Diagrid sleeve structure for restricting connection of high strength concrete nodes

A high-strength concrete and node connection technology, applied in the direction of building structure, construction, etc., can solve the problems of difficulty in meeting the basic requirements of strong nodes and weak components, low bearing capacity of reinforced concrete nodes, and difficulty in making and supporting formwork, so as to improve the ductility of nodes. , The effect of simplifying the production of joints and supporting the formwork, and simplifying the construction procedures of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

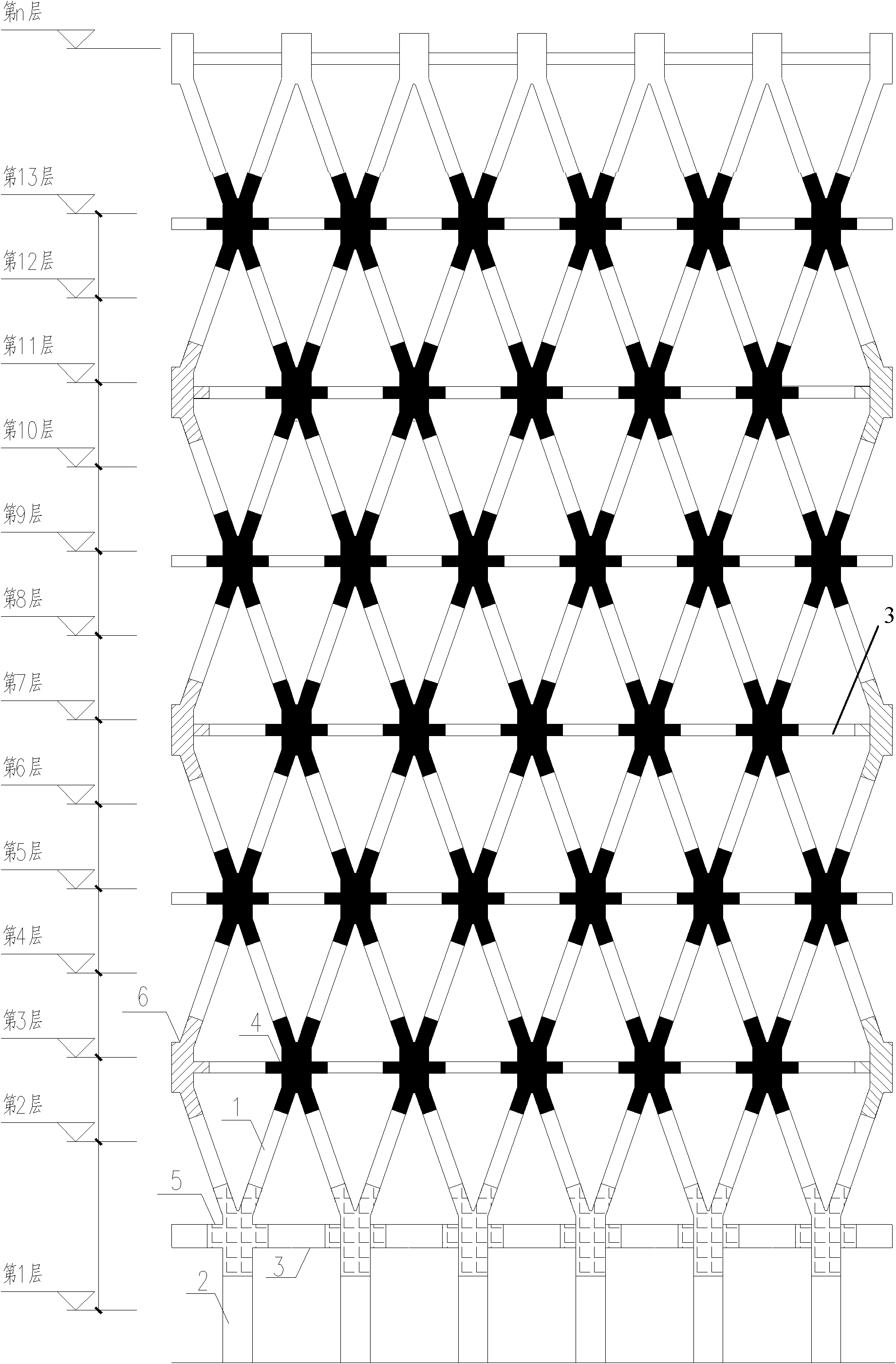

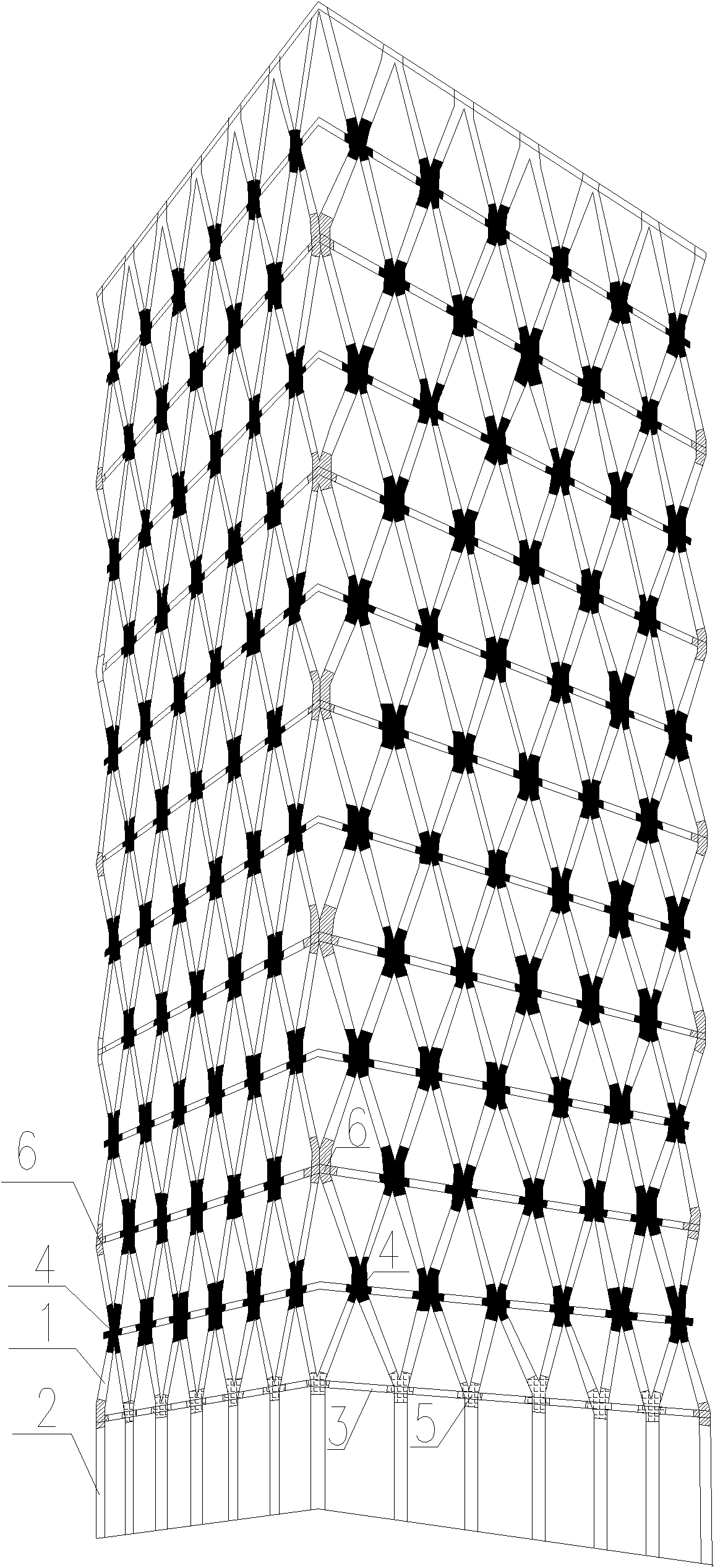

[0009] Specific implementation mode one: as Figure 1~5 As shown, the oblique grid tube structure connected by constrained high-strength concrete nodes in this embodiment includes a plurality of reinforced concrete cross slanted columns 1, a plurality of reinforced concrete columns 2, a plurality of reinforced concrete girders 3, and a plurality of A constrained high-strength concrete facade intersection node 4, multiple constrained high-strength concrete slanted column conversion nodes 5, and multiple constrained high-strength concrete space intersection nodes 6; multiple reinforced concrete columns 2 are all arranged on the ground floor, and each reinforced concrete column The upper end of 2 is connected to the lower ends of two reinforced concrete cross slanted columns 1 through a constrained high-strength concrete slanted column conversion node 5, and every two constrained high-strength concrete slanted column conversion nodes 5 are connected through a reinforced concrete g...

