Method for increasing freezing speed and quality of ice creams through double-point variable-intensity ultrasonic waves

A technology of freezing speed and ultrasonic waves, which is applied in frozen sweets, food science, applications, etc., can solve the problems of not fundamentally controlling the number, size and distribution of ice crystals, not being able to fully utilize the cavitation effect of ultrasonic waves, and not being able to effectively stimulate crystallization, etc. Achieve the effects of shortening the freezing time, obvious seasoning effect and small ice crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

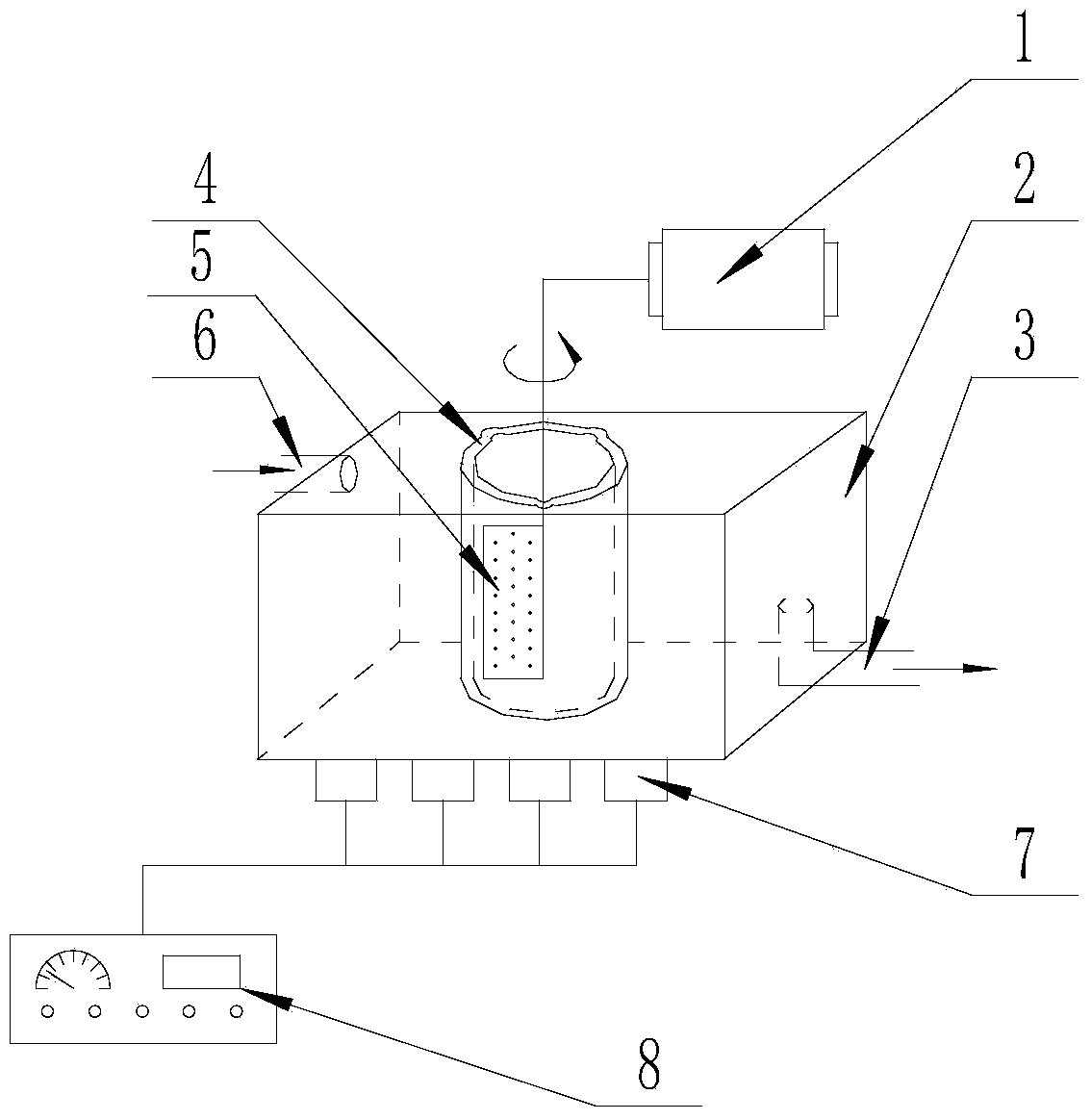

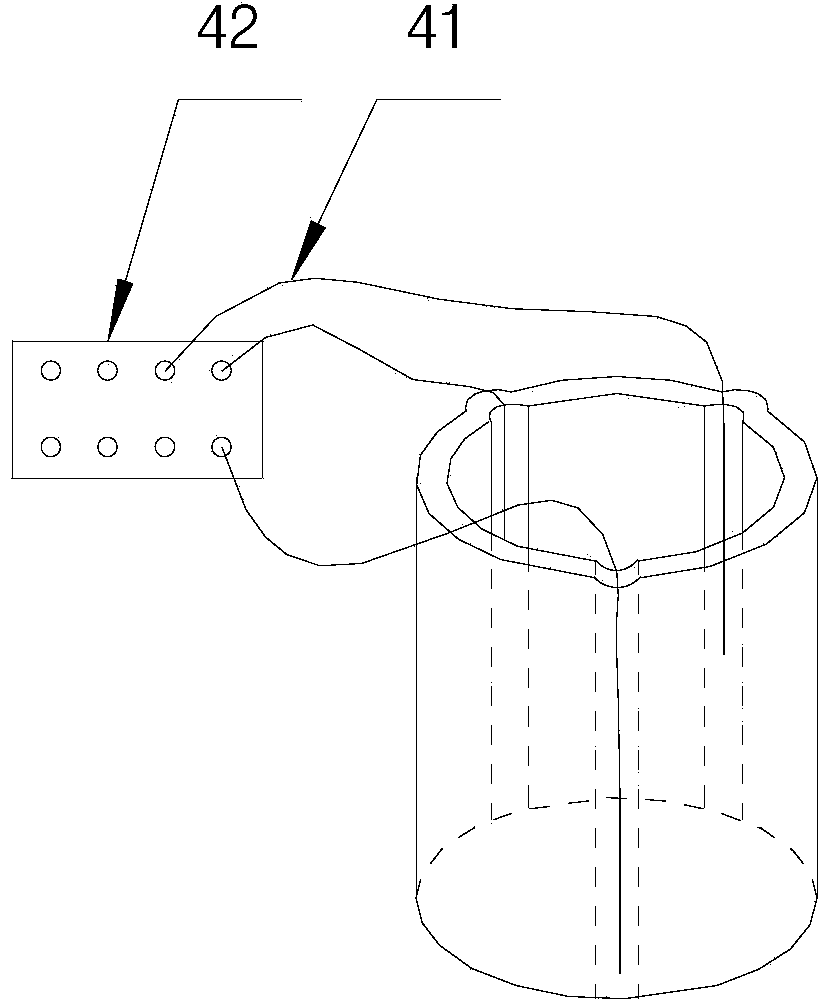

[0038] figure 1 A schematic diagram of the processing apparatus used in this example. Such as figure 1 As shown, it includes a motor 1, an ultrasonic treatment tank 2, a circulating refrigerant outlet 3, an ice cream freezing chamber 4, a porous stirring scraper 5, a circulating refrigerant inlet 6, an ultrasonic transducer 7 and an ultrasonic control panel 8.

[0039] The components of the processing device of this embodiment are described in detail below:

[0040] Motor: The motor is used to provide kinetic energy to the rotation of the porous mixing blade. After the ice cream sample enters the freezing chamber, the motor is turned on to drive the porous stirring scraper to rotate.

[0041] Ultrasonic processing tank: it is filled with freezing liquid to provide an immersion freezing environment for the ice cream freezing cavity. At the same time, it is used as an ultrasonic emitting device. When the sonication condition is reached, trigger the button to perform sonicat...

Embodiment 2

