Preparation of polyvinyl alcohol-based hydroge

A polyvinyl alcohol-based and polyvinyl alcohol technology is applied in the field of preparation of polyvinyl alcohol-based hydrogels, which can solve the problems of complicated preparation methods of PVA hydrogels, achieve easy wound recovery, reduce production costs, and be easy to observe. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation methods of PVA hydrogel include physical cross-linking methods (freeze-thaw cycle method, freezing-partial dehydration method) and chemical cross-linking methods (reagent cross-linking method, radiation cross-linking method).

[0039] The invention here relates to freeze-thaw cycling, which is a physical cross-linking method. The physical cross-linking method is to form a three-dimensional network between molecular chains through hydrogen bonds and microcrystalline regions, that is, physical cross-linking points, and these cross-linking points change with changes in external conditions such as temperature. Therefore, the physical cross-linking process is reversible.

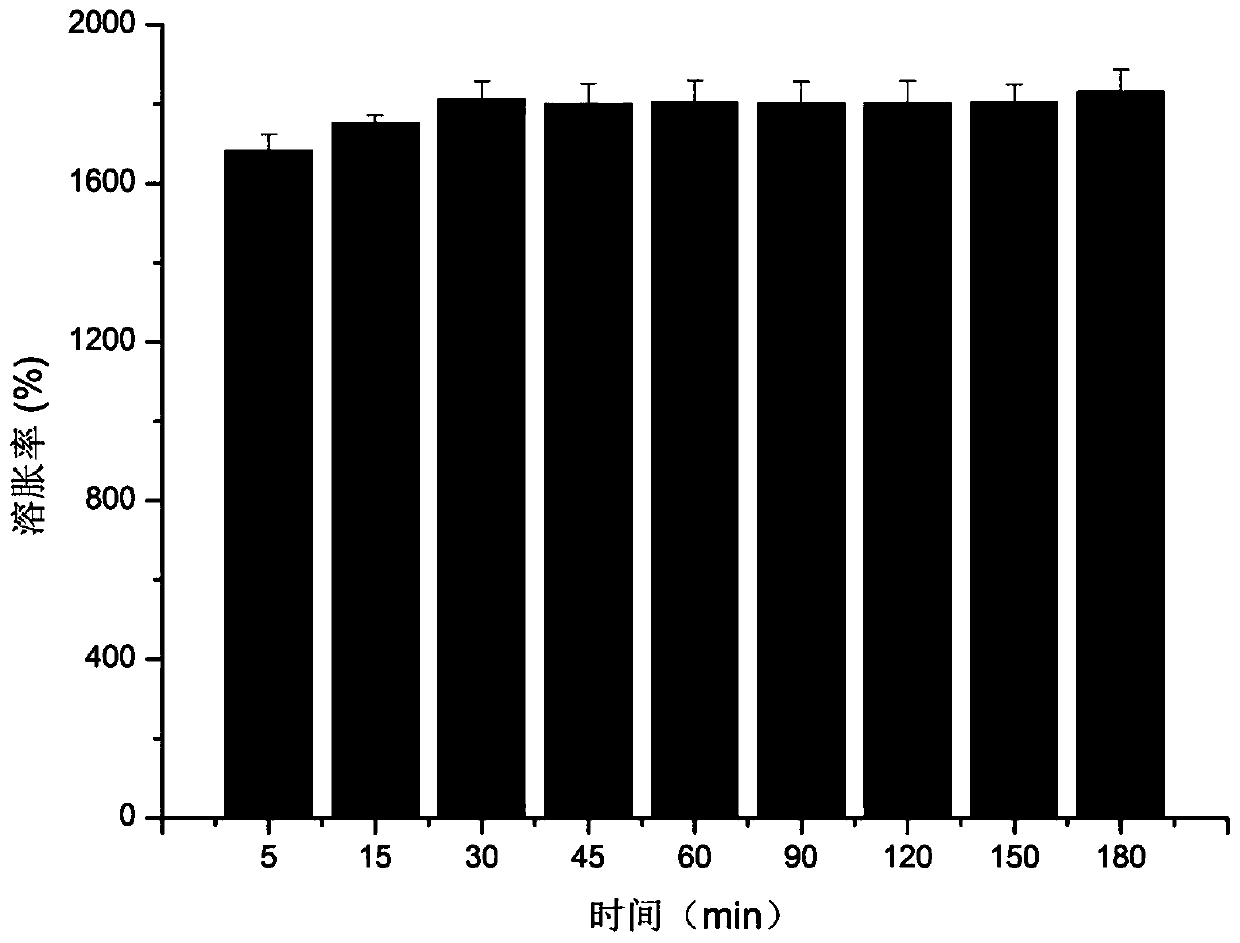

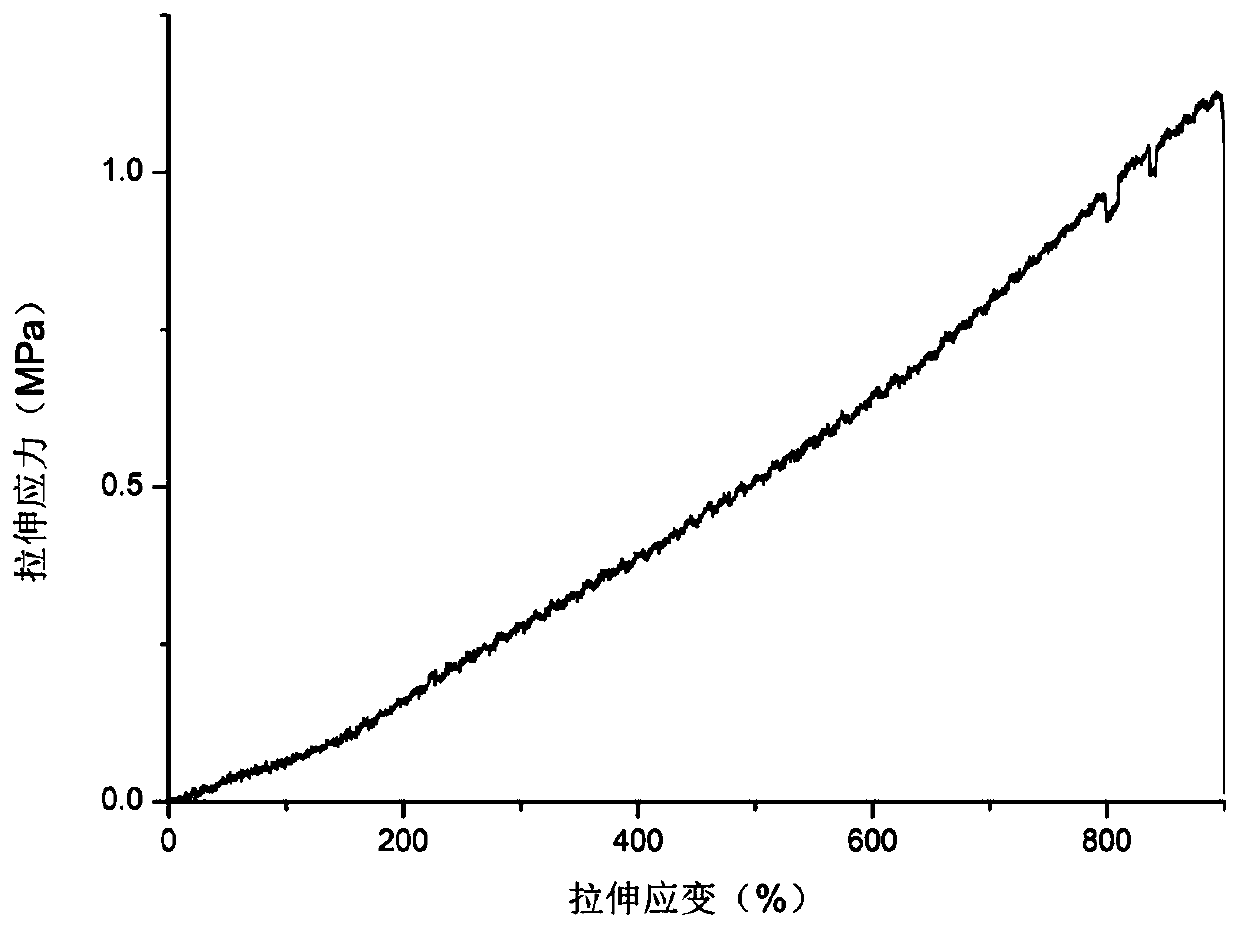

[0040] The advantage of the physical cross-linking method is that it does not use toxic organic cross-linking agents and maintains good biocompatibility. Can be dissolved, the method is simple. After repeated thawing, the hydrogel has high strength, high elasticity and high water content....

Embodiment 1

[0067] Step 1: In a water bath at 90°C, polyvinyl alcohol (purchased from Sigma, model number 341584-1KG) was dissolved in 20 mL of deionized water to obtain a clear solution of 11% polyvinyl alcohol.

[0068] Step 2: Dissolve polyethylene glycol (purchased from Sigma, model number 86101-1KG-F) powder into the solution in Step 1 at a content of 9%, and dissolve until clear.

[0069] Step 3: Dissolve nano-hydroxyapatite powder (purchased from Nanjing Epurui Nano Material Co., Ltd. model as HAP-04-20) into the mixed solution in step 2 with a content of 7%, stir evenly, pour into the mold, and put Freeze in -20°C freezer for 4 hours.