specific Embodiment approach 2

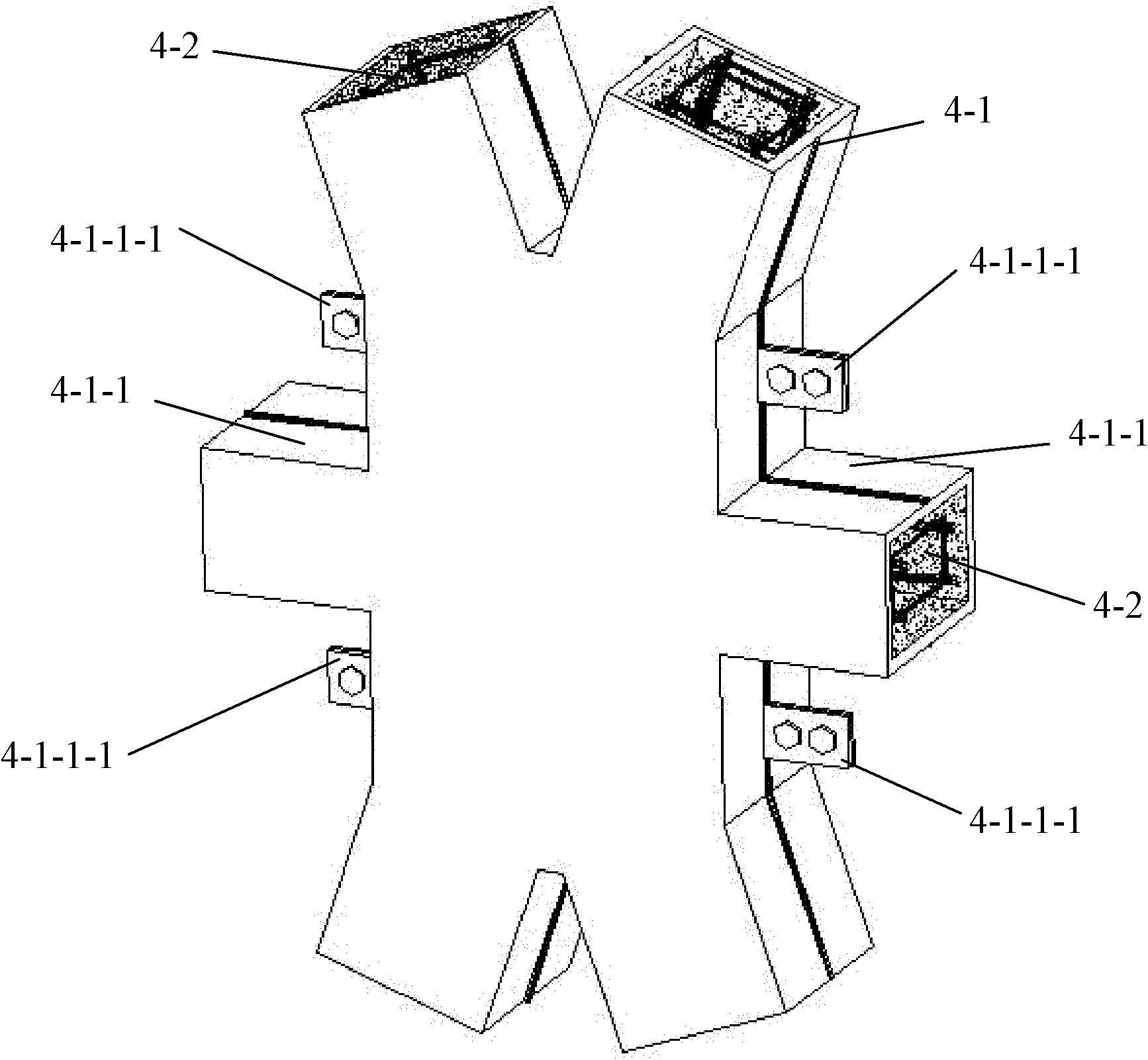

[0011] Specific implementation mode two: as Figure 1~5 As shown, each constrained high-strength concrete façade intersection node 4 in this embodiment is composed of an external intersection node steel formwork 4-1 and an intersection node reinforced high-strength concrete 4-2 built in its cavity. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: as Figure 1~5 As shown, each constrained high-strength concrete slanted column transfer node 5 in this embodiment is composed of an external transfer node steel formwork 5-1 and a transfer node reinforced high-strength concrete 5-2 built in its cavity. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com