Patents

Literature

37results about How to "Minimize air leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

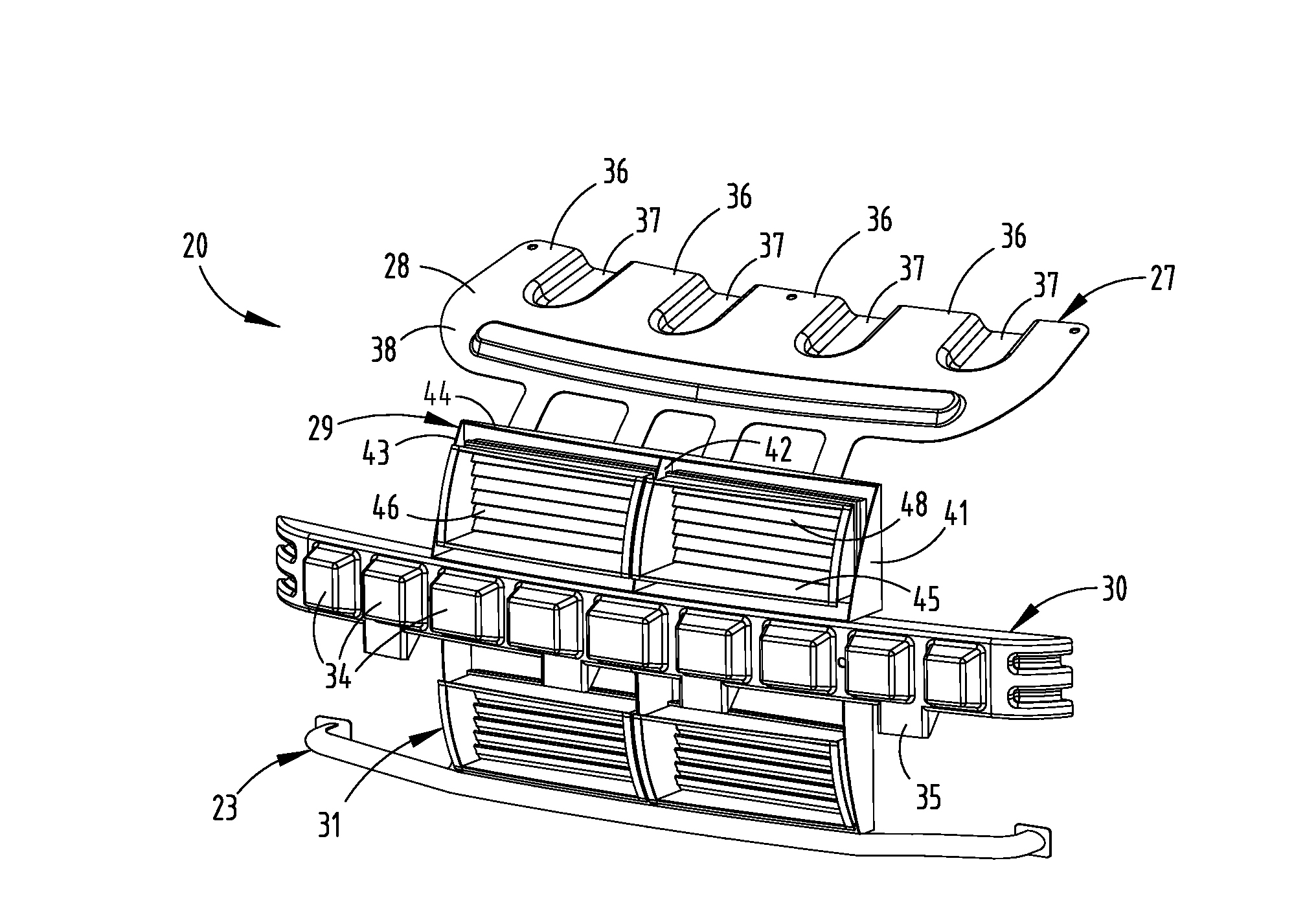

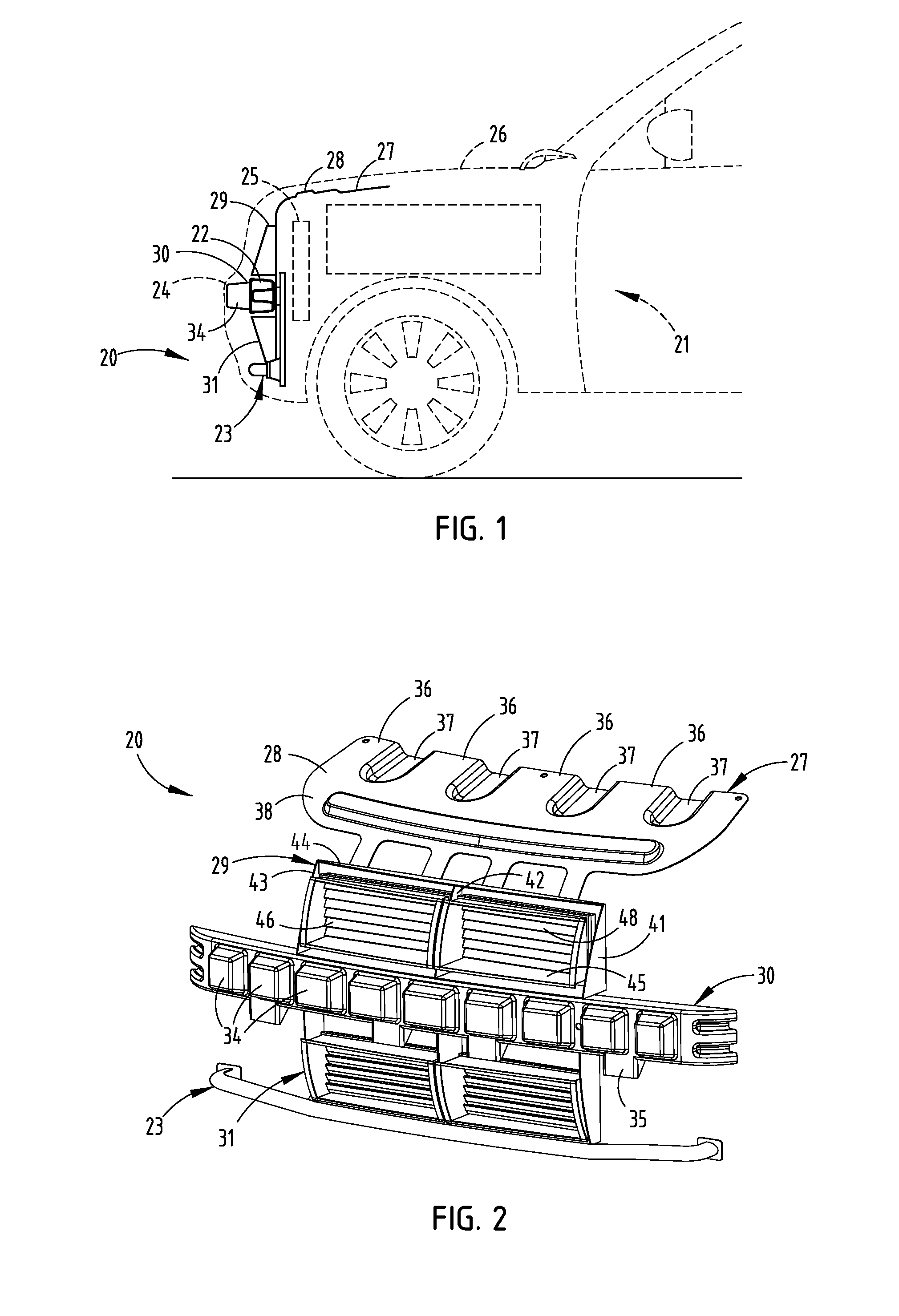

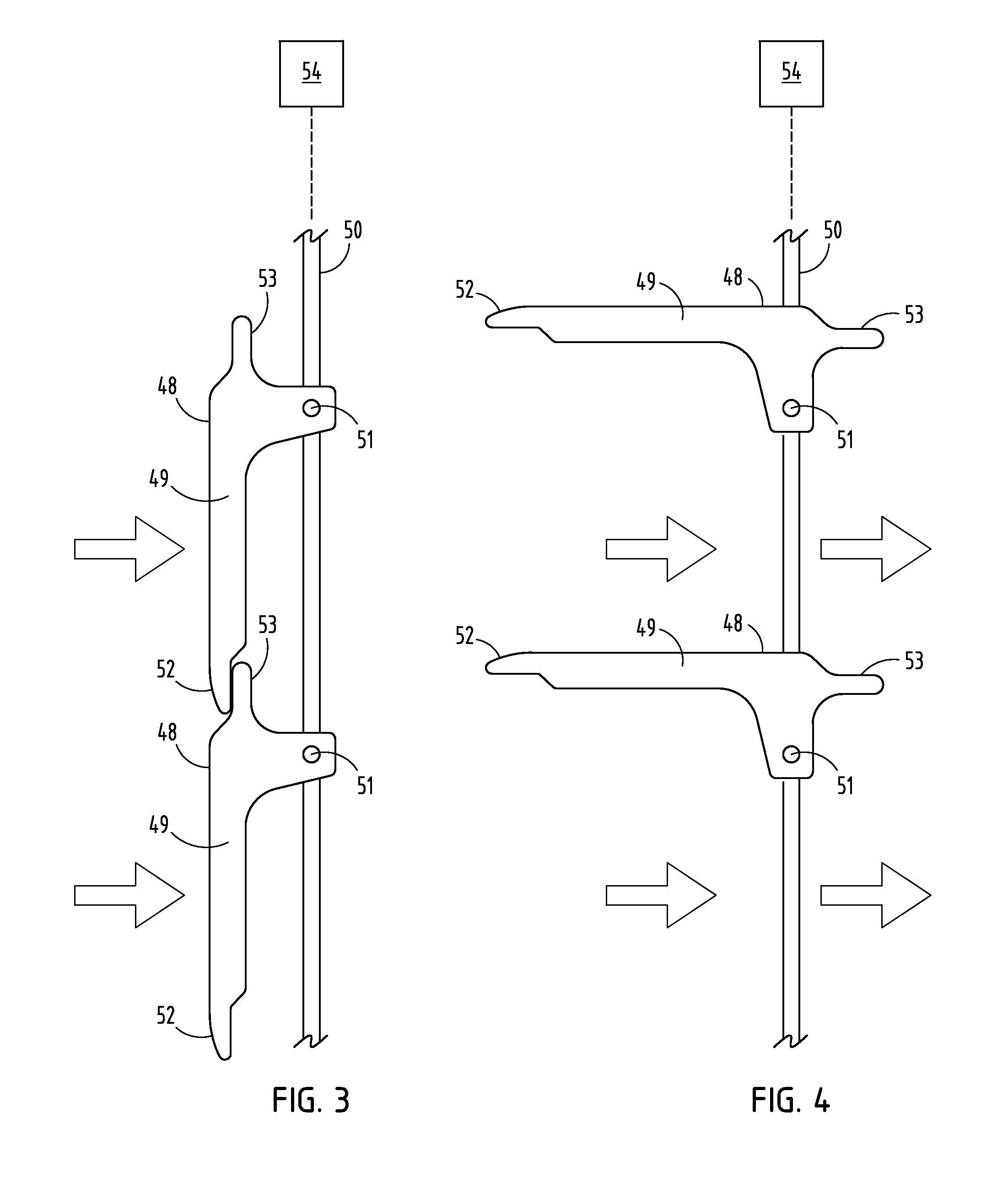

