Stabilizer Assembly and Method

a technology of stabilizer and assembly, which is applied in the direction of drilling pipes, drilling casings, and accessories for wellbores/wells, etc., can solve the problem of increasing the chance that the releasable stabilizer does not transmit torque during us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

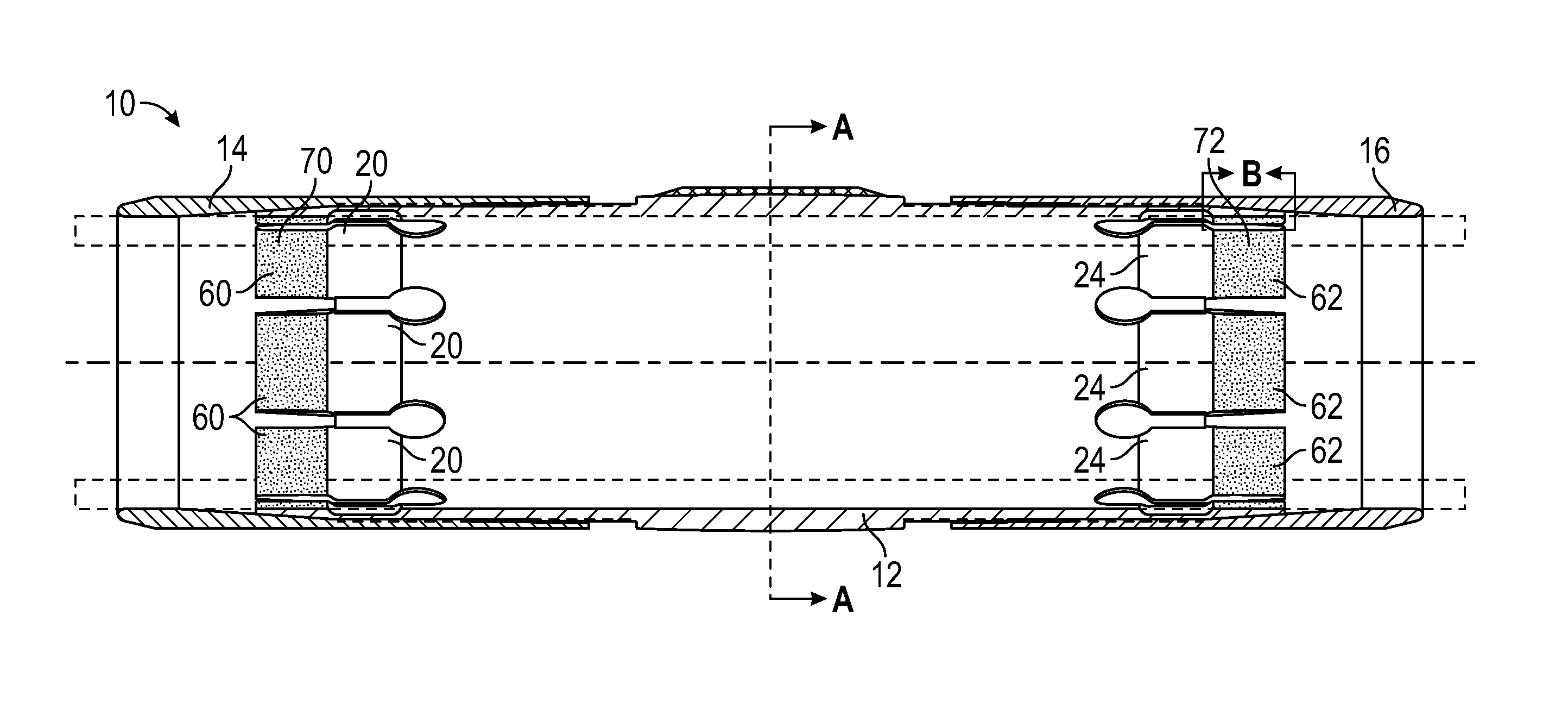

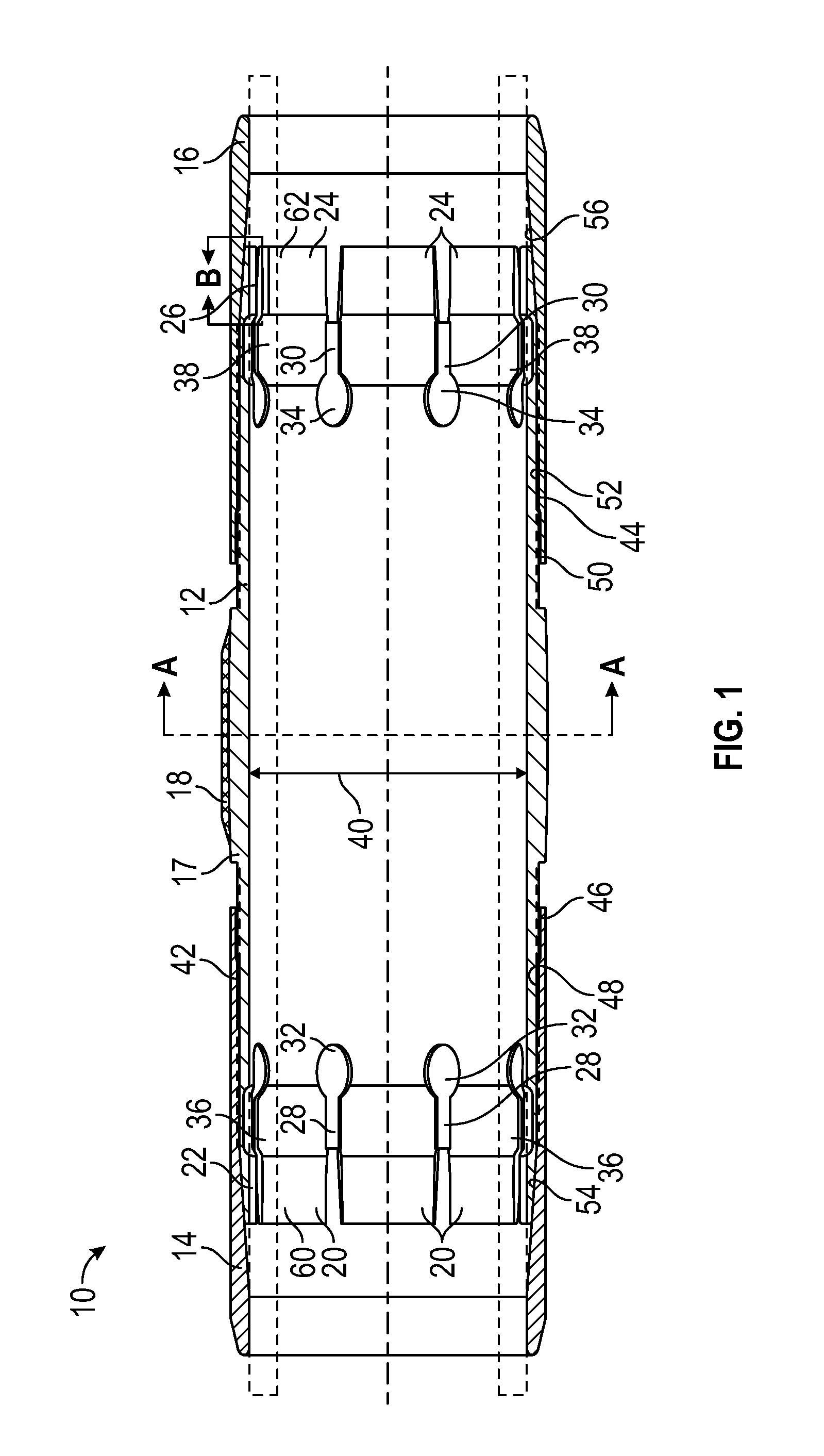

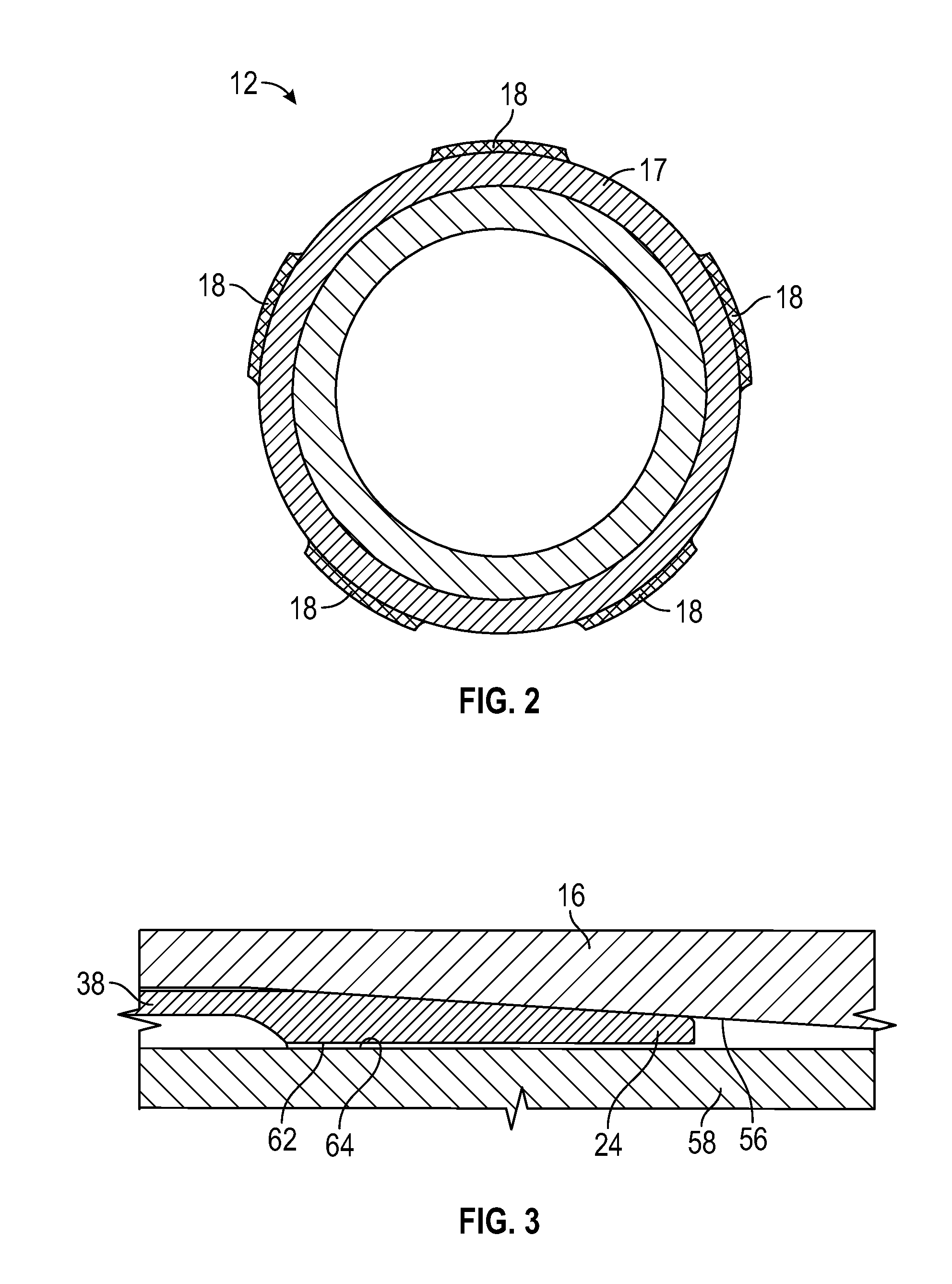

[0017]With reference to FIG. 1, stabilizer assembly 10 includes stabilizing body 12, first nut member 14, and second nut member 16. Stabilizing body 12 may be dimensioned to fit over a tubular member, such as a portion of a drill string or a drilling motor. Central portion 17 of stabilizing body 12 may include radial projection 18 extending from the outer surface of stabilizing body 12. Central portion 17 may have an increased diameter in relation to the remainder of stabilizing body 12. Radial projection 18 may be any projection extending in a radial direction beyond the outer surface of stabilizing body 12. In one embodiment, radial projection 18 may extend around the entire circumference of the outer surface of stabilizing body 12. In another embodiment, radial projection 18 may extend only partially around stabilizing body 12. As shown in FIG. 2, a set of radial projections 18 may be spaced apart around the outer surface of central portion 17 of stabilizing body 12.

[0018]Referri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com