Patents

Literature

186results about How to "Good force transmission effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

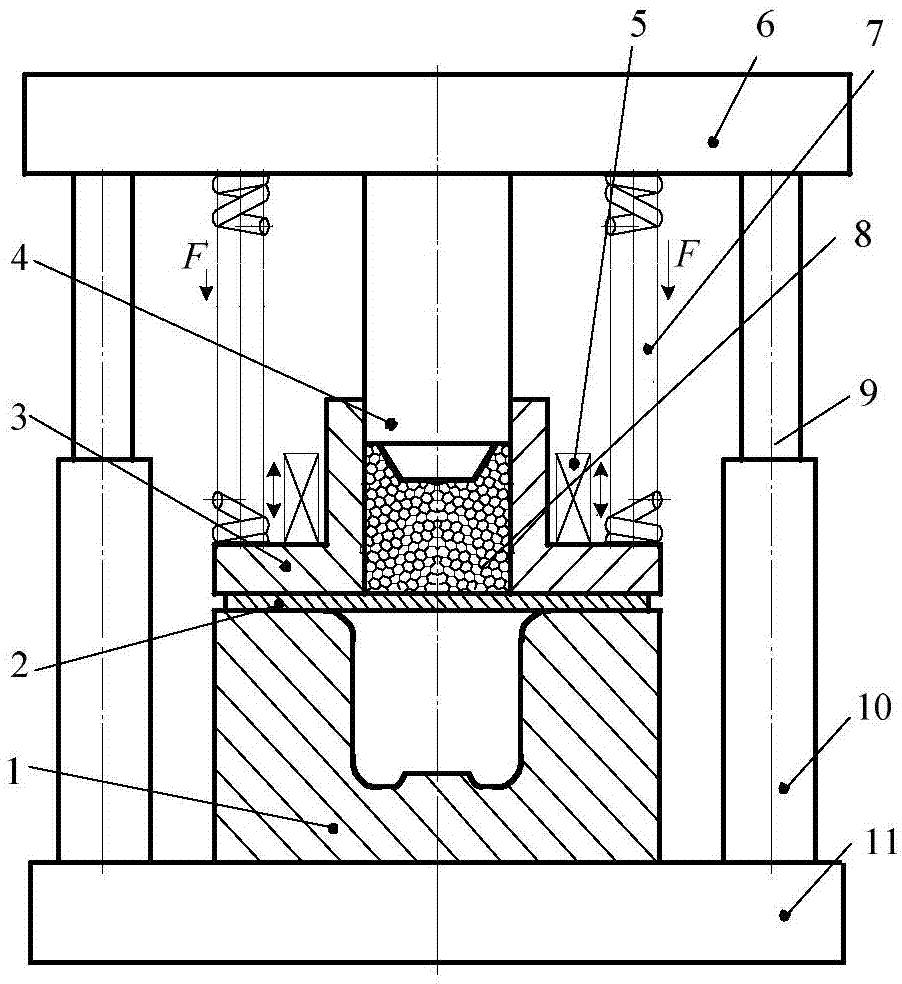

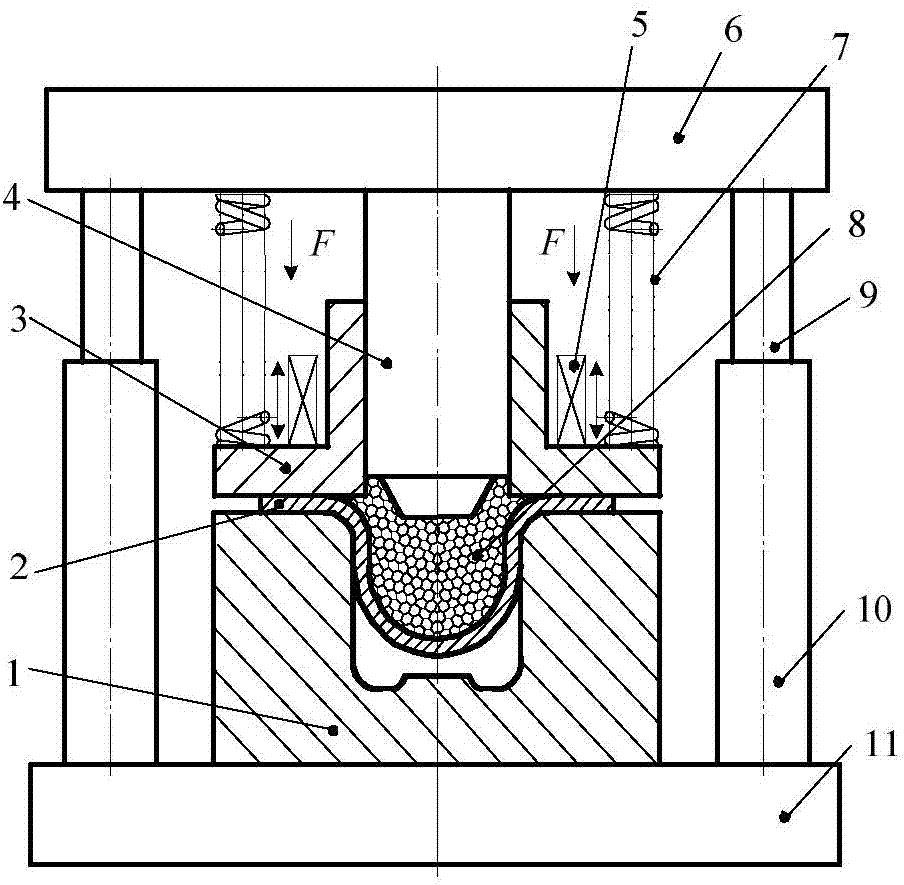

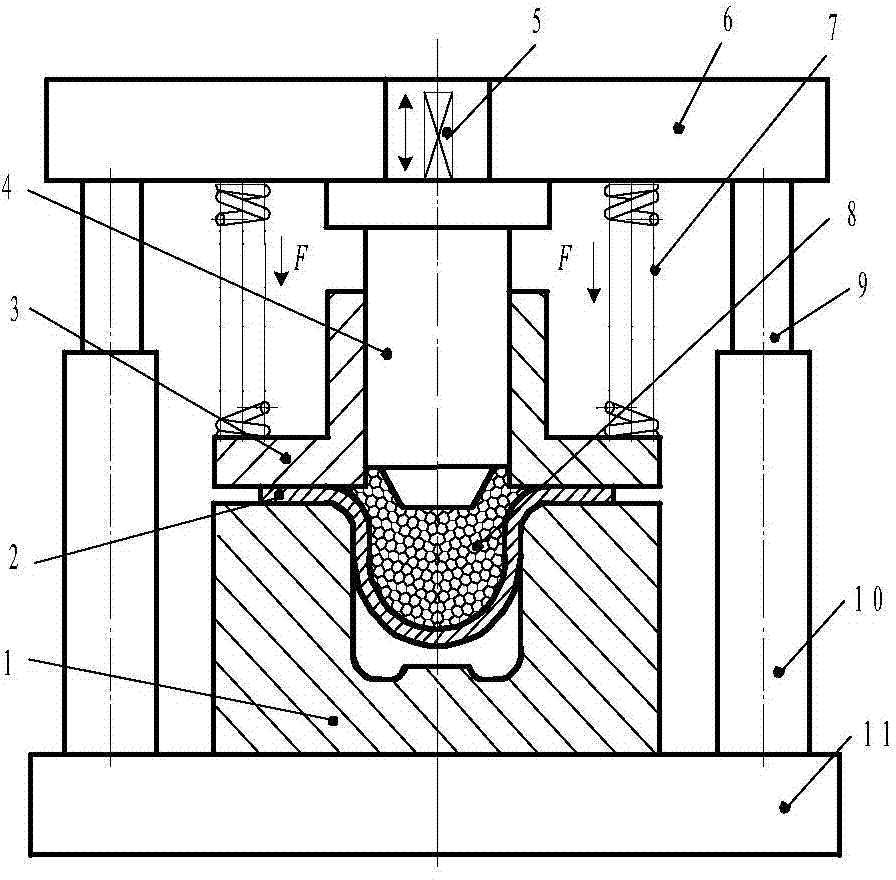

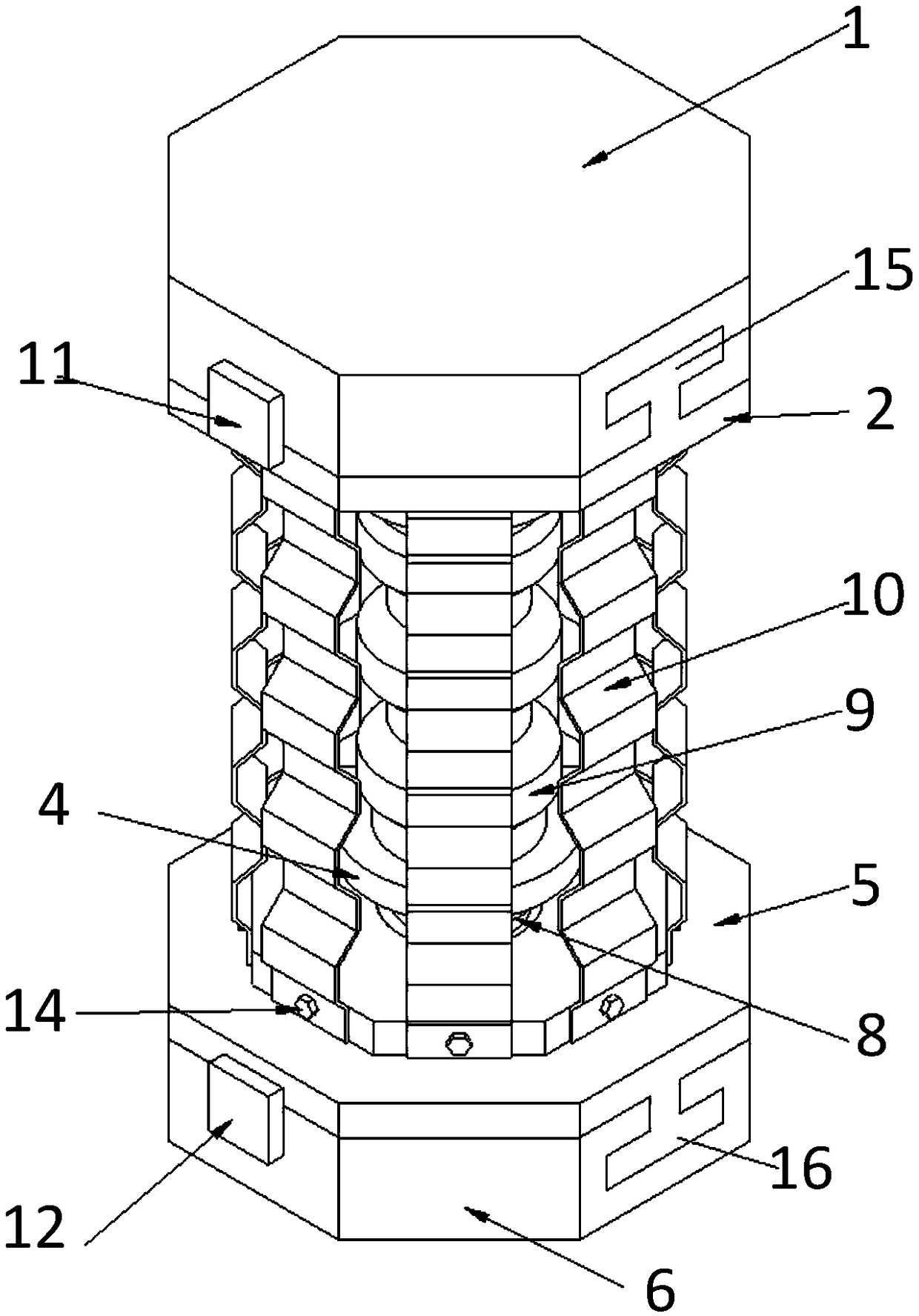

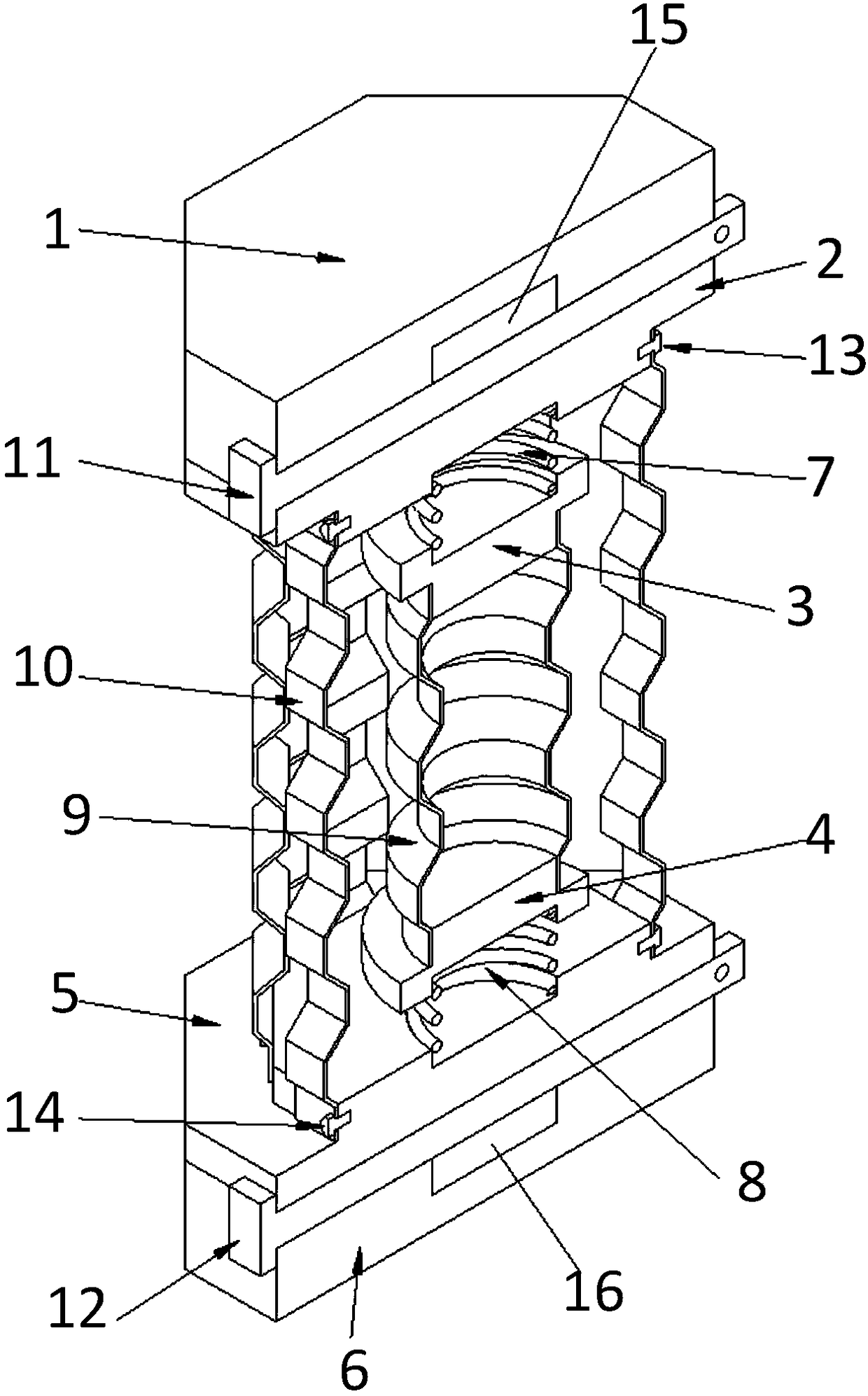

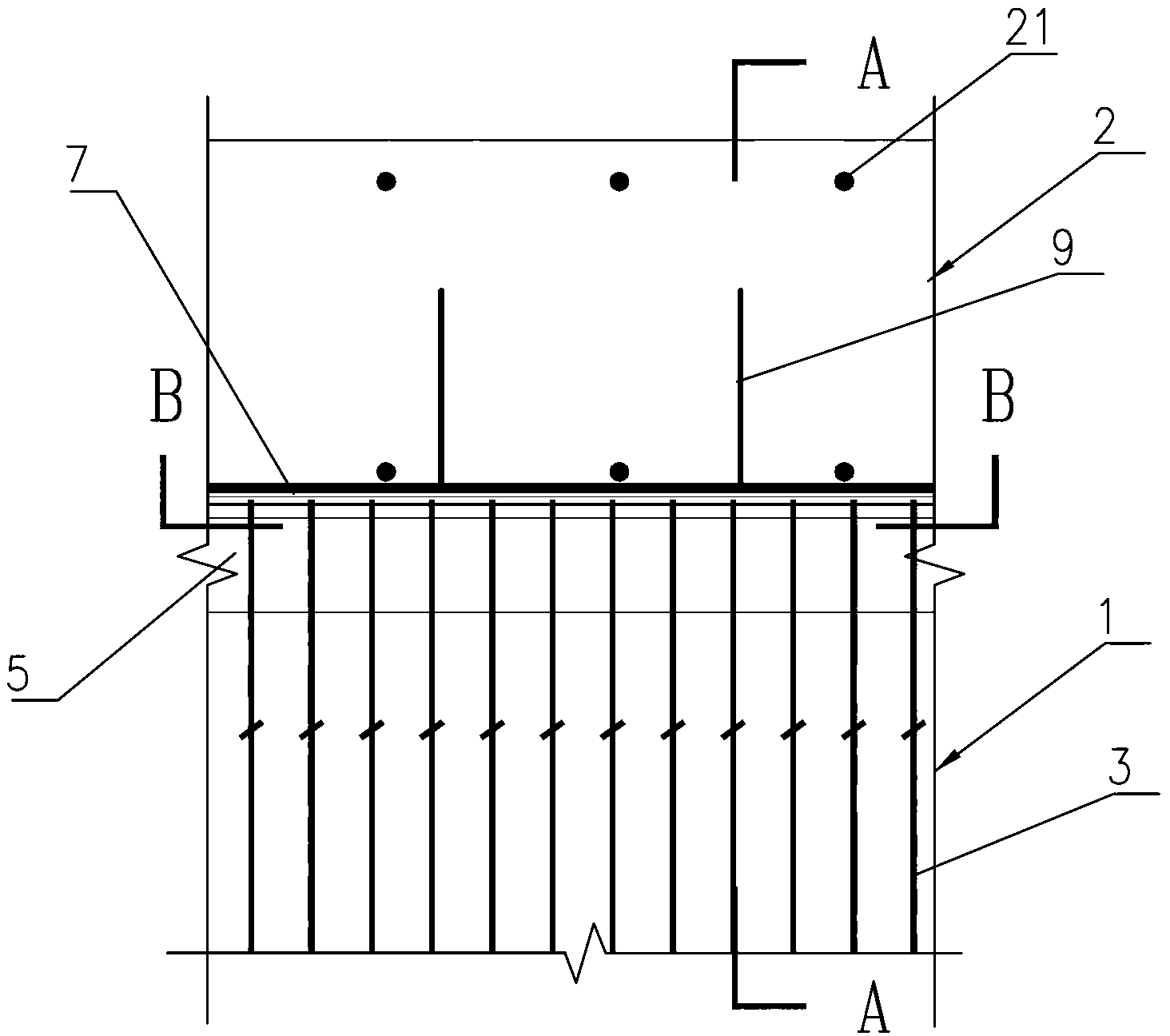

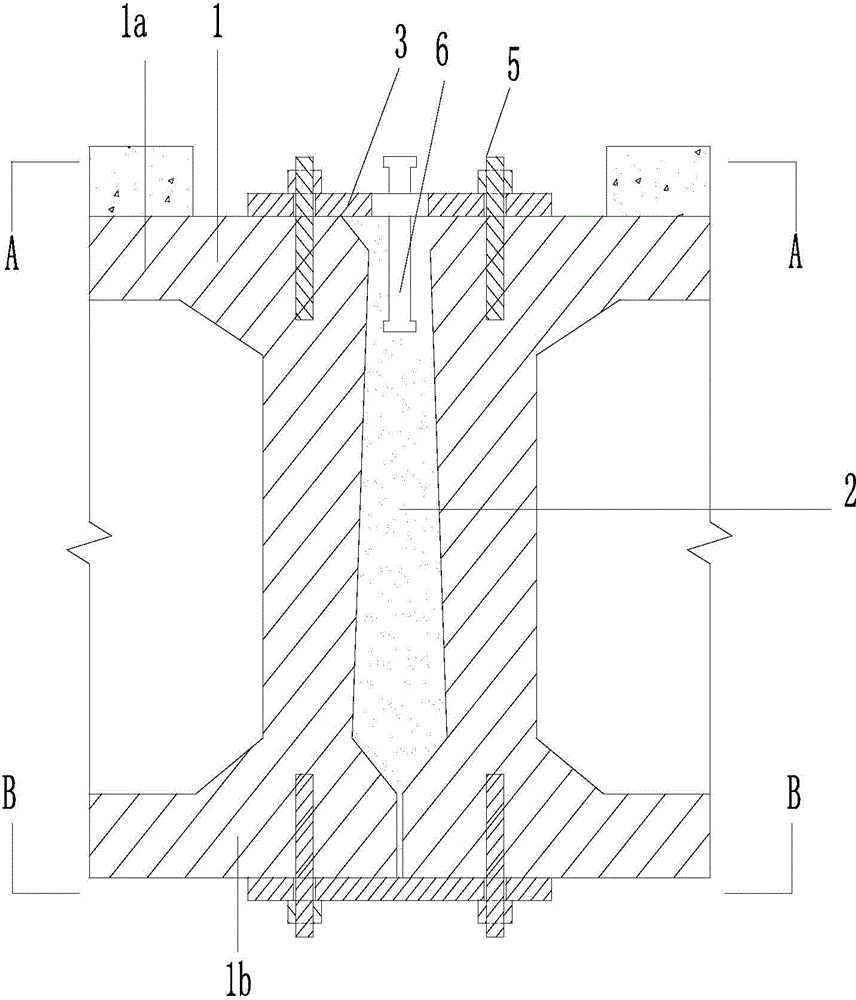

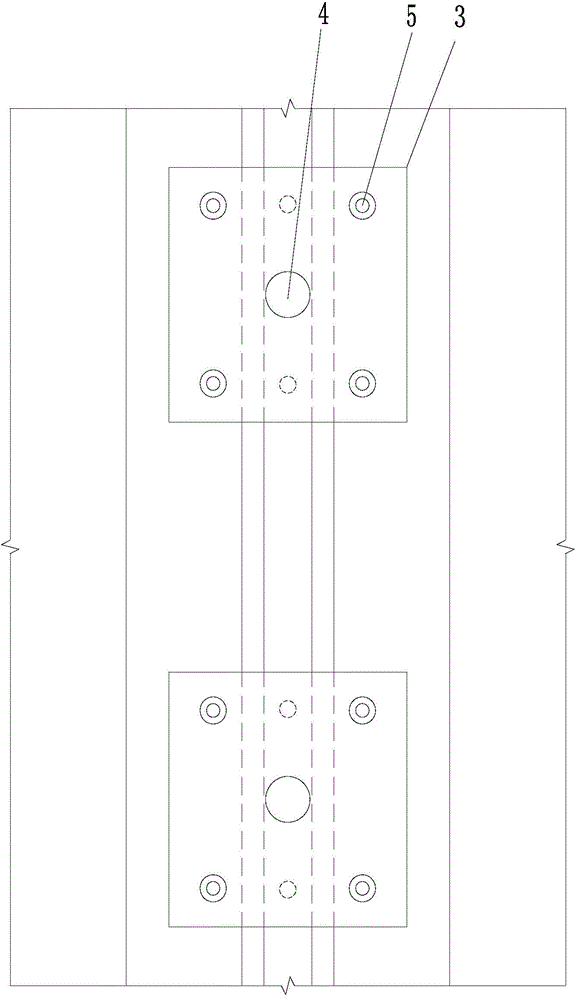

Method for forming plates on basis of vibration by aid of flexible male die

The invention discloses a method for forming plates on the basis of vibration by the aid of a flexible male die. Machining equipment for implementing the method mainly comprises a lower die holder, a female die, a blank holder, granular media, a blank holder force applying device, a vibration device, a punch, an upper die holder, guide columns, guide sleeves and the like. The method includes placing a metal plate between the female die and the blank holder when the metal plate is about to be machined and formed, enabling the blank holder to apply blank holder force, then adding the granular media into a barrel formed by the blank holder and the metal plate, enabling a pressure head to compress the media under the effect of pressure, applying the pressure to the plate and performing deep drawing forming on the plate by the aid of the flexible male die; enabling the vibration device to apply vibration on the punch, the blank holder and the female die individually or jointly. The method has the advantages that friction and deformation resistance among the plate and the dies can be reduced under the effect of vibration excitation, the flowability and the force transfer property of the granular media can be promoted, plate forming limit can be upgraded, and the method is favorable for machining and forming components in complicated shapes; the granular media can be reused, accordingly, the die machining cost and energy consumption can be reduced, and the method is favorable for environmental protection.

Owner:YANSHAN UNIV

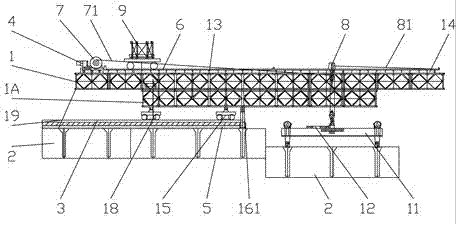

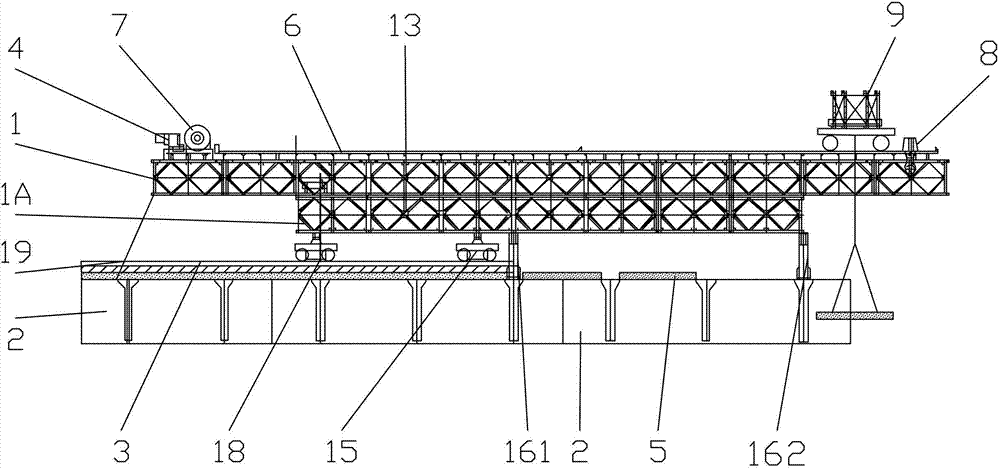

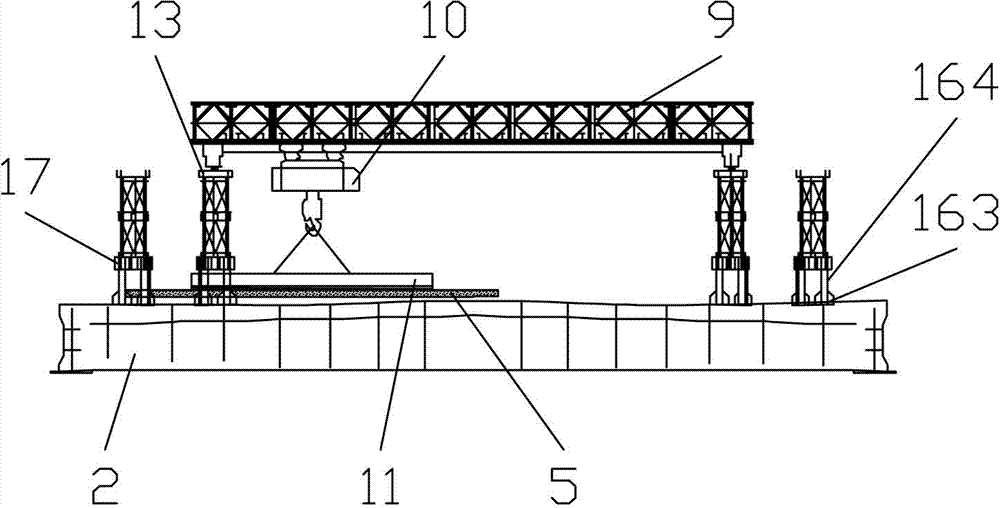

Bridge floor crane for cable-stayed bridge

InactiveCN103882811AGuaranteed stabilityImprove stabilityBase supporting structuresBraking devices for hoisting equipmentsSupporting systemArchitectural engineering

The invention relates to a construction device for a cable-stayed bridge, in particular to a bridge floor crane for the cable-stayed bridge. The bridge floor crane for the cable-stayed bridge comprises two sets of main trusses arranged oppositely, a craning system arranged above the main trusses and a walking system arranged below the main trusses, wherein the walking system comprises a main track laid on a mounted steel beam and a walking device in sliding fit with the main track, and an upper layer and lower layer structure is adopted by the main trusses. The bridge floor crane for the cable-stayed bridge further comprises a supporting system arranged on the lower portions of the main trusses, a rear anchoring system arranged on the outer sides of the two sets of the main trusses, a balance weight device and a safety device, the balance weight device and the safety device are arranged at the rear ends of the main trusses, and the supporting system comprises a middle supporting device arranged in the middles of the main trusses and a temporary supporting device arranged at the front ends of the main trusses. Through the adoption of the technical scheme, the bridge floor crane for the cable-stayed bridge has the advantages of being proper in craning height, strong in bearing capacity, good in construction stability, high in construction efficiency and high in safety.