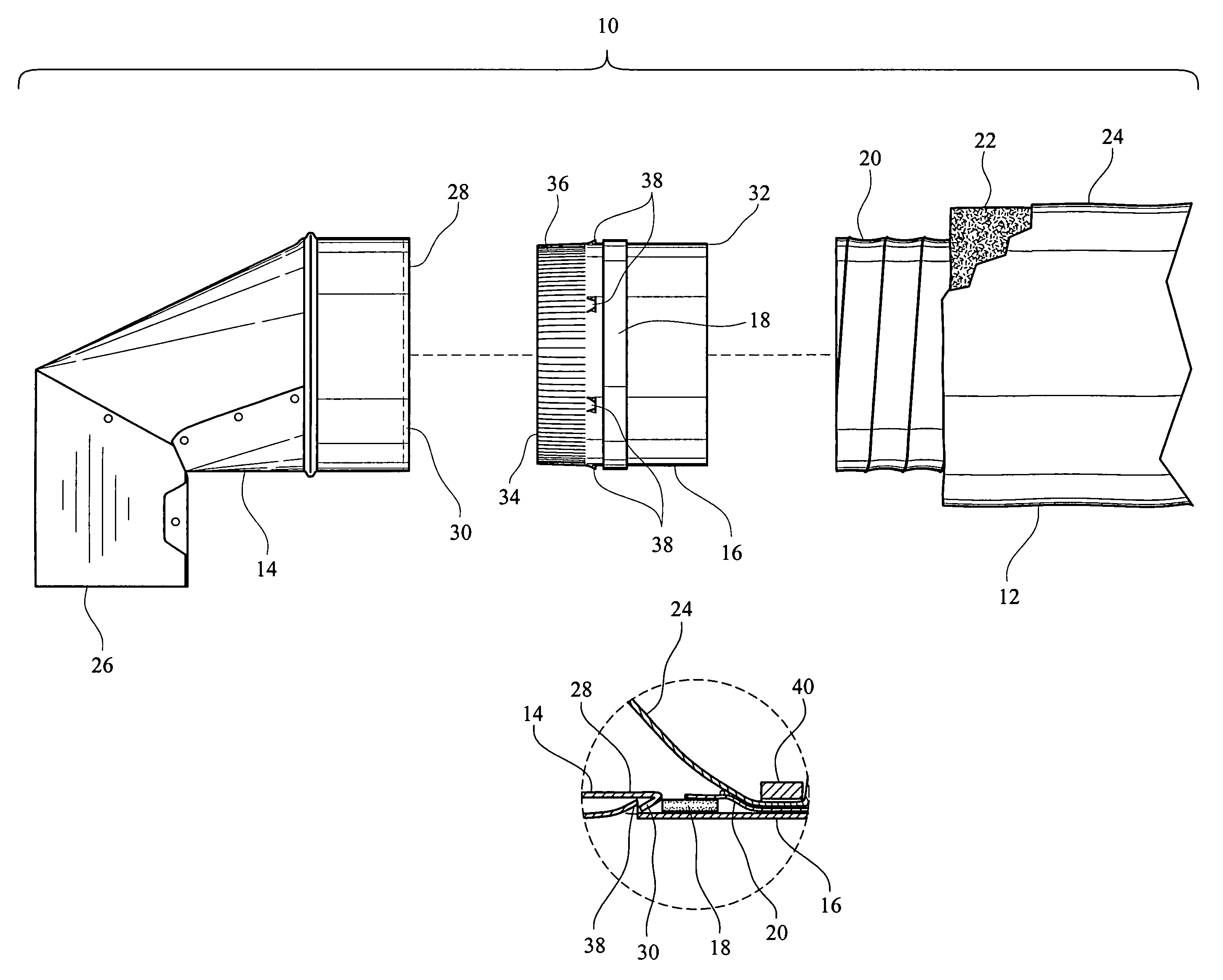

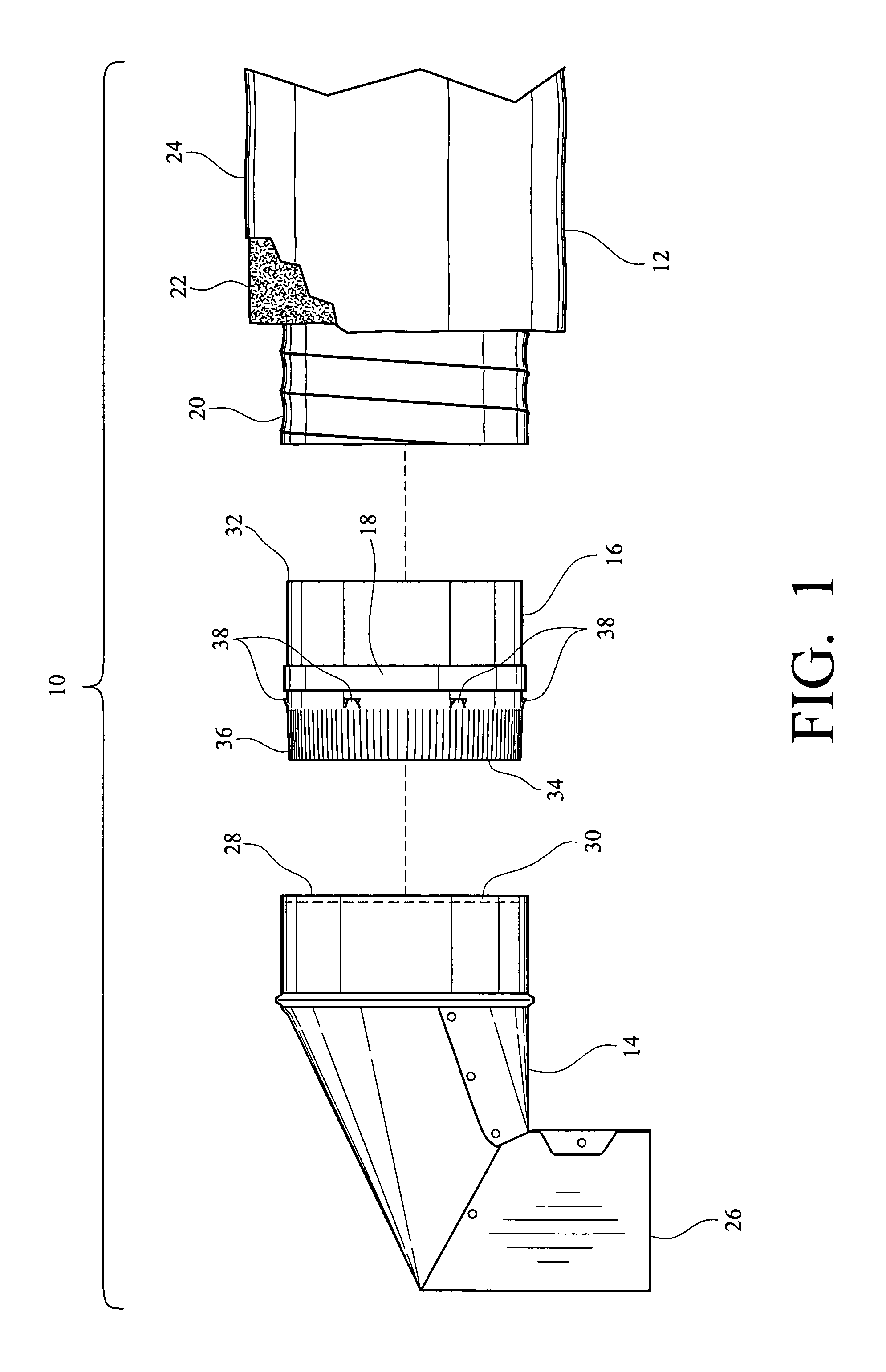

Integrated energy absorber and air flow management structure

An integrated assembly includes a bumper energy absorber section with crush lobes for abutting a bumper beam, an upper air shutter section with subassembled shutter members movable between closed and open positions, a first actuator mechanism for moving the shutter members between positions, an upper fascia support section with upper leg crush lobe therein above the upper air shutter section, a lower air shutter section with subassembled lower shutter members movable between closed and open positions, a second actuator mechanism for moving the lower shutter members between the positions; and a lower leg energy absorber section attached below the lower air shutter section and configured to abut (or replace) a face of a secondary pedestrian impact bar. The shutter members may be molded to a shutter frame using over molding technology rather than separately, manually assembled.