[0051] Ingredients: 2L of water, 400g of skimmed milk powder, 500g of butter, 550g of white sugar, 10g of xanthan gum, carrageenan and gelatin. Among them, the white granulated sugar is crushed with a pulverizer; the polysaccharide gum is first soaked in water, and then completely dissolved in a 70°C water bath. Add water to the milk powder and boil until it boils. After cooling down slightly, add butter, pour in powdered sugar while heating, and mix in xanthan gum and gelatin while it is hot, and add other additives after cooling down slightly. After pasteurization, cooling to 4°C, homogenization, and aging, it enters the freezing chamber for freezing. During the freezing process, variable-intensity ultrasonic waves are used for treatment. The refrigerant is 50% ethylene glycol aqueous solution (v / v), and the freezing liquid in the ultrasonic tank is kept at -18°C. Put three T-type thermocouples into the freezing cavity from the groove, the depths are 1 / 3, 2 / 3, and 3 / 3 of th...

Embodiment 3

[0054] Raw materials: 2L of water, 350g of whole milk powder, 175g of margarine, 120g of glucose syrup, 400g of white sugar, 15g of xanthan gum, gelatin, CMC, etc. Among them, the white granulated sugar is crushed with a pulverizer; the polysaccharide gum is first soaked in water, and then completely dissolved in a 70°C water bath. First add milk powder and water to boil until boiling, pour in powdered sugar while stirring, and mix in polysaccharide gum while it is hot, add other additives after cooling slightly. After pasteurization, cooling to 4°C, homogenization, and aging, it enters the freezing chamber for freezing. During the freezing process, variable-intensity ultrasonic waves are used for processing. The refrigerant is 50% ethylene glycol aqueous solution (v / v), and the freezing liquid in the ultrasonic tank is kept at -19°C. Put three T-type thermocouples into the freezing cavity from the groove, the depths are 1 / 3, 2 / 3, and 3 / 3 of the freezing cavity respectively, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com