Antifreeze polypeptide, bionic antifreeze surface related to antifreeze polypeptide, and screening method and application of antifreeze polypeptide

An anti-freezing polypeptide and anti-freezing protein technology, applied in the field of biochemistry, can solve the problems of unsatisfactory anti-icing effect of hydrophobic materials, protein inactivation, complicated preparation methods of super-hydrophobic materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] Screening of antifreeze peptides:

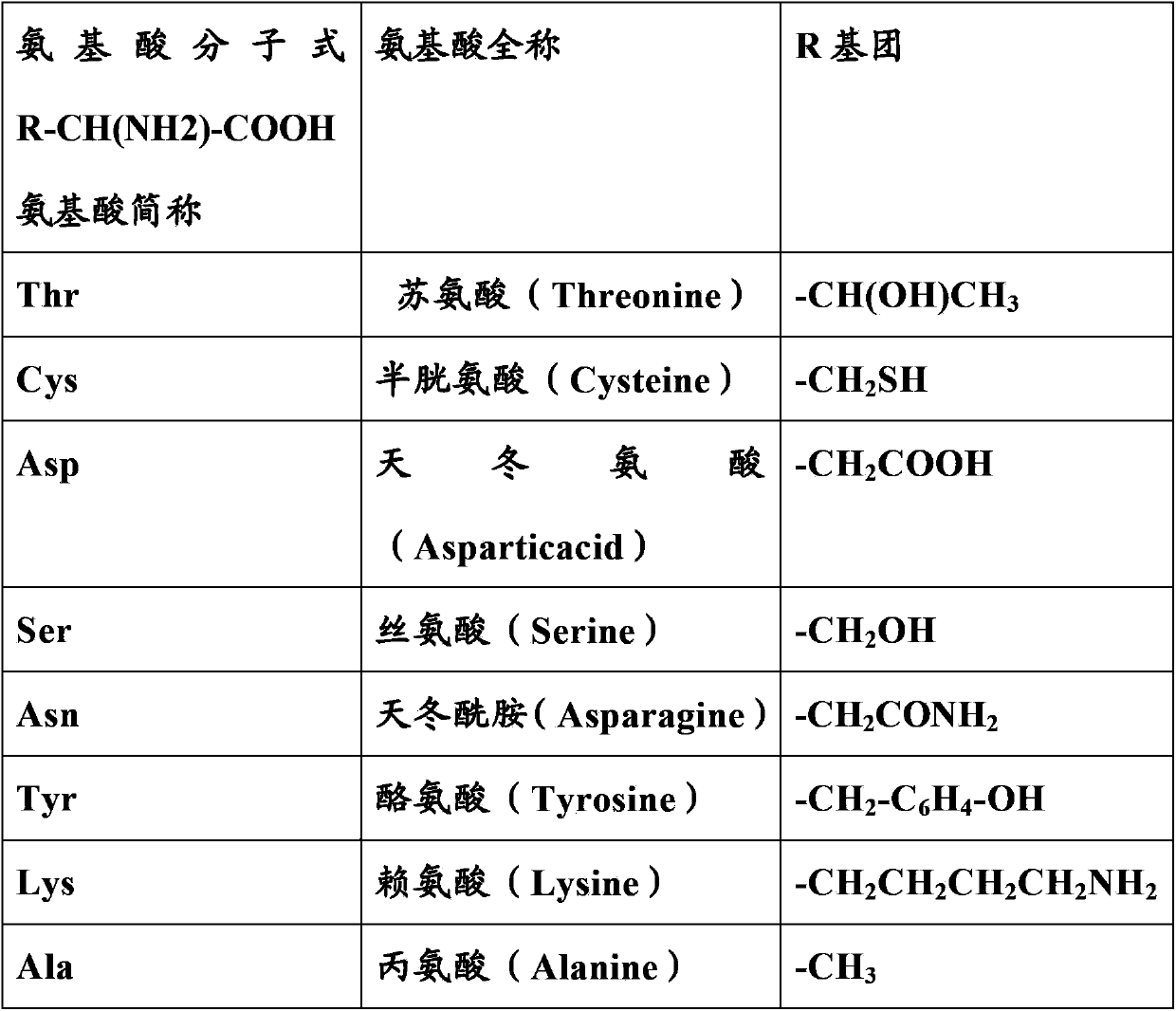

[0106] All kinds of highly active proteins, due to the high thermal hysteresis value of insect antifreeze proteins, and the repeated amino acid sequence Thr-Cys-Thr-X-Ser-X-X-Cys-X-X-Ala-X in insect antifreeze proteins can form a flat The β sheet structure can be well combined with the ice surface. The same repeated amino acid sequence Thr-Cys-Thr-Asp-Ser-Thr-Asn-Cys-Tyr-Lys-Ala-Thr in the antifreeze protein of Tenebrio molitor and A. The negative singlet in the circular dichroism spectrum confirmed the existence of its β-sheet structure. It is found that the polypeptide has a thermal hysteresis value of 0.4° C. in a 1 mg / ml aqueous solution through differential scanning calorimetry measurement. This kind of polypeptide has a high thermal hysteresis value at a lower concentration, and is a preferred antifreeze polypeptide.