Owner:SHAPE CORP

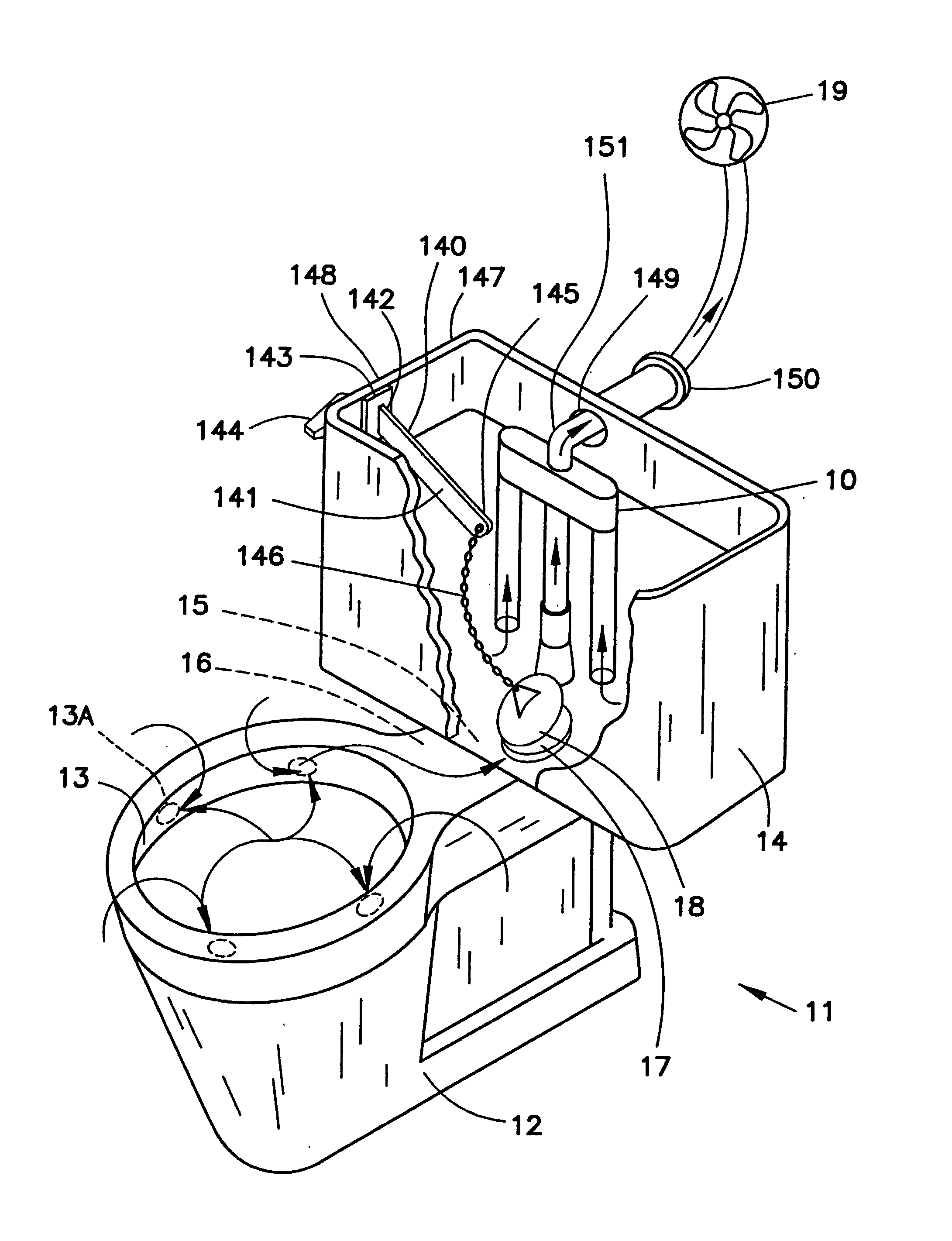

