Patents

Literature

159results about How to "Shorten freeze time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

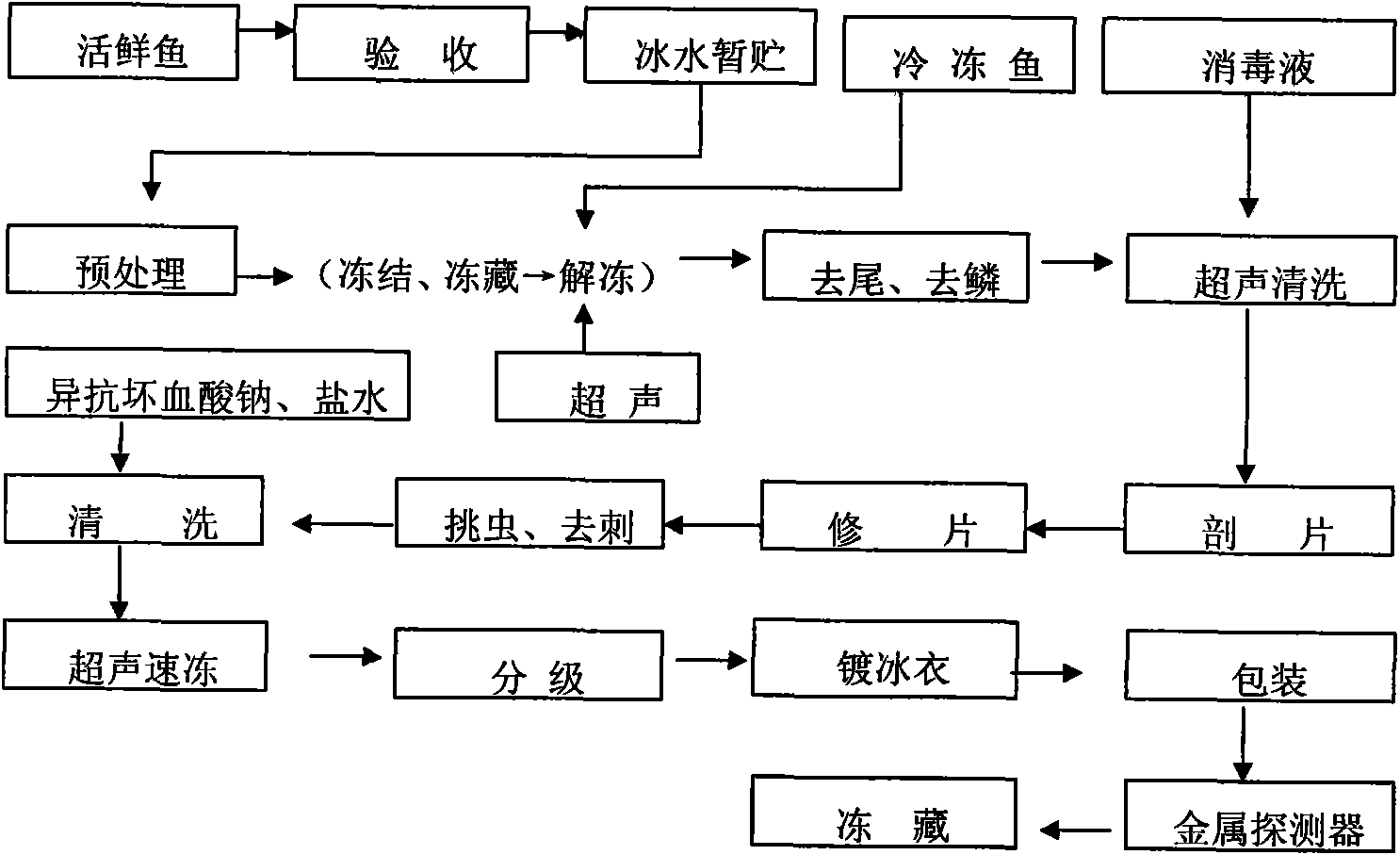

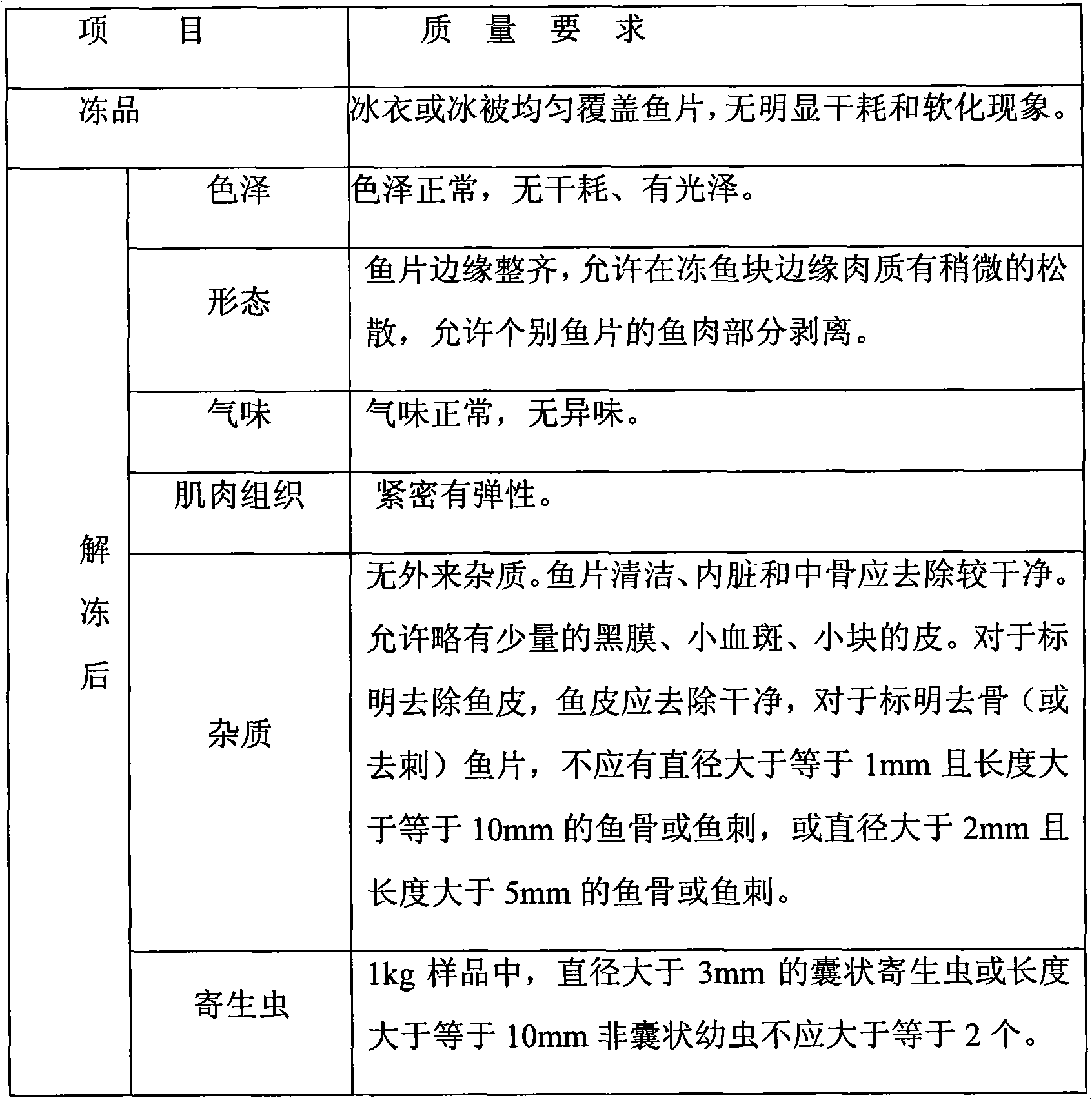

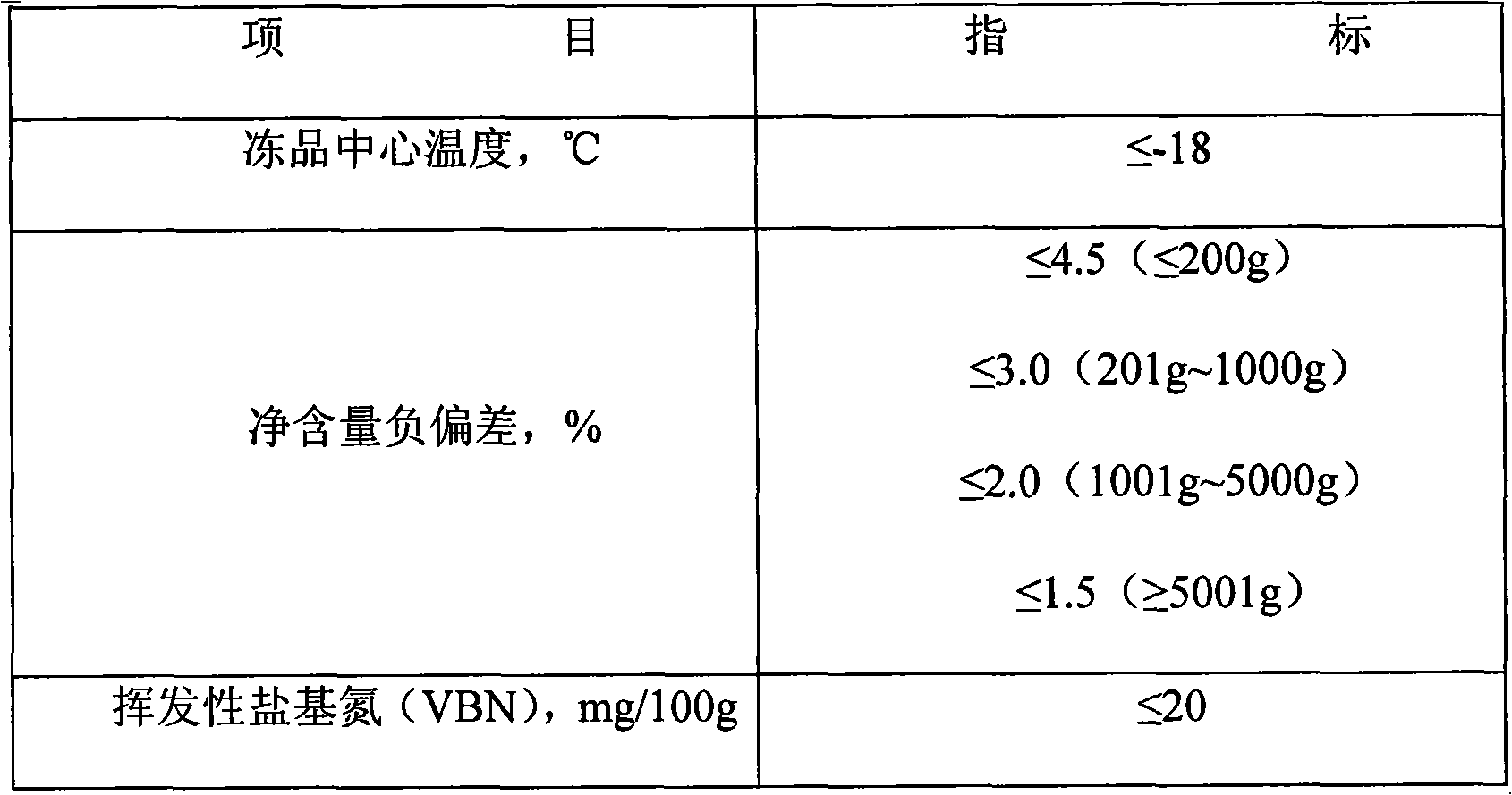

Processing method of sushi sashimi

InactiveCN101919539AExtended shelf lifeAvoid "cooking"Fish washing/descalingMeat/fish preservation by freezing/coolingIce waterAquatic product

The invention provides a processing method of sushi sashimi, which belongs to the field of processing of aquatic products. The processing method comprises the steps of taking a live fresh scaly fish as a raw material, carrying out acceptance, temporary storage in ice water and pretreatment, or taking a frozen scaly fish as the raw material, firstly carrying out ultrasonic thawing, further removing a tail, removing scales, carrying out ultrasonic cleaning, cutting into slices, trimming, picking out insects, removing bones, cleaning, carrying out ultrasonic quick freezing, classifying, glazing, packaging, carrying out metal detection, freezing, and carrying out other process steps for processing the sushi sashimi. The sushi sashimi processed by adopting the method has good quality, and the sensory, the physical and the chemical properties, as well as the safety sanitation quality are in line with requirements; furthermore, the processing method has short thawing time, short freezing time and high processing efficiency, and can be popularized in the processing of the aquatic products.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for improving quick-freezing fruit vegetables thawing quality through low-frequency ultrasound wave

InactiveCN101138362AImprove defrosting qualityShorten freeze timeFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by freezing/coolingOperational costsUltrasonic assisted

A method for improving the unfreezing quality of fast frozen fruit and vegetables with low-frequency ultrasonic belongs to the processing technical field of fruit and vegetable food. The present invention adopts ultrasonic for freezing in the process of fast freezing; the process is that the raw materials of fruit and vegetables are selected, cleaned and burnt to kill the enzyme; and then the materials are cooled, refrigerated and frozen with ultrasonic; at last the materials are packed up. The present invention adopts the process that the ultrasonic processing is combined in the process of dipping and freezing fruit and vegetable and improves the unfreezing quality of the fast frozen fruit and vegetables; the present invention is characterized by a short freezing time, excellent initial shape maintenance and low operational cost.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

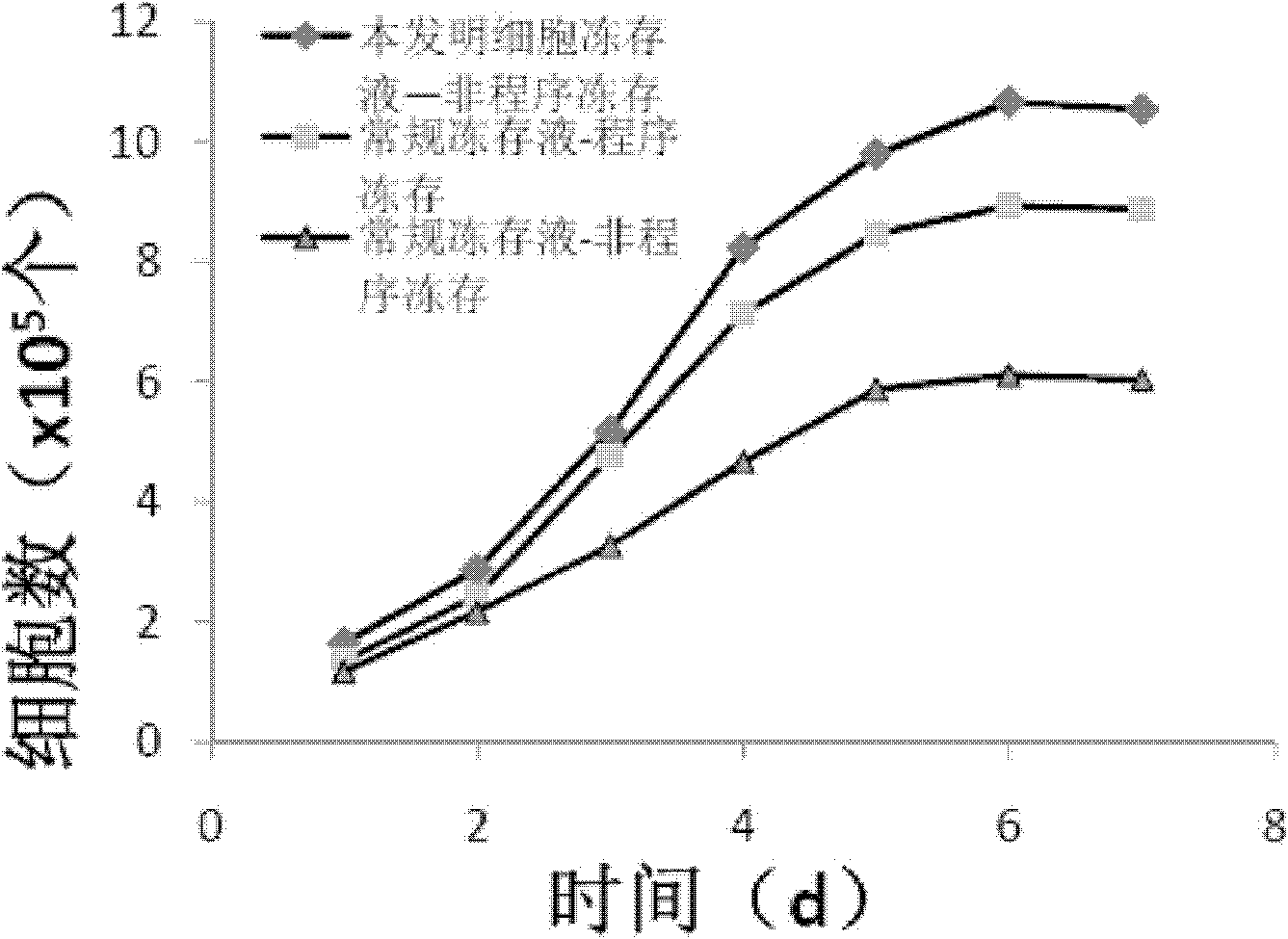

Cell freezing solution without complicated procedures for freezing

ActiveCN101983562AApplicable for freezingImprove protectionDead animal preservationCell membraneSolvent

The invention discloses a cell freezing solution without complicated procedures for freezing, which comprises 1.0-28w / v% of cell membrane protective agent, 1.0-18w / v% of permeable cell membrane inner protective agent, 3.0-28% of cell settlement stabilizer and balance of solvent. The cell freezing solution of the invention has good protective effect on cells, after the freezing solution is added, the cells can be directly put into a refrigerator of -80DEG C for freezing, and complicated procedures are not needed for freezing, thereby greatly shortening the freezing time of the cells, improvingthe freezing efficiency and being suitable for freezing a large quantity of cells. The recovery rate of the frozen cells is high, the growth and differentiation of the recovered cells are normal, thecomponents of the cell freezing solution have stability and a long quality guarantee period, and the cell freezing solution does not need to be prepared or diluted before use and has good batch stability.

