the high pressure circuit to depressurize the captive fluid. Safe startup and shutdown procedures are also specified. The system provides for safe operation of a hydraulic hybrid vehicle that includes an engine pump and drive motor, at least one of which operates over-center. The system optionally provides a displacement control valve that is controlled by feedback from an actuator or displacement position sensor and that on loss of electric power to the displacement control valve will cause the controlled pump / motor to stroke to a zero displacement position.

Owner:ENVIRONMENTAL PROTECTION AGENCY US

Hydraulic hybrid vehicle with integrated hydraulic drive module and four-wheel-drive, and method of operation thereof

InactiveUS20070278027A1Small sizeReduce weightAuxillary drivesGearing controlHydraulic motorElectric power

A vehicle includes an integrated drive module coupled to an axle thereof. The module includes a hydraulic motor configured to provide motive power at an output shaft, and a differential for distributing the motive power to right and left portions of the axle. The hydraulic motor and the differential are encased within a common housing. The vehicle may include a second integrated drive module having, within a housing, a second hydraulic motor (or multiple hydraulic motors), and a second differential coupled thereto and configured to distribute motive power to right and left portions of a second axle. The second module may also include a transmission within the same housing. The transmission may be a two speed or other multi-speed transmission. The second module is configured to operate in neutral while power demand is below a threshold, and to engage while the power demand exceeds the threshold. The second module may be configured to remain engaged for full-time four-wheel-drive operation.

Owner:ENVIRONMENTAL PROTECTION AGENCY US

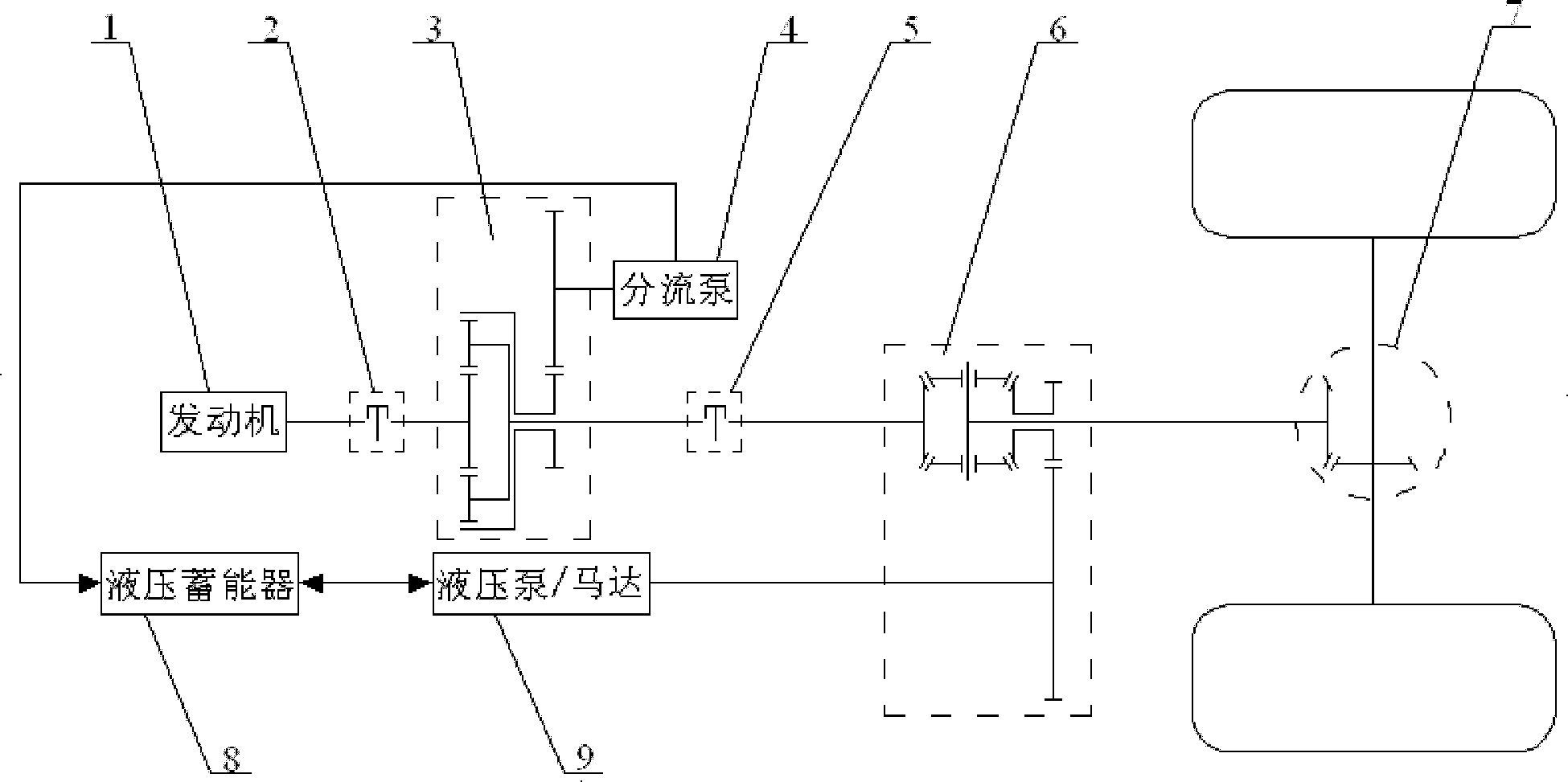

Series-parallel combined hydraulic power system of hybrid electric vehicle

InactiveCN102514474AEmission reductionBest working characteristicsGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingPower flowElectric vehicle

