Traceable batch preparation method of dried tangerine peel

A kind of tangerine peel and batch technology, which is applied in the field of traceable batch tangerine peel preparation, can solve the problems of high labor cost, low efficiency, and failure to meet hygienic requirements, and achieve the effects of high automation, reduced labor cost, and guaranteed cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

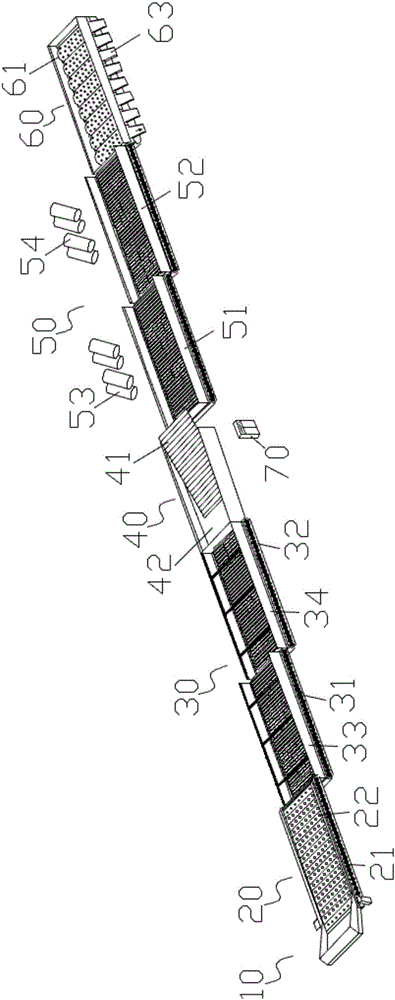

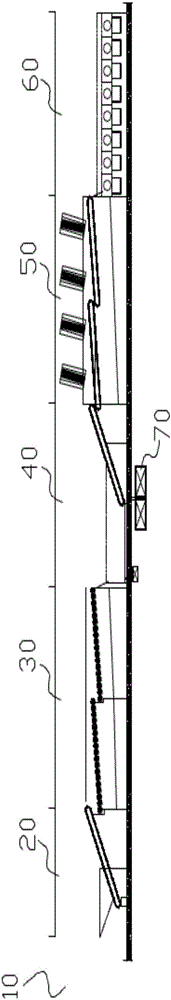

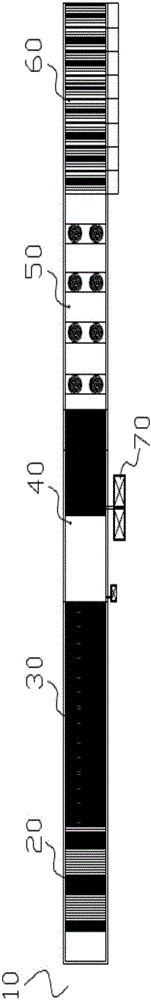

Image

Examples

Embodiment Construction

[0062] The traceable batch orange peel preparation method of the present invention comprises the following steps:

[0063] S1: Preliminary selection of citrus fruits, quality inspection, boxing and initial sealing and labeling. This step is to preliminarily select citrus fruits in the citrus orchard, and put the citrus fruits that have passed the quality inspection into special tin boxes. The special tin boxes are affixed with Two-dimensional code, and use a one-time seal to seal the box. The two-dimensional code is printed and generated by the warehouse management system of the processing base. The content of the two-dimensional code includes: age of the tree, place of origin, year, name of the head of the household, ID number, and picking time , weight, one-time block ID and other information;

[0064] S2: Batch cleaning and sorting of the citrus fruits of the same householder on the cleaning and sorting line equipment. In this step, the information of the same householder i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com