Owner:CYAGEN BIOSCI INC

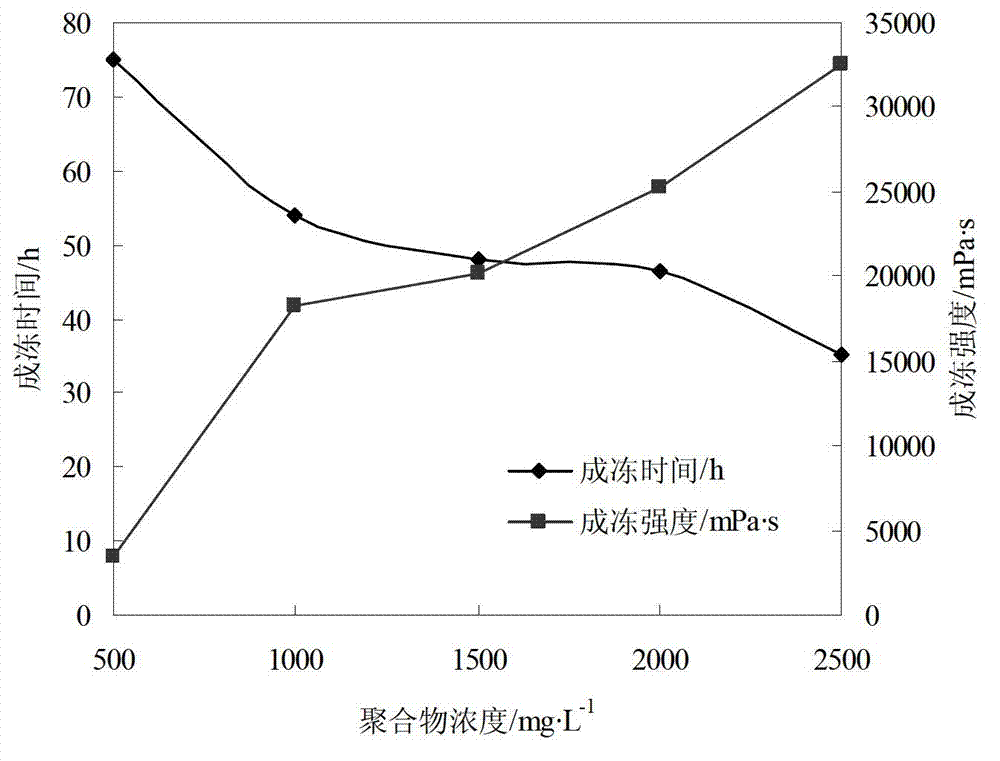

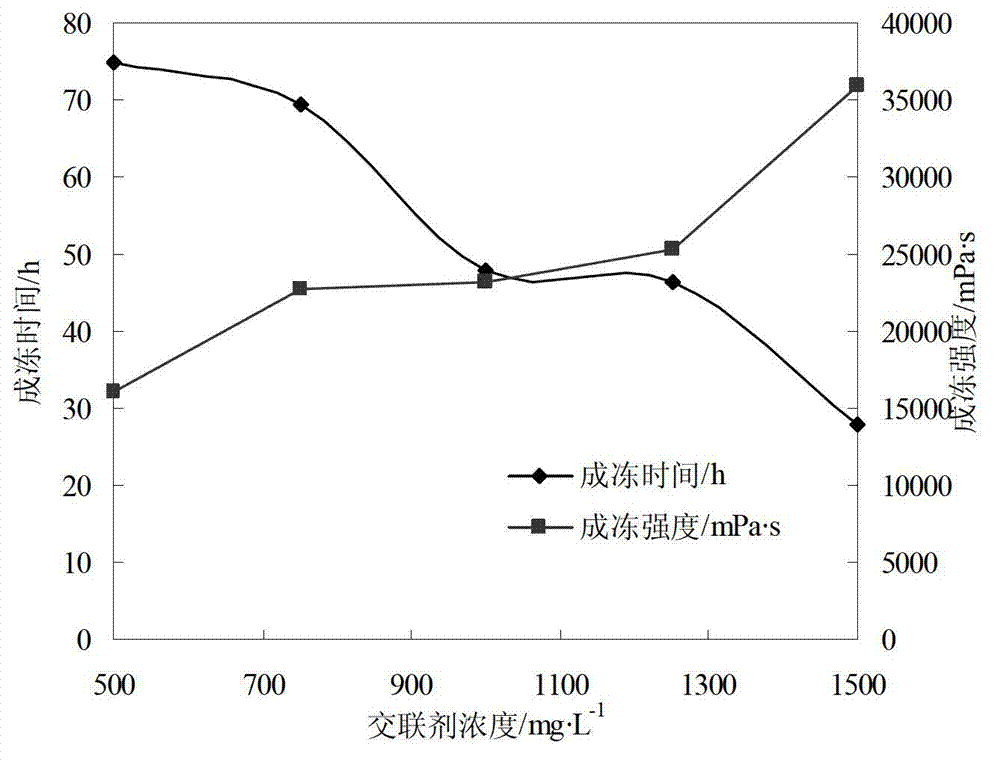

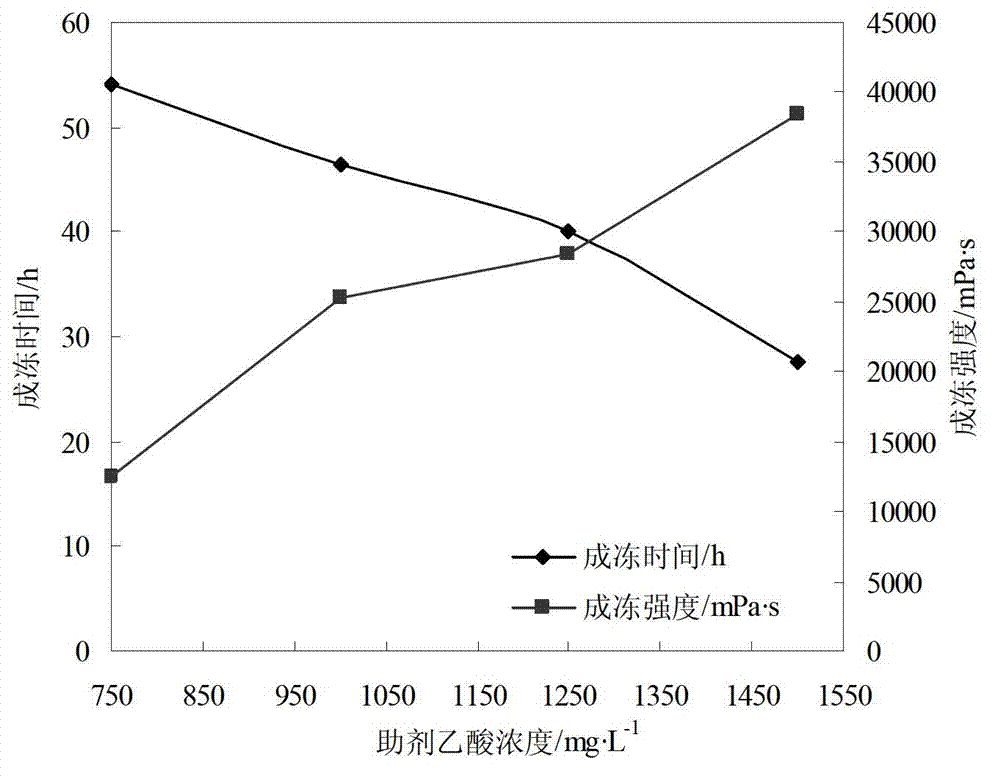

Composite crosslinking deep profile control agent for oil reservoir deep profile control and preparation method thereof

InactiveCN102965093AFreezing time shortenedFreezing time is adjustableDrilling compositionEngineeringWater cut

The invention discloses a composite crosslinking deep profile control agent for oil reservoir deep profile control and a preparation method thereof. The composite crosslinking deep profile control agent is prepared from a polymer, a phenolic crosslinking agent, an auxiliary agent and water, wherein the auxiliary agent is a pH value regulator, and the concentrations of the polymer, the phenolic crosslinking agent and the auxiliary agent in the composite crosslinking deep profile control agent are 1,500 to 2,000mg / L, 750 to 1,250mg / L and 1,000 to 1,500mg / L in sequence. The preparation method of the composite crosslinking deep profile control agent comprises the steps of preparing the phenolic crosslinking agent and the polymer through crosslinking reactions. By the composite crosslinking deep profile control agent for the oil reservoir deep profile control, along with the rise of the concentration of each component, the gelation time is shortened, the gelation strength is enhanced, and the gelation time is adjustable; and the composite crosslinking deep profile control agent has high injectivity, shearing resistance, thermal stability and plugging performance, is suitable for deep profile control operation processing of an injection well, and has a good application prospect for improving the producible oil index through oil stabilization and water control during later-stage development of a high-water-cut oilfield.

Owner:CHINA NAT OFFSHORE OIL CORP +1

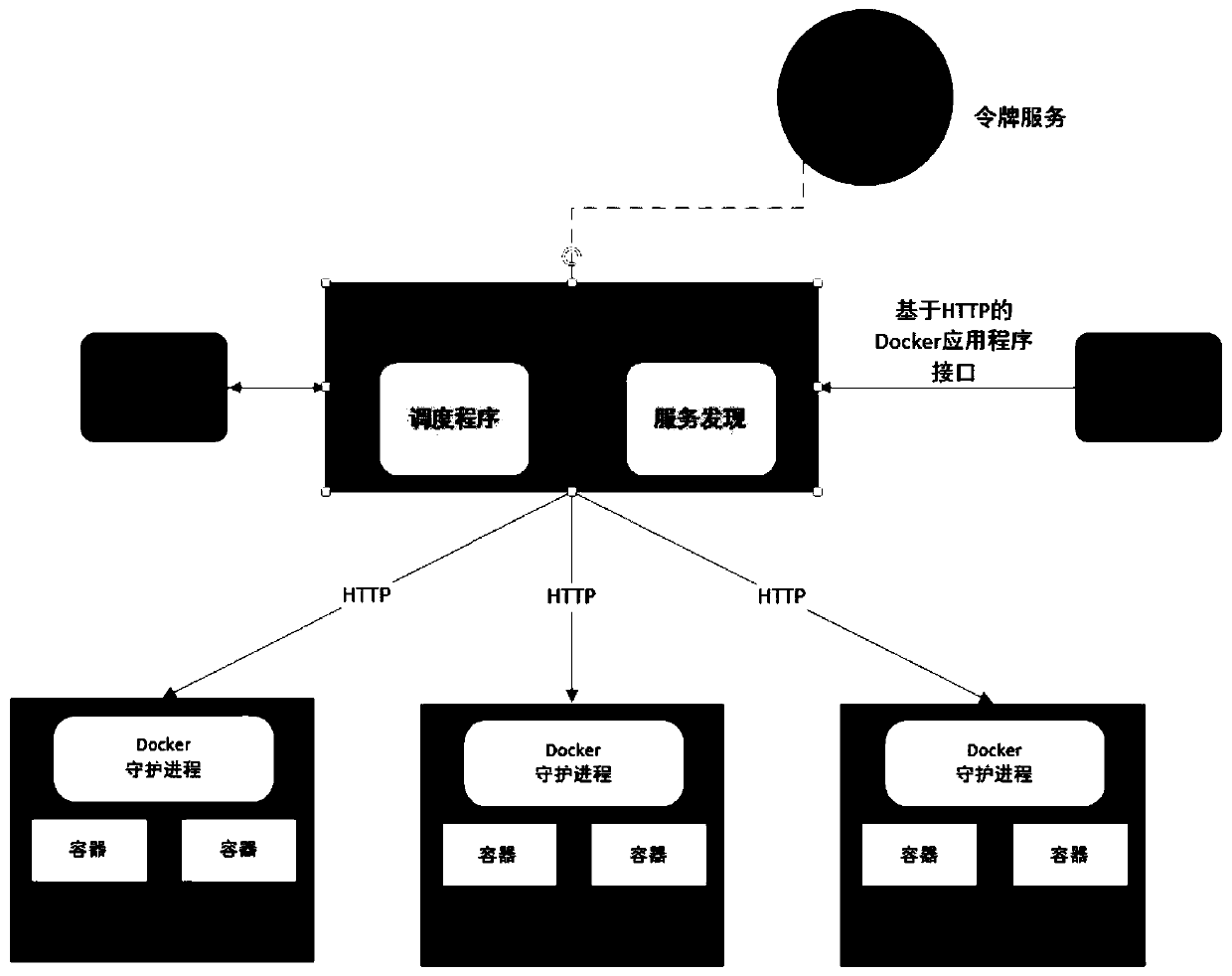

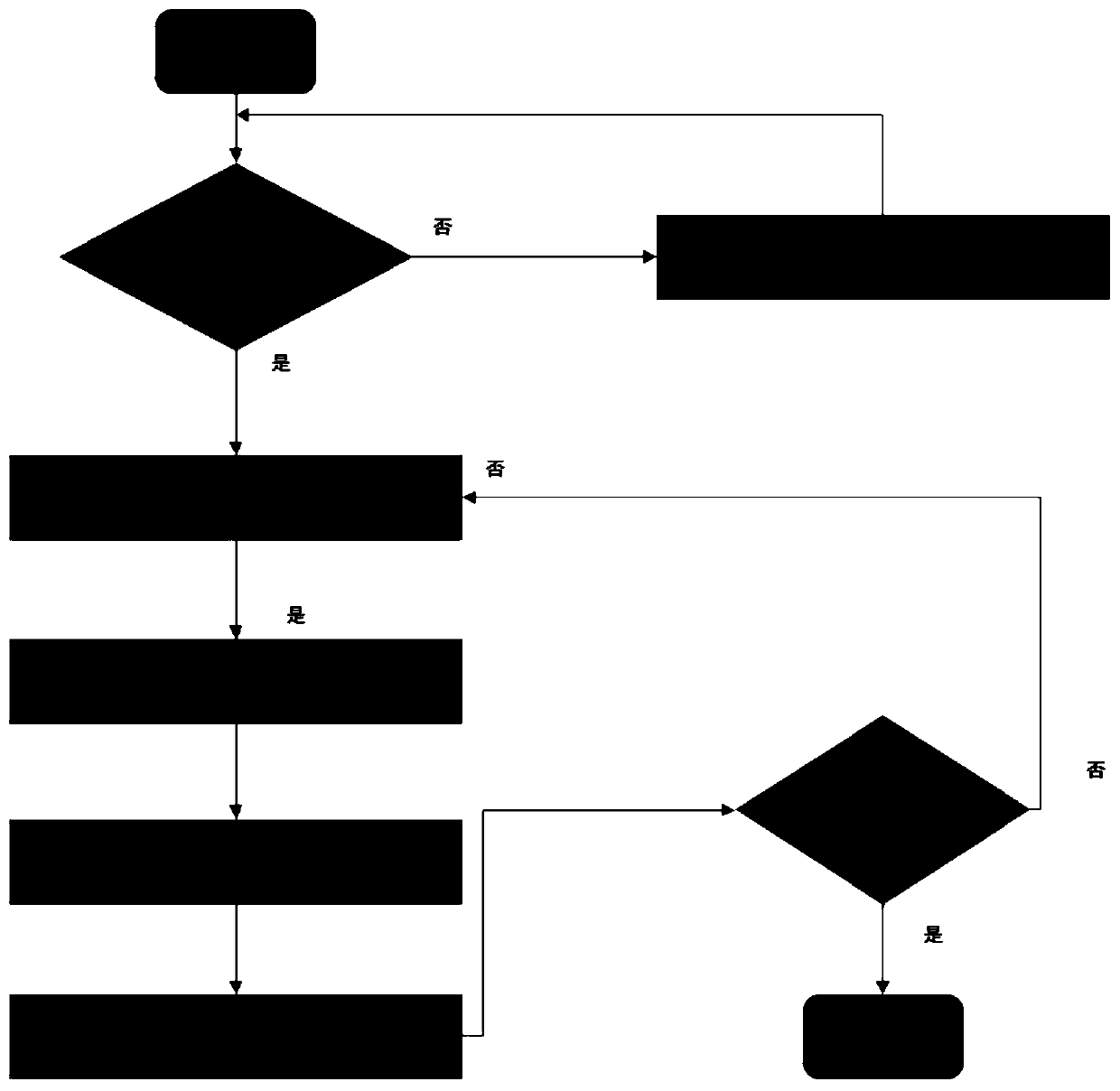

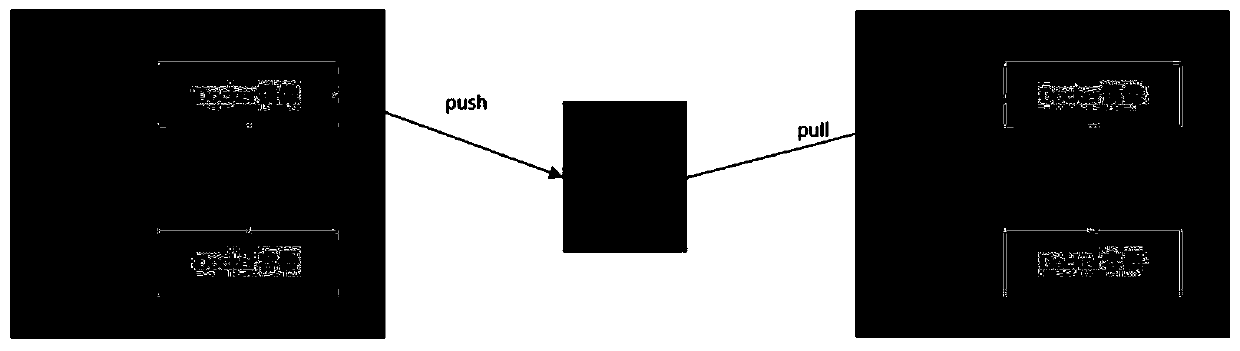

Container cross-host online migration method, storage medium and terminal equipment

ActiveCN110134495ALoad balancingRealize flexible schedulingResource allocationSoftware simulation/interpretation/emulationTerminal equipmentComputer terminal

The invention provides a container cross-host online migration method, a storage medium and terminal equipment. The method comprises the following steps of carrying out resource monitoring on each physical node of the cloud platform; setting a migration threshold as a judgment condition for triggering container migration; selecting a container with the minimum migration cost as a container to be migrated; determining a physical node of which the comprehensive load value is smaller than a set value, calculating an average value of the comprehensive load values of the physical nodes; selecting aphysical node with a comprehensive load value closest to the average value as a target node; and executing migration until the comprehensive load value of a certain node is smaller than a migration threshold value, so that load balance of each physical node in the cluster can be maintained, services in the container are not interrupted while the container migrates, and thus elastic scheduling ofDocker cloud platform resources is realized.

