Patents

Literature

142 results about "Body force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A body force is a force that acts throughout the volume of a body. Forces due to gravity, electric fields and magnetic fields are examples of body forces. Body forces contrast with contact forces or surface forces which are exerted to the surface of an object.

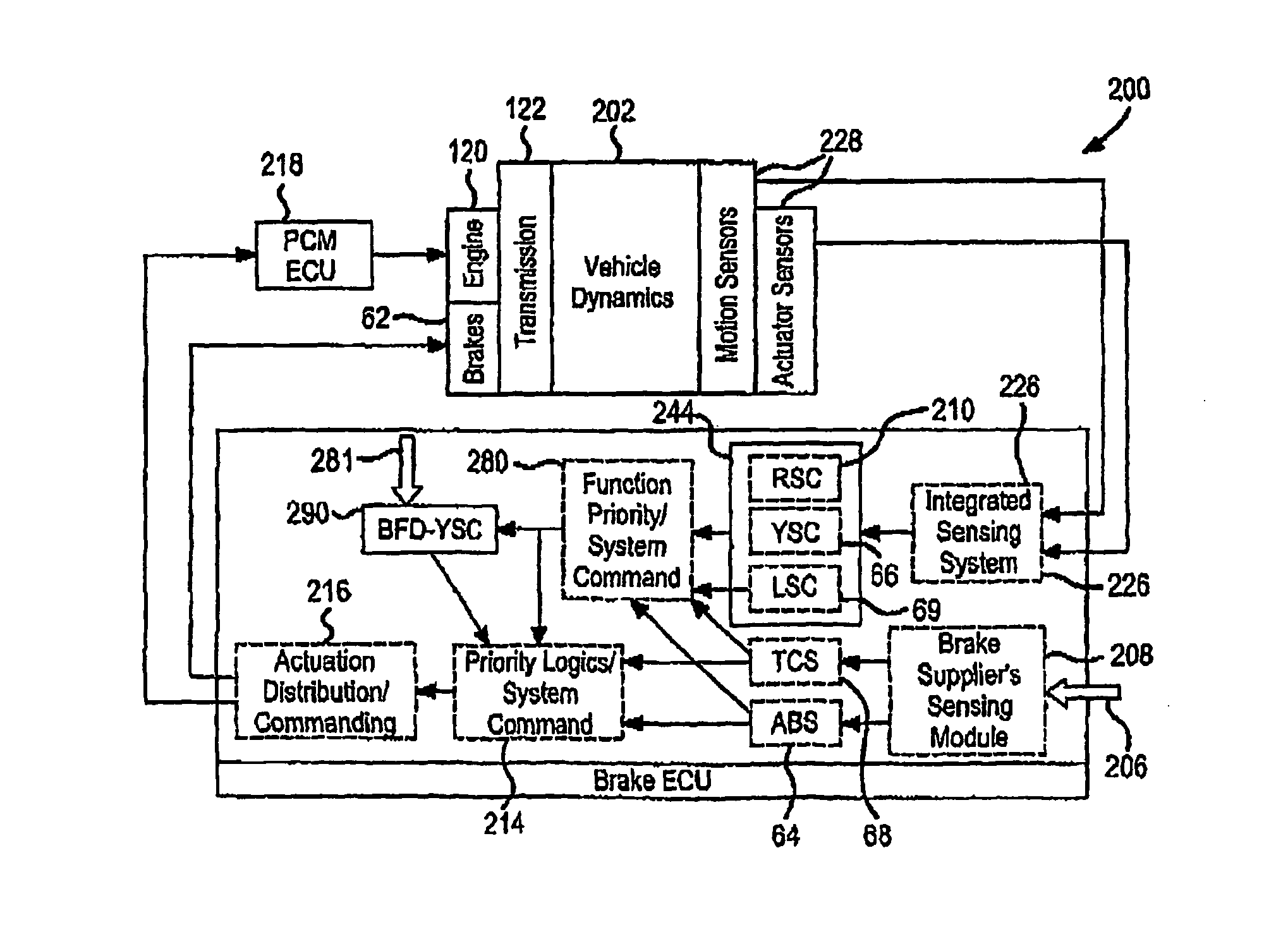

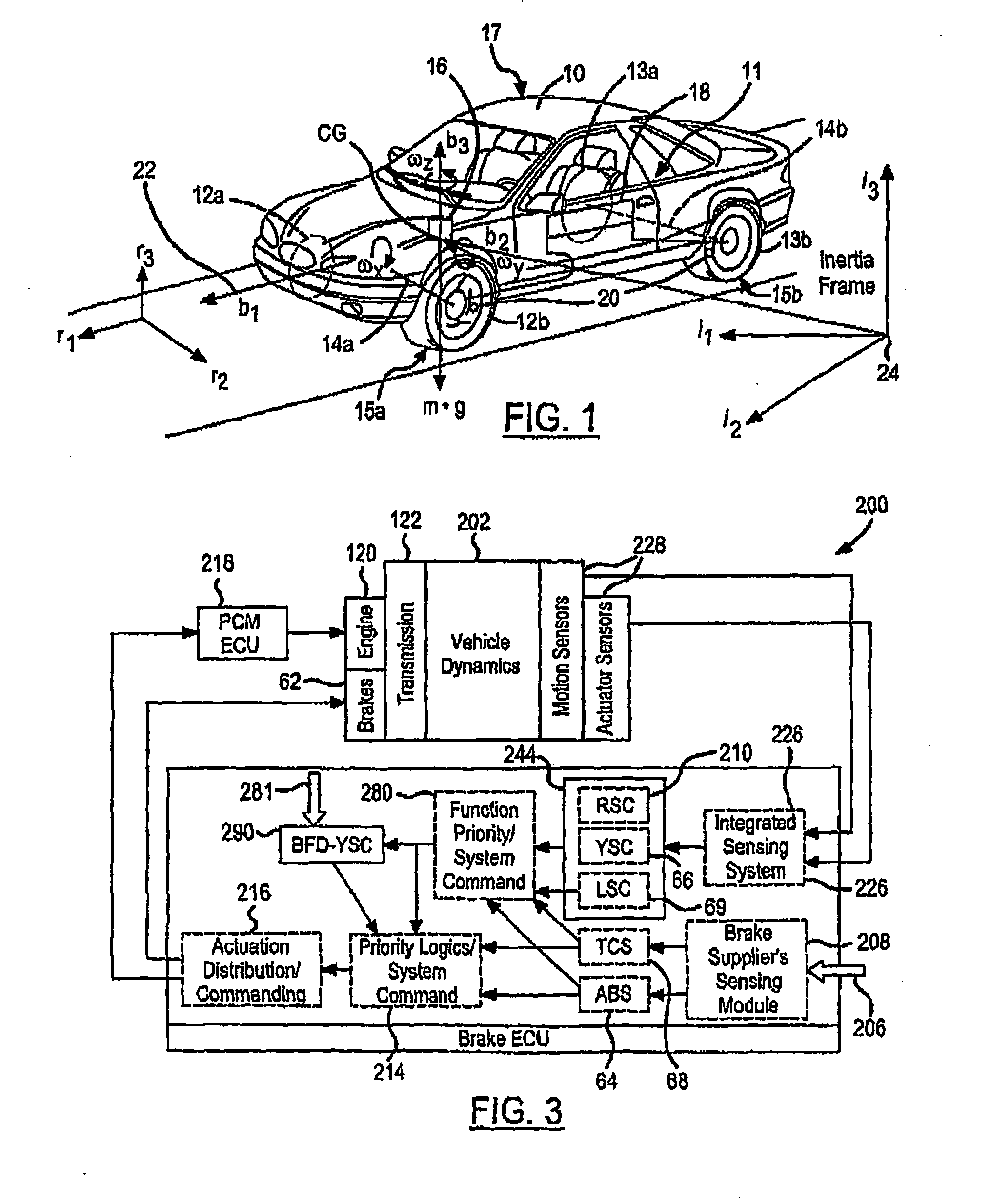

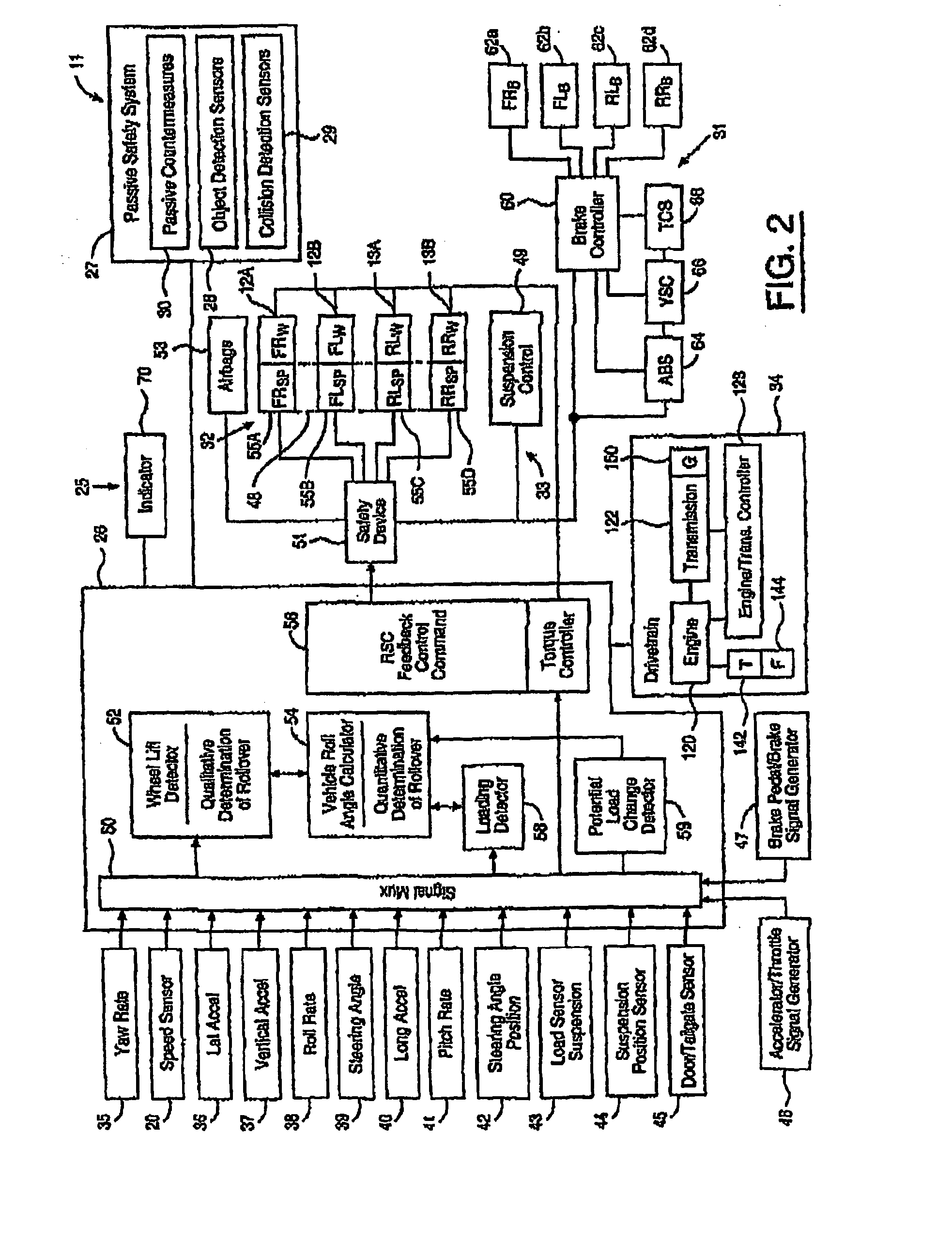

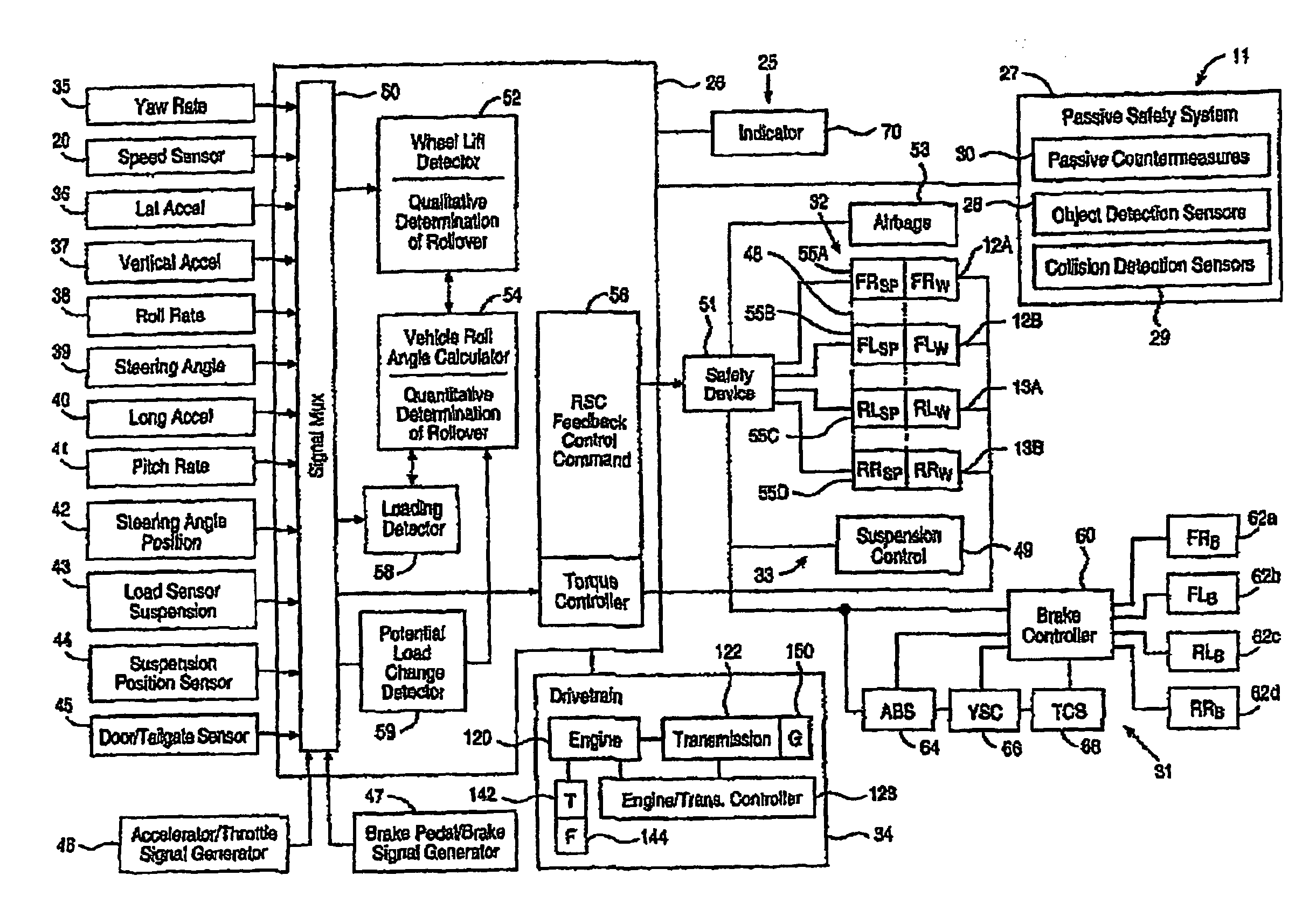

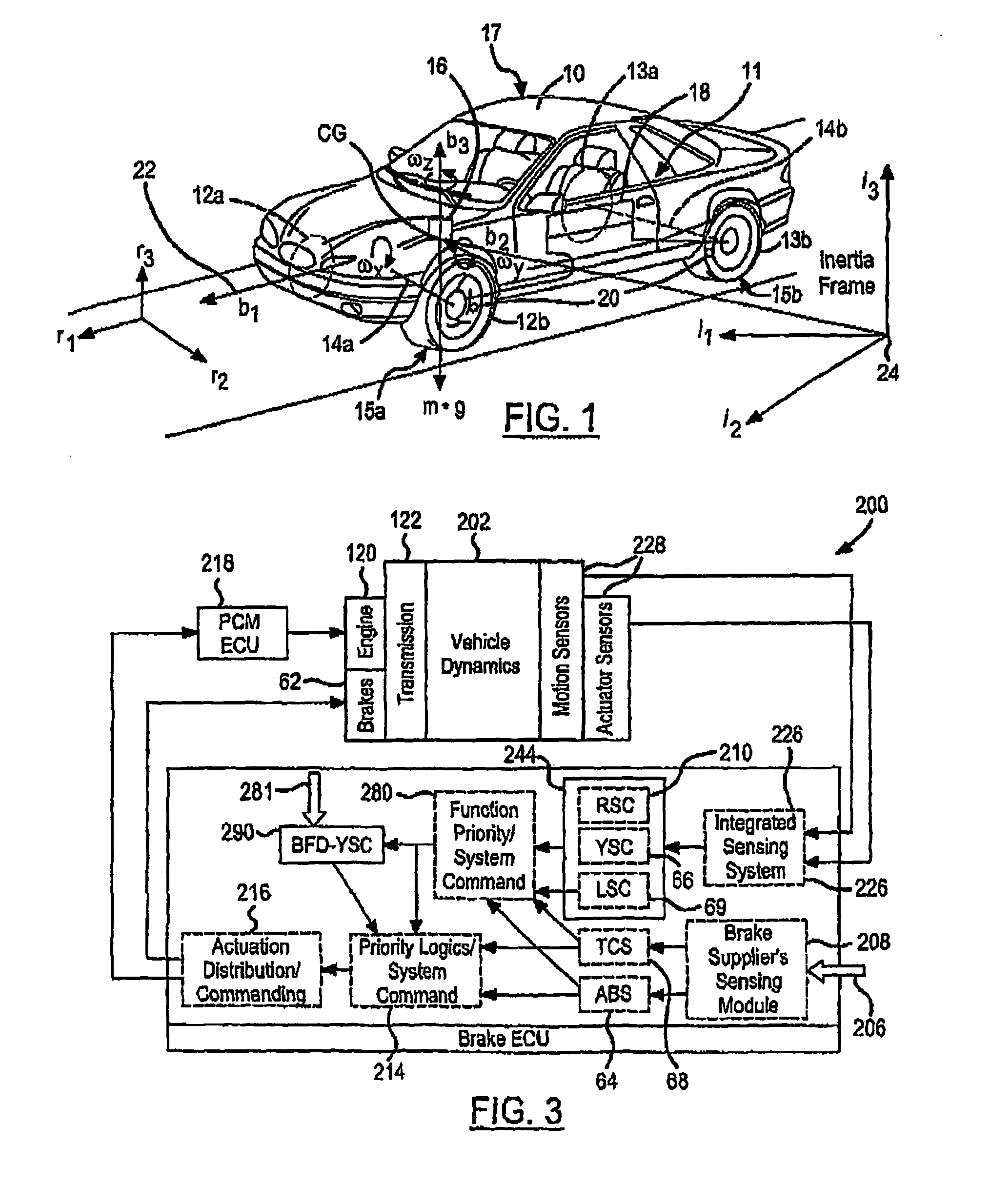

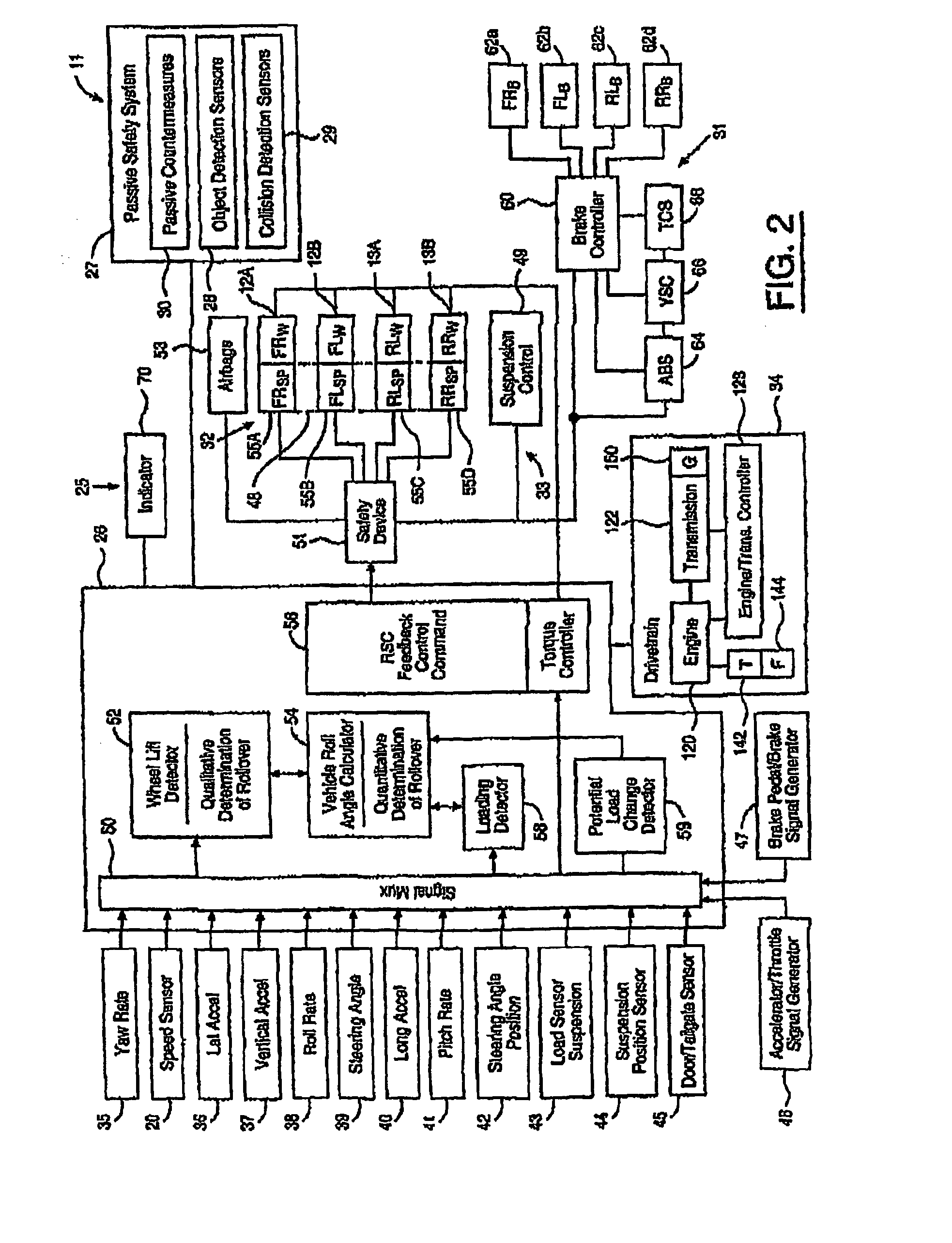

Enhanced Yaw Stability Control to Mitigate a Vehicle's Abnormal Yaw Motion Due to a Disturbance Force Applied to Vehicle Body

ActiveUS20110166744A1Reduce yaw motionEasy to operateVehicle testingAnalogue computers for trafficControl systemNormal functioning

An enchanced stability control system (200) for a vehicle includes a vehicle status sensor that generates a sensor signal. A driver input sensor that generates an input signal. A controller (214) may disable normal yaw stability control operation and enable body-force- disturbance (BDF) yaw stability control (YSC) operation, which includes at least partially reducing response functions of the normal yaw stability control associated with the input signal, in response to the sensor signal and performing BFD-YSC functions to achieve desired control performance upon the detection of BFD reception. The controller (214) may also or alternatively compare the sensor signal to a threshold and detect an improperly functioning / inoperative vehicle status sensor. The controller (214) disregards information associated with the improperly functioning / inoperative vehicle status sensor, and continues to perform enhanced yaw stability control operations.

Owner:VOLVO CAR CORP

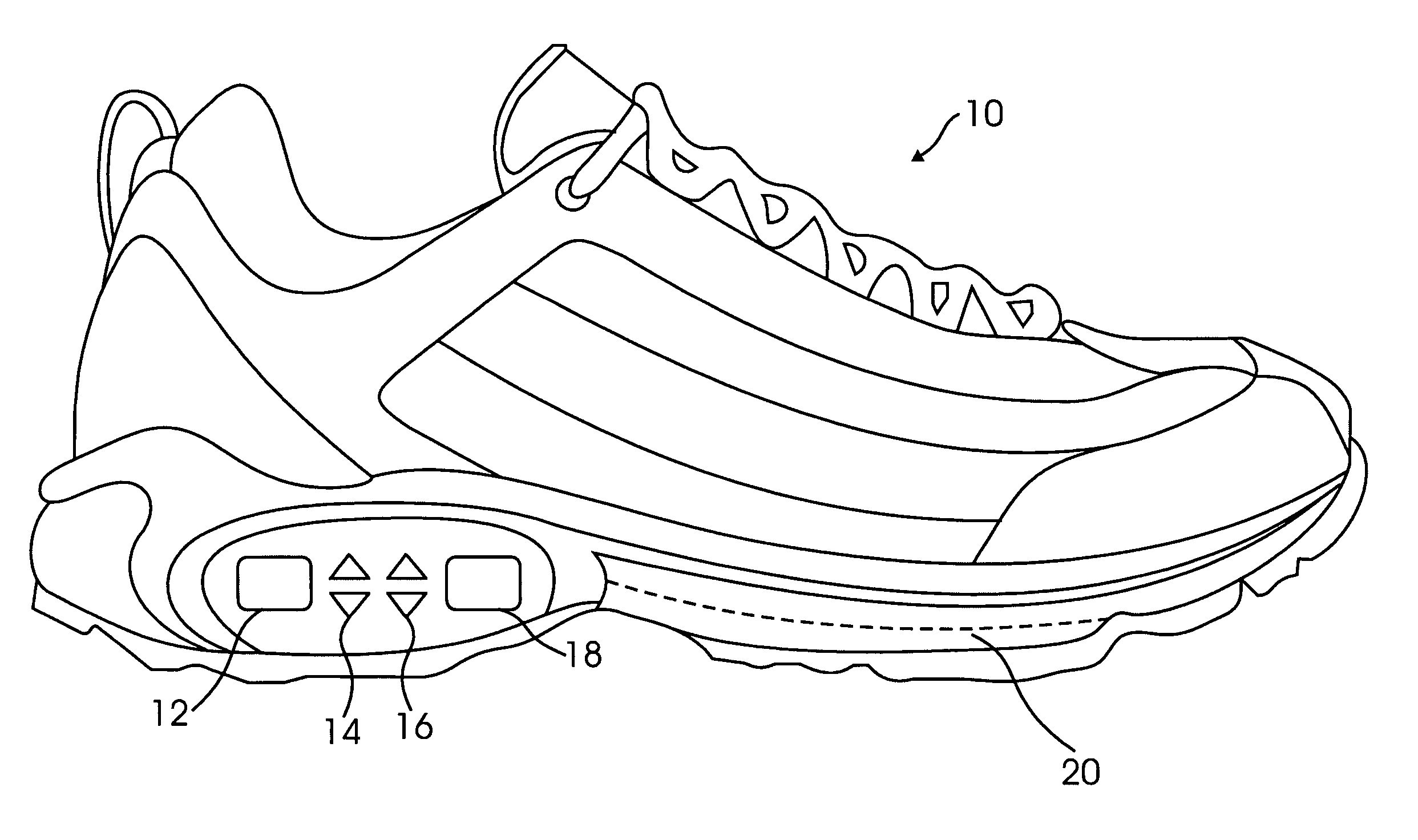

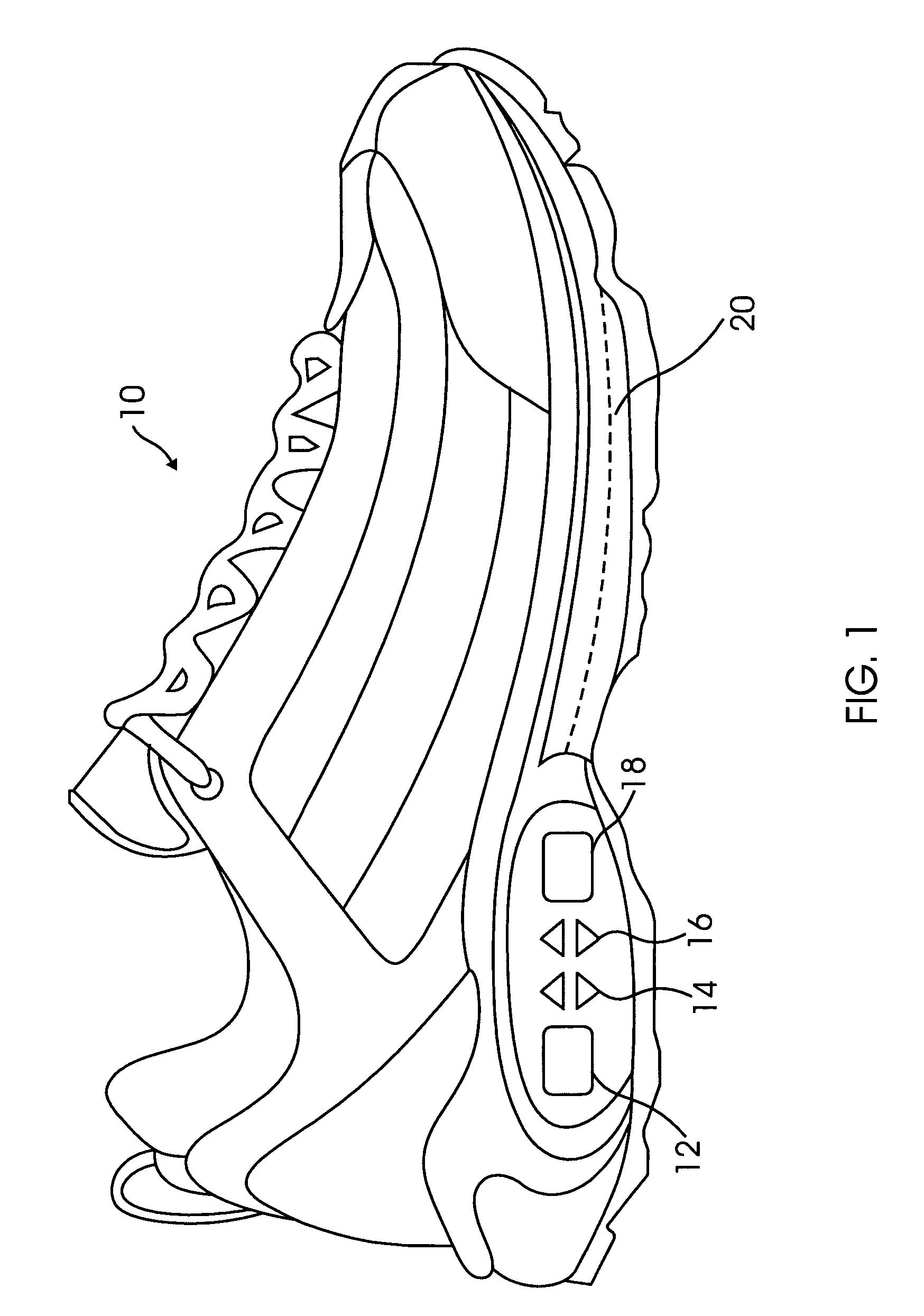

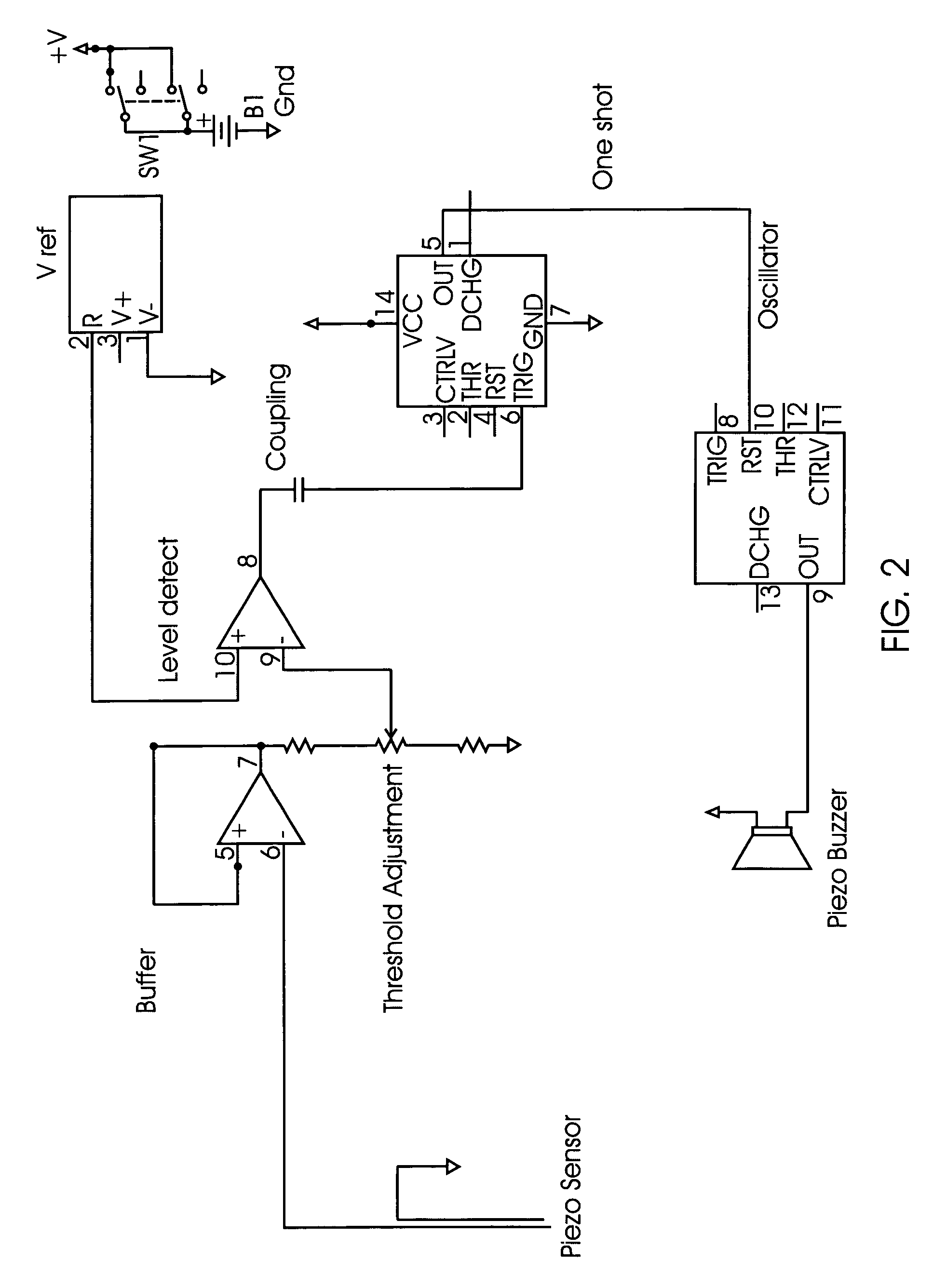

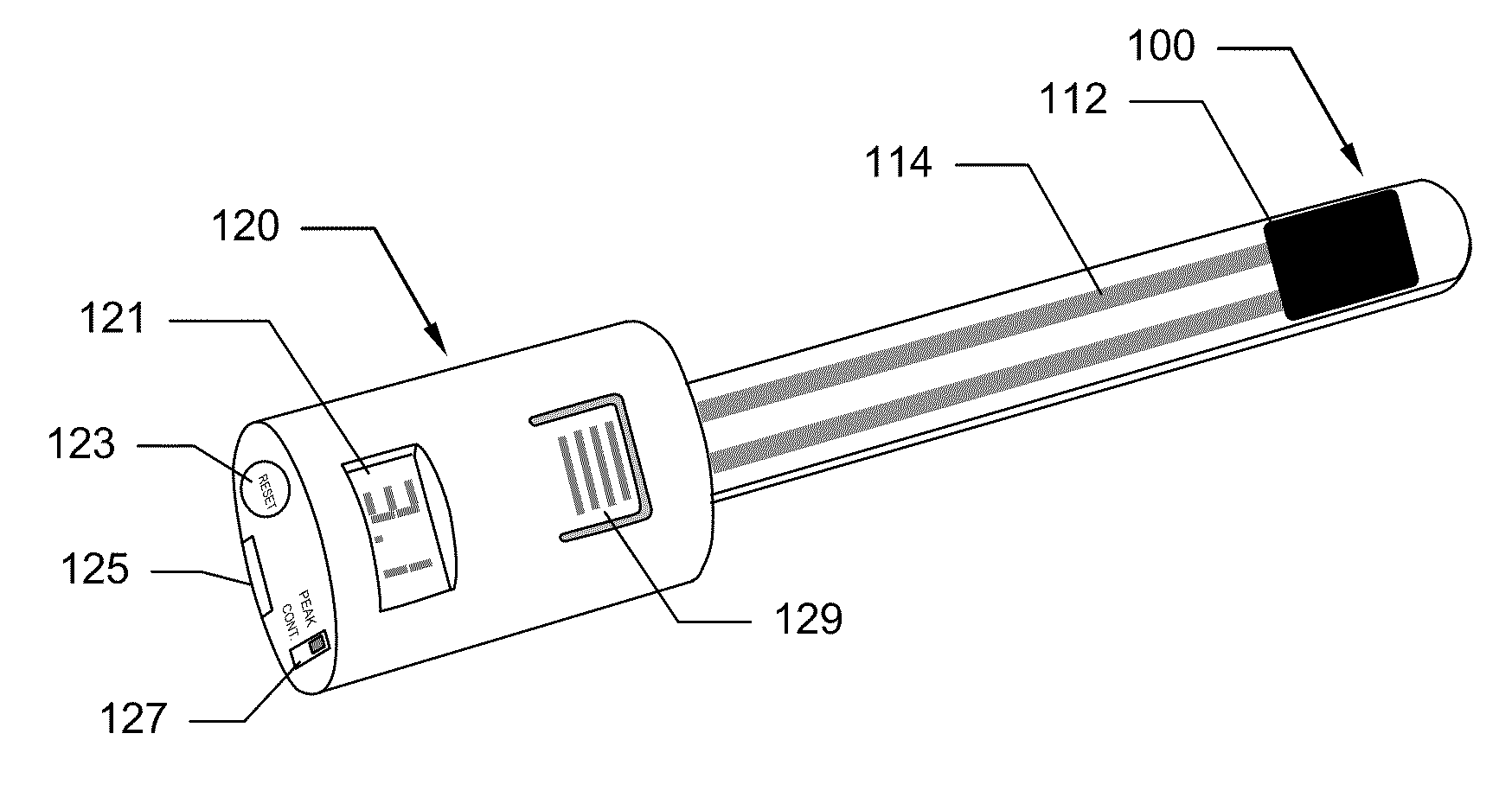

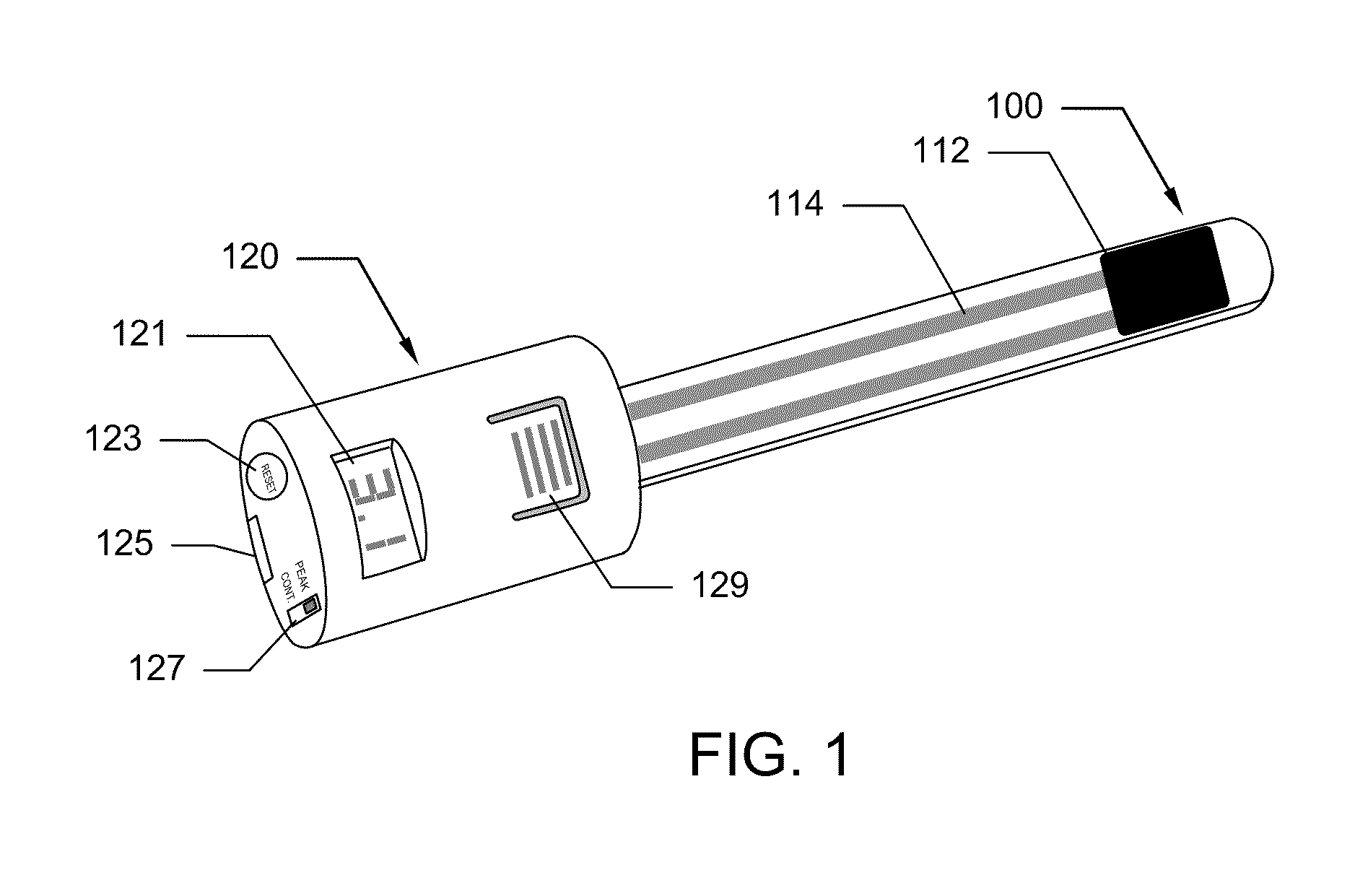

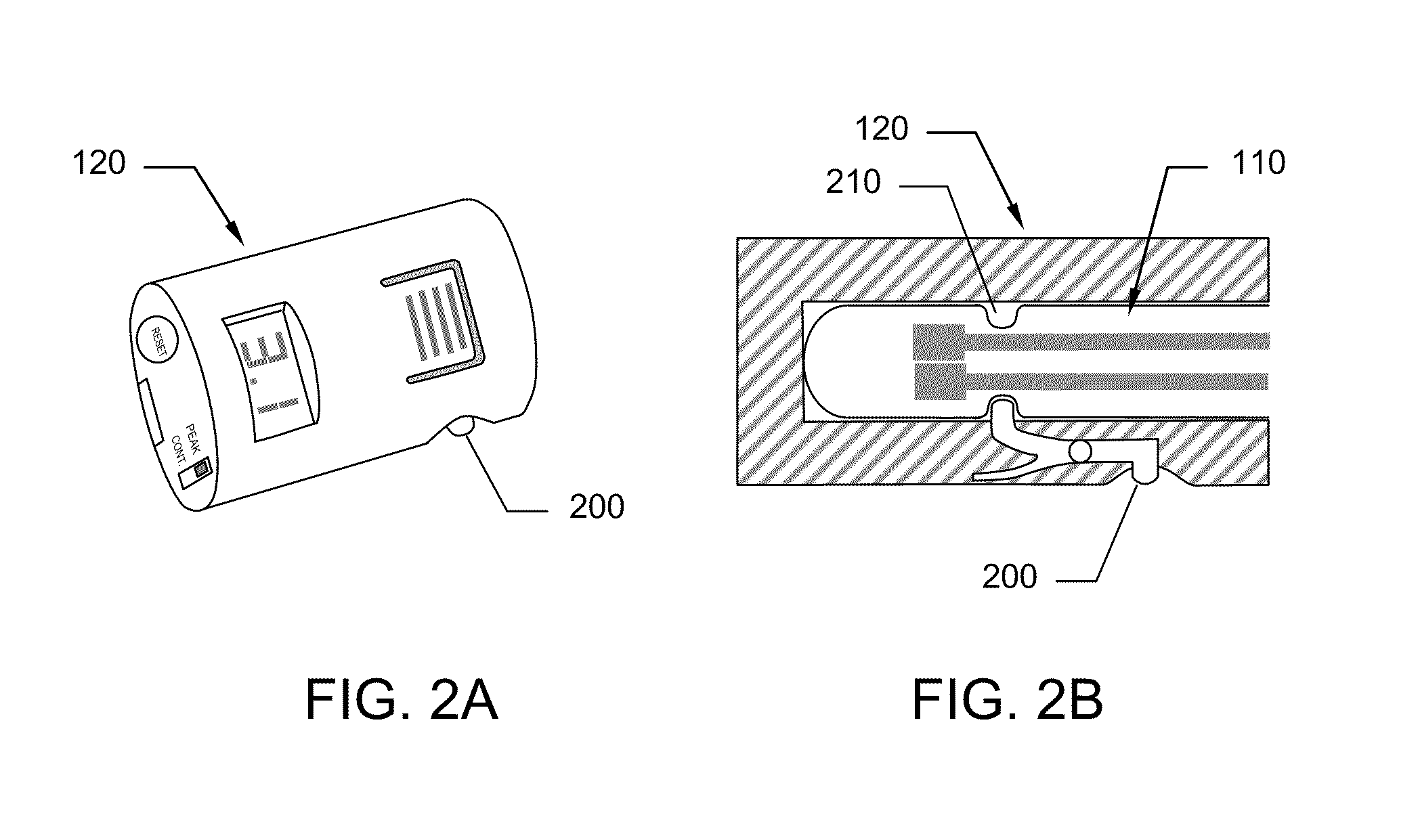

Body force alarming apparatus and method

A device and method to detect force and provide feedback to a runner or jogger so that the person can judge whether to adjust his or her stride in order to lessen the impact on his or her body. The device includes a housing, a power supply, a piezo sensor, a controller, and an output generator. The piezo sensor is accommodated within a user's shoe and is connected to the controller, and the controller, output generator and power supply are accommodated within the housing. The controller is connected to the output generator so that it is set to generate a signal to the output generator when a threshold level of force signal is received from the piezo sensor. The sensor signals the controller when force from an impact is applied to the piezo sensor and the controller signals the output generator when one or more signals indicating threshold levels of force have been reached, and the output generator generates a perceivable signal in response to the controller's one or more signals.

