Concrete road pavement structure

A technology for concrete road and pavement structure, which is applied in the field of construction engineering to achieve the effects of avoiding local deformation and depression, increasing the overall strength and improving the overall connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

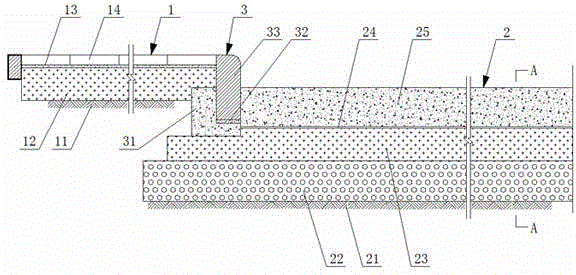

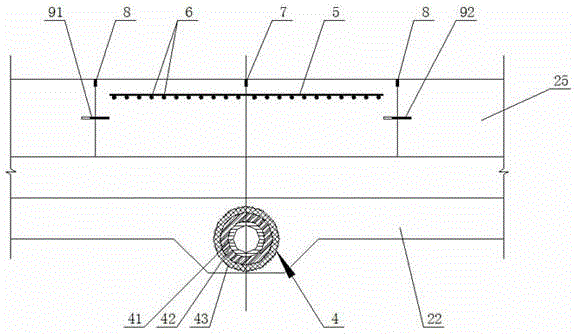

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] Such as figure 1 and figure 2 As shown, a concrete road pavement structure includes a pedestrian road surface 1 and a vehicle road surface 2, and an isolation curb 3 is arranged between the pedestrian road surface 1 and the vehicle road surface 2. Described sidewalk surface 1 comprises the first base soil layer 11 that is arranged on the lowest layer, and the compactness of described first base soil layer 11 is 87%~90%, is laid on described first base soil layer 11 with 13 ~16cm thick first cement macadam base 12, wherein the first cement macadam base 15cm thick is preferred, the cement content in the first cement macadam base 12 is 6%~8%, usually can be controlled at 7%; the first mortar layer 13 is laid on the first cement gravel base 12, and the thickness of the first mortar layer 13 is 2~3cm, wherein 2.3cm is the best. A permeab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com