Owner:CHONGQING CONSTR BRIDGE ENG +2

Wind power generation tower prestress anchor bolt cage

InactiveCN103938647AImprove force transmission performanceOverall goodBulkheads/pilesSteel platesEngineering

The invention relates to a wind power generation tower prestress anchor bolt cage which comprises an anchor bolt, an upper flange and a lower flange. The anchor bolt penetrates through an anchoring nut, the lower flange, a positioning nut, an anchor bolt casing pipe, an adjusting nut, the upper flange, a T-shaped flange at the bottom of a wind power generation tower and a locking nut in sequence. The upper flange is an annular steel plate, an anchor bolt hole is an inverted-cone hole, and the adjusting nut can support the upper flange and adjust the levelness of the upper flange; the lower flange is an annular steel plate, a lower flange support bolt and a support nut bear the weight of the lower flange and can adjust the levelness of the lower flange, the lower flange is fixed through a pressing nut, and the lower flange support bolt is supported on a base plate. According to the wind power generation tower prestress anchor bolt cage, the anchor bolt and foundation concrete are separated through the anchor bolt casting pipe, the anchor bolt applies pretension force, and the concrete is subjected to the stress; the position and levelness of the upper flange are adjusted through the adjusting nut; the inverted-cone hole of the upper flange enables the center area, the inner edge and the outer edge of the T-shaped flange at the bottom to be pressed against the upper flange more tightly, and the inverted-cone hole is filled with sealing materials. The wind power generation tower prestress anchor bolt cage enables the integrality of the connection of a tower frame and the foundation to be good, is even in rigidity, and improves durability and anti-fatigue performance of connection.

Owner:闵怡红

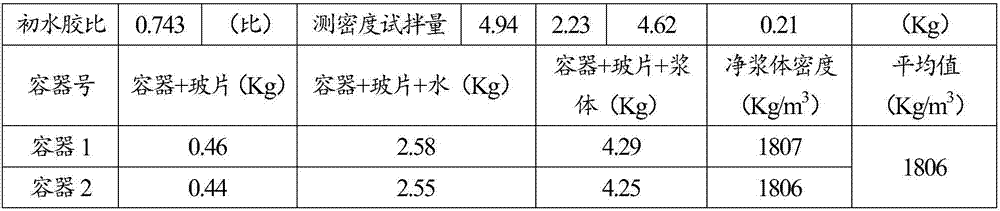

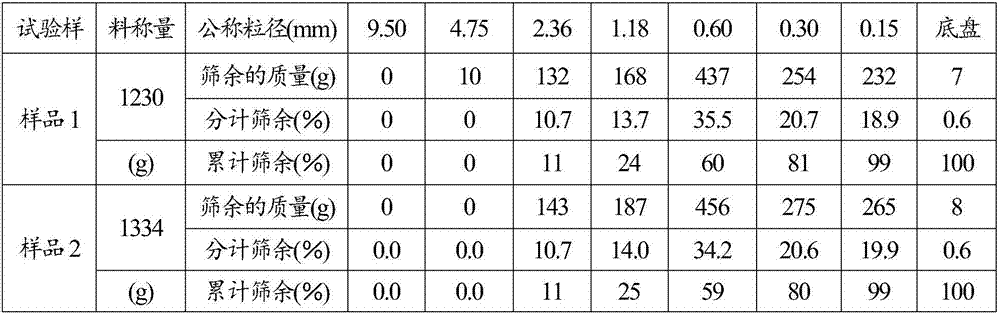

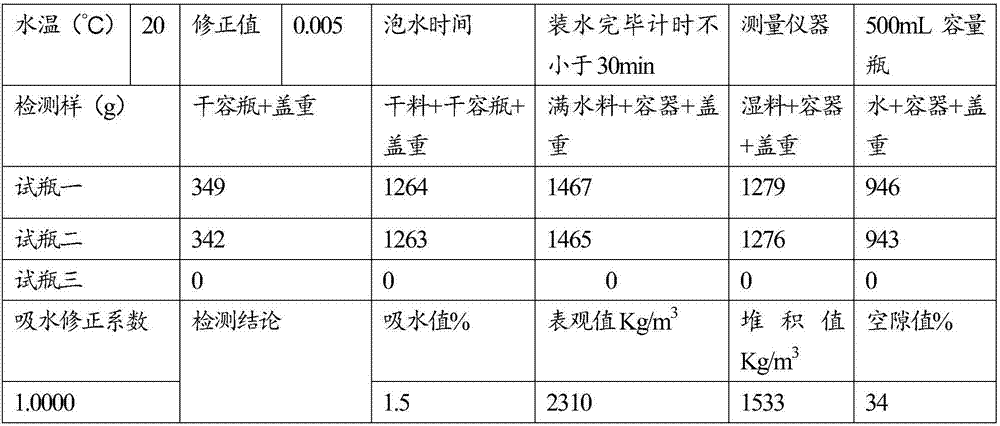

Mortar preparation method

The invention discloses a mortar preparation method. The method comprises the steps as follows: (1) the neat slurry amount is determined initially and the density is measured; (2) fine aggregate and the amount are determined; (3) the initial standard mix proportion of mortar is determined; (4) premixing is performed according to the initial standard mix proportion and the workability is detected; (5) the production mix proportion is determined and premixing detection is performed. Fine aggregate and neat slurry are mixed, local materials are used according to fluctuation of raw materials as well as influence of production and construction links, actual raw material detection data are based, divorcing from reality due to the use of empirical data is avoided, and the effects that the quality is controllable, the cost is reduced and the resources are saved can be realized.

Owner:四川省三台县波特兰商品砼有限公司

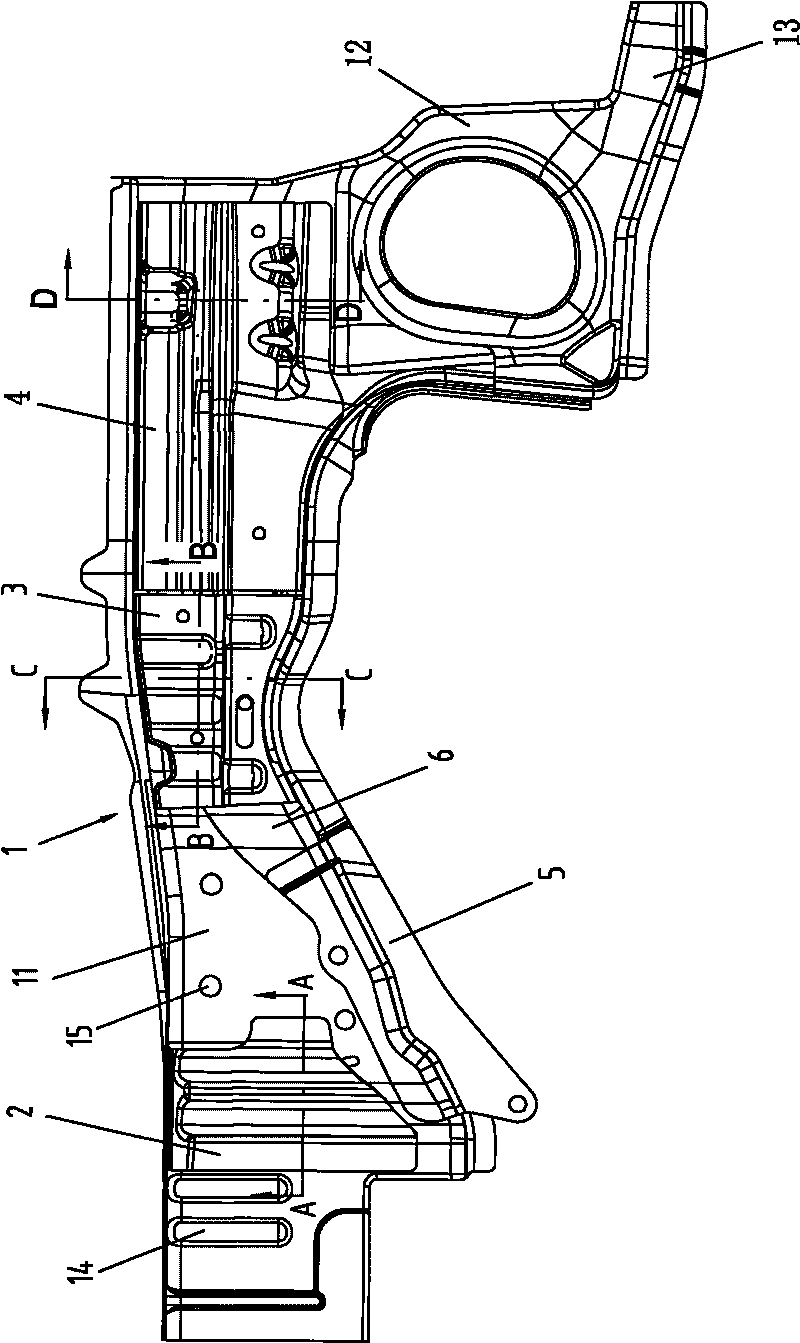

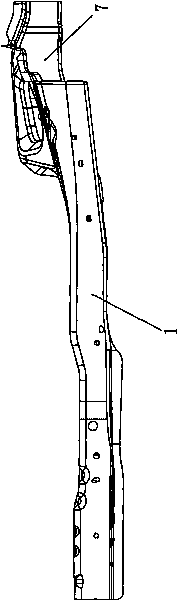

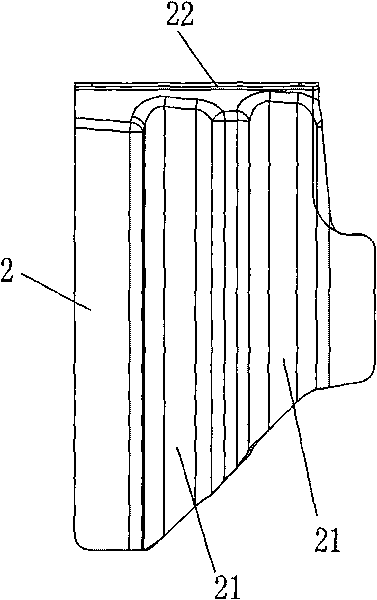

Front rail structure of automobile body

InactiveCN101708737AImprove energy absorptionAbsorb impact energyUnderstructuresEngineeringMechanical engineering

The invention discloses a front rail structure of an automobile body, which has a Z-shaped front rail extending along the fore and aft direction of the automobile body. The front rail comprises a transverse upper section and the cross section of the front rail in the fore and aft direction is of trench structure. The front rail structure is characterized in that a front reinforcing plate, a middle reinforcing plate and a rear reinforcing plate are respectively welded on the front, middle and rear parts in a trench on the upper section of the front rail; the upper edges of the three reinforcing plates are provided with turnup edges which are welded with the turnup edge of the upper edge of the upper section in a sticking manner; the front rail between the front side and the rear side of the front reinforcing plate is a buffer energy absorbing zone; the middle reinforcing plate and the rear reinforcing plate respectively encircle cavities with the front rail; a gap is reserved between the middle reinforcing plate and the rear reinforcing plate; and the rear end of the rear reinforcing plate is close to the rear end of the front rail. The invention is strengthened as a whole and can effectively absorb and attenuate the impact energy generated during automobile crash. In addition, the force transmission property of the rear force bearing zone is greatly enhanced and the rear force bearing zone can absorb more impact energy during deformation.

Owner:力帆科技(集团)股份有限公司

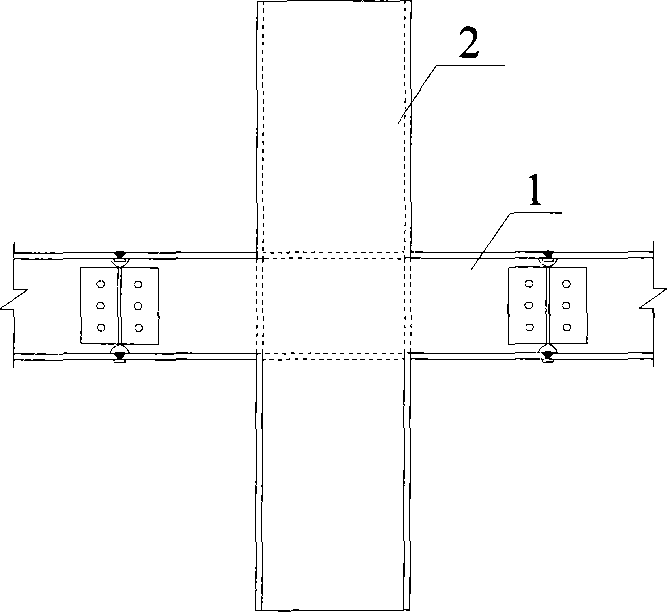

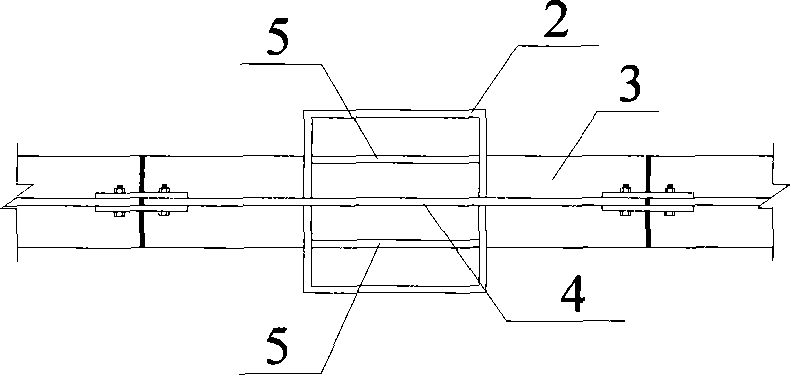

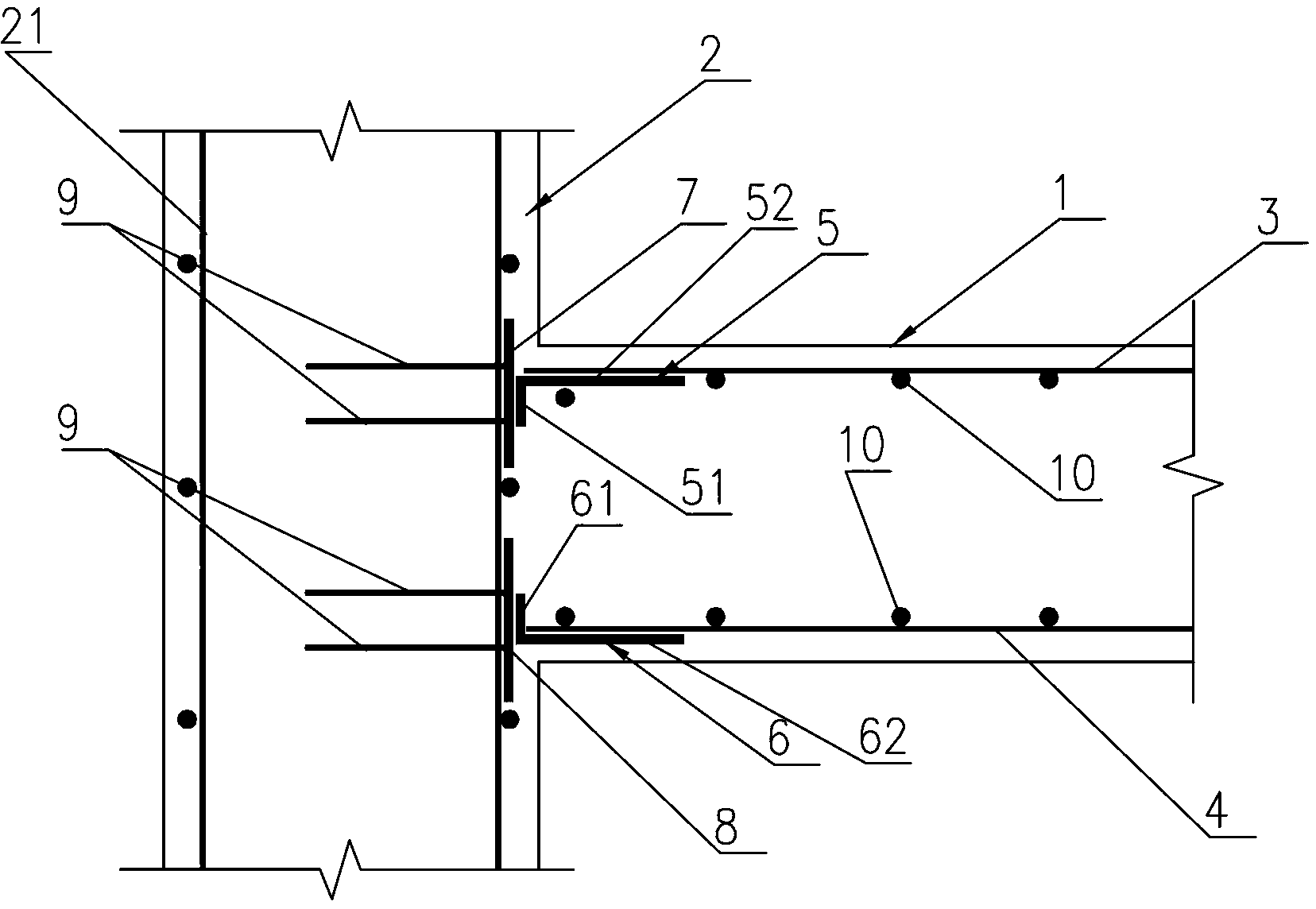

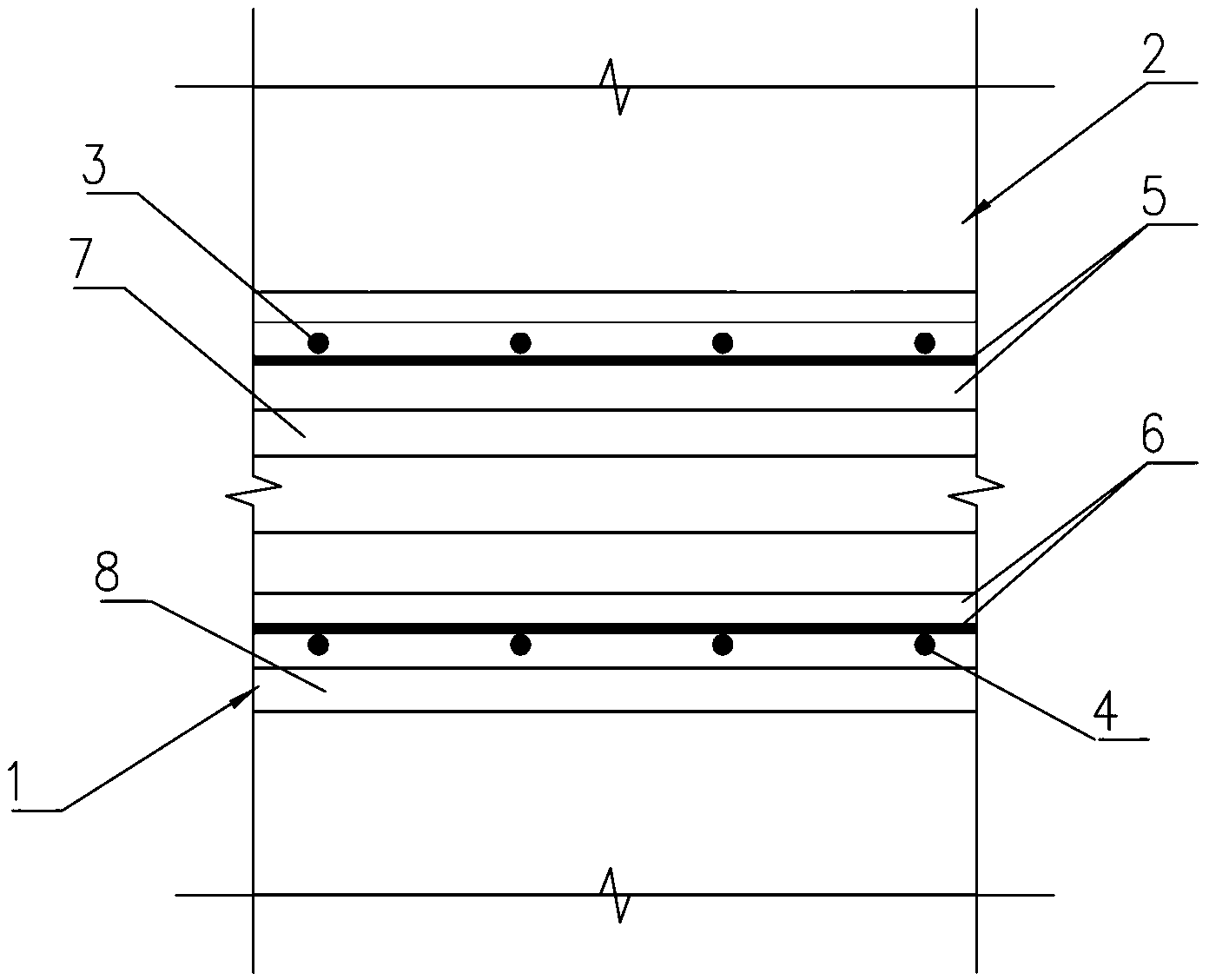

Square steel pipe concrete and H-shaped steel beam nod connection structure

The present invention relates to a structure for connecting the square steel tube concrete column with the node of the axle I-beam in the construction engineering technique field, comprising a square steel tube concrete column, an axle I-beam and a built-in steel plate. The position of the axle I-beam web plate on the wallboard of the square steel tube concrete column is arranged with a vertical groove with dimension same to the girder steel web plate and the groove is taken as the channel that the axle I-beam web plate passes through the wallboard of the square steel tube concrete column. The axle I-beam web plate runs through the wallboard of the square steel tube concrete column, the wing rim of the axle I-beam is directly welded on the external wall of the square steel tube concrete column. The placing mode of the build-in steel plate in the square steel tube concrete column is vertical and is parallel with the web plate of the axle I-beam, and the edge is accordant with the wing rim of the axle I-beam. The invention increases the whole shearing resistance and bending-resisting bearing ability of the node, and guarantees the coordinate operation of the square steel tube concrete column and the axle I-beam.

Owner:SHANGHAI JIAO TONG UNIV

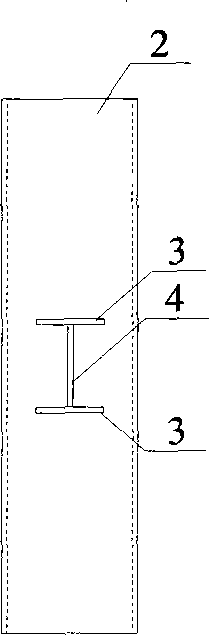

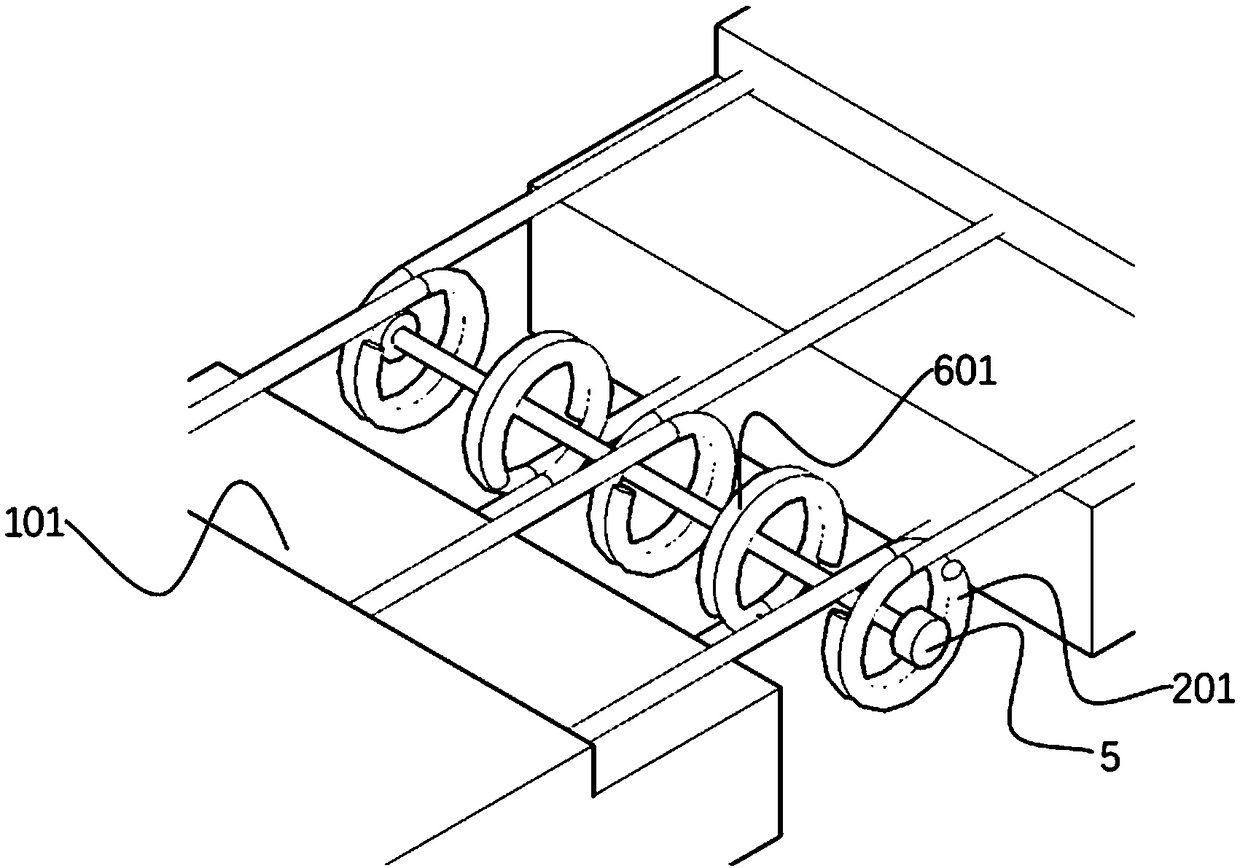

Metal pipe forming equipment and method thereof

The invention relates to metal pipe forming equipment, which comprises a mold, primary-secondary punch heads, a feeding compression ring, a base plate, buffer elements, particulate media and vibration-assisted systems. The mold comprises a first half mold and a second half mold; the primary-secondary punch heads comprise upper primary-secondary punch heads and lower primary-secondary punch heads; stepped hole structures are arranged in the primary punch heads; the secondary punch heads are of stepped structures matched with primary punch head stepped holes; the feeding compression ring is arranged in a forming hole of the first half mold; the base plate is arranged on the bottom end of the second half mold and is provided with a through hole; the buffer elements are arranged between the second half mold and the base plate; the particulate media are arranged in a metal pipe to be formed; the vibration-assisted systems comprise hydraulic vibrators which are arranged on the upper surface of the feeding compression ring, the upper surface of one primary punch head and the surface of the mold, so that the forming process of a complex section is simple, the forming process is easy to control, and the problems of fracture, buckling and wrinkling occurred during the forming process are avoided.