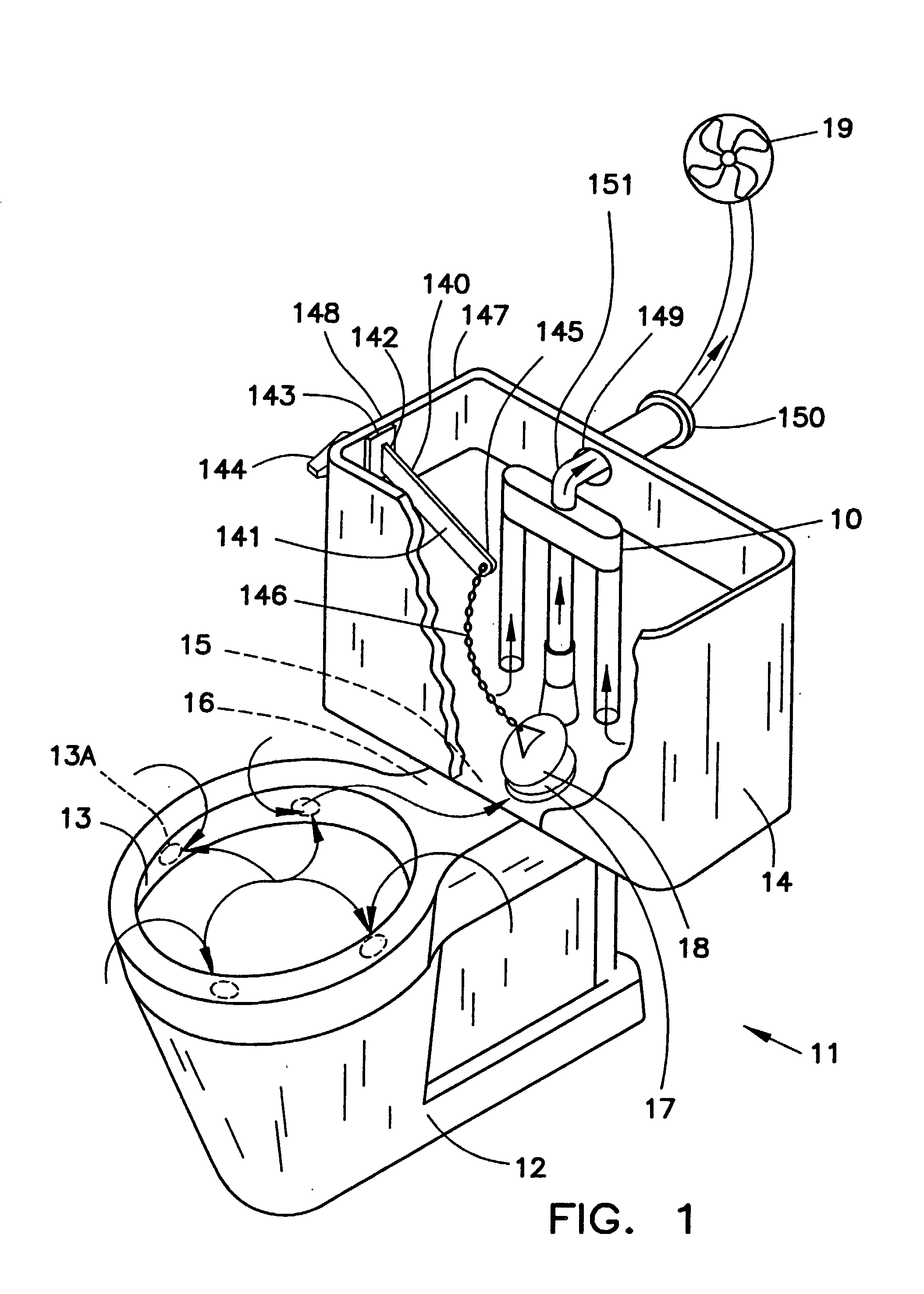