The invention discloses a series-parallel combined hydraulic power system of a hybrid electric vehicle, which belongs to the field of hydraulic hybrid vehicles and aims to solve the problem that advantages of series connection and advantages of parallel connection cannot be integrated in an existing hybrid vehicle system. The series-parallel combined hydraulic power system comprises an engine, a first one-way clutch, a power flow distributor, a flow distributing pump, a second one-way clutch, a coupler, a driving axle, a hydraulic energy accumulator and a hydraulic pump / motor, the engine is connected with a torque input end of the power flow distributor by the first one-way clutch, a first torque output end of the power flow distributor is connected with a torque input end of the flow distributing pump, an oil outlet of the flow distributing pump is communicated with an oil inlet of the hydraulic energy accumulator, an energy accumulation input and output oil outlet of the hydraulic energy accumulator is communicated with an oil port of the hydraulic pump / motor, a torque output end of the hydraulic pump / motor is connected with a first torque input end of the coupler, a second torque output end of the power flow distributor is connected with a second torque input end of the coupler by the second one-way clutch, and a torque output end of the coupler is connected with a torque input end of the driving axle.

Owner:HARBIN INST OF TECH

Hydraulic hybrid power system of excavator

ActiveCN101705700AAchieve recyclingAchieve reuseMechanical machines/dredgersHydraulic motorMature technology

The invention relates to a hydraulic hybrid power system of an excavator, belonging to excavators. An engine of the hydraulic hybrid power system is sequentially and mechanically connected with a hydraulic variable output pump, a driving mechanism hydraulic pump / motor. The oil outlet port of the hydraulic variable pump is communicated with an oil inlet port of a main control valve and an oil inlet port of a second overflow valve; the main control valve is respectively communicated with a first wheel motor, a second wheel motor, a bucket arm cylinder, a bucket cylinder, and the oil inlet port and the oil outlet port of a boom cylinder; a one-way valve is respectively communicated with a fifth oil return port of the main control valve and the oil inlet port of a hydraulic motor; a swing mechanism hydraulic pump / motor is connected mechanically with a rotary table; an oil outlet port of a third two-position two-way shuttle valve is communicated with the oil inlet port of a driving mechanism hydraulic motor; and all the oil outlet ports are communicated with an oil tank. The system has the advantages of simple structure, mature technology, high reliability, low cost and stable and accurate control, and the reduction of the energy loss of a hydraulic system and capability of recycling the inertial potential energy of a swing mechanism with low oil consumption.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