Owner:SHANDONG UNIV

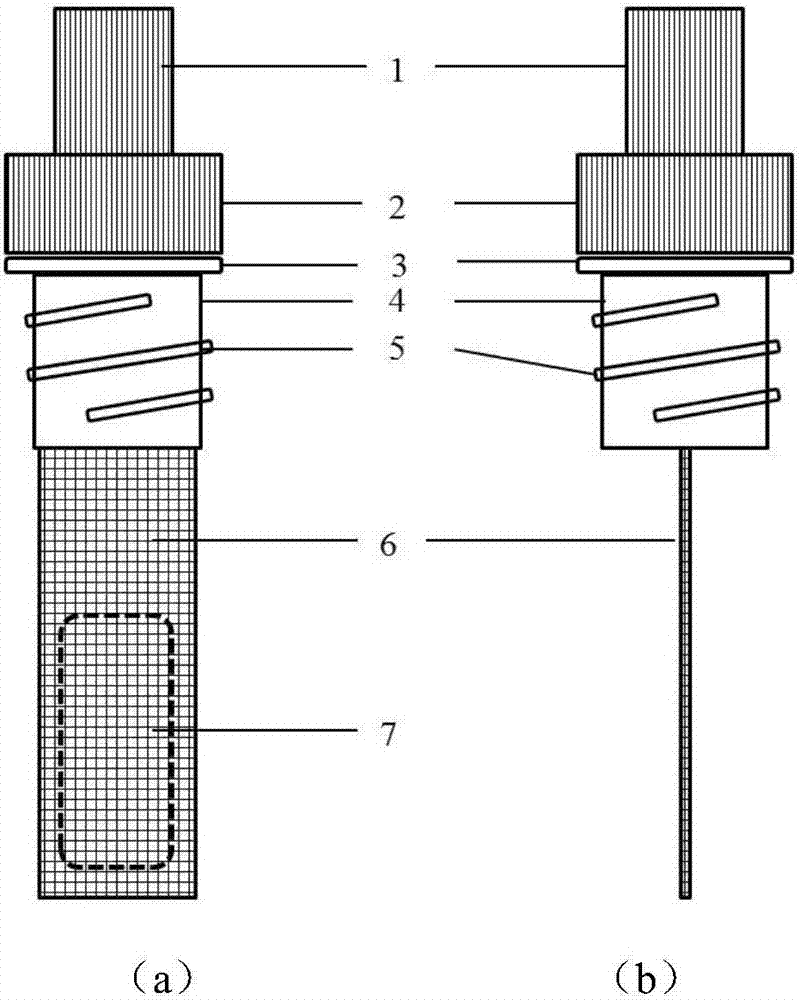

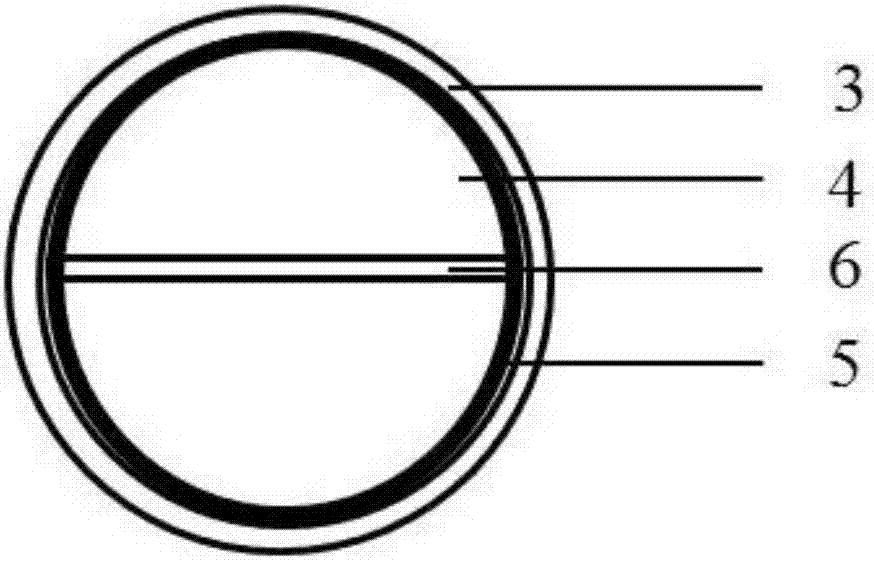

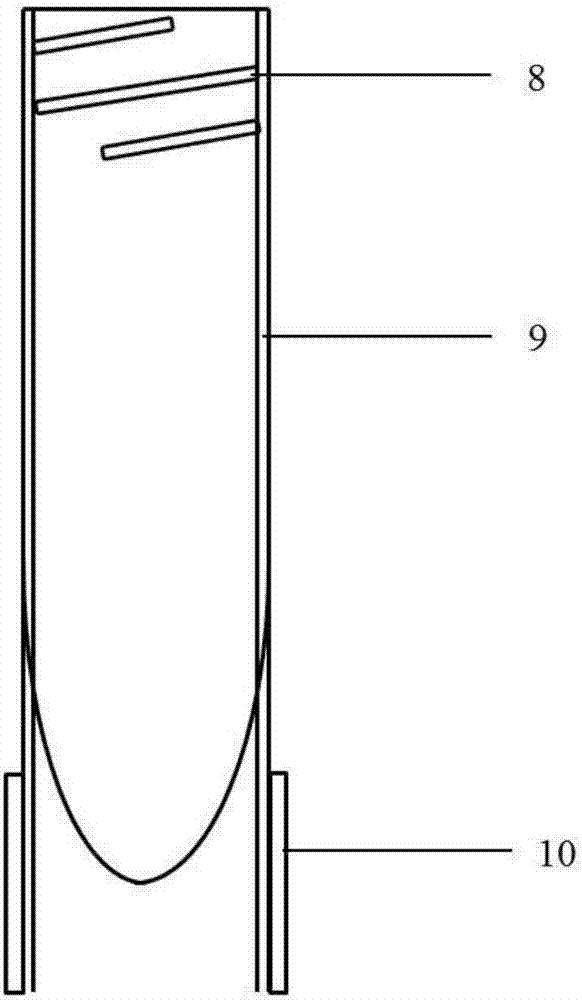

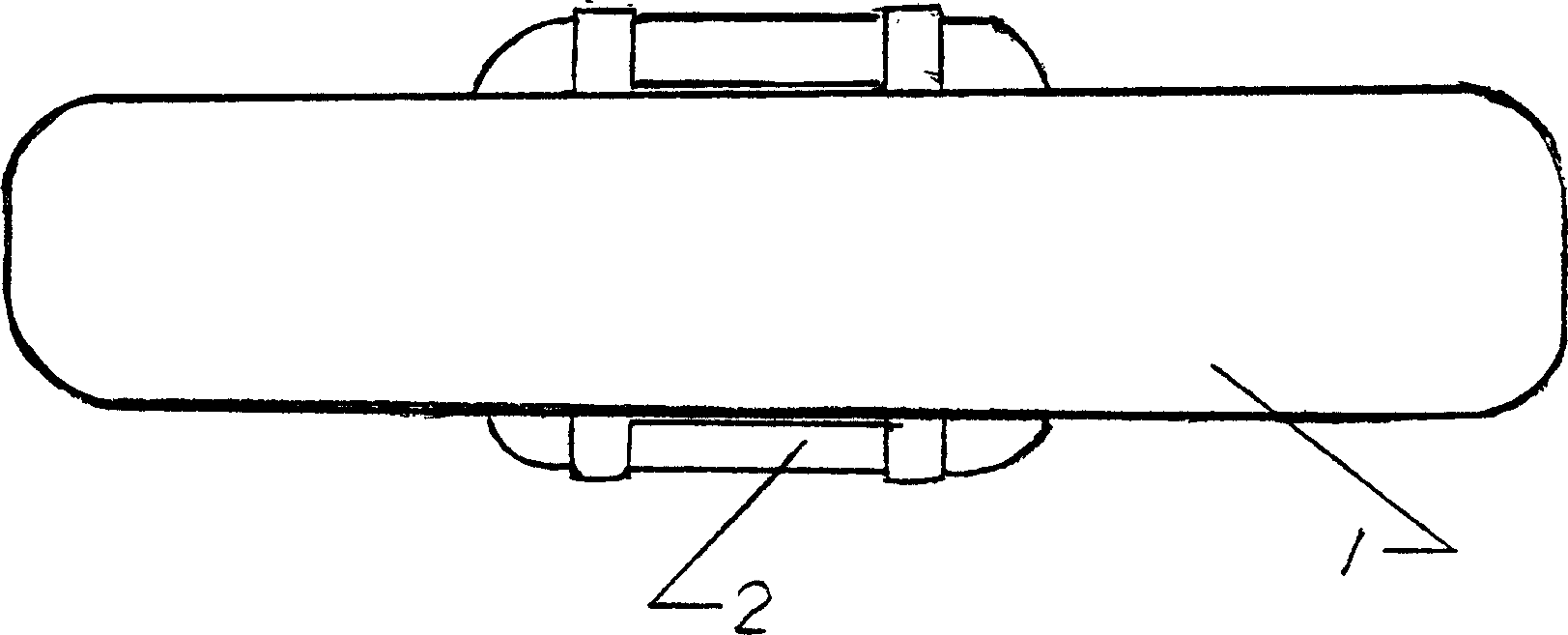

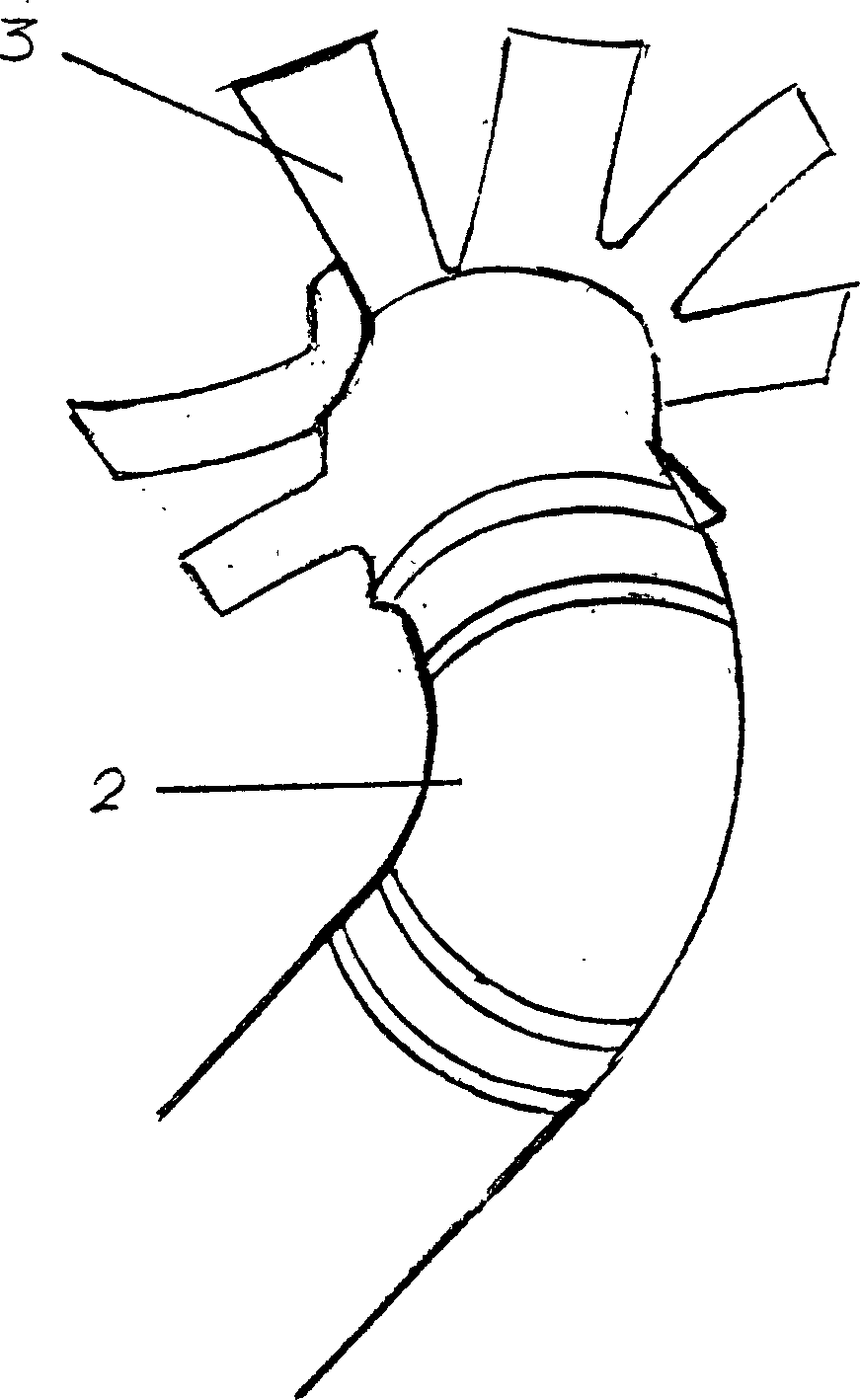

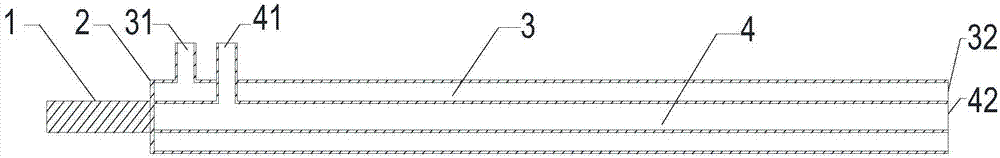

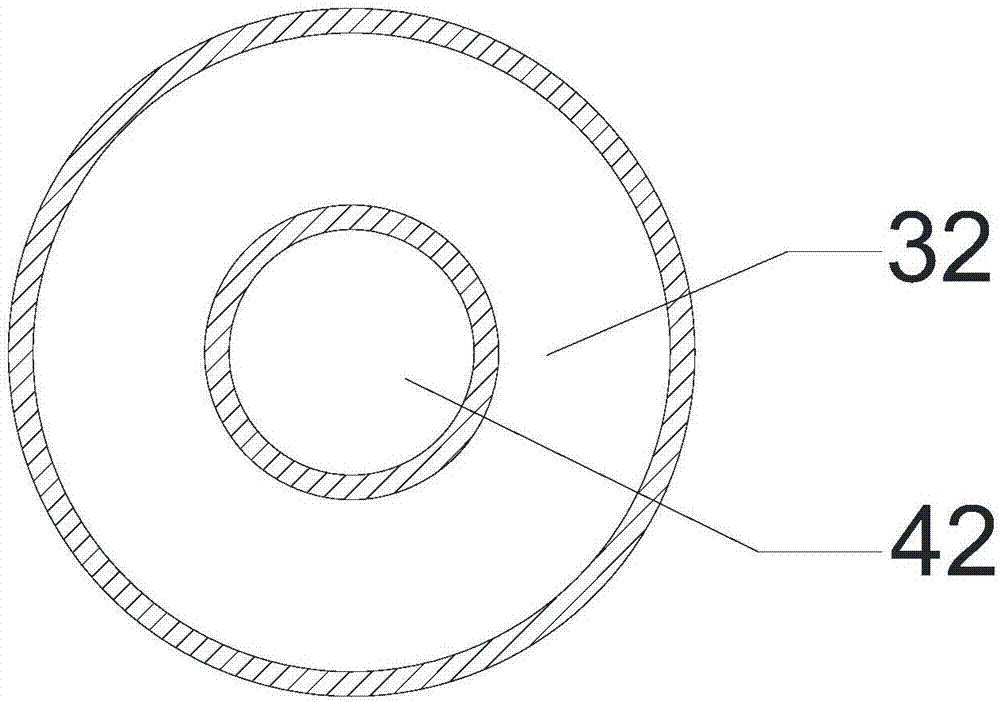

Large ovarian tissue vitrification freezing carrier and application thereof

PendingCN107535482ALow priceWide selection of materialsDead animal preservationGerm cellsVitrificationEngineering

The invention discloses a large ovarian tissue vitrification freezing carrier. The carrier consists of a carrier inner core and an outer sleeve, wherein the carrier inner core is in threaded connection with the outer sleeve, maintaining high airtightness and preventing cross infection of the ovarian tissue; meanwhile, the user operation is also facilitated; the carrier inner core consists of a handheld part, a cap part, a support part and a bearing part sequentially from top to bottom; the bearing part is clamped and fixed by the support part; when in use, a large ovarian tissue is put on an end part of the bearing part, away from the support part; the end part is a large ovarian tissue loading area; experiments prove that by using the carrier disclosed by the invention, the permeation efficiency of a refrigerant is improved; moreover, the operation is simple, the price is low, batch storage of large ovarian tissues is convenient, and the carrier is suitable for promotion and application.

Owner:SHANDONG UNIV QILU HOSPITAL

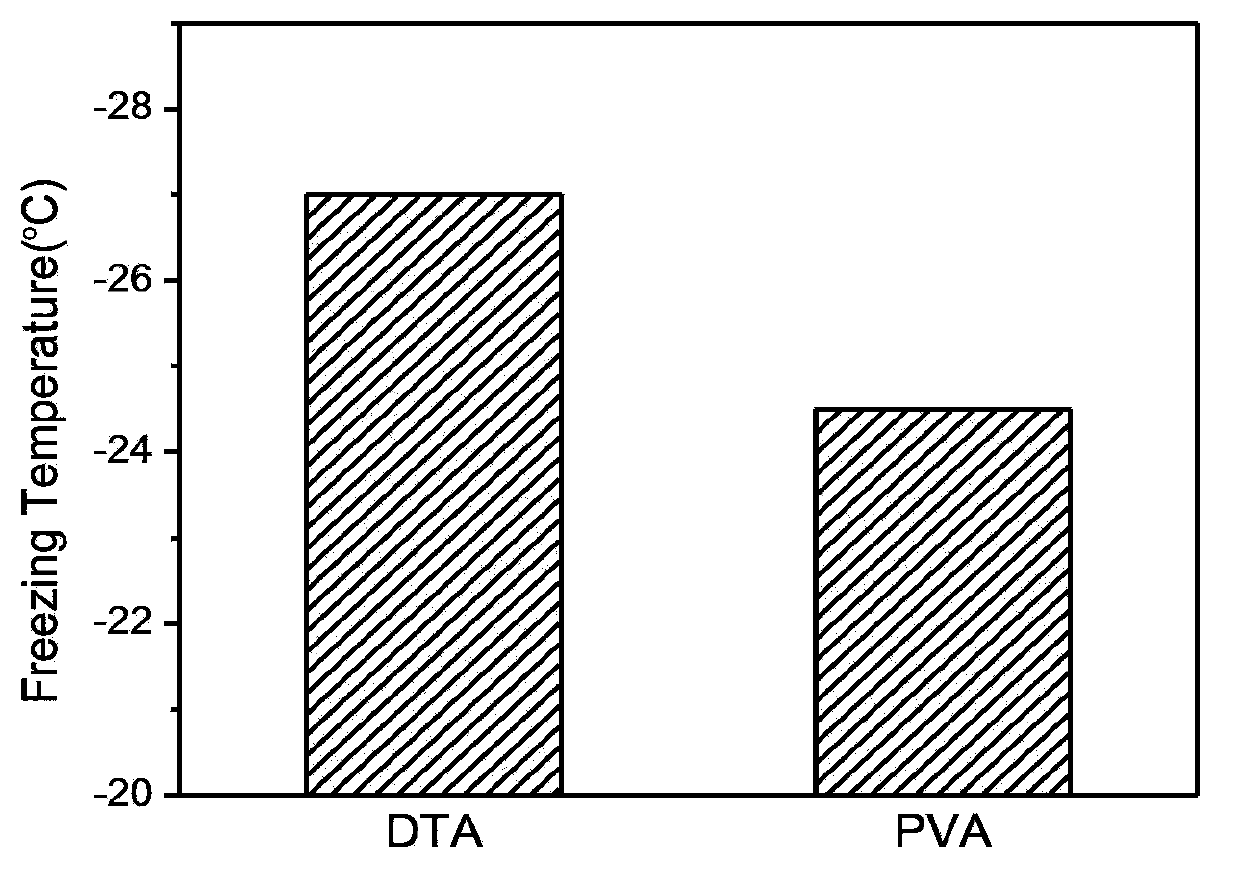

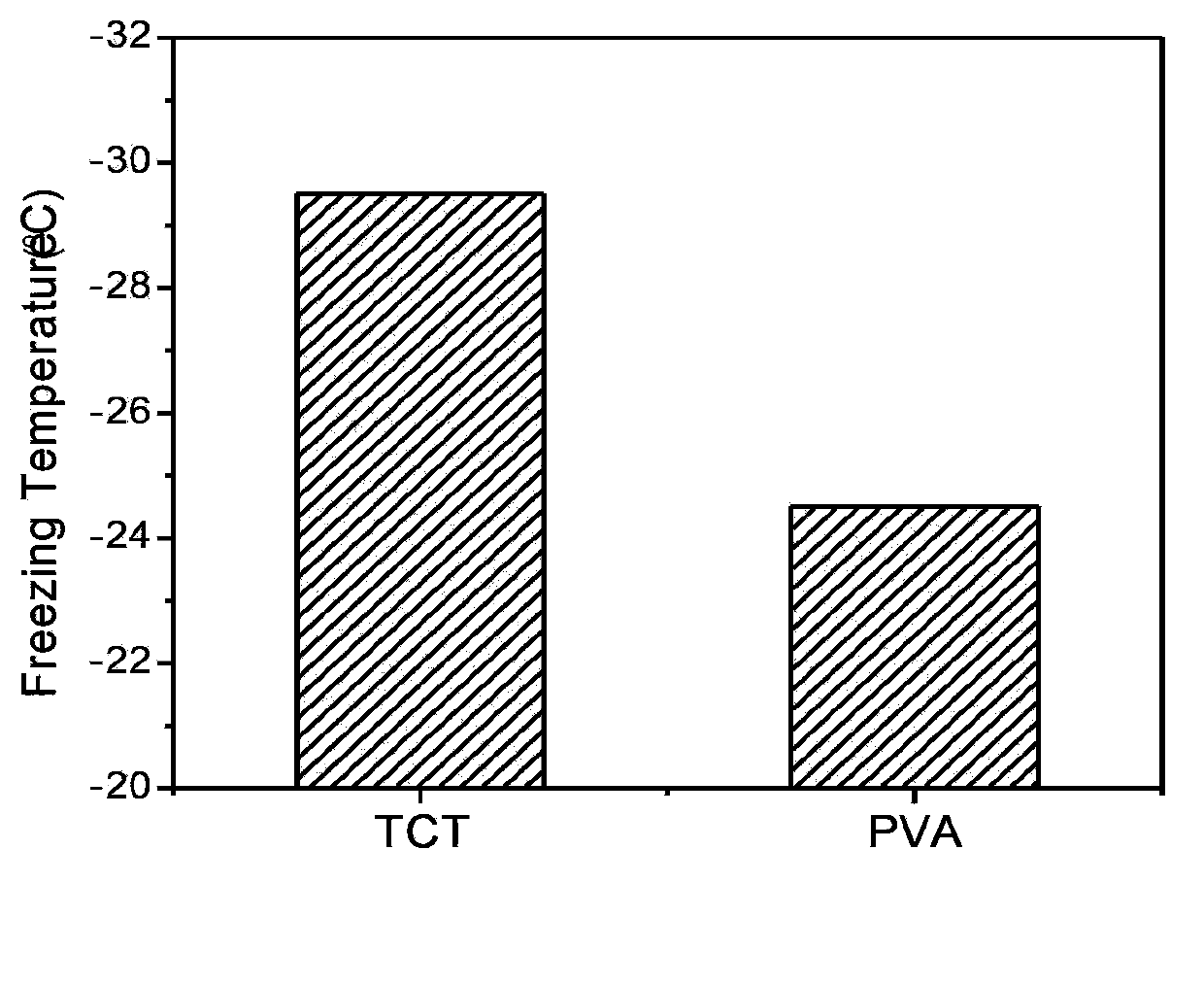

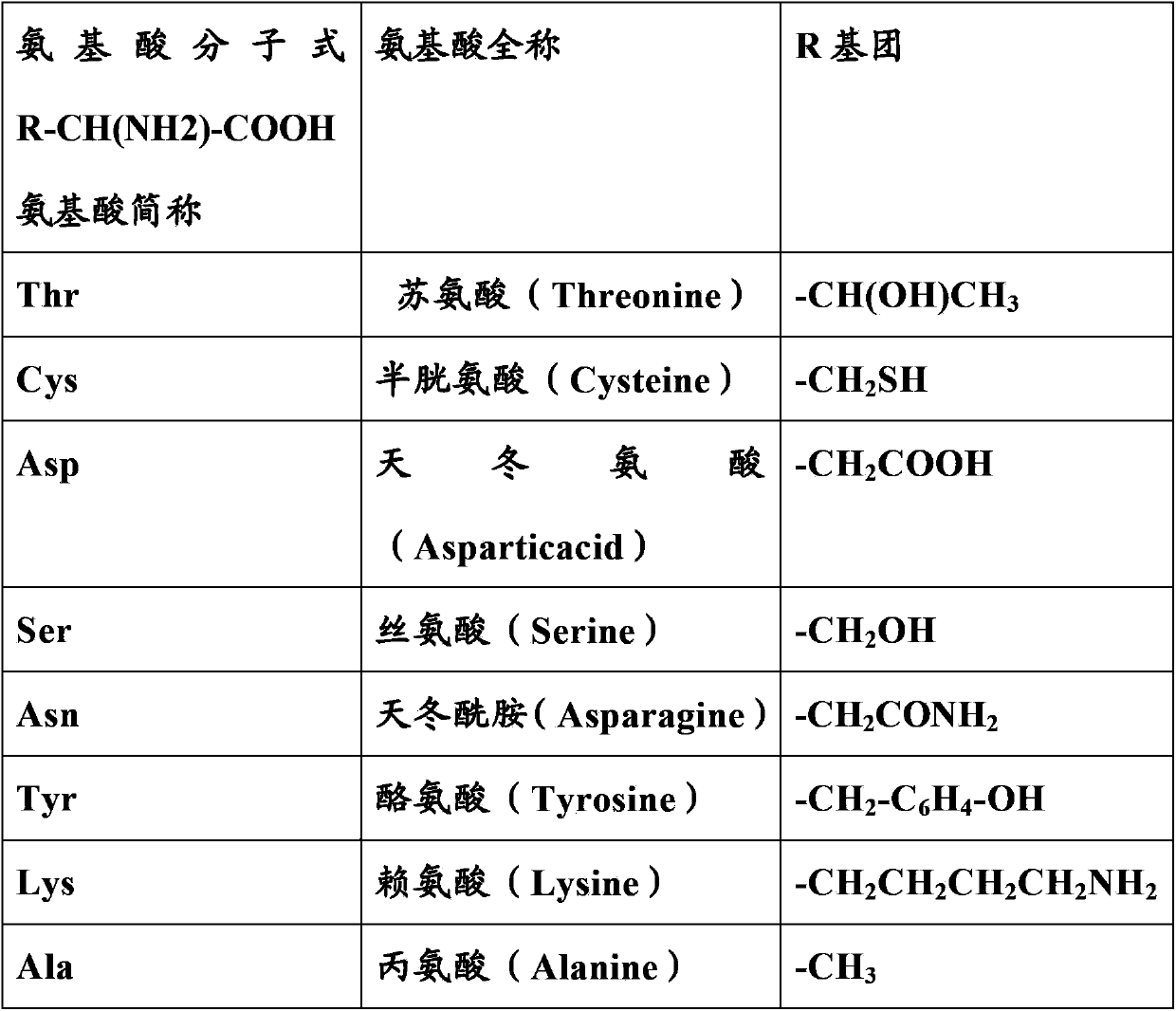

Antifreeze polypeptide, bionic antifreeze surface related to antifreeze polypeptide, and screening method and application of antifreeze polypeptide

InactiveCN103965294ALowering the freezing pointLower freezing temperatureOther chemical processesPeptidesScreening methodAntifreeze activity

The invention relates to a method for screening a polypeptide fragment with antifreeze activity. The method comprises a step of screening amino acid sequences of natural antifreeze protein, antifreeze protein or antifreeze glycoprotein or properly improving amino acid sequences of natural antifreeze protein, antifreeze protein or antifreeze glycoprotein. The invention further relates to antifreeze polypeptide, a bionic antifreeze surface related to the antifreeze polypeptide, a coating containing the antifreeze polypeptide and a preparation method and application of antifreeze polypeptide. The antifreeze polypeptide inherits antifreeze characteristics of the antifreeze protein, has a simple structure, is easy to synthesize on large scale and to produce in batches and exerts better effects compared with the antifreeze protein when used for preparation of the antifreeze surface.