Owner:YANSHAN UNIV

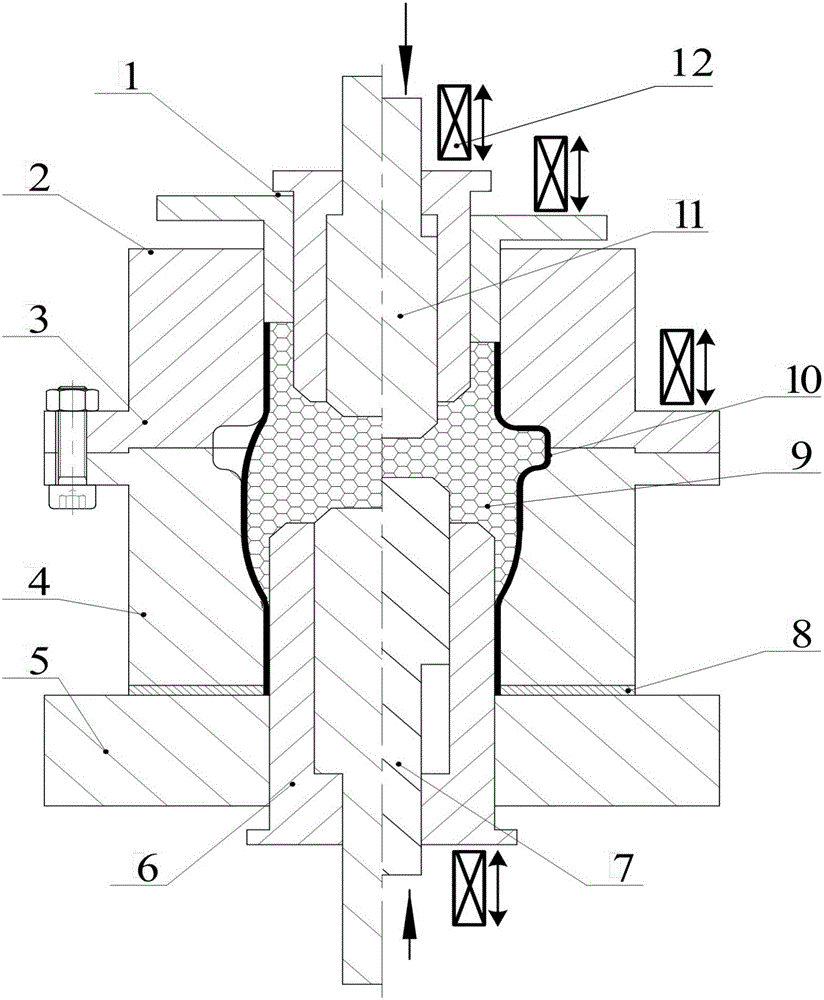

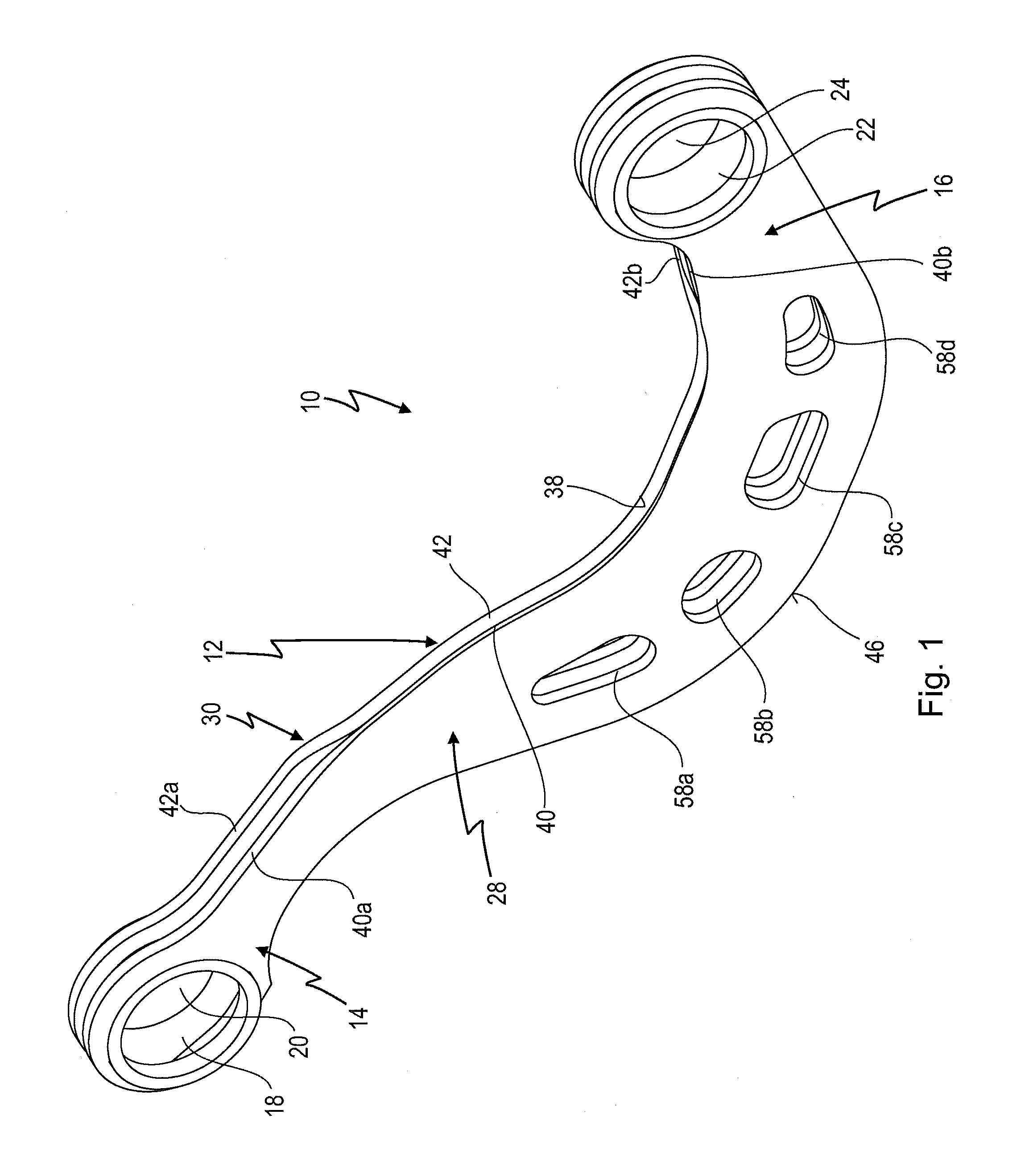

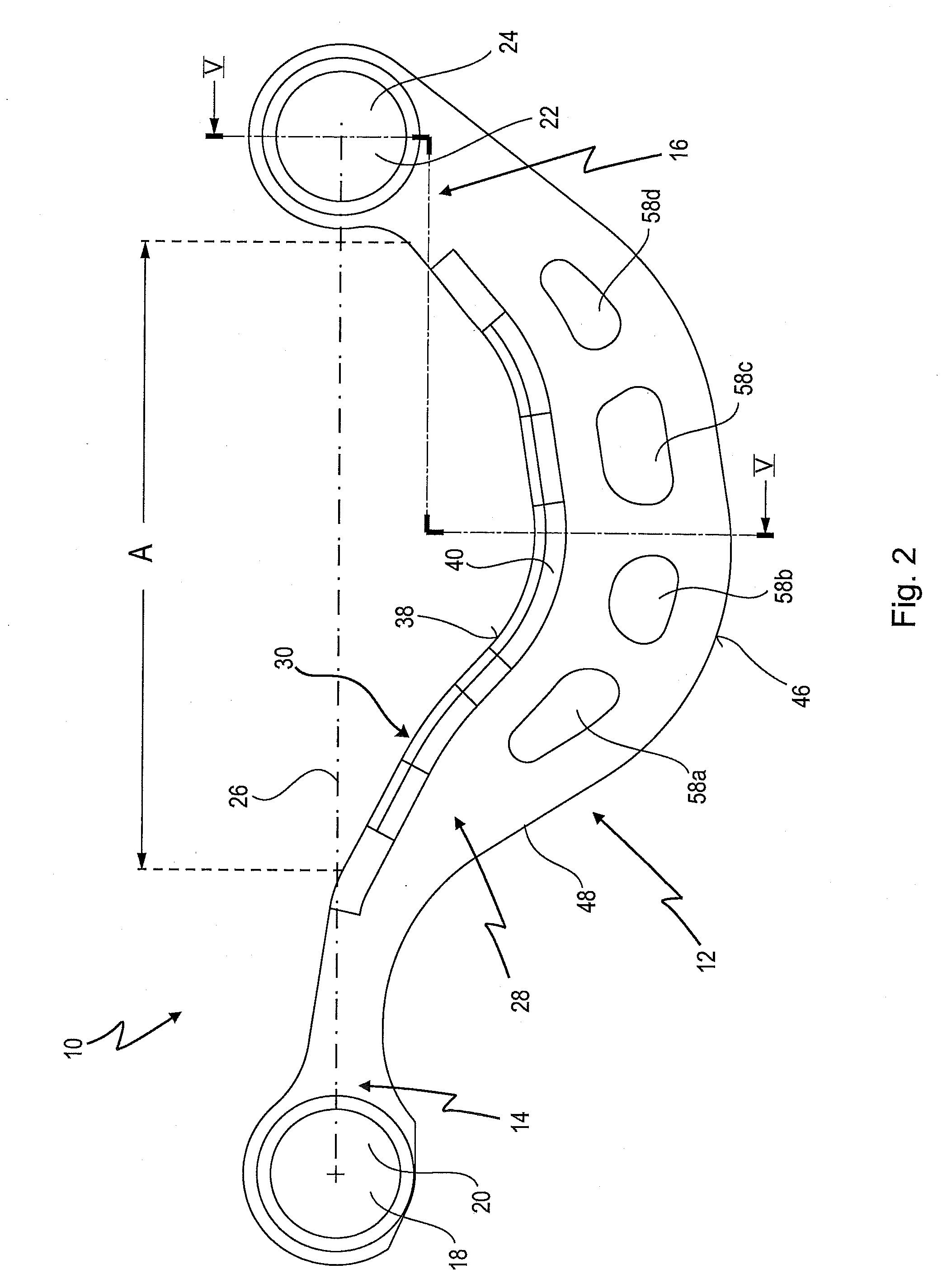

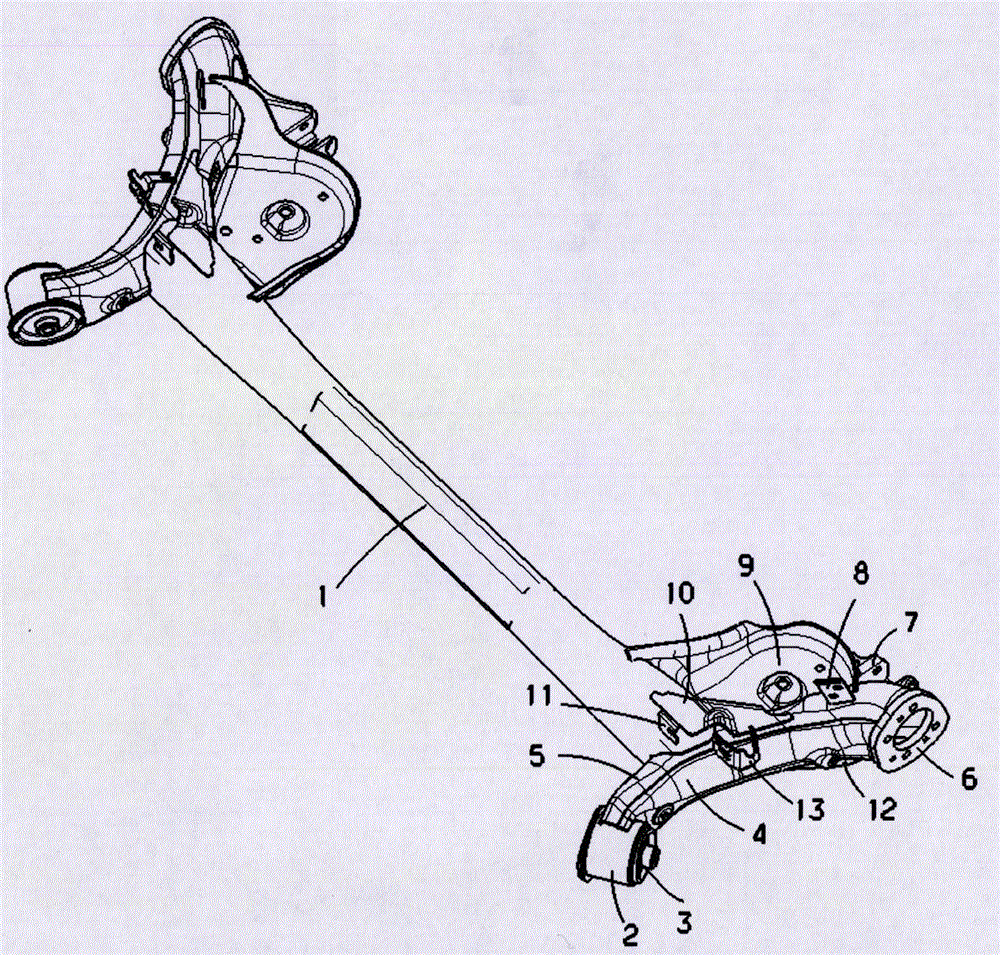

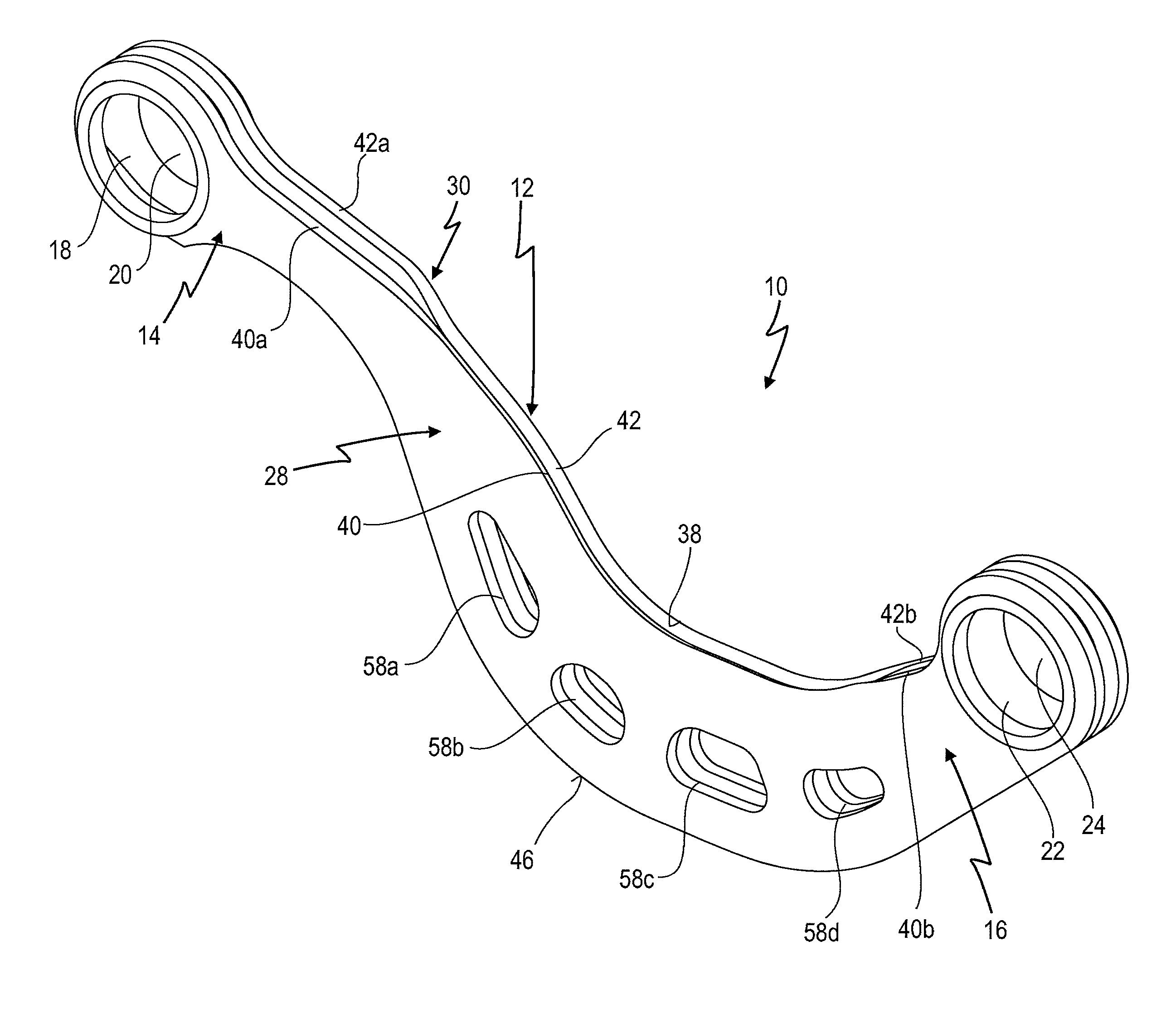

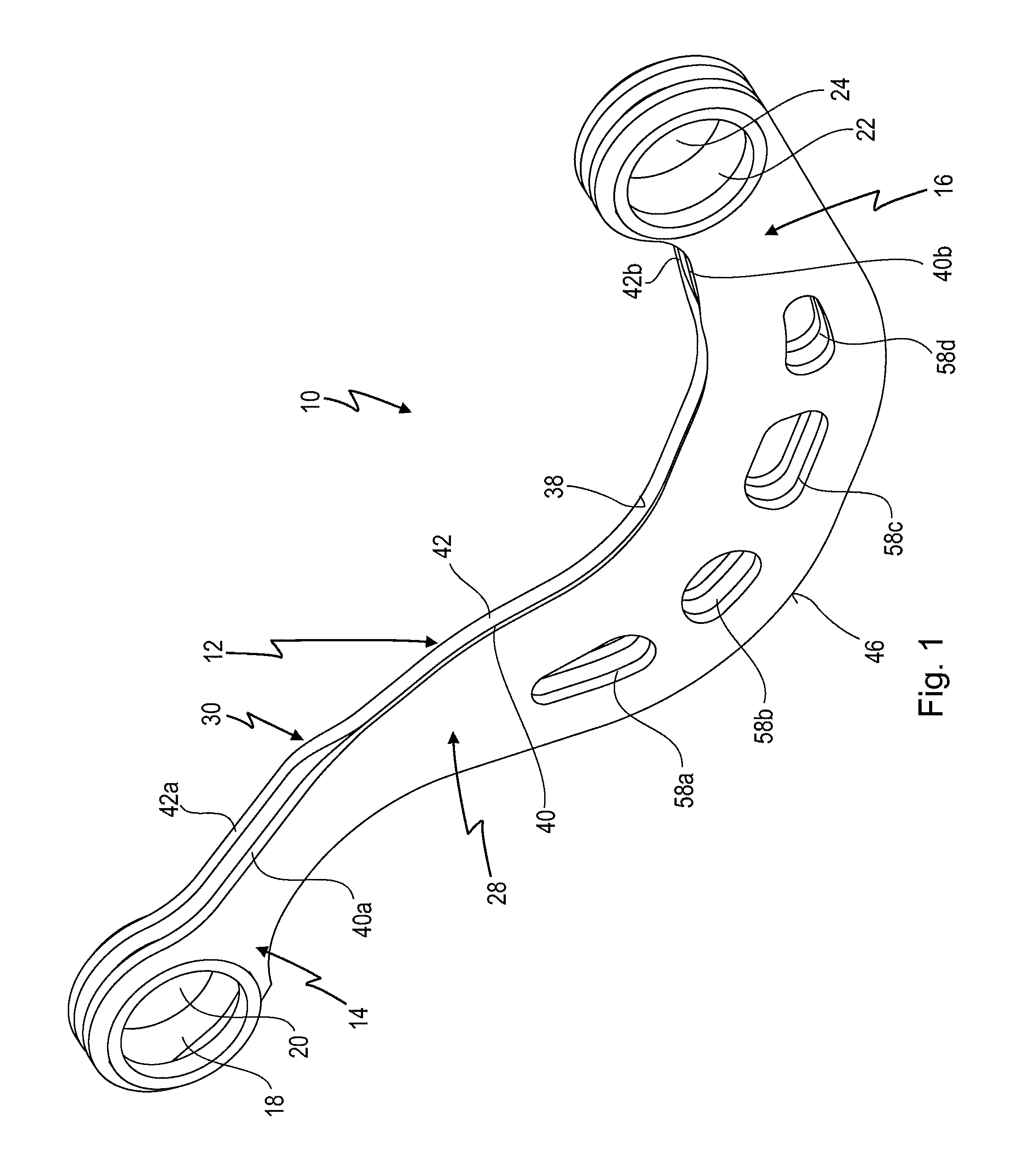

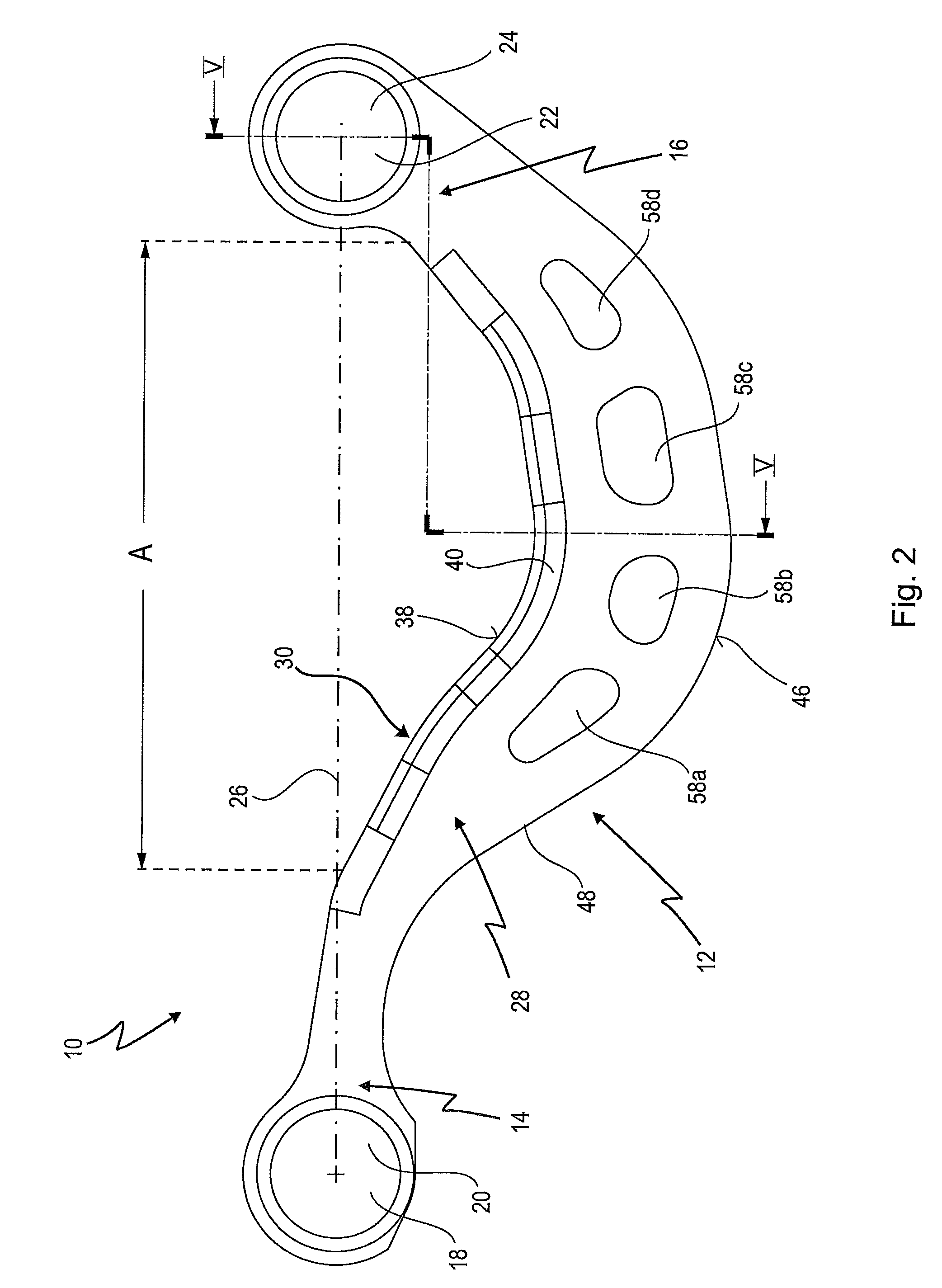

Stabilizing strut for a chassis of a vehicle

InactiveUS20110210528A1Good force transmission effectLow costConnecting rodsInterconnection systemsEngineeringRolling chassis

A stabilizing strut for a chassis of a vehicle has an elongated strut body made of sheet metal which has at least one first eye at a first longitudinal end and at least one second eye at a second longitudinal end. The strut body has a curvature at least such that the strut body lies completely outside an imaginary connecting straight line between the at least one first and the at least one second eye at least in a partial region. The strut body is built up from two individual sheet metal parts which are arranged one on each side of a longitudinal centre plane. The two sheet metal parts are joined to one another between the at least one first eye and the at least one second eye at their peripheral edges on a longitudinal side of the sheet metal parts oriented towards the imaginary connecting straight line, at least over a partial length of this longitudinal side of the strut body which amounts to at least 50% of the total length of this longitudinal side of the strut body. The surfaces oriented towards one another of the two sheet metal parts are spaced from one another. The peripheral edges of the sheet metal parts on the longitudinal side oriented away from the imaginary connecting straight line are not joined to one another, or at most are joined over a partial length of this longitudinal side of the strut body which amounts to not more than 50% of the total length of this longitudinal side.