Embodiment 2

[0108] Antifreeze polypeptides (proteins) are used in the preparation of antifreeze surfaces:

[0109] Prepare an alkaline buffer solution Bicine (N,N-bishydroxyethylglycine) with a concentration of 10mM / ml, and the pH value is 8.3. Dilute dopamine with alkaline buffer solution Bicine to prepare 2mg / ml dopamine solution. Soak the cleaned silicon wafer in the dopamine solution and soak it in an oxygen environment. The obtained dopamine-modified silicon wafers were rinsed with water, and the silicon wafers were blown dry. Prepare antifreeze polypeptide (protein) solution. The concentration of antifreeze polypeptide (protein) solution is 0.2mg / ml. Soak the silicon chip modified with the polydopamine layer in the antifreeze polypeptide solution. Soak the silicon chip modified with antifreeze polypeptide (protein) in water, soak, repeat this process three times. Blow dry the silicon, or hang to dry. That is, a frost-resistant surface with antifreeze properties is obtained.

Embodiment 3

[0111] Antifreeze surface prepared by antifreeze polypeptide with α-helical structure and its characteristics:

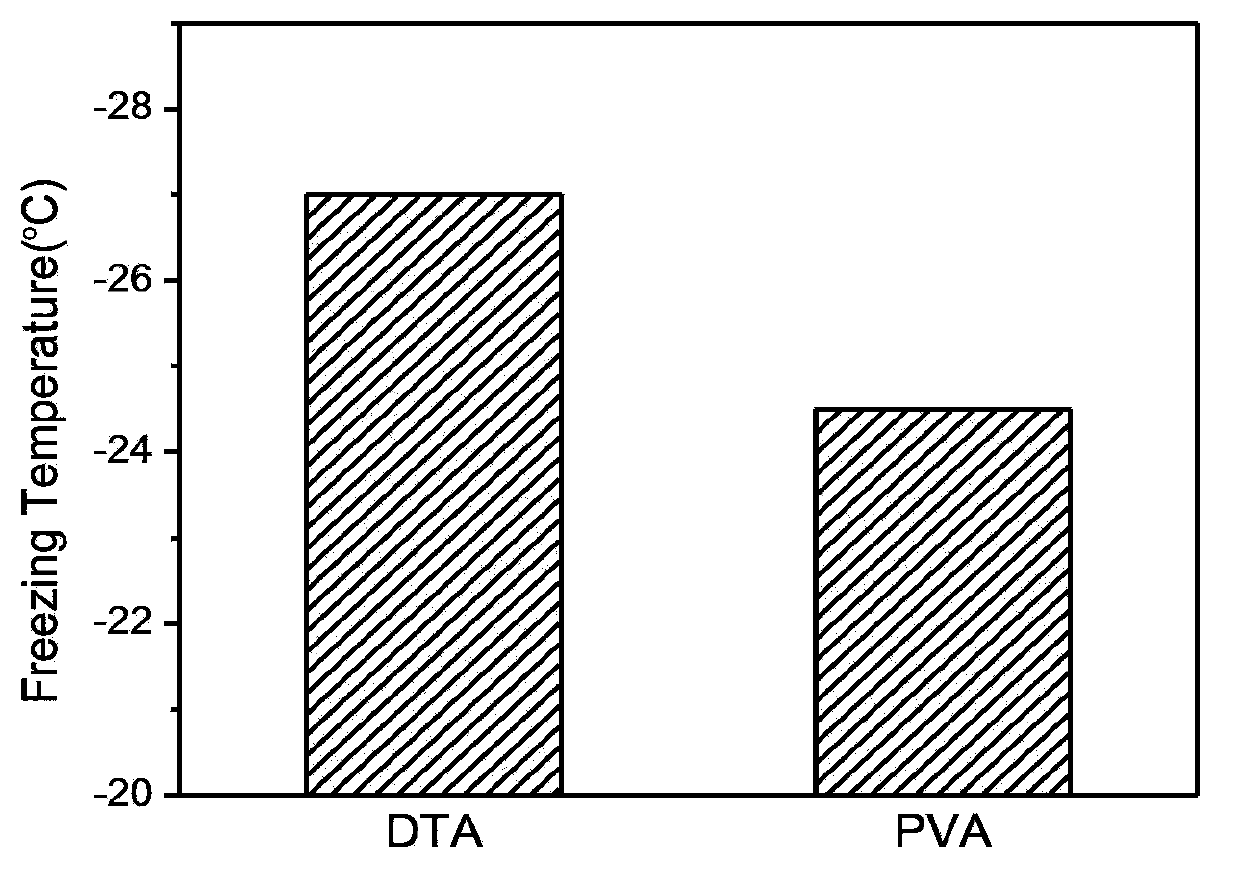

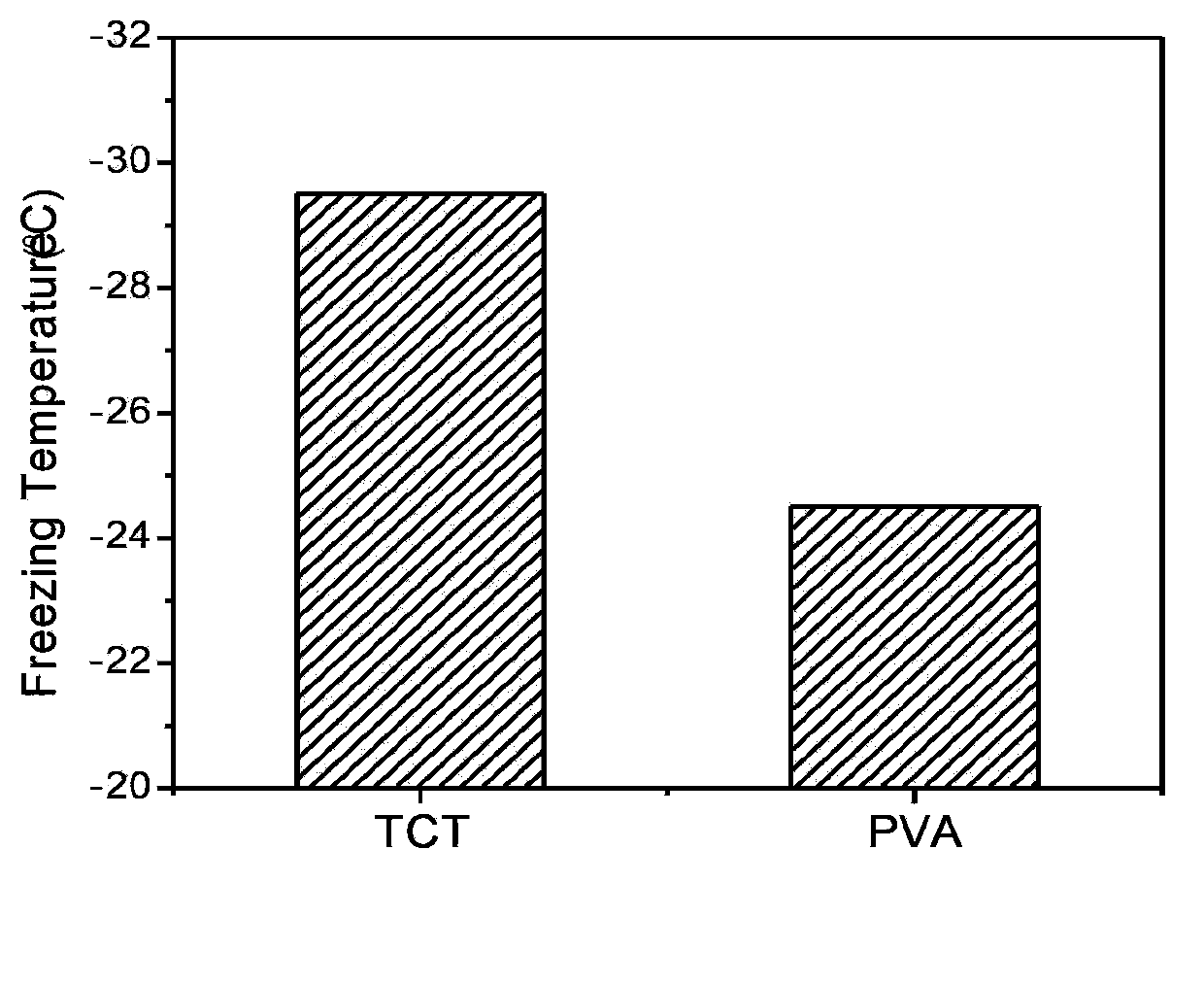

[0112] The antifreeze polypeptide DTA with α-helical structure was bound to the surface of the silicon substrate by the method of Example 2. DTA has a thermal hysteresis value of 0.1°C in a 1 mg / ml solution. The modified silicon substrate was placed in a closed chamber, 0.5uL of water was dropped on the modified surface, and the closed chamber was placed on a cold stage. The surface temperature was raised to 50°C at a rate of 10°C / min, and the temperature was kept at 50°C for 10 minutes to evaporate water droplets in a closed chamber. Decrease from room temperature to minus 40°C at a rate of 5°C / min to condense saturated water vapor on the surface and freeze. Record the freezing temperature of each droplet. The freezing temperature of the water droplets condensed on the surface of the substrate is counted, and the average freezing temperature of the condensed wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com