Energy-saving hydraulic hybrid power system of loader

A hybrid power system and loader technology, applied in the field of power systems, can solve the problems of wasting energy, reducing operating efficiency, and high emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

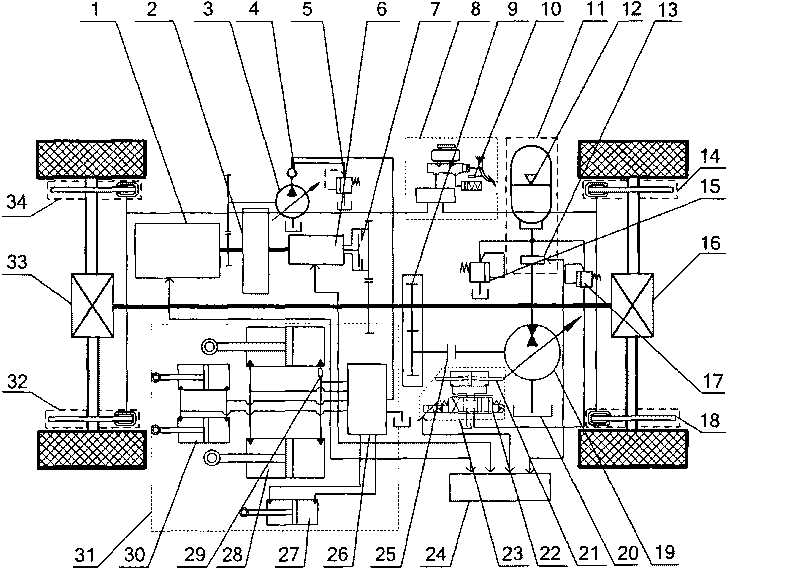

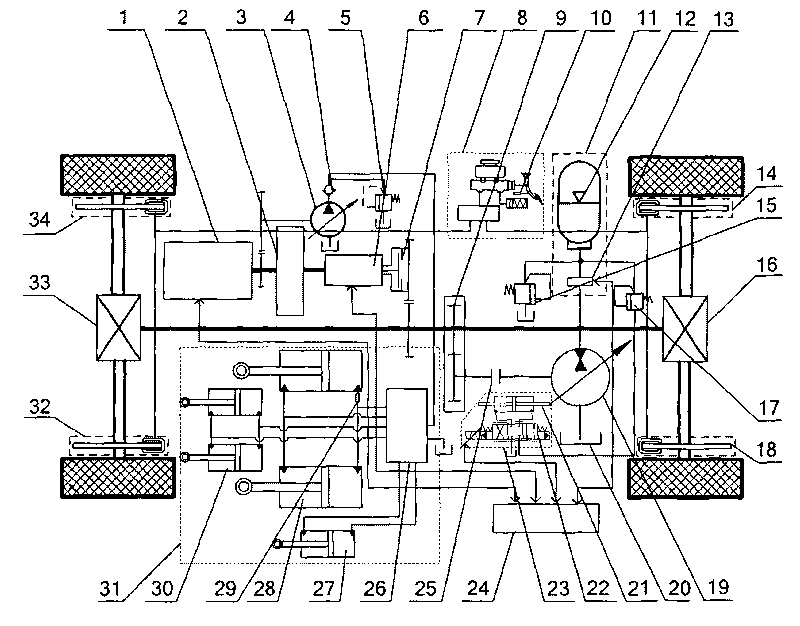

[0020]Embodiment 1: The hybrid system includes an engine 1, a hydraulic torque converter 2, a hydraulic variable pump 3, a one-way valve 4, a second overflow valve 5, a transmission 6, a wet clutch 7, and a mechanical friction brake controller 8 , torque coupler 9, internal displacement sensor 10, high-pressure hydraulic energy storage assembly 11, high-pressure hydraulic accumulator 12, two-position two-way reversing valve 13, first rear axle mechanical friction brake 14, first overflow valve 15, Rear axle 16, pressure reducing valve 17, second rear axle mechanical friction brake 18, hydraulic pump / motor 19, oil tank 20, variable cylinder 21, electro-hydraulic servo valve 22, hydraulic pump / motor control unit 23, central controller 24, Electromagnetic clutch 25, distribution valve 26, steering cylinder 27, boom cylinder 28, pressure sensor 29 of excavation mechanism, bucket cylinder 30, hydraulic actuator 31, second front axle mechanical friction brake 32, front axle 33 and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com