Owner:PROGRESS WERK OBERKIRCH

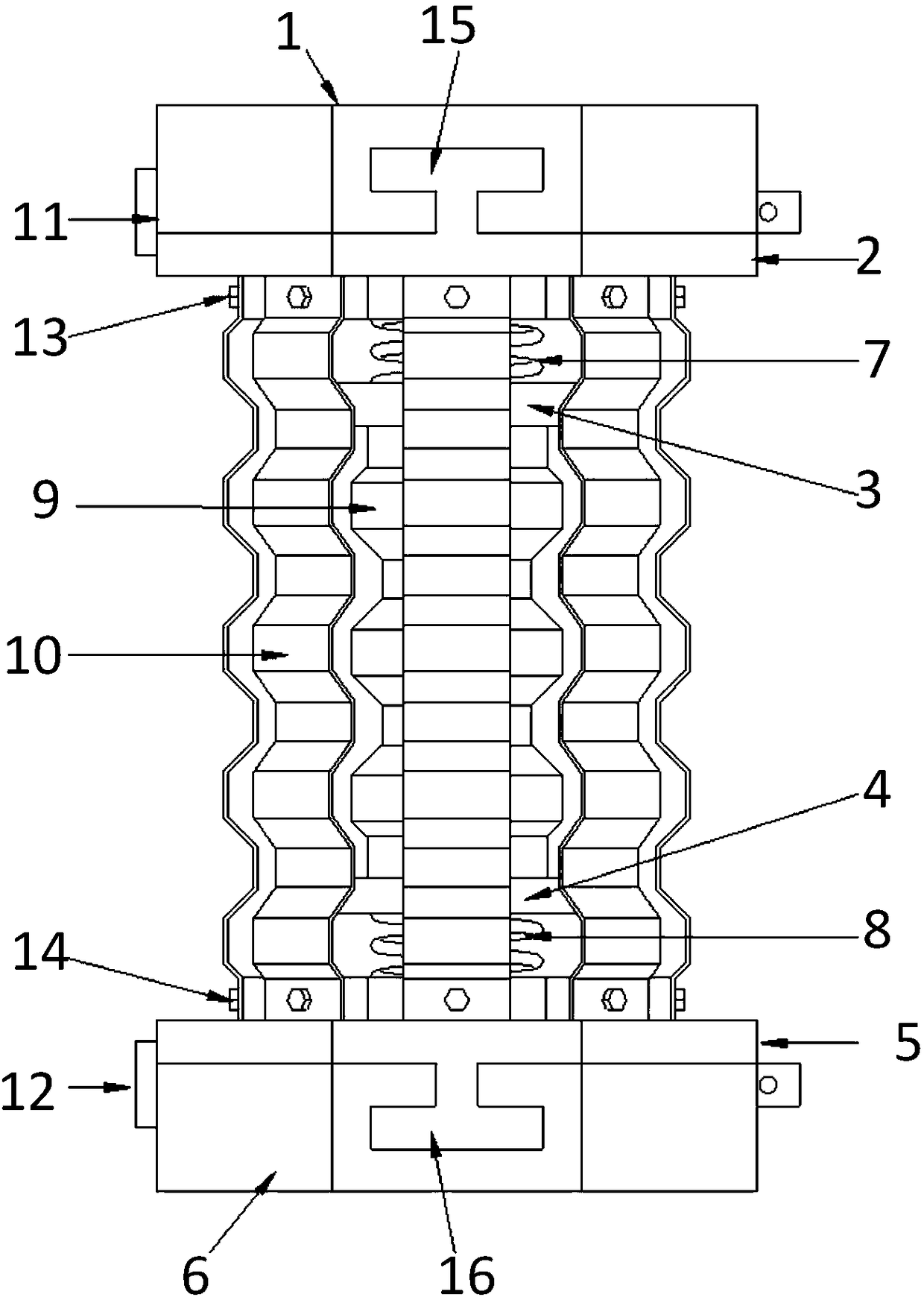

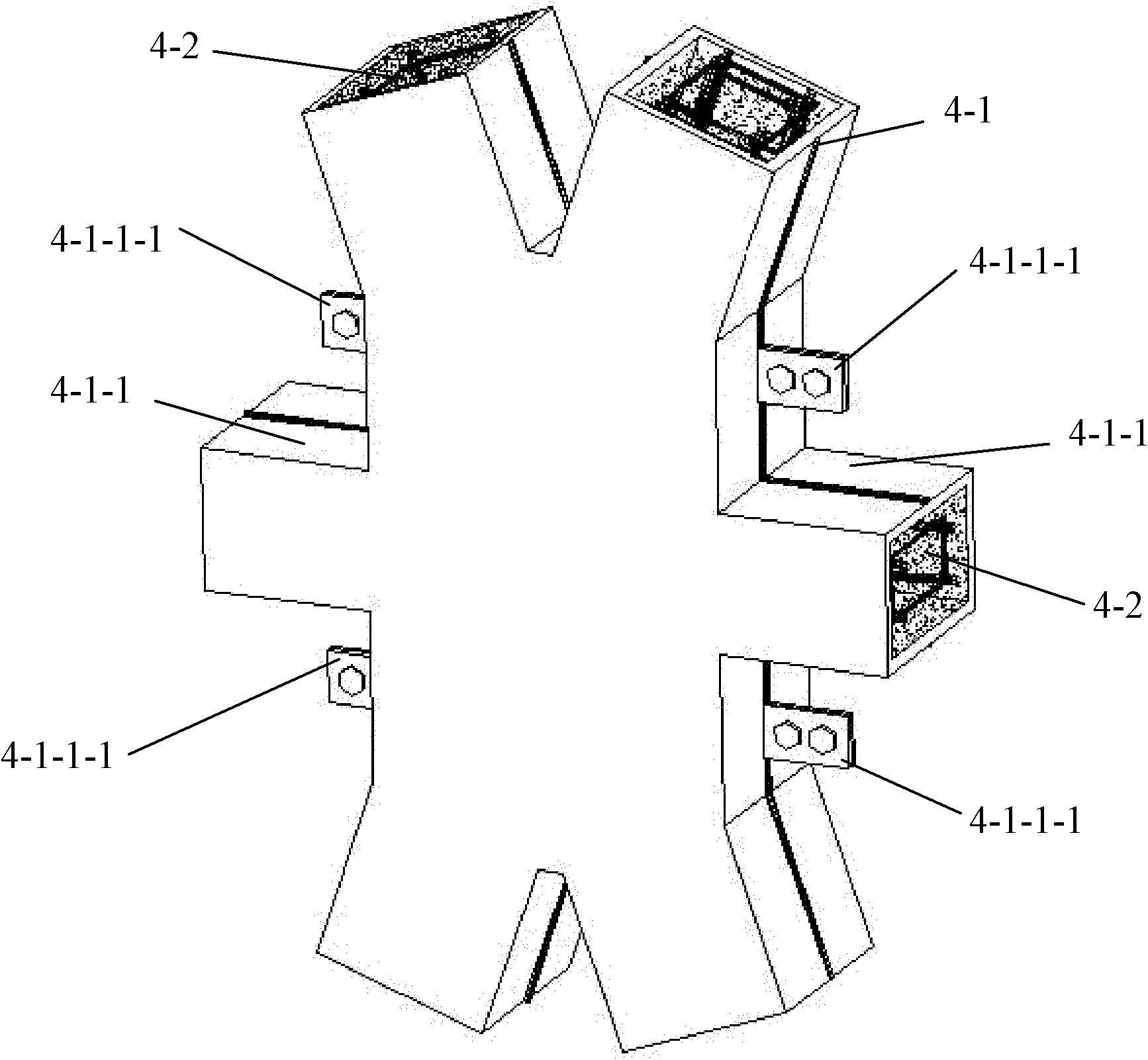

Inward-outward double-bent soft steel transverse-wave vertical-bent buckle damper

ActiveCN108118938AQuick recovery energy dissipation shock absorptionEasy to operateProtective buildings/sheltersShock proofingAgricultural engineeringTransverse wave

The invention discloses an inward-outward double-bent soft steel transverse-wave vertical-bent buckle damper. An upper base, a first connection plate, a first spring, a second connection plate, a wavysoft steel barrel, a third connection plate, a second spring, a fourth connection plate and a lower base are sequentially distributed from top to bottom, the first connection plate is fixed at the bottom of the upper base, one end of the first spring is connected with the bottom of the first connection plate while the other end of the same is connected with the upper portion of the second connection plate, the upper end of the wavy soft steel barrel is connected on the second connection plate in a sleeved manner while the lower end of the same is connected on the third connection plate in a sleeved manner, the upper end of the second spring is connected with the bottom of the third connection plate while the lower end of the same is fixed on the fourth connection plate which is fixed on the lower base, and wavy steel plates are distributed on the periphery of the wavy soft steel barrel circumferentially. The damper can realize staged energy-consuming damping.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

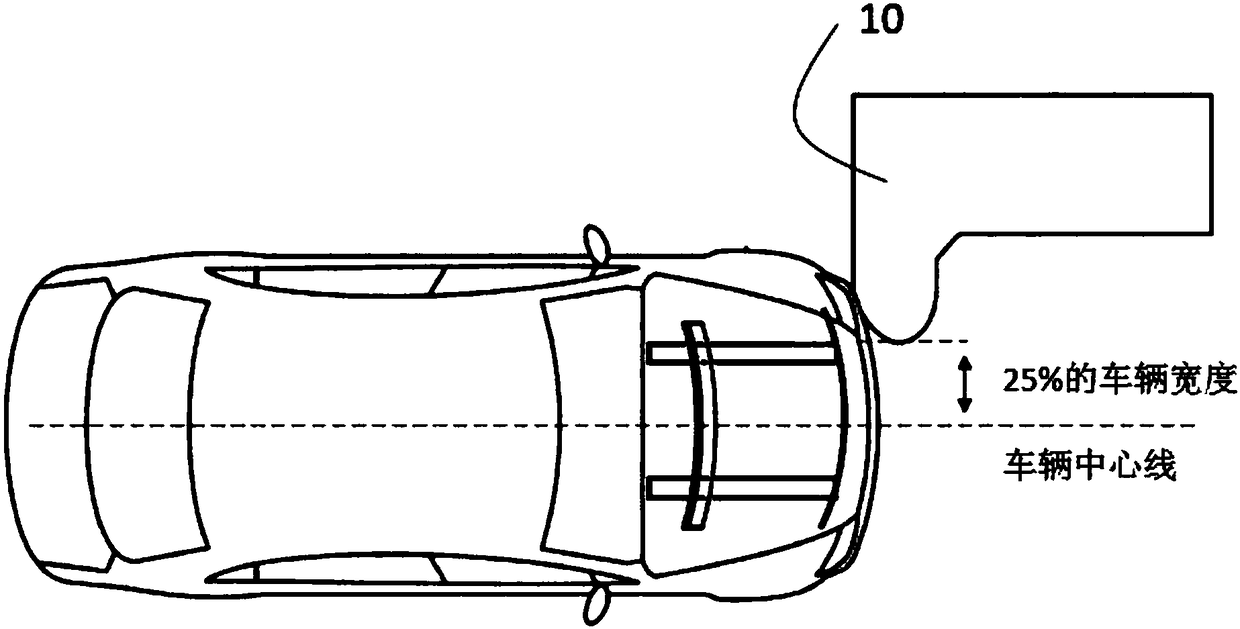

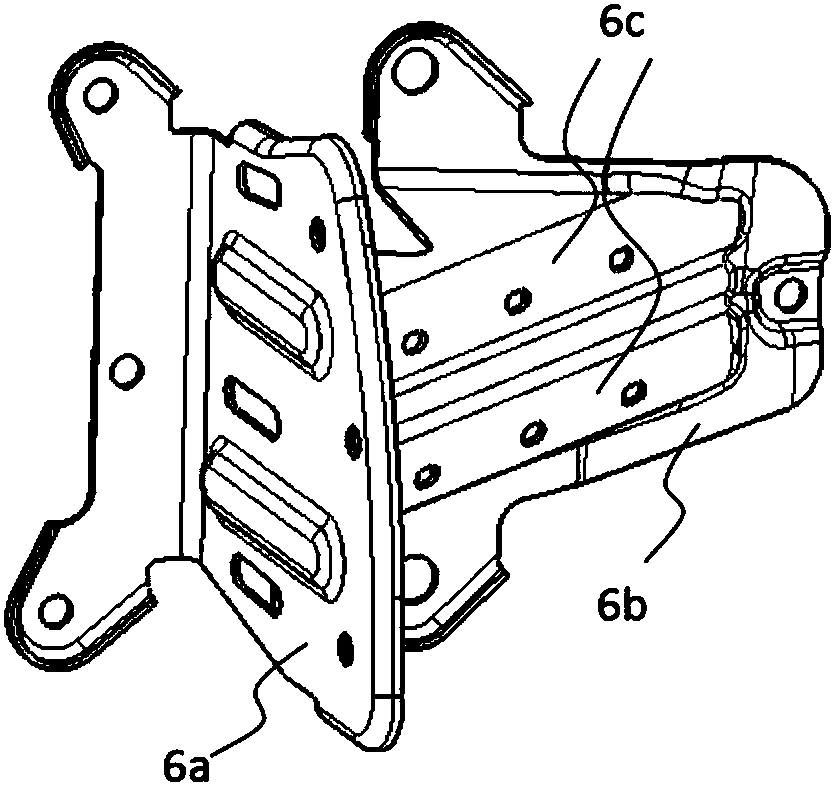

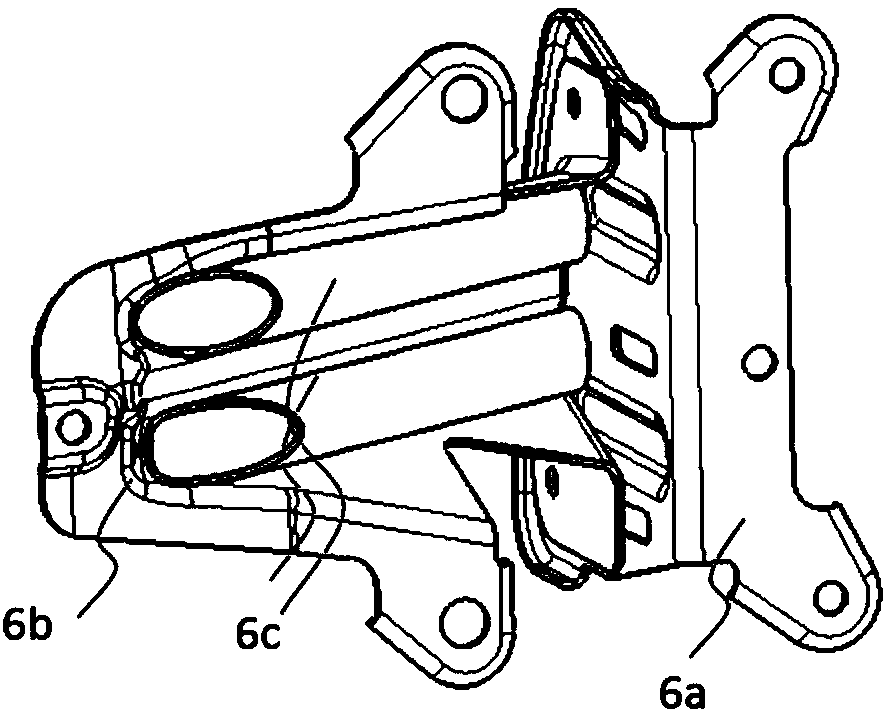

Engine room force transfer structure dealing with automobile small offset crashes

InactiveCN108248533AEnough supportImprove power transmissionUnderstructuresSuperstructure subunitsEnergy absorptionEngineering

The invention relates to an engine room force transfer structure dealing with automobile small offset crashes. The structure comprises a front anti-collision beam assembly, an engine room longitudinalbeam assembly and a force transfer component which is positioned and connected to the engine room longitudinal beam assembly and corresponds to the front anti-collision beam assembly; the front anti-collision beam assembly comprises an anti-collision beam and an energy absorption box; the structure is characterized in that the force transfer component is formed by connecting a stress component, asupporting component and a main force transfer component, and the whole structure is in a triangular shape. When small offset crashes of automobiles happen, the engine room longitudinal beam sufficiently participates in deformation and energy absorption, and the automobile body kinetic energy is lowered; a power assembly is forced to move in the reverse direction of the crash side, crash impact force on the crash side is timely and effectively transferred to the non-crash side through the power assembly, the longitudinal crash impact force of the automobile body is greatly reduced, the passenger compartment deformation amount is reduced, and life safety of passengers is ensured.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

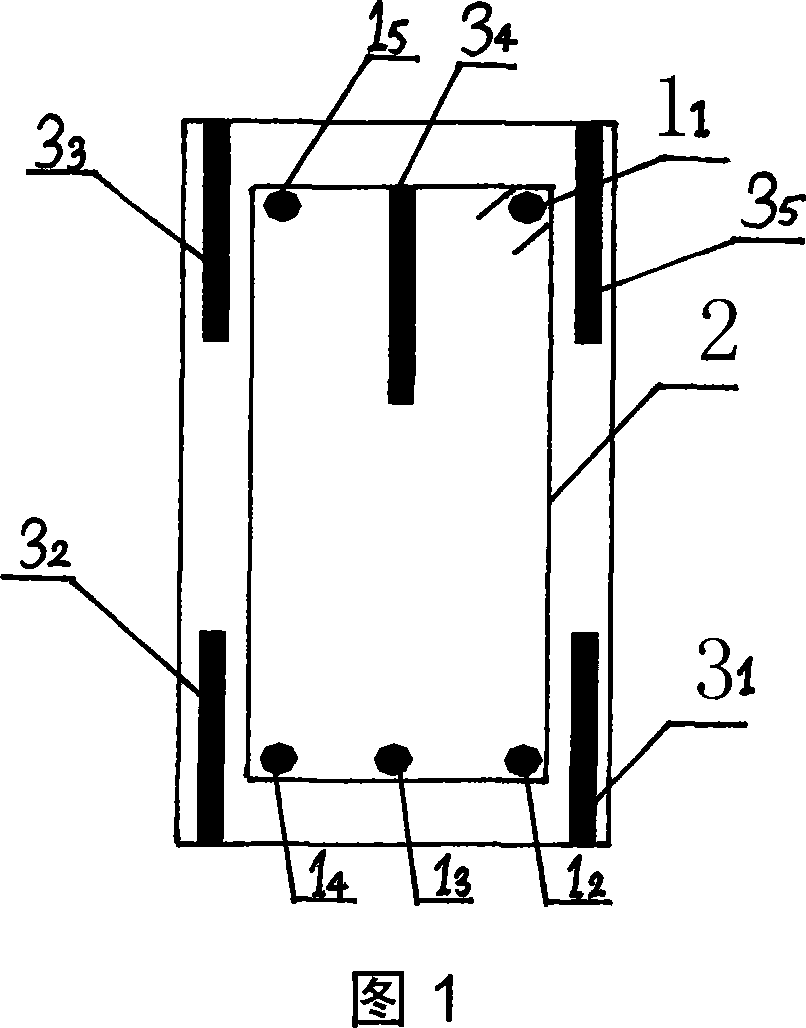

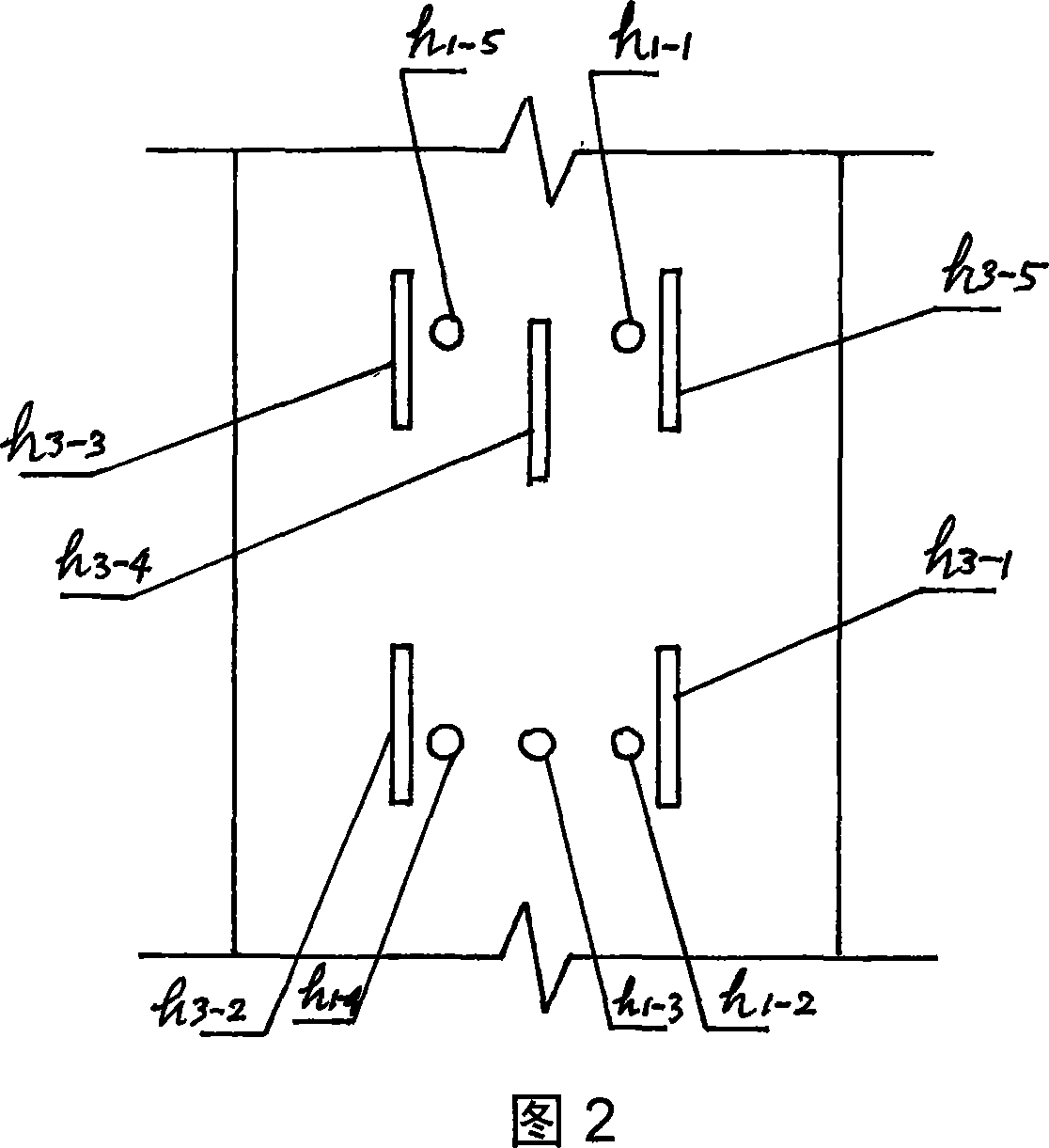

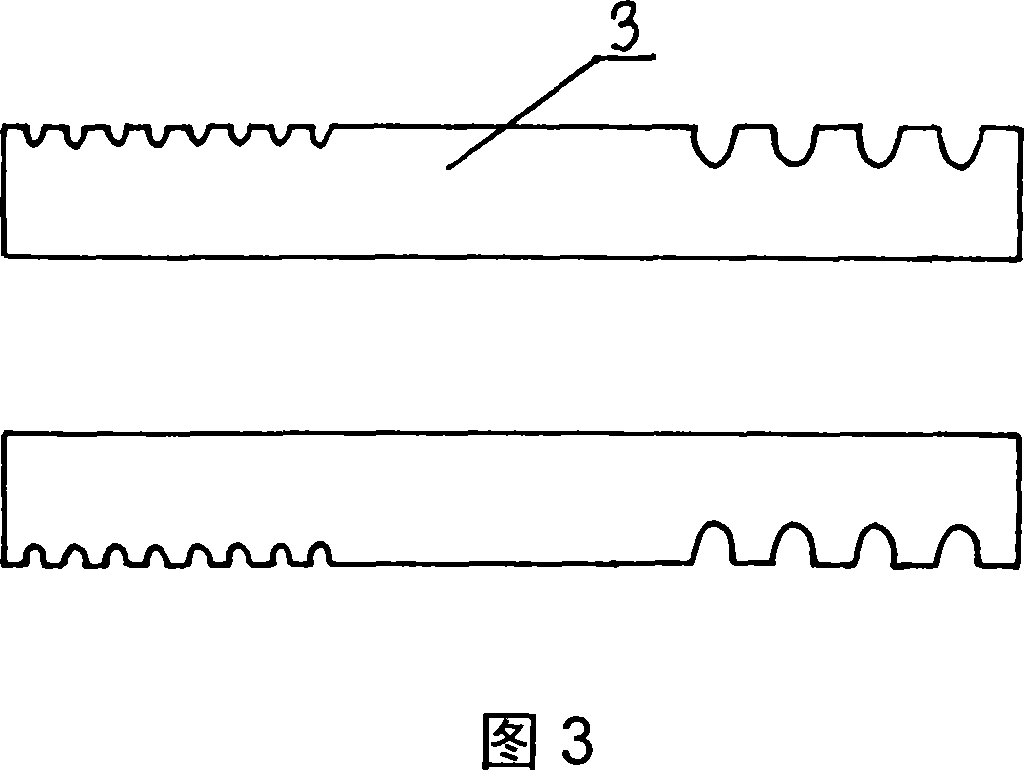

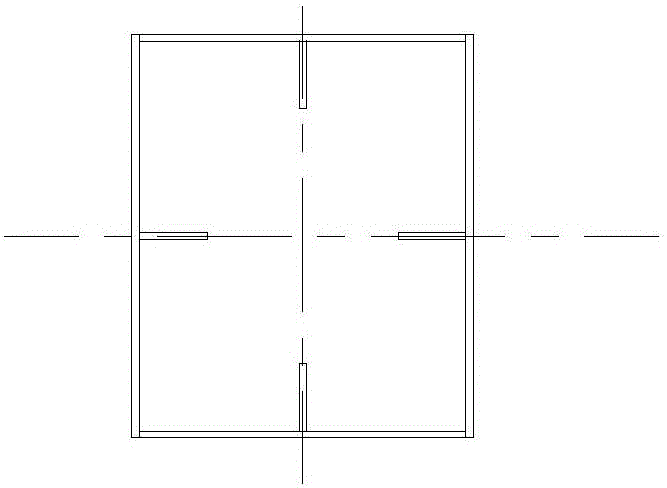

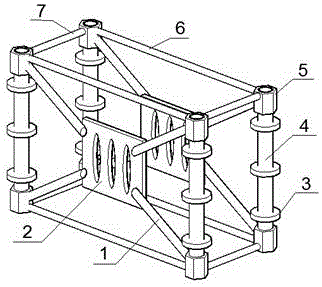

Connecting structure for steel tube concrete beam and column node

InactiveCN101059000AImprove mechanical performanceGuaranteed integrityBuilding constructionsSEMI-CIRCLEConcrete beams

Steel pipe concrete beam-column joints connecting structure, and it aims at improving the shear and flexural strength of beam-column joints and ensuring the steel plate and node work together. The cross section of steel pipe 4 in steel pipe concrete column is rectangular, the steel beam 31, 32, 33, 34, 35 in beam and the reinforcing bar 11, 12, 13, 14, 15 cross through the rectangular hole h3-1, h3-2, h3-3, h3-4, h3-5 and round hole h1, h2, h3, h4, h5 separately, two ends of the steel plate 31, 32, 33, 34, 35 are opened 8-16 semi-circle holes separately.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

