Method for treating blast furnace hearth freezing and iron notch oxygen lance for use

A hearth freezing and oxygen lance technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of loss of fluidity of slag and molten iron, labor consumption, coke collapse and gushing, etc., to shorten the freezing time and save energy. The effect of human and material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

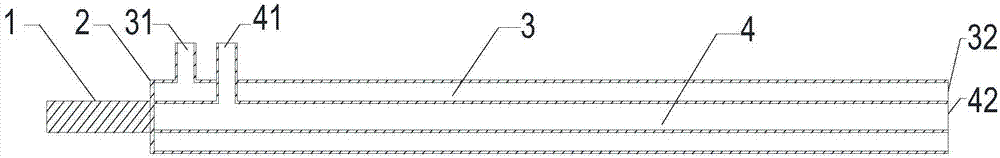

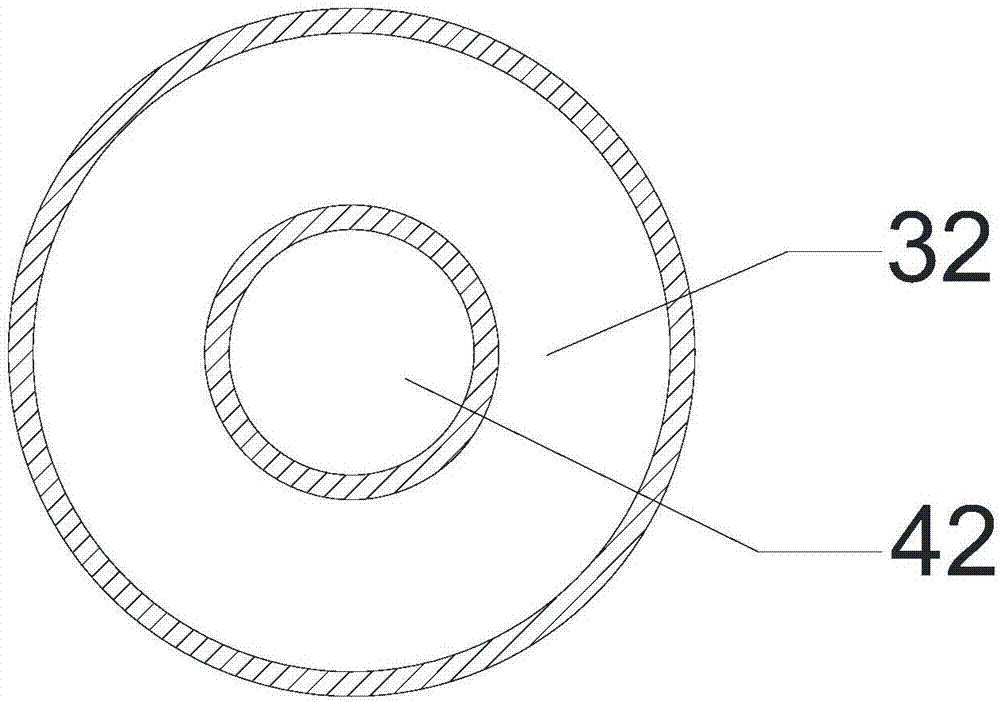

[0019] The method for processing furnace hearth freezing of the present invention adopts the oxygen lance of following structure: as figure 1 As shown, it includes the screw 1 and the gun body 2, the tail of the gun body 2 is closed with a stainless steel plate, the screw 1 is welded on the stainless steel plate at the tail of the gun body 2, the diameter of the screw 1 matches the blast furnace opening machine, and can be installed on the blast furnace opening machine; the gun body 2 is a casing structure composed of two seamless steel pipes with different diameters, the outside is a DN50 air-cooled pipe 3, and a cooling air inlet 31 is arranged on it, and the air inlet 31 is located near the tail of the gun body 2, The cooling air is compressed air with adjustable pressure, and the pressure adjustment range is 0.3-0.8Mpa; the inside is a DN32 oxygen blowing pipe 4, and an oxygen inlet 41 is arranged on it, and the oxygen inlet 41 is located near the tail of the gun body 2 po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com