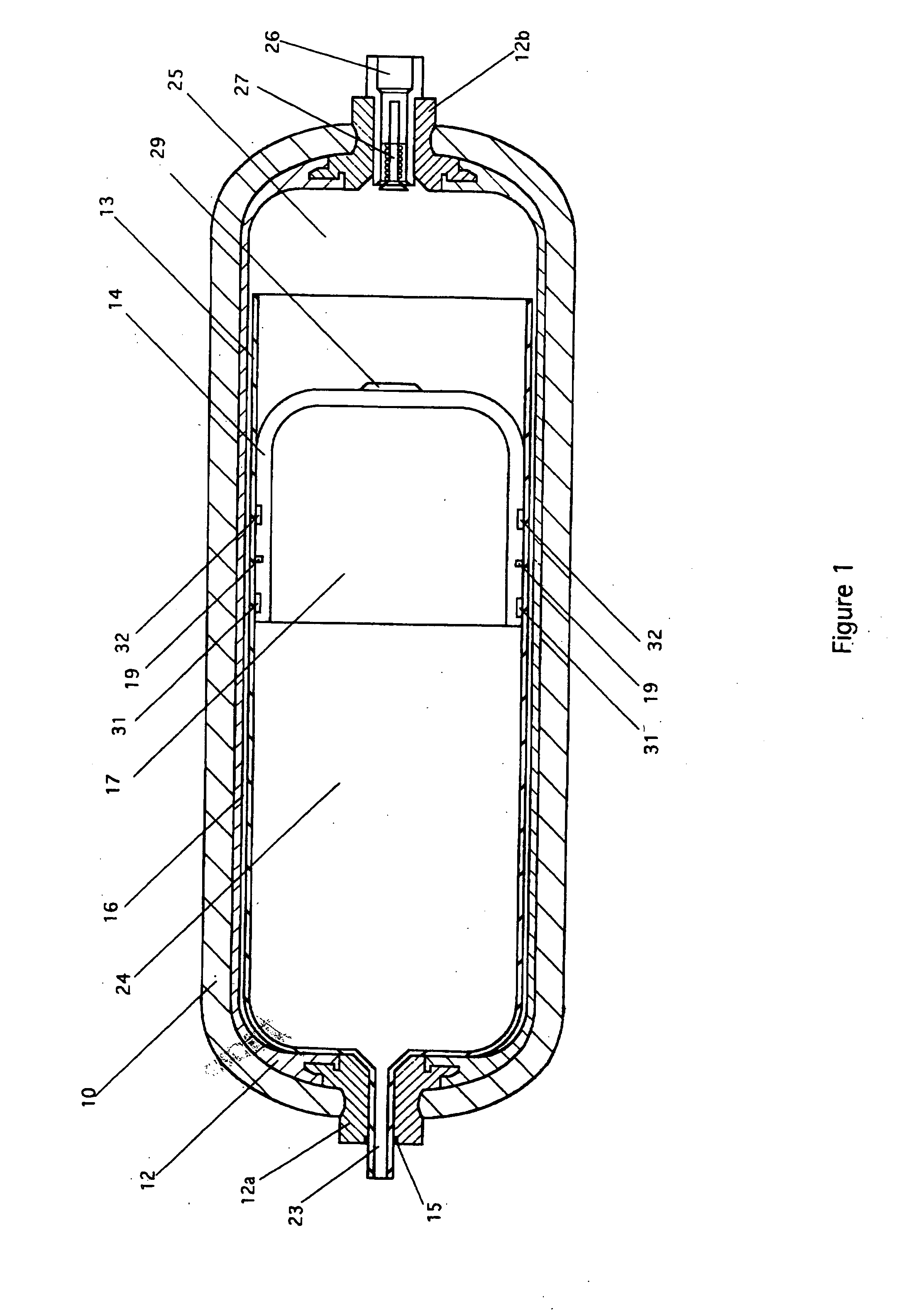

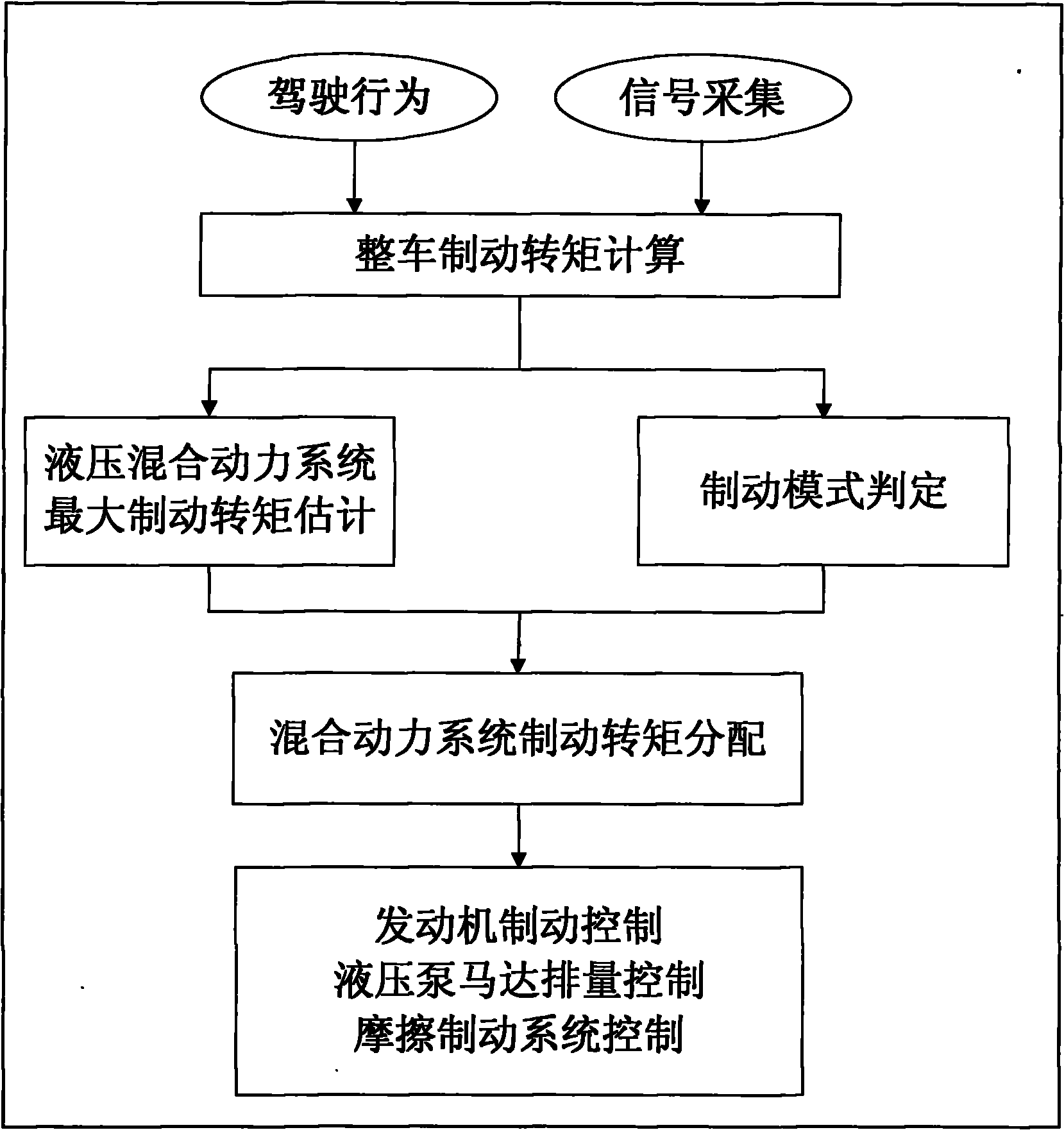

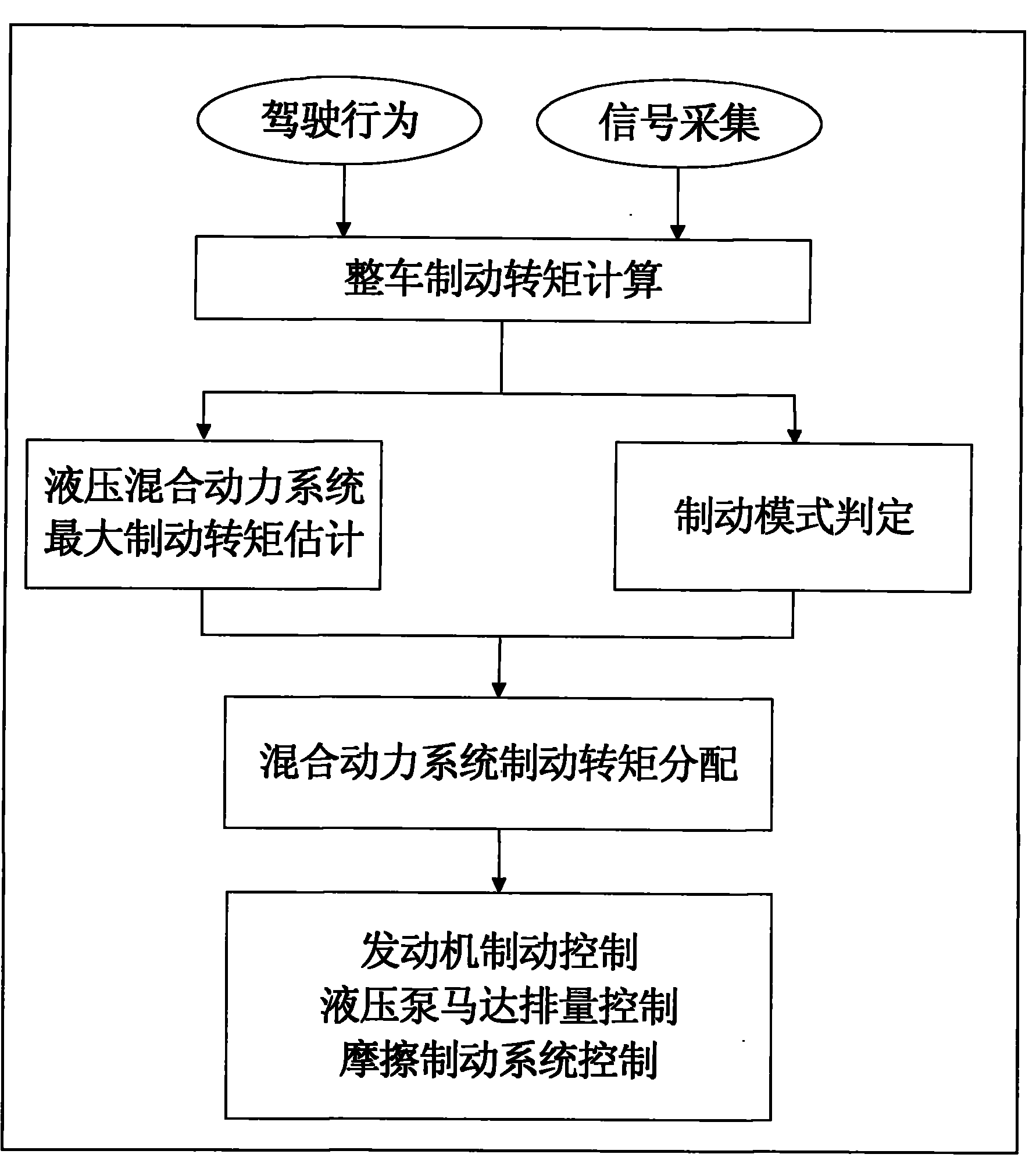

Braking torque control method for hydraulic hybrid vehicle

InactiveCN101973260ASolve the problem of not working togetherHigh recovery rateApplication and release valvesBrake torqueHydraulic motor

The invention discloses a braking torque control method for a hydraulic hybrid vehicle, which belongs to a braking control method of a hybrid vehicle. A method for distributing the braking torque comprises the following steps: determining an expected drive torque of the entire vehicle under the current conditions according to the operation behavior of a driver on a braking pedal along with the speed condition and load state in the current state; judging the braking mode of the entire vehicle according to the downlink speed and acceleration of the braking pedal; reasonably distributing a braking torque proportional relationship among an engine, a hydraulic hybrid system and the conventional friction braking system; and determining an instruction signal of the friction braking system and a hydraulic regenerative braking system according to a hydraulic accumulator pressure signal and a rotation speed signal of a hydraulic pump motor. The braking torque control method reasonably coordinates the working relationship among the engine, the hydraulic hybrid system and the conventional braking system, and on the premise of ensuring safe braking, improves the recovery rate of the braking kinetic energy of the vehicle, and has relatively high reliability and high engineering practical value.

Owner:XUZHOU CONSTR MACHINERY INST XUZHOU CONSTR MACHINERY GRP

Hydraulic hybrid four wheel drive

InactiveUS7549499B2Improve fuel efficiencySmall modificationHybrid vehiclesBraking action transmissionHydraulic motorHydraulic pressure

An hybrid four wheel drive system characterized by a vehicle having a conventional rear wheel driveline as well as a conventional driving front steer axle powered by an hydraulic motor. The hybrid four wheel drive system is provided in multiple embodiments, particularly with and without an hydraulic pressure accumulator.