Owner:INST OF CHEM CHINESE ACAD OF SCI

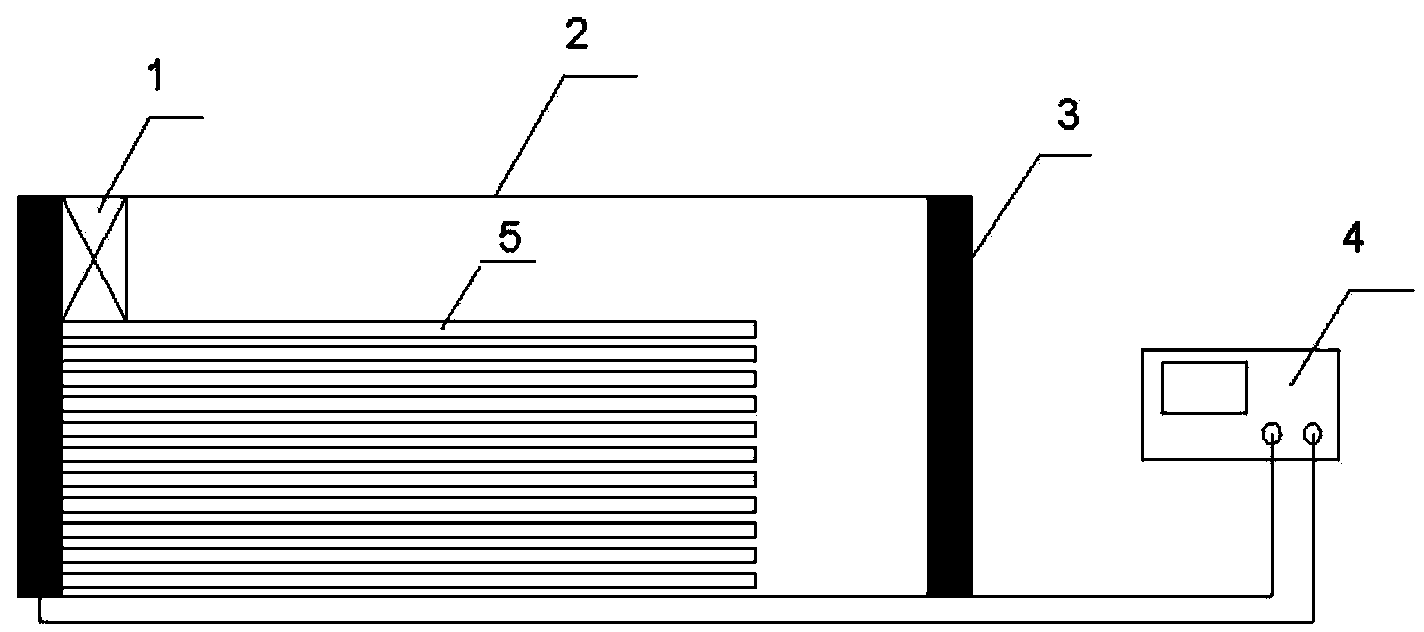

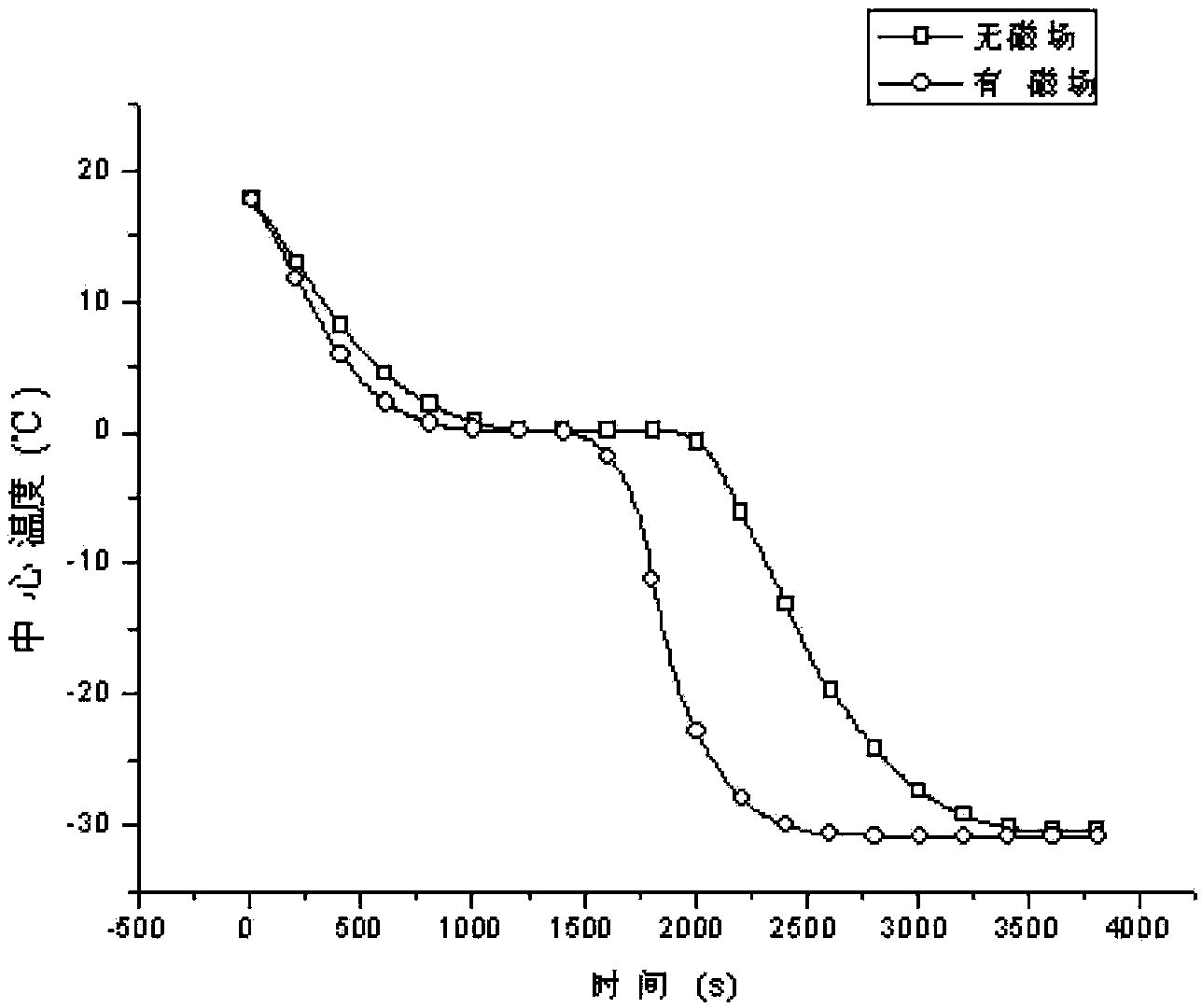

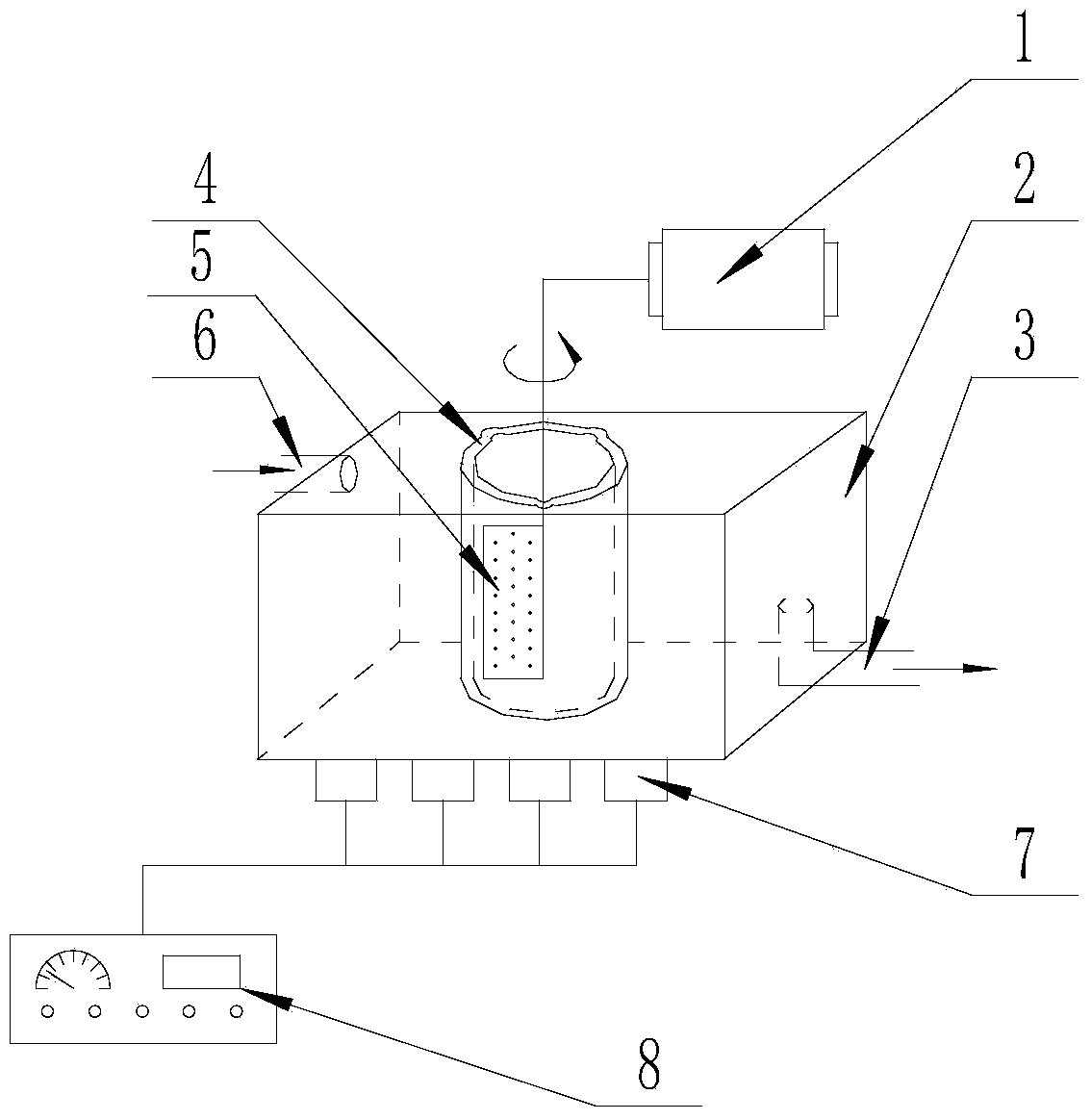

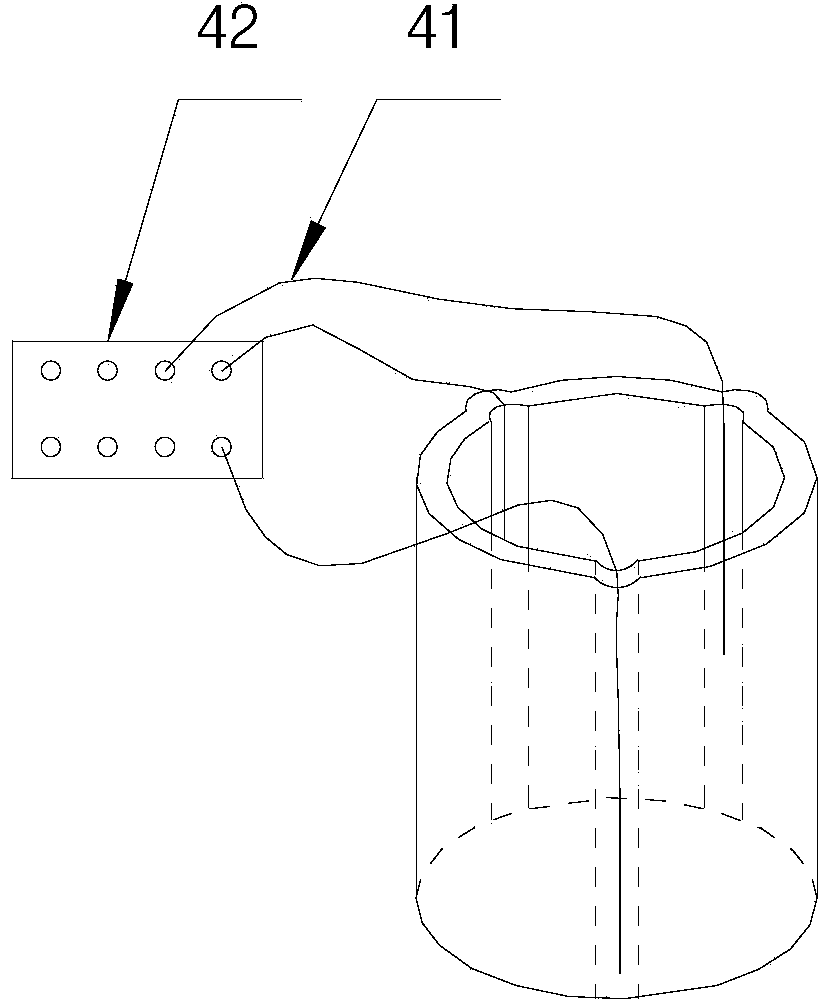

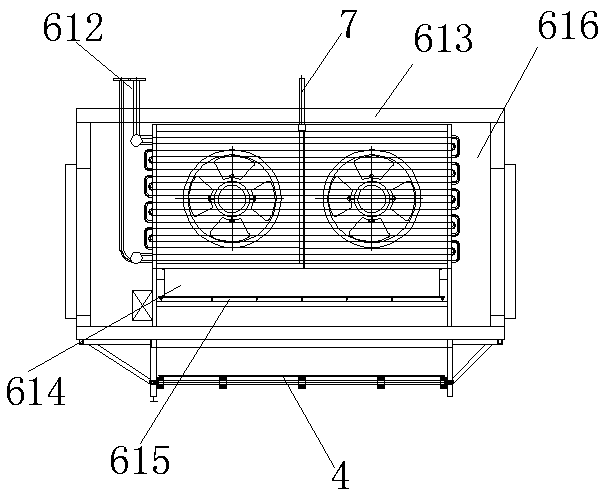

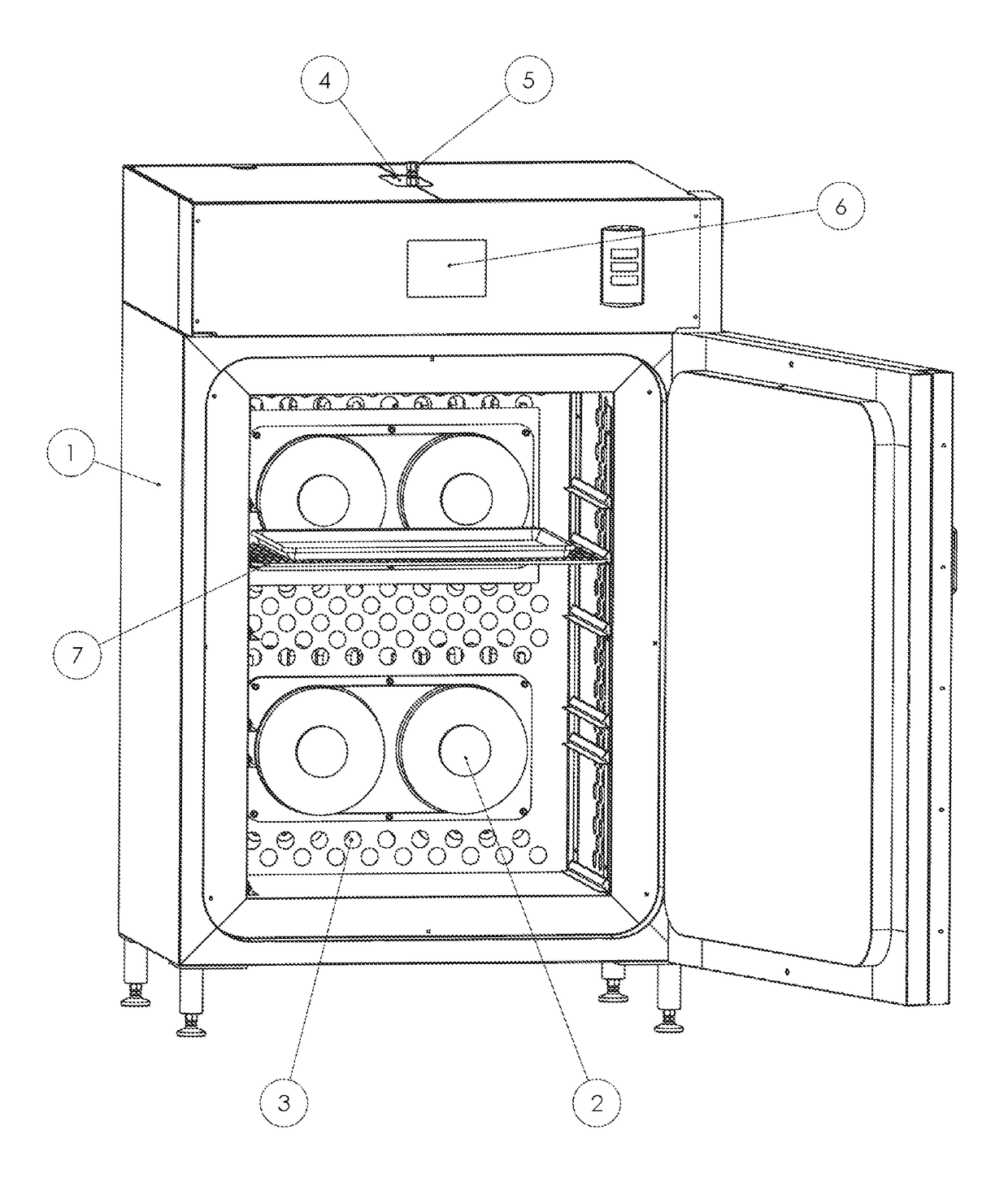

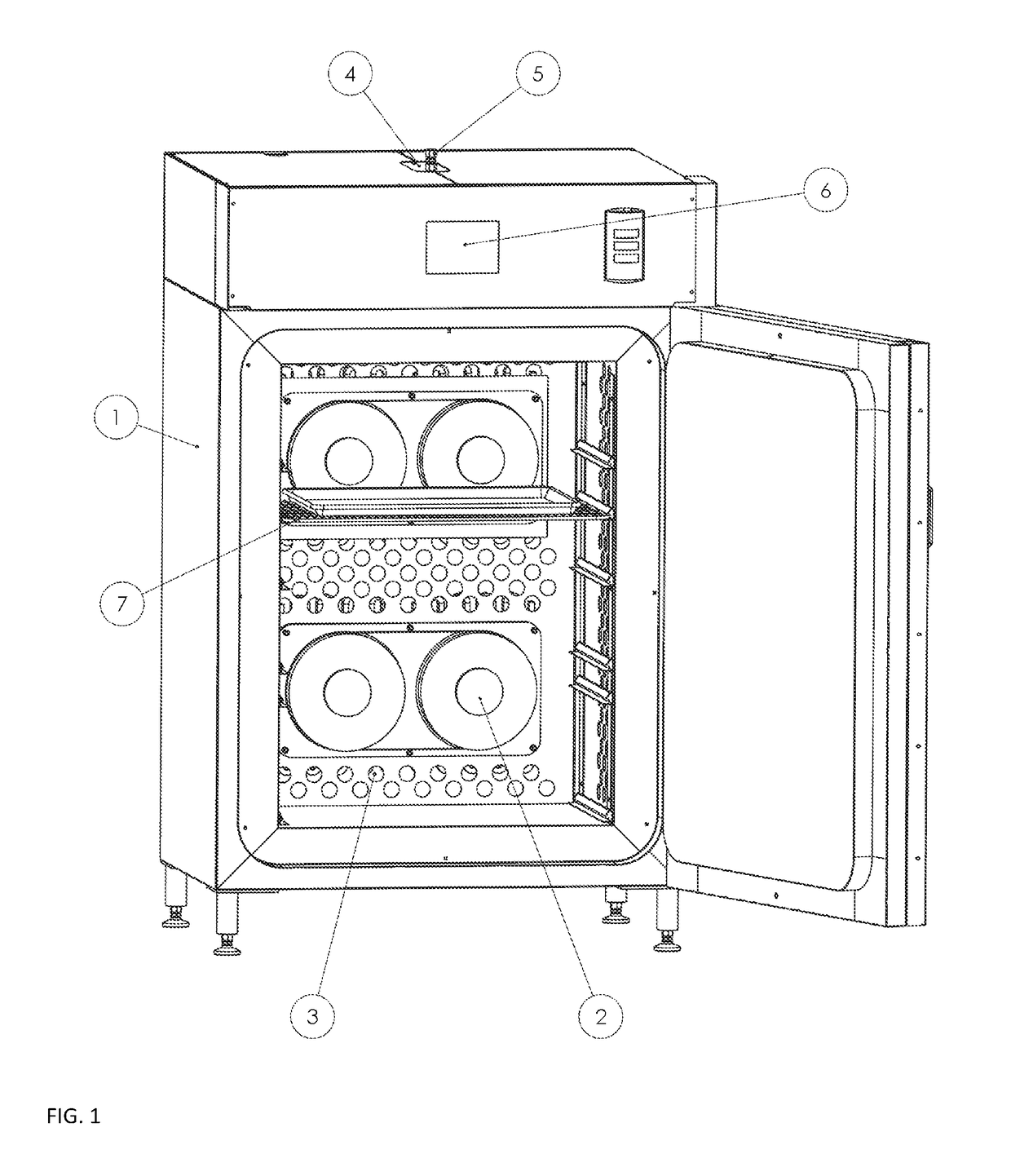

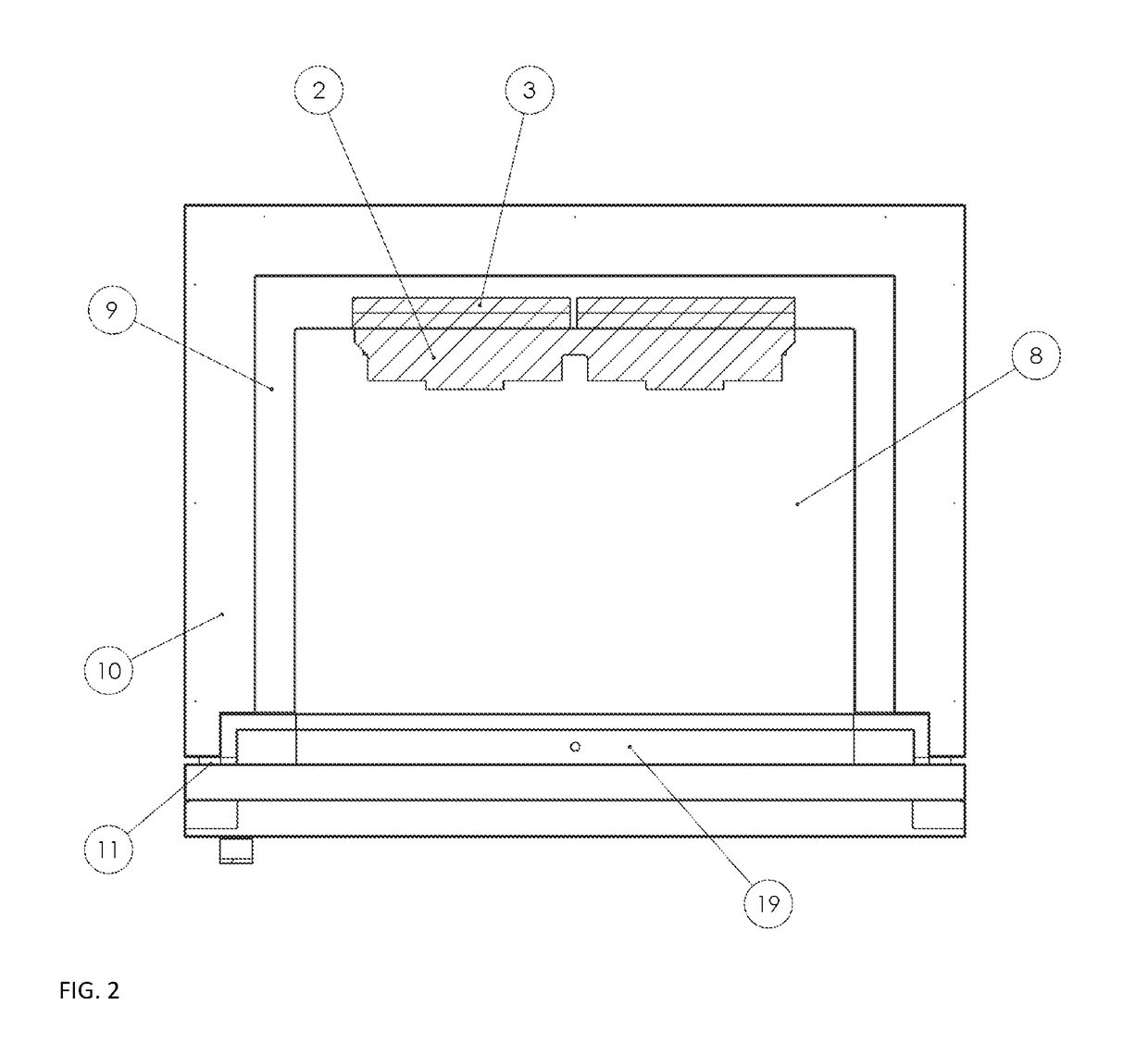

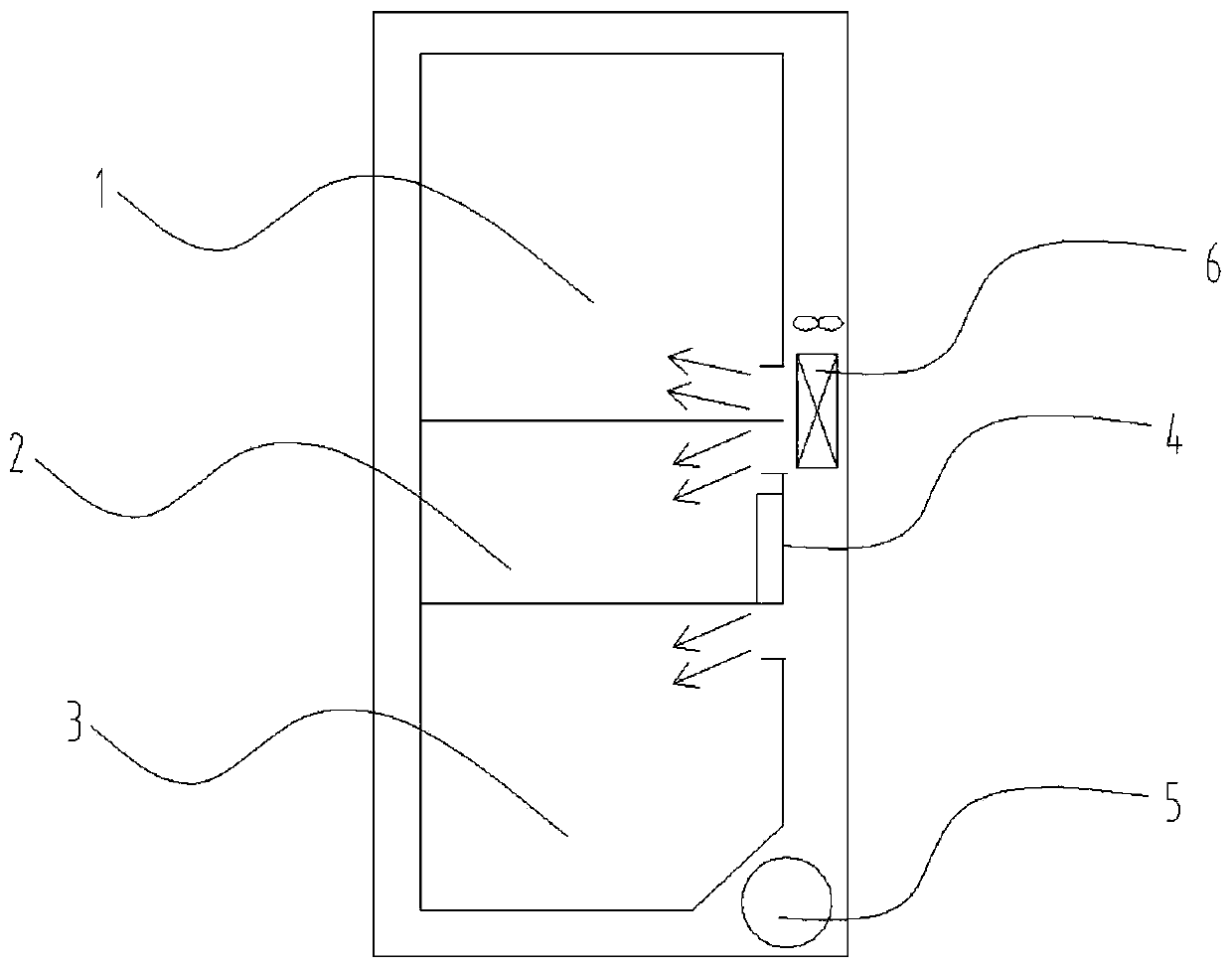

Quick-freeze storage with magnetic field device and operation method of quick-freeze storage with magnetic field device

InactiveCN103900322AReduce consumptionGuaranteed qualityLighting and heating apparatusStationary refrigeration devicesQuick FreezeHelmholtz coil

The invention relates to a quick-freeze storage with a magnetic field device and an operation method of the quick-freeze storage with the magnetic field device. The quick-freeze storage with the magnetic field device is simple in structure, convenient to use, good in quick-freeze effect and capable of effectively reducing energy consumption, and comprises a magnetic field generation device. The magnetic field generation device is disposed in the blowing type quick-freeze storage and connected with a control circuit outside the blowing type quick-freeze storage and consists of Helmholtz coils in pairs, and the Helmholtz coils are connected with the control circuit which controls the Helmholtz coils under direct current. A magnetic field generated by the Helmholtz coils is distributed in a whole freezing space of the blowing type quick-freeze storage, and the magnetic field intensity of the magnetic field generation device is 0-1000GS. During quick freeze of food, temperature of the food in the quick-freeze storage is monitored in real time, the magnetic field is not added in an initial temperature-fall period but added when the temperature falls to a set temperature, and after a phase change process is completed, the temperature continues to fall to the set temperature, the control circuit is disconnected, the magnetic field is not added any more, and freezing continues.

Owner:SHANDONG COMMERCIAL GRP CO LTD

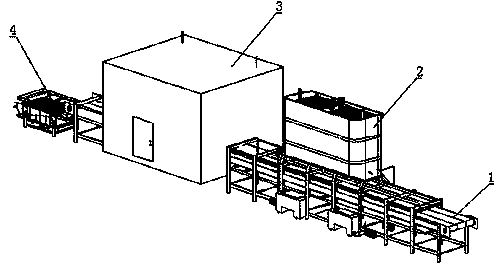

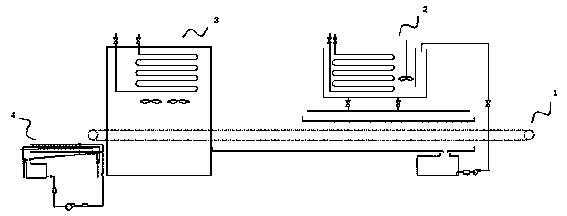

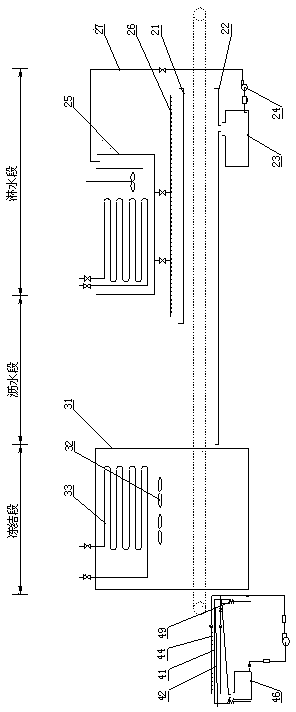

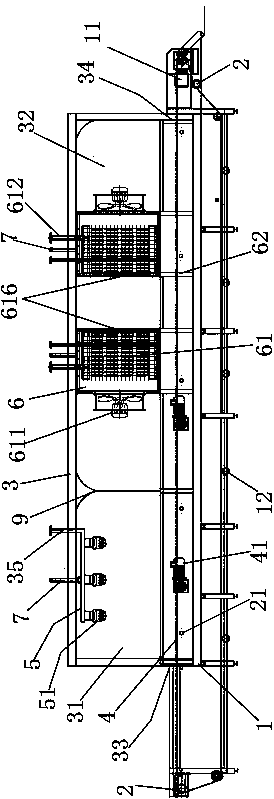

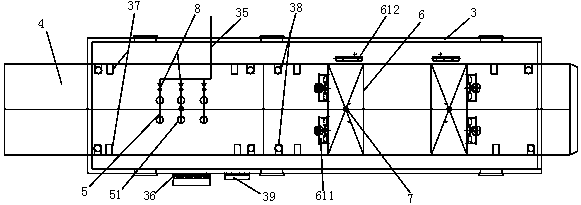

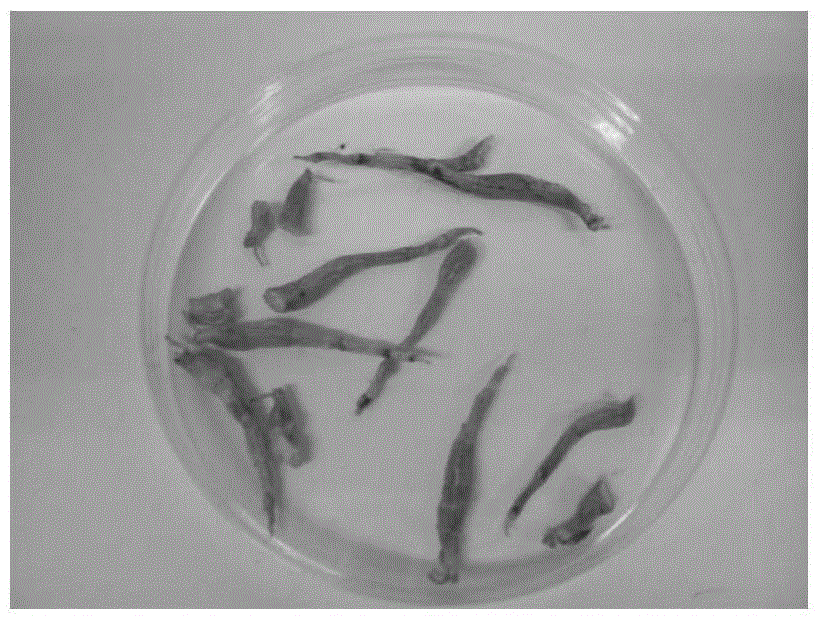

Refrigeration pretreatment production line for shrimps

ActiveCN103431495AWeaken the U-turn phenomenonCurb corruptionFood preservationQuick FreezeEngineering

The invention relates to a refrigeration pretreatment production line for shrimps. The production line is characterized in that: the production mainly comprises a conveying mesh belt, the conveying mesh belt is divided into a water spraying segment conveying mesh belt, a water draining segment conveying mesh belt and a freezing segment conveying mesh belt from the front to the rear according to technological requirements; the water spraying segment conveying mesh belt and the water draining segment conveying mesh belt are provided with a salt brine spraying, cooling and water draining device; the freezing segment conveying mesh belt is provided with a fast freezing device; the discharging end of the freezing segment conveying mesh belt is provided with a vibration ice coating device; and thus the refrigeration pretreatment production line for the shrimps is formed, and the whole refrigeration pretreatment on the shrimps in the production line is realized, the treatment efficiency on the shrimps is substantially improved, and the health status of the shrimps is improved. Also, the salt brine sprayed on the surface of the shrimps helps to inhibit corrosion caused by biological action and enzyme action, weaken the generation conditions of large ice crystal in the freezing segment, reduce possibility of damages to shrimp tissues and guarantee the quality of the shrimps; and the shrimps do not need secondary freezing because of vibration ice coating, and thus energy consumption is reduced.

Owner:NANTONG SINROFREEZE EQUIP

Storage tolerance cell cryopreservation liquid

InactiveCN107439536AShorten freezing timeEasy to storeDead animal preservationSodium bicarbonateVitamin C

The invention discloses a storage tolerance cell cryopreservation liquid which comprises propylene glycol, dextran, potassium chloride, magnesium chloride, disodium hydrogen phosphate, monopotassium phosphate, sodium chloride, vitamin C, cholesterol, sodium bicarbonate, albumin, glucose, creatinine, chloramphenicol, streptomycin, glycerinum, sodium carboxymethylcellulose and sterile injection water. The components of the storage tolerance cell cryopreservation liquid disclosed by the invention are coordinated with one another and act with one another, so that the cryopreservation liquid disclosed by the invention can be easily preserved and has a relatively long shelf life, that is, the shelf life is as long as 3 months or grater, the operation is simple, the cryopreservation liquid does not need to be prepared temporarily on site, the time and the labor are saved, the cryopreservation liquid can be preserved at low temperature directly, no complex cryopreservation procedure is needed, the cell cryopreservation time is greatly shortened, the cryopreservation efficiency is improved, and the cryopreservation liquid is stable and reliable in preservation effect, convenient to transport, convenient to use, simple and easily available in raw material and worthy of market popularization and application.

