Hydraulic hybrid power system of excavator

A hybrid power system, excavator technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of complicated connection of electrical components, difficult installation and use, inconvenient maintenance, etc., and achieves simple and feasible control principle and simple installation. , The effect of convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

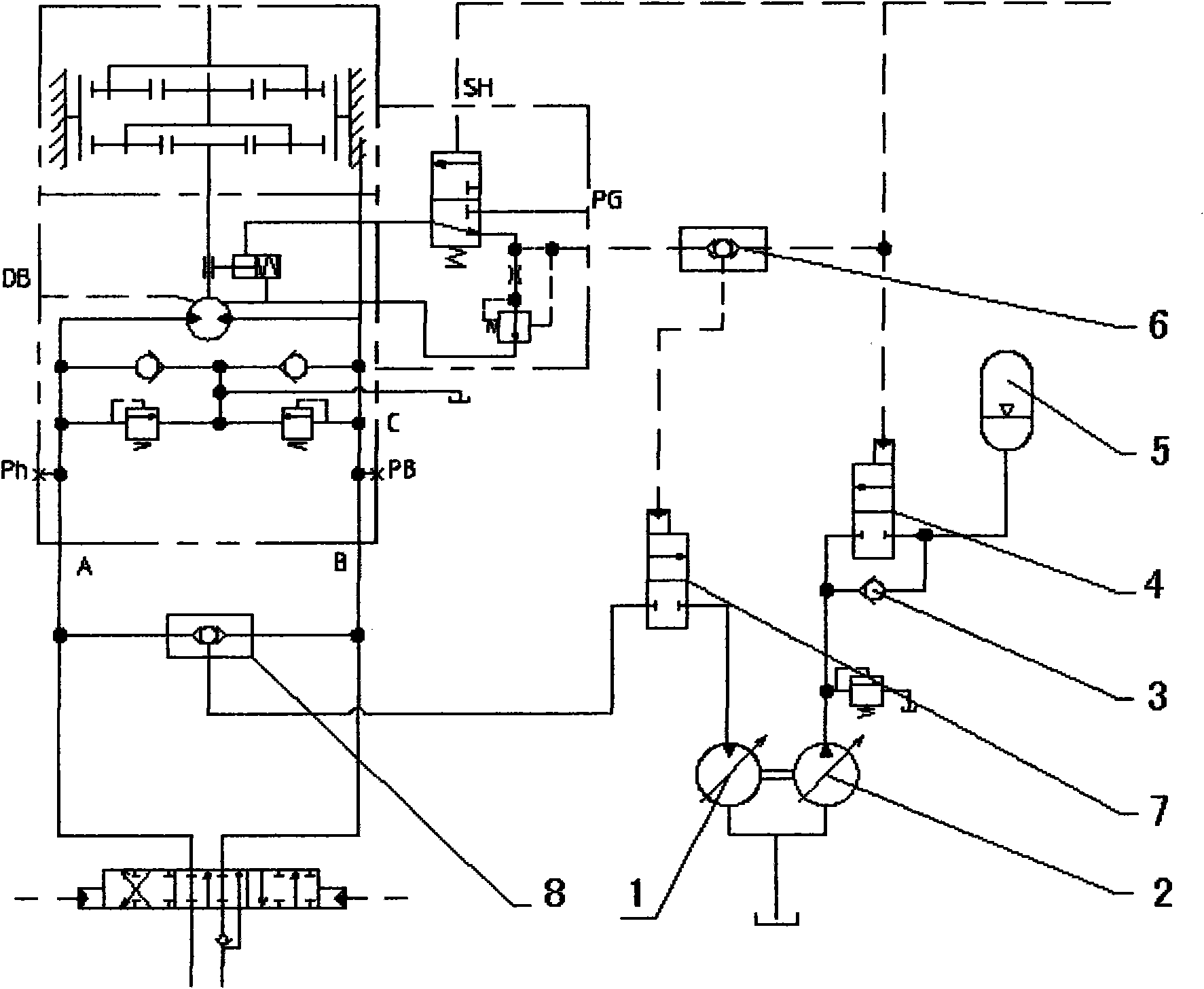

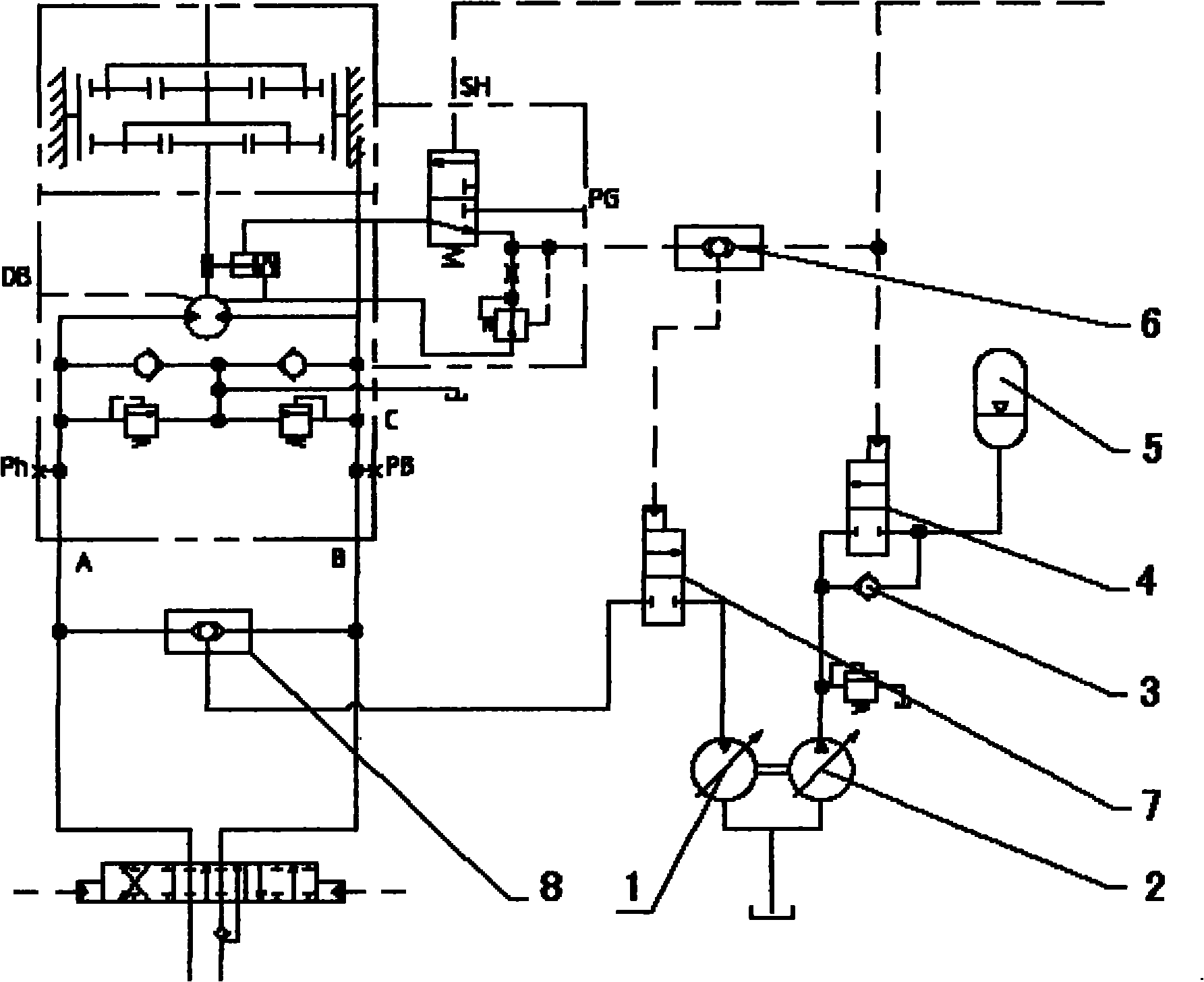

[0020] refer to figure 1 , the excavator hydraulic hybrid power system of the present embodiment is connected with the hydraulic slewing motor of the excavator, and it includes the variable pump I 1, the variable pump II2 connected in reverse, and the check valve 3, the reversing valve I 4, the reversing valve Valve II 7, accumulator 5, shuttle valve I 6, shuttle valve II8, the two ends of the shuttle valve are connected to the oil inlet and outlet of the rotary motor, the variable pump I and the variable pump II are respectively connected to the two shuttle valves through the reversing valve, the accumulator The accumulator 5 is connected with the reversing valve I4, and the variable displacement pump II2 is connected with the accumulator 5 through the check valve 3.

[0021] In the excavator hydraulic hybrid power system of this embodiment, when the swing motor starts to rotate in the forward direction, it is assumed that oil enters port A and oil exits port B, and the high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com