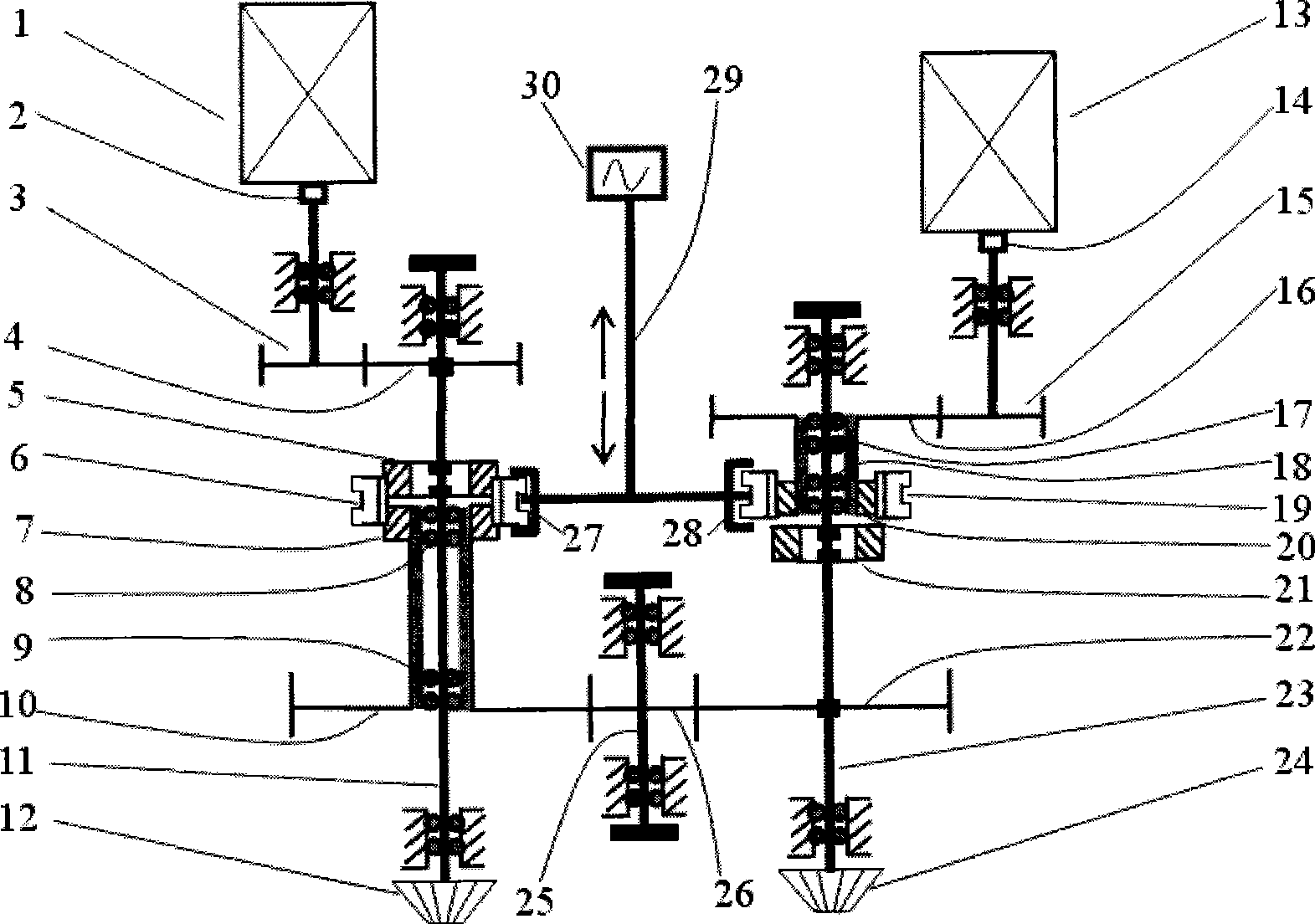

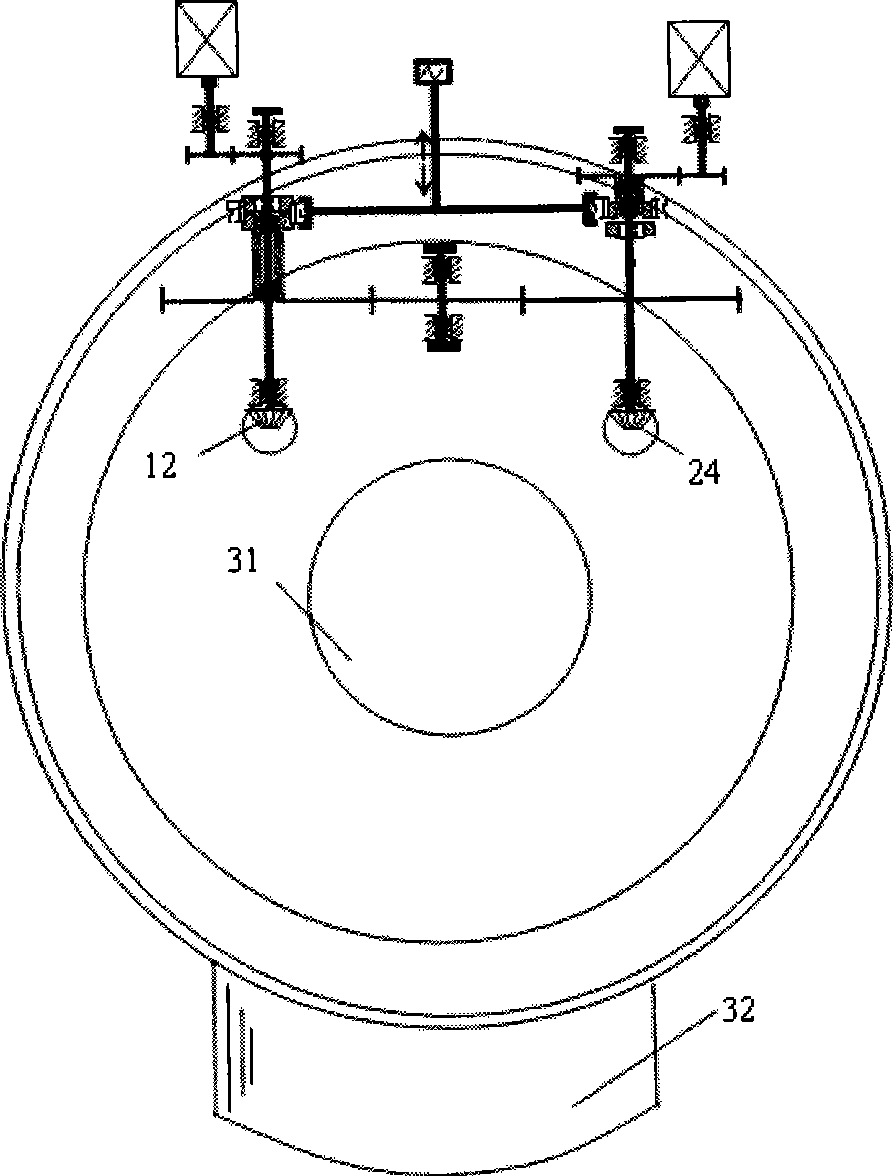

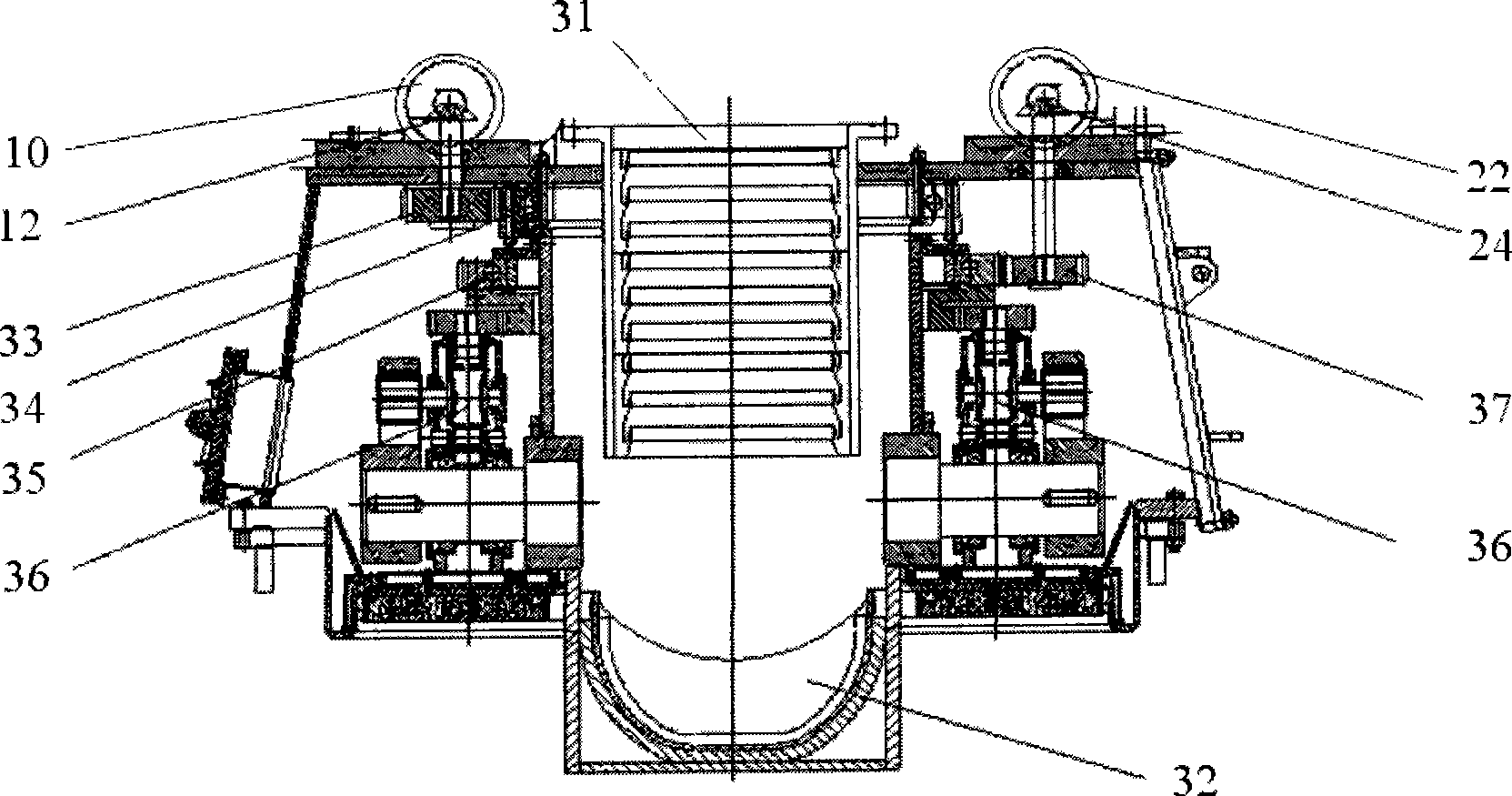

Synchronous gear direct-drive gear apparatus for blast furnace bellless furnace top distributor

InactiveCN101476005ASimple compositionReduce manufacturing costBell-and-hopper arrangementRotational axisMotor drive

A synchronous gear direct drive apparatus for blast furnace bellless furnace top distributor contains a main rotary motor, a main rotary reduction gear pair, a main rotary driveshaft, a main rotary incoming gear, a tilting motor, a tilting reduction gear, a tilting drive shaft as well as a tilting incoming gear, a synchronous gear transmission mechanism provided between the main rotational axis and the tilting driving shaft, main rotary teeth cover clutch structure and tilting clutch structure respectively provided on the main rotational axis and the tilting driving shaft, and a fork spreader mechanism controlling the clutch and detaching. The present invention can realize transmission in three ways, firstly, the main rotary motor driving the main rotating revolving ring and chute to realize the synchronous main rotation; secondly, the tilting motor driving the tilting rotational axis to rotate to realize the angle adjustment of the chute; thirdly realizing the simultaneous adjustment of main rotation and chute angle. The invention has features of simple transmission mechanism, smaller manufacturing difficulty, less transmission links, high reliability, large transmission torque, good operation synchronism, long service life and so on.

Owner:TSINGHUA UNIV

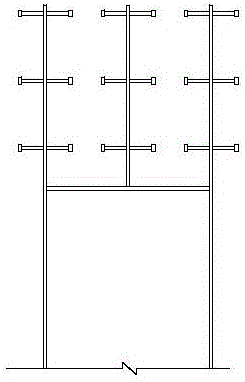

Integrated beam-slab-column formwork structural system and construction method

The invention relates to the technical field of constructional engineering, in particular to an integrated beam-slab-column formwork structural system and a construction method. The structural system is a frame structure formwork system composed of a non-dismantling column formwork, a beam formwork, a beam-column joint formwork and a slab formwork which are connected to each other; the column formwork, the beam-column joint formwork, the beam formwork and the slab formwork are respectively composed of corresponding formwork units by means of splicing; a non-dismantling formwork unit is made of a thin-wall shell structure and used as a formwork when pouring concrete, and also used as finishing material in the later stage, wherein one side of the non-dismantling formwork unit is processed into a rough surface and the other side is smooth; the splicing parts of the formwork units are built in by adopting a form of concave-convex groove and tongue; an outer side of the non-dismantling formwork is fastened by using a fastening hoop to resist the cast-in-situ concrete side pressure; the beam-column joint formwork makes the integrated beam-slab-column formwork structural system applicable to a preformed structural member, and also applicable to cast-in-situ; the preformed member is spliced or concrete is casted in situ to the preformed member to form one building unit of the frame structure, and a plurality of building units form a multilayer or a high-rise frame structure.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

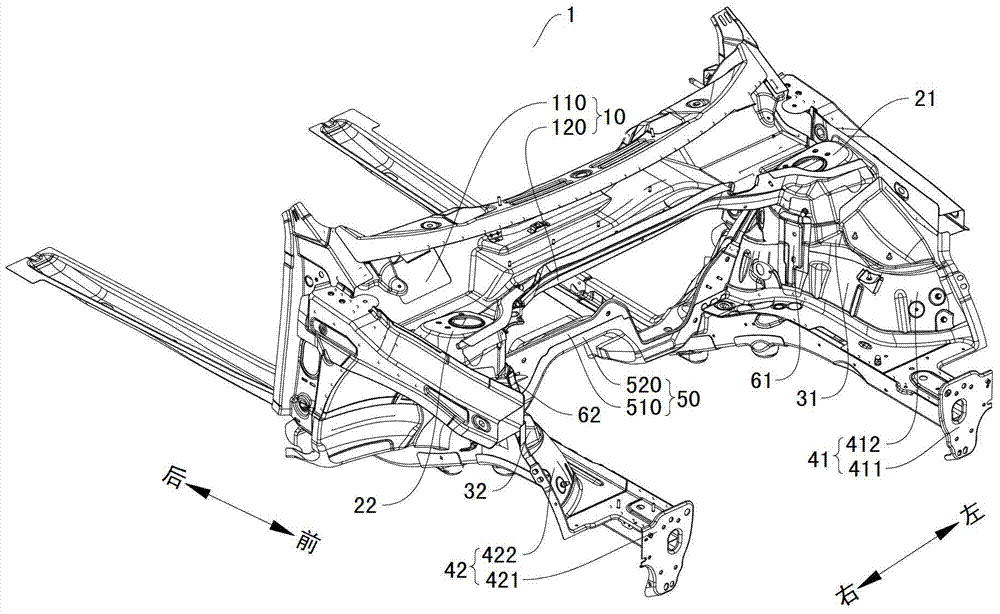

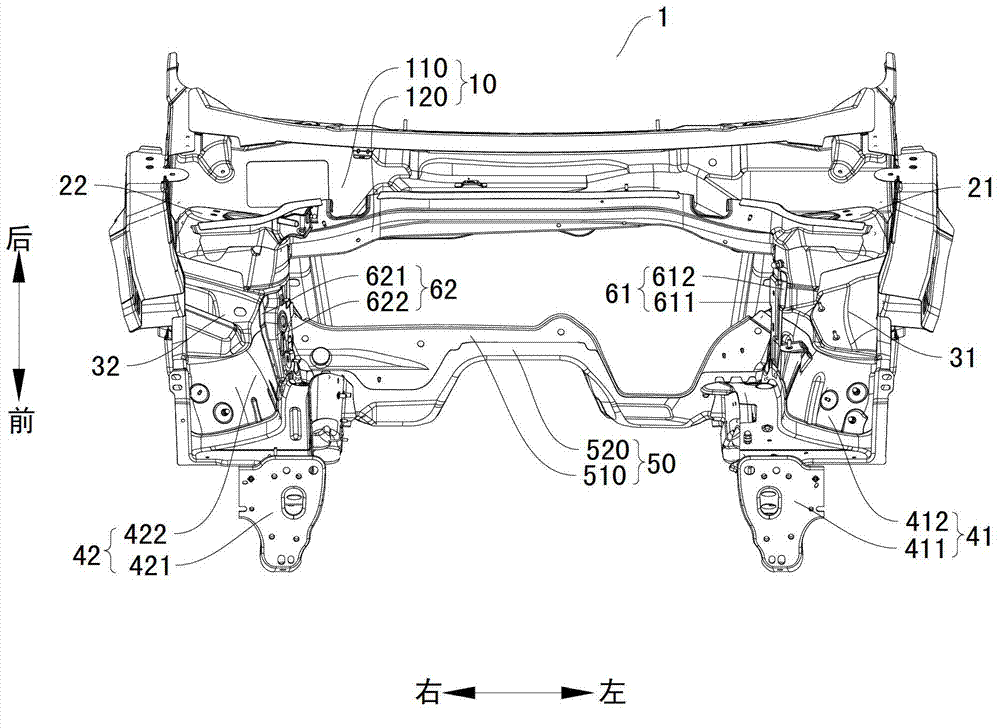

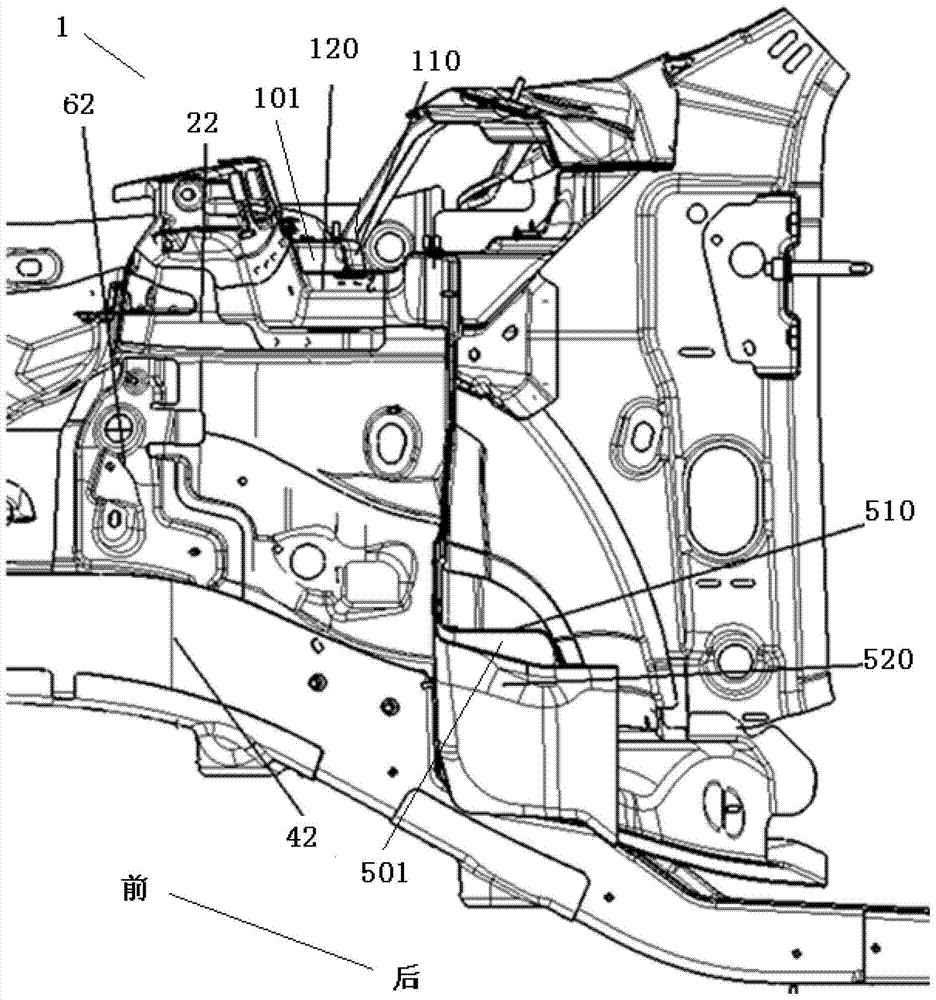

Vehicle body and vehicle with vehicle body

ActiveCN104512466AIncrease stiffnessImprove force transmissionSuperstructure subunitsFlexural rigidityEngineering

The invention discloses a vehicle body and a vehicle with the vehicle body. The vehicle body comprises a ventilation hood component which extends leftwards and rightwards, a left absorber supporting seat, a right absorber supporting seat, a left wheel hood, a right wheel hood, a left longitudinal beam assembly, a right longitudinal beam assembly, a left wheel hood reinforcing plate, a right wheel hood reinforcing plate and a lower crossbeam component, wherein the left absorber supporting seat and the right absorber supporting seat are respectively connected to the left end and the right end of the ventilation hood component; the left wheel hood is fixed below the left absorber supporting seat, and the right wheel hood is fixed below the right absorber supporting seat; the left longitudinal beam assembly is fixed below the left wheel hood, and the right longitudinal beam assembly is fixed below the right wheel hood; the left wheel hood reinforcing plate is respectively fixed to the left absorber supporting seat, the left wheel hood and the left longitudinal beam assembly, and the right wheel hood reinforcing plate is respectively fixed to the right absorber supporting seat, the right wheel hood and the right longitudinal beam assembly; and the left end of the lower crossbeam component is fixed to the left wheel hood and the left longitudinal beam assembly, and the right end of the lower crossbeam component is fixed to the right wheel hood and the right longitudinal beam assembly. According to the vehicle body disclosed by the embodiment of the invention, a framework type structure is formed at the front part of the vehicle body through the connections of the components, so that the rigidity of the vehicle body is improved, and the bending rigidity and the torsional rigidity of the front part of the vehicle body are improved.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

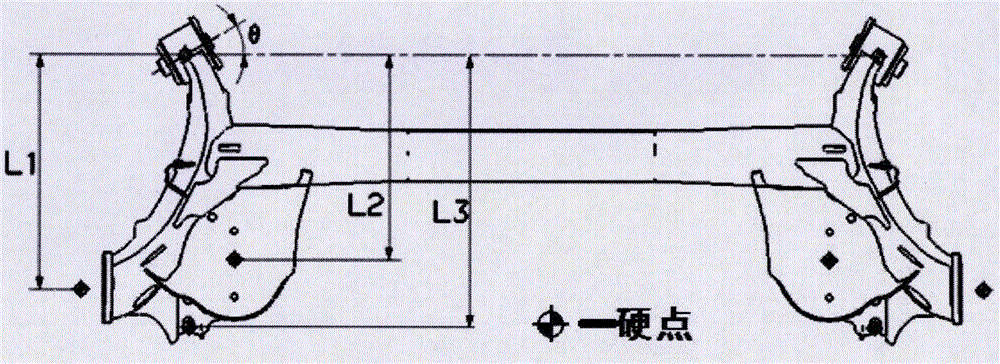

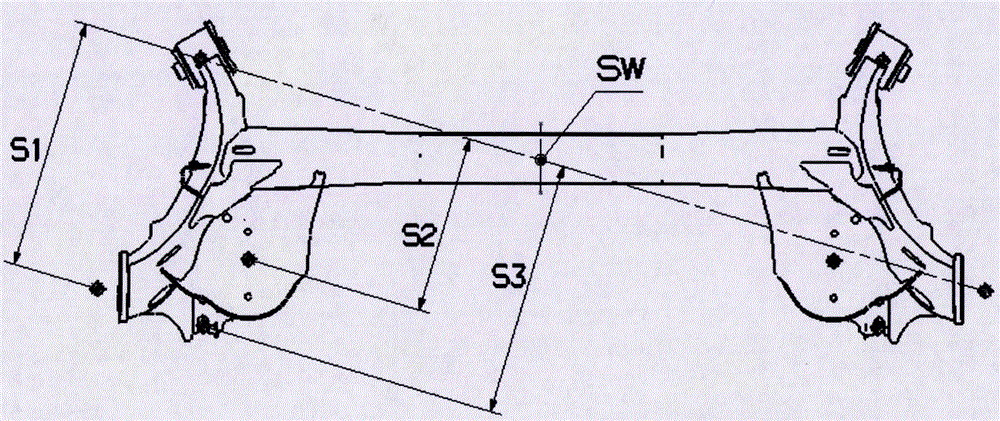

Torsion beam structure of rear suspension

PendingCN106828009ALarge sectionGood force transmission effectInterconnection systemsEngineeringClassical mechanics

The invention relates to a torsion beam structure of a rear suspension, and belongs to the technical field of suspensions of automobiles. The torsion beam structure of the rear suspension comprises a transverse beam, front sleeves, front lining assemblies, outer plates of longitudinal arms, inner plates of the longitudinal arms, a brake bottom plate, shock absorber supports, rear vertical harness supports, spring trays, triangular connecting plates, front vertical harness supports, spring tray reinforcement plates and hardness integrated supports, and the structures of the left side and the right side of a torsion beam are symmetric with each other. The torsion beam structure has the advantages that the torsion beam structure is designed under comprehensive consideration in multiple angles of performance, strength, reliability, stamping, welding, coating, assembling, materials and the like and is good in kinetic characteristic, high in fatigue and durability safety factor and wide in platform modification extensibility, components are high in structural strength, and manufacturing processes are feasible.

Owner:袁璐

Connection joint between basement base plate and underground diaphragm wall

ActiveCN103061357AImprove bending resistanceImprove shear resistanceArtificial islandsUnderwater structuresSlurry wallBasement

The invention discloses a connection joint between a basement base plate and an underground diaphragm wall. The connection joint comprises a transition connection component for being arranged between the basement base plate and a steel plate on the inner surface of the underground diaphragm wall. The underground diaphragm wall and an outer wall of the basement are the same wall. The transition connection component which is a long profile extends along the length direction of the underground diaphragm wall and is provided with connection faces corresponding to the steel plate and transverse reinforcements of the basement base plate respectively. The transverse reinforcements are perpendicular to the underground diaphragm wall, the steel plate surface is connected with the corresponding connection face, and the transverse reinforcements extend onto the corresponding connection face to be fixed. By means of the connection joint, on the premise that the prior bearing capacity of the underground diaphragm wall is guaranteed, the bending resistance and the shearing resistance between the basement base plate and the underground diaphragm wall are enhanced, the joint wholeness can be guaranteed, and the strength and the rigidity of the joint are improved effectively, so that the joint is provided with good force transmission performance and impervious performance.

Owner:广东省建科建筑设计院有限公司

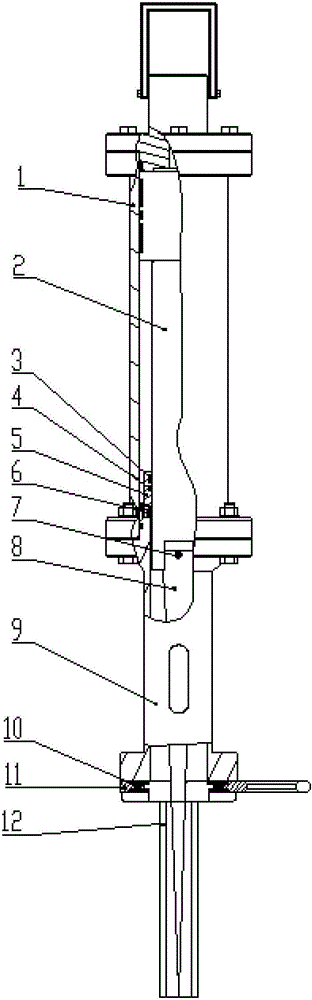

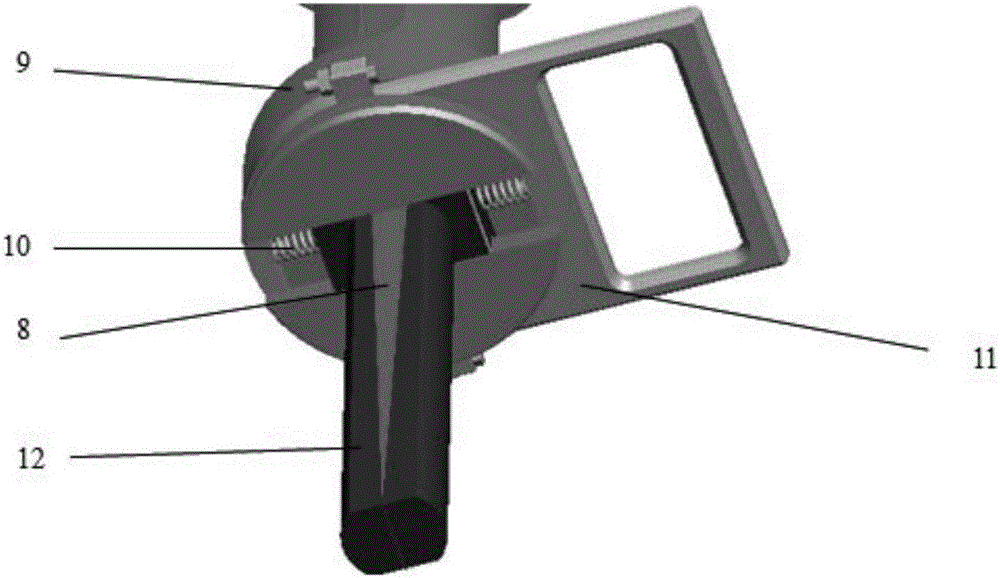

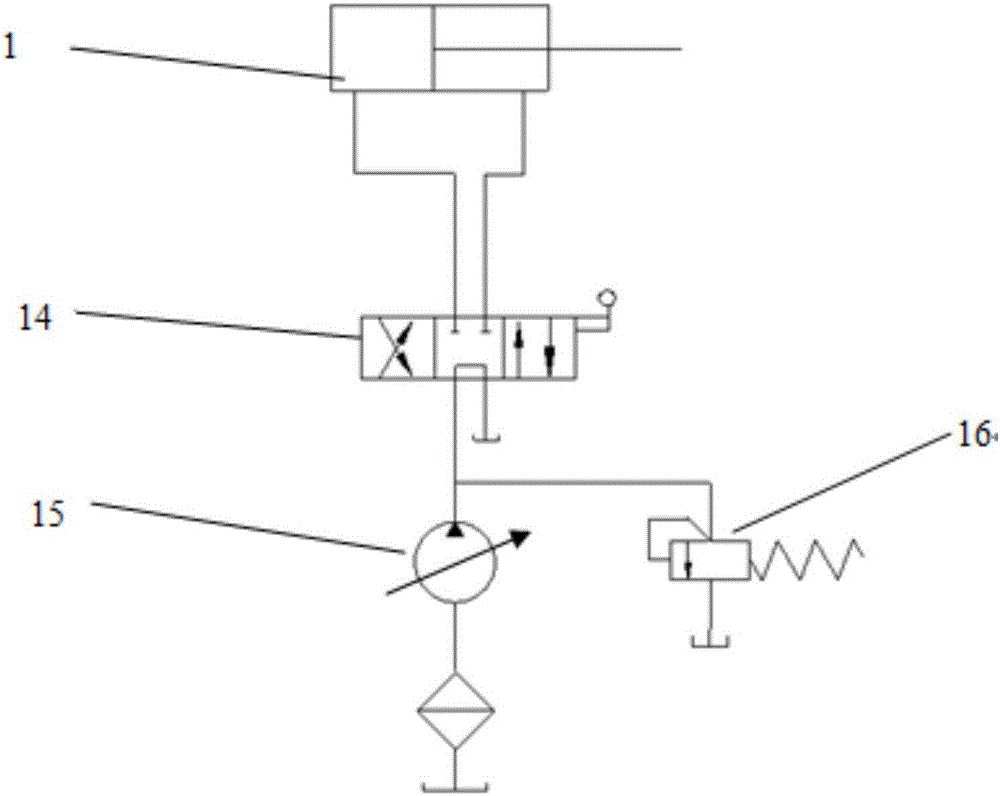

Hydraulic rock splitter

PendingCN106003428AImprove sealingImprove rigidityDisloding machinesFluid-pressure actuatorsHydraulic cylinderClassical mechanics

The invention discloses a hydraulic rock splitter which comprises a hydraulic cylinder body, a piston rod, a sealing block, a connector, a splitting block, a wedge block, a spring and a handle. The hydraulic cylinder body is composed of a hydraulic cylinder barrel and the connector, and the hydraulic cylinder body is sealed through the connector and a sealing piece. A force transmission device of the splitter is composed of the piston rod and the wedge block, and the piston rod and the wedge block are matched through a cylindrical hole and a cylinder and connected through a fastening screw. A sealing guide device of the piston rod is composed of a piston rod guide sleeve, an O-type sealing ring and an ASW-type dustproof ring which are mounted in an inner hole of the sealing block. A motion part of the splitting block is composed of the connector, the wedge block, the spring and the splitting block. The splitting block is mounted in a T-shaped groove of the connector. The inclined plane of the wedge block is attached to the inclined plane of the splitting block. The hydraulic rock splitter has the beneficial effects of being uniform in part stress, small in equipment abrasion, high in durable degree, convenient to take, high in decomposition efficiency and little in early preparation work, and is suitable for secondary decomposition of exploited granite and large rock, and the cleanliness and yield of stone can be effectively improved.