Owner:重庆斯德姆生物技术有限公司

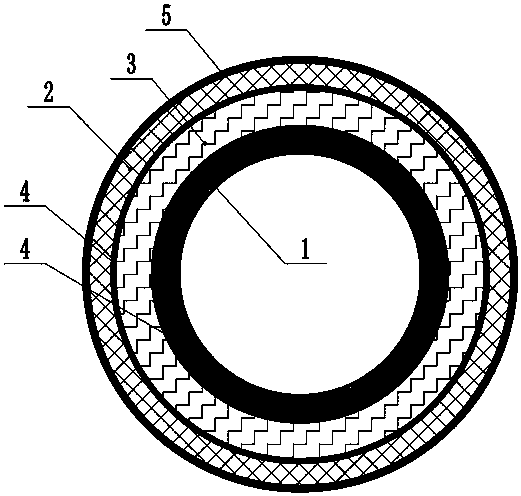

Unidirectional heat conduction apparatus

InactiveCN1570294AMaintain stability and securityResolve outstanding conflictsFoundation engineeringThermal insulationEngineering

This invention design carries on the railroad in many years frozen earth area, the road and in the project construction construction one kind of unidirectional heat conduction installment, it is by the thermal insulation material, the working substance carrier, the metal tube composes, the metal tube through the thermal insulation material and the working substance carrier nesting, encircles annular channel. Installs underground this installment level in in the certain position soil body; Using its unidirectional heat conduction performance, summer the external environment temperature is higher, the quantity of heat unceasingly spreads to in the soil body, this equipment may effectively prevent this part of thermal spreading to; Is lower in the winter external environment temperature, soil body unceasingly exothermic, flows through carrier the heavy working substance with the convection, enables lower part the soil body the quantity of heat to release. From this may effectively avoid many years frozen earth season activity the freezing and thawing to the roadbed and the project construction stable influence, causes on many years frozen earth the project construction stable establishment in a higher level.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

Method for increasing freezing speed and quality of ice creams through double-point variable-intensity ultrasonic waves

The invention discloses a method for increasing the freezing speed and the quality of ice creams through double-point variable-intensity ultrasonic waves. A preparation process of the ice creams comprises the steps of raw material mixing, pasteurization, homogenizing, ageing, stirring, congelation, filling forming and hardening, wherein in the congelation stage of the ice creams, the variable-intensity ultrasonic waves are adopted for processing the ice creams; more specifically, in the nucleus forming stage, the ultrasonic wave with the intensity of 0.2-0.6W / cm<2> is used and in the crystal nucleus growth stage, the ultrasonic wave with the intensity of 0.5-0.9W / cm<2> is used. The method disclosed by the invention has the advantages that the freezing speed of the ice creams is increased; the taste and the quality of the ice creams are improved; the influence of temperature fluctuation to the ice crystal form in transportation and storage processes is reduced.

Owner:SOUTH CHINA UNIV OF TECH

Quick-freezing fresh-keeping method and tunnel-type fresh-keeping quick-freezing machine

PendingCN109990543AFreeze fast and keep freshGood fresh-keeping effectLighting and heating apparatusStationary refrigeration devicesQuick FreezeEngineering

The invention discloses a quick-freezing fresh-keeping method and a tunnel-type fresh-keeping quick-freezing machine. The tunnel-type fresh-keeping quick-freezing machine comprises a fixing frame, a transmission roller shaft and a storehouse body, wherein the storehouse body is provided with a transmission mesh belt; the storehouse body is arranged on the fixing frame; a fresh-locking chamber anda freezing chamber are arranged in the storehouse body; the fresh-locking chamber and the freezing chamber are mutually connected; a liquid nitrogen spraying device is arranged in the fresh-locking chamber; a plurality of atomizing spray heads are arranged on the liquid nitrogen spraying device; an air cooling device is arranged in the freezing chamber; the storehouse body is provided with a regulating and controlling system electrically connected with the liquid nitrogen spraying device and the air cooling device; and the two ends of the storehouse body are provided with a feeding port and adischarging port. According to the quick-freezing fresh-keeping method and the tunnel-type fresh-keeping quick-freezing machine, the mechanical compression refrigeration and the liquid nitrogen refrigeration are effectively combined, a frost protection layer is formed on the surface of material by spraying liquid nitrogen to protect the moisture of the material from losing so as to ensure the freshness of the material, and then a mechanical compression refrigeration is adopted to carry out deep refrigeration so as to avoid dehydration of the surface of the material due to direct air cooling soas to ensure the freshness and taste of the material; and meanwhile, the fresh-locking and fresh-keeping effect are achieved, full-automatic operation is achieved according to set parameters, and energy consumption is reduced.

