Overcooling freezing method, refrigerator and refrigerator control method

A freezing method and supercooling technology, which are applied in cooling fluid circulation devices, household refrigeration devices, lighting and heating equipment, etc., can solve the problem of easy accidental release of control, and achieve the goal of shortening freezing time, improving storage quality, and reducing damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

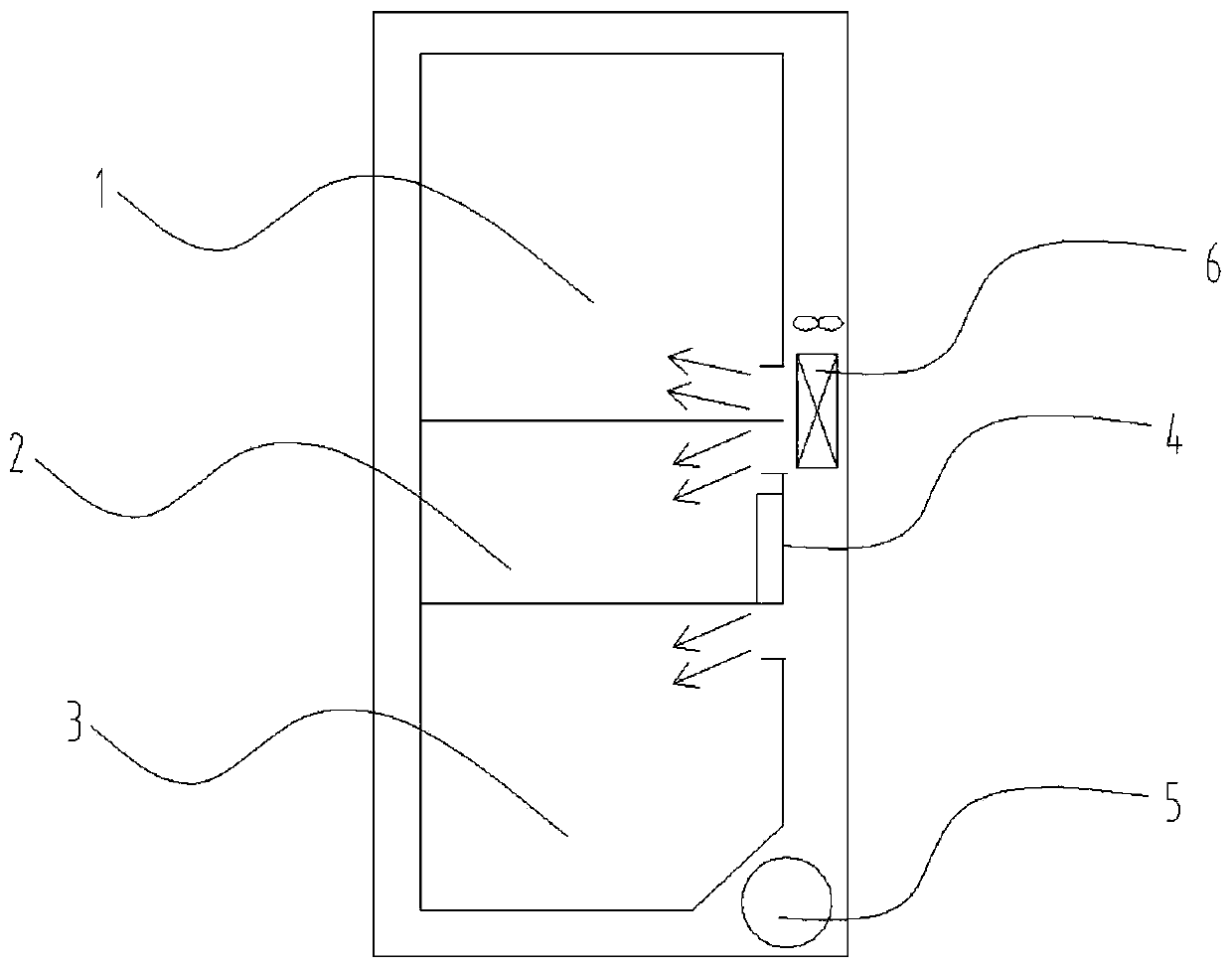

[0052] Such as figure 1 This embodiment provides a refrigerator, which is provided with a freezer compartment 3 for supercooling and freezing of stored items. The freezer compartment 3 is provided with an energy field device 4, which is controlled to generate an energy field during the rapid freezing process , So that the water molecules of the articles stored in the freezer compartment 3 generate water molecular resonance under the action of the energy field.