Owner:INT TRUCK INTPROP LLC

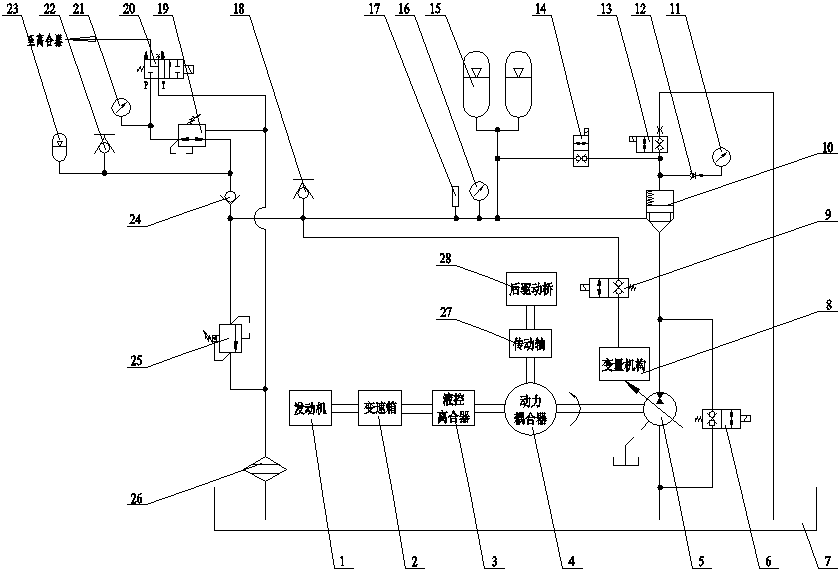

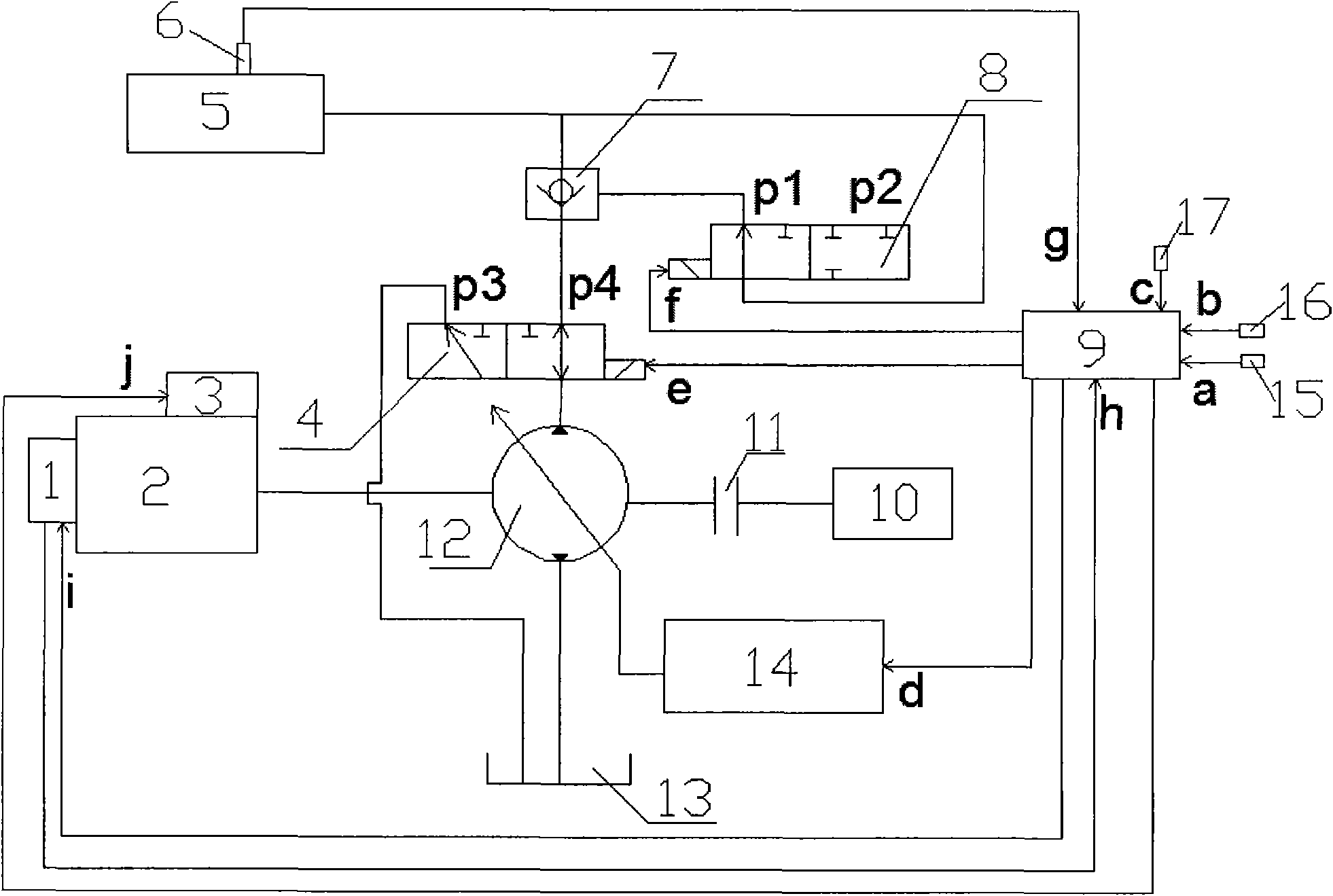

Mechanic and hydraulic hybrid type power transmission system and control method

InactiveCN101654060AHybrid vehiclesElectrodynamic brake systemsHigh pressureInternal combustion engine

The invention relates to a mechanic and hydraulic hybrid type power transmission system and a control method. The power transmission system is characterized in that a hydraulic pump / motor (12) is in rigid connection between an internal-combustion engine (2) and a clutch (11); a high-pressure oil port of the hydraulic pump / motor (12) is connected to a two-position three-way valve A (4) and connected to a high-pressure accumulator (5) by a hydraulic control one-way valve (7); a low-pressure oil port of the hydraulic pump / motor (12) is connected to a low-pressure accumulator (13); the hydraulic pump / motor (12) is further connected to the hydraulic control one-way valve (7) by a two-position three-way valve B (8); a pressure sensor (6) of the high-pressure accumulator (5), a brake pedal position sensor (15), an accelerating pedal position sensor (16) and an internal-combustion engine starting key position sensor (17) are connected to a hybrid power control unit (9) by electric cables; thehybrid power control unit (9) is connected to the hydraulic pump / motor (12) by a pump / motor discharge electric hydraulic control device (14). The system has simple structure, convenient operation andlow cost. The system can be applied to transforming the in-use vehicle or a new vehicle.