Owner:广州鲜之源生态冷链技术有限公司

Method for quickly freezing mango

ActiveCN103211005AIncrease productivityShorten freeze timeFood processingFruits/vegetable preservation by freezing/coolingHigh concentrationSucrose

The invention belongs to the technical field of food processing, and relates to a method for quickly freezing mango. The method can reduce the freezing time, improve the freezing frequency, save the energy and improve the quality of the frozen mango. The method specifically comprises the steps of selecting: selecting mangos being consistent in maturity and out of mechanical damage; pre-processing: cleaning the mangos, removing the peel and kernels, and cutting the pulp into blocks or pieces; penetrating and dehydrating: placing the mango blocks or mango pieces into high-concentration penetrating fluid which is selected from one or some out of sucrose, glucose, fructose and maltose and has the concentration of 40 to 50wt%, penetrating temperature of 20 to 35 DEG C, material-to-liquid ratio of 1: 5 to 1: 10, and penetrating time of 1 to 2 hours; taking out the mangos after penetrating and dehydrating; washing with clean water to remove sugar on the surface; drying the surface; sealing and packaging after sterilizing: packaging the penetrated and dehydrated mangos through polyethylene bags, and sterilizing and sealing; and general freezing: freezing and refrigerating the packaged mangos at -20 DEG C, thus obtaining the frozen mangos.

Owner:CHINA AGRI UNIV

Novel method for improving fruit and vegetable unfreezing quality

InactiveCN102475127AImprove defrosting qualityShorten freeze timeFruits/vegetable preservation by freezing/coolingUltrasonic assistedFruits and vegetables

The invention relates to a novel method for improving fruit and vegetable unfreezing quality. According to the invention, ultrasonic waves are adopted for assisting in freezing in the quick freezing process of quick-frozen fruits and vegetables. The method comprises the steps of selecting, cleaning, cutting, bleaching and heating for inactivation of enzyme, cooling, freezing, freezing with the assistance of the ultrasonic waves, and packing fruits and vegetables as raw materials. According to the invention, the technology of treatment with the combination of the ultrasonic waves is adopted in the fruit and vegetable immersing and freezing process, thus the fruit and vegetable unfreezing quality is improved; and the novel method has the characteristics of shortening of freezing time, good keeping of initial shape, low operation cost and the like.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

Extremely fast freezing, low-temperature blast freezer

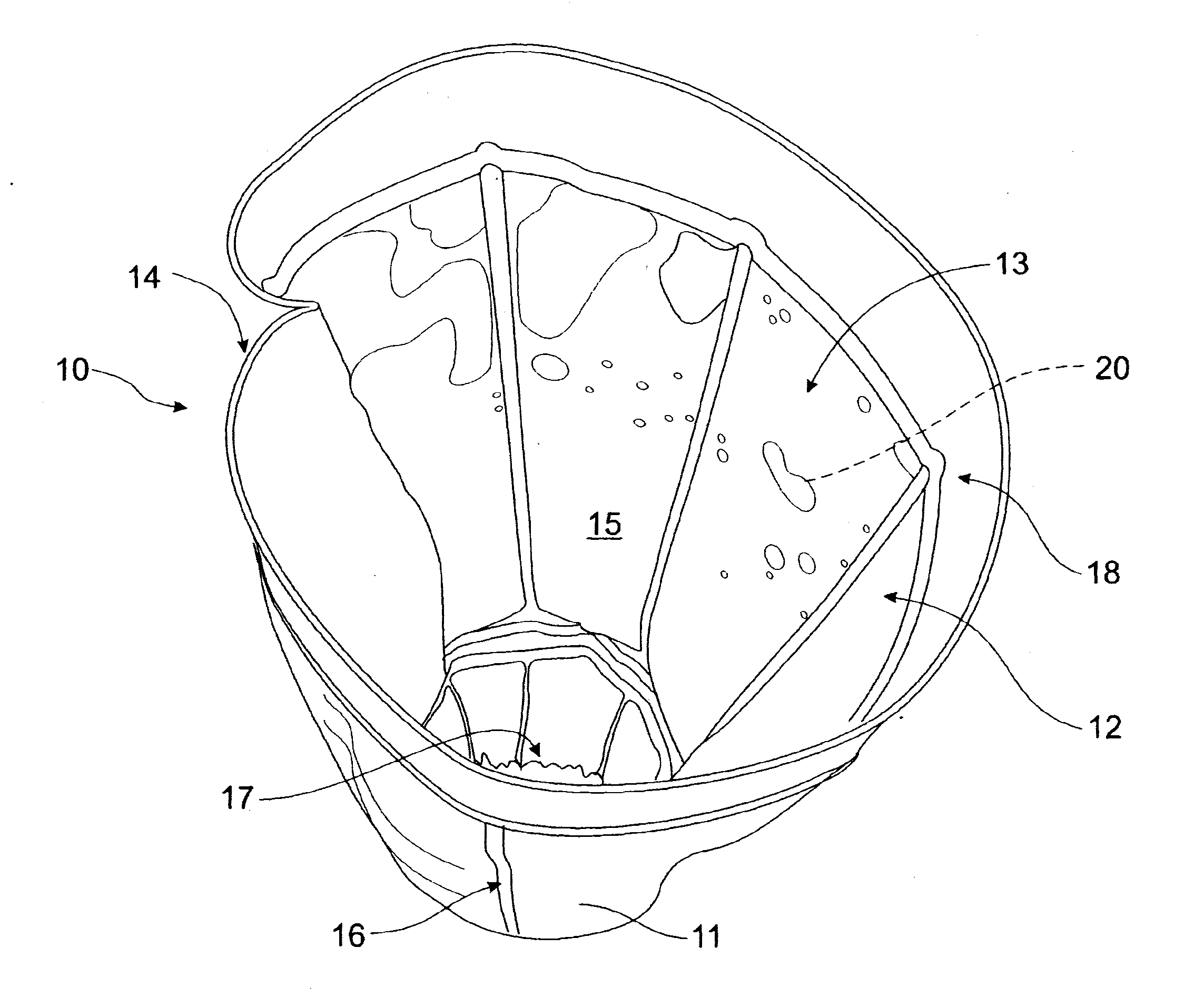

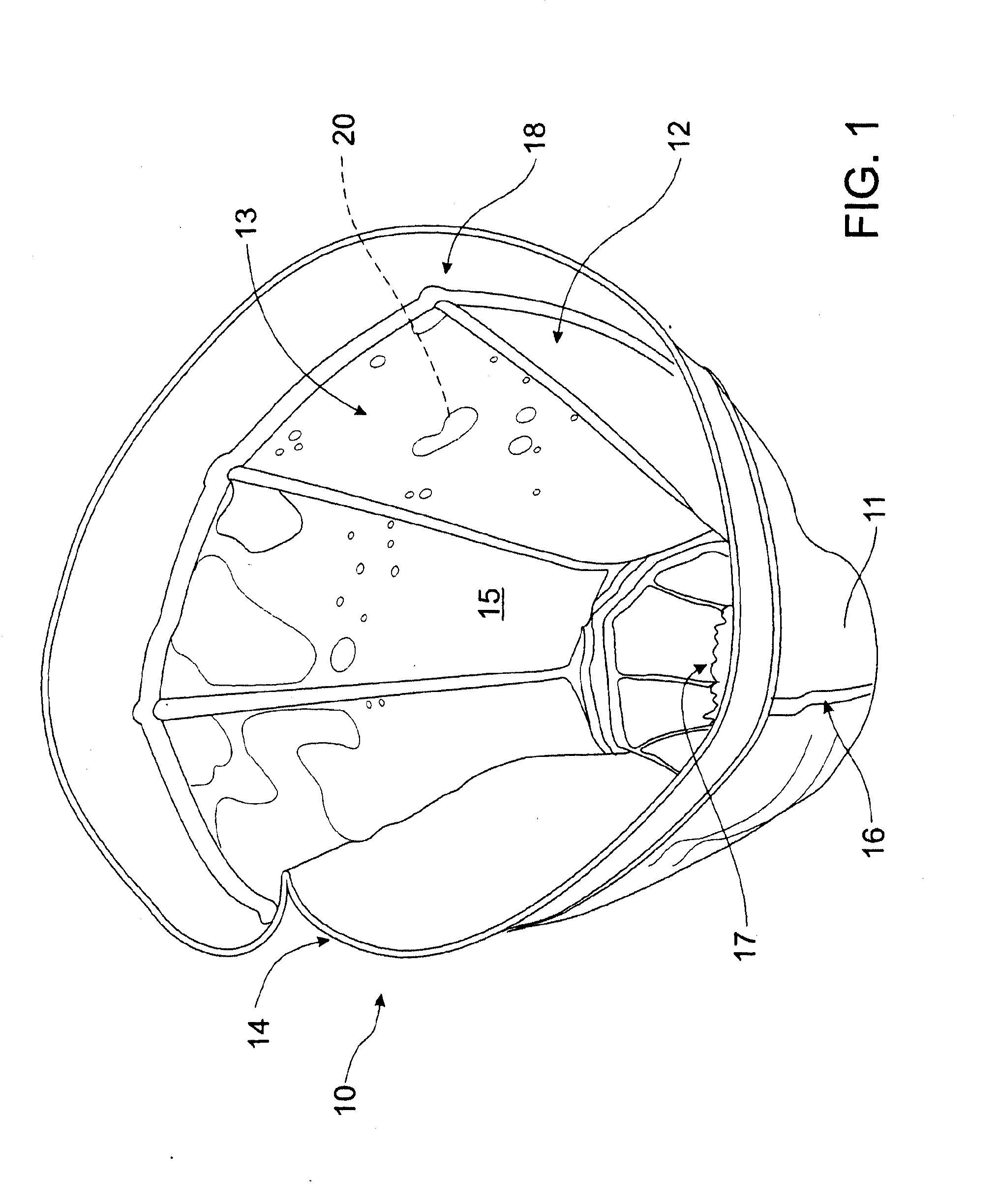

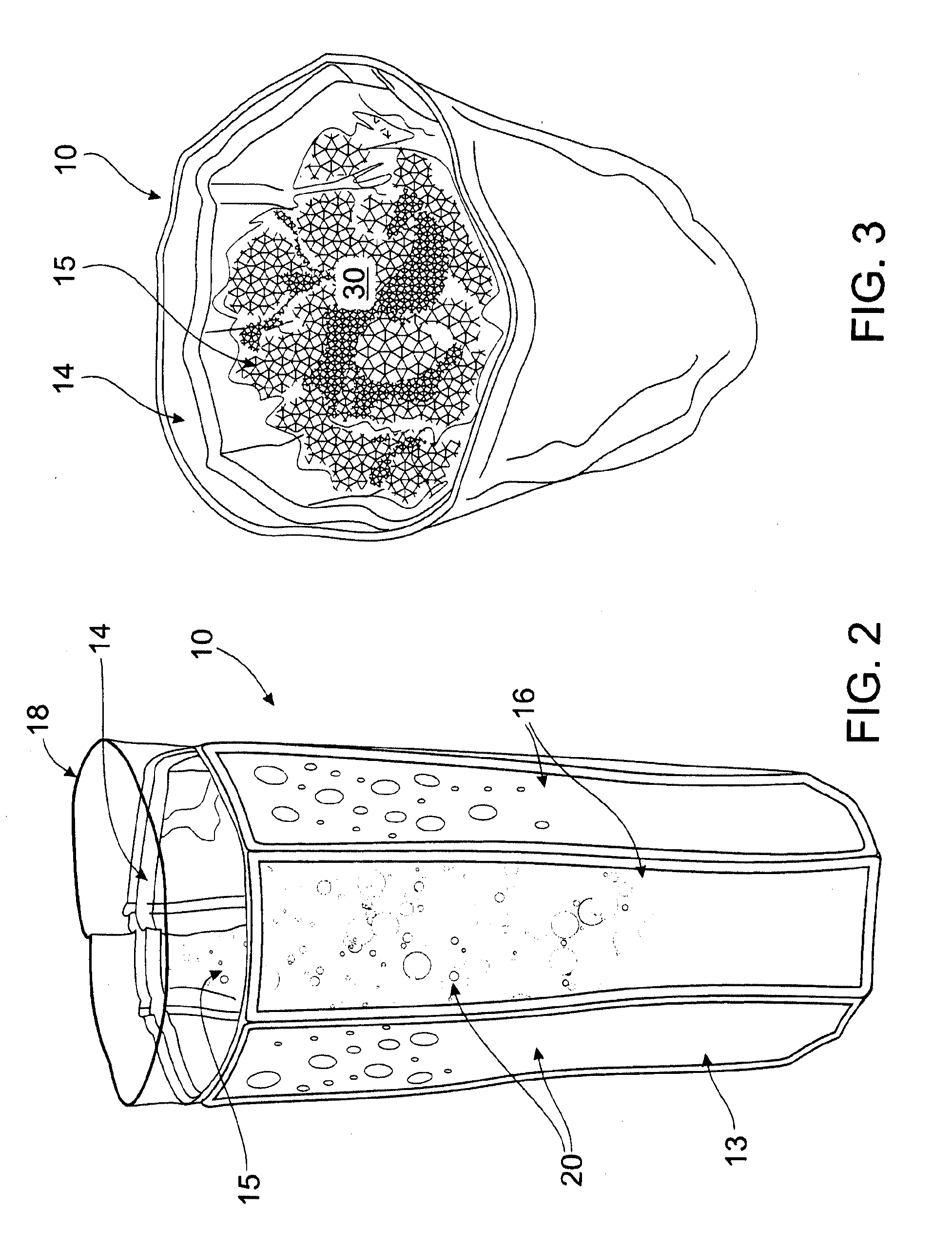

ActiveUS20170234597A1Increase coolant flowConvective cool property be greatly enhancedLighting and heating apparatusDead animal preservationFast freezingEvaporator

Owner:REFLECT SCI

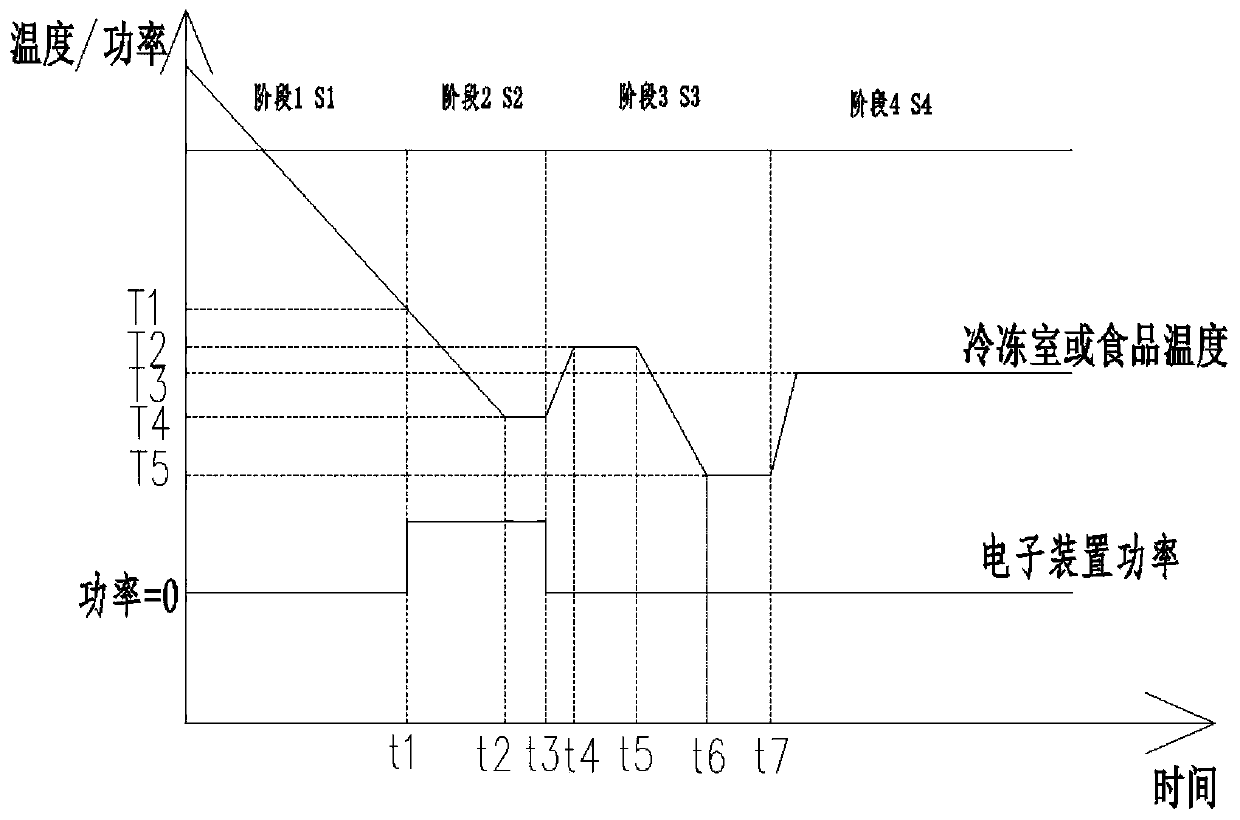

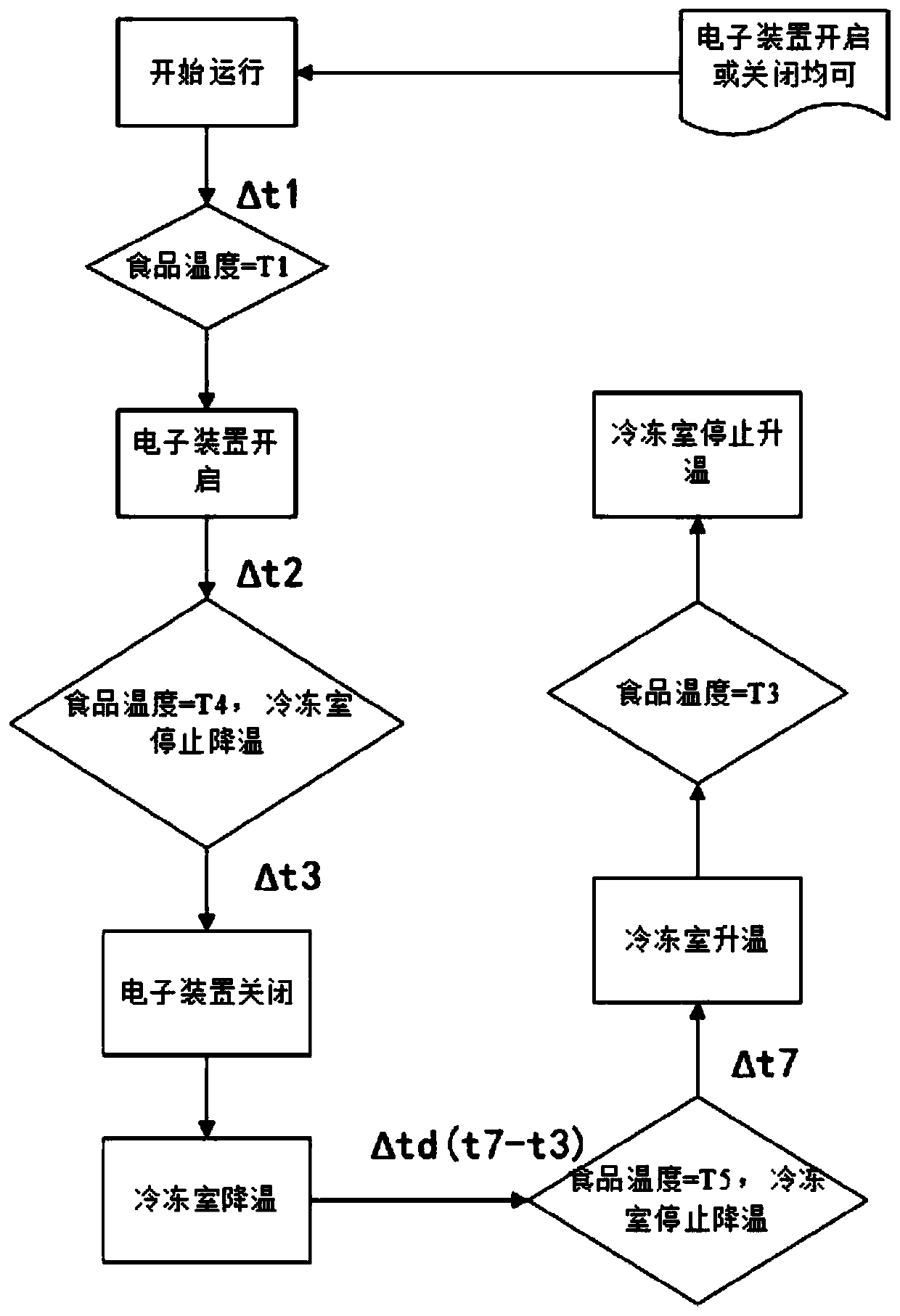

Overcooling freezing method, refrigerator and refrigerator control method

PendingCN110671876AImprove storage qualityAvoid damageLighting and heating apparatusCooling fluid circulationThermodynamicsIcebox

The invention discloses an overcooling freezing method, a refrigerator and a refrigerator control method, and relates to the technical field of freezing and fresh keeping. By controlling the temperature of a freezing compartment and applying an internal energy field to the freezing compartment at different stages, the problems that nutrients are lost due to ice crystals squeezing or puncturing food cells during freezing and frozen food cannot be processed again without thawing are solved.