Owner:GROLD KEVIN

Overflow downdrawn glass forming method and apparatus

InactiveUS6889526B2Reduce unevennessEfficient degradationGlass furnace apparatusGlass drawing apparatusThermal creepEngineering

Owner:CORNING INC

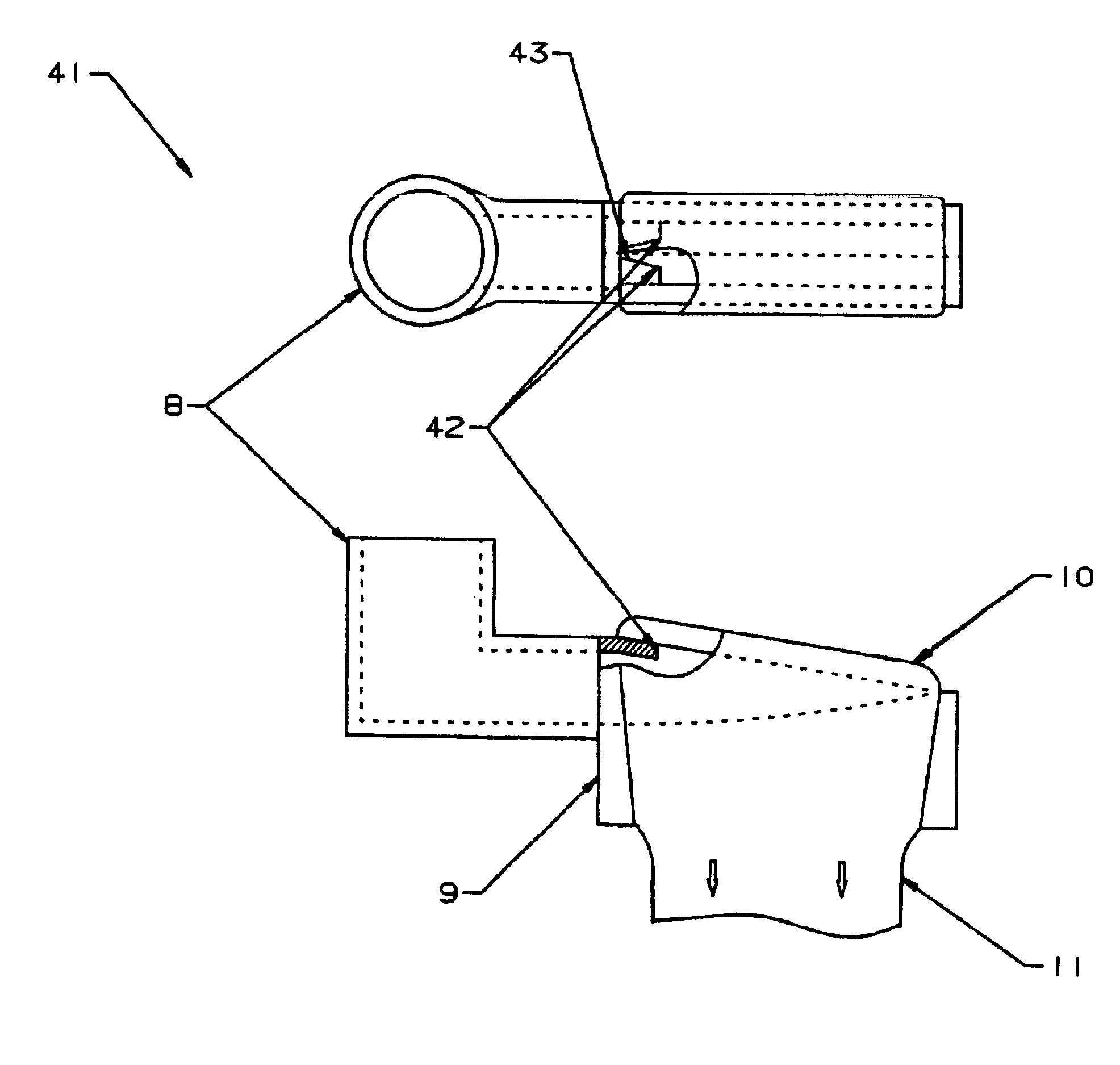

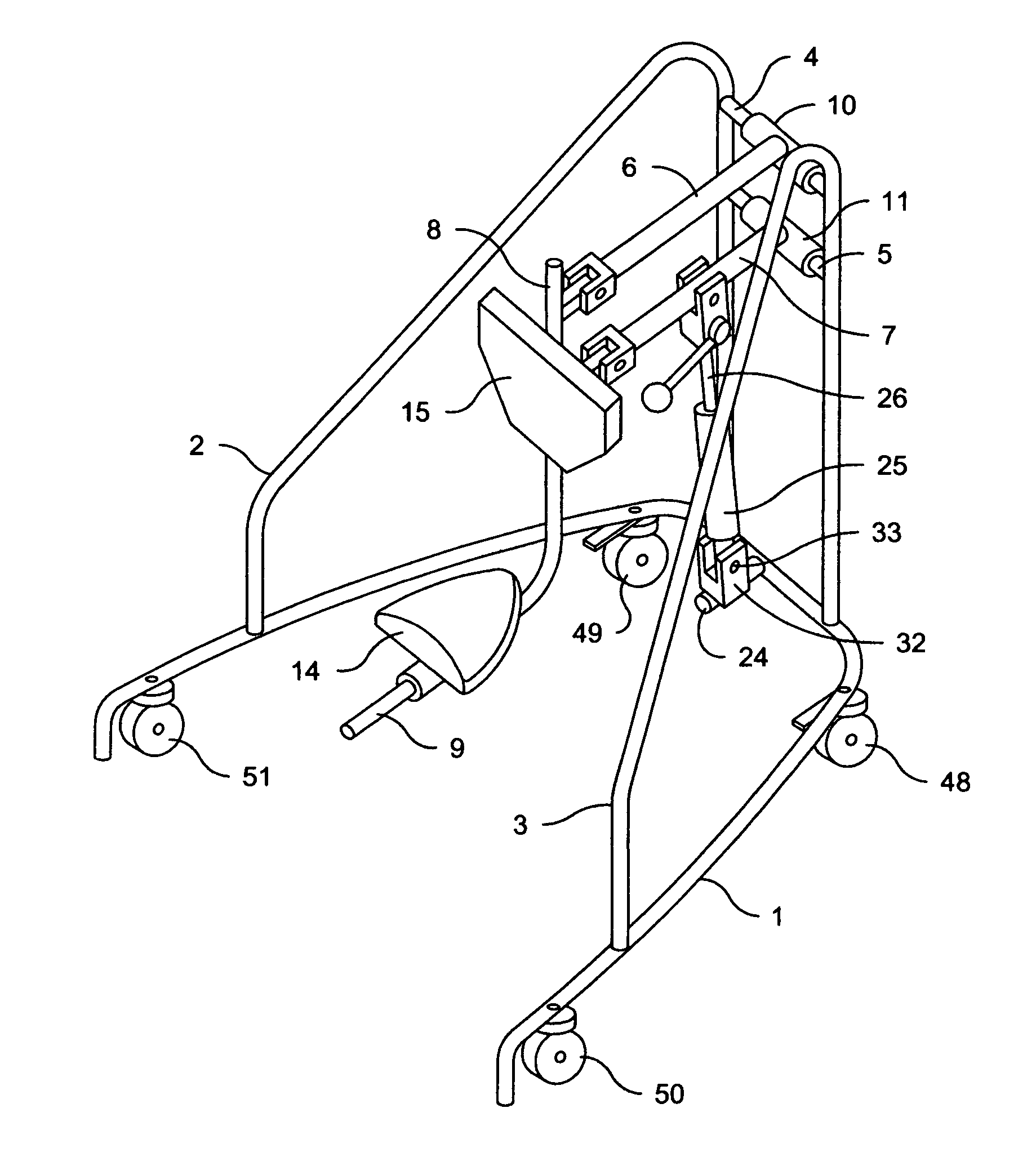

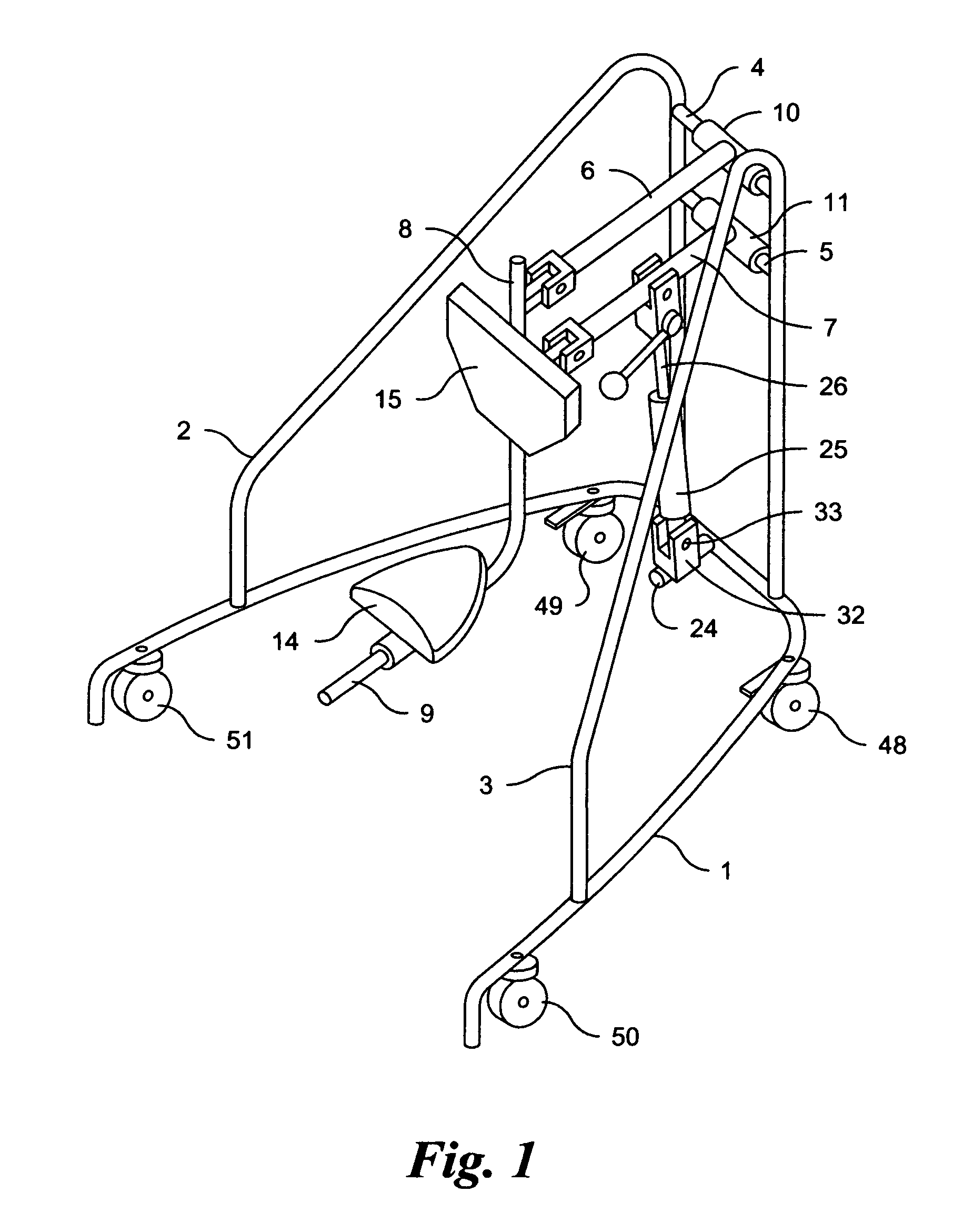

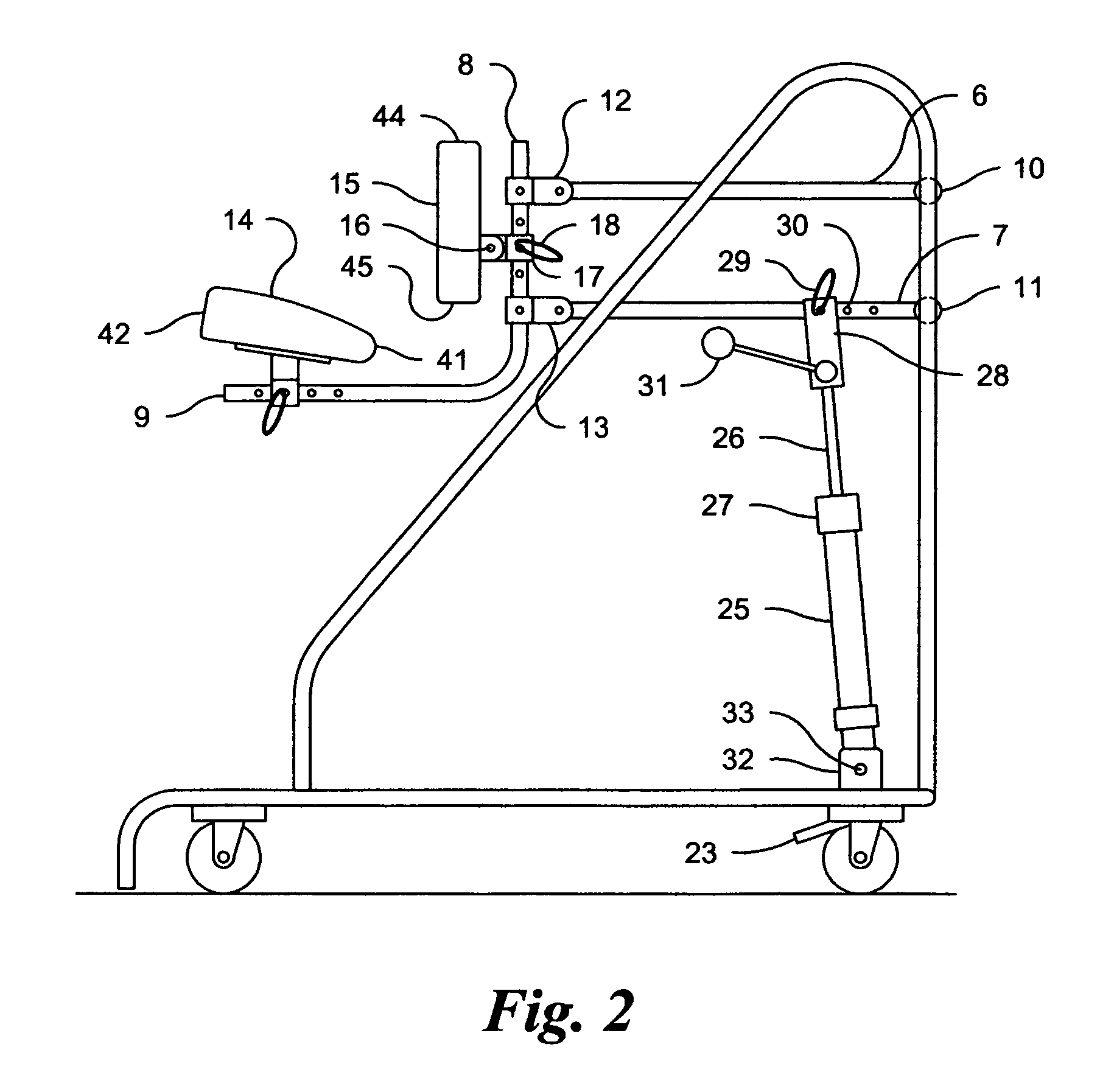

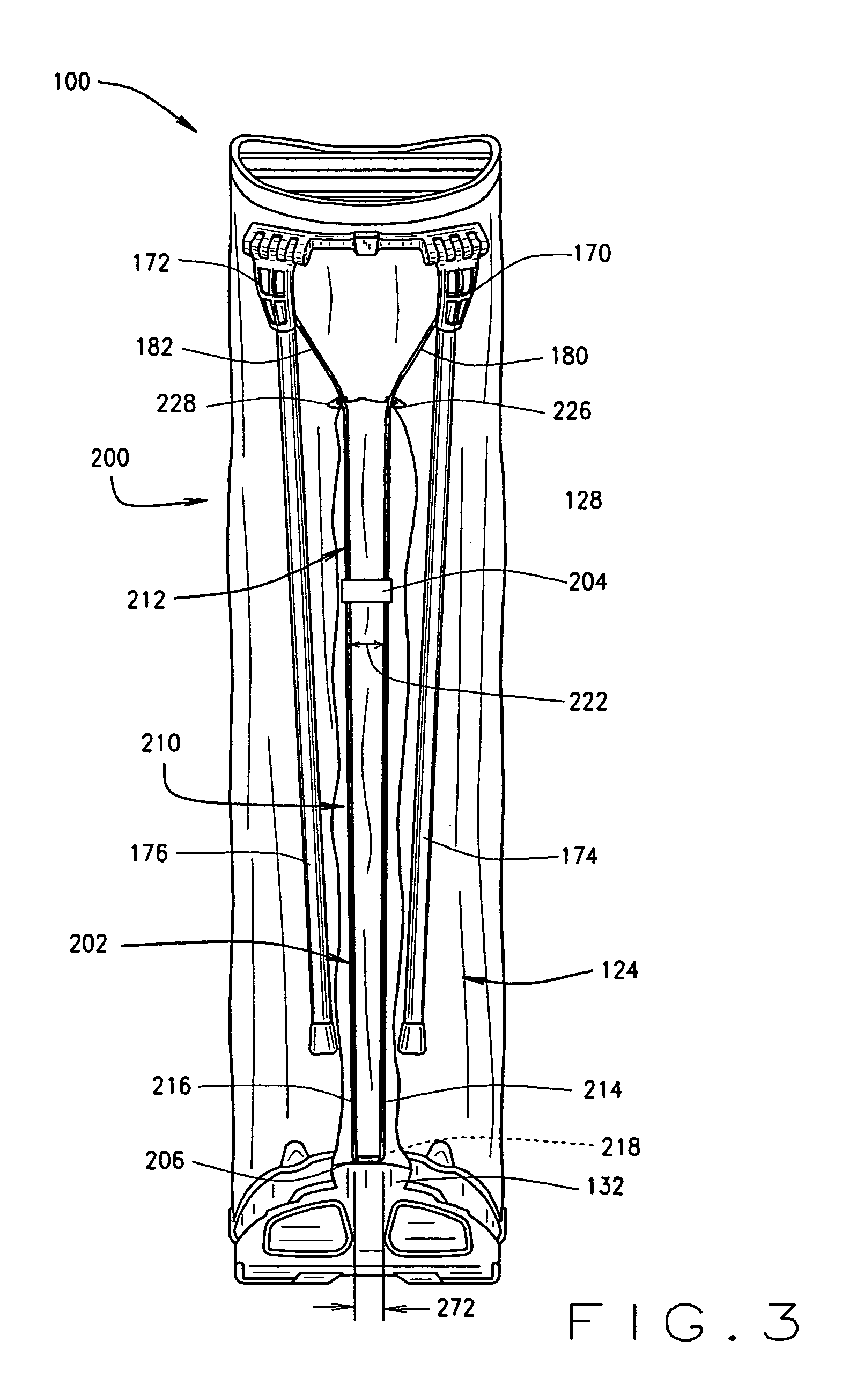

Sit down and stand up walker with seat assembly

ActiveUS8151812B2Loss of balanceEfficiently enableWalking sticksOperating chairsHand heldFull weight bearing

A sit down and stand up walker for assisting a user during walking and when not walking in a standing, partially standing or sitting positions with partial or full weight bearing support and with means to change from standing, partially standing to sitting positions with partial weight bearing support to a fixed elevation with full weight bearing support in any varied or repeated sequence. The partial or full weight bearing means supports a seat assembly which includes a seat and front body support with adjustable positioning to provide pelvic stability. The angle of the seat assembly relative to a flat ground surface is maintained at any elevation of the seat assembly between a standing and sitting position. The weight bearing means is responsive to the variable force supplied by the user as the user walks, stands or sits allowing the seat assembly to move up or down. The weight bearing means in a preferred embodiment is an enclosed gas spring cylinder with piston rod that can be locked at differing elevations or released to respond to a user's body force as the user walks, stands or sits. The walker is intended to be moved without the user's hands holding onto the frame thereby promoting a normal gait and posture. The walker enables the user to expend less energy as the body's center of gravity with partial or full weight bearing support rises and falls with each stride. The walker facilitates transfers from a sitting to standing positions and vice versa by the user independently without the intervention of caregivers.