Owner:QINGDAO UNIV OF SCI & TECH

Stabilizing strut for a chassis of a vehicle

InactiveUS8322738B2Good force transmission effectLow costConnecting rodsInterconnection systemsEngineeringRolling chassis

A stabilizing strut for a chassis of a vehicle has an elongated strut body made of sheet metal which has at least one first eye at a first longitudinal end and at least one second eye at a second longitudinal end. The strut body has a curvature at least such that the strut body lies completely outside an imaginary connecting straight line between the at least one first and the at least one second eye at least in a partial region. The strut body is built up from two individual sheet metal parts which are arranged one on each side of a longitudinal center plane. The two sheet metal parts are joined to one another between the at least one first eye and the at least one second eye at their peripheral edges on a longitudinal side of the sheet metal parts oriented towards the imaginary connecting straight line, at least over a partial length of this longitudinal side of the strut body which amounts to at least 50% of the total length of this longitudinal side of the strut body. The surfaces oriented towards one another of the two sheet metal parts are spaced from one another. The peripheral edges of the sheet metal parts on the longitudinal side oriented away from the imaginary connecting straight line are not joined to one another, or at most are joined over a partial length of this longitudinal side of the strut body which amounts to not more than 50% of the total length of this longitudinal side.

Owner:PROGRESS WERK OBERKIRCH

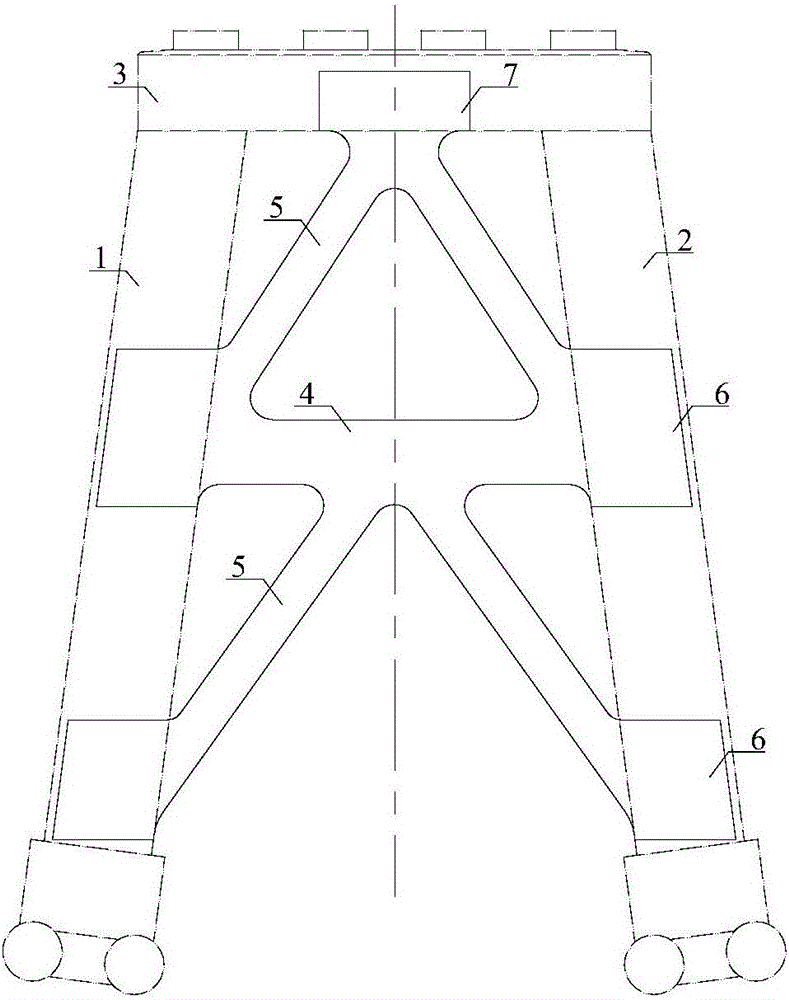

Steel K brace-hollow concrete column pier

InactiveCN106835955AShorten the construction periodIncrease stiffnessBridge structural detailsBridge materialsEngineeringHollow core

The invention discloses a steel K brace-hollow concrete column pier for effectively shortening a construction period of a bridge and reducing bridge construction investment. The steel K brace-hollow concrete column pier comprises a left hollow concrete pier stud, a right hollow concrete pier stud, a stud roof beam, and a steel K brace formed by a steel K brace cross bar and a steel K brace sway rod; pier body force transfer connecting components are pre-buried into the left hollow concrete pier stud and the right hollow concrete pier stud along a longitudinal interval; a roof beam force transfer connecting component is pre-buried into the middle of the stud roof beam; two ends of the steel K brace cross rod are fixedly connected with the pier body force transfer connecting components and the top end is fixedly connected with the roof beam force transfer connecting component; and two ends of the stud roof beam and the left hollow concrete pier stud and the right hollow concrete pier stud are solidified into a whole separately.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

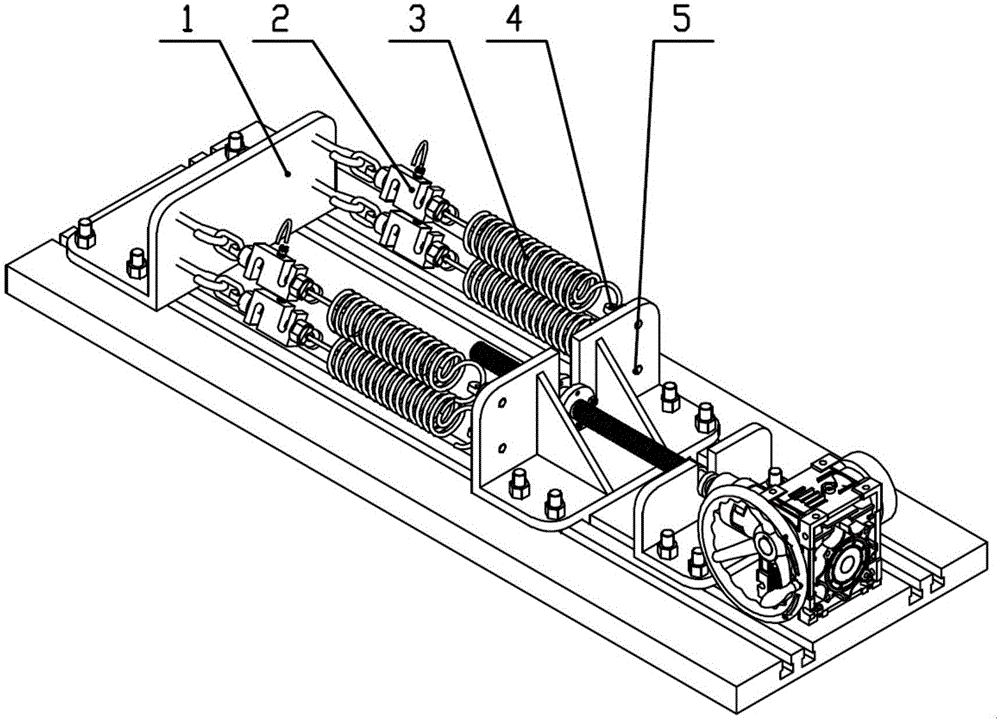

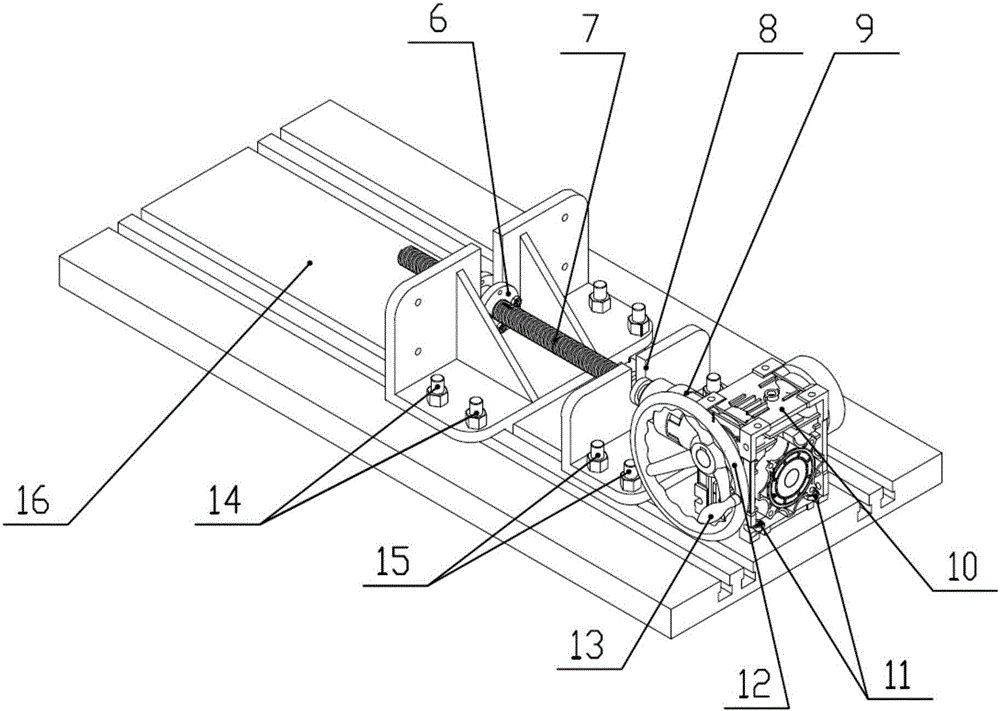

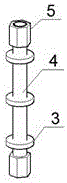

Testing table for detecting the relaxation of high voltage breaker closing spring stress

ActiveCN106370402ATest for stress relaxationQuantitative description of stress relaxationMachine part testingPull forceEngineering

The invention discloses a testing table for detecting the relaxation of high voltage breaker closing spring stress, which comprises a substrate, a spring fixing plate, a spring moving platform, a screw rod fixing plate, a hand wheel and a speed reducer. The spring fixing plate and the screw rod fixing plate are fixedly arranged on the substrate; the spring moving platform is capable of sliding in the track of the T shaped groove arranged on the substrate through a T shaped sliding block. The spring fixing plate is provided with a plurality of pressure pulling sensors. The spring moving platform is provided with corresponding suspension ring screw nails. The to-be-tested springs are placed between the suspension ring screw nails and the pressure pulling sensors. The spring moving platform is connected with the screw rod fixing plate through a leading screw and nut mechanism; the screw rod fixing plate is provided with a clamping groove. The transmission screw rod of the leading screw and nut mechanism is provided with a clamping ring cooperating with the clamping groove. The hand wheel is connected to the end part of the transmission screw rod through the speed reducer. Through the hand wheel and the speed reducer, great torque is provided to the transmission screw rod so that the leading screw and nut mechanism can provide strong pulling force to the spring moving platform and that a plurality of the to-be-tested springs are tested at the same time.

Owner:WUHAN UNIV

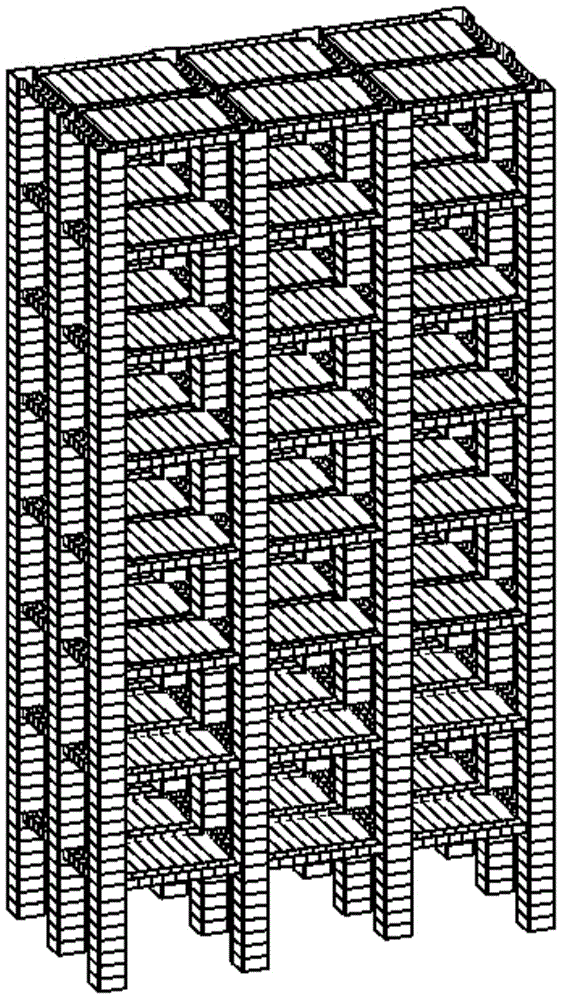

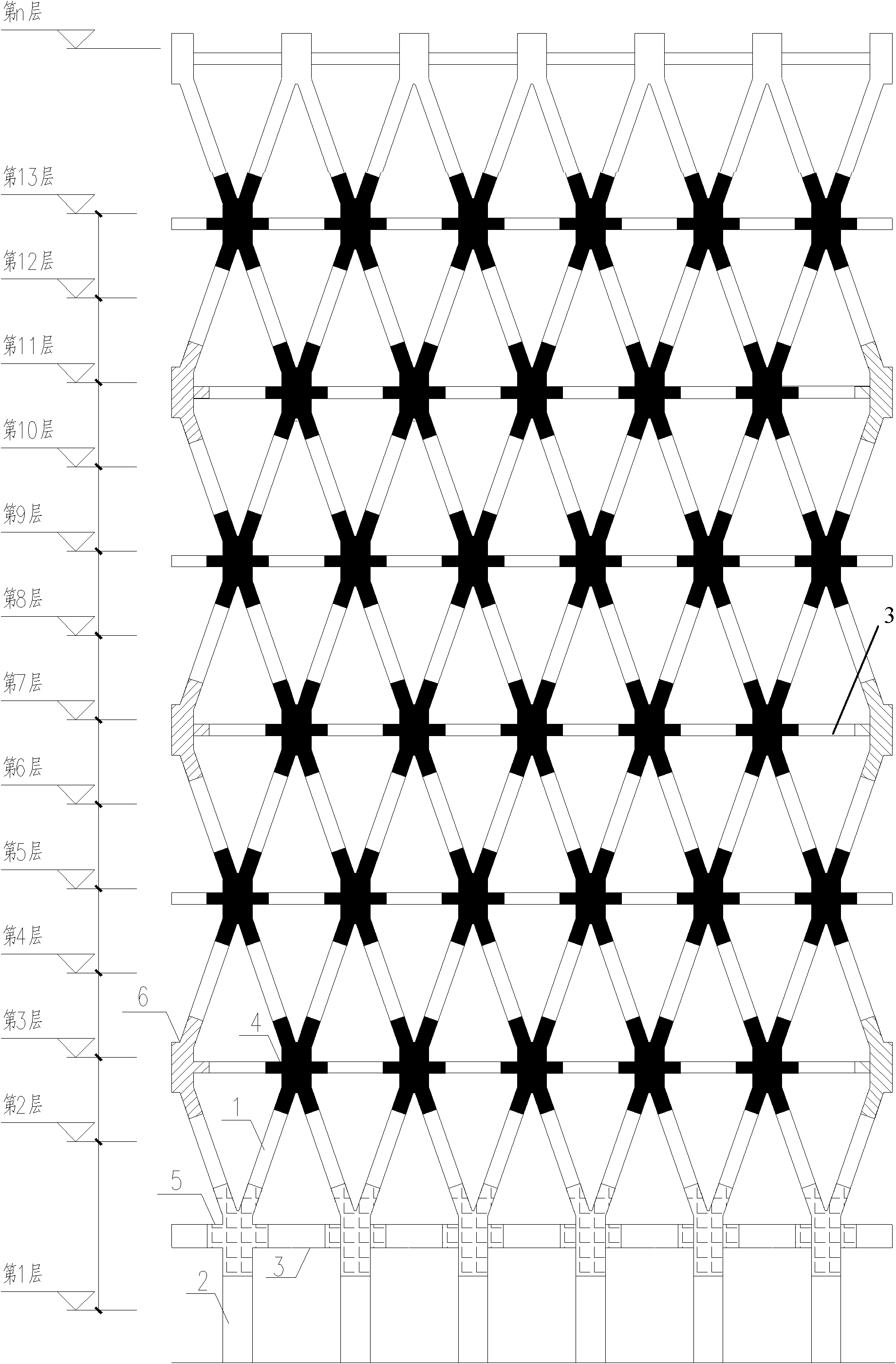

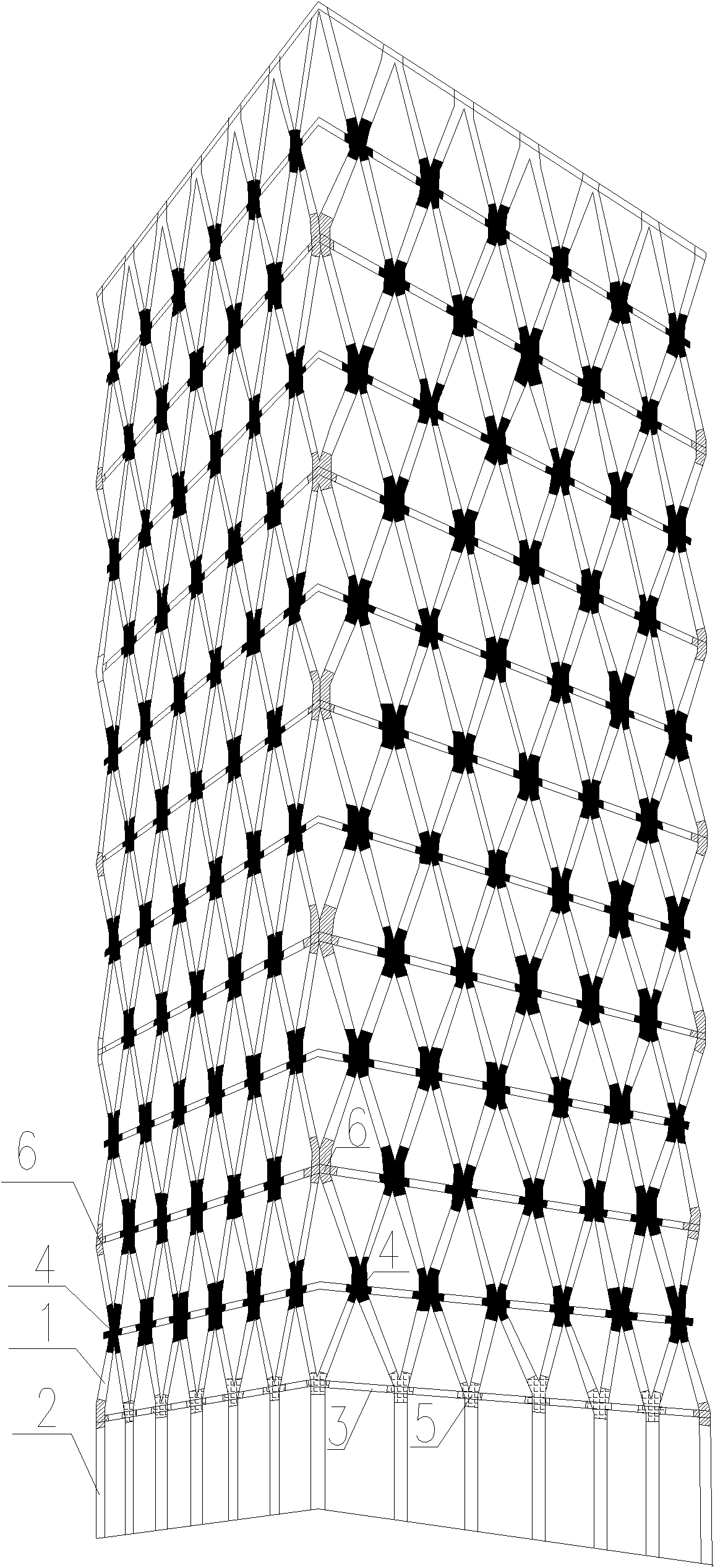

Diagrid sleeve structure for restricting connection of high strength concrete nodes

InactiveCN102031829AQuality assuranceGuaranteed Node DuctilityBuilding constructionsHigh strength concreteReinforced concrete column

The invention provides a diagrid sleeve structure for restricting connection of high strength concrete nodes, relates to a diagrid sleeve structure in the field of civil engineering, and aims to solve the problems that the conventional reinforced concrete node with the diagrid sleeve structure has lower bearing capacity and high brittleness, is difficult to meet the basic requirements of strong nodes and weak components, and the like. In the structure, the upper end of each reinforced concrete column is connected with lower ends of two reinforced concrete counter braces through a high-strength concrete brace conversion node; every two high-strength concrete brace conversion restriction nodes are connected through a reinforced concrete gird; every four reinforced concrete counter braces are connected through a high-strength concrete vertical surface restriction cross node; every two high-strength concrete vertical surface restriction cross nodes are connected through a reinforced concrete gird to form a diagrid vertical surface; and the diagrid vertical surfaces in two adjacent directions are connected through a high-strength concrete space joint node to form the diagrid sleeve structure. The diagrid sleeve structure can be used for an outer sleeve of a super-high rise tube in a tube structure.

Owner:HARBIN INST OF TECH

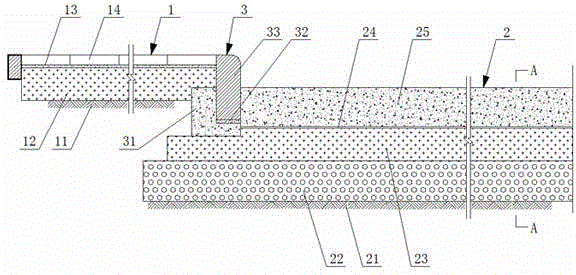

Concrete road pavement structure

InactiveCN104631268AImprove integrityLess bendingPaving reinforcementsIn situ pavingsBrickSurface layer

The invention relates to a concrete road pavement structure which comprises a sidewalk pavement and a roadway pavement, wherein an isolation road edge is arranged between the sidewalk pavement and the roadway pavement; the sidewalk pavement comprises a first base soil layer; a first cement macadam base layer is laid on the first base soil layer; a first mortar layer is laid on the first cement macadam base layer; a water permeable brick layer is laid on the first mortar layer; the roadway pavement comprises a second base soil layer; a macadam sub-base layer is laid on the second base soil layer; a second cement macadam base layer is laid on the macadam sub-base layer; an asphalt seal layer is laid on the second cement macadam base layer; a concrete surface layer is laid on the asphalt seal layer; an embedded pipe is arranged in the macadam sub-base layer; a connecting reinforcing steel bar is arranged in the concrete surface layer just above the embedded pipe along the transverse direction; a kerf is formed in the concrete surface layer. The concrete road pavement structure has the advantages of being good in overall strength, low in construction difficulty and good in bearing capability.