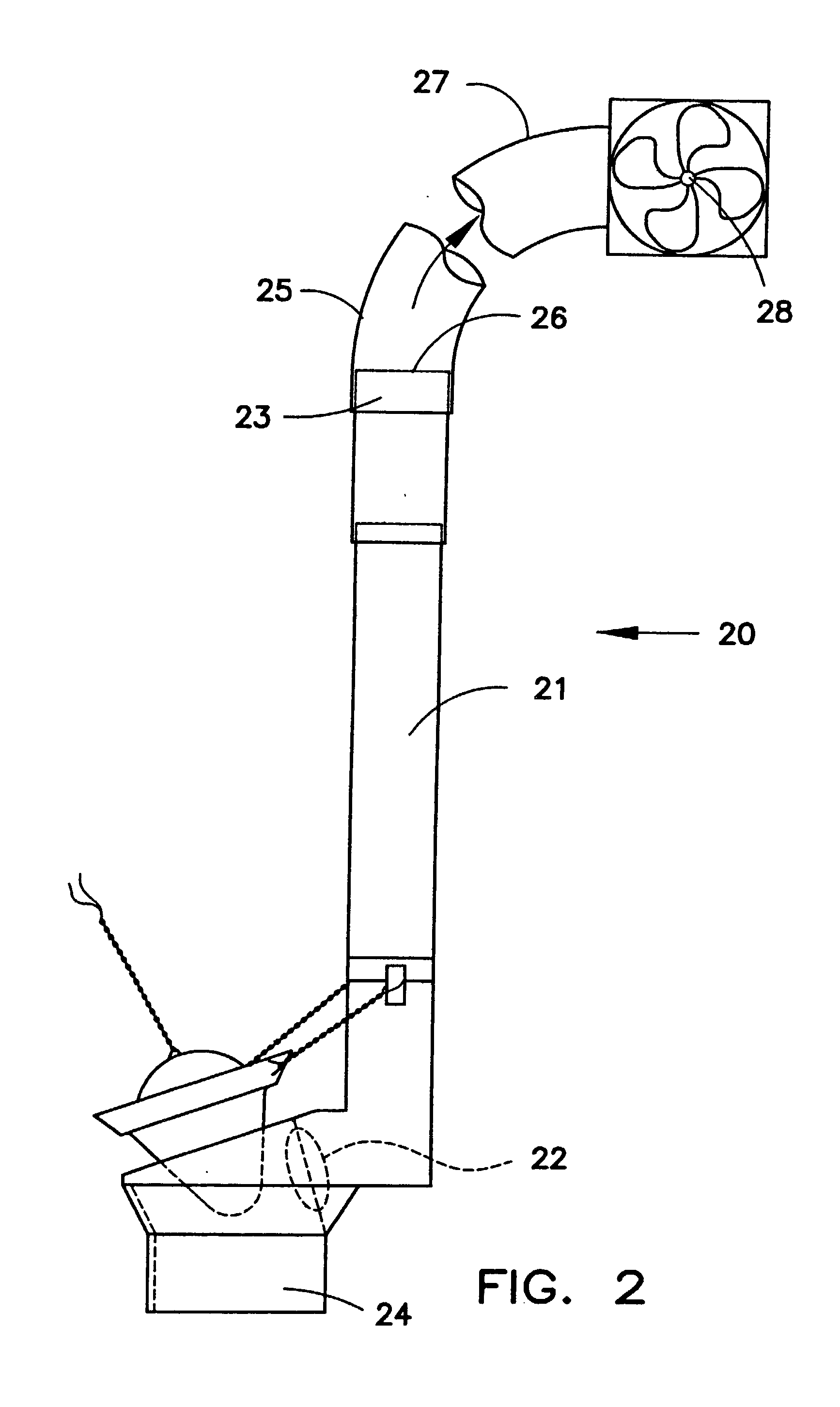