Owner:GREE ELECTRIC APPLIANCES INC

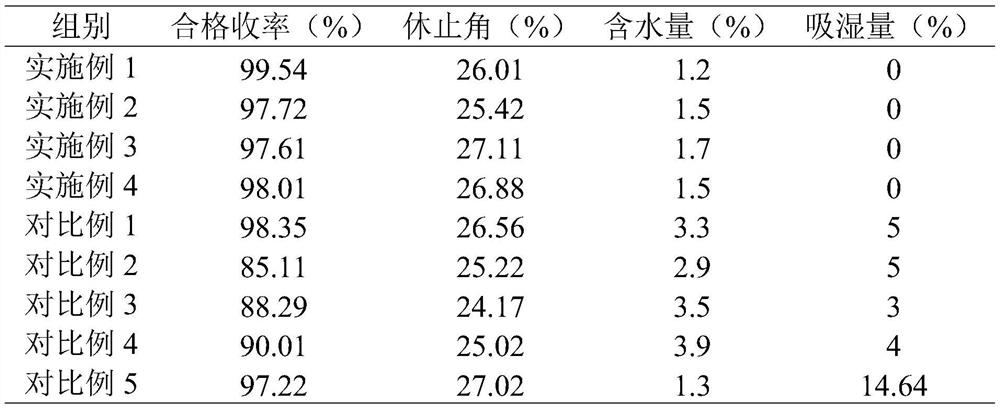

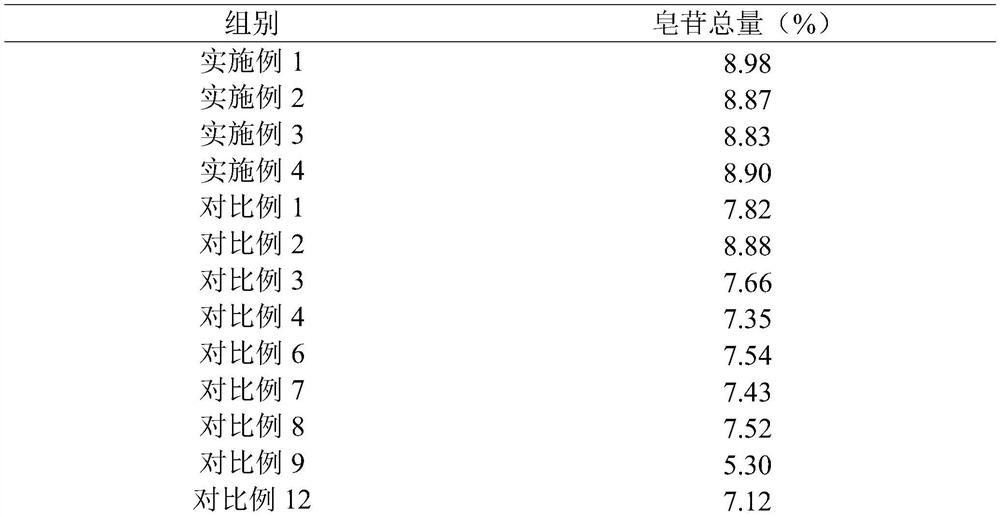

Pseudo-ginseng vacuum freeze-drying method and application thereof

InactiveCN112229148APrevent local melting and disintegrationAvoid affecting product qualityDrying solid materials without heatDaily livingFreeze-drying

The invention relates to a pseudo-ginseng vacuum freeze-drying method and application thereof, and relates to the technical field of traditional Chinese medicine processing. According to the vacuum freeze-drying method, pseudo-ginseng homogenate is subjected to pre-freezing and vacuum drying treatment, in the pre-freezing step, pre-freezing is carried out in stages at the temperature of minus 20-minus 75 DEG C, and in the vacuum drying treatment step, vacuum drying is carried out at the temperature of minus 20-30 DEG C. The vacuum freeze-drying method is applied to preparation of pseudo-ginseng processed products, and the obtained pseudo-ginseng processed products are high in cleanliness, fine and smooth in taste, stable in quality, accurate in dosage, convenient to apply and carry, high in dissolution and absorption speed, higher in product standardization, higher in production efficiency and suitable for daily life of normal people.

Owner:湖北金贵中药饮片有限公司

Freezing method of Luchuan pork

InactiveCN106879715APrevent the loss of pork nutrientsImprove water resistanceMeat/fish preservation by coatingMeat/fish preservation by freezing/coolingChemistryCentral layer

The invention belongs to the field of fresh keeping of foods, and particularly relates to a freezing method of Luchuan pork. The freezing method comprises the following steps of (1) preparing a film coating agent; (2) performing micro-freezing treatment on pork; (3) performing film coating packaging treatment on the micro-frozen pork; and (4) performing ultrasonic assisted freezing preservation on the packaged pork: conveying the packaged pork into a freezing room, performing freezing until the temperature of the central layer of the pork is reduced to 2-4 DEG C, performing ultrasonic-assisted freezing for 3-6h, when the temperature of the central layer of the pork is reduced to minus 6 to minus 8 DEG C, stopping performing ultrasonic-assisted freezing, and continuing freezing the pork to minus 18 to minus 23 DEG C so as to obtain the frozen pork. The freezing method disclosed by the invention is simple to operate and stable in technology conditions, ice crystals generated during freezing of the pork can be reduced, the pork freezing speed can also be increased, the preservative effect is achieved, bacteria are restrained, the freezing storage time of the pork can be prolonged, the cell activity of frozen fresh meat can be guaranteed, and the phenomenon that juice flows outwards after the frozen pork is unfrozen is reduced.

Owner:广西神龙王农牧食品集团有限公司

Method of, and apparatus for, making frozen beverage, ice cream and other frozen confections

ActiveUS20150253067A1Eliminate manual squeezingEasy to manufactureDomestic cooling apparatusLighting and heating apparatusRefrigerantIce cream

A frozen beverage device to convert a liquid beverage into a semi-frozen or frozen form has inner and outer walls forming at least one refrigerant cavity containing a refrigerant material with a freezing point below the freezing point of the liquid, the refrigerant material occupying at least 60% of the volume of the refrigerant cavity. The walls of the device can be squeezed to accelerate the heat transfer from the liquid to the refrigerant material; and the device may be placed in a squeezing apparatus. Where the device is to be disposable, the device can be placed in a flexible sheath or outer container before being squeezed to protect the device and / or insulate the user from the refrigerant material. A freezing spoon or stirrer can be used to assist, or accelerate, the freezing process.

Owner:CHARACTER PROMOTIONS LTD

Processing method for freshwater fish

The invention relates to a processing method for a freshwater fish. The processing method includes following steps: 1) removing viscera of the freshwater fish and cleaning the freshwater fish; 2) slicing the freshwater fish cleaned in the step 1) and obtaining freshwater fish slices; 3) successively adding edible salt, soft sugar, monosodium glutamate, chilli powder, star aniseed powder and netmeg powder into the freshwater fish slices obtained in the step 2) to season, and continuously stirring the freshwater fish slices uniformly to obtain seasoned freshwater fish slices; 4) stringing the freshwater fish slices seasoned in the step 3); and 5) freezing and packaging. The processing method for the freshwater fish keeps original delicious nutritional tastes of the freshwater fish, and the processed freshwater fish slices do not contain any chemical addition agent.

Owner:PENGLAI JINGLU FISHERY

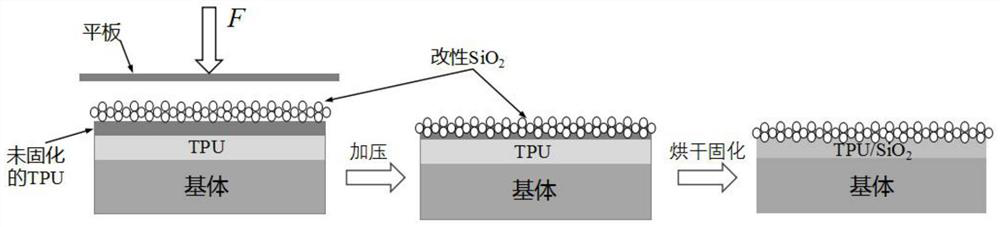

Anti-corrosion anti-icing wear-resistant super-hydrophobic coating and preparation method thereof

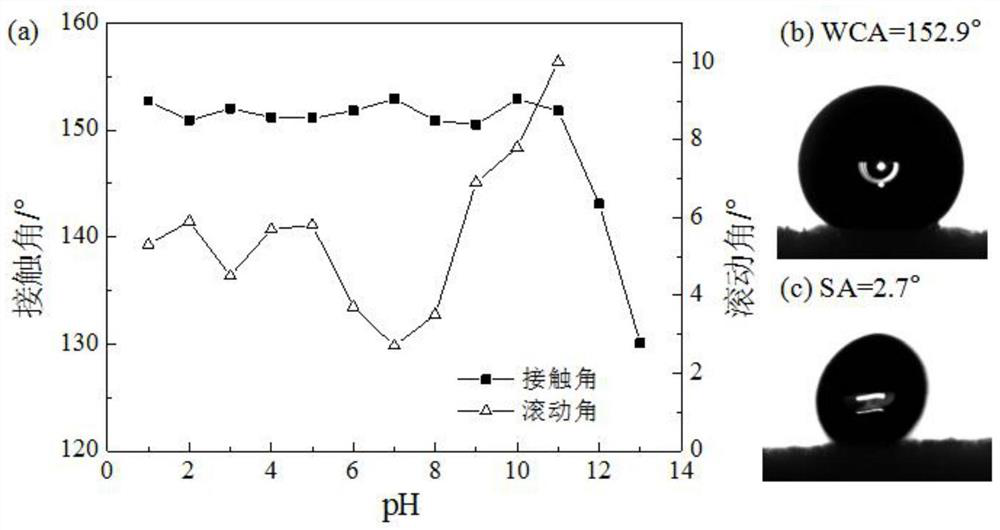

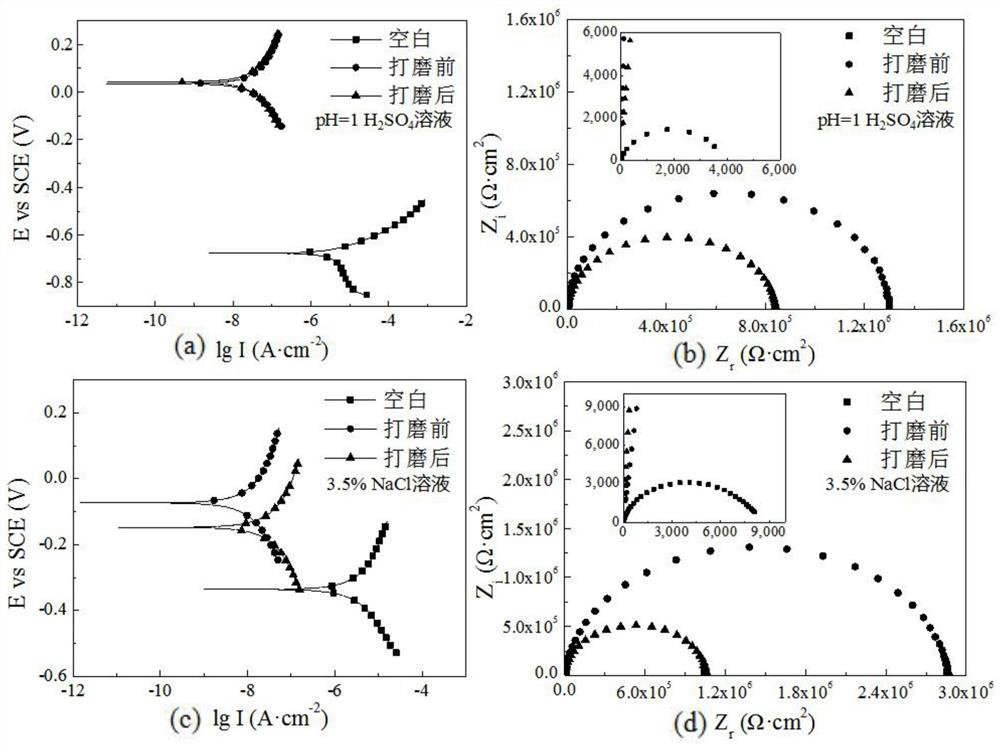

ActiveCN112898886AImprove hydrophobicityLow water adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsNano sio2Wear resistance

The invention discloses an anti-corrosion anti-icing and wear-resistant super-hydrophobic coating and a preparation method thereof, and belongs to the technical field of metal protection materials, and the preparation method comprises the following steps: preparation of modified nano SiO2 particles, preparation of TPU / DMF film forming liquid, pretreatment of base material film coating, and preparation of the anti-corrosion, anti-icing and wear-resistant super-hydrophobic coating. The prepared coating has excellent hydrophobicity, corrosion resistance, icing resistance and wear resistance, the safety risk of equipment and components is effectively reduced, and the service life is prolonged; the preparation method is simple, can realize industrial production, and has a good market prospect.

Owner:NORTHWEST UNIV(CN)

Villiform edible keep-fit massage towel made of konjak and grain

ActiveCN101011163ASoft succulent textureElegant natural colorSpecial ornamental structuresVibration massageChemistryOrganic fertilizer

The invention relates to a villiform edible health massage towel made from konjak and rice, wherein, the production comprises that adding water and pulping the konjak powder, to be mixed with rice powder, fermenting with fermenting agent, adding solidifier to solidify it, breaking some material into powder, to be mixed, molded, aged, frozen, defrozen, dewatered and dried. The invention comprises 70-95 deals of konjak, 10-35 deals of rice powder, 0.35-0.95 deals of fermenting agent and 10-15 deals of solidifiers. The invention uses natural konjak as material, while the product has long service life and the veilliform can massage human body. And the invention can be used as organic fertilizer or food, without pollution.

Owner:贵州中山魔芋农业发展有限公司

Method for treating blast furnace hearth freezing and iron notch oxygen lance for use

InactiveCN107254560AQuick activationReturn to workBlast furnace componentsBlast furnace detailsPresent methodSlag

The invention discloses a method for treating blast furnace hearth freezing and an oxygen lance used, comprising the following steps: (1) shutting down the blast furnace, dredging the slag and iron ditch in front of the furnace, and preparing for the discharge of slag and iron; (2) opening the iron hole Install the drill pipe on the machine, and use the drill bit to pre-drill the iron hole to the red point; (3) replace the iron hole opening machine with the oxygen lance, and push the oxygen lance into the red point in the iron hole tunnel; (4) feed the oxygen lance Oxygen and compressed air; (5) The oxygen lance is withdrawn from the iron hole regularly, and the molten slag-iron mixture is discharged; (6) When the volume of the discharged slag-iron mixture reaches 20%-40% of the hearth volume, the blast furnace is re-aired; (7) Repeat the operation of step 5, and gradually add air to fully restore the working state of the hearth. When this method is used to treat hearth freezing, the oxygen lance used can completely discharge the solidified slag-iron mixture in the hearth, quickly restore the working state of the hearth, significantly shorten the time for processing hearth freezing, and save a lot of manpower and material resources cost.