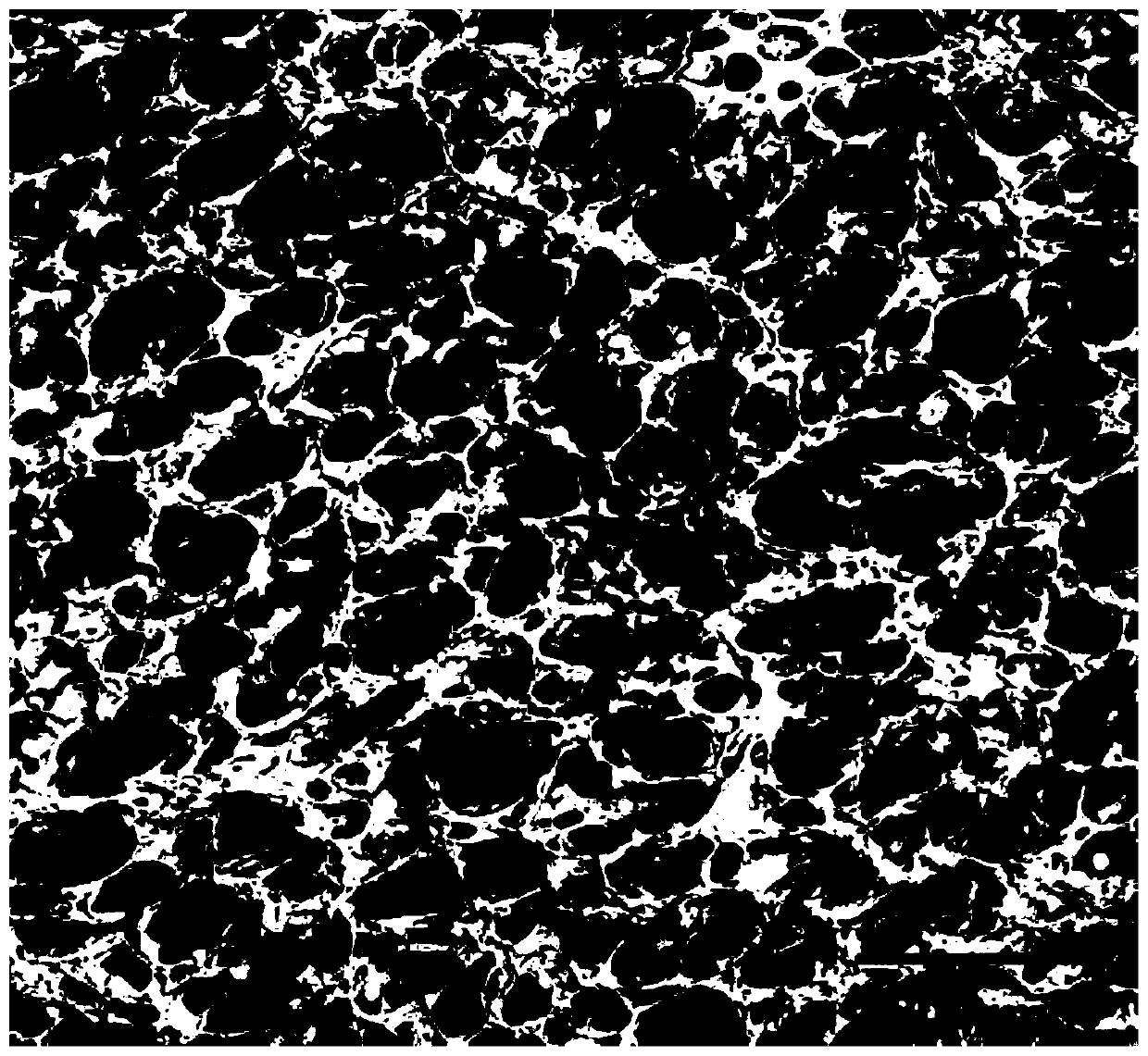

[0070] Step 4: The frozen hydrogel was placed at 20° C. for three hours, and then put into deionized water to wash out polyethylene glycol and nano-hydroxyapatite.

[0071] The polyvinyl alcohol used in step 1 has a molecular weight of 89000-98000Da, the polyethylene glycol used in step 2 has a molecular weight of 1500Da, and the particle size of ...

Embodiment 2

[0075] Step 1: In a water bath at 90° C., the same polyvinyl alcohol as in Example 1 was dissolved in 20 mL of deionized water to obtain a 10% clear solution of polyvinyl alcohol.

[0076] Step 2: Dissolve the same polyethylene glycol powder as in Example 1 in the solution of Step 1 with a content of 9%, and make it dissolve until clear.

[0077] Step 3: Dissolve the same nano-hydroxyapatite powder as in Example 1 at a content of 8% into the mixed solution in Step 2, stir evenly, pour into a mold, and freeze in a -20°C refrigerator for 4 hours.

[0078] Step 4: The frozen hydrogel was placed at 20° C. for three hours, and then put into deionized water to wash out polyethylene glycol and nano-hydroxyapatite.

[0079] The polyvinyl alcohol used in step one has a molecular weight of 89000-98000Da, the polyethylene glycol used in step two has a molecular weight of 1500Da, and the nano-hydroxyapatite used in step three has a particle size of 20nm.

[0080] By the preparation metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com