Wood fire-retarding treatment technology method

A technology of flame retardant treatment and process method, which is applied in wood treatment, wood treatment details, wood processing equipment, etc., can solve the problems of high equipment requirements, difficult realization, complex process, etc., and achieve strong standardization, convenient operation, and convenient feeding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

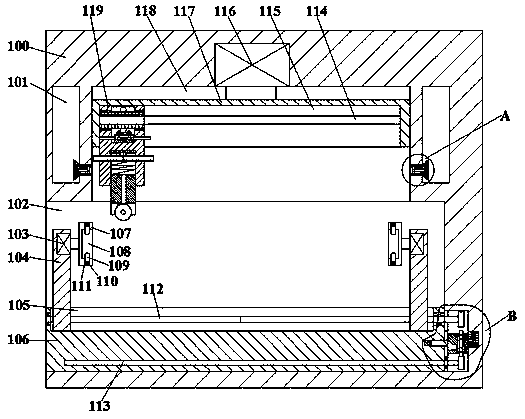

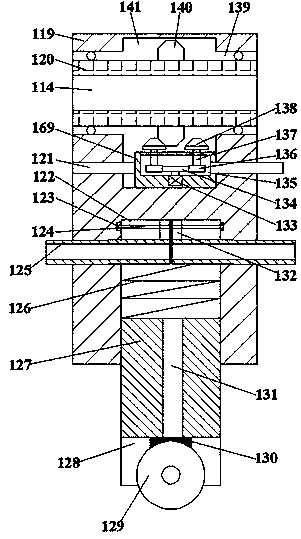

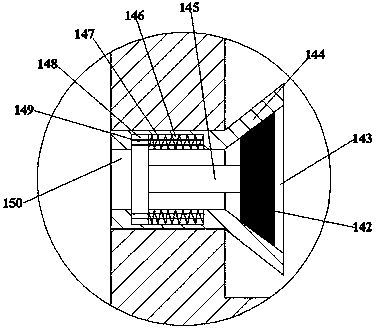

[0021] Such as Figure 1-Figure 4 As shown, a wood flame-retardant treatment process method of the present invention uses a flame-retardant material coating device, including a fuselage 100 and a coating chamber 102 arranged in the fuselage 100, and the coating chamber The inner wall of the top of 102 is connected with a first guide chute 118, and the left and right inner walls of the first guide chute 118 are provided with symmetrical liquid storage chambers 101, and the right end of the coating chamber 102 is provided with a second guide chute 152, The inner wall of the bottom of the coating chamber 102 is slidably connected with a carrier block 106, and the inner thread of the carrier block 106 is connected with a first threaded rod 113 extending left and right, and the right end of the first threaded rod 113 extends into the The second guide chute 152 is provided with a first tooth runner 161, and the top end surface of the carrier block 106 is provided with a third guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com