Owner:BEIJING UNIV OF TECH

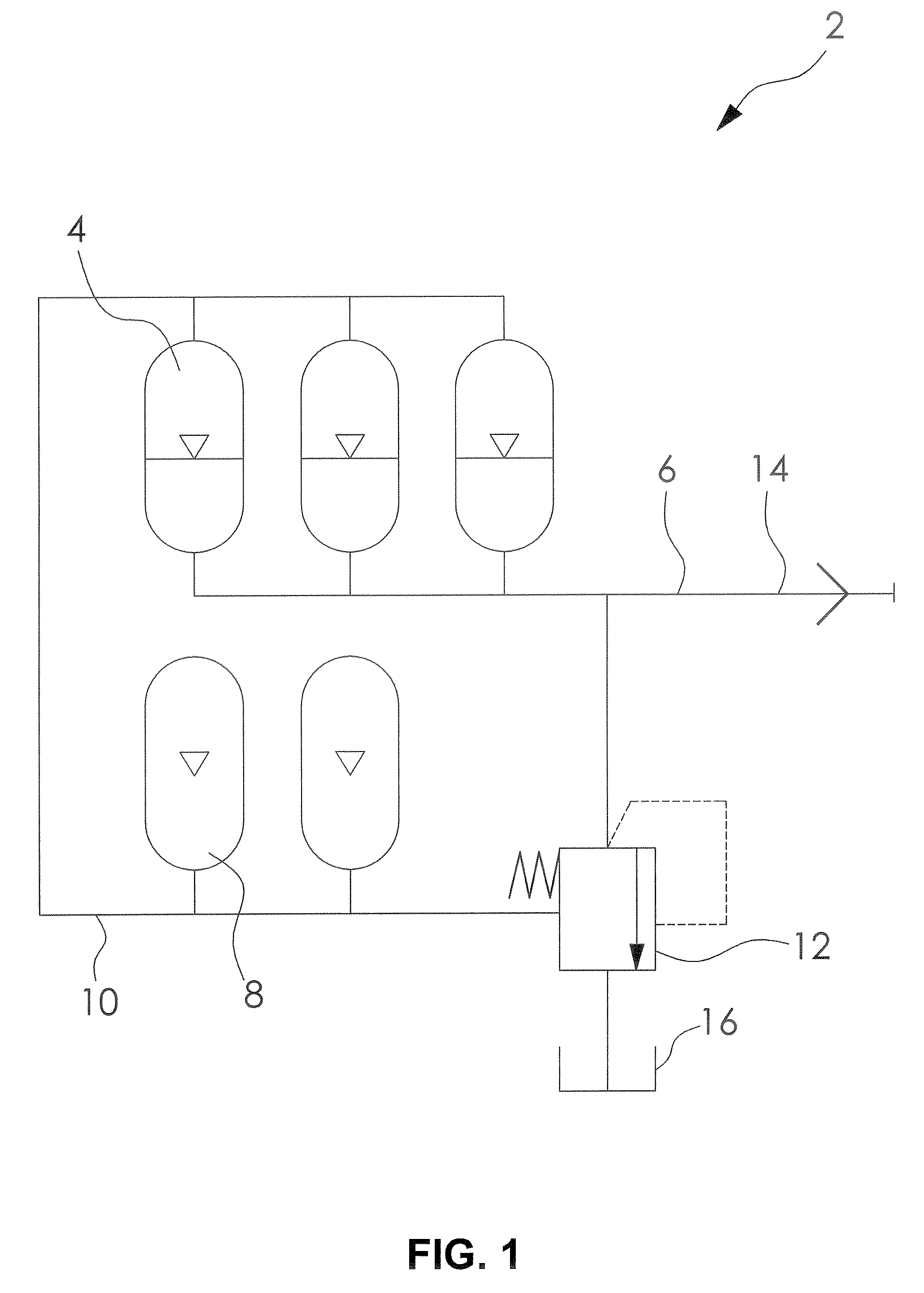

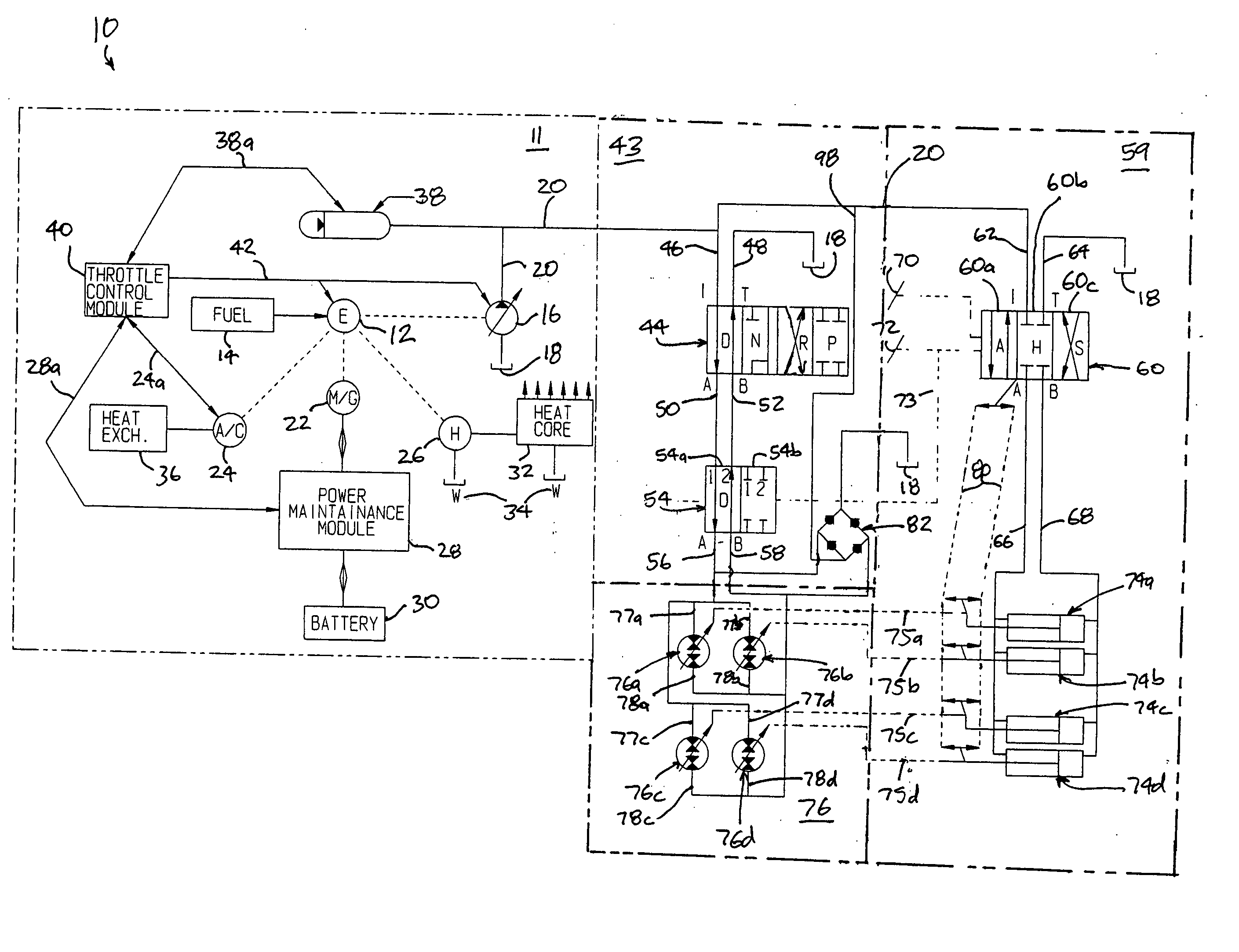

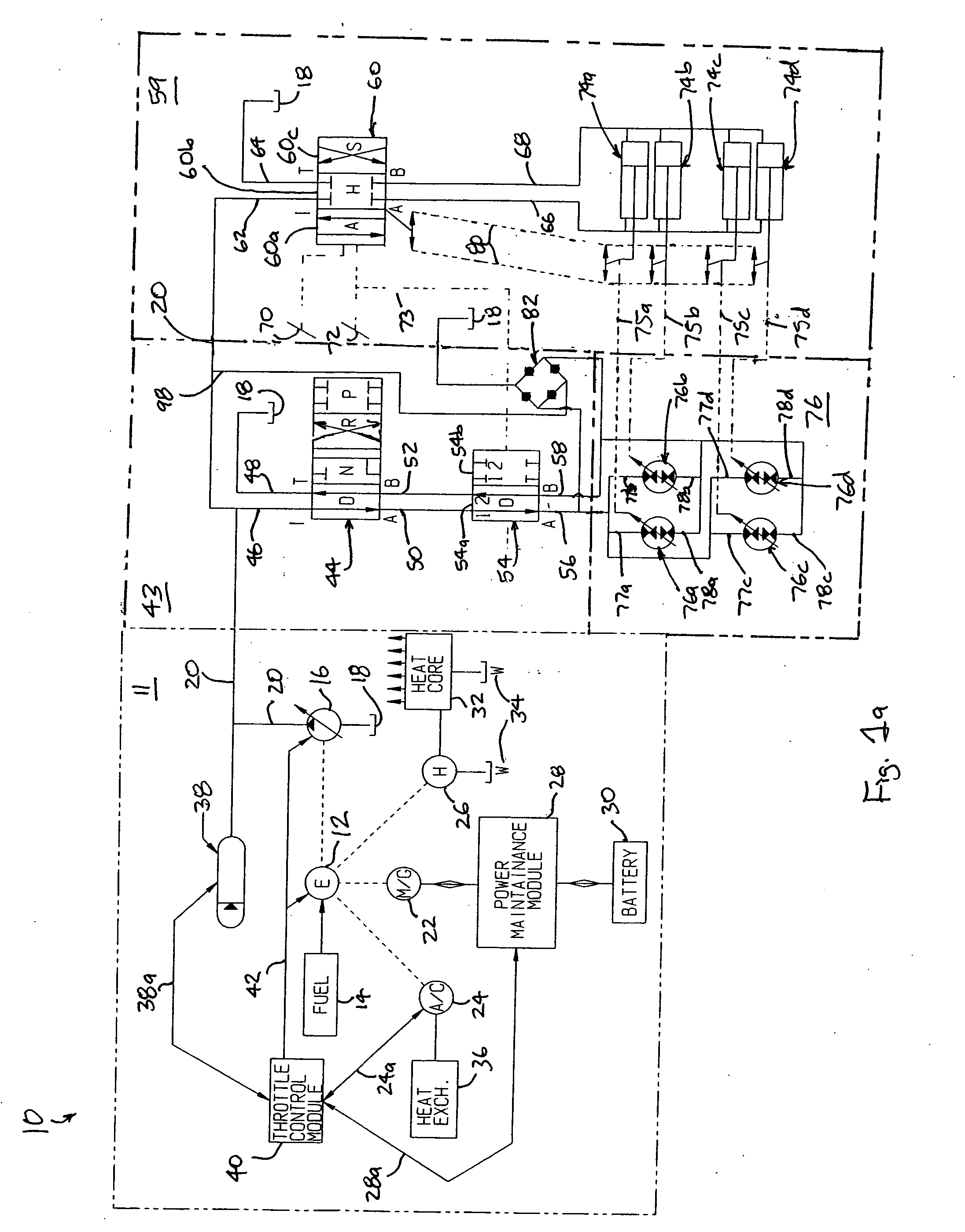

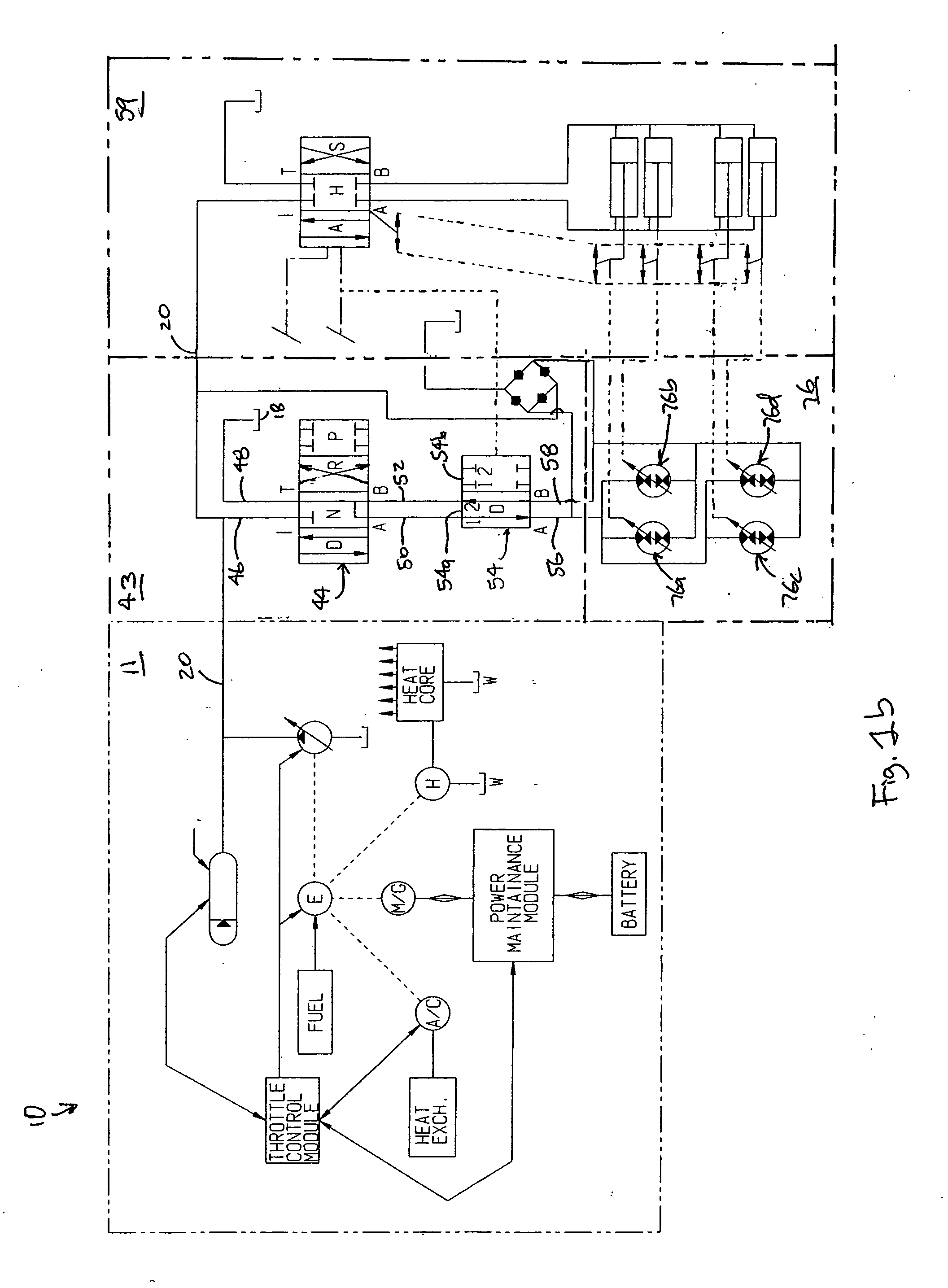

Hydraulic hybrid powertrain system

A hydraulic hybrid powertrain system includes a power plant generating a high pressure fluid at an output, at least one drive motor responsive to the high pressure fluid for generating rotary motion at an output, and a mode selection means connected to the power plant output and the drive motor for selecting a mode of operation from a plurality of drive motor modes of operation including at least two of a drive mode, a neutral mode, a reverse mode and a park mode. The system includes a control means connected to the power plant and the drive motor for controlling operation of the drive motor in the plurality of modes of operation, a selectively actuated brake means for interrupting high pressure fluid flow to the drive motor, and a check valve bridge circuit for connecting the drive motor to a low pressure fluid source when the brake means is actuated.

Owner:LIMO REID INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com