Owner:CHONGQING CREATION VOCATIONAL COLLEGE

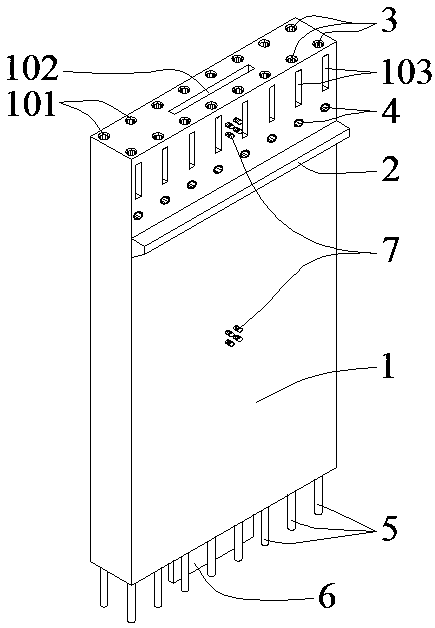

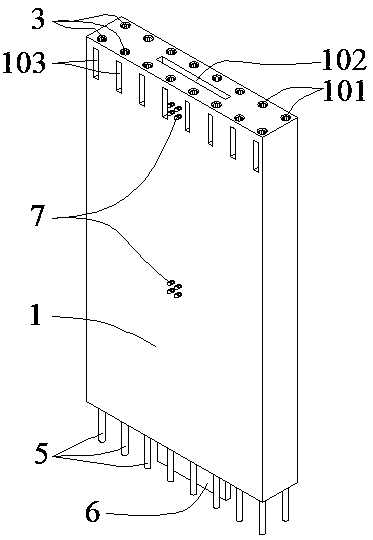

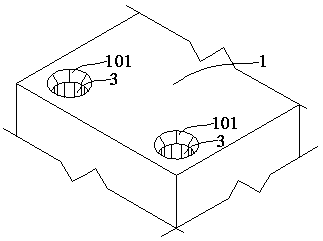

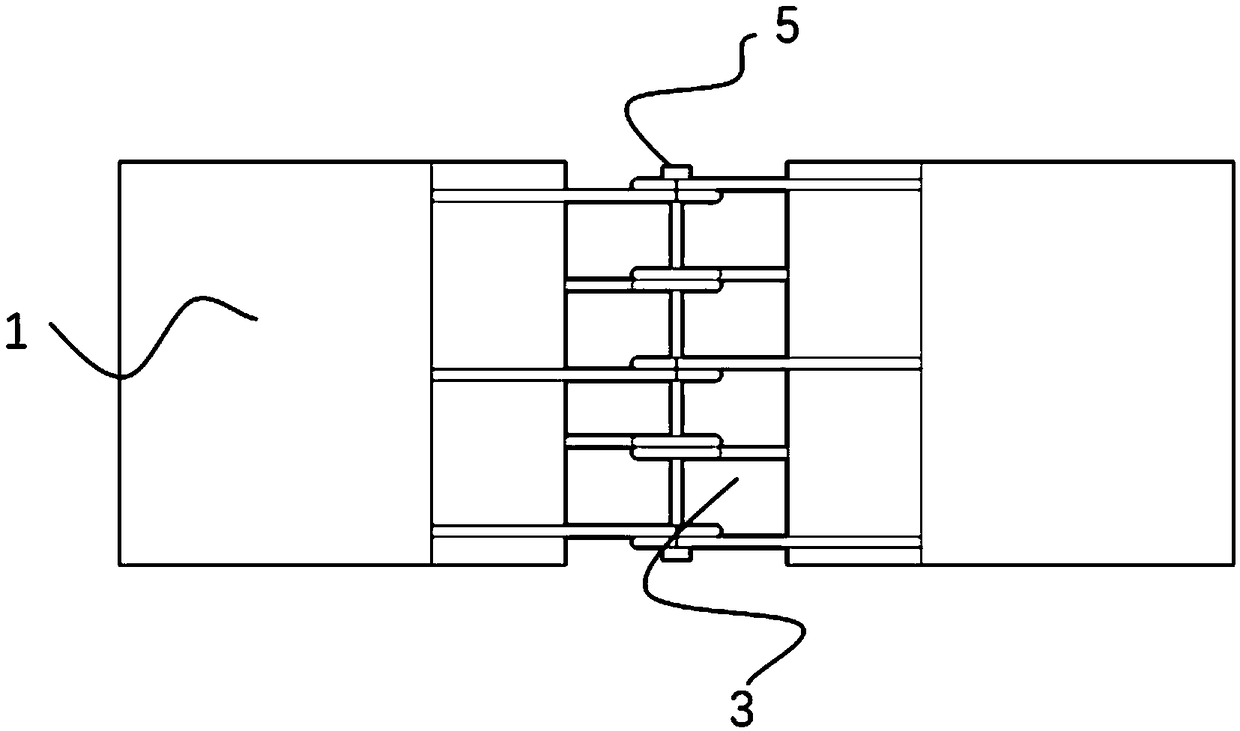

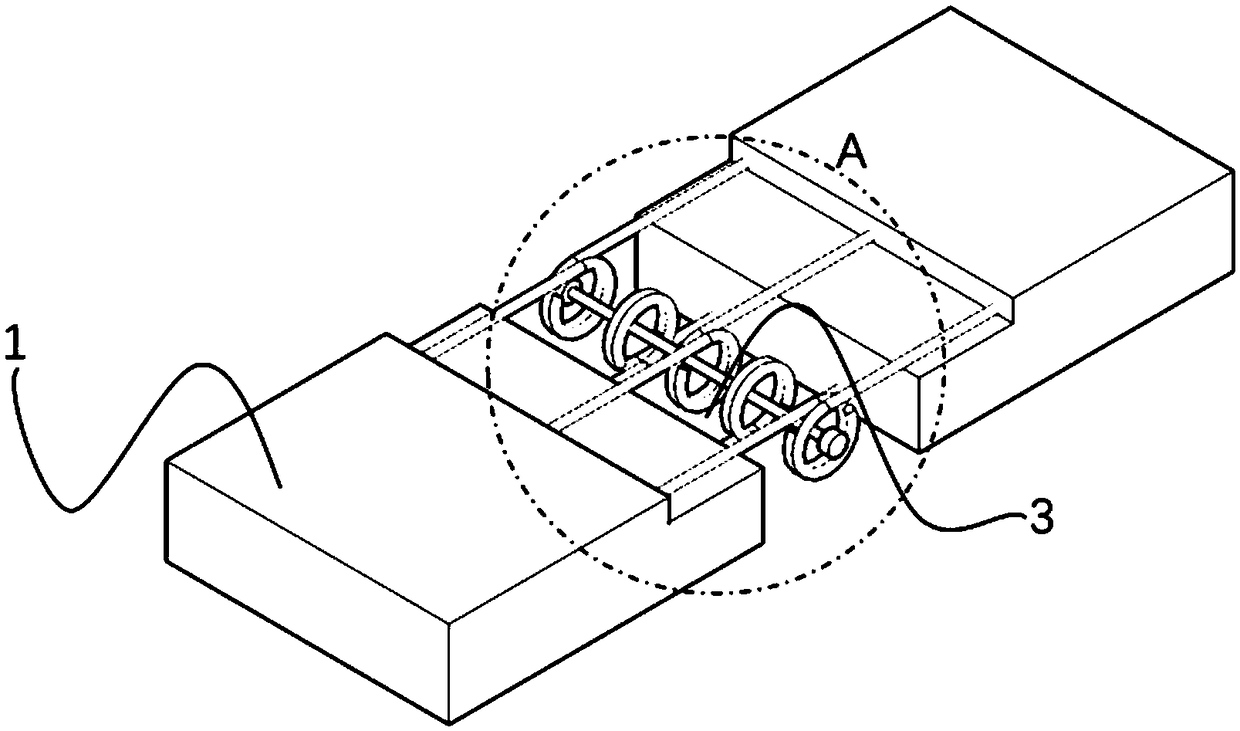

Prefabricated reinforced concrete shear wall and construction method

The invention relates to a prefabricated reinforced concrete shear wall and a construction method. The shear wall comprises a wall board, a bracket, sleeves, casing pipes, joint bars, a steel plate and anchor bolts and is characterized in that the bracket is located on the lateral side of the wall board, the sleeves are pre-embedded into the upper portion of the wall board, the casing pipes are pre-embedded into the lateral side of the wall board, the joint bars and the steel plate extend out from the bottom surface of the wall board, and the anchor bolts are pre-embedded into two lateral sides of the wall board; each sleeve comprises an outer tube, a pressing piece and bolts, the upper portion of each sleeve is in squeezing connection with one joint bar, and the lower portion of each sleeve is connected with one joint bar in a threaded and sleeved manner. During construction, downward pressure is applied through supports to allow two walls to contact tightly, and bolts on the sleevesare screwed to clamp the joint bars to achieve squeezing connection. The prefabricated reinforced concrete shear wall has the advantages that the stress and construction problems of the prefabricatedreinforced concrete shear wall can be solved, node areas are good in stress performance and seismic performance, firm vertical reinforcing bar connection is achieved, and the shear wall is easy to construct.

Owner:SHANDONG UNIV OF SCI & TECH

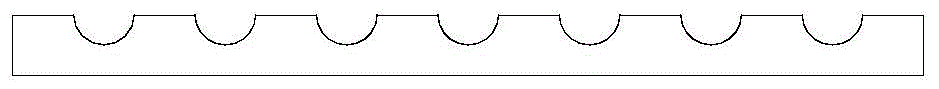

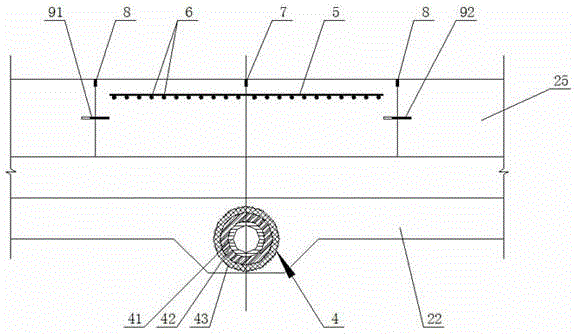

Prefabricated concrete bridge deck slab wet joint structure

PendingCN108708274AImproved ability to transmit shear and bending momentsPrevent generation and expansionClimate change adaptationBridge structural detailsRebarBending moment

The invention provides a prefabricated concrete bridge deck slab wet joint structure. The wet joint structure comprises a plurality of prefabricated concrete bridge deck slabs erected on longitudinalbeams; a step-shaped wet joint in the direction along a bridge is formed between the every two adjacent prefabricated concrete bridge deck slabs in a spaced mode; and the sides, close to the wet joints, of the prefabricated concrete bridge deck slabs are provided with upper-layer pre-embedded steel bars and lower-layer pre-embedded steel bars which all extend to the outer sides of the prefabricated concrete bridge deck slabs; engineered cementitious composites (ECC) concrete is poured into the wet joints in a cast-in-place mode; and the every two adjacent prefabricated concrete bridge deck slabs are connected into a whole through adjacent ECC concrete. According to the wet joint structure, the ability of transmitting shear force and bending moment of the wet joints is improved, and generating and expansion of cracks at the wet joints can be effectively prevented.

Owner:CHONGQING UNIV

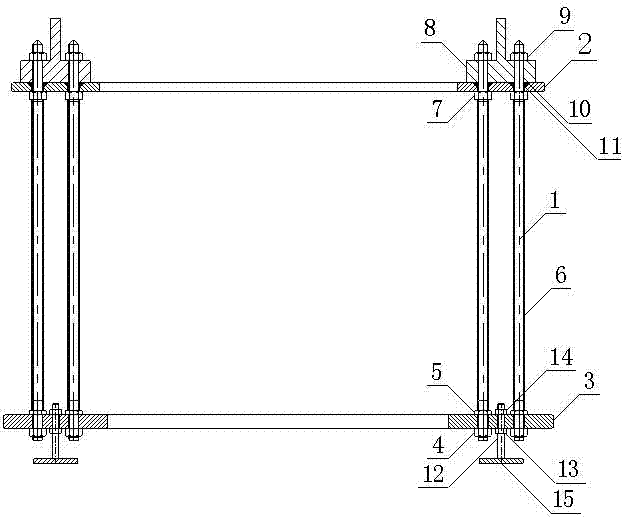

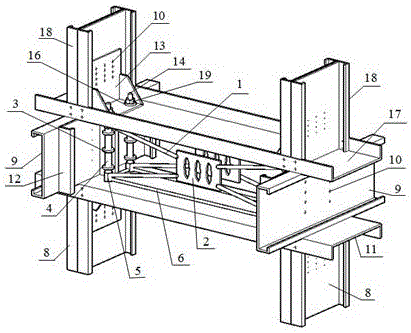

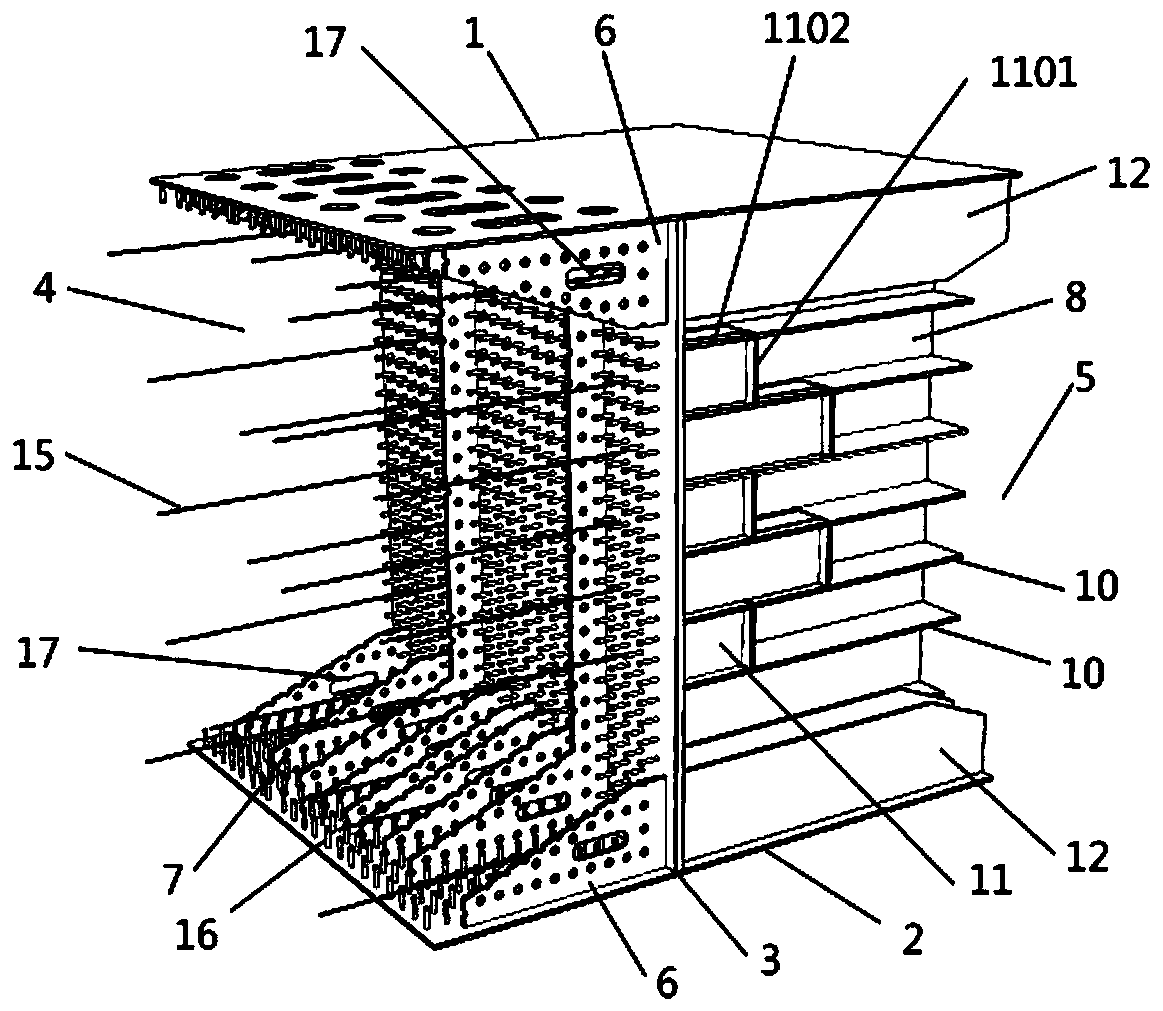

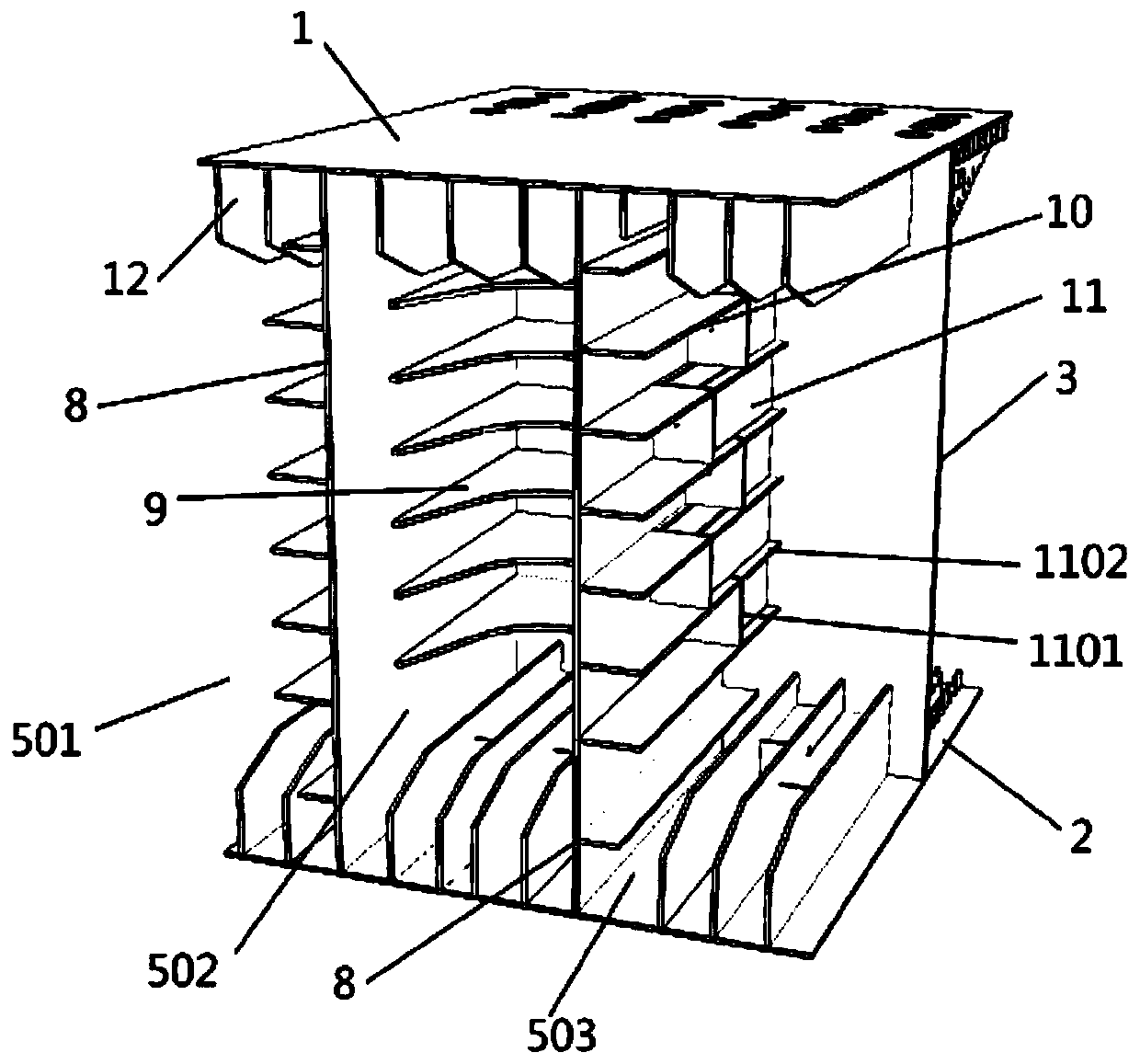

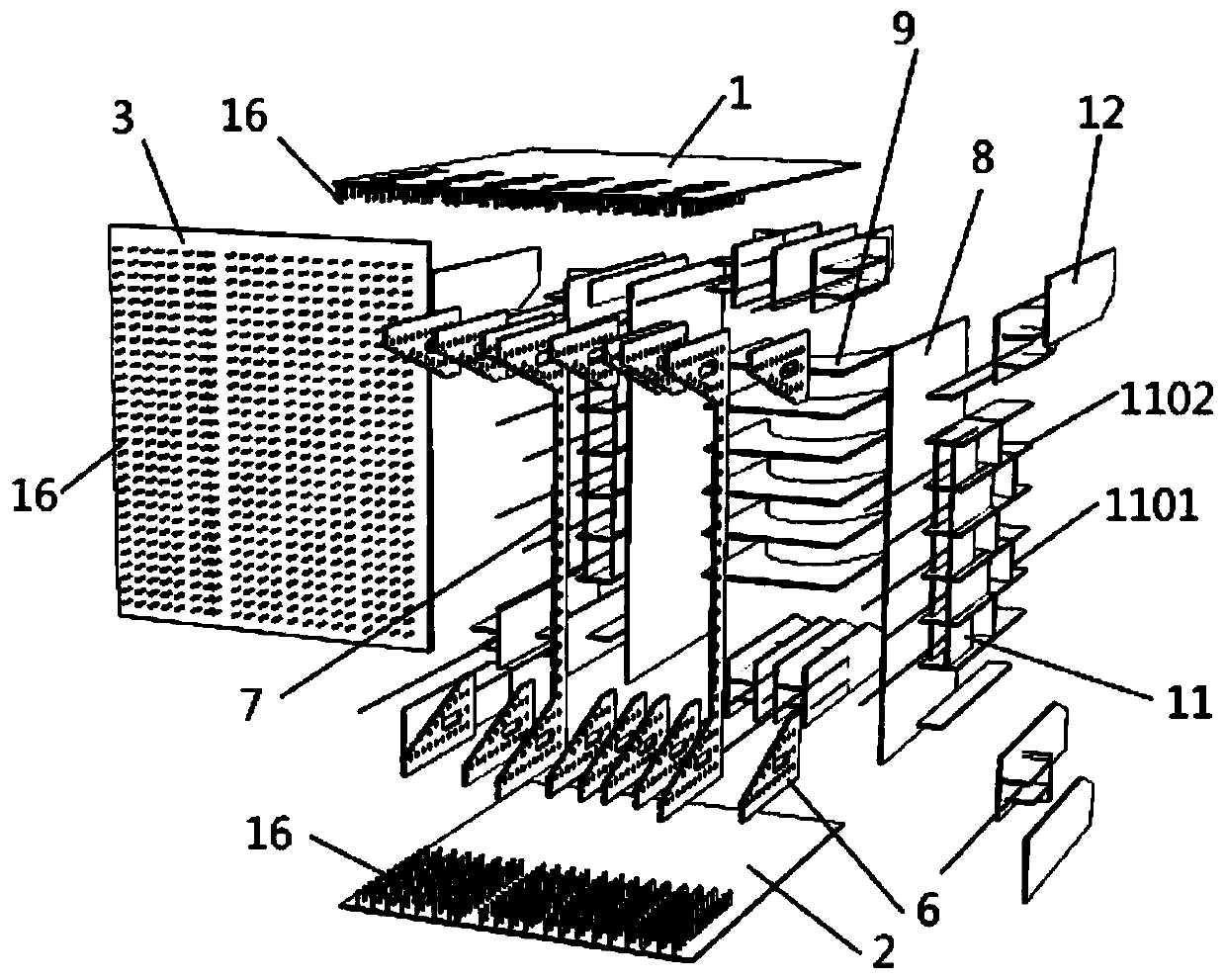

Cold-formed thin-walled steel-structure house outer wall structure system

A cold-formed thin-walled steel-structure house outer wall structure system comprises beams and wall frame pillars, and the beams and the wall frame pillars are in cooperation with one another. The cold-formed thin-walled steel-structure house outer wall structure system is characterized in that the wall frame pillars comprise lower layer pillars (8) and upper layer pillars (18); the beams comprise floor beams (9), a top beam (11) and a bottom beam (17); the tops of the two adjacent lower layer pillars (8) are fixedly embedded in the top beam (11); pulling resistant pieces (13) are connected between the inner walls of the lower layer pillars (8) and the top beam (11), the floor beams (9) are fixed above the top beam (11), and the bottom beam (17) is fixed above the floor beams (9); the bottoms of the two adjacent upper layer pillars (18) are fixedly embedded in the bottom beam (17); pulling resistant pieces (13) are connected between the inner walls of the upper layer pillars (18) and the bottom beam (17); and a truss type strengthening part is installed between the top beam (11) and the bottom beam (17), and the truss type strengthening part is fixed to the top beam (11) and the bottom beam (17) through spacers (16) and nuts (19) after pulling resistant anchor bolts (14) penetrate through bolt holes (15), the top beam (11), steel sleeves (4) and the bottom beam (17).

Owner:SOUTHWEAT UNIV OF SCI & TECH

Large-span steel box hybrid beam short combination section structure of high-speed rail

PendingCN110965457AImprove stabilityEasy construction and installationBridge structural detailsBridge erection/assemblySteel platesRebar

The invention discloses a large-span steel box hybrid beam short combination section structure of a high-speed rail which comprises a steel top plate, a steel bottom plate and a bearing plate, and thebearing plate is clamped between the steel top plate and the steel bottom plate and divides a steel box hybrid beam short combination section into a steel-concrete combination section and a steel beam transition section in the longitudinal bridge direction. Two steel webs of the transition section divide the steel beam transition section into a box girder outer chamber, a box girder compartment and a box girder inner chamber in the transverse bridge direction, PBL steel bars transversely penetrate through PBL perforated steel plates and C-shaped perforated steel plates on a steel top plate and a steel bottom plate of the steel-concrete combined section, and a concrete partition wall is poured in the steel-concrete combined section; the transition section steel top plate, the bottom and the web plate are provided with prestressed tendon anchor chambers, longitudinal prestressed reinforcements are anchored in the prestressed tendon anchor chambers, and the prestressed reinforcements penetrate through the bearing plate and the steel-concrete combined section and are anchored on the concrete beam section behind the combined section so as to reinforce connection between the bearing plate and the concrete partition wall. A short combination section structure has the advantages of being simple in structure, short in combination part, high in bearing capacity, convenient to constructand small in operation and maintenance workload.

Owner:SOUTHWEST JIAOTONG UNIV +2

Half-through bracket haunching type multibarrel tube-confined concrete column-steel beam node

InactiveCN105507426AIncrease stiffnessHigh strengthBridge structural detailsBuilding constructionsBridge engineeringUltimate tensile strength

The invention discloses a half-through bracket haunching type multibarrel tube-confined concrete column-steel beam node, relates to a node connecting form of a multibarrel tube-confined concrete column and a steel beam, and belongs to the technical field of constructional engineering and bridge engineering. The node comprises the multibarrel tube-confined concrete column, the steel beam and a force-transmission component. The multibarrel tube-confined concrete column comprises an inner steel pipe, an outer steel pipe and poured concrete. The steel beam comprises upper and lower flanges and a web. The force-transmission component comprises a steel bracket and an oblique haunching plate. The steel bracket comprises upper and lower flanges and a web. One end of the steel bracket penetrates the outer steel pipe to be welded to the wall of the inner steel pipe, and the other end of the steel bracket is in bolt-weld connection with the steel beam. Meanwhile, the oblique haunching plate is welded between the steel beam and the multibarrel tube-confined concrete column. The half-through bracket haunching type multibarrel tube-confined concrete column-steel beam node is simple in structure, convenient in construction, high in rigidity and strength, good in anti-seismic property, clear in force transmission path, and the like. By the node, effective force transmission between the multibarrel tube-confined concrete column and the steel beam can be achieved.