Owner:江苏金基特钢有限公司

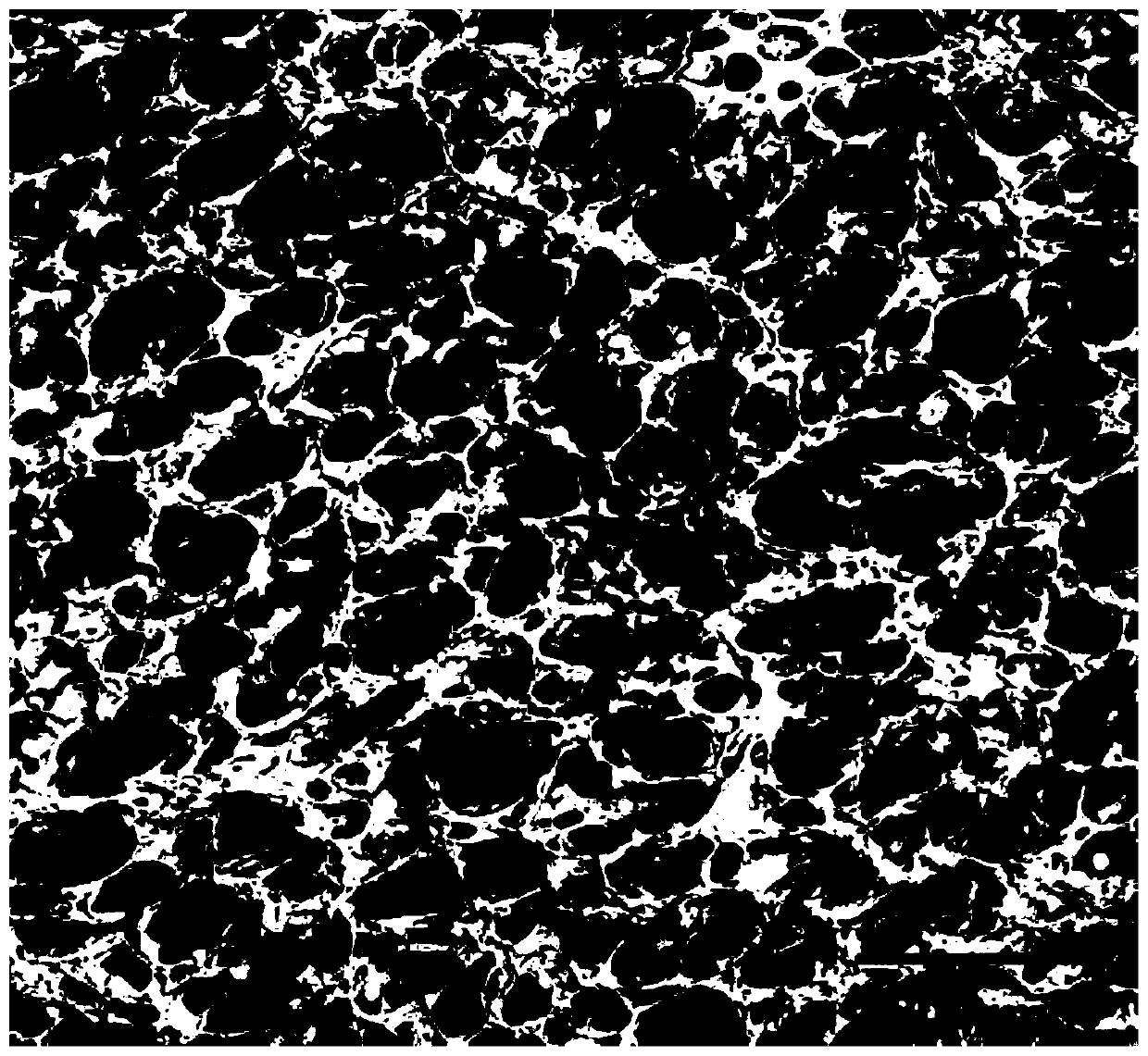

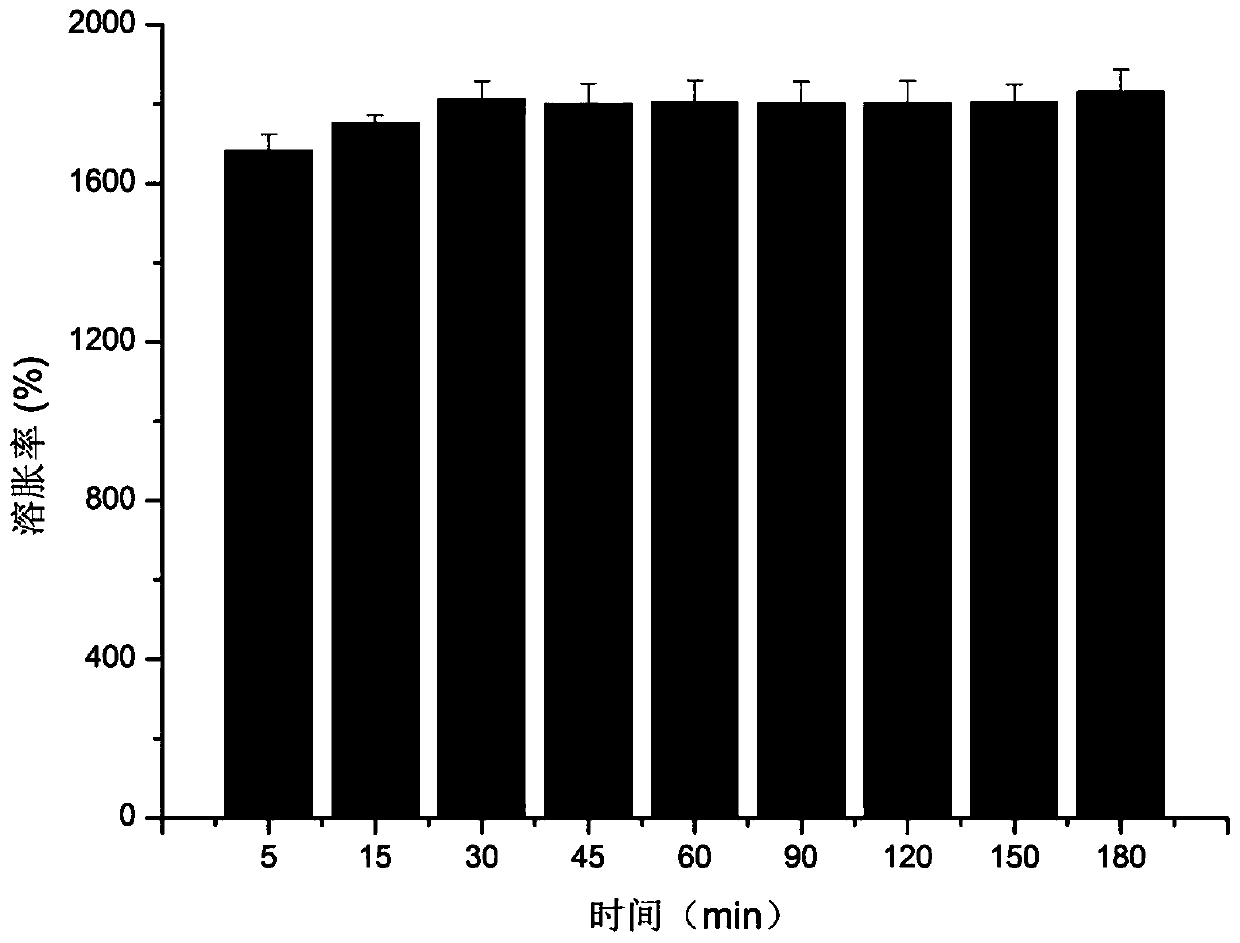

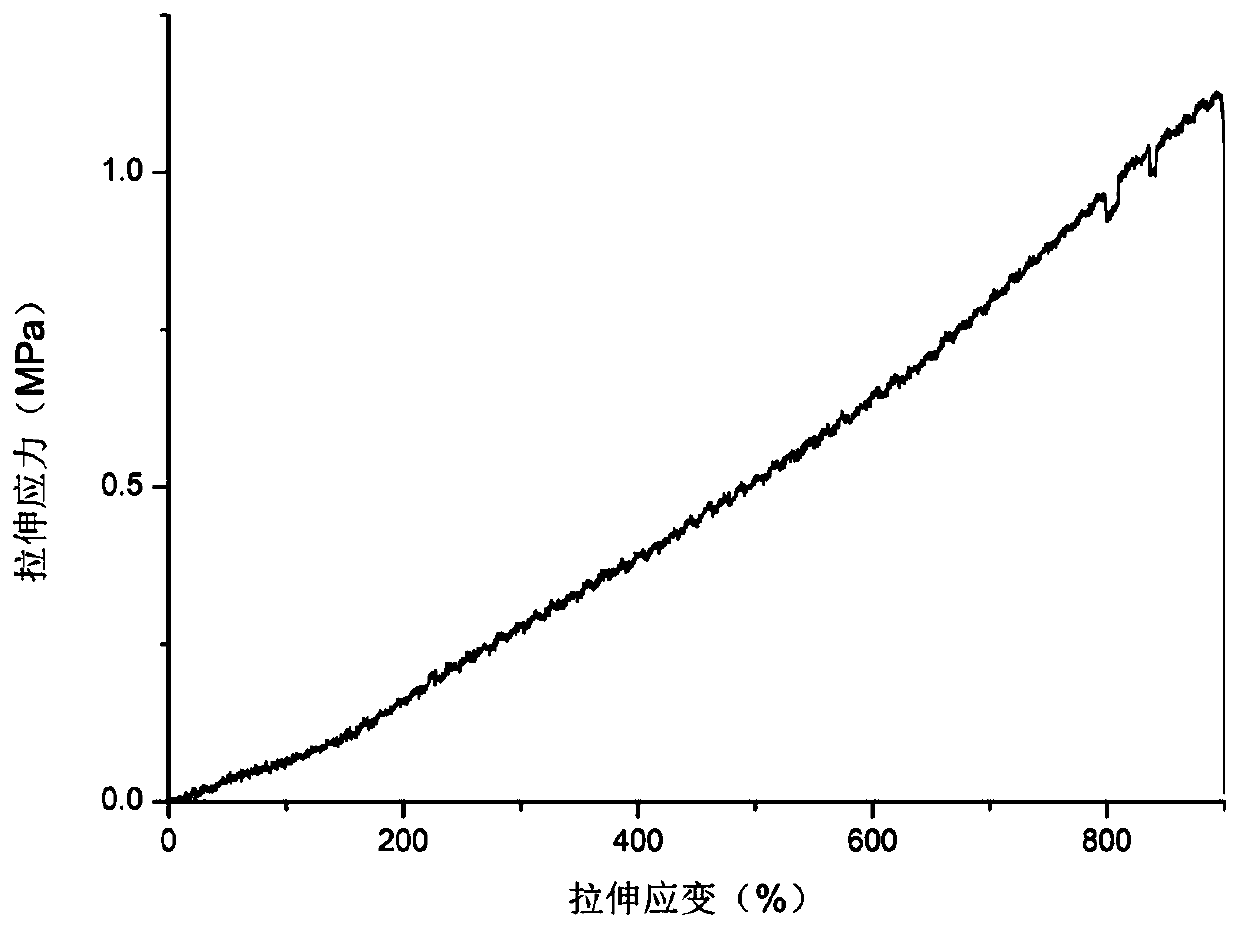

Preparation of polyvinyl alcohol-based hydroge

InactiveCN110698719AEasy to observe recoveryGood biocompatibilityBandagesPolyethylene glycolNano hydroxyapatite

The invention relates to a polyvinyl alcohol-based hydrogel, wherein the raw materials are polyvinyl alcohol, polyethylene glycol and nanometer hydroxyapatite. The synthesis method comprises: dissolving polyvinyl alcohol in deionized water in a 90-DEG C water bath kettle, dissolving polyethylene glycol in the polyvinyl alcohol solution, adding nanometer hydroxyapatite, uniformly stirring, pouringinto a mold, and freezing for 4 h. According to the invention, the prepared polyvinyl alcohol hydrogel has excellent biocompatibility, high porosity, excellent mechanical properties and the like.

Owner:SHAANXI GIANT BIOTECHNOLOGY CO LTD

Freeze-dried dendrobe product and preparation method thereof

ActiveCN105168958ADelicate entranceImprove utilizationDrying solid materials without heatPlant ingredientsFreeze thawingFreeze-drying

The invention provides a freeze-dried dendrobe product and a preparation method thereof. The preparation method comprises the following steps: performing freezing-thawing processing repeatedly on fresh dendrobe strips; performing freezing processing on the fresh dendrobe strips which are subjected to the freezing-thawing processing repeatedly; performing freezing-dehydrating on the obtained frozen dendrobe strips to obtain the freeze-dried dendrobe product. The inventor discovers that ditch-shaped fractures with different widths are generated in the outer surface of a dendrobe medicinal material when the freezing temperature is lower than -150 DEG C and the freezing time is shorter than 60 seconds, and simultaneously, honeycombed uniform gaps are generated in the medicinal material. The areas of the fractures and honeycombs can be enlarged remarkably by freezing and thawing repeatedly; after entering a freezing-drying environment, the sublimation surface area can be increased greatly by the honeycomb and fracture structures; the freezing-drying time can be shortened; the dehydration rate of finished products are improved.

Owner:ANHUI ZHILAN BIOENG

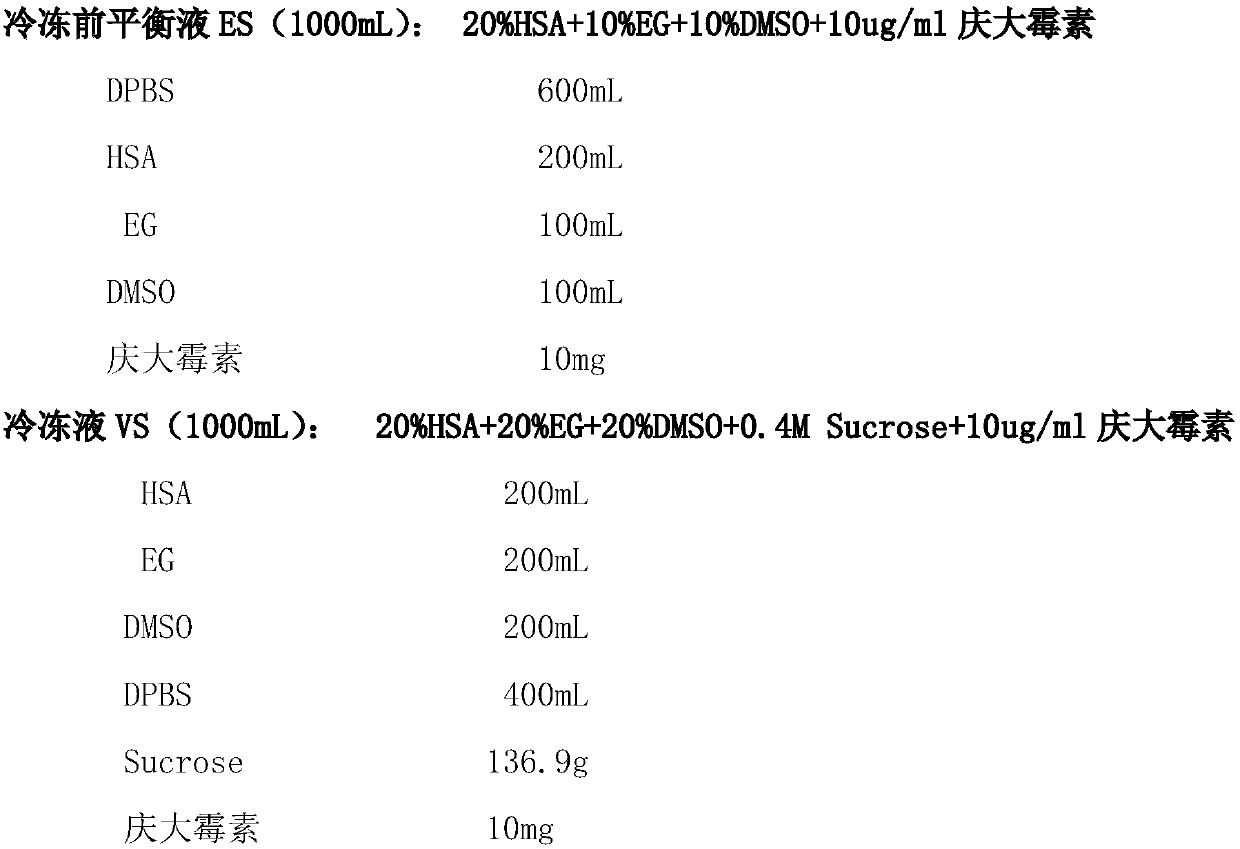

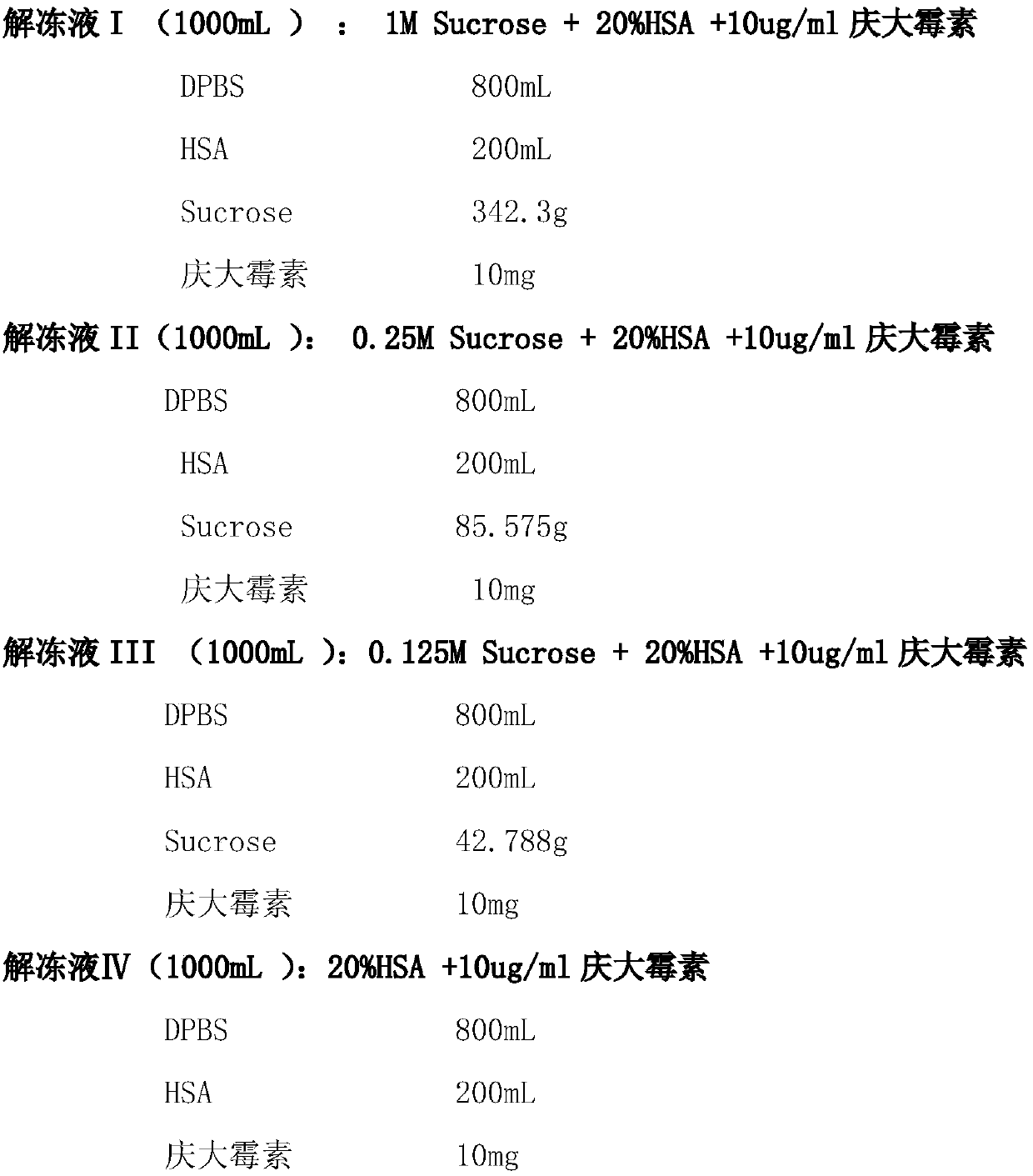

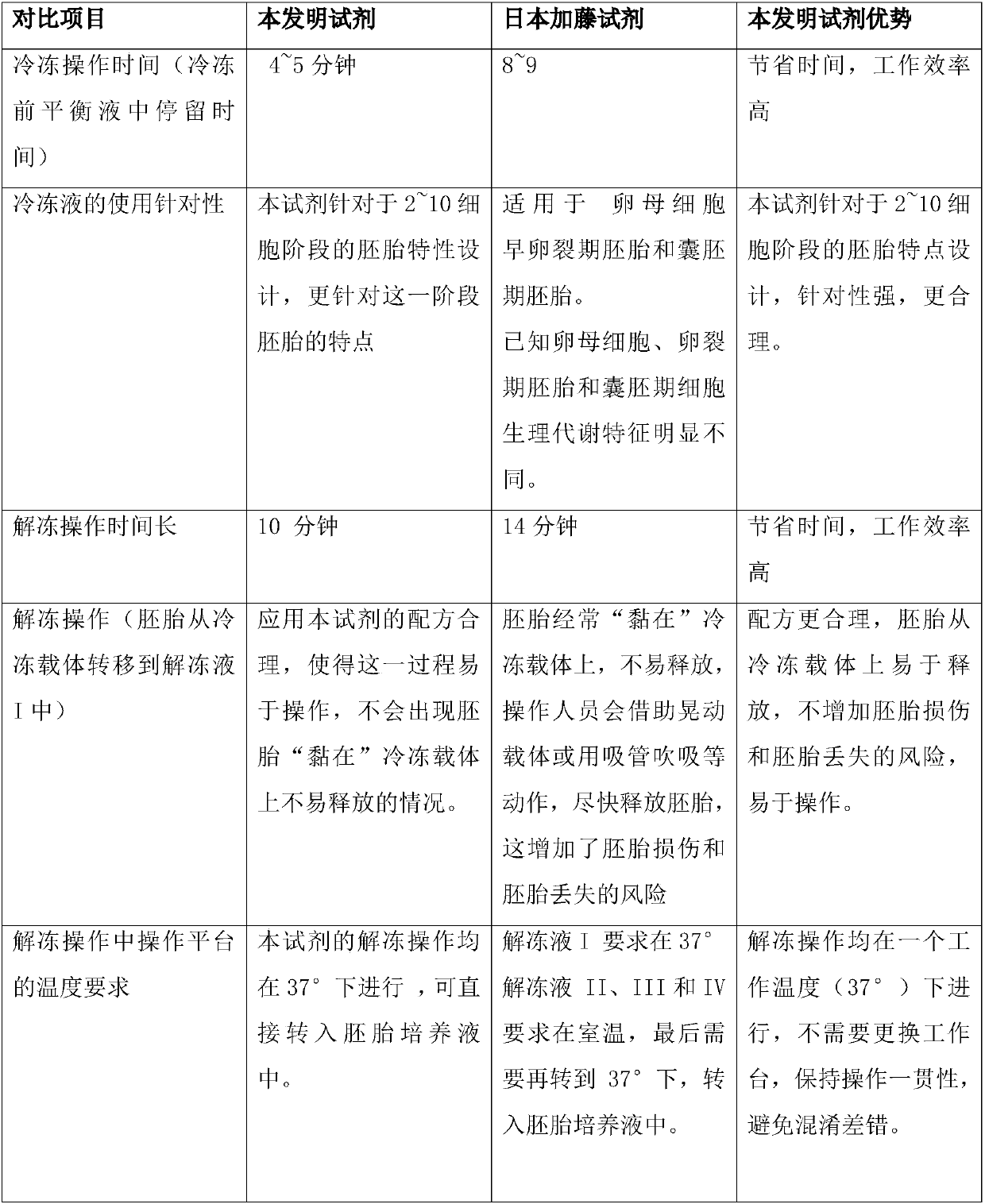

Vitrification freezing reagent and vitrification unfreezing reagent as well as application and use method thereof

InactiveCN109673623AReasonable solute concentrationEasy to break awayCulture processDead animal preservationVitrificationWorking temperature

The invention relates to the technical field of freezing and unfreezing and in particular relates to a vitrification freezing reagent and a vitrification unfreezing reagent as well as application anda use method thereof. The invention provides the vitrification freezing reagent and the vitrification unfreezing reagent which are short in freezing time and unfreezing time, convenient to operate andcapable of preventing embryo damage. Compared with a current imported reagent, the freezing and unfreezing method provided by the invention has the benefits that (1) both the freezing time and the unfreezing time are shortened, and the working efficiency is improved; (2) freezing reagent solute has a reasonable concentration, an embryo can be easily dissociated from a freezing carrier, and excessive operation and damage to the embryo are avoided; (3) an unfreezing liquid has a working temperature of 37 DEG C, the unfreezing process can be continuously carried out on a working table, and the working table does not need to be replaced, so that operation procedures are simplified and errors are avoided.

Owner:白晓红

Preparation method for gemcitabine hydrochloride lyophilized preparation for injection

ActiveCN102641248AProduct looseStable qualityPowder deliveryOrganic active ingredientsChemistryPre cooling

The invention discloses a preparation method for a gemcitabine hydrochloride lyophilized preparation for injection, comprising the following steps: step A of pre-cooling: reducing temperature of gemcitabine hydrochloride solution to negative 12-negative 14 degrees centigrade at the first, then reducing temperature of a heat transfer oil to negative 20 degrees centigrade at a speed of 1 degree centigrade per 10 minutes, keeping the temperature for 2-3 h, after temperature of products is reduced to negative 16-negative 20 degrees centigrade, fast reducing temperature to negative 38-negative 42 degrees centigrade, and keeping temperature for 4-5 h; step B of sublimating a drying step: vacuumizing to 7-12 Pa in a box body, heating the heat transfer oil at the speed of 1-2 degrees centigrade per hour, when the temperature of the heat transfer oil is increased to 0 degree centigrade, keeping the temperature, wherein total time is not less than 30 h, temperature difference of the sample and the heat transfer oil is less than 22 degrees centigrade; step C of analyzing and drying step: heating the heat transfer oil at the speed of 1 degree centigrade per 10 minutes, increasing the temperature of products to 38-42 degrees centigrade and keeping the temperature for 3-5 h. The lyophilized preparation prepared by the invention is featured with sponginess, reliable quality, fast re-dissolving property and good clarity.

Owner:湖北一半天制药有限公司

Electric heating type anti-freezing water pipe

InactiveCN107816086AFast defrostingShorten freeze timeService pipe systemsOhmic-resistance heatingElectrical resistance and conductanceElectricity

The invention relates to the field of water pipe antifreeze technology, and discloses an electrically heated antifreeze water pipe, which includes a metal pipe body, a layer of heat insulation layer wrapped on the outside of the metal pipe body, and an electric heating pipe is installed between the heat insulation layer and the body. A heating layer, the electric heating layer is composed of a heating resistance wire and an insulating isolation layer; the outer side of the heat insulating layer is wrapped with an aluminum skin protection layer. The outer side of the water pipe of the present invention is provided with an electric heating layer, and the water pipe can be turned on for heating when it freezes, so as to ensure the normal progress of production and life; the outer side of the heating layer is provided with an insulating layer, which not only prevents heat from being lost, but also slows down the freezing of the water pipe Over time, the aluminum skin protection layer can also reflect the heat emitted by the electric heating layer, so that the water pipes can defrost faster and improve efficiency.

Owner:济宁市友领机械设备制造有限公司

Marine fish refrigeration processing method

InactiveCN107960449AImprove protectionBacteriostaticFood freezingClimate change adaptationMarine fishRefrigeration

The invention discloses a marine fish refrigeration processing method. The method comprises the following steps: raw material selection, cleaning and slicing, fresh-keeping treatment, draining by grading, immersion with a coolant, quick-freezing, and vacuum packaging. The method greatly shortens quick-freezing time, fresh mouthfeel of the unfreezed marine fish can be kept, and zero loss is realized for nutrition.

Owner:东兴市长瀛食品有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com