[0053] The energy field device 4 is an energy field device that can generate one or more of electromagnetic field, electric field, magnetic field, microwave or sound wave, such as low-voltage oscillating electric field, high-voltage electrostatic field generating equipment, high-frequency electromagnetic wave generating equipment, and ultrasonic generating equipment. The equipment can be provided with the air outlet or air flow path of the freezer compartment, can also be provided on the partition of the freezer compartmen...

Embodiment 2

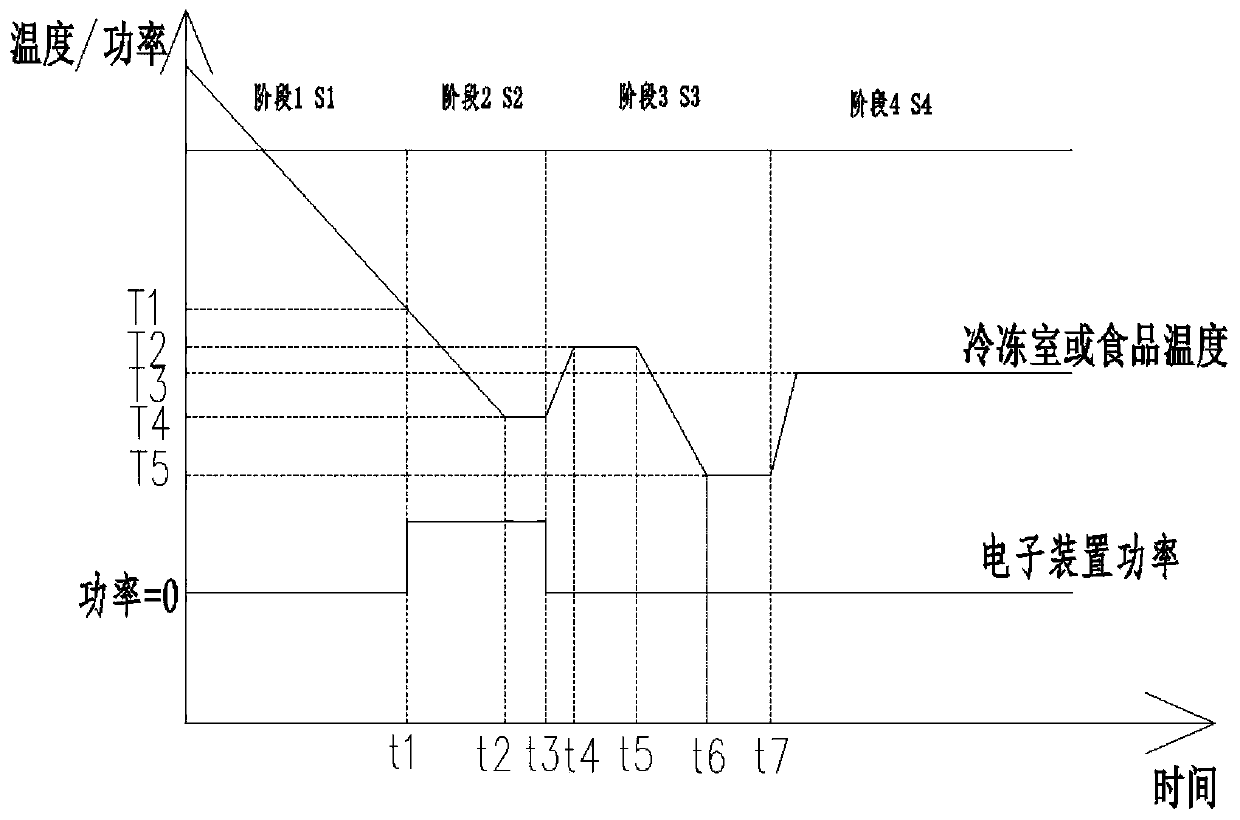

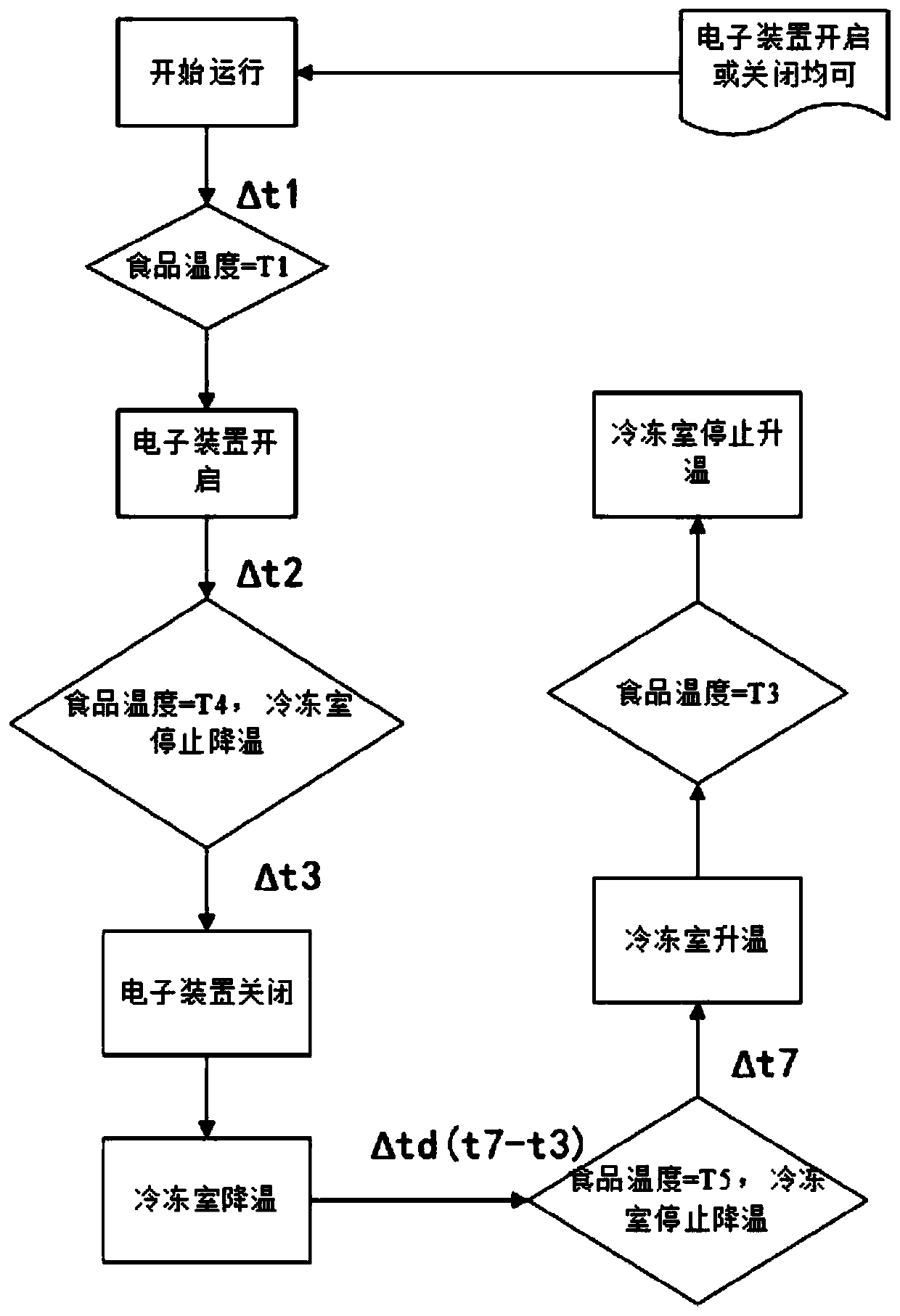

[0073] Such as Figure 2-3 In this embodiment, the refrigerator provided in Embodiment 1 is taken as an example to provide a refrigerator control method, including a pre-cooling stage S1, an over-cooling stage S2, a rapid freezing stage S3, and a normal storage stage S4. In the over-cooling stage, the controller The energy field device 4 is controlled to be energized to directly apply an energy field to the food in the freezer compartment.

[0074] Pre-cooling stage S1: start running, place the food to be frozen in the freezer 3, turn on or not turn on the energy field device 4 as needed, at this stage, control the temperature of the food to drop continuously or step by step, so that the storage items that need to be frozen are at Δt1 The temperature is lowered to the first temperature T1 which is greater than the freezing point temperature T2 of the stored items within the time. The advantage of not turning on the energy field device 4 at this stage is that it can save a certain ...

Embodiment 3

[0084] Such as Figure 4-5 In this embodiment, the refrigerator provided in Example 1 is taken as an example to provide a supercooling freezing control method for foods arranged in the freezer compartment of the refrigerator, which includes a pre-cooling stage S1, a super-cooling stage S2, a rapid freezing stage S3, Normal preservation stage S4:

[0085] Pre-cooling stage S1: start running, place the food to be frozen in the freezer 3, turn on or not turn on the energy field device 4 as needed, at this stage, control the temperature of the food to drop continuously or step by step, so that the storage items that need to be frozen are at Δt1 The temperature is reduced to the first temperature T1 equal to the freezing point temperature T2 of the storage item within the time. The advantage of not turning on the energy field device 4 at this stage is that a certain amount of electrical energy can be saved. Preferably, the first temperature and the second temperature -5°C≦T1= T2≦0°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com