Anti-corrosion anti-icing wear-resistant super-hydrophobic coating and preparation method thereof

A super-hydrophobic coating and anti-icing technology, applied in anti-corrosion coatings, coatings, polyurea/polyurethane coatings, etc., can solve the problems of easy freezing of water vapor, easy corrosion of metal substrate surfaces, etc., and achieve low water adhesion , lower surface energy, excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a method for preparing an anti-corrosion, anti-icing and wear-resistant super-hydrophobic coating, which is characterized in that it comprises the following steps:

[0036] Step 1, modified nano-SiO 2 Particle preparation

[0037] The nano-SiO 2 The particles were immersed in a modified solution of fluorosilane-absolute ethanol and modified at room temperature, and the modified nano-SiO 2 Particles are dried and ground to disperse;

[0038] Preparation of film-forming liquid: dissolving thermoplastic polyurethane elastomer rubber (TPU) in N,N-dimethylformamide (DMF) to prepare TPU / DMF film-forming liquid;

[0039] Step 2, coating

[0040] Scrape-coat the TPU / DMF film-forming solution in step 1 on the surface of the pretreated substrate, dry and cool, and then repeat the scrape-coat several times to form a bottom film layer on the surface of the metal substrate, that is, the TPU coating;

[0041] Step 3, preparation of anti-corrosion, anti-ici...

Embodiment 1

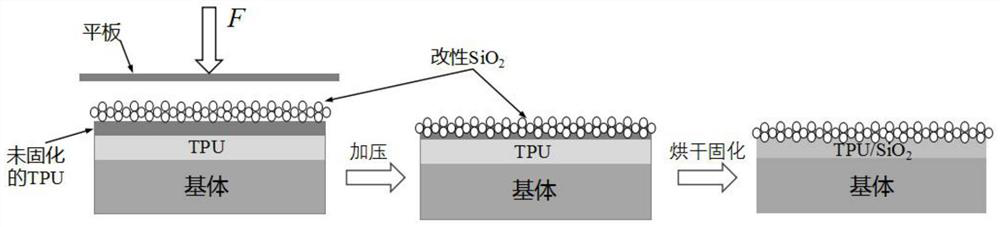

[0046] A preparation method for anti-corrosion, anti-icing and wear-resistant superhydrophobic coating, such as figure 1 shown, including the following steps:

[0047] Step 1, modified nano-SiO 2 Particle preparation: 1g of nano-SiO with a particle size of 10nm 2 The particles were immersed in 20g of 0.8wt% trimethoxy (1H, 1H, 2H, 2H-heptadecafluorodecyl) silane-absolute ethanol modification solution and stirred at room temperature. After modification for 0.5h, the modified nano-SiO 2 The particles were dried in an oven at 90°C for 6 hours, and after drying, they were ground and dispersed to obtain modified nano-SiO with a particle size of 20nm. 2 particle;

[0048] Step 2, preparation of TPU / DMF film-forming solution: dissolve thermoplastic polyurethane elastomer rubber (TPU 5377A) in N,N-dimethylformamide (DMF), and configure TPU / DMF with a concentration of 0.35g / ml Film-forming liquid;

[0049] Step 3, pretreatment of the base material: 45# steel (50×80mm) is polished...

Embodiment 2

[0053] A preparation method for anti-corrosion, anti-icing and wear-resistant superhydrophobic coating, such as figure 1 shown, including the following steps:

[0054] Step 1, modified nano-SiO 2 Particle preparation: 1g of nano-SiO with a particle size of 20nm 2 Particles were immersed in 25g of 1.5wt% trimethoxy (1H, 1H, 2H, 2H-heptadecafluorodecyl) silane-absolute ethanol modification solution and stirred at room temperature. After modification for 1 hour, the modified nano-SiO 2 The particles were dried in an oven at 110°C for 4 hours. After drying, they were ground and dispersed to obtain modified nano-SiO with a particle size of 40nm. 2 particle;

[0055] Step 2, preparation of TPU / DMF film-forming solution: dissolve thermoplastic polyurethane elastomer rubber (TPU 5377A) in N,N-dimethylformamide (DMF), and configure TPU / DMF with a concentration of 0.3g / ml Film-forming liquid;

[0056] Step 3, pretreatment of the substrate: use 400-mesh sandpaper to polish 45# stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com