Owner:RAZON ELI

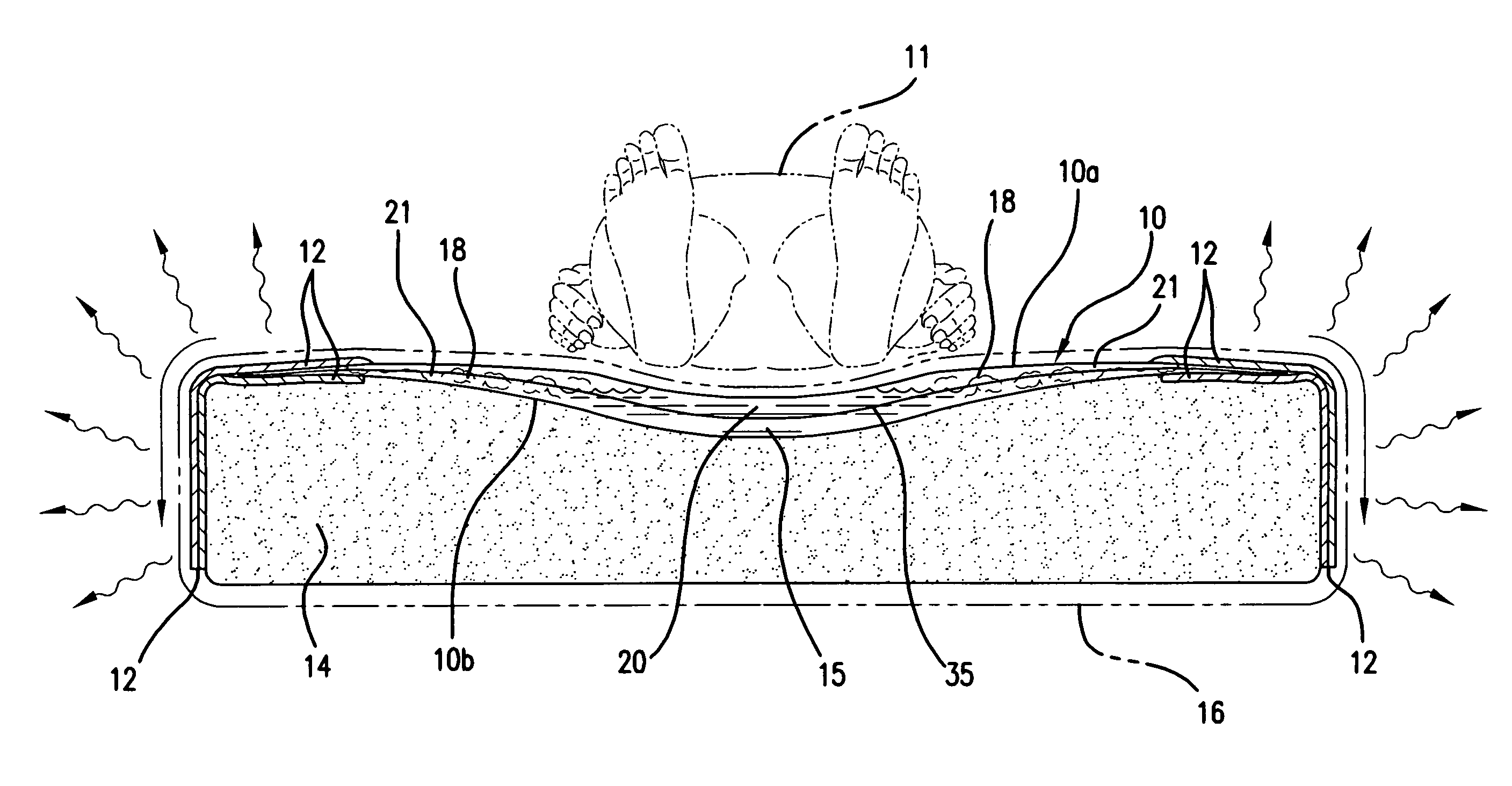

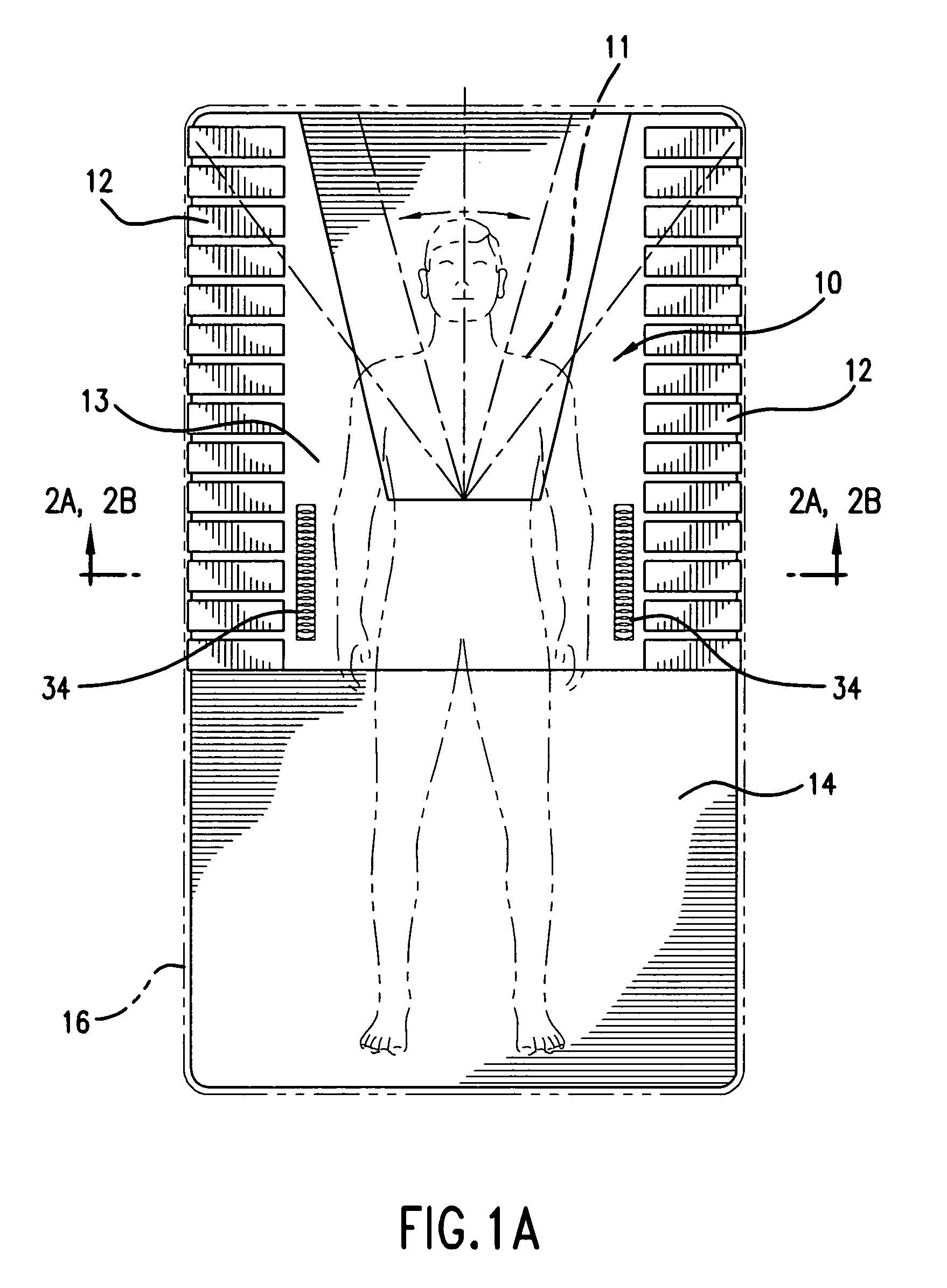

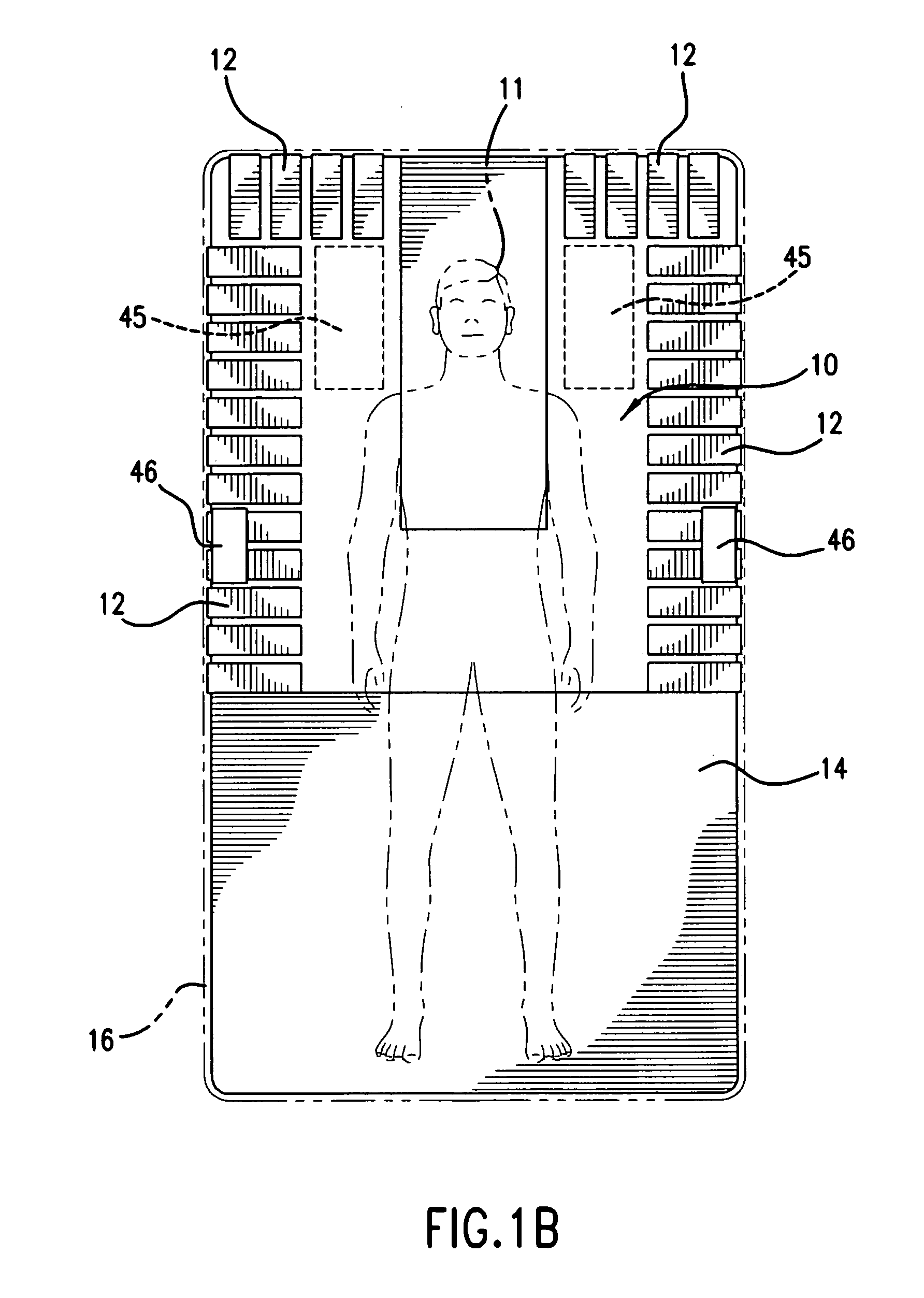

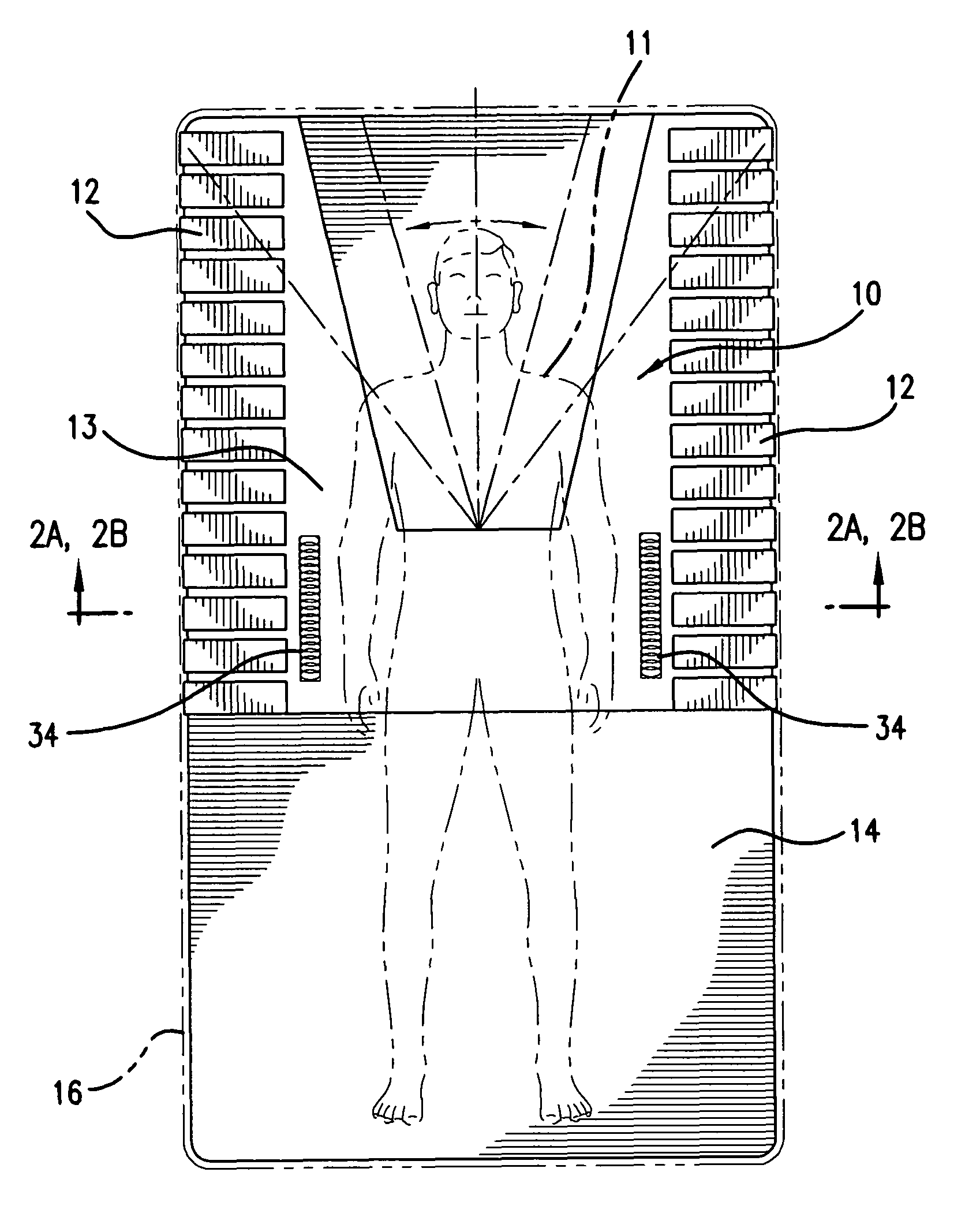

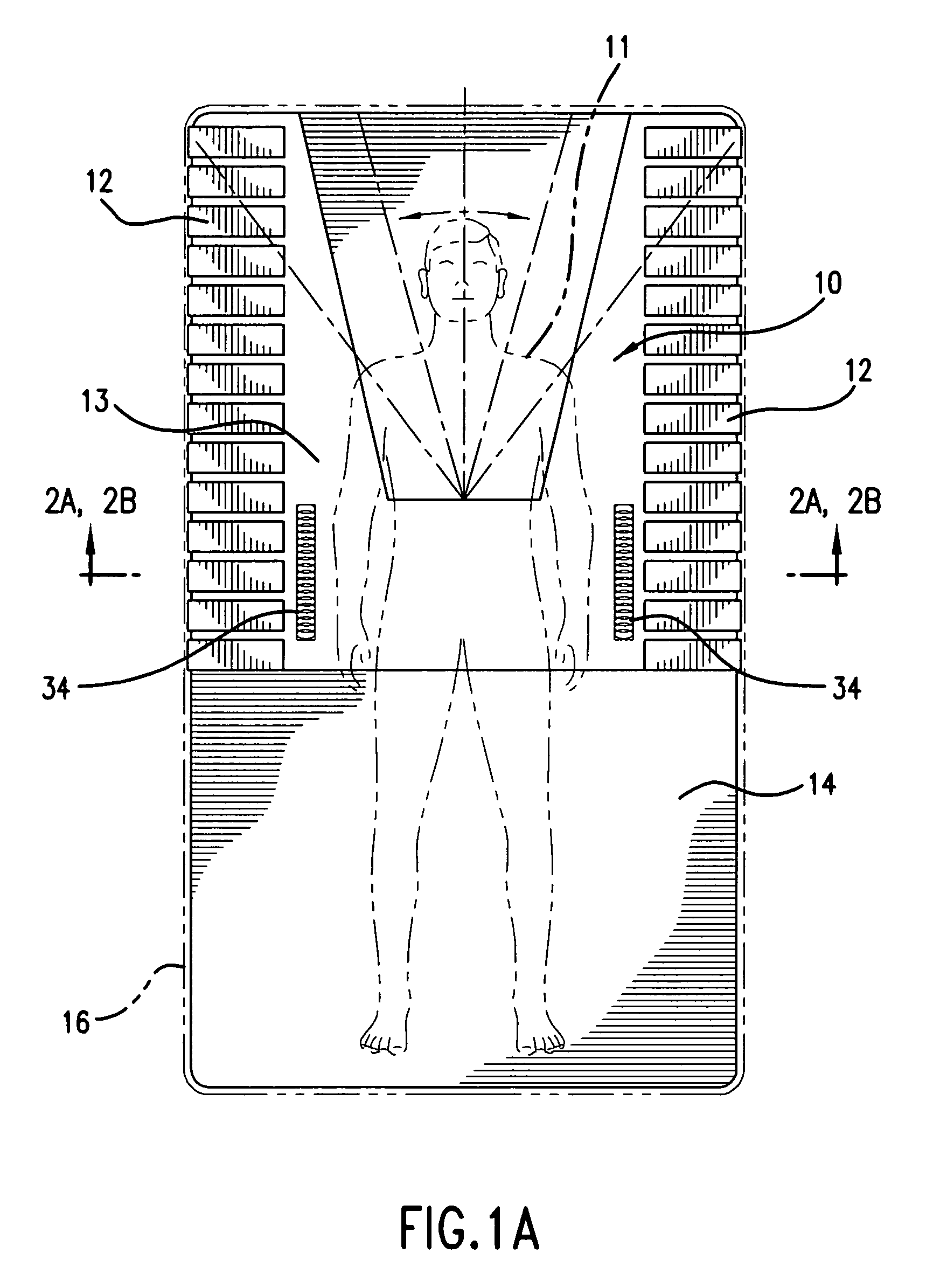

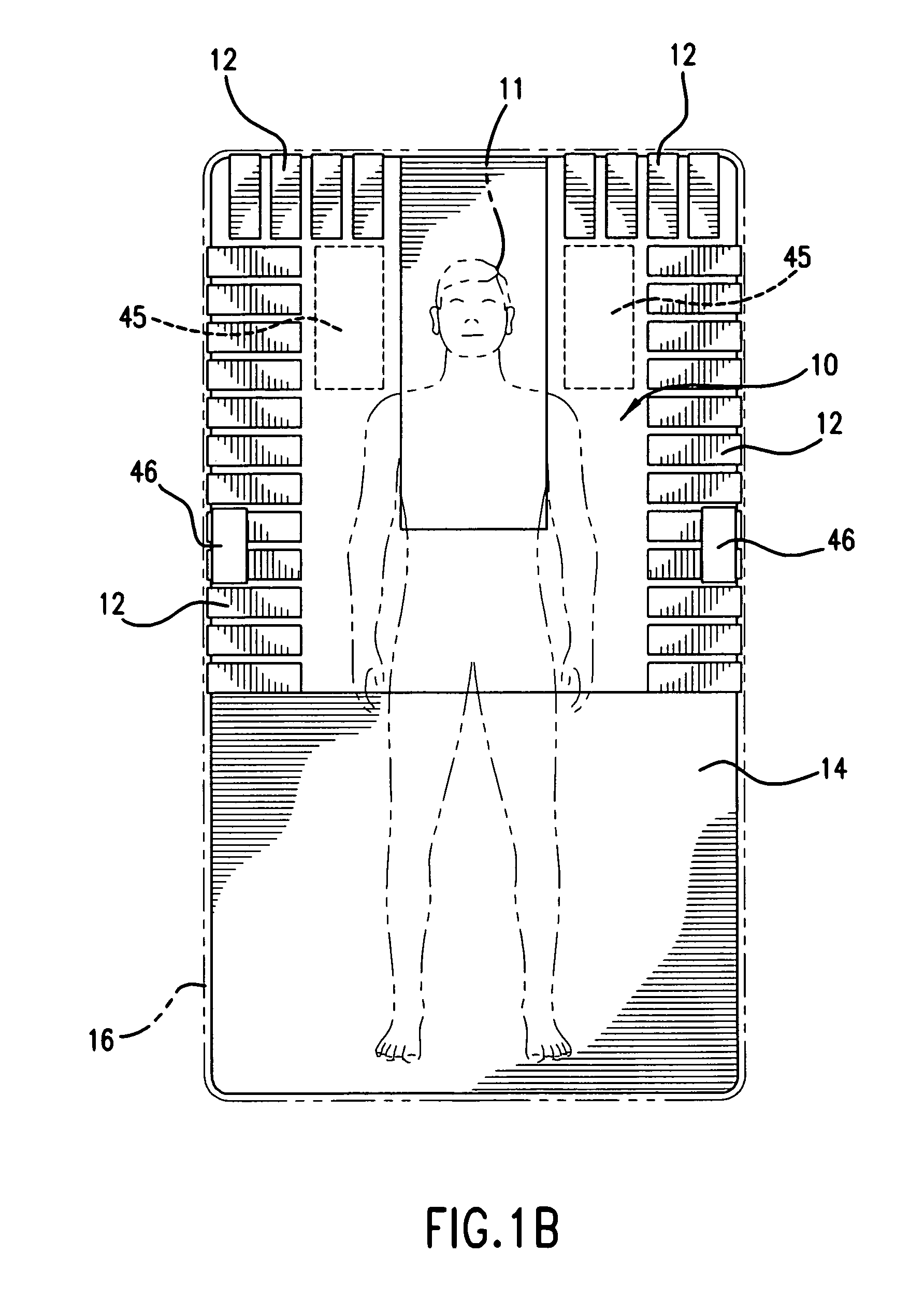

Self-powered steady-state skin-cooling support surfaces

A refrigerant-containing bladder or container is positioned underneath the body. Heat absorbed from the body vaporizes the refrigerant, which expands to cooler remote regions of the bladder. Heat is then withdrawn from the edges of the container by thermally conductive pathways that distribute heat from this container to a cooler area that is not underneath the body. The cooled refrigerant condenses, and is returned to the regions of the device that are under or adjacent to the central and warmest parts of the body. The heavier and warmer portions of the body force the bladder to the lowest point. Alternatively, heat is transferred from the body via a specific highly thermally conductive layer or layers of material(s) that is (are) soft, pliable, and comfortable to sit or lie on. This layer joins conductive materials that are configured to transport heat and diffuse it to the cooler environment.

Owner:LACHENBRUCH CHARLES ARTHUR

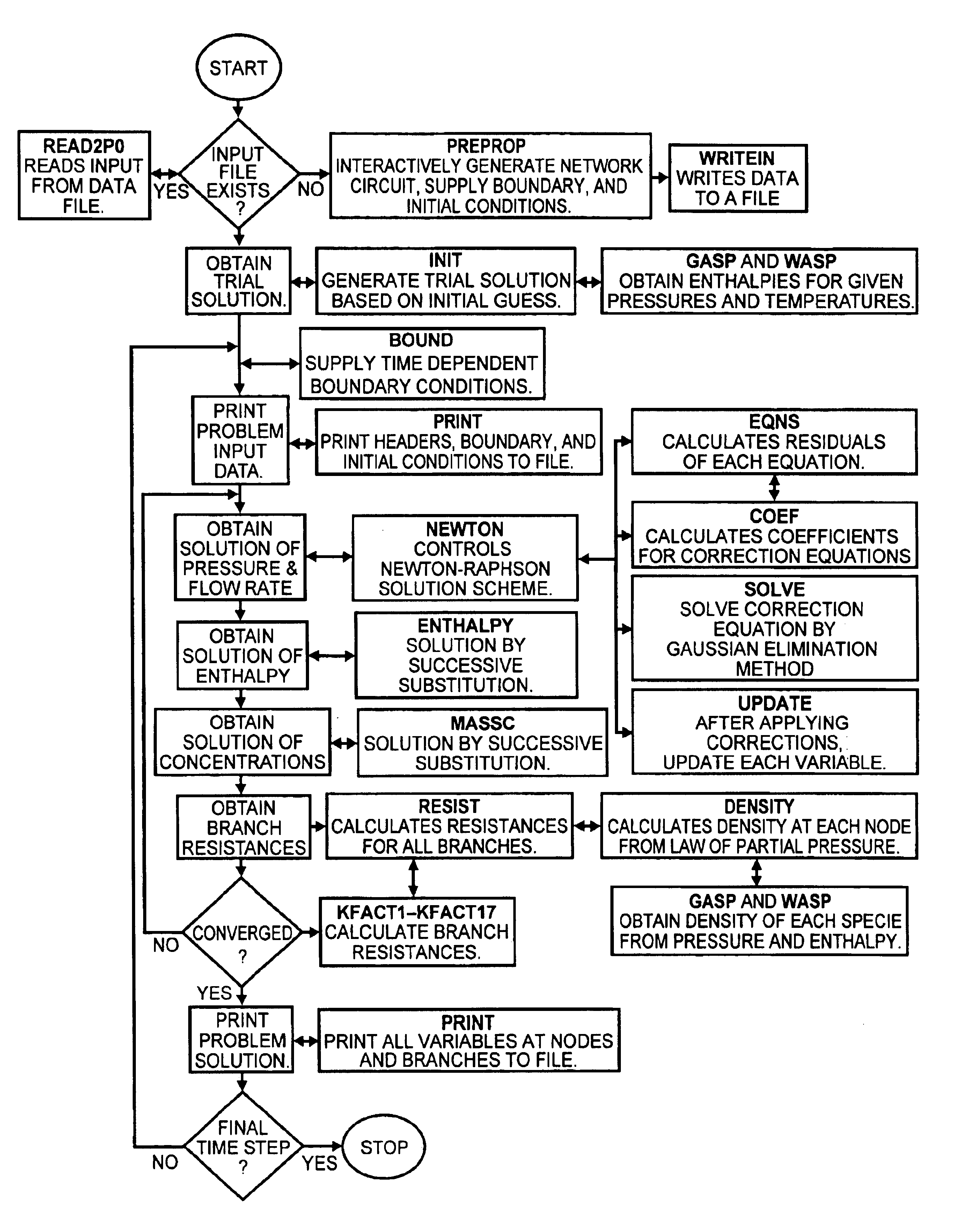

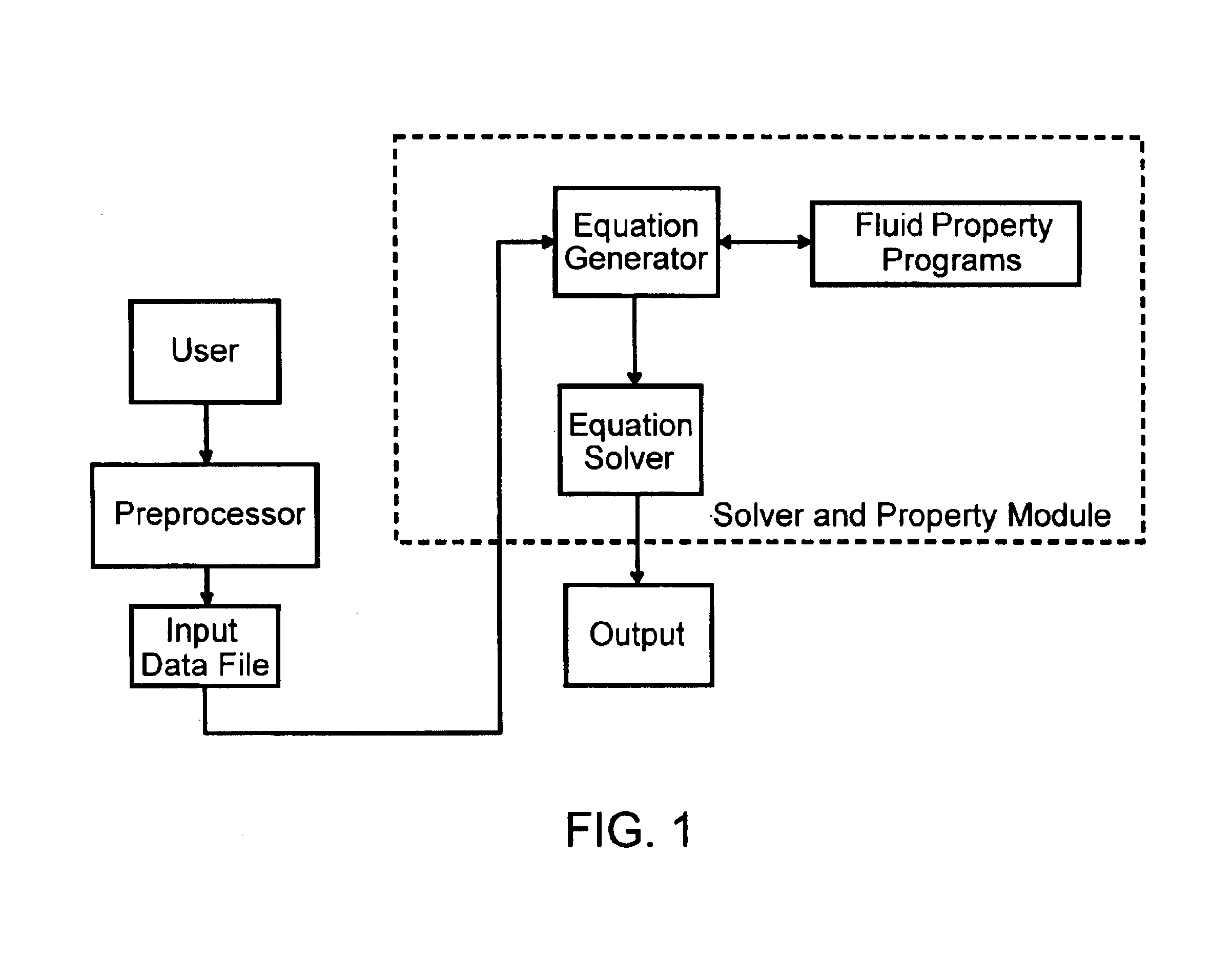

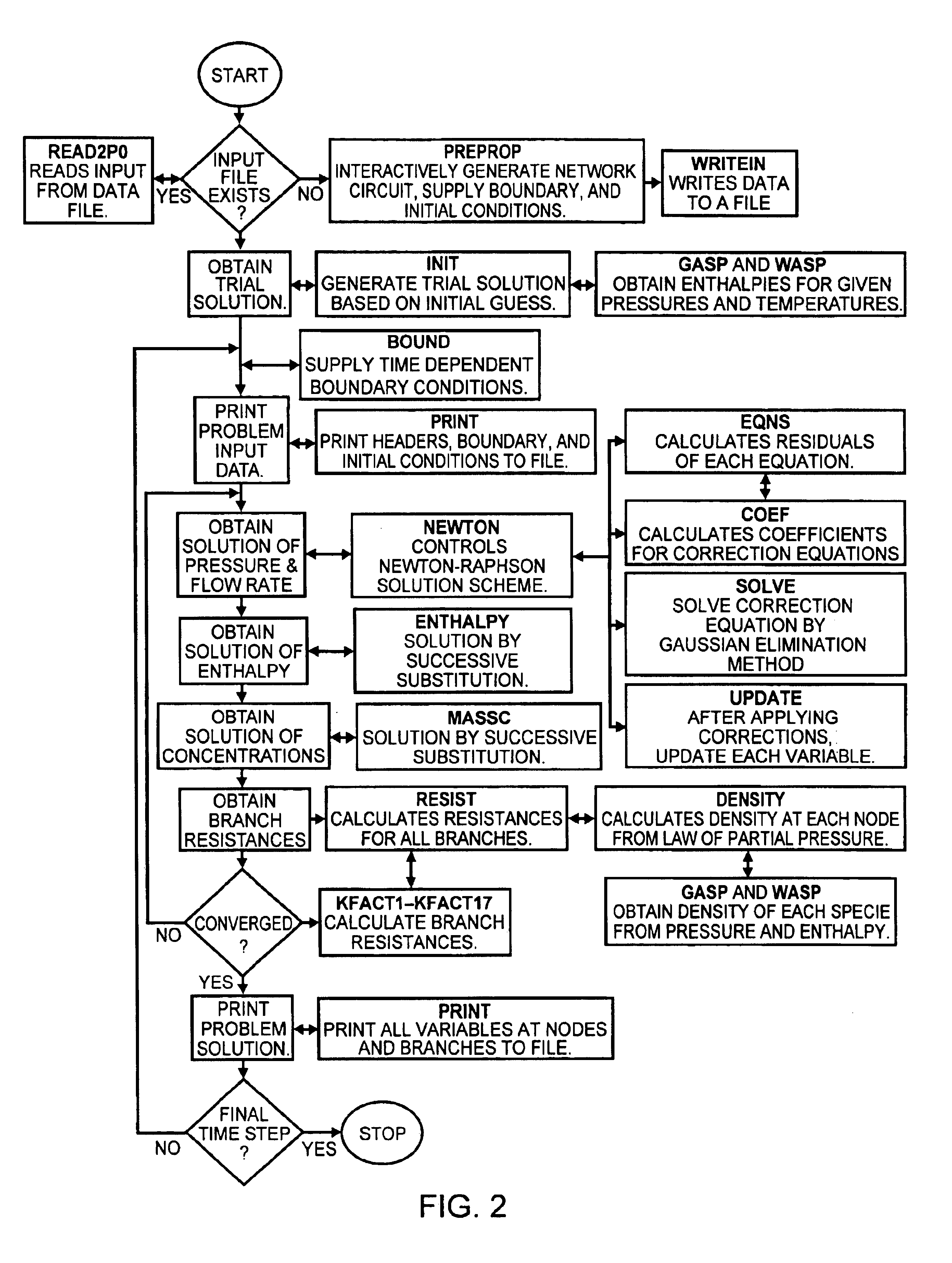

Generalized fluid system simulation program

InactiveUS6748349B1Simulator controlComputation using non-denominational number representationCompressibilitySubstitution method

A general purpose program implemented on a computer analyzes steady state and transient flow in a complex fluid network, modeling phase changes, compressibility, mixture thermodynamics and external body forces such as gravity and centrifugal force. A preprocessor provides for the interactive development of a fluid network simulation having nodes and branches. Mass, energy, and specie conservation equations are solved at the nodes, and momentum conservation equations are solved in the branches. Contained herein are subroutines for computing "real fluid" thermodynamic and thermophysical properties for 12 fluids, and a number of different source options are provided for modeling momentum sources or sinks in the branches. The system of equations describing the fluid network is solved by a hybrid numerical method that is a combination of the Newton-Raphson and successive substitution methods. Application and verification of this invention are provided through an example problem, which demonstrates that the predictions of the present invention compare most reasonably with test data.

Owner:NASA

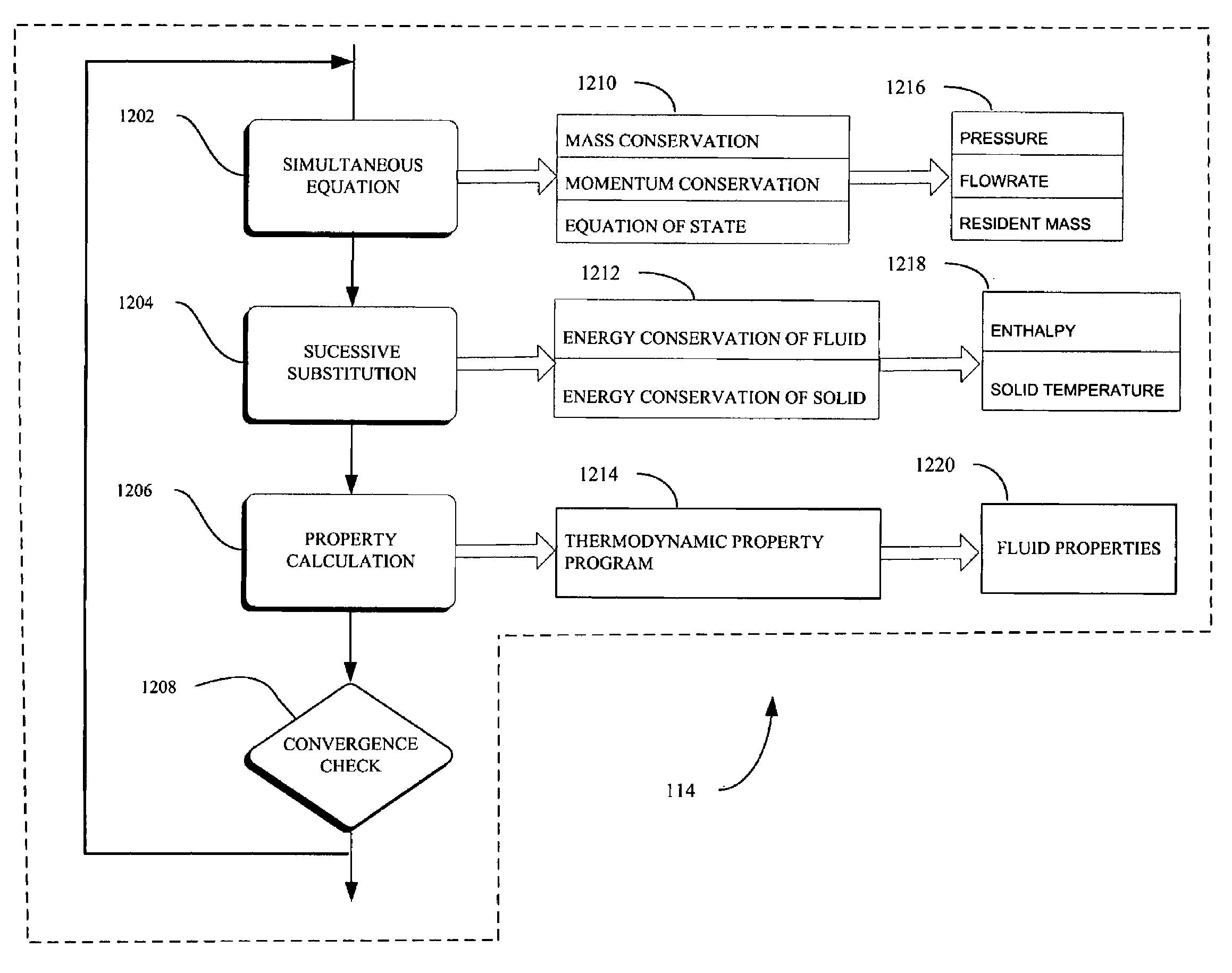

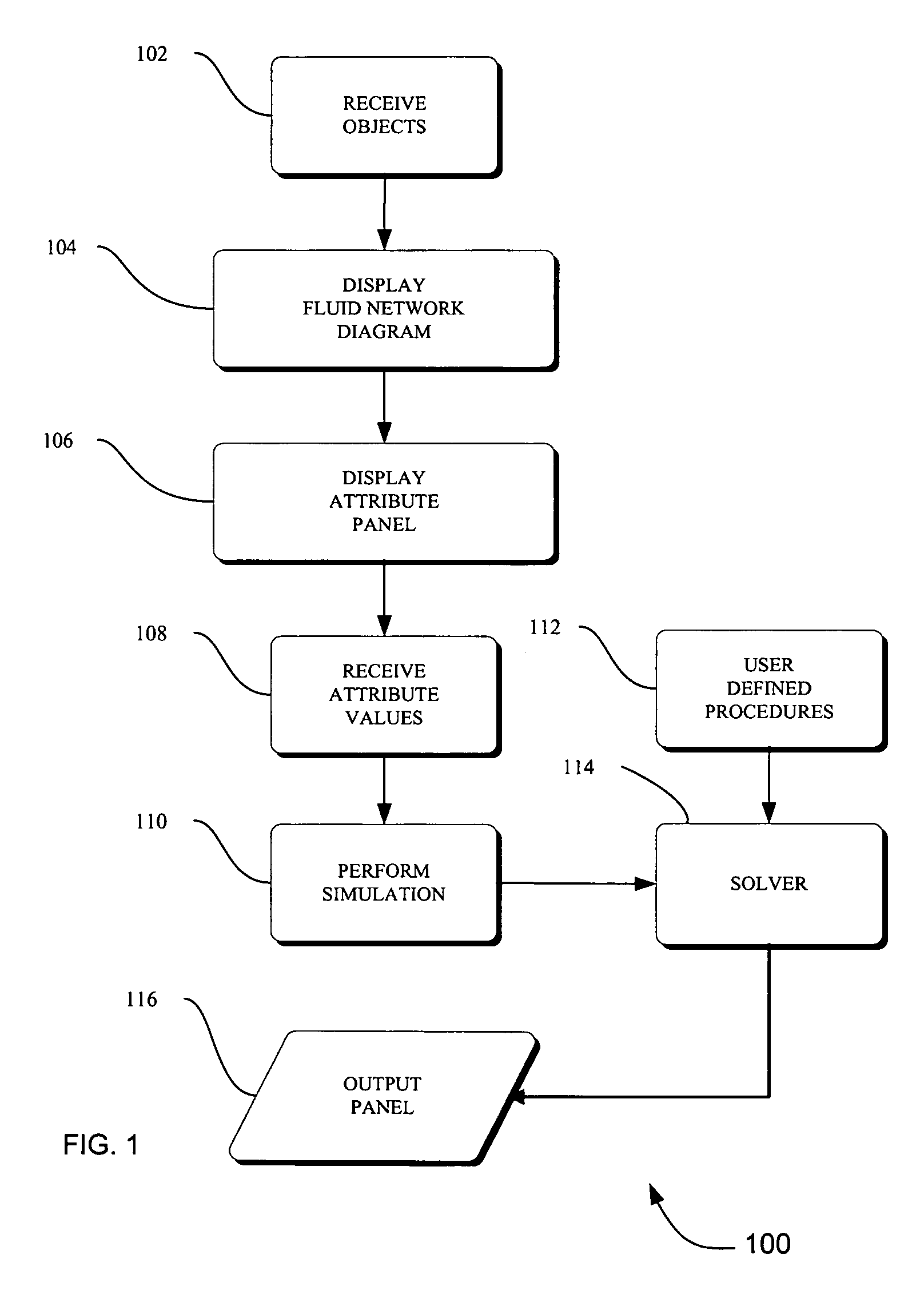

Method and apparatus for predicting unsteady pressure and flow rate distribution in a fluid network

InactiveUS7542885B1Computer controlComputation using non-denominational number representationCompressibilitySubstitution method

A method and apparatus for analyzing steady state and transient flow in a complex fluid network, modeling phase changes, compressibility, mixture thermodynamics, external body forces such as gravity and centrifugal force and conjugate heat transfer. In some embodiments, a graphical user interface provides for the interactive development of a fluid network simulation having nodes and branches. In some embodiments, mass, energy, and specific conservation equations are solved at the nodes, and momentum conservation equations are solved in the branches. In some embodiments, contained herein are data objects for computing thermodynamic and thermophysical properties for fluids. In some embodiments, the systems of equations describing the fluid network are solved by a hybrid numerical method that is a combination of the Newton-Raphson and successive substitution methods.

Owner:NASA

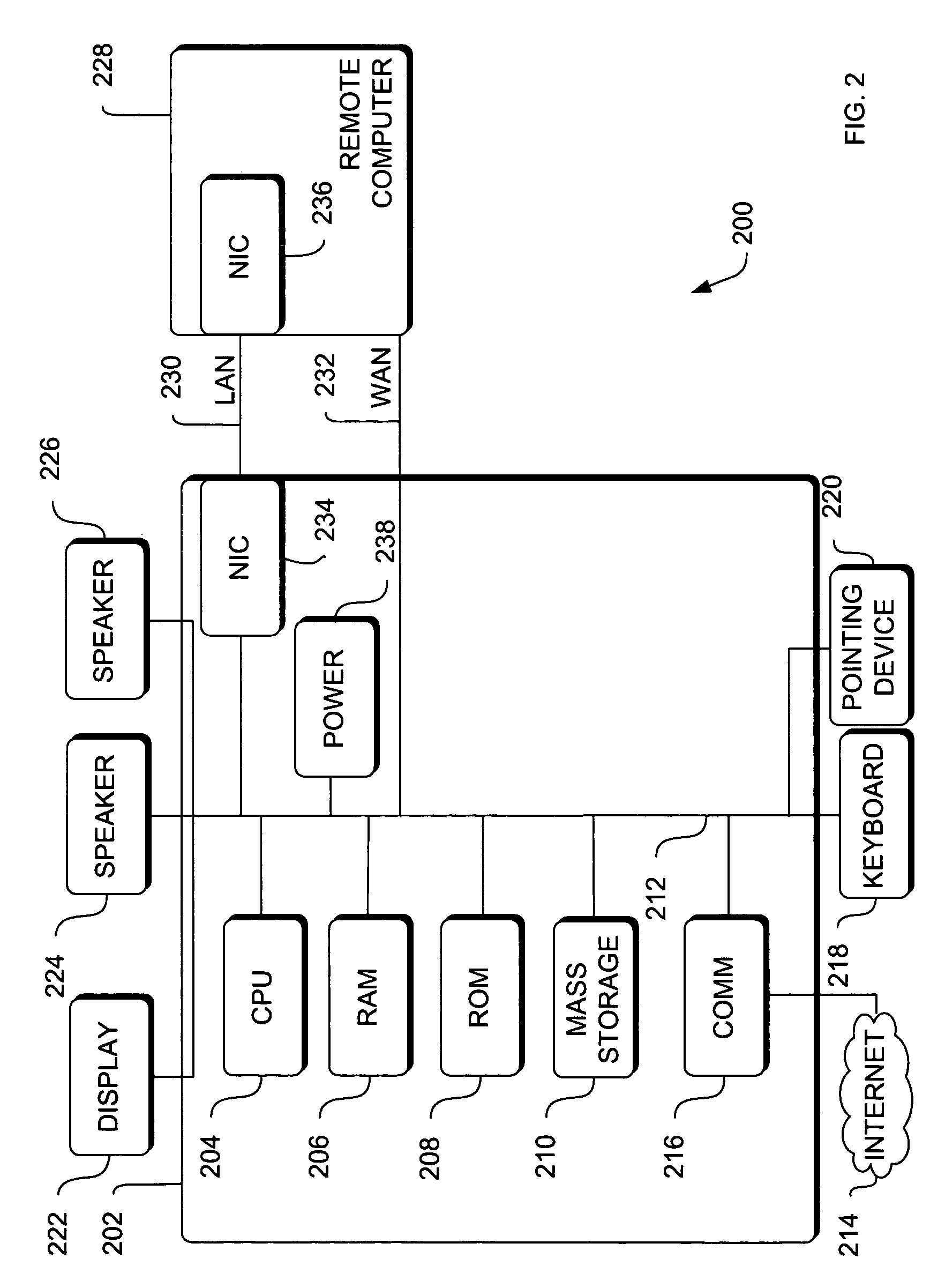

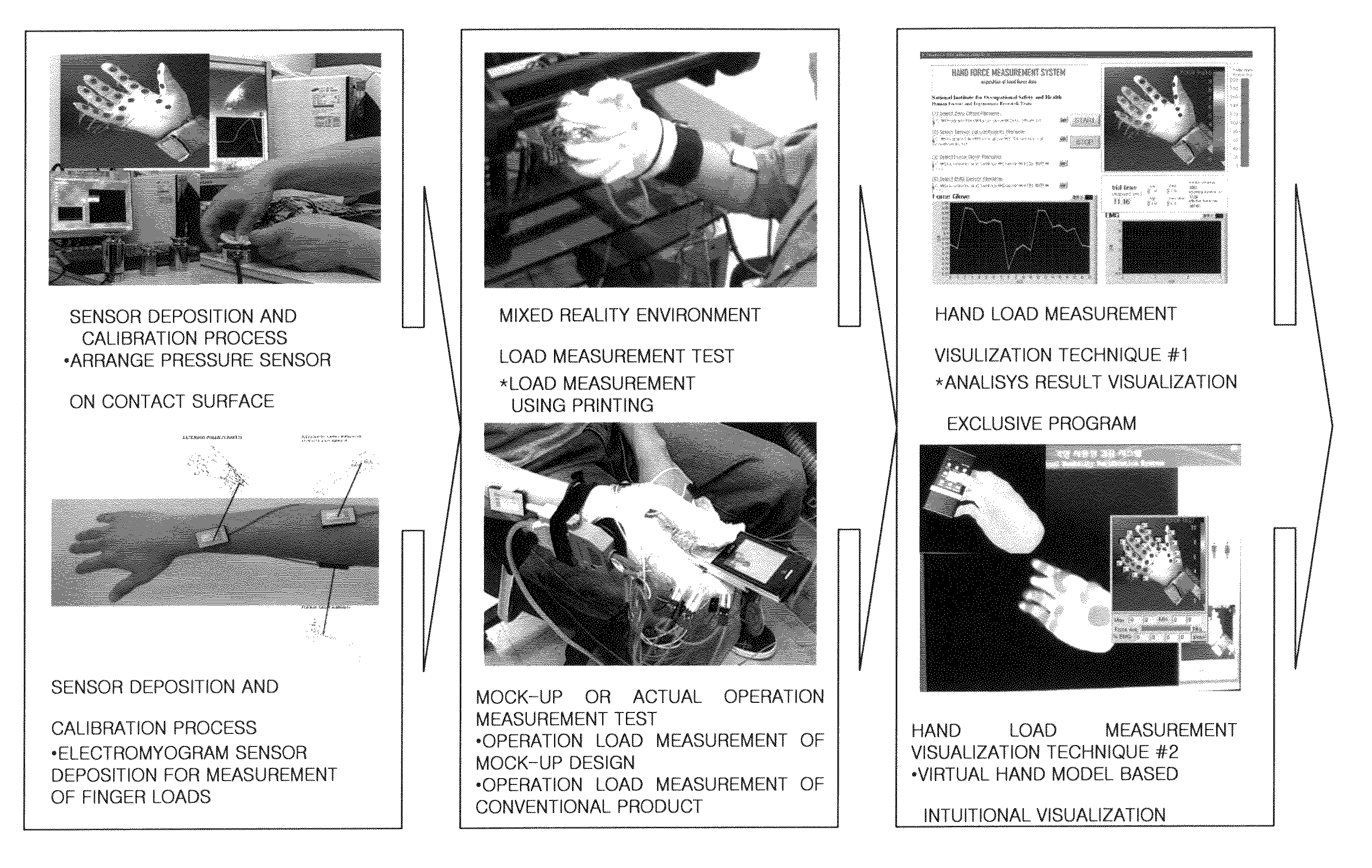

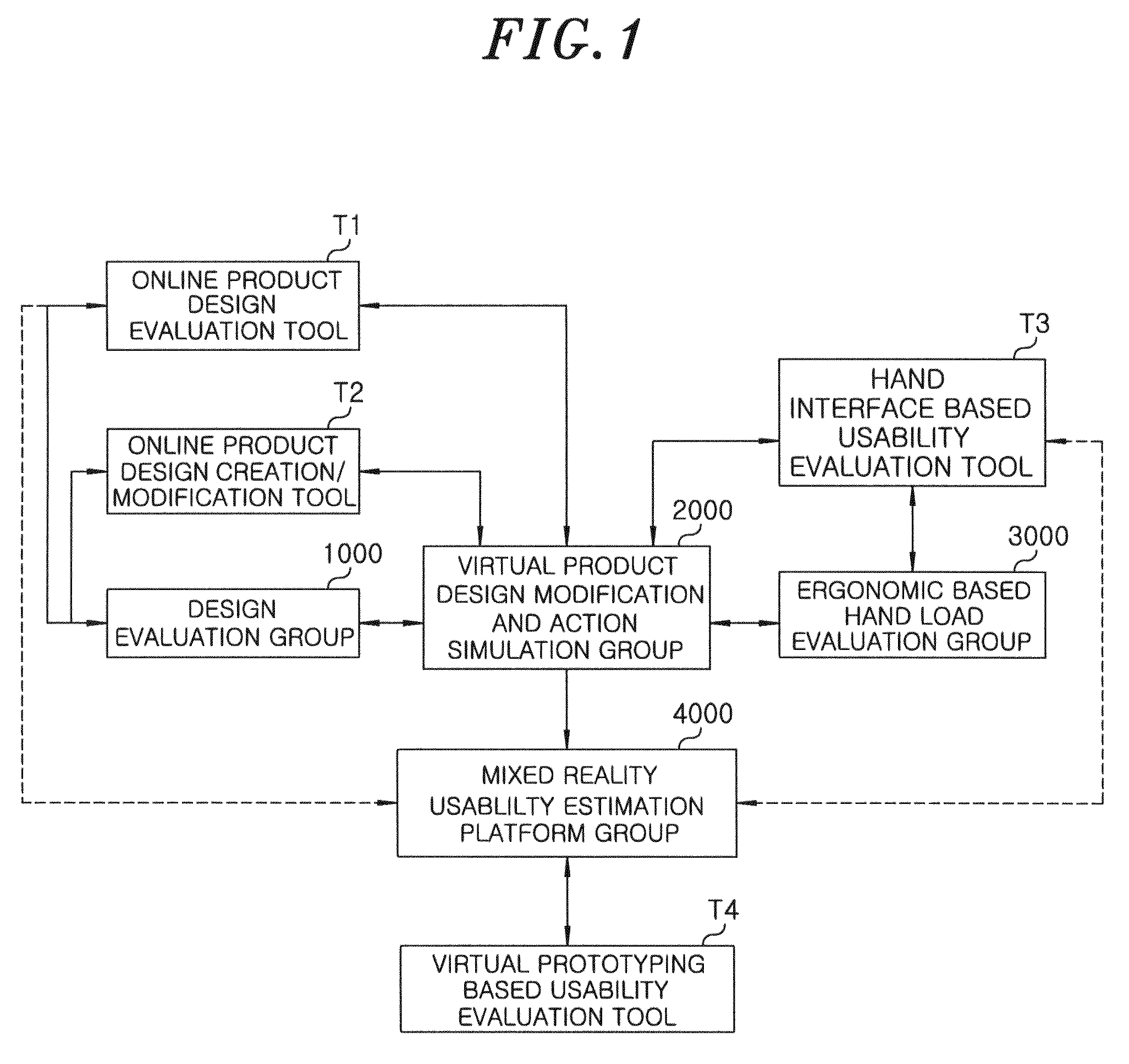

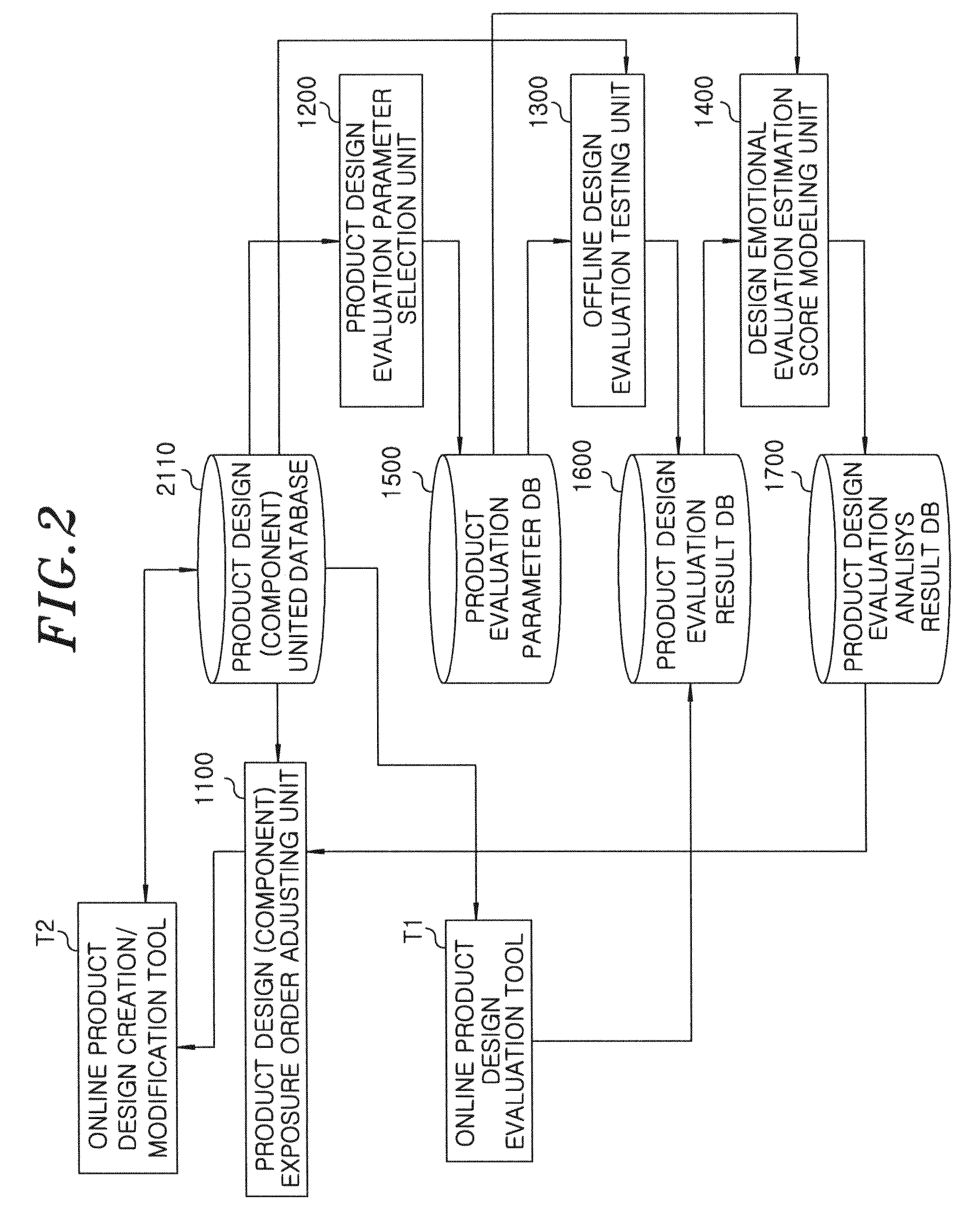

Usability evaluation method and system of virtual mobile information appliance

InactiveUS20090157478A1Digitally marking record carriersLink editingDigital dataUsability assessment

A system for evaluating usability of a virtual mobile information appliance unites a virtual reality technology integrating various digital data created in planning and in designing a product to operate a virtual product and visualizing the virtual product in photo-realistic level, an affective technology organizing a customer's emotional evaluation on a product's design in view of engineering, an ergonomic technology quantatively measuring and analyzing body force activity involved in the operation of a product in a biomechanic manner, and a mixed reality technology supporting both tangible interface capable of directly touching the digital data and a photo-realistic visualization, to thereby finding problems of usability early, obtaining improvements such as a design of the product, improving efficiently an overall quality of the product and managing product-lifetime-cycle in a company manufacturing the product.