Owner:HEBEI UNIV OF TECH

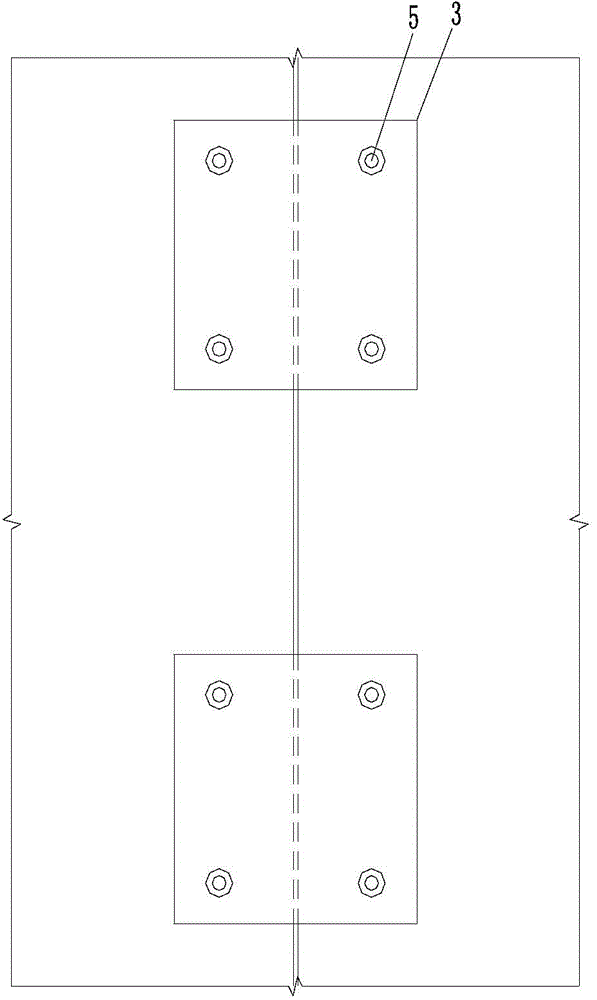

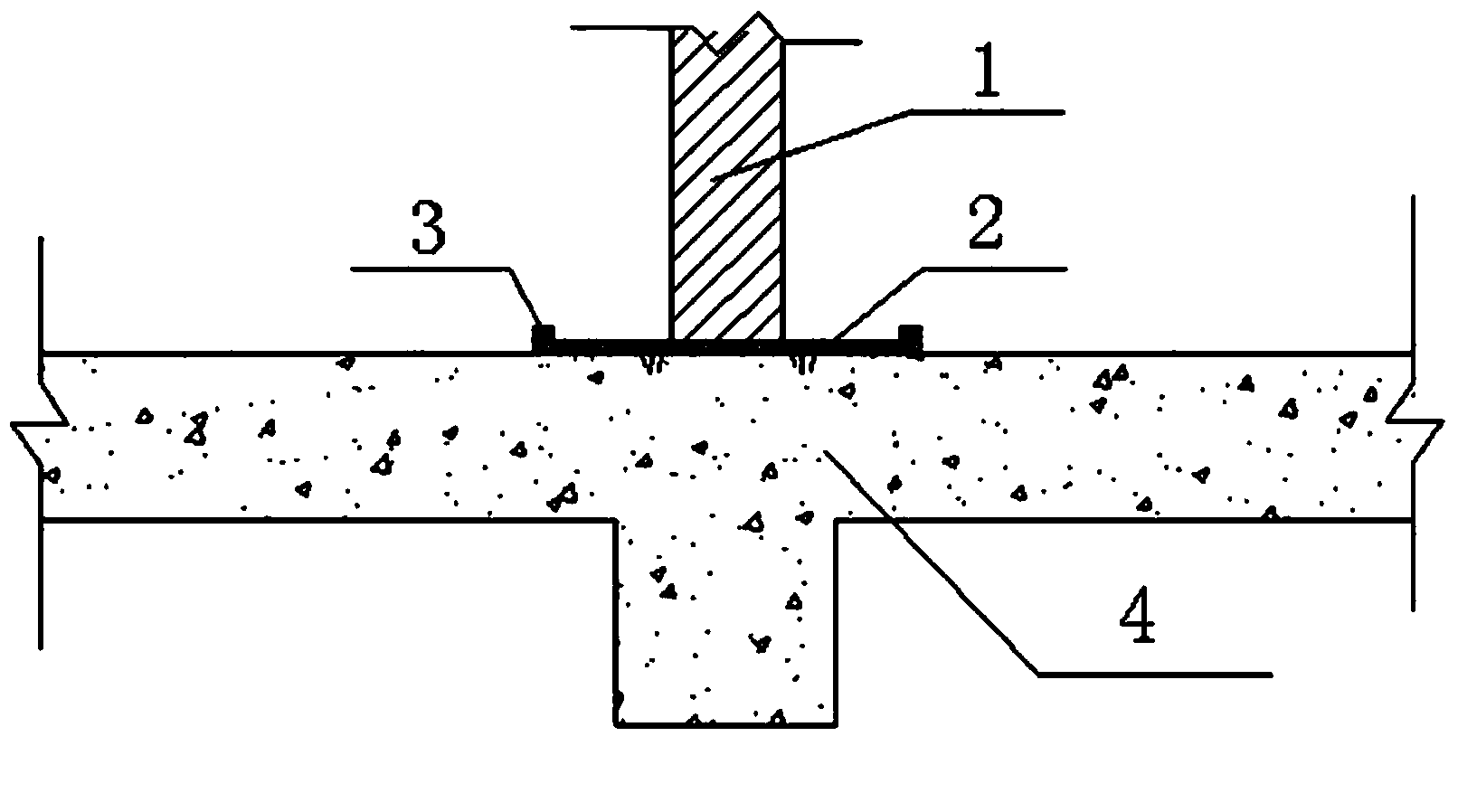

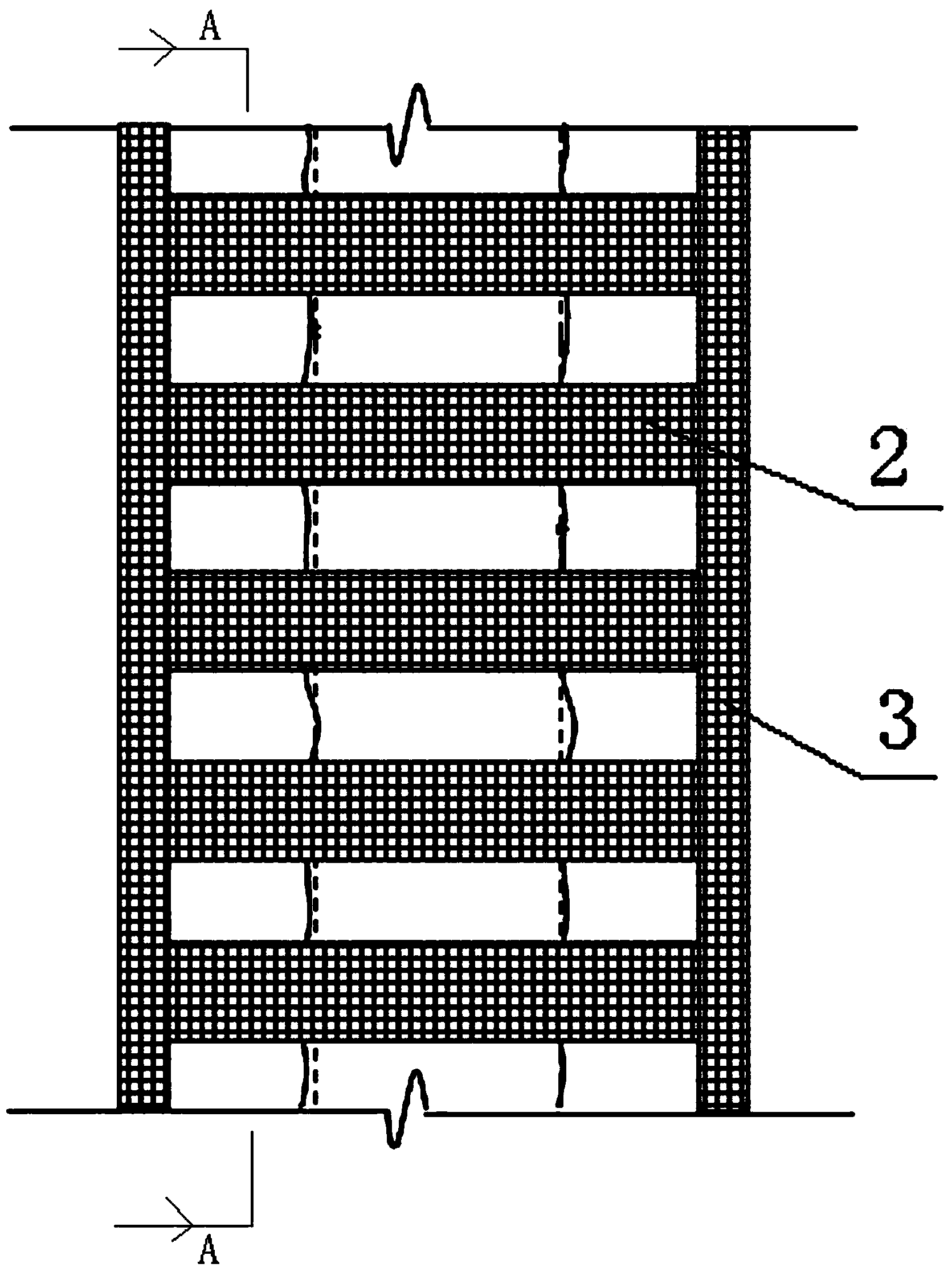

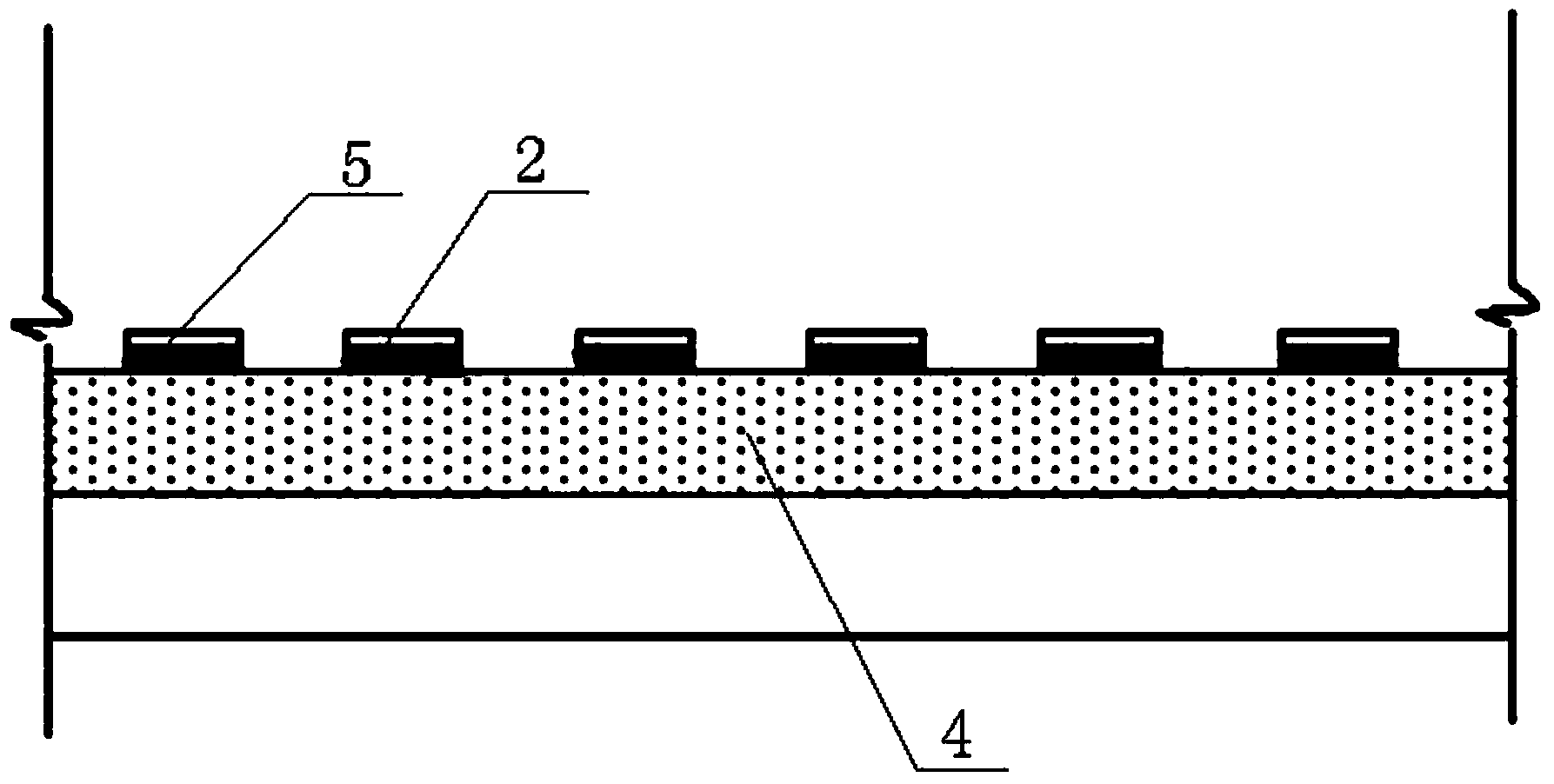

Hinge joint structure with composite shear keys and precast slab bridge thereof

ActiveCN104594189AImproved ability to transfer loadsGuaranteed coordinated deformationBridge structural detailsBridge deckShear force

The invention discloses a hinge joint structure with composite shear keys, which comprises a plurality of precast slabs, a hinge joint is formed between the precast slabs, and connecting keys which can transfer horizontal shearing force and vertical shearing force and are integrally connected with the precast slabs and the hinge joint are transversely distributed on the hinge joint; the connecting keys are stiffened steel plates with bolted shear keys which span the hinge joint and are fixed on the surfaces of the precast slabs at both sides of the hinge joint, and the stiffened steel plates are provided with through holes capable of transferring horizontal shearing force which correspond to the hinge joint; the stiffened steel plates with the through holes are shear keys, horizontal shearing force is transferred by the through holes and vertical shearing force is transferred by the stiffened steel plates, so that the force transfer property is enhanced, and thereby the stiffness and overall performance of the structure are enhanced; the bolted shear keys can transfer horizontal shearing force and enhance connection property. The coordinate deformation of a bridge deck pavement, the hinge joint and the precast slabs is ensured, the load transfer capability of the hinge joint structure is enhanced, the service life of the hinge joint structure is prolonged, maintenance cost is reduced, construction is simple and convenient, the hinge joint structure can be applied in the construction of new precast slab bridges or the maintenance and reinforcement of precast slab bridges, and effectively solves the defect of insufficient shear-resisting capability existing in precast slab bridges, and the integrity and force-transferring effectiveness of the structure are increased.

Owner:何小兵

Carbon fiber sheet through-wall reinforcement treatment method for cast-in-place floor beam top cracks

InactiveCN103470066AMeet the bearing capacity requirementsPrevent extensionBuilding repairsIndustrial buildingsEpoxyFiber

The invention relates to a carbon fiber sheet through-wall reinforcement treatment method for cast-in-place floor beam top cracks. The method includes the steps: (1) perforating the bottom of a roof brick wall; (2) performing pressure grouting on the cracks with epoxy resin grout, after grouting, trowelling and sealing positions of grout nipples with epoxy resin plaster, and performing surface treatment after sealing; (3) polishing and cleaning the floor surface at the positions for adhering carbon fiber sheets by a grinding wheel; (4) brushing the positions for adhering the carbon fiber sheets with epoxy resin binders; (5) adhering the carbon fiber sheets to the epoxy resin binders; (6) adhering carbon fiber sheet pressing strips to two ends of each carbon fiber sheet; (7) restoring a floor. The method has the advantages that pressure grouting treatment is adopted at the cracks to adhere floors on two sides of each crack together again, so that integrity of the floor and the structure is improved; due to through-wall adherence of the carbon fiber sheets, continuity, adhering, anchoring and direct tension of the carbon fiber sheets are guaranteed; the pressing strips are arranged at the ends of the carbon fiber sheets, so that combined action of the carbon fiber sheets is guaranteed.

Owner:郑州长发网络科技有限公司

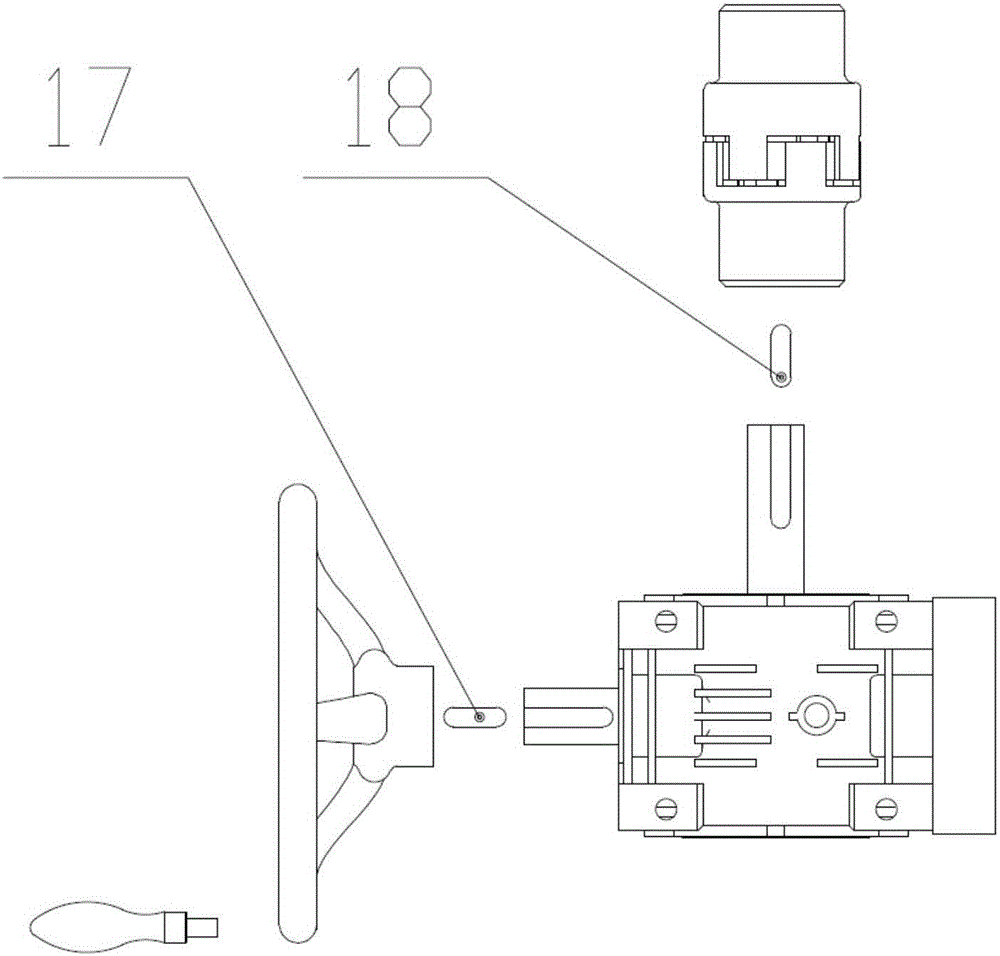

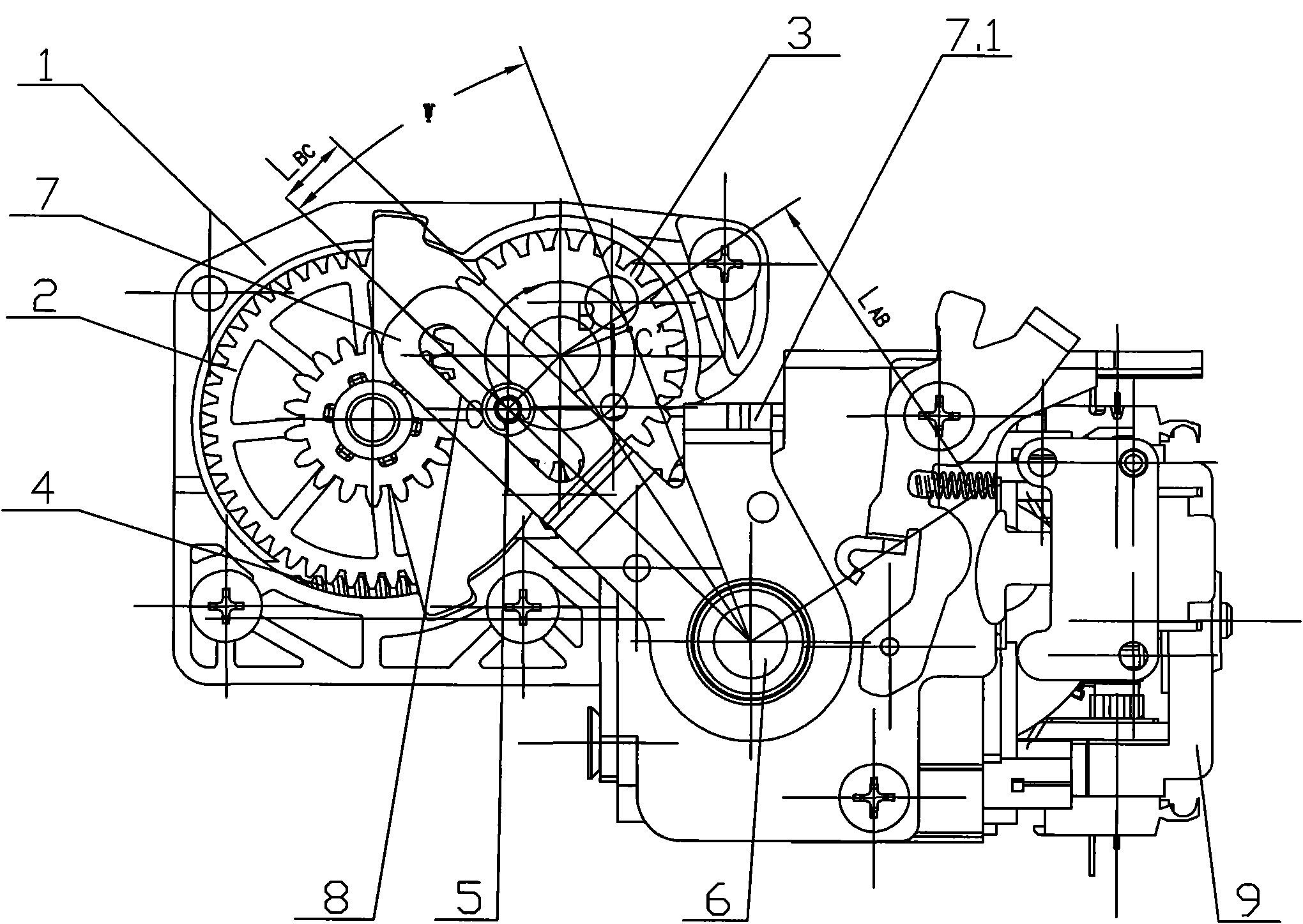

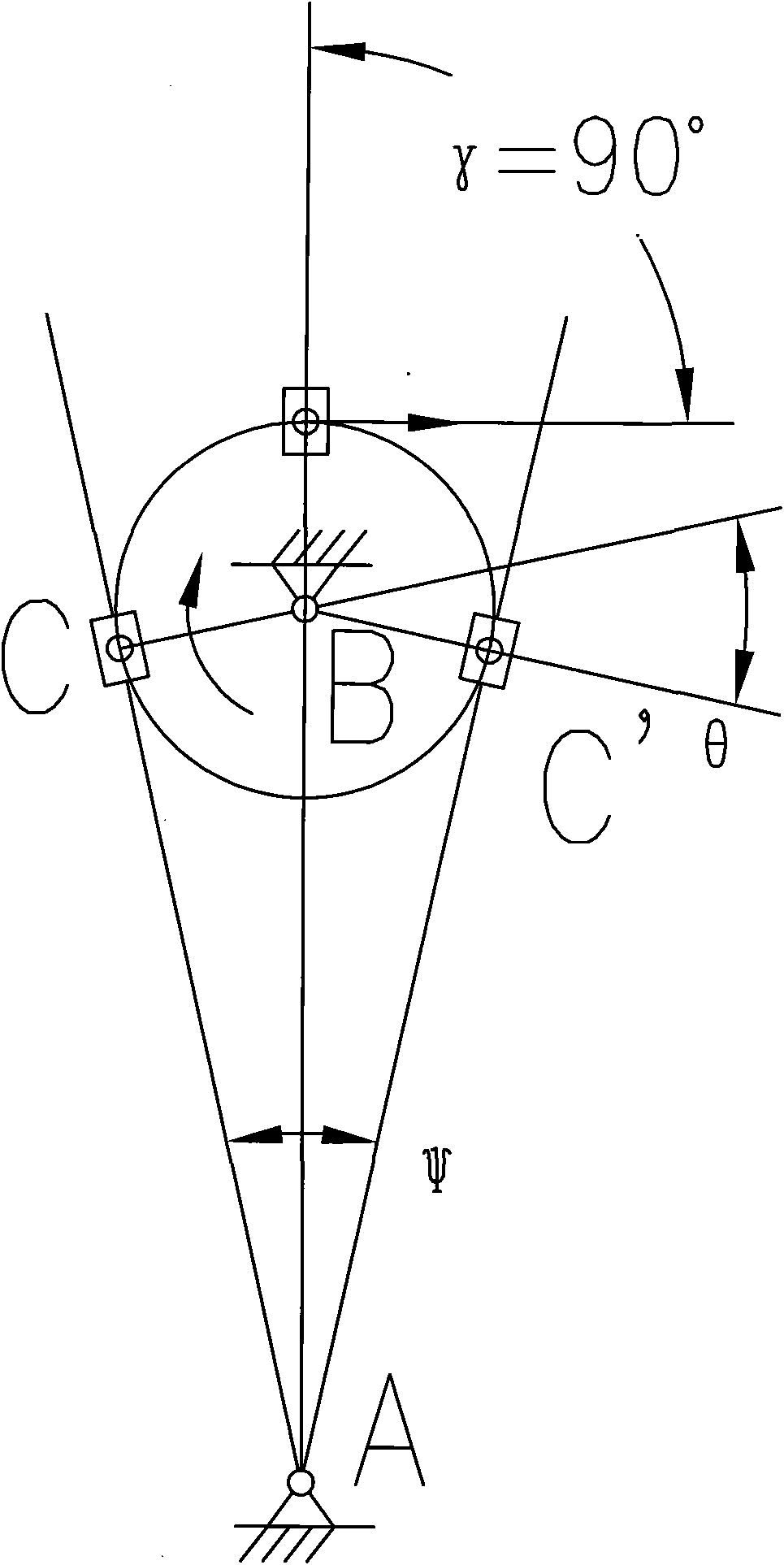

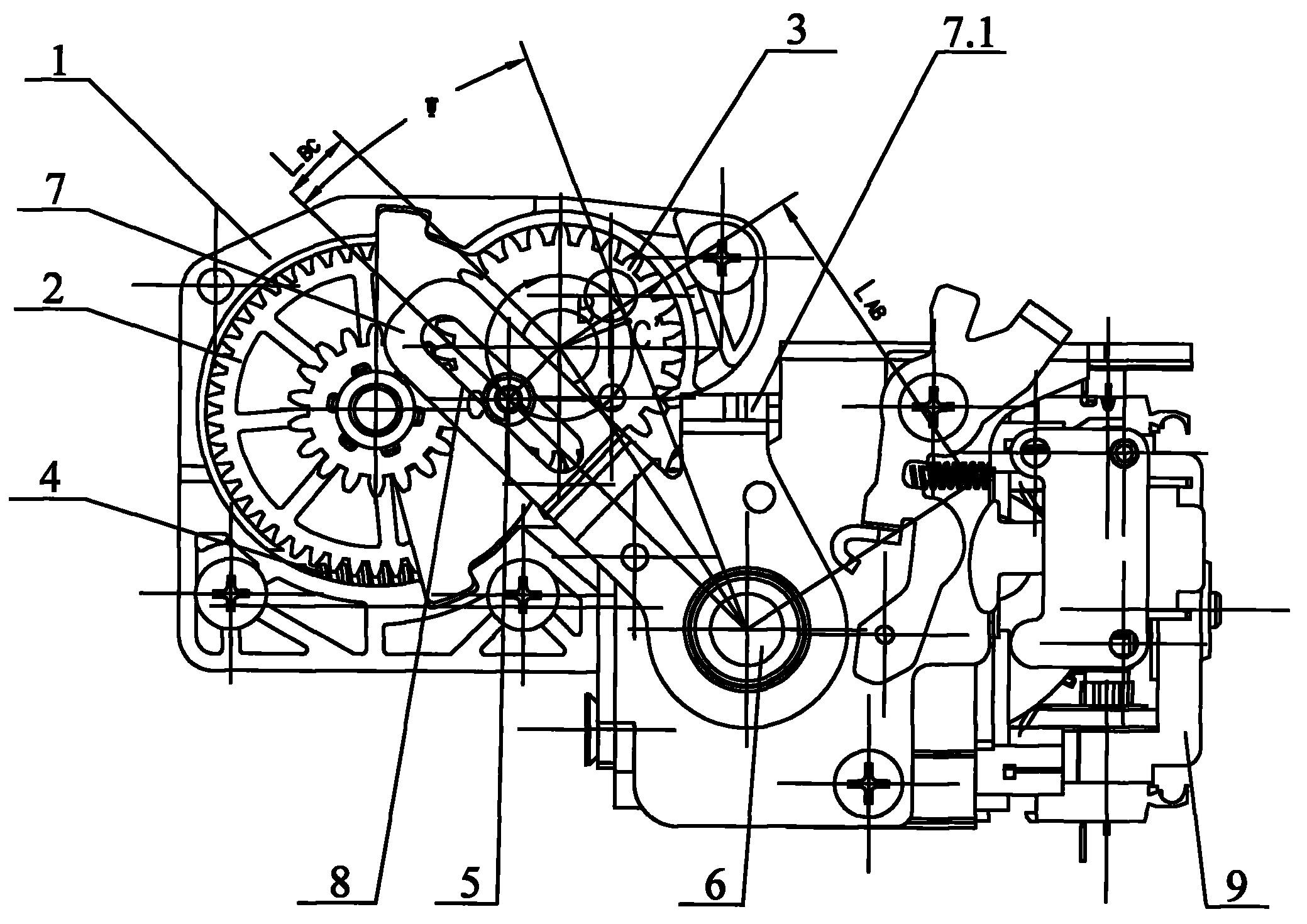

Rocking guide rod type electric operating mechanism for circuit breaker

ActiveCN101789337AGood force transmission effectSimple structureContact driving mechanismsSwitch power arrangementsGear wheelEngineering

The invention relates to a rocking guide rod type electric operating mechanism for a circuit breaker, comprising a first transmission gear, a second transmission gear and a worm which are rotationally erected in a reduction box shell by a motor, wherein the first transmission gear is meshed with the second transmission gear; the second transmission gear is fixedly provided with an eccentric shaft; the reduction box shell is provided with a pin shaft; the pin shaft is articulated with a rocking beam; the rocking beam is provided with an output tooth part and a waist-shaped hole; and the eccentric shaft is inserted into the waist-shaped hole. The invention has very good force transmitting performance because a transmission angle of the guide rod mechanism is equal to 90 degrees all the time, simple structure, small size, and the like.

Owner:WUXI KAIXUAN MOTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com