Owner:ELECTRONICS & TELECOMM RES INST

Self-powered steady-state skin-cooling support surfaces

A refrigerant-containing bladder or container is positioned underneath the body. Heat absorbed from the body vaporizes the refrigerant, which expands to cooler remote regions of the bladder. Heat is then withdrawn from the edges of the container by thermally conductive pathways that distribute heat from this container to a cooler area that is not underneath the body. The cooled refrigerant condenses, and is returned to the regions of the device that are under or adjacent to the central and warmest parts of the body. The heavier and warmer portions of the body force the bladder to the lowest point. Alternatively, heat is transferred from the body via a specific highly thermally conductive layer or layers of material(s) that is (are) soft, pliable, and comfortable to sit or lie on. This layer joins conductive materials that are configured to transport heat and diffuse it to the cooler environment.

Owner:LACHENBRUCH CHARLES ARTHUR

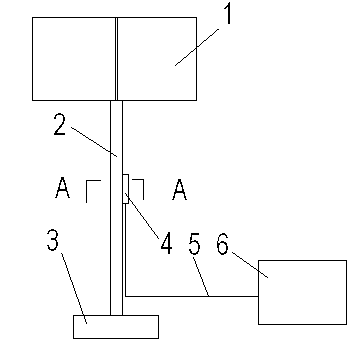

Device for measuring wind speed and direction

InactiveCN103018477ASimple structureSolve technical problemsIndication/recording movementFluid speed measurementTensile strainElectricity

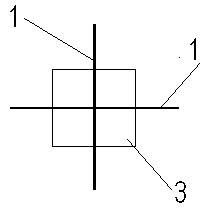

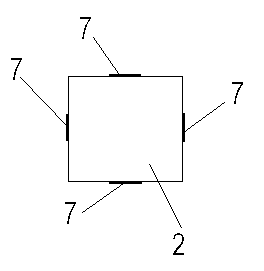

The invention discloses a device for measuring the wind speed and direction. The device comprises a windward force body, a transformation rod (2), a mount (3), a sensor (4), a data line (5) and a host computer (6) with special software, wherein the windward body force, the transformation rod (2) and the mount (3) are sequentially assembled from top to bottom, the sensor (4) is arranged on the transformation rod (2) and the output terminal of the sensor is electrically connected with the host computer (6) through the data line (5), and the windward force body is composed of two perpendicular vertical plates (1) which are mutually perpendicular in a three-dimensional interphase perpendicular and / or mutual penetration perpendicular mode. The cross-section of the portion of the transformation rod (2) where the sensor (4) is arranged is in rectangular structure. The sensor (4) is a tensile strain gage (7) or a tensile strain gage (7) and a pressure strain gage (8). The device for measuring the wind speed and direction has the advantages of simple and reasonable structure, solves the technical problems in relative technical field, and overcomes the technical problem of critical reynolds number, thereby obtaining more accurate and reliable measurement accuracy.

Owner:CENT SOUTH UNIV

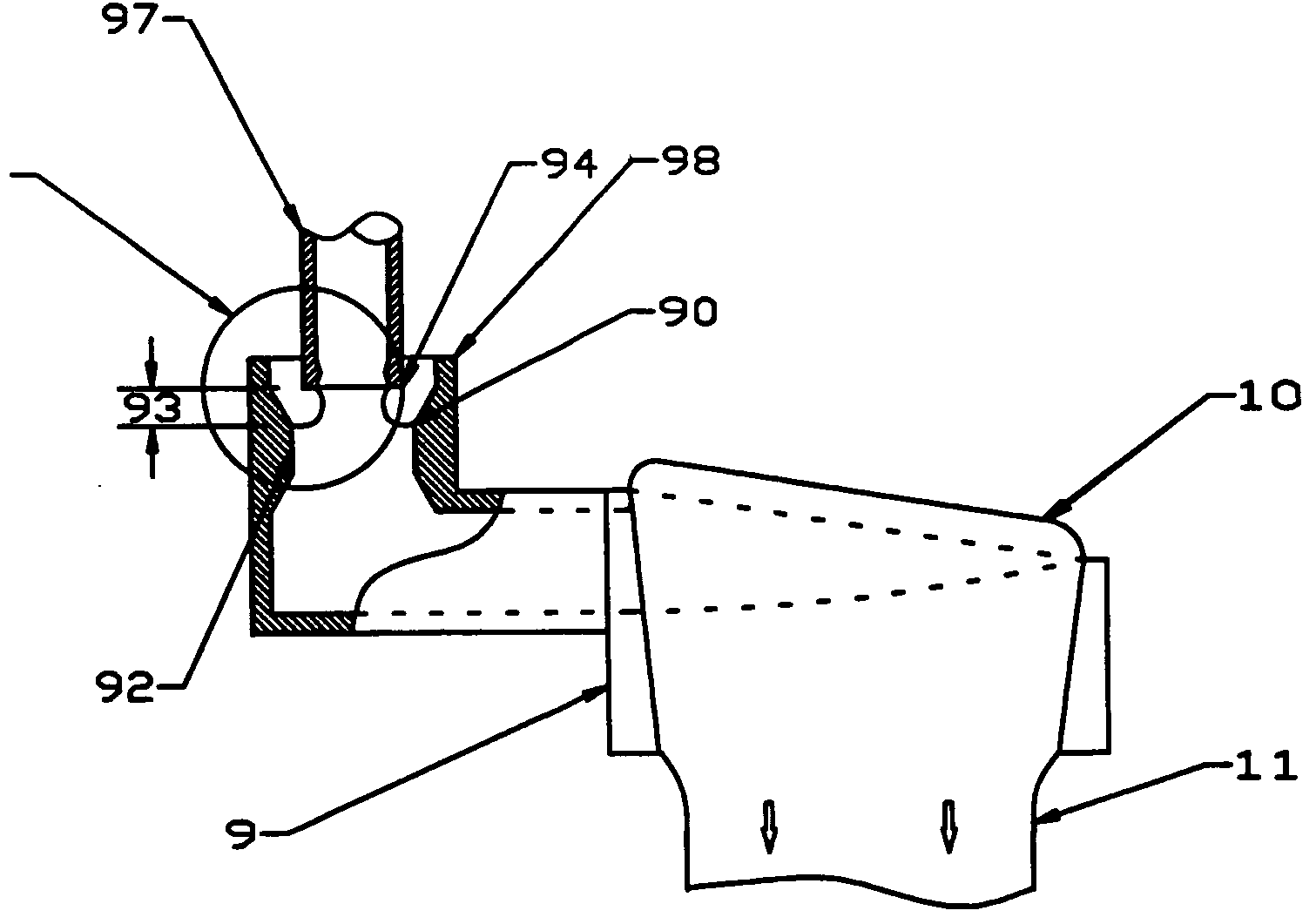

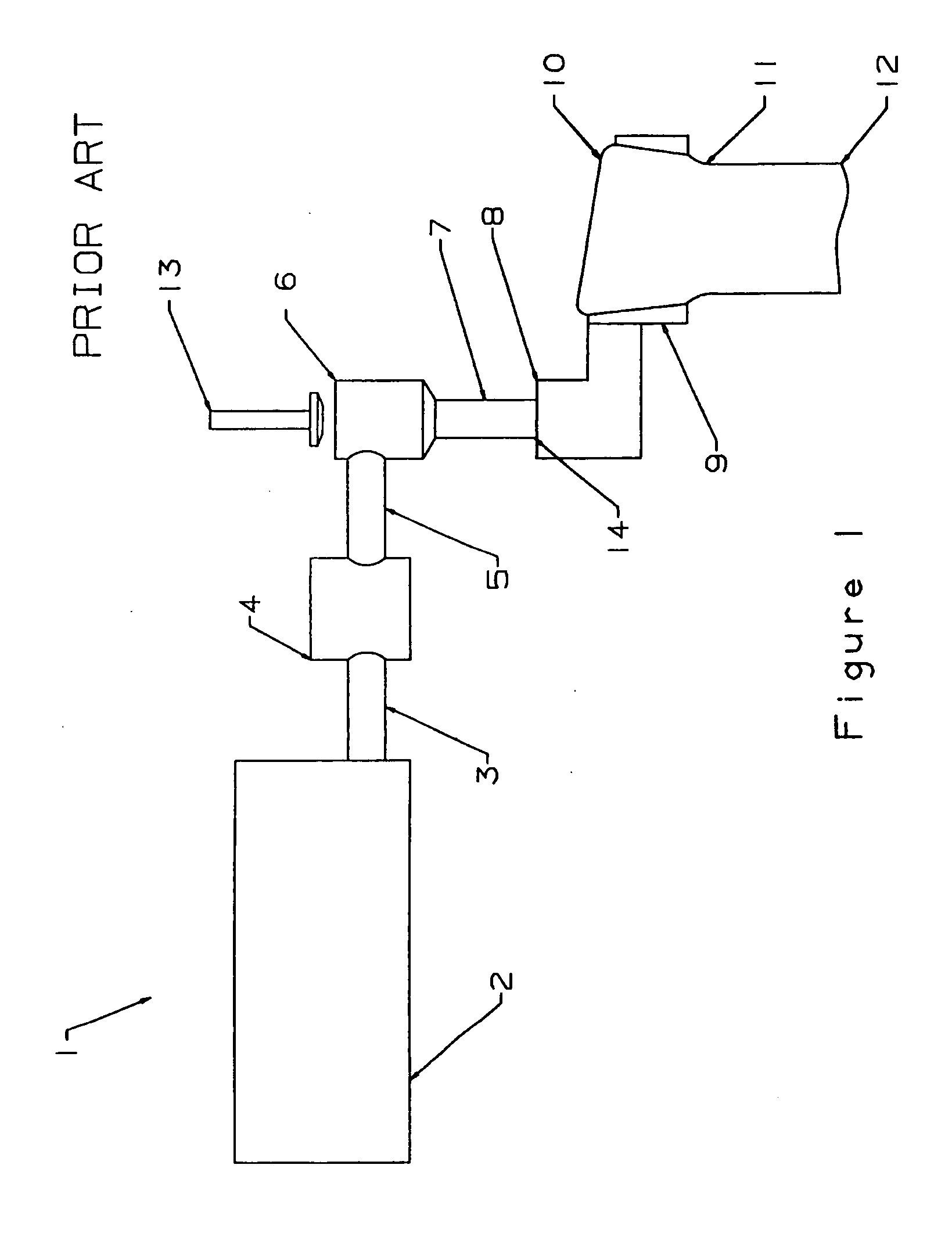

Sheet glass forming apparatus

InactiveUS20050092027A1Minimize air leakageReduce unevennessGlass furnace apparatusGlass drawing apparatusFlat glassInternal pressure

One embodiment of the present invention is an improved sheet glass forming apparatus. In another embodiment, a precise thermal control system redistributes the flow of molten glass at the weirs to counteract the degradation of the sheet forming apparatus which inevitably occurs during manufacturing. In yet another embodiment, the invention introduces a counteracting force to the stresses on the trough in a manner such that the thermal creep which inevitably occurs has a minimum impact on the glass flow characteristics of the forming trough. Another embodiment creates a variable external cross-section which provides hydraulic stresses that are in opposition to the surface tension and body force stresses and thus, reduces the influence of surface tension and body forces. In an alternative embodiment, the glass is preferentially cooled across its width to create forming stresses during solidification, which ensures that the glass sheet drawn is inherently flat. In an additional embodiment, the internal pressure is adjusted in each of the major components of the forming apparatus such that the pressure difference across any leakage path to the forming zone is essentially zero. Therefore, air leakage in the apparatus is minimized even though the cracks and openings exist during initial operation and develop during manufacturing.

Owner:CORNING INC

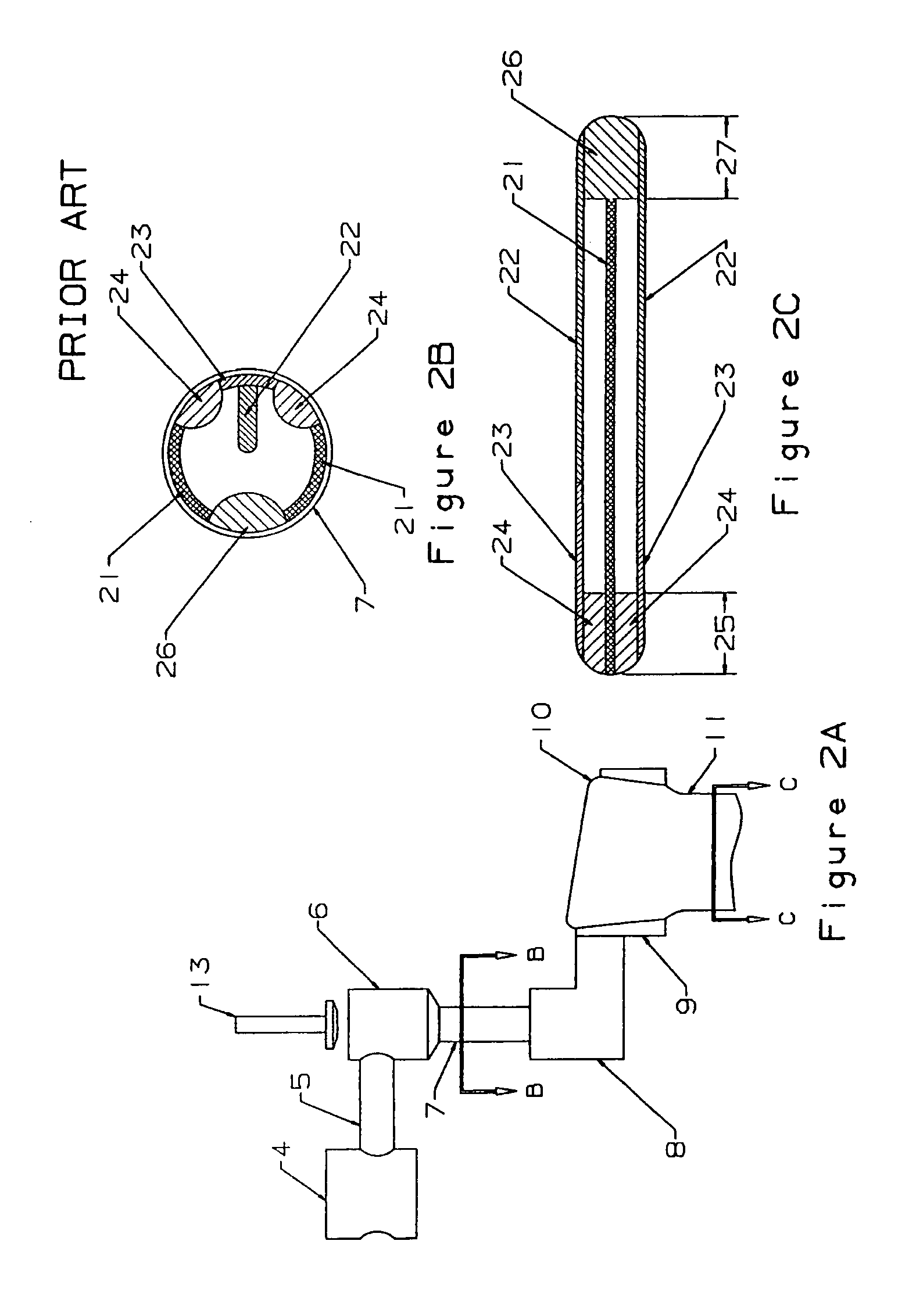

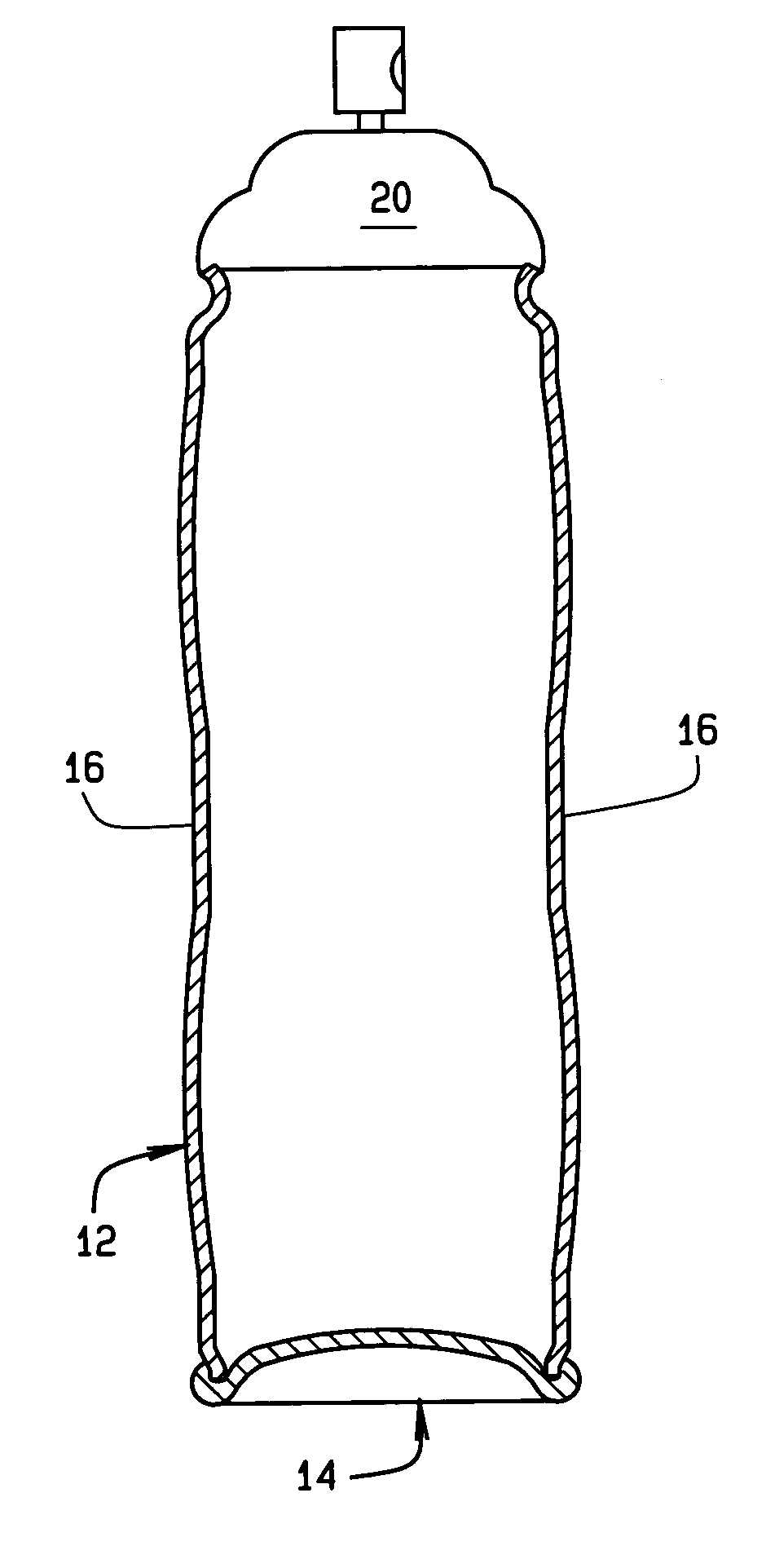

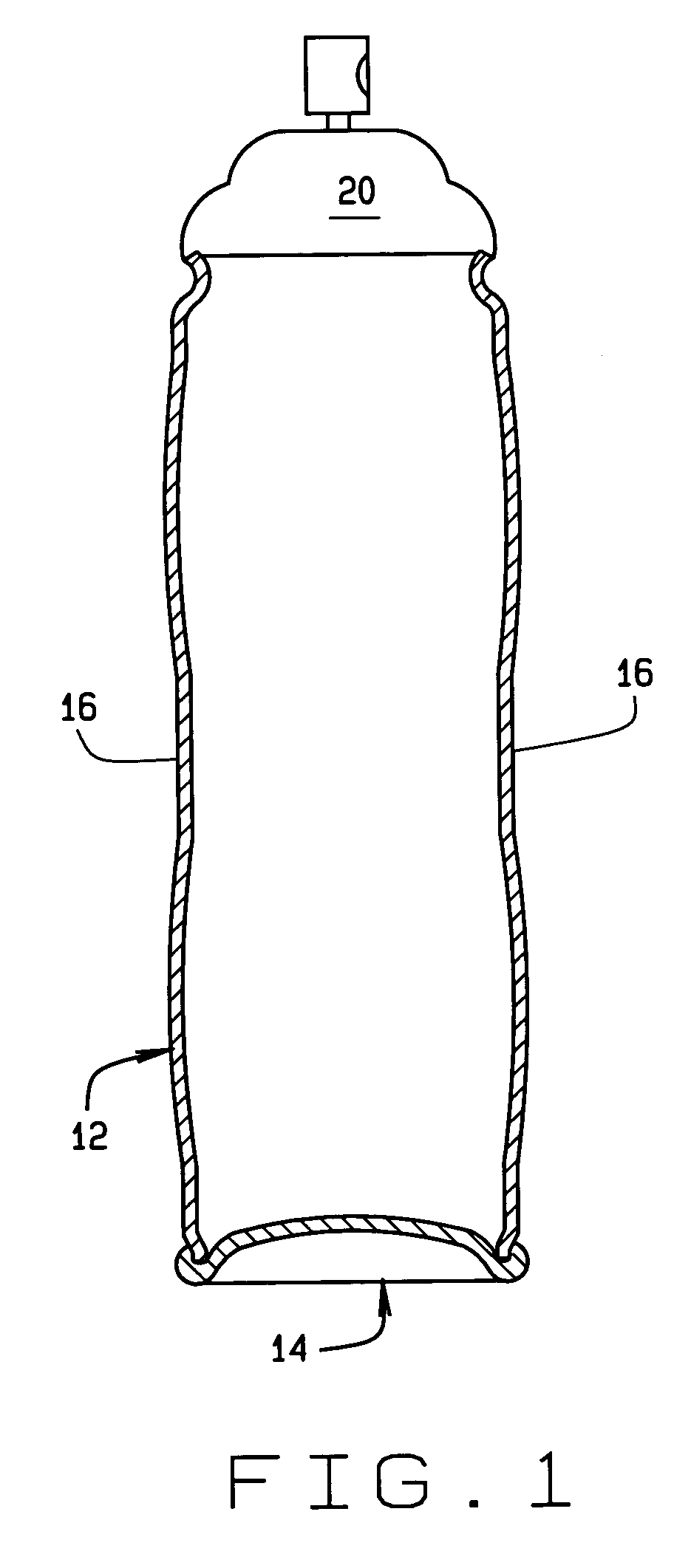

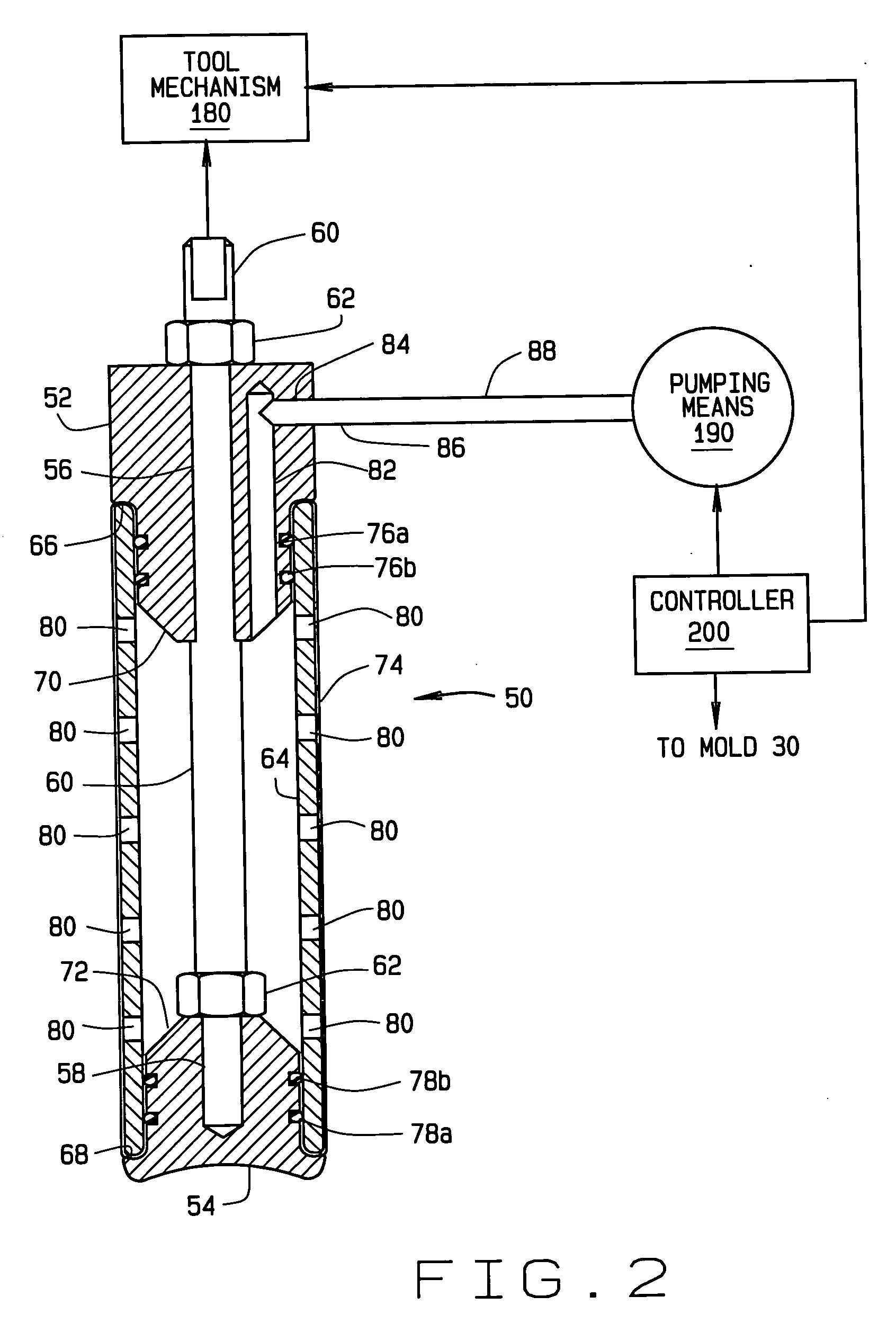

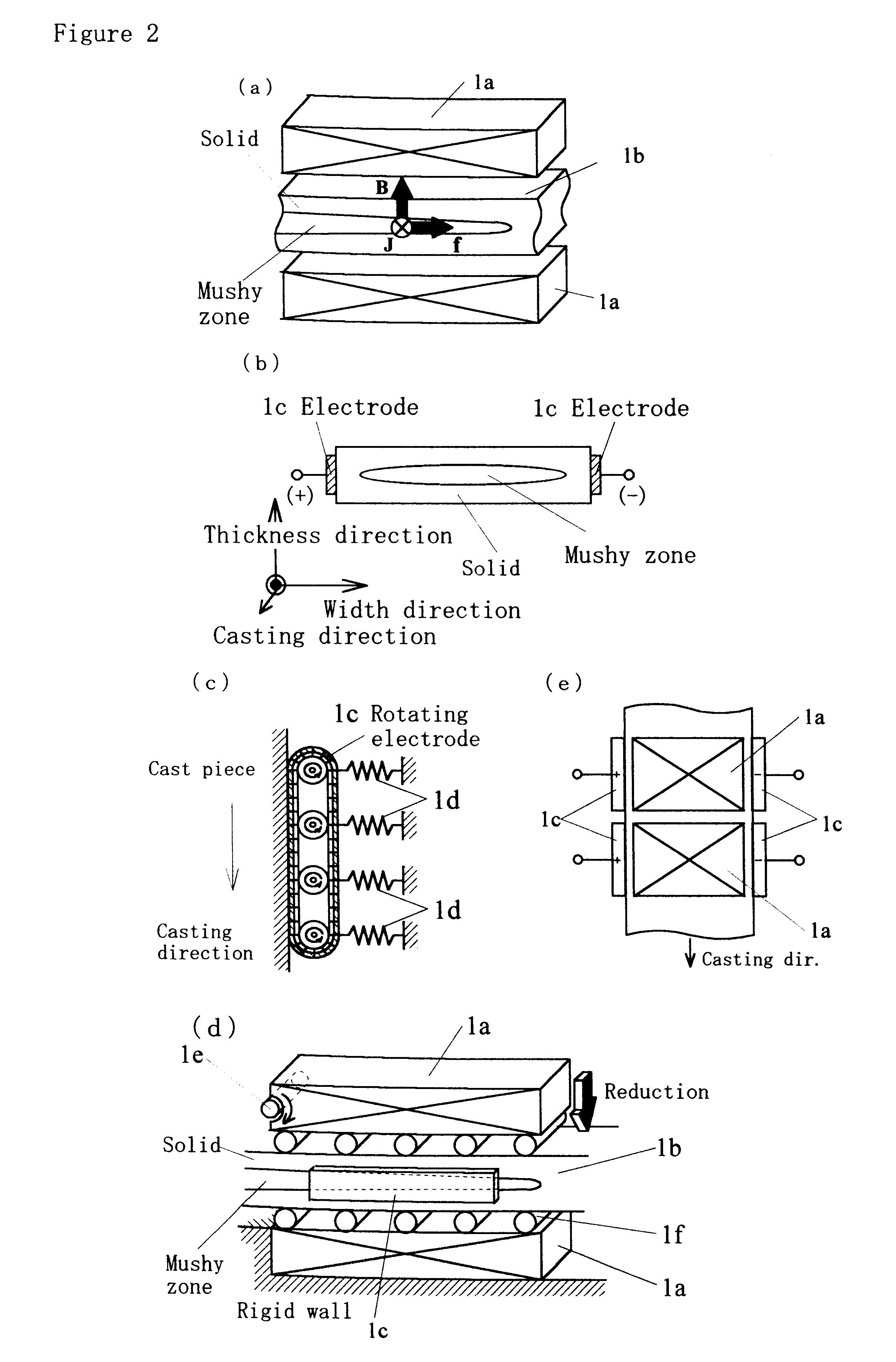

Dry hydraulic can shaping

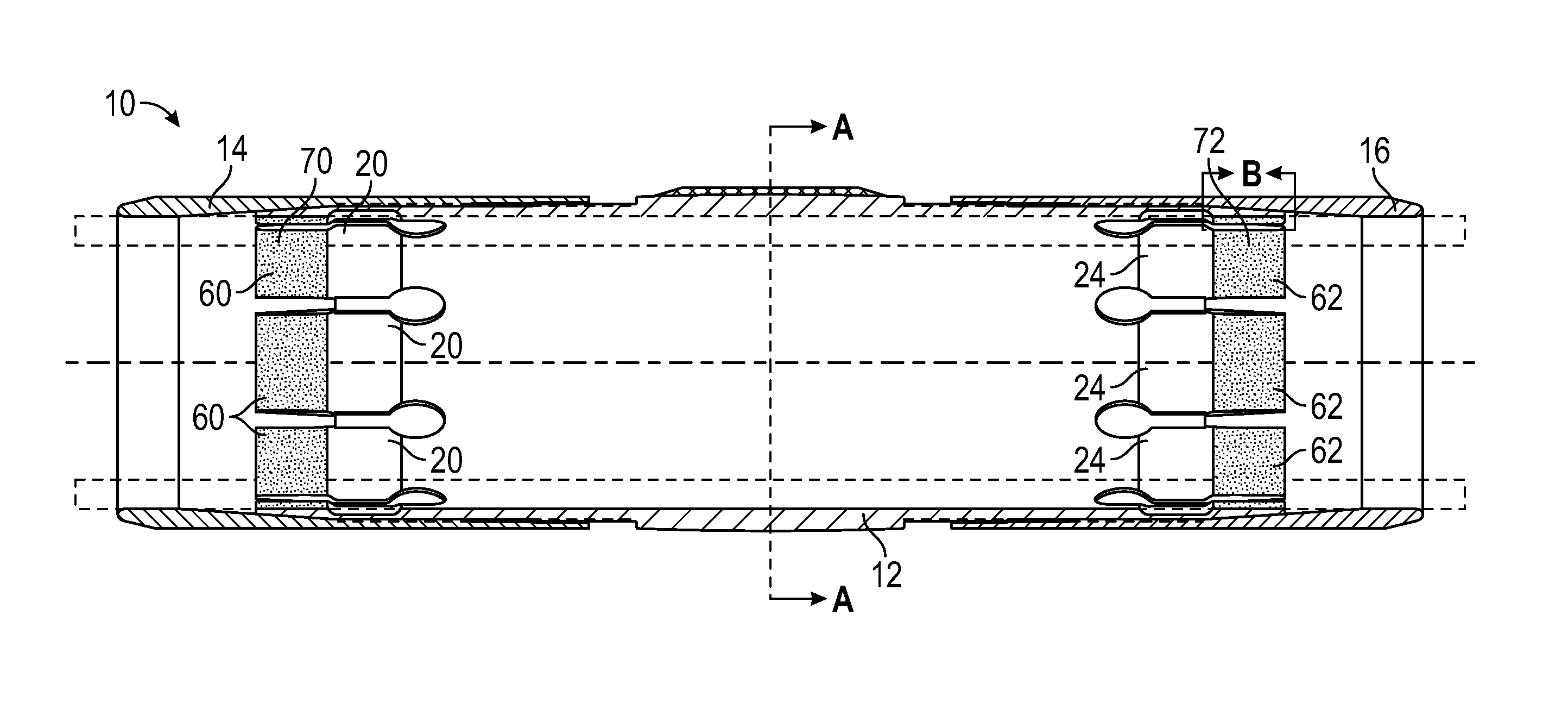

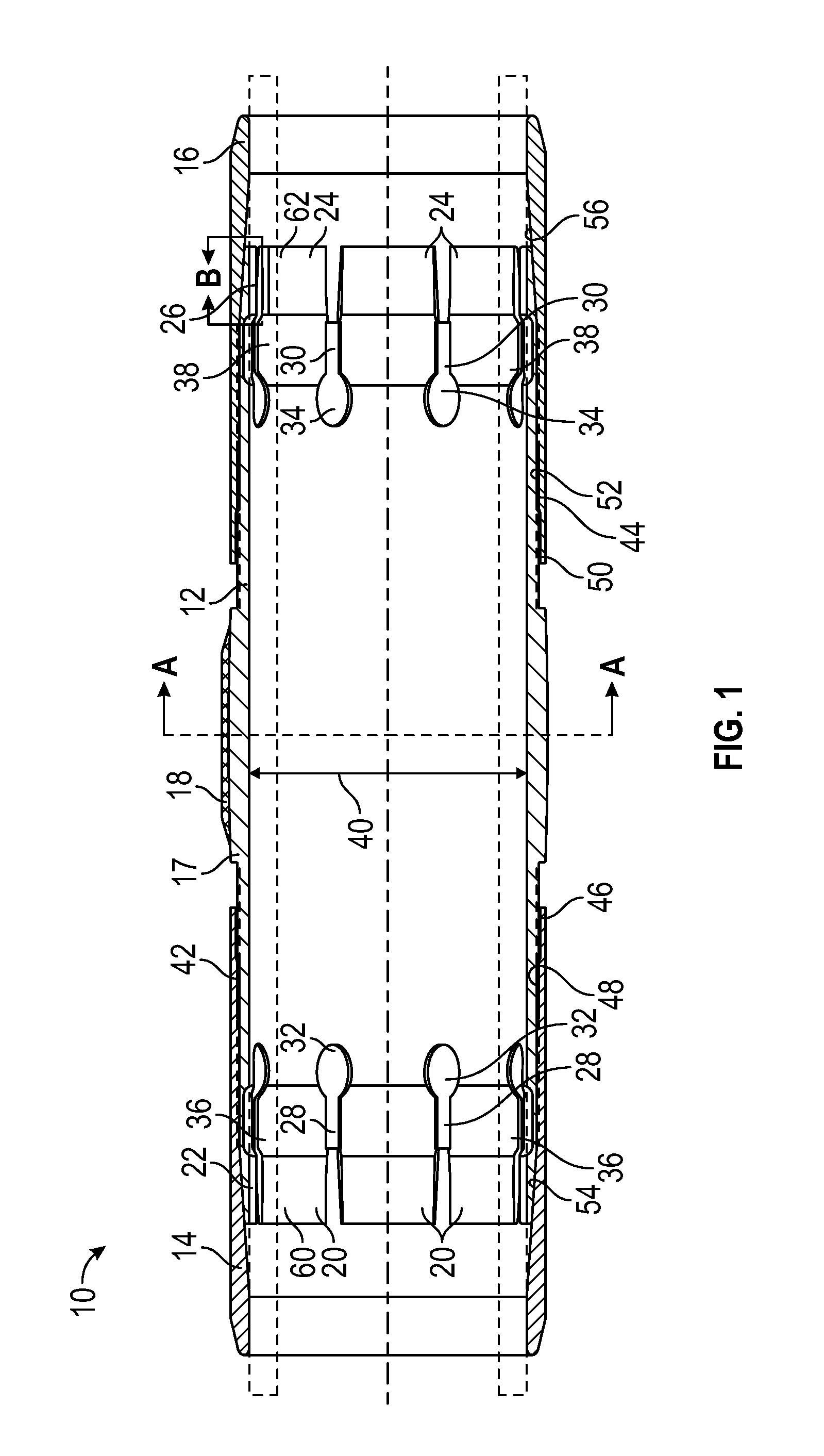

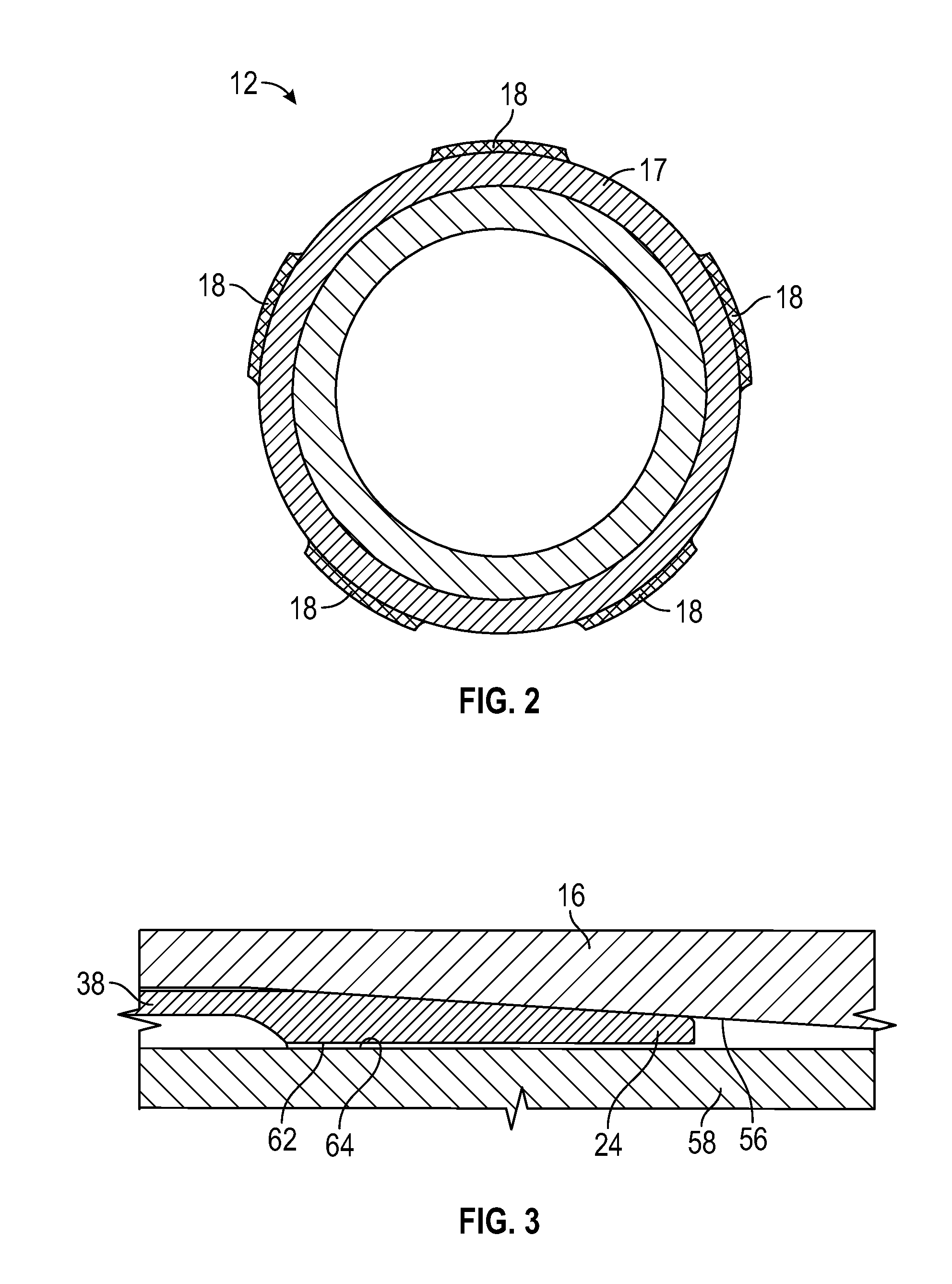

ActiveUS20060060601A1Reduce manufacturing stepsShorten production timeOpening closed containersBottle/container closureEngineeringHydraulic fluid

A method for shaping an aerosol container (10) to a desired body contour. A container body (12) is formed into a cylindrical shape and installed into a mold (30) whose inner surface defines the desired body contour. A bladder (74) is fitted onto a tool (50) insertable into an open end (M) of the container body. Once the tool is inserted, the bladder is inflated with a hydraulic fluid. Pressurizing the bladder forces the bladder against a sidewall of the body forcing the body outwardly and deforming it against the inside of the mold. After the container body is shaped, the bladder is de-pressurized and the tool withdrawn leaving the container with a defined body contour. The hydraulic fluid with which the bladder is pressurized is, at all times, contained within the bladder and does not contact the container sidewall so no subsequent drying of the container is required after the shaping process is complete.

Owner:BALL METALPACK LLC

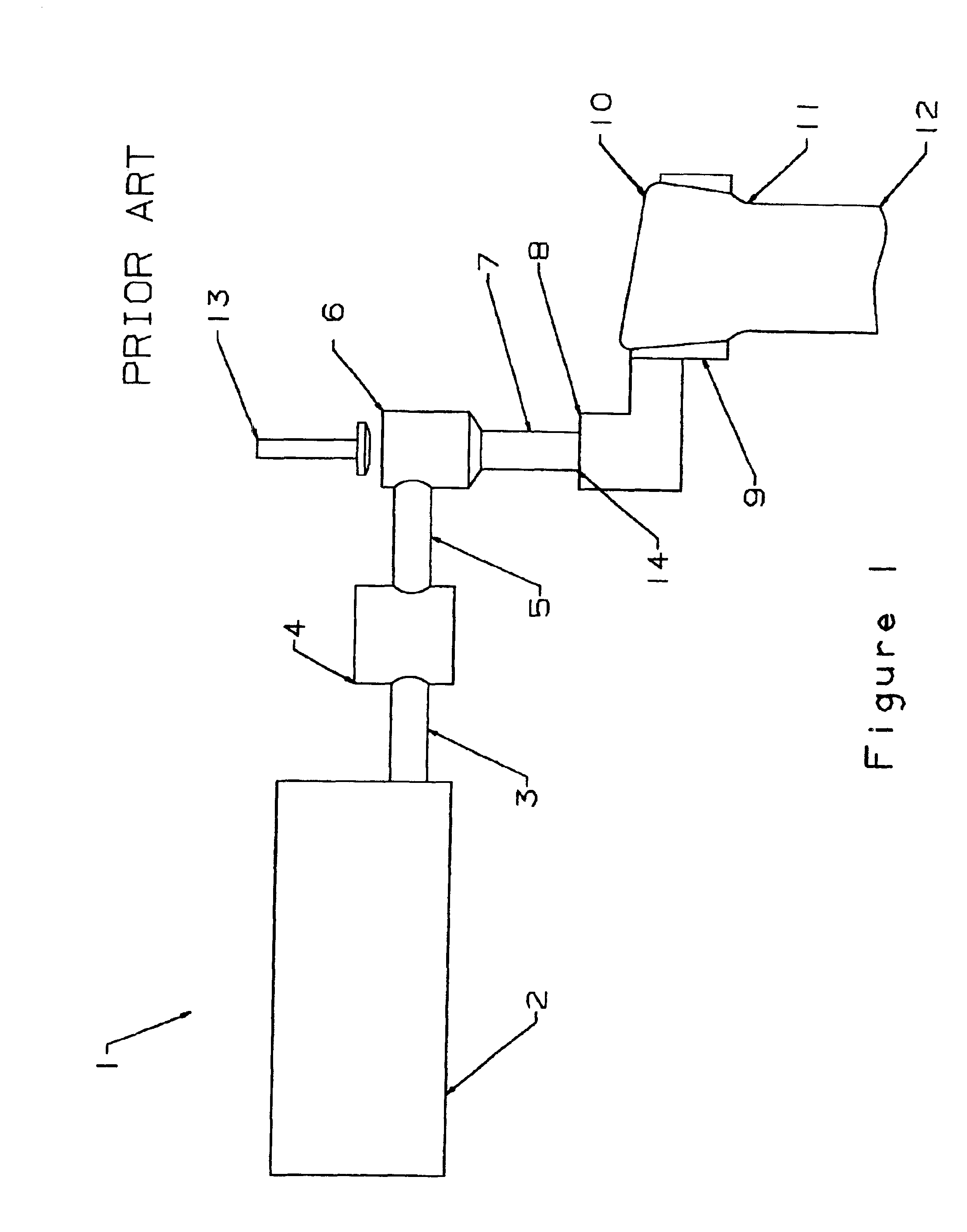

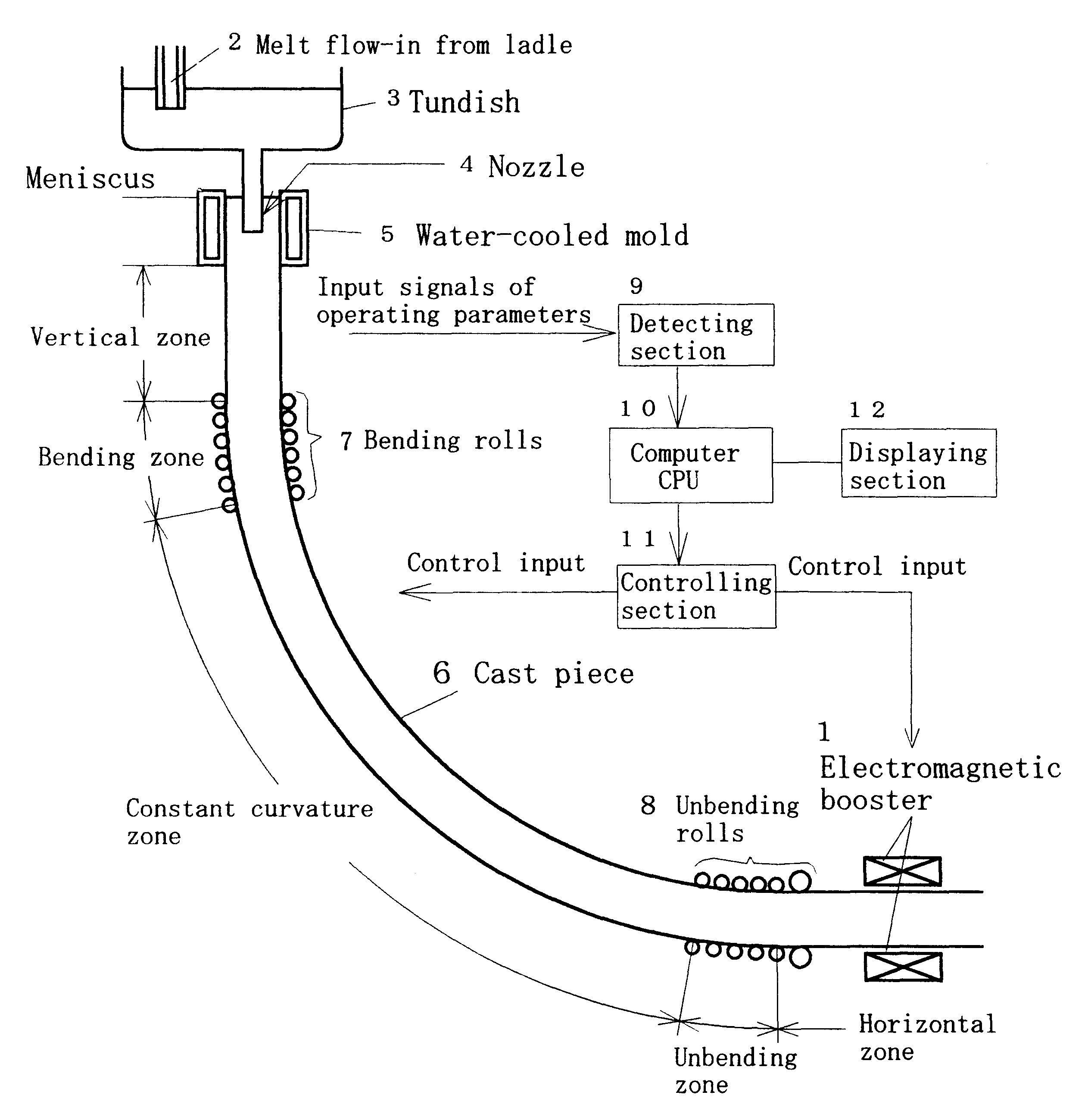

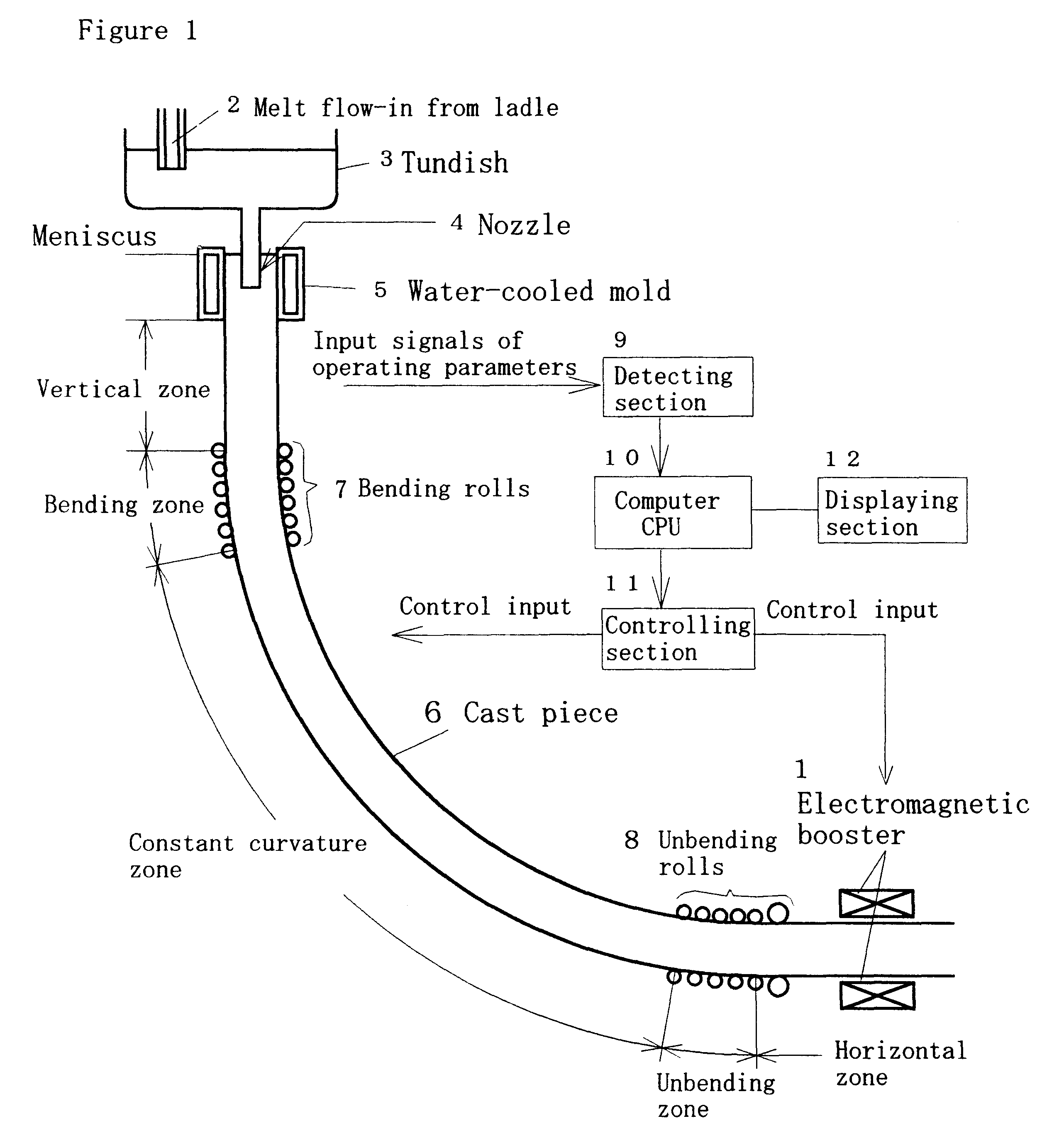

Method and apparatus for continuous casting

Method and apparatus for continuous casting, especially casting of steel that can easily provide high quality steel that has no central segregation and central porosity. In other words, in the method and apparatus, central defects are to be eliminated first by identifying the solidifying conditions in the full range from the meniscus (the surface position of the upper portion of molten metal) to the crater end (a final solidification position), based on the type (profile) of continuous casting machine, type of steel, cross-sectional shape and size of a cast piece and the operating conditions such as casting speed, casting temperature and cooling conditions, with special attention paid to the pressure drop of liquid phase induced by the liquid flow between dendrites resulting from the solidification contraction in casting direction in the solid-liquid coexisting zone, second by calculating the condition of the formation of the above internal defects and their positions, and finally by applying an electromagnetic body force (Lorentz force) in the casting direction in the vicinity of the region where the internal defects are formed.

Owner:EBISU

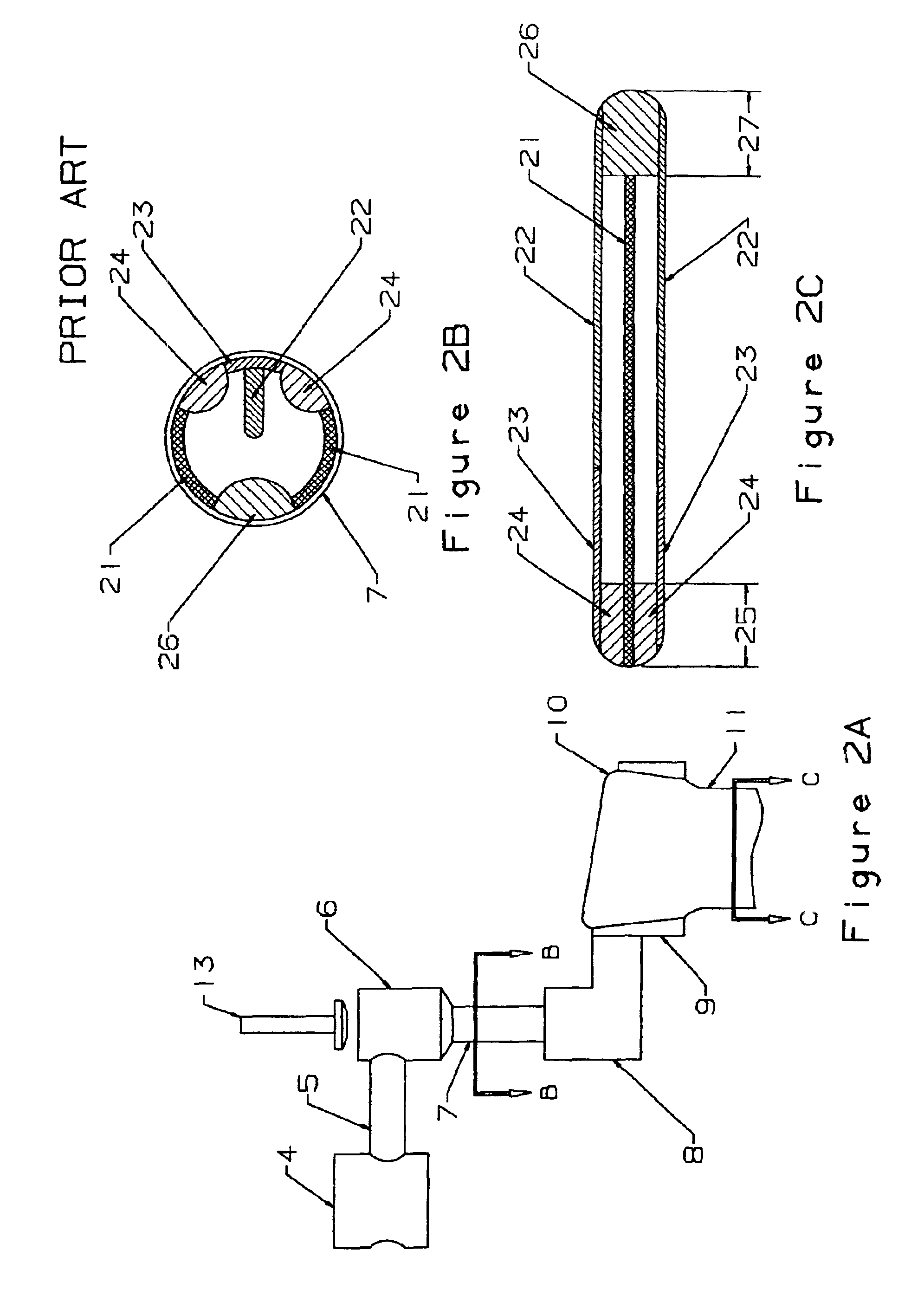

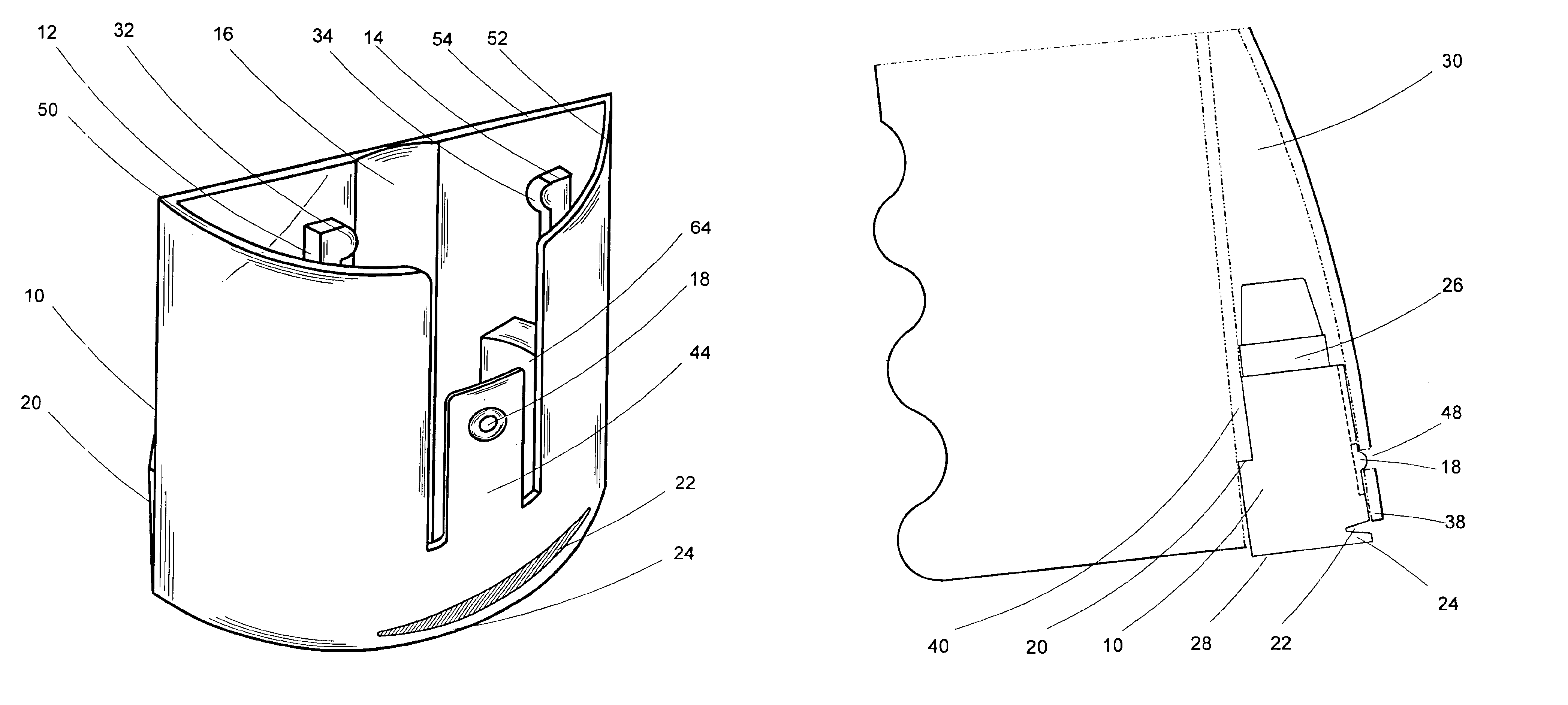

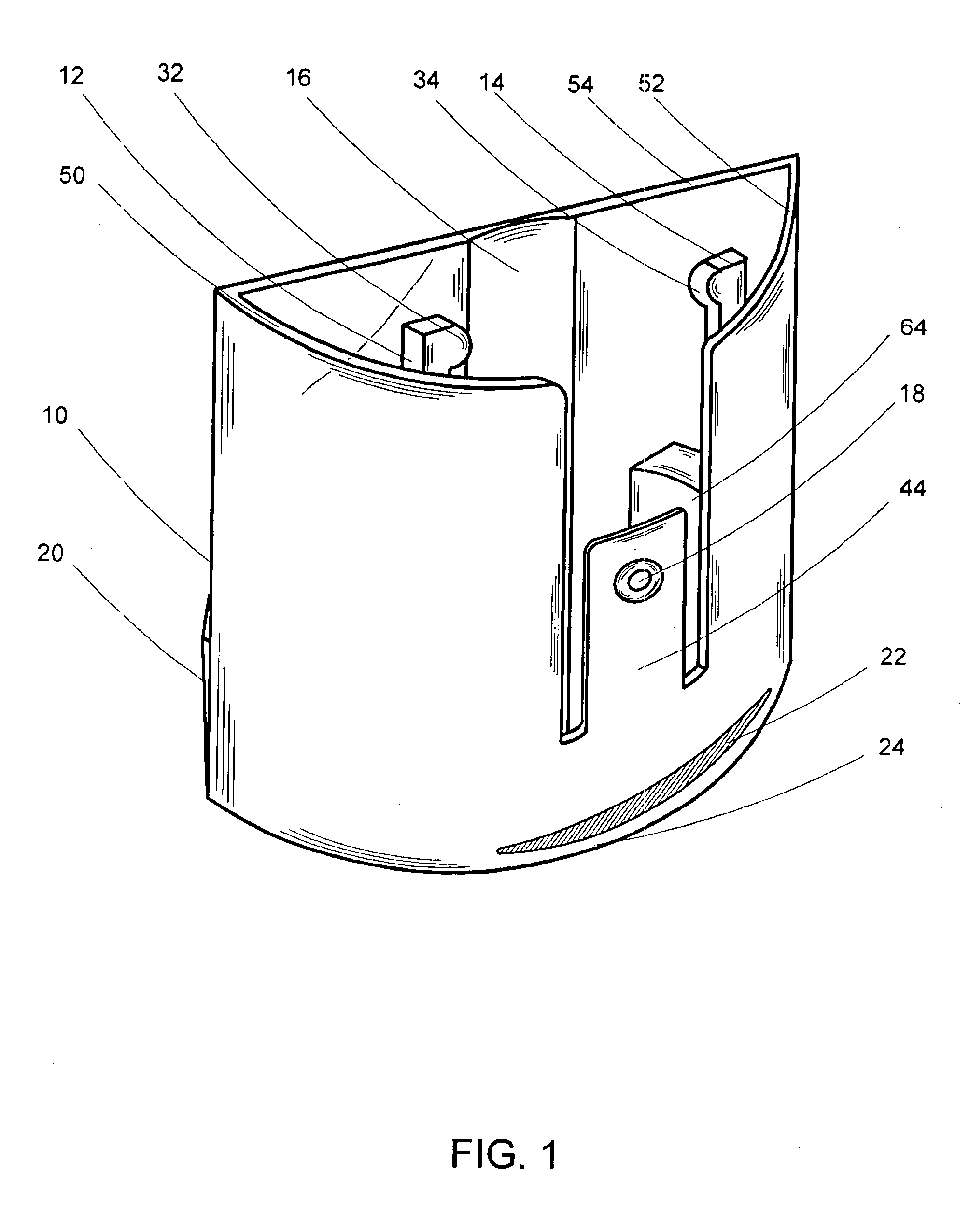

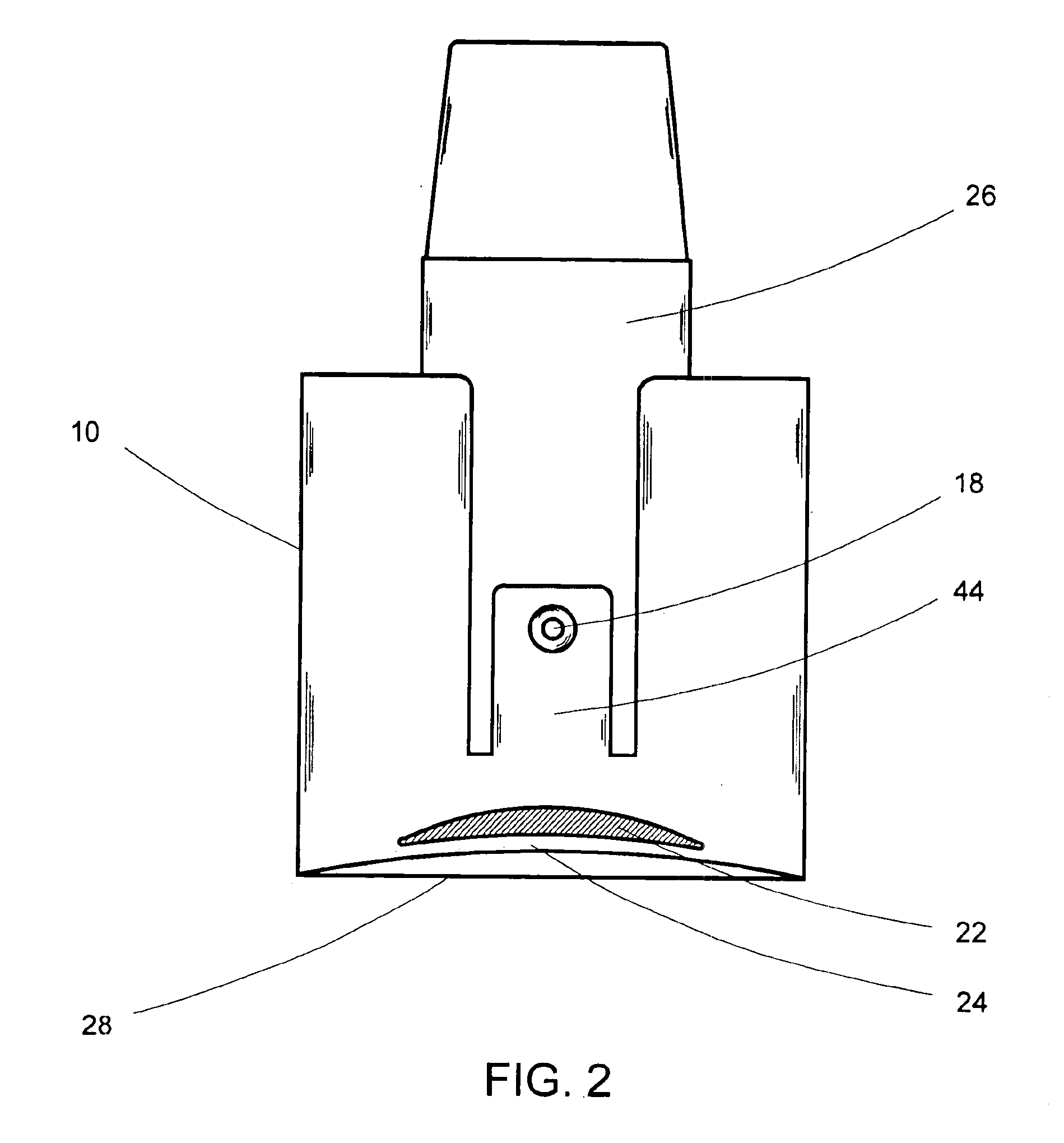

Insert for storing a firearm cartridge within cavity of handgun grip

InactiveUS6874266B1Safe and secure storageConveniently engageAmmunition storageAmmunition loadingCircular discEngineering

A device to provide storage of a firearm cartridge (26) within a firearm frame cavity (30) consisting of an insert body (10) shaped to fit within the frame cavity of the firearm while securely holding the firearm cartridge. The insert body contains a pair of rigid poles (12,14) attached to a pair of half disks (32,34) that secure the inserted cartridge by tensions created due to the rigidity of the poles when the inserted firearm cartridge forces the poles to their proximal positions. During insertion to the firearm frame cavity, the rigid stopper support (44) of the insert body is urged to its proximal position, but returns to its distal position when the stopper (18) engages the lanyard hole (48) of the frame cavity. Applying a downward force to the front bottom edge (24) of the insert body forces the rigid stopper support back to its proximal position and disengages the stopper from the lanyard hole facilitating removal of the insert body with the stored firearm cartridge still attached. Inspection hole (60) provides a visual check of the stored cartridge's presence while the insert body is within the firearm cavity (30).

Owner:KONG LARRY SHUMING

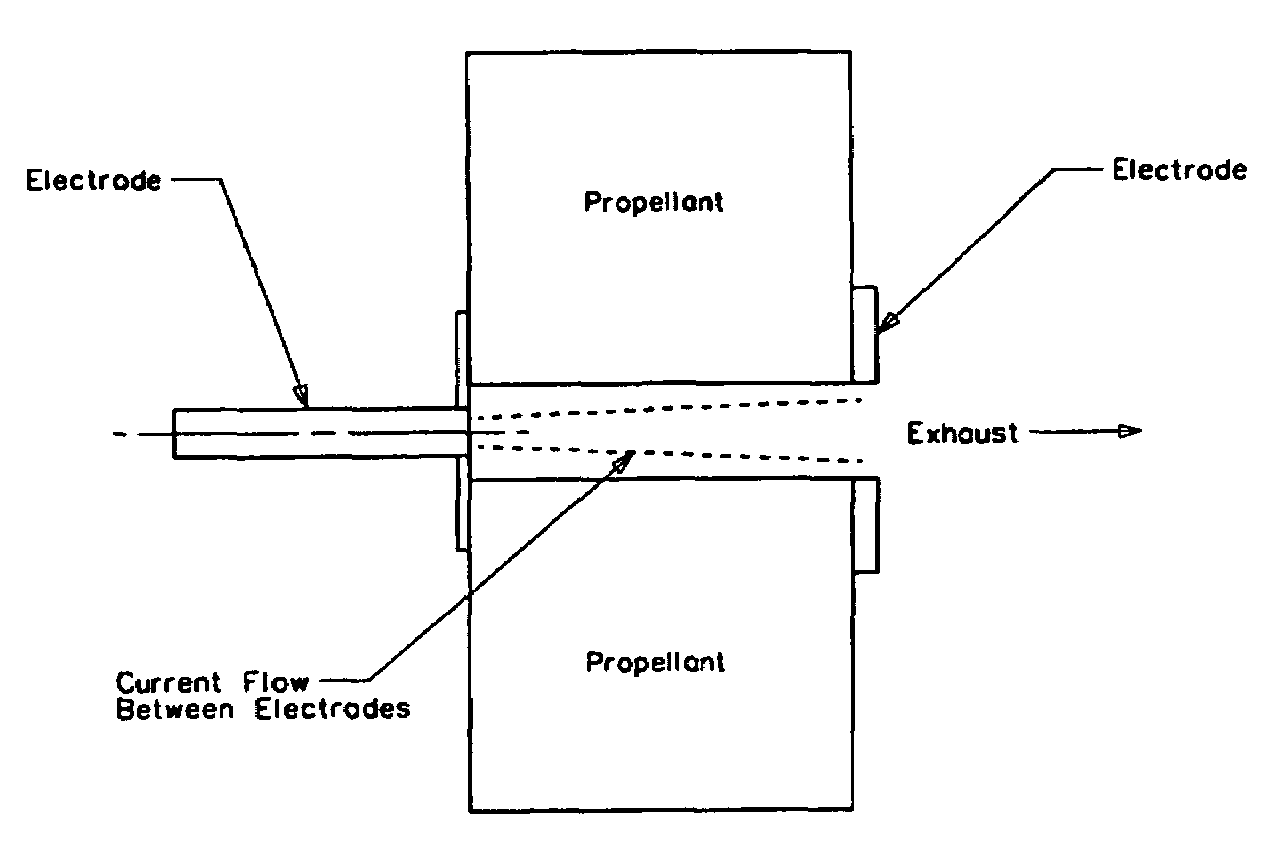

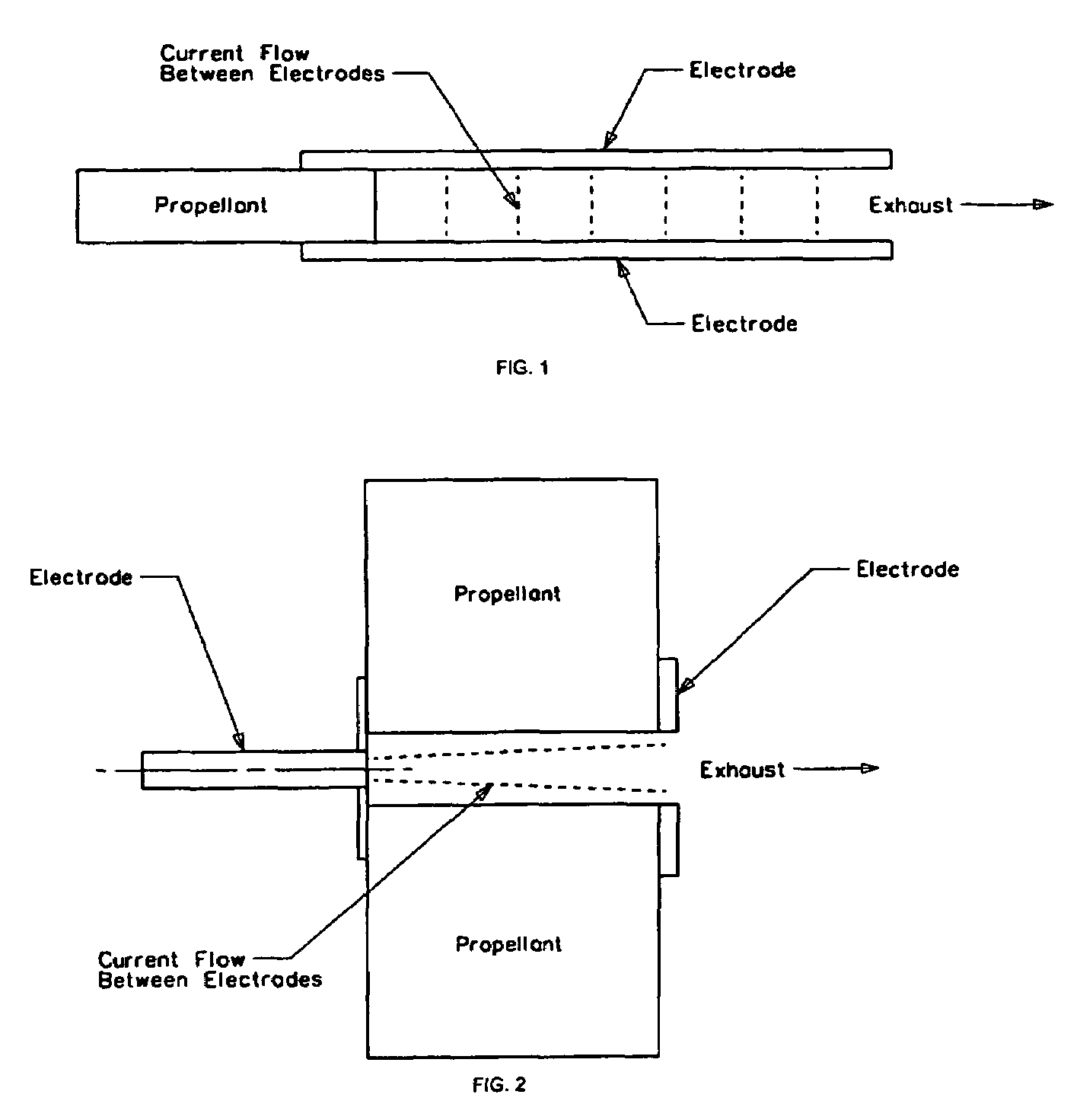

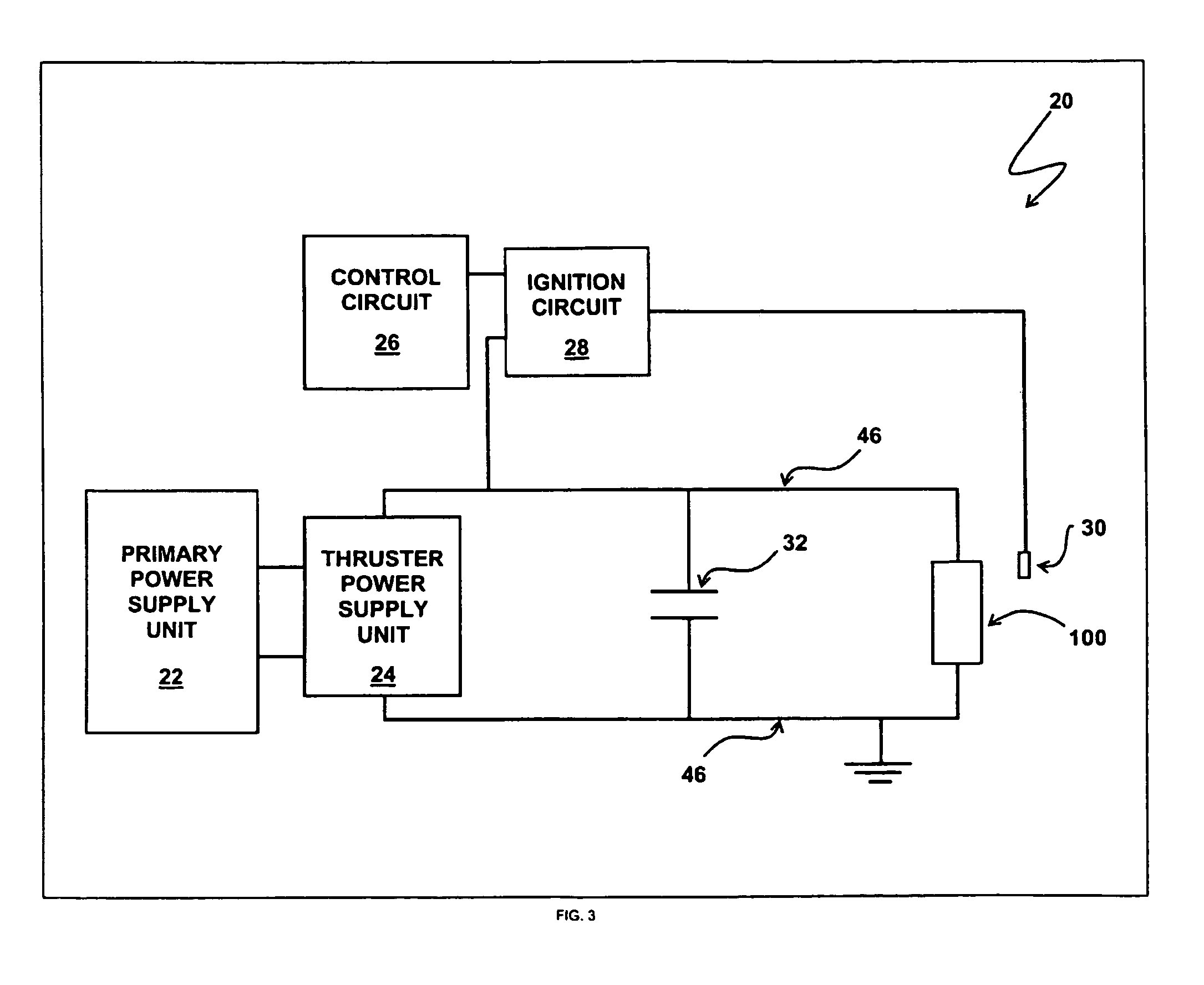

Advanced pulsed plasma thruster with high electromagnetic thrust

ActiveUS7530219B1Reduce resistanceHigh currentMachines/enginesUsing plasmaElectrical resistance and conductanceCoaxial geometry

A pulsed plasma thruster provides for an advanced lightweight design with solid propellant and predominately electromagnetic thrust in a coaxial geometry. Electromagnetic forces are generated in a plasma by current flowing from a small central electrode to an electrically conducting diverging nozzle electrode. The thruster employs a series of electric current pulses of limited duration and varying frequency between the pair of electrodes creating a series of electric arcs. The electric arcs pass over a propellant surface located between the electrodes, forming a plasma, which is then exhausted from the device to produce thrust. The thruster maintains a low plasma resistance and cavity pressure, which in turn yields strong electromagnetic body forces, resulting in a high efficiency and consistent pulse-to-pulse performance.

Owner:CU AEROSPACE

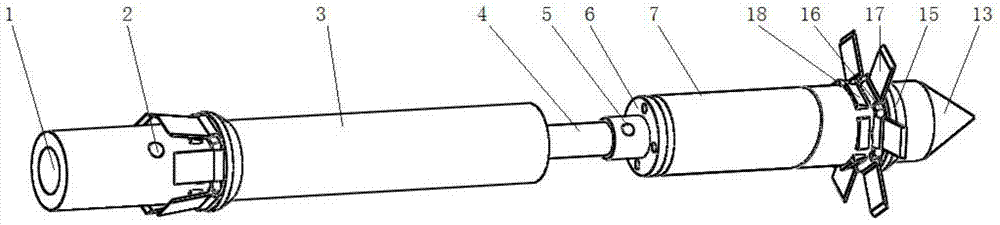

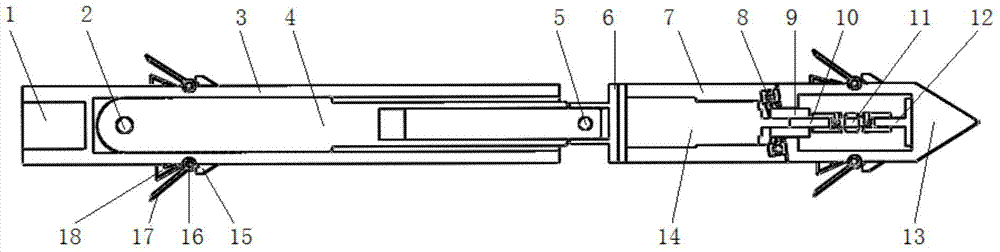

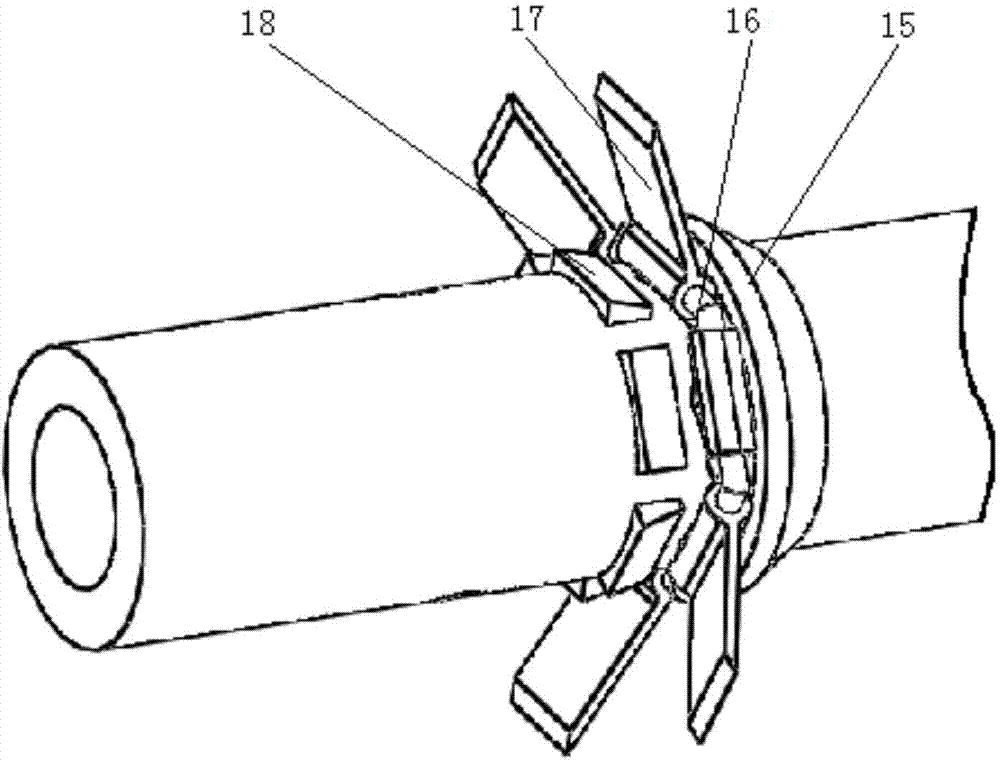

Creeping ground drilling robot

InactiveCN104727749AReduce resistanceStable thrustDrilling without earth removalEngineeringSearch and rescue

The invention relates to a creeping ground drilling robot which comprises an electric push rod mechanism, a motor steering mechanism and a drill bit mechanism which are sequentially connected. The outer wall of the electric push rod mechanism and the outer wall of the drill bit mechanism are each provided with a scale device capable of expanding and retracting, the electric push rod mechanism stretches and retracts periodically, each scale device expands or retracts under the action of soil body force and is used for providing supporting counterforce in the drilling direction, the motor steering mechanism adjusts steering of the drill bit mechanism, and a good platform is provided for the task that the robot is provided with a sensor to go deep into soil for geological prospecting, mine disaster search and rescue or soil sample collection in the future. Compared with the prior art, the robot has the advantages of being simple in structure, low in manufacturing cost, convenient to control and the like.

Owner:TONGJI UNIV

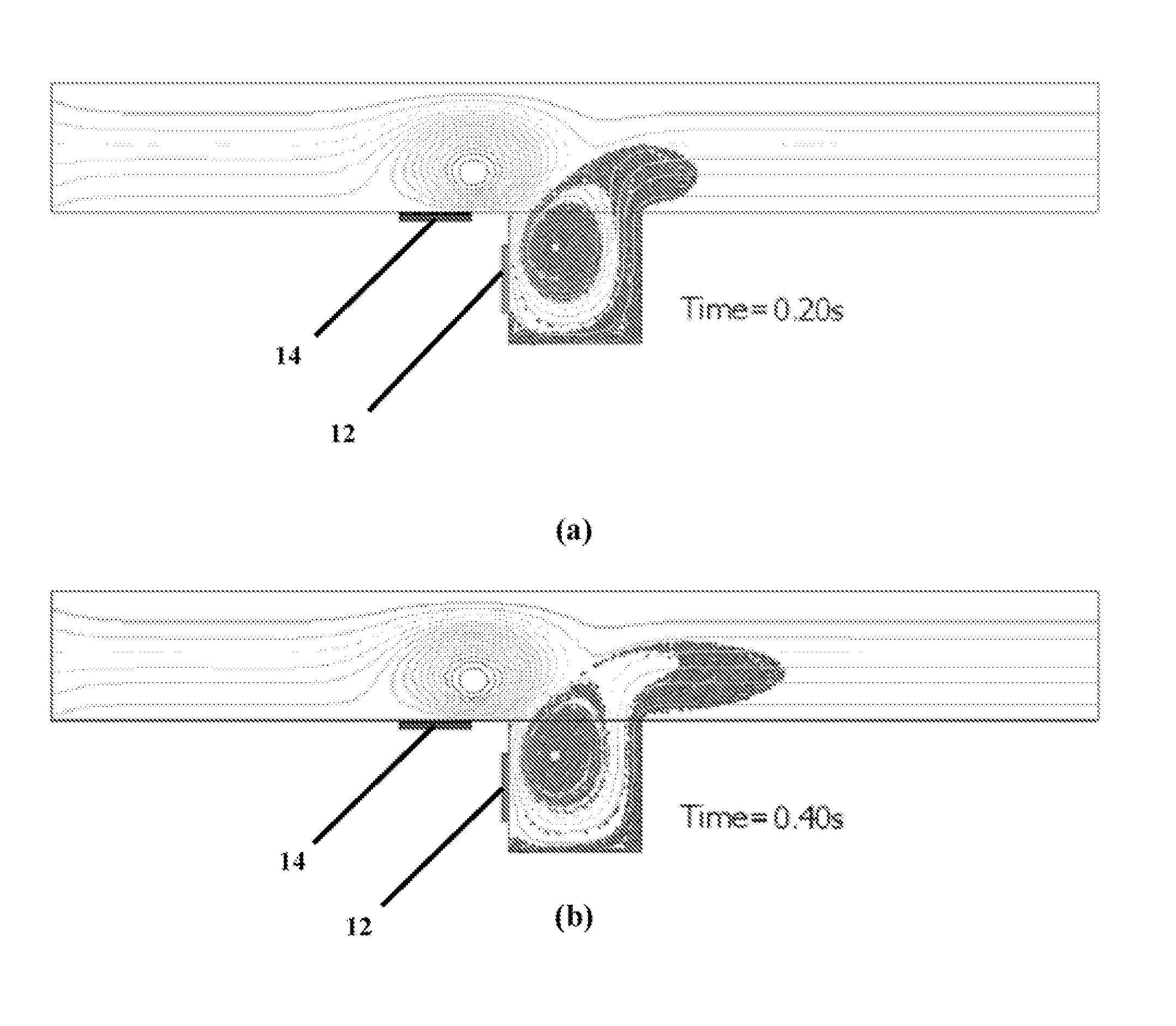

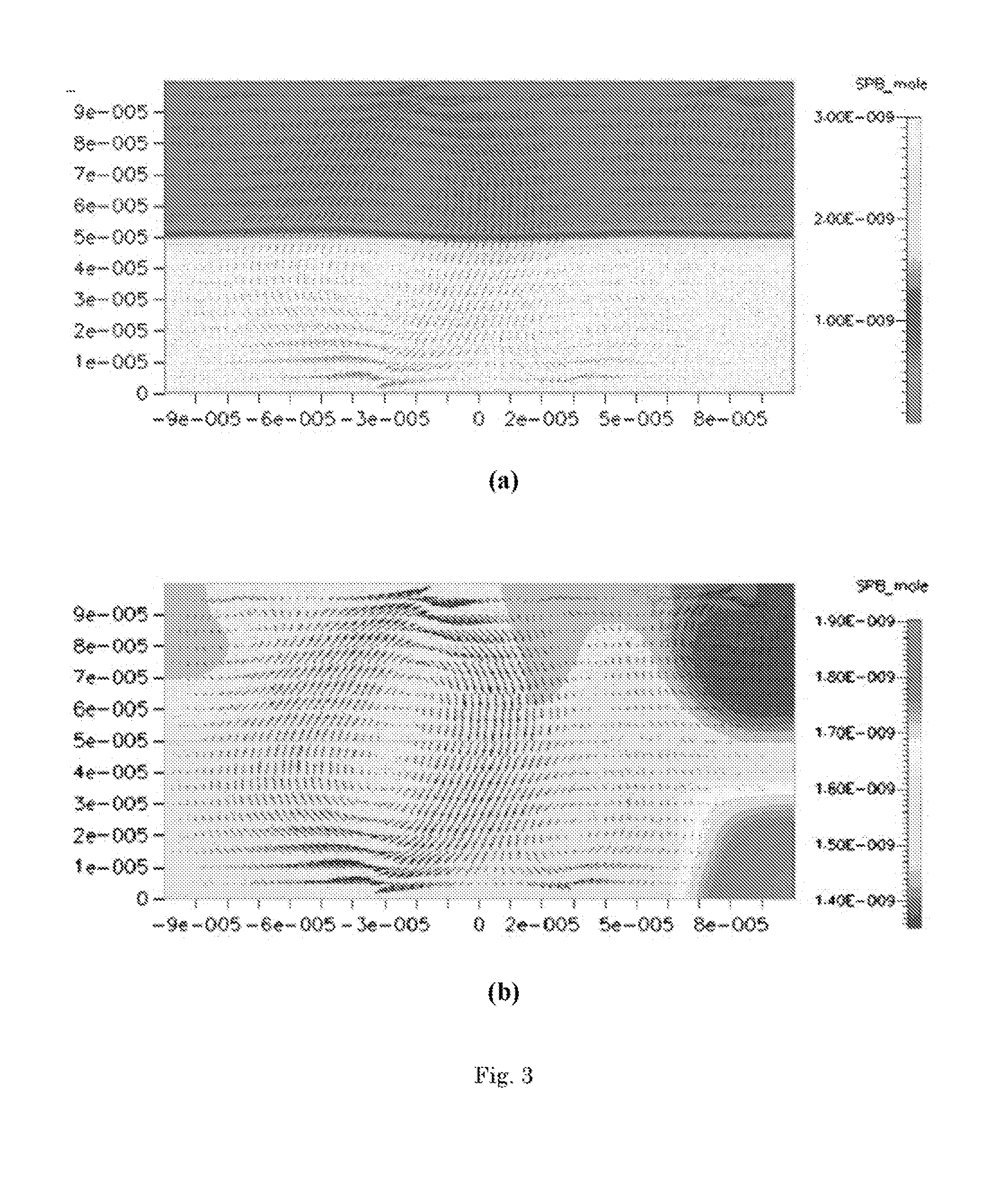

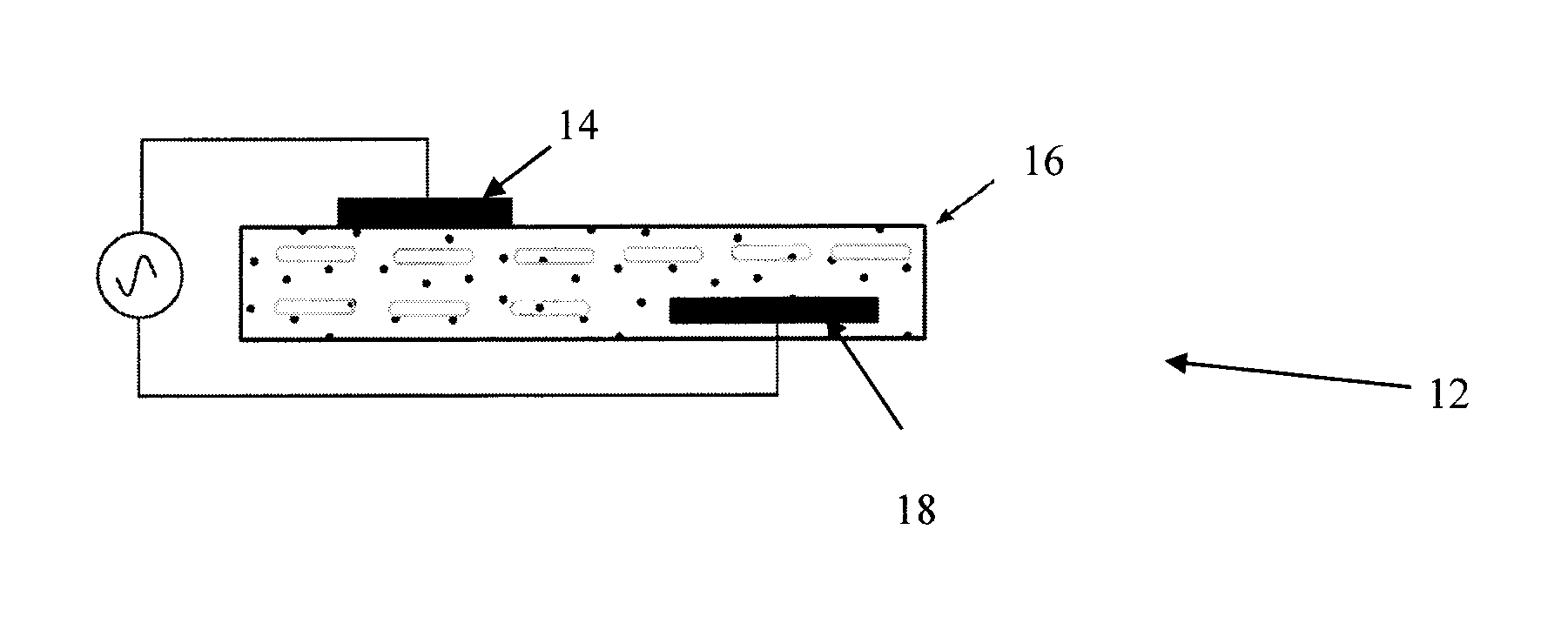

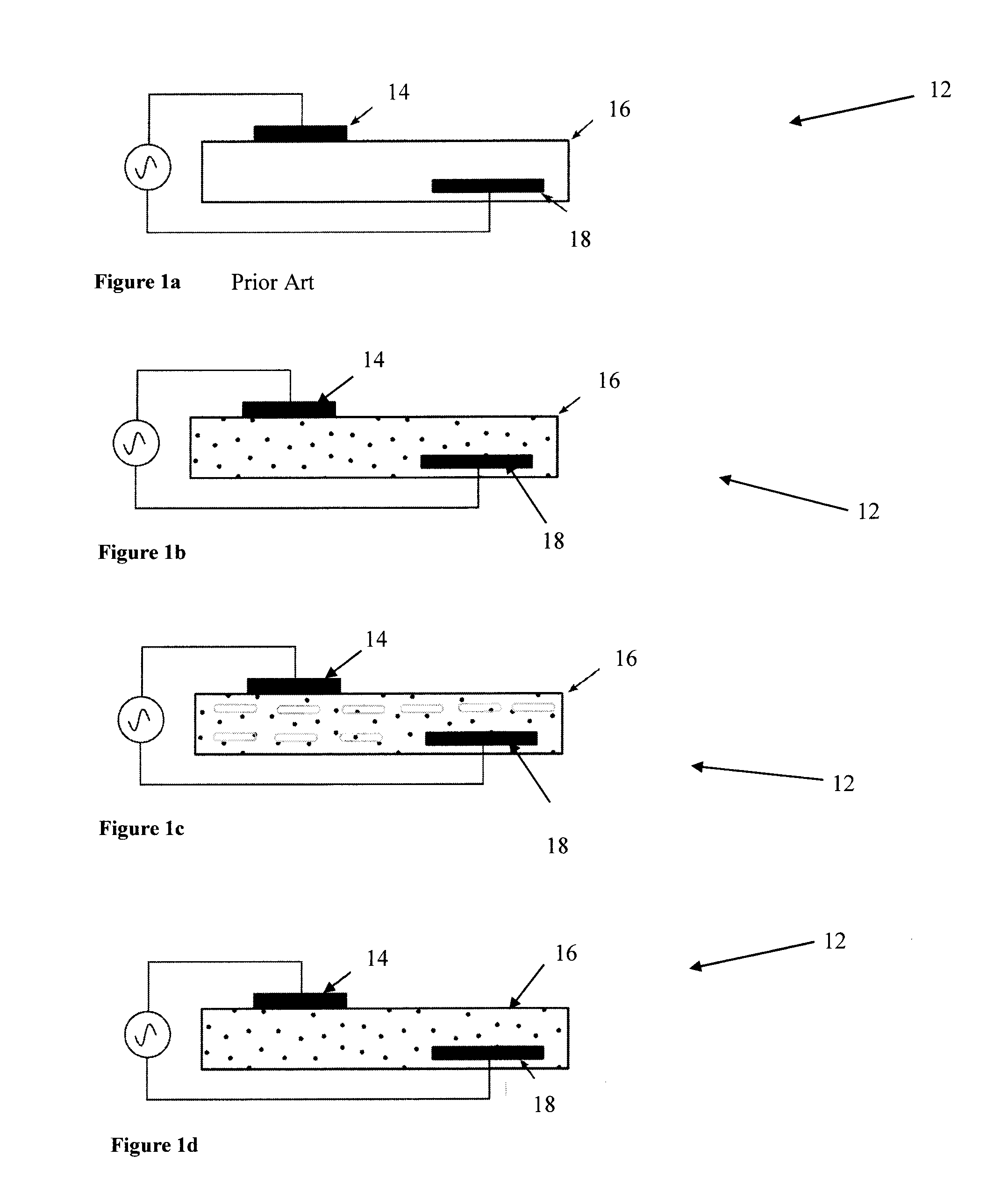

Methods and systems employing electrothermally induced flow for mixing and cleaning in microsystems

ActiveUS7189578B1Reduced Power RequirementsEasy to measureElectrolysis componentsVolume/mass flow measurementEngineeringDc voltage

A method and system for controlling flow motion in a channel / cavity in a microfluidic system includes positioning at least one pair of electrodes in and / or proximate to the channel / cavity. A buffer solution is placed in the channel / cavity, the buffer solution having at least one dielectric property that varies in response to changes in temperature of the solution. An AC / DC voltage is applied to the electrodes to generate an electric field in the channel / cavity; the AC voltage having a known magnitude and frequency and the DC voltage having a known magnitude. The magnitude of the AC / DC voltage is adjusted to cause Joule heating of the buffer solution in the channel / cavity. The geometry and position of the electrodes is adjusted to generate a temperature gradient in the buffer solution, thereby causing a non-uniform distribution of the dielectric property within the solution in the channel / cavity. The dielectric non-uniformity produces a body force and flow in the solution. Also, the frequency of the AC voltage is adjusted to generate flow of the buffer solution in the channel / cavity in response to the non-uniform distribution of the dielectric property.

Owner:SYNVIVO INC

Tongue depressor with a force/pressure sensing element

A body force measurement system for both assessment and therapeutic usage comprising a non-rigid tongue depressor with a force sensing element attached to it and a means of converting the force sensed into quantifiable data. The system provides convenient method for making body force measurements consistent with current clinical practice and without the need for a fixed registration point.

Owner:FRIEDLAND ERIC MITCHELL +1

Enhanced yaw stability control to mitigate a vehicle's abnormal yaw motion due to a disturbance force applied to vehicle body

ActiveUS8565993B2Improved stability controlReducing response functionVehicle testingAnalogue computers for trafficControl systemSignal correlation

An enhanced stability control system (200) for a vehicle includes a vehicle status sensor that generates a sensor signal. A driver input sensor that generates an input signal. A controller (214) may disable normal yaw stability control operation and enable body-force-disturbance (BFD) yaw stability control (YSC) operation, which includes at least partially reducing response functions of the normal yaw stability control associated with the input signal, in response to the sensor signal and performing BFD-YSC functions to achieve desired control performance upon the detection of BFD reception. The controller (214) may also or alternatively compare the sensor signal to a threshold and detect an improperly functioning / inoperative vehicle status sensor. The controller (214) disregards information associated with the improperly functioning / inoperative vehicle status sensor, and continues to perform enhanced yaw stability control operations.

Owner:VOLVO CAR CORP

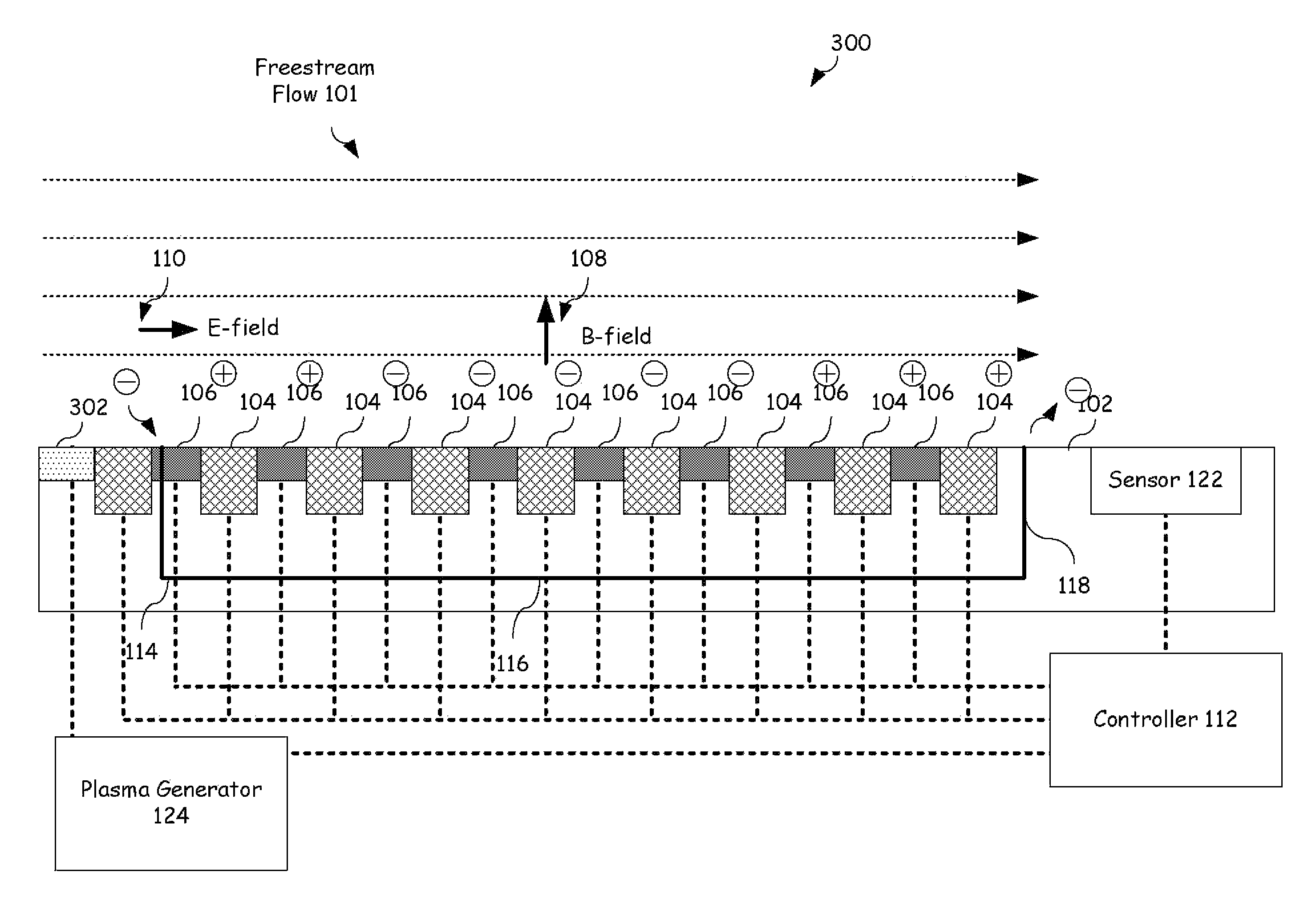

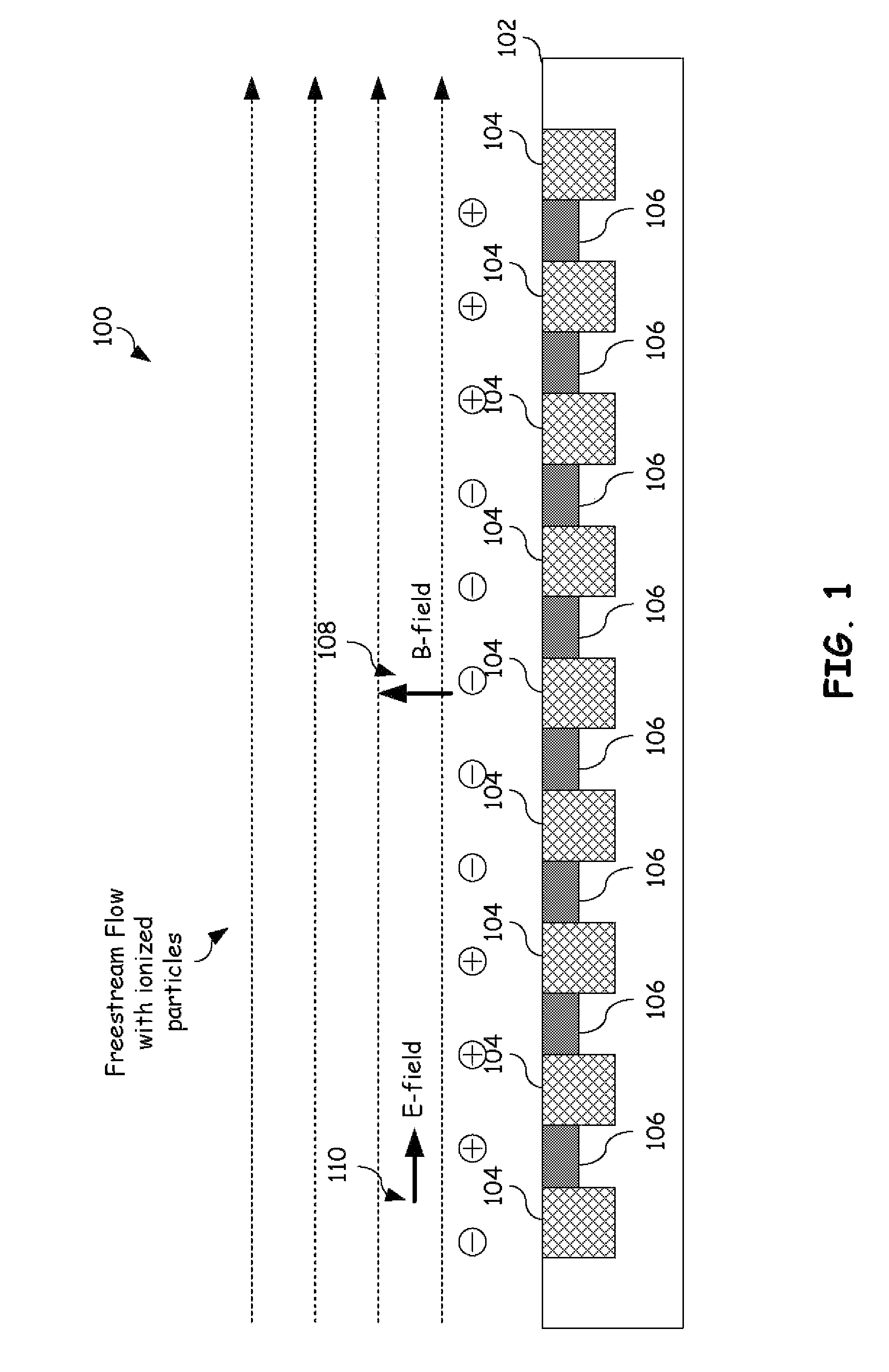

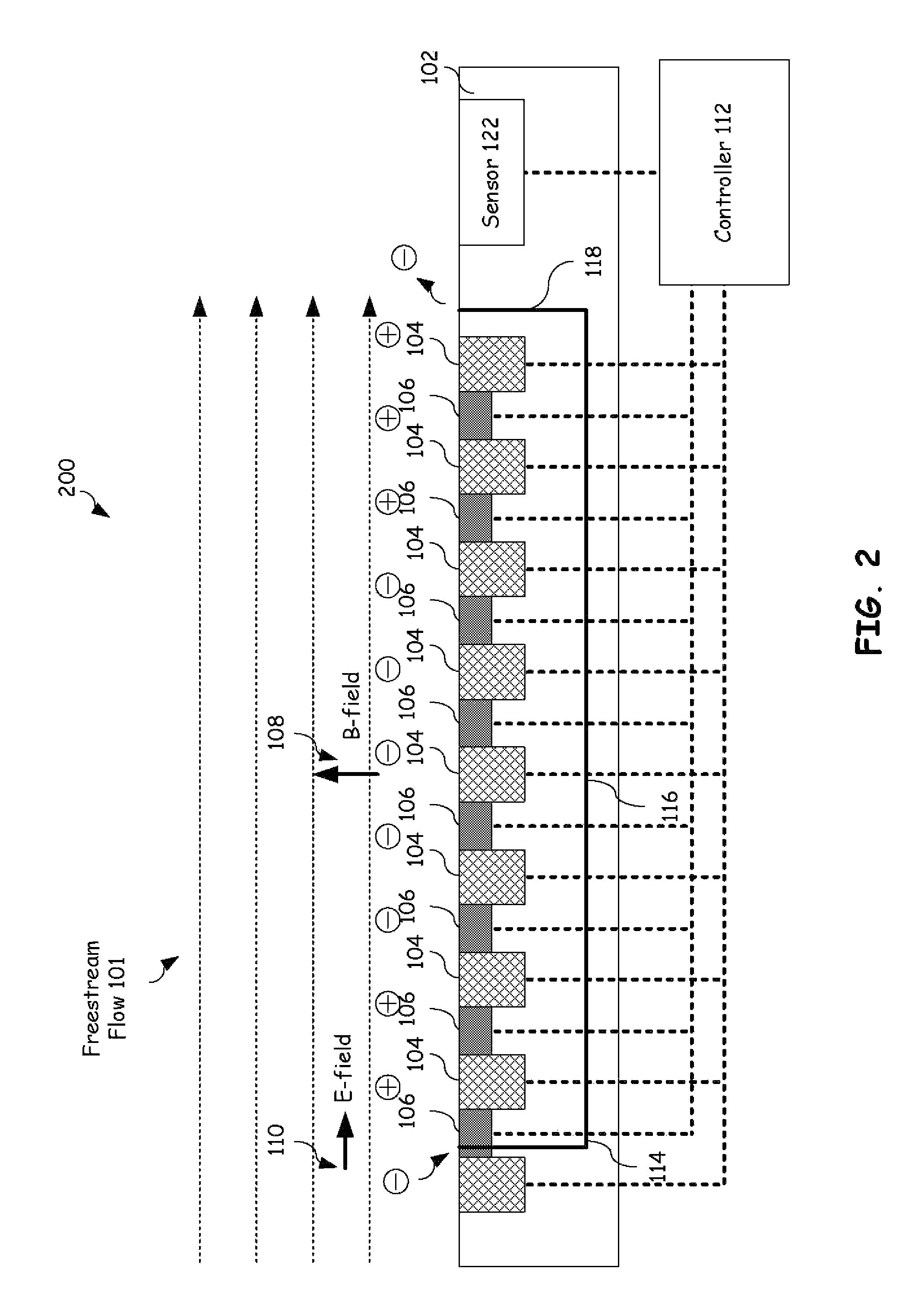

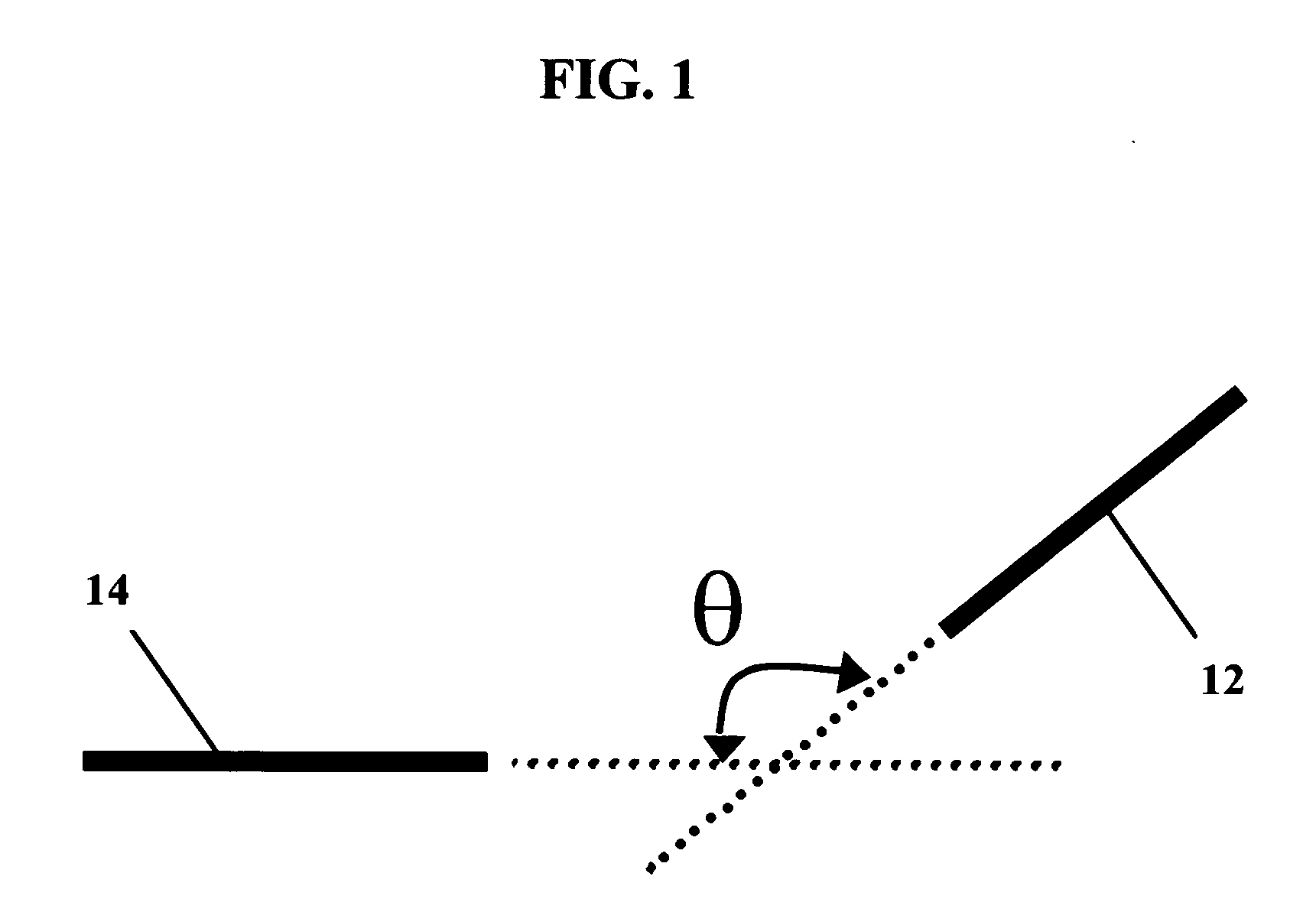

Over-wing traveling-wave axial flow plasma accelerator

A method to manipulate a fluid flow over a surface is provided. This method may be used to reduce drag, improve the lift to drag (L / D) ratio, attach fluid flow, or reduce flow noise at the surface. This involves flowing a fluid over the surface wherein the fluid contains positively charged ions and electrons. An electric field accelerates ions and electrons in directions parallel to the electric field. A magnetic field at the surface redirects ions and electrons based on their velocity and charge. The magnetic field imparts little force on the relatively heavy and slow moving positive ions but has a significant impact on the relatively fast moving, light weight electrons. This results in a non-zero net change in the total momentum of the positive ions and electrons allowing thrust to be realized. This thrust may be sufficient for vehicle propulsion or manipulation of the fluid flow around the vehicle. Pulsed and traveling wave implementations of this body force enable exploitation of frequencies to which the flow is sensitive, improving effectiveness of this method.

Owner:LOCKHEED MARTIN CORP

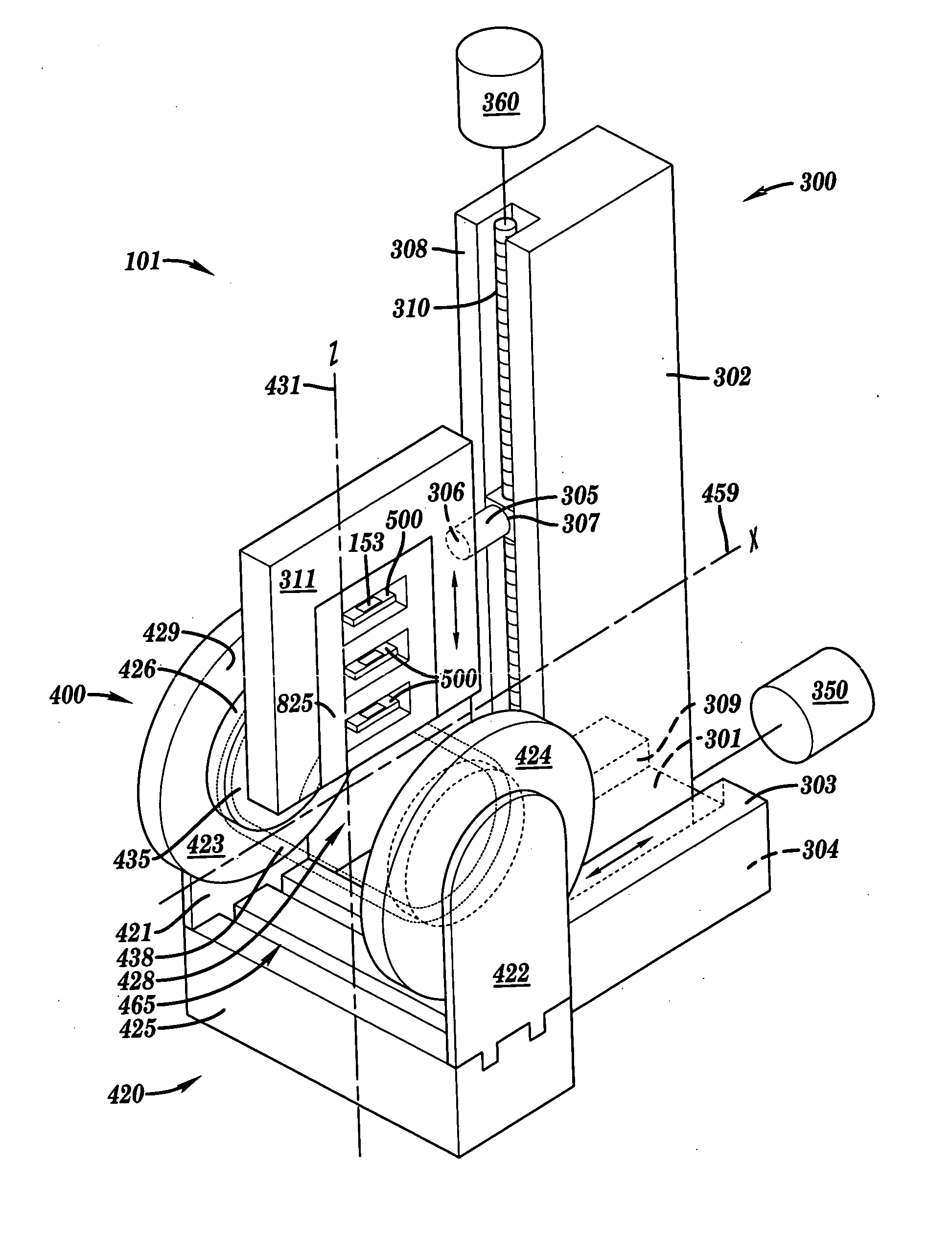

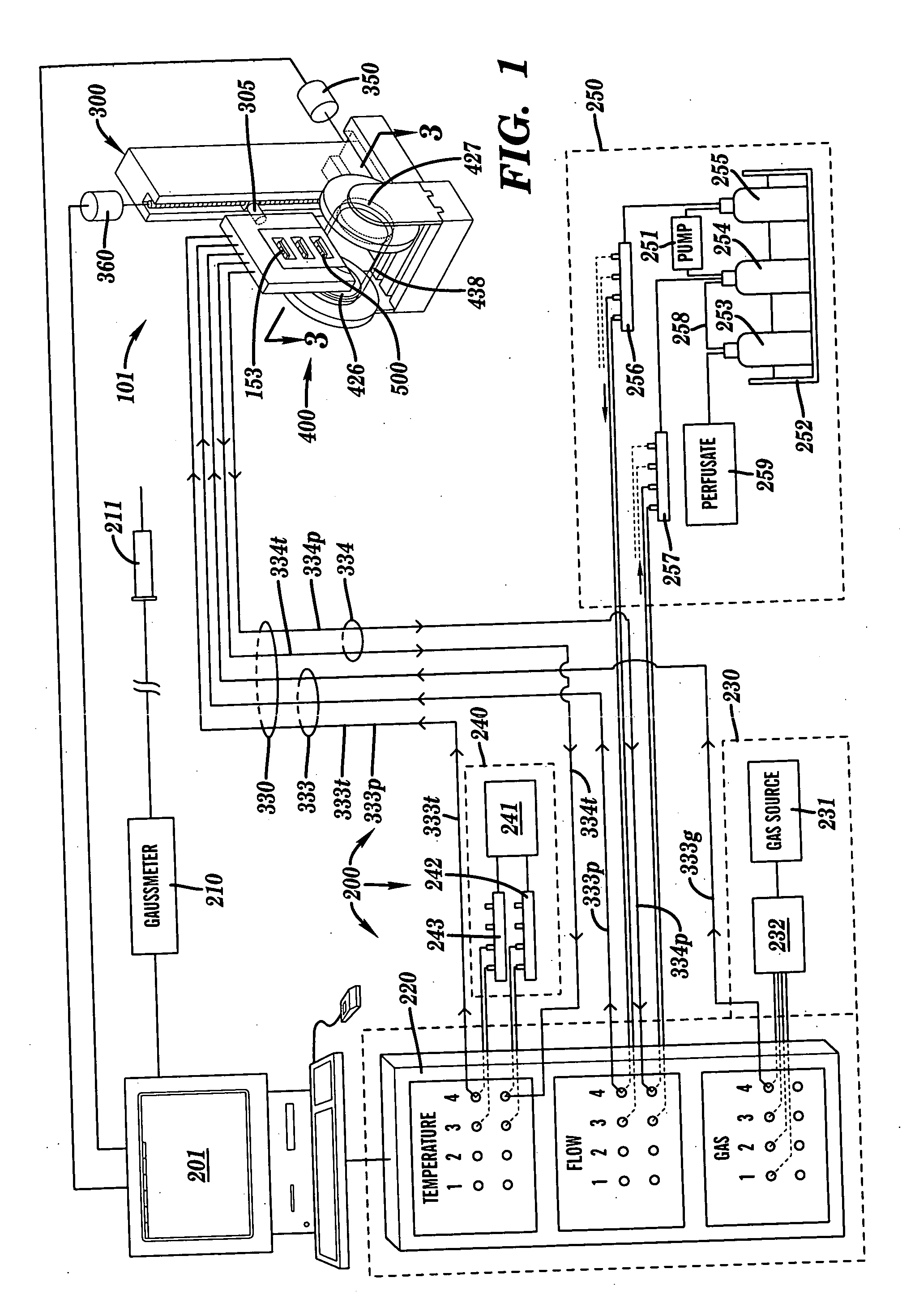

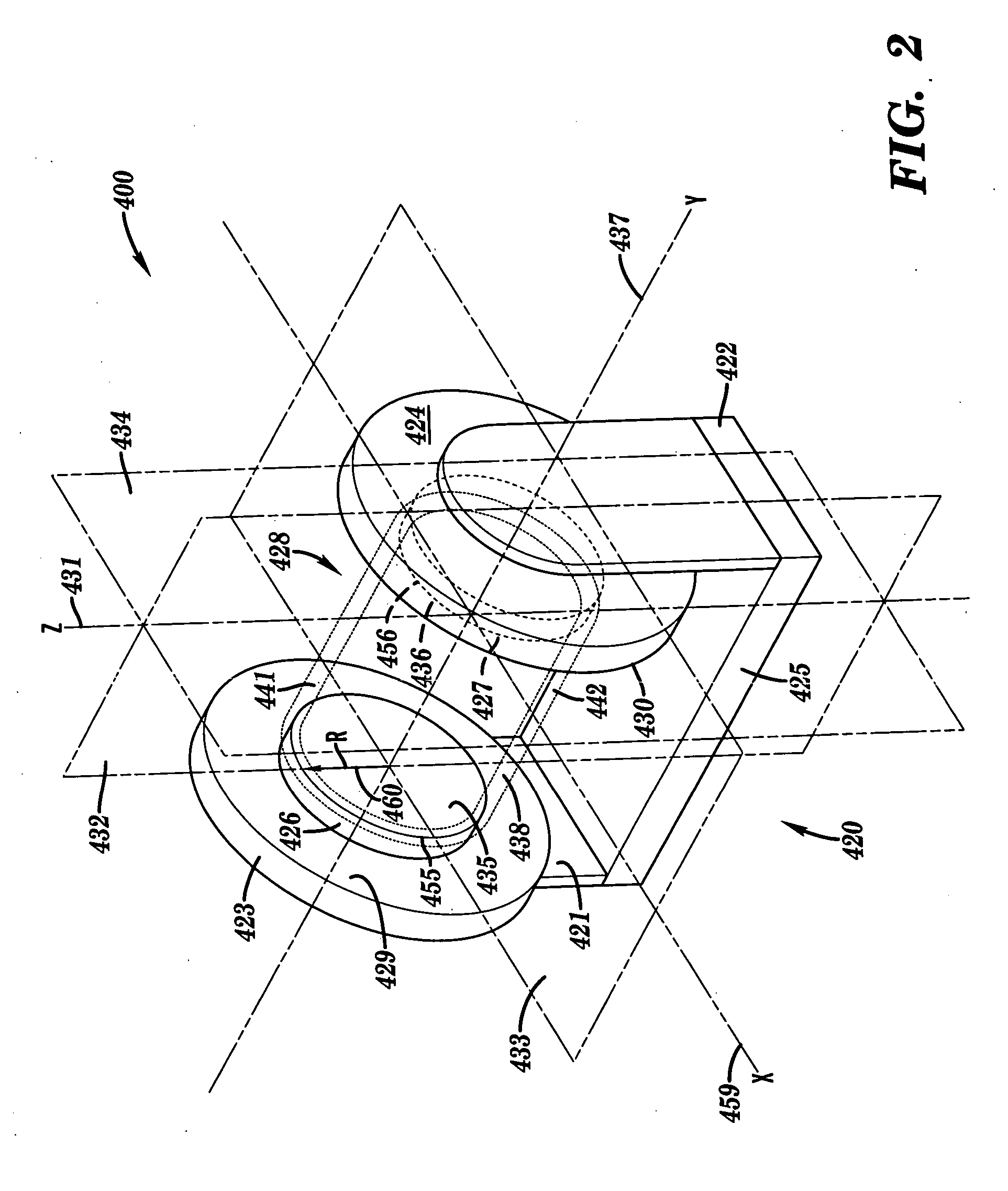

Diamagnetic force field bioreactor

InactiveUS20050255583A1Bioreactor/fermenter combinationsBiological substance pretreatmentsMagnetic tension forceEngineering

The invention is an apparatus comprising a magnet adapted to create a diamagnetic force field at all points in space at which a magnetic field-field gradient product of the magnet has a value greater than or equal to a threshold value. At or above the threshold value, the diamagnetic force field induces a diamagnetic body force within a biological specimen supported within a bioreactor chamber that is disposed within the diamagnetic force field. The apparatus may alter the magnitude of the induced diamagnetic body force and may alter the direction of the induced diamagnetic body with respect to a spatial coordinate system or with respect to the direction of a secondary body force acting upon or within the biological specimen, thereby altering the vector sum of the induced diamagnetic body force and the secondary body force acting on the biological specimen.

Owner:RENESSELAER POLYTECHNIC INST

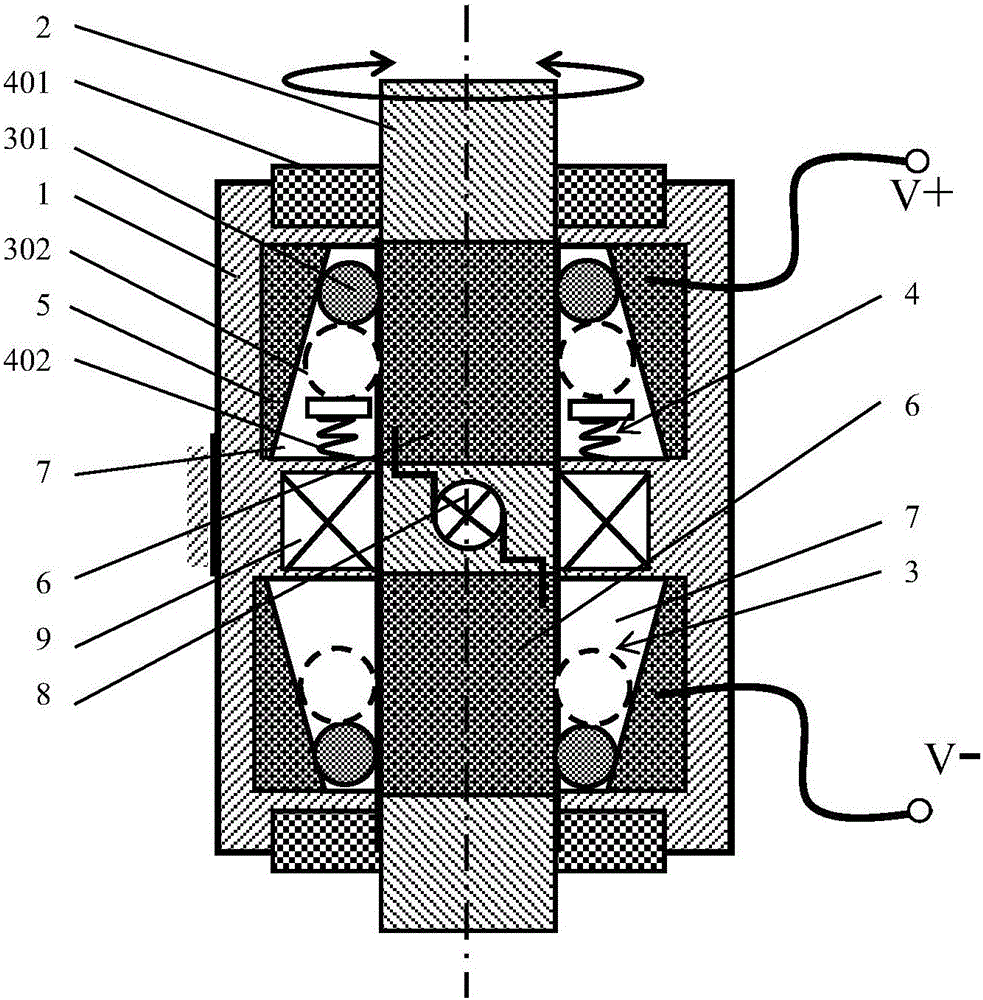

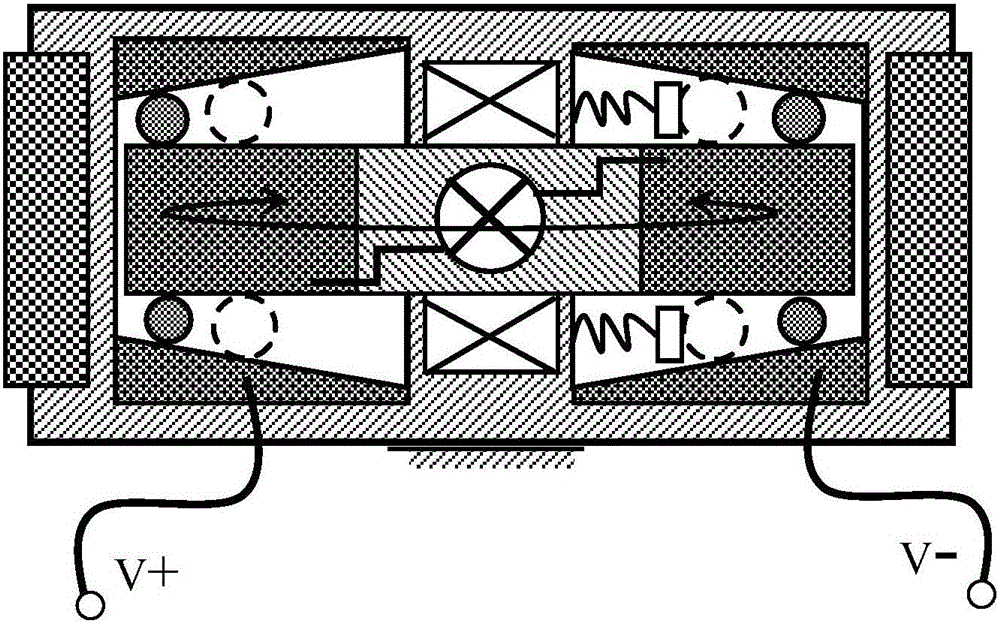

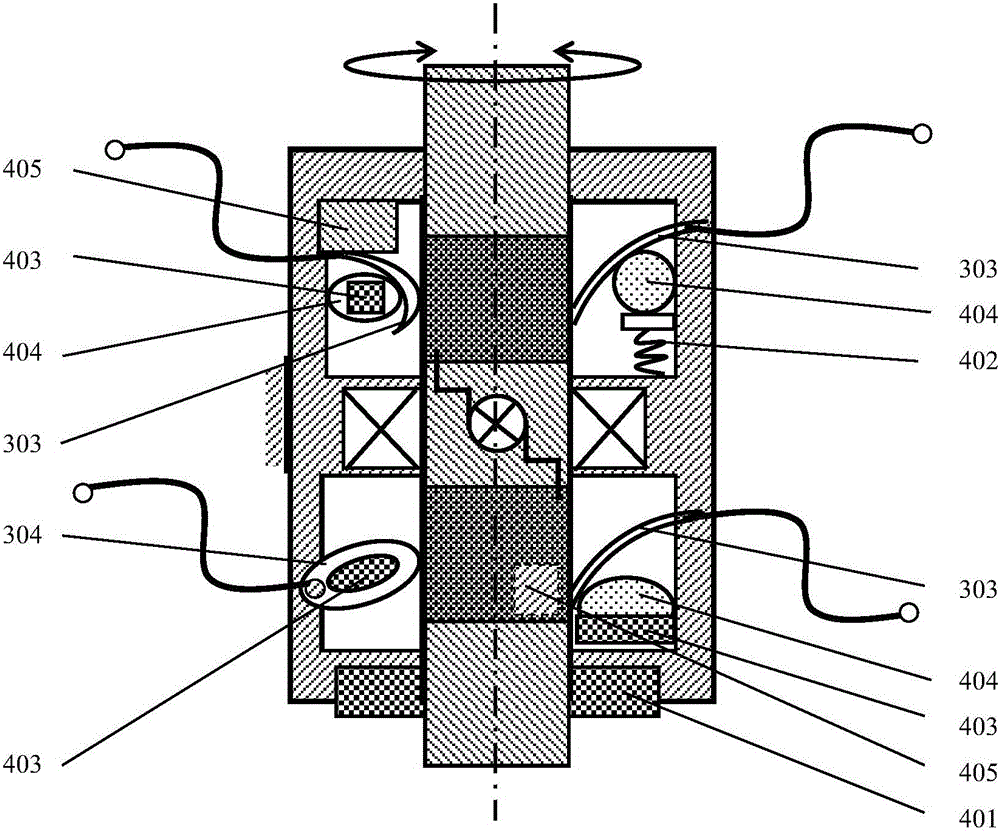

Nested high-reliability contact rotation system and combined system and method thereof

ActiveCN106058598ANo gap beatingSmooth rotationRotary current collectorContact member assembly/disassemblyBody contactEngineering

The invention provides a nested high-reliability contact rotation system and a combined system and a method thereof. A single motion contacting body, multiple motion contacting bodies or multiple motion contacting bodies contacting one another as a whole is / are in contact with a first contacted body and a second contacted body under a force applied by a motion contacting body force applying mechanism. Motion contacting bodies like ball-shaped contacting bodies ensure that rotating bodies rotate relatively through gap-free contact, and make rotating bodies free of gap jump. The ball-shaped contacting bodies ensure that rotating bodies are not affected by relative rotation wear of the contact surfaces and are always in contact through motion following, ensure contact, and can be used for conducting. Multiple fulcrums can be obtained through multiple ball-shaped contacting bodies, so rotating bodies are aligned stably and rotate smoothly. Rotating bodies do not produce axial endplay under the condition of no radial run-out. Controlled movable contact can be easily realized.

Owner:NANJING LINGJI YIDONG DRIVING TECH CO LTD

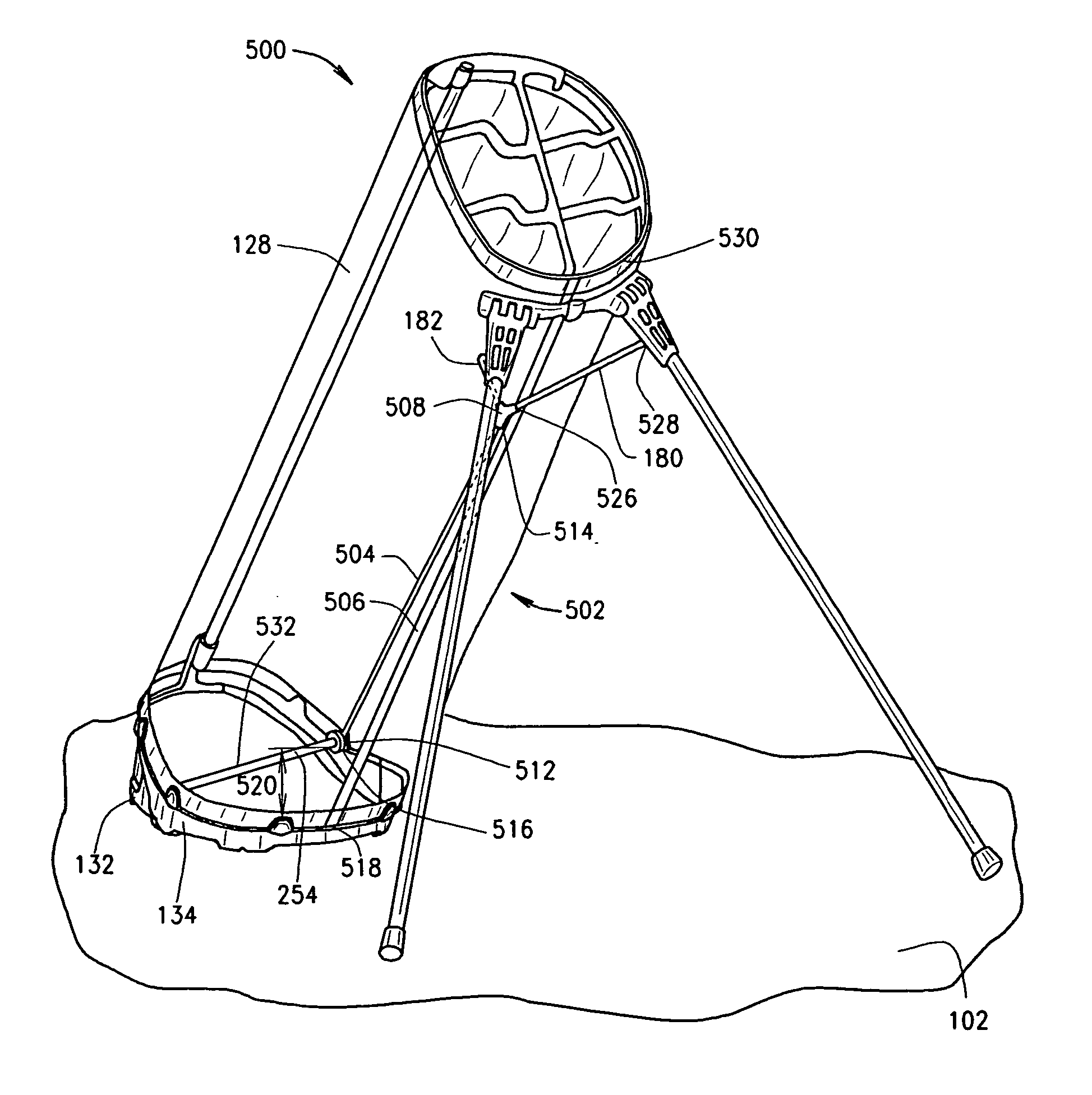

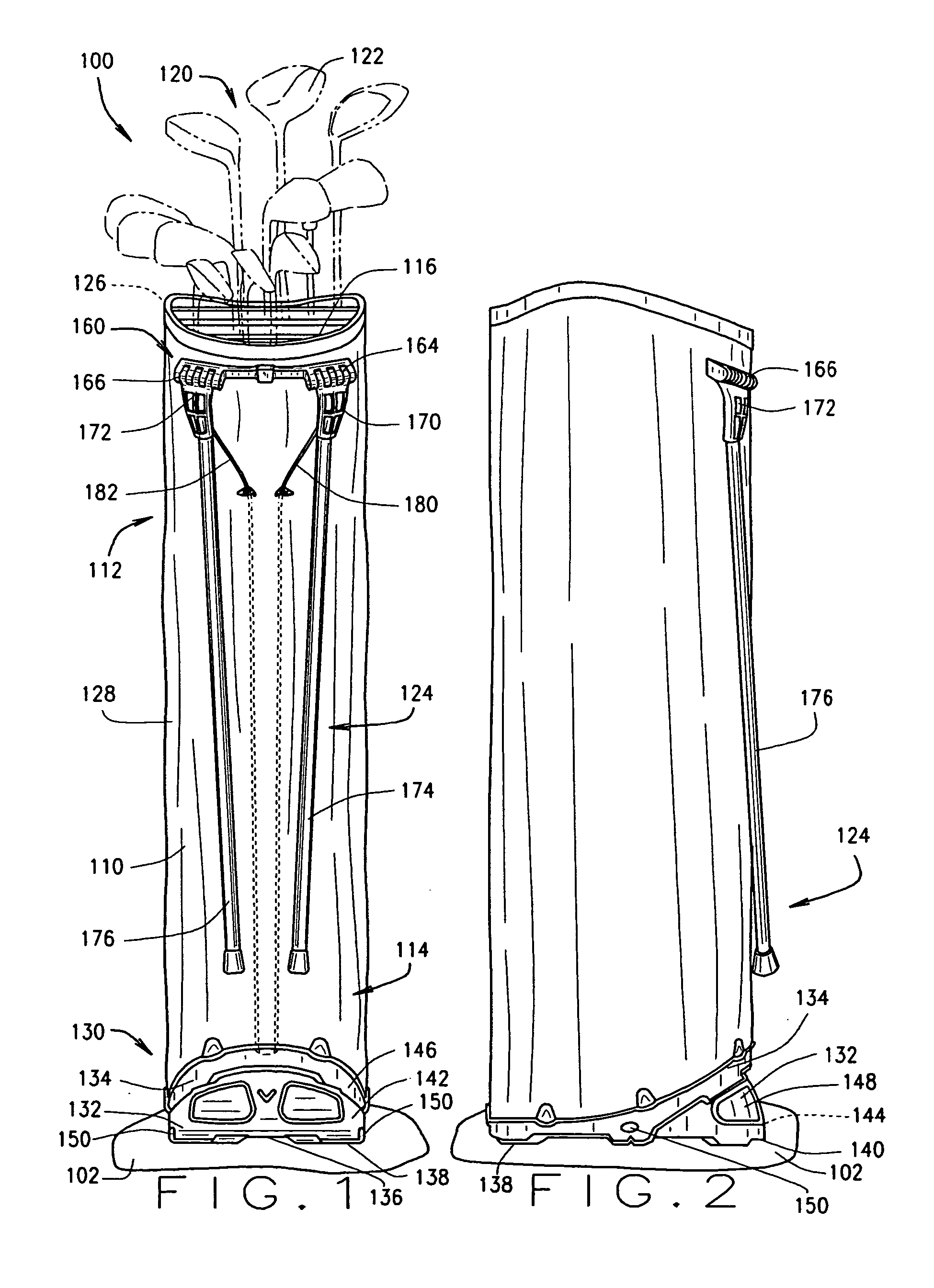

Golf bag with self actuating stand

A golf bag includes a self actuating stand having a base assembly, a support mount assembly and an actuating mechanism. The base assembly includes a base ring and a foot is coupled to the base ring and includes a ground engaging surface covering the lower end of the body of the bag. The base ring is mounted to the foot wherein the base ring is selectively positionable relative to the foot to position the body between an upright position and an inclined position when the ground engaging surface is located stationary on a supporting surface. The support mount includes a plurality of interlocking hinge elements extending radially outward from an outer surface of the body, and at least one support leg is rotatably coupled to the support mount via the plurality of interlocking hinge elements. At least one actuator arm is coupled to the support leg and an activation rod coupled to the foot, wherein when the body is positioned in the inclined position, relative movement of the activation rod with respect to the body forces the actuator arm to extend the support leg to the deployed position.

Owner:TRG ACCESSORIES

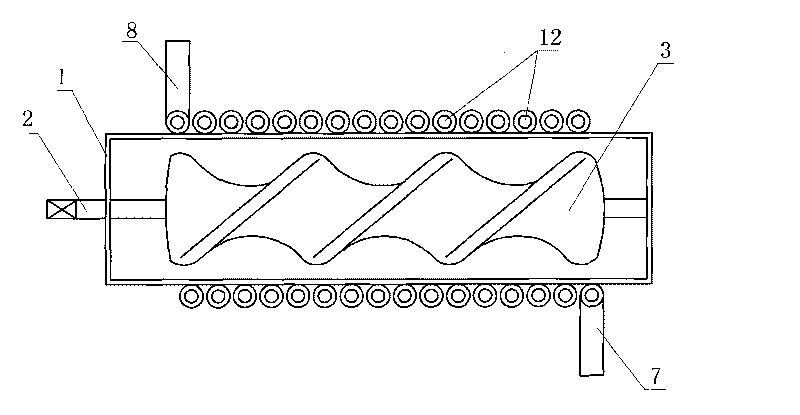

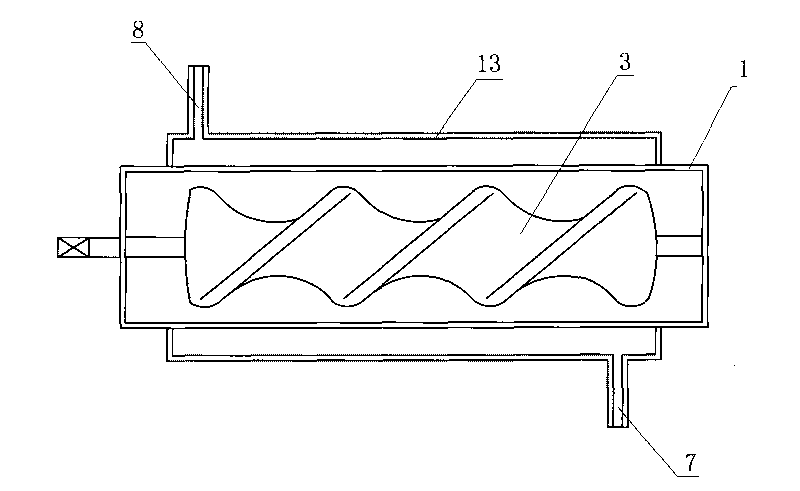

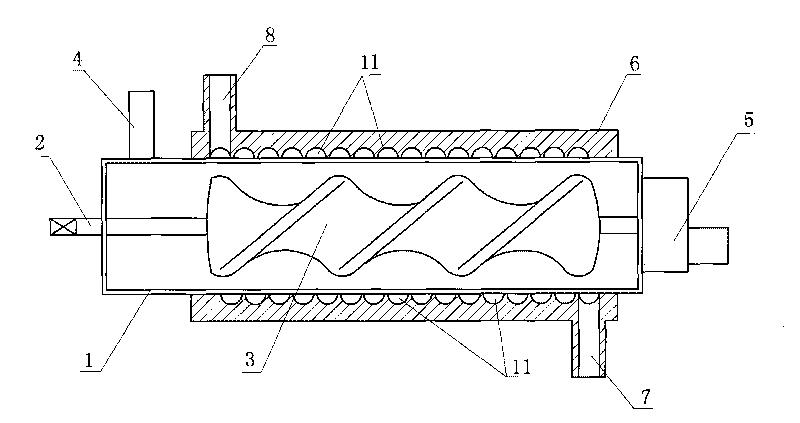

Ice cream mixing drum

The invention relates to an ice cream mixing drum belonging to food processing machinery. The ice cream mixing drum comprises a cylinder body, a drive shaft, a propeller and a heat exchange sleeve, wherein a raw material inlet is arranged at one side of the cylinder body, an ice cream output valve is arranged at the other side of the cylinder body, the propeller is installed in the cylinder body, the drive shaft is connected with the propeller, the heat exchange sleeve encircles the cylinder body and is provided with a working medium inlet and a working medium outlet, and a continuous inside spiral groove is arranged between the working medium inlet and the working medium outlet on the inner wall of the heat exchange sleeve and forms a continuous spiral channel with the outer wall of the cylinder body. In the invention, a working medium channel in a continuous spiral shape combined by the inside spiral groove of the heat exchange sleeve and the outer wall of the cylinder body forces working medium to flow along the spiral channel; the working medium exchanges heat with the cylinder body with longer time and larger contact area when flowing, thereby having the advantage of high heat exchange efficiency; and pasteurization is carried out on ice cream in a stirring cylinder body when heated to 60-80 DEG C. The invention is suitable for use on various ice cream freezers and slush machines.

Owner:黎永雄

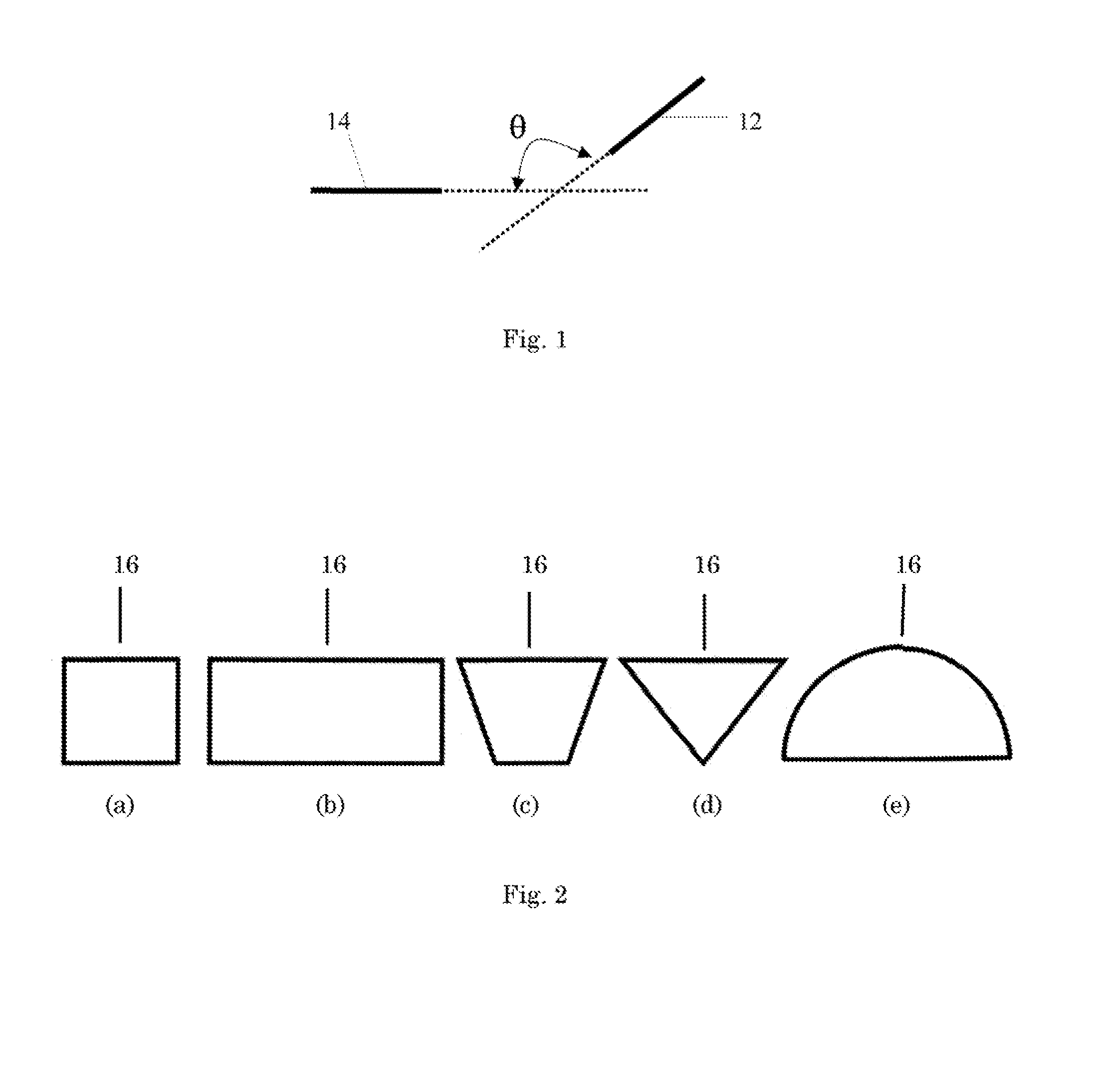

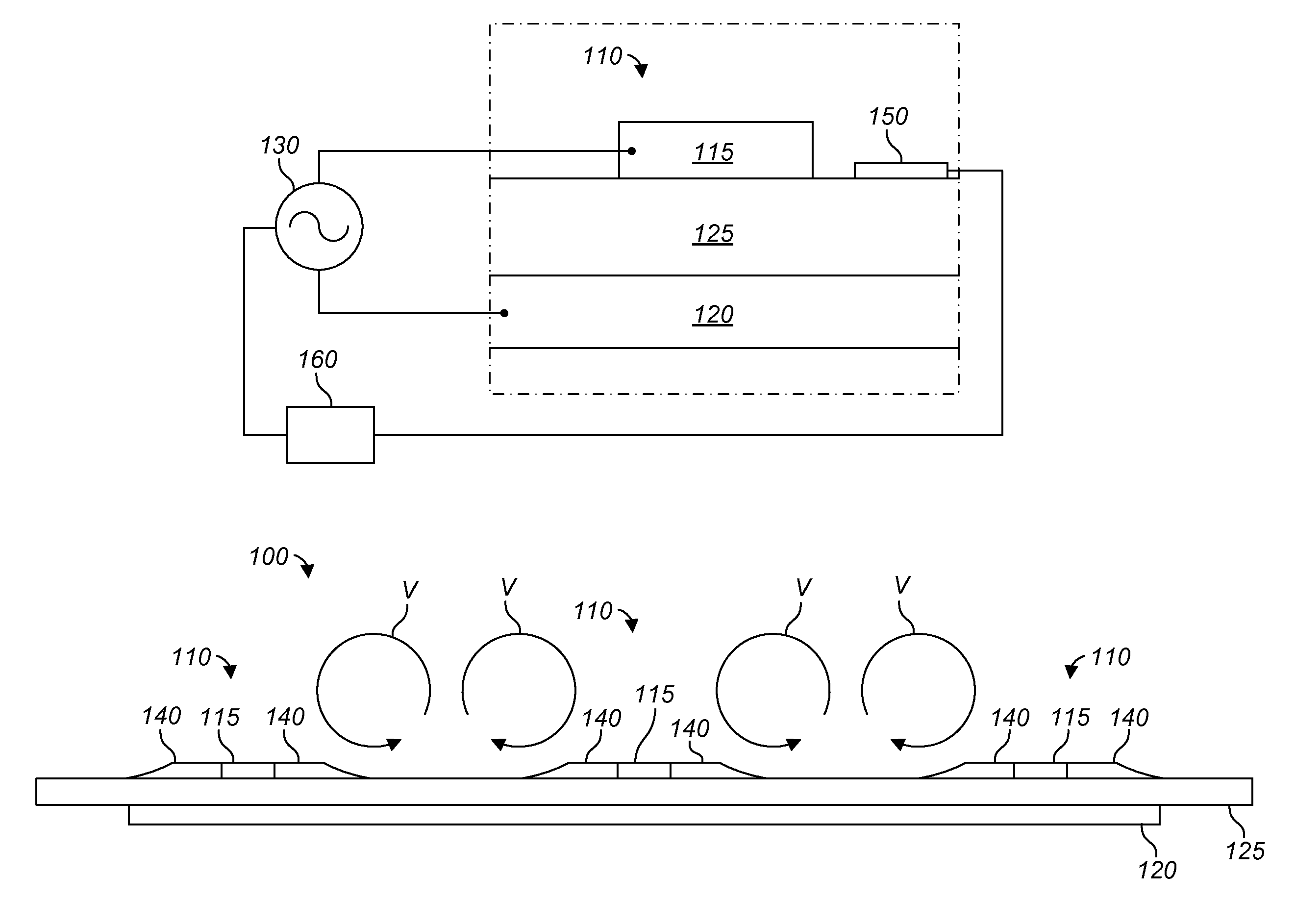

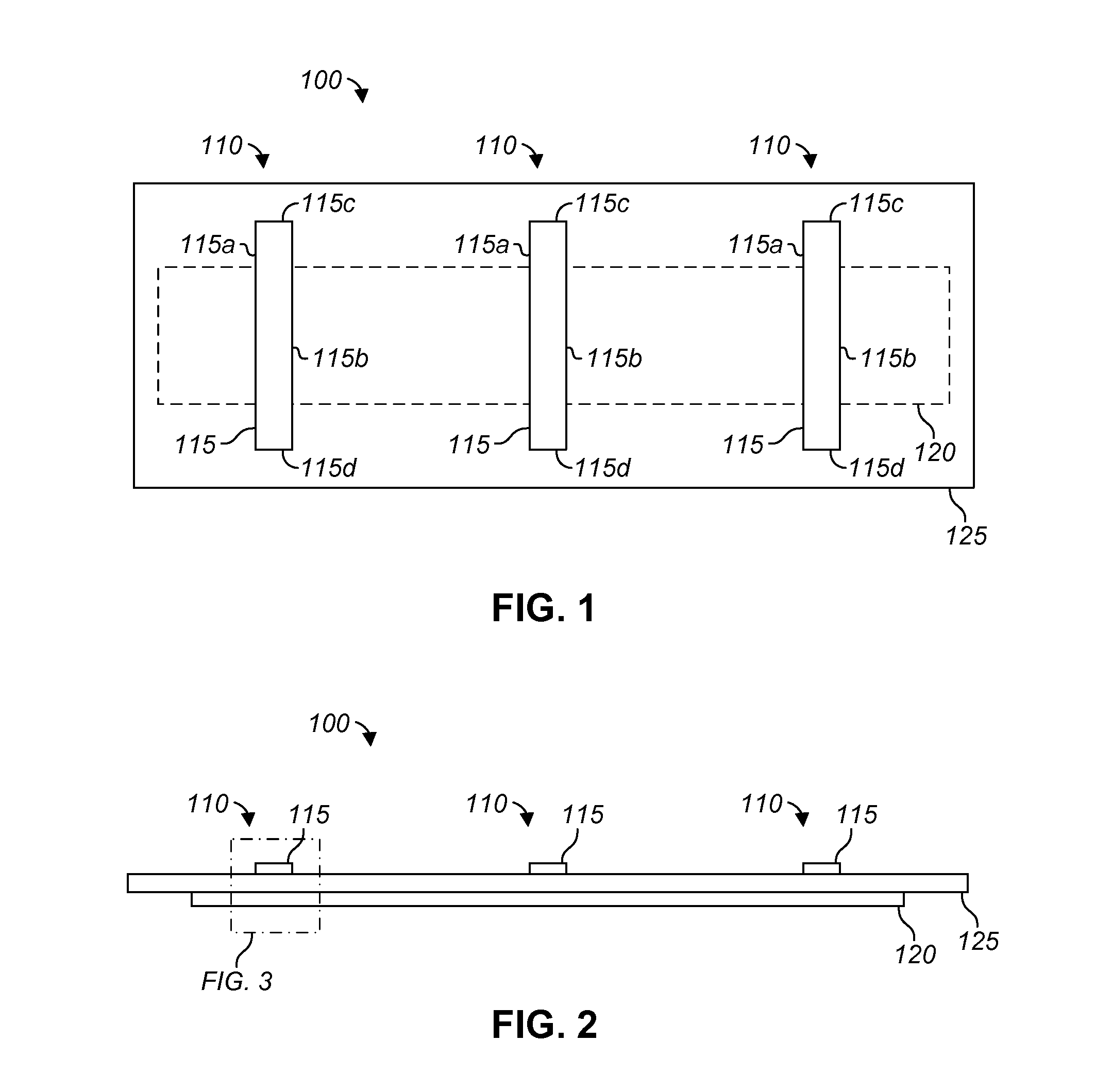

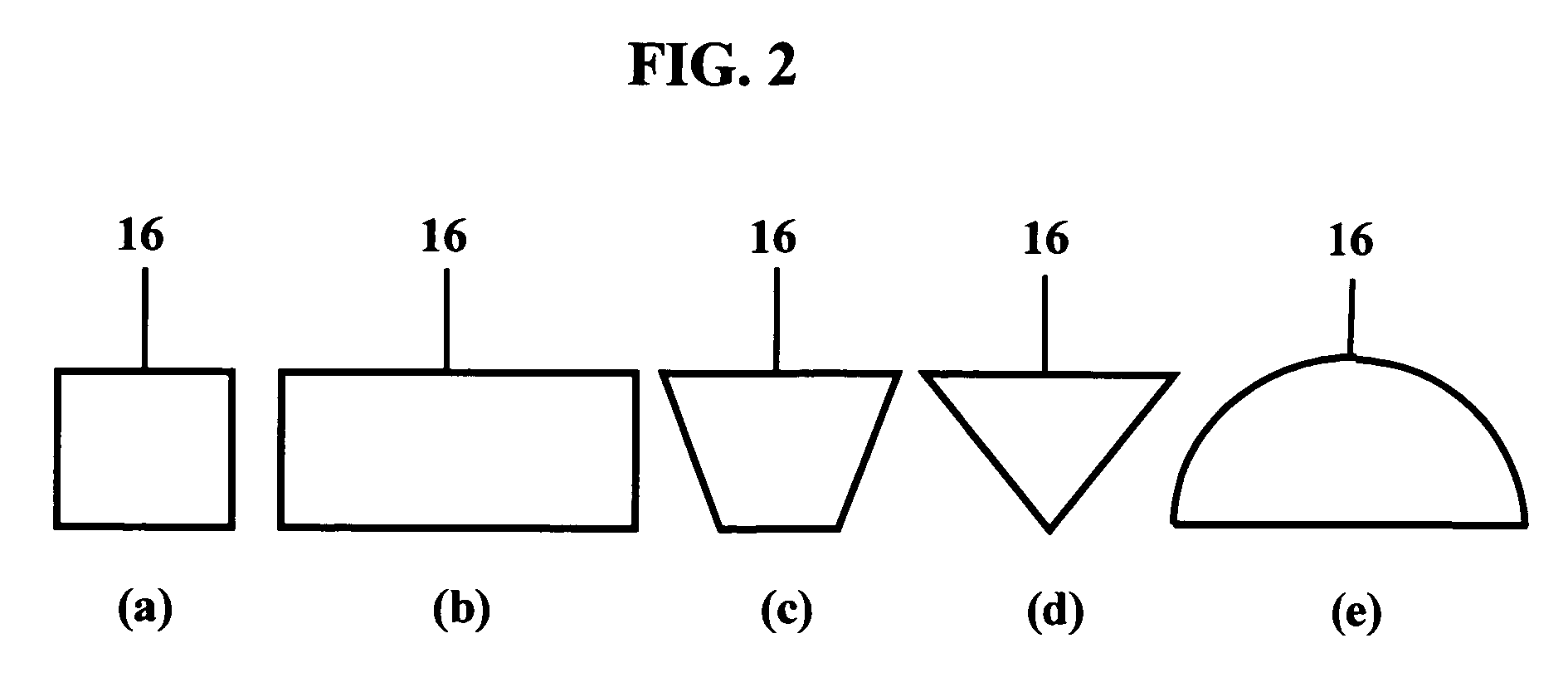

System and method for aerodynamic flow control

A vortex generator system comprises one or more plasma streamwise vortex generators (PSVGs) or plasma wedge vortex generators (PWVGs). The PSVGs and PWVGs each comprises a first electrode and a second electrode separated by a dielectric layer. The first electrode extends in a longitudinal direction. The PSVGs and PWVGs can be installed on a surface arranged to receive airflow in a certain flow direction. The PSVGs have a rectangular first electrode is exposed and extends at least somewhat parallel to the expected flow direction, whereas the first electrode of the PWVGs is more triangular in shape. When an AC voltage is applied to the first and second electrodes, a plasma forms along edges of the first electrode. The plasma imposes a body force in a cross-flow direction, which induces a cross-flow velocity that, in combination with the mean flow, produces streamwise-oriented counter-rotating vortices.

Owner:TEXTRON INNOVATIONS

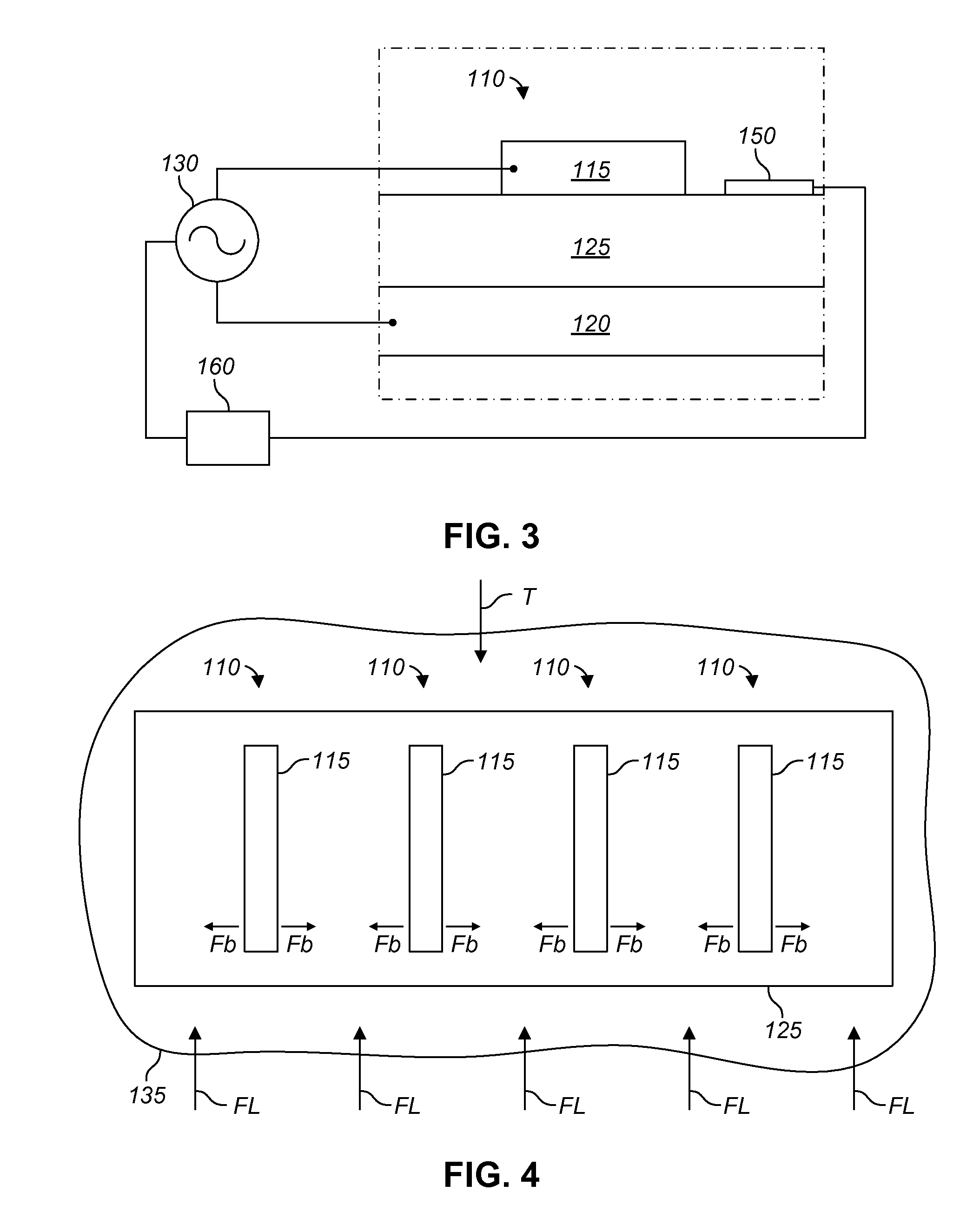

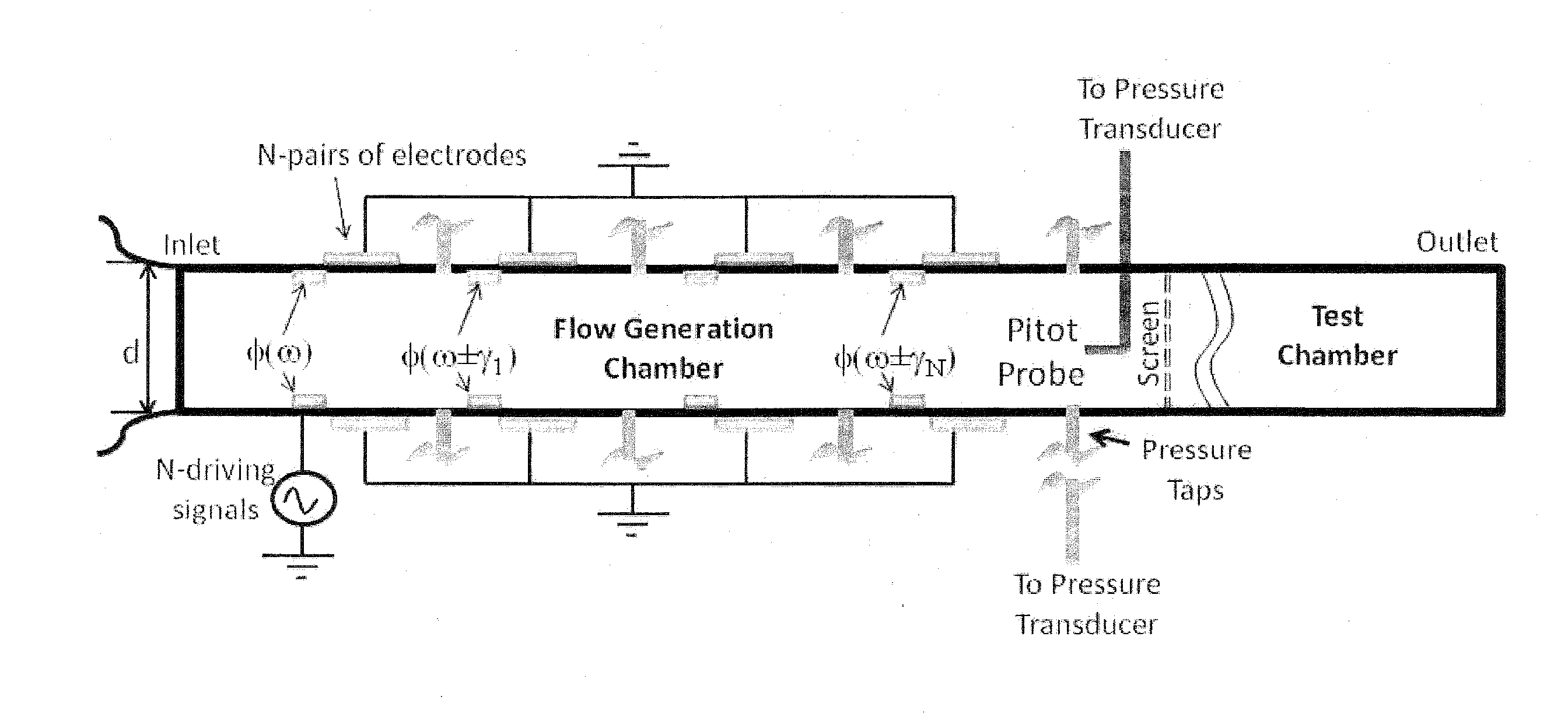

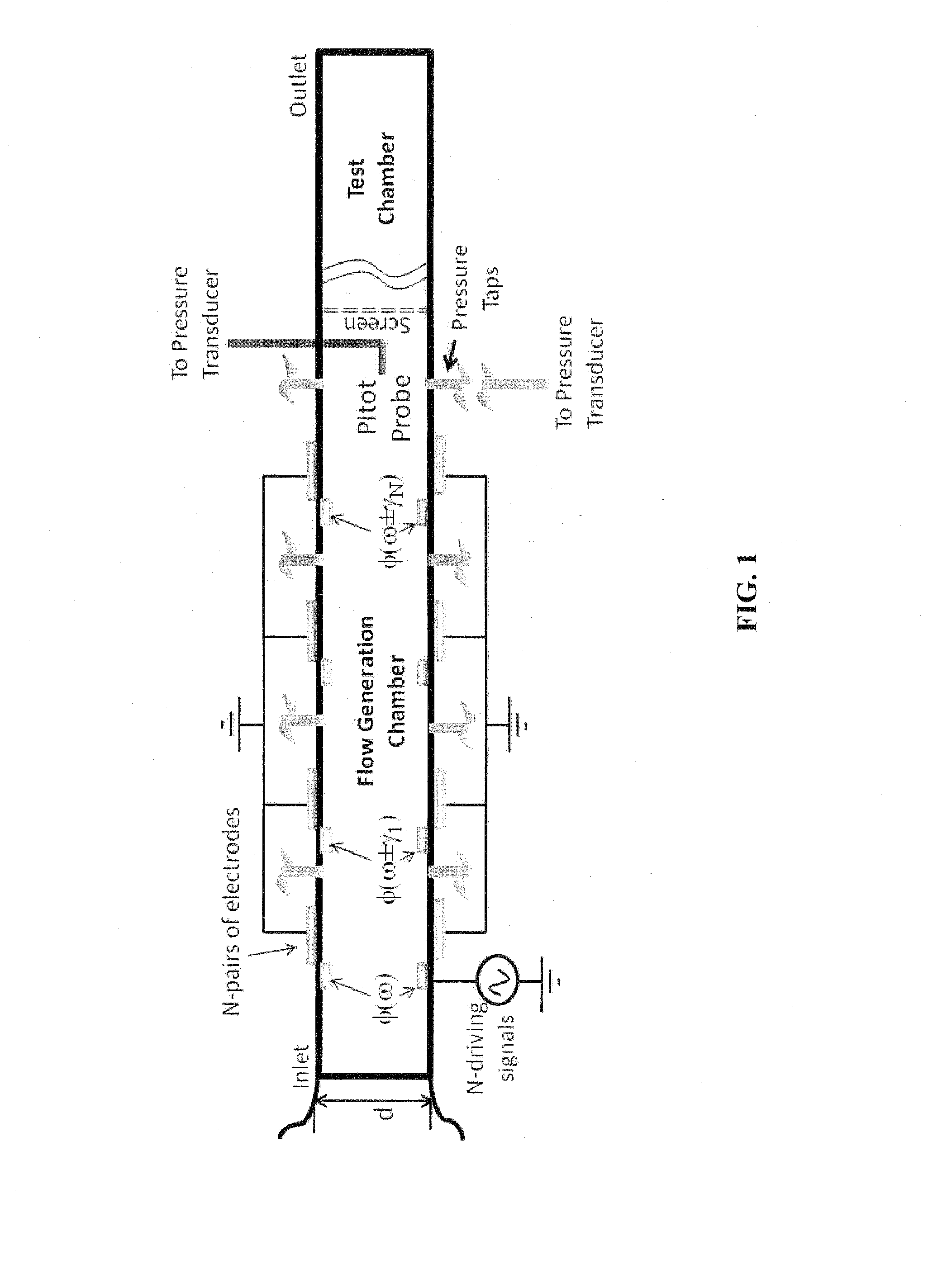

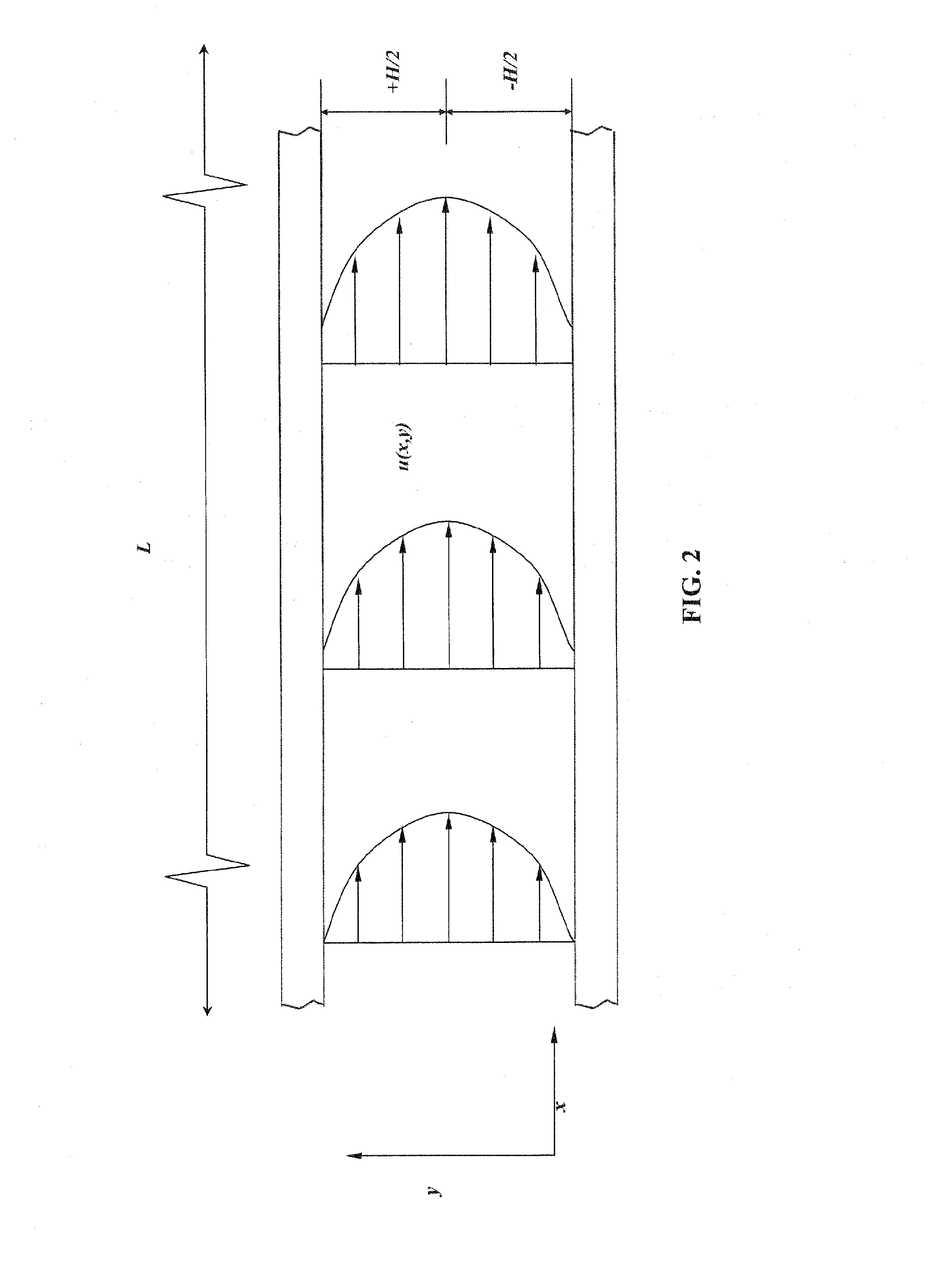

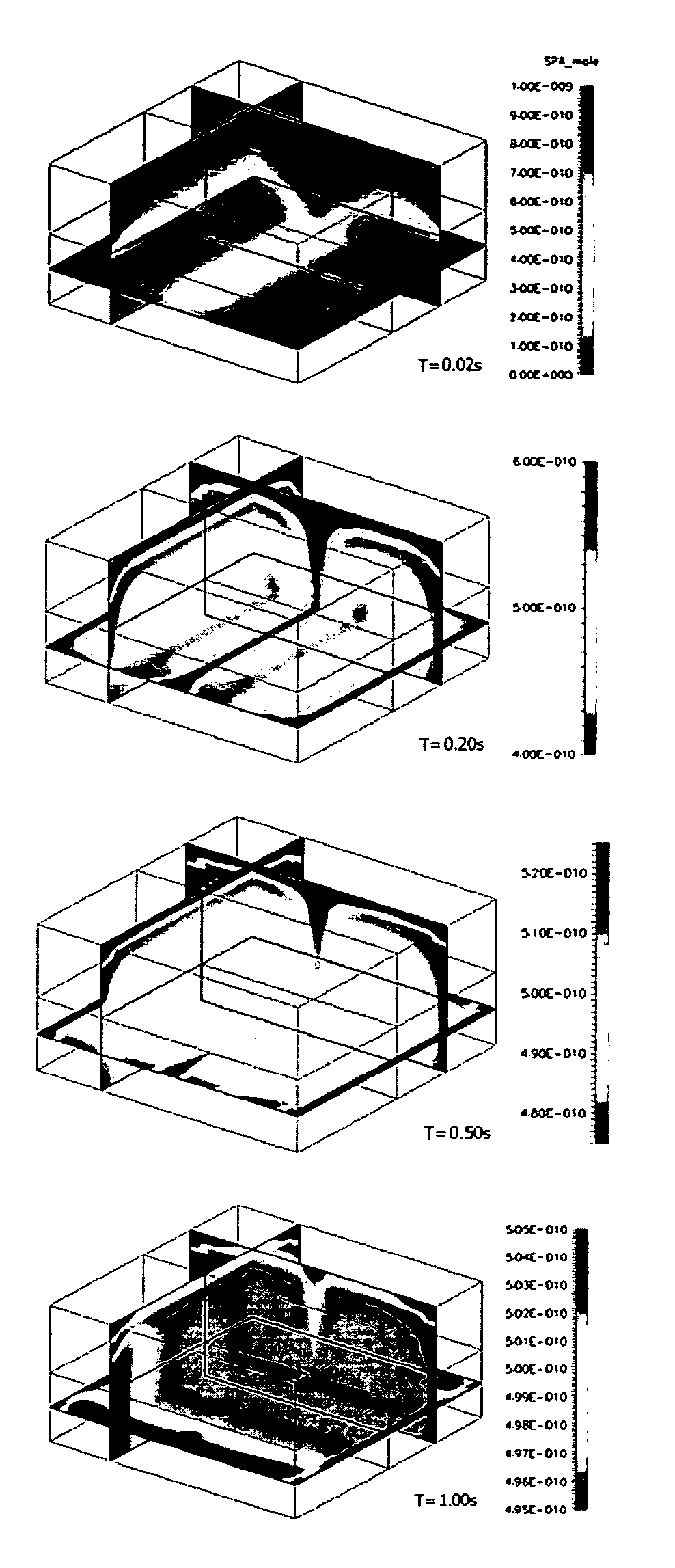

Dielectric barrier discharge wind tunnel

InactiveUS20130075382A1Speed up the flowReduce total pressure lossAerodynamic testingOhmic-resistance heatingPlasma actuatorEngineering

Embodiments of the subject invention are directed to methods and apparatus for inducing fluid flow in a wind tunnel using one or more plasma actuators. In an embodiment, a wind tunnel is provided having a flow passage. A pair of electrodes is positioned on at least one surface of the flow passage, and a voltage potential is applied across the pair of electrodes producing a plasma discharge in the flow passage. In an embodiment, the pair of electrodes is positioned on the at least one surface of the flow passage such that when the plasma discharge is produced an electrohydrodynamic (EHD) body force is generated that induces flow of a fluid in the flow passage.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

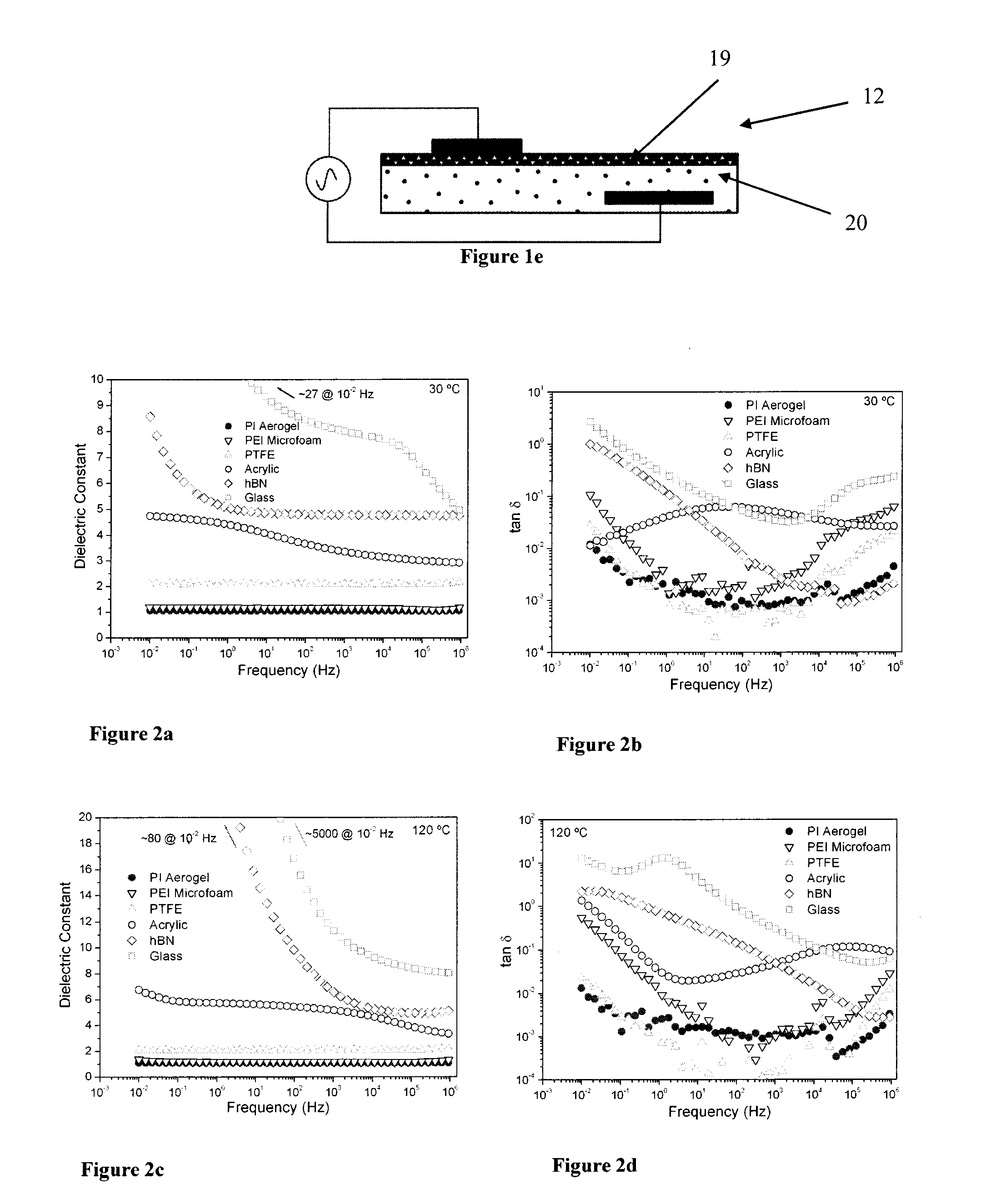

Robust, Flexible and Lightweight Dielectric Barrier Discharge Actuators Using Nanofoams/Aerogels

ActiveUS20150076987A1High breakdown strengthIncrease surface chargeMachines/enginesUsing plasmaNanofoamPlasma actuator

Robust, flexible, lightweight, low profile enhanced performance dielectric barrier discharge actuators (plasma actuators) based on aerogels / nanofoams with controlled pore size and size distribution as well as pore shape. The plasma actuators offer high body force as well as high force to weight ratios (thrust density). The flexibility and mechanical robustness of the actuators allows them to be shaped to conform to the surface to which they are applied. Carbon nanotube (CNT) based electrodes serve to further decrease the weight and profile of the actuators while maintaining flexibility while insulating nano-inclusions in the matrix enable tailoring of the mechanical properties. Such actuators are required for flow control in aeronautics and moving machinery such as wind turbines, noise abatement in landing gear and rotary wing aircraft and other applications.

Owner:NASA +1

Stabilizer Assembly and Method

A stabilizer assembly for a tubular member includes a stabilizing body dimensioned to fit around the tubular member, a central portion having a radial projection, and a first end having a first threaded outer surface and a set of integral first elastic members. A first nut member includes a proximal end with a threaded inner surface configured to engage the first threaded outer surface of the stabilizing body and a central portion with a first tapered inner surface configured to engage the first elastic members of the stabilizing body. Threading the first nut member onto the first end of the stabilizing body forces the first elastic members to engage the first tapered inner surface of the first nut member thereby radially flexing the first elastic members to engage the tubular member. An inner surface of a distal end of each first elastic member may include a grip section.

Owner:ASHMIN HLDG LLC

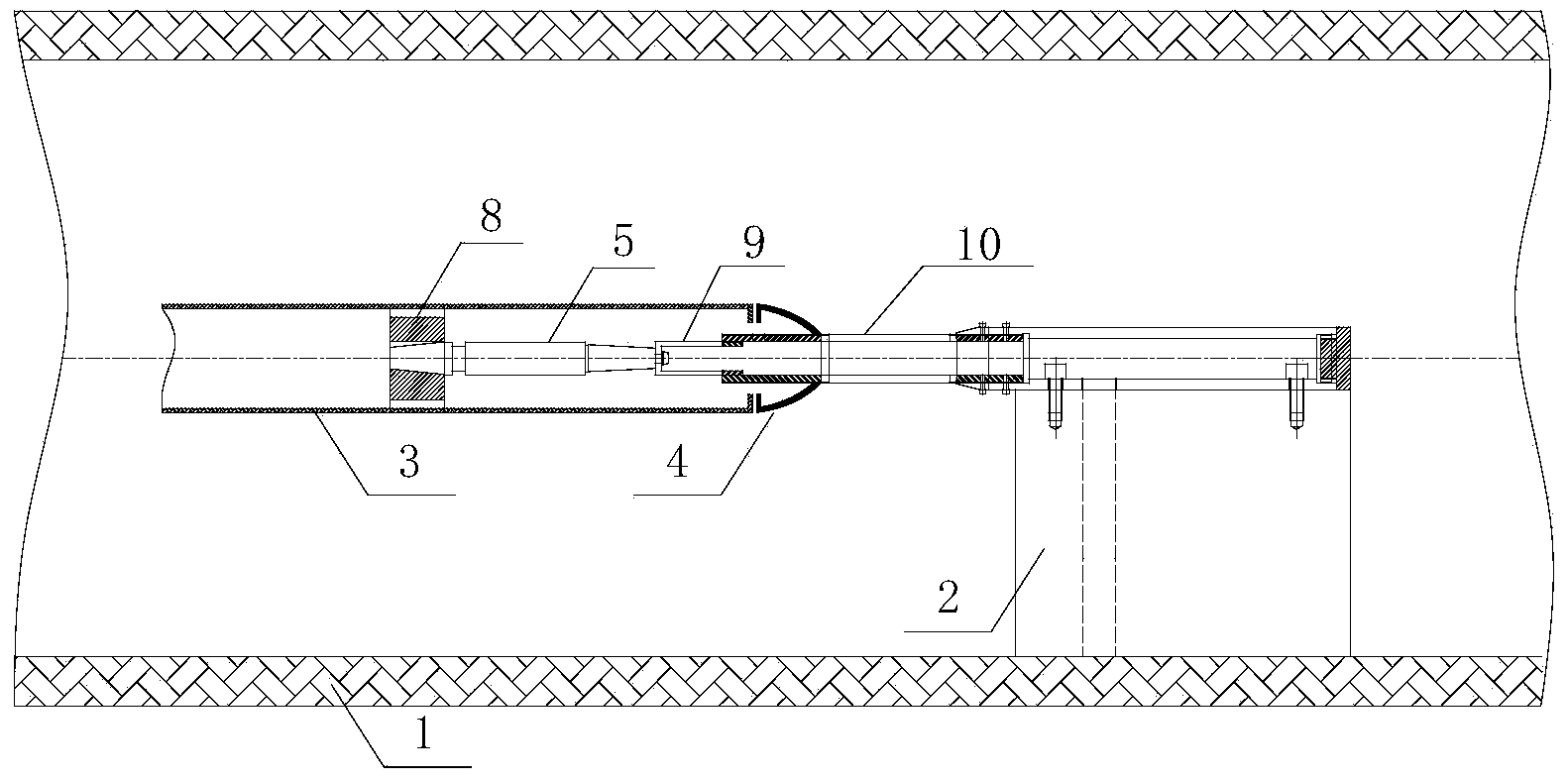

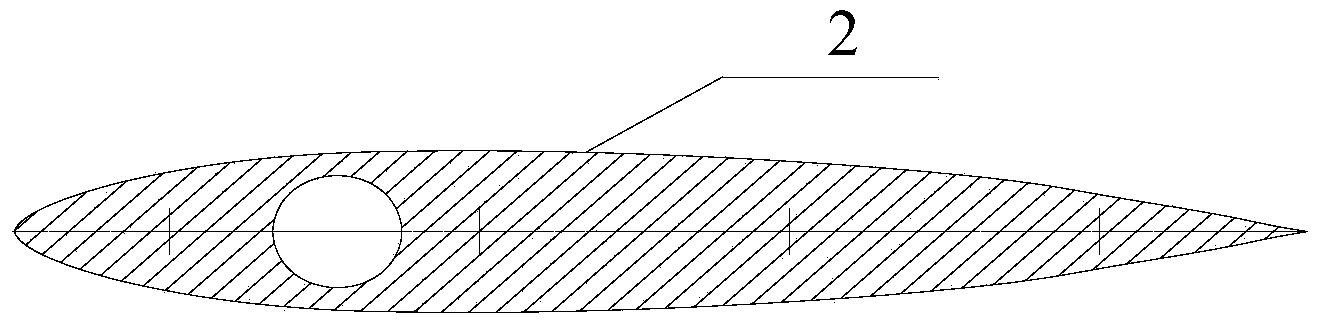

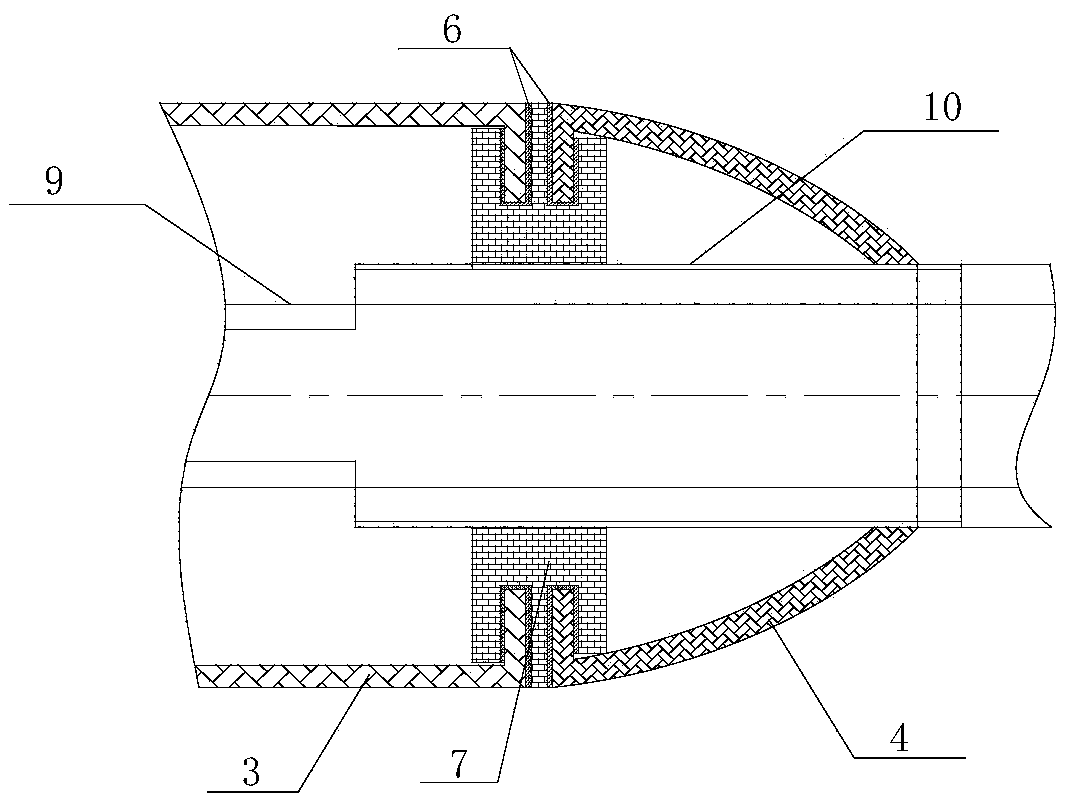

Hydrodynamic force measuring system of underwater vehicle

ActiveCN104236849APrevent slit flow shockReduce the impactHydrodynamic testingBody balanceCavitation

The invention discloses a hydrodynamic force measuring system of an underwater vehicle. The hydrodynamic force measuring system comprises an anti-cavitation tail support key (2), an underwater vehicle front body (3), a tail force measuring six-component balance (4), a front body force measuring six-component balance (5), a soft brush (6), a sealing part (7), an inside-underwater-vehicle balance support (8), a front body balance support rod (9) and a tail balance support rod (10). The tail force measuring six-component balance (4) is in the shape of the tail of the underwater vehicle, thereby being capable of serving as the tail of the underwater vehicle and measuring hydrodynamic force on the tail of the underwater vehicle, stress on the underwater vehicle front body is transmitted to the front body force measuring six-component balance through the support in the balance, hydrodynamic force of the underwater vehicle front body is directly measured through the front body six-component balance, and the joint of the tail of the underwater vehicle and the front body is sealed by the sealing part and the soft brush. The hydrodynamic force measuring system can accurately measure the hydrodynamic force of the underwater vehicle front body and the tail in a separated type, and influence on measuring caused by hydrodynamic fluctuation of the tail is reduced.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

Self-cleaning and mixing microfluidic elements

ActiveUS20070209940A1Reduced Power RequirementsEasy to measureElectrolysis componentsElectrostatic separatorsParticulatesElectrode placement

Apparatus and methods are disclosed for mixing and self-cleaning elements in microfluidic systems based on electrothermally induced fluid flow. The apparatus and methods provide for the control of fluid flow in and between components in a microfluidic system to cause the removal of unwanted liquids and particulates or mixing of liquids. The geometry and position of electrodes is adjusted to generate a temperature gradient in the liquid, thereby causing a non-uniform distribution of dielectric properties within the liquid. The dielectric non-uniformity produces a body force and flow in the solution, which is controlled by element and electrode geometries, electrode placement, and the frequency and waveform of the applied voltage.

Owner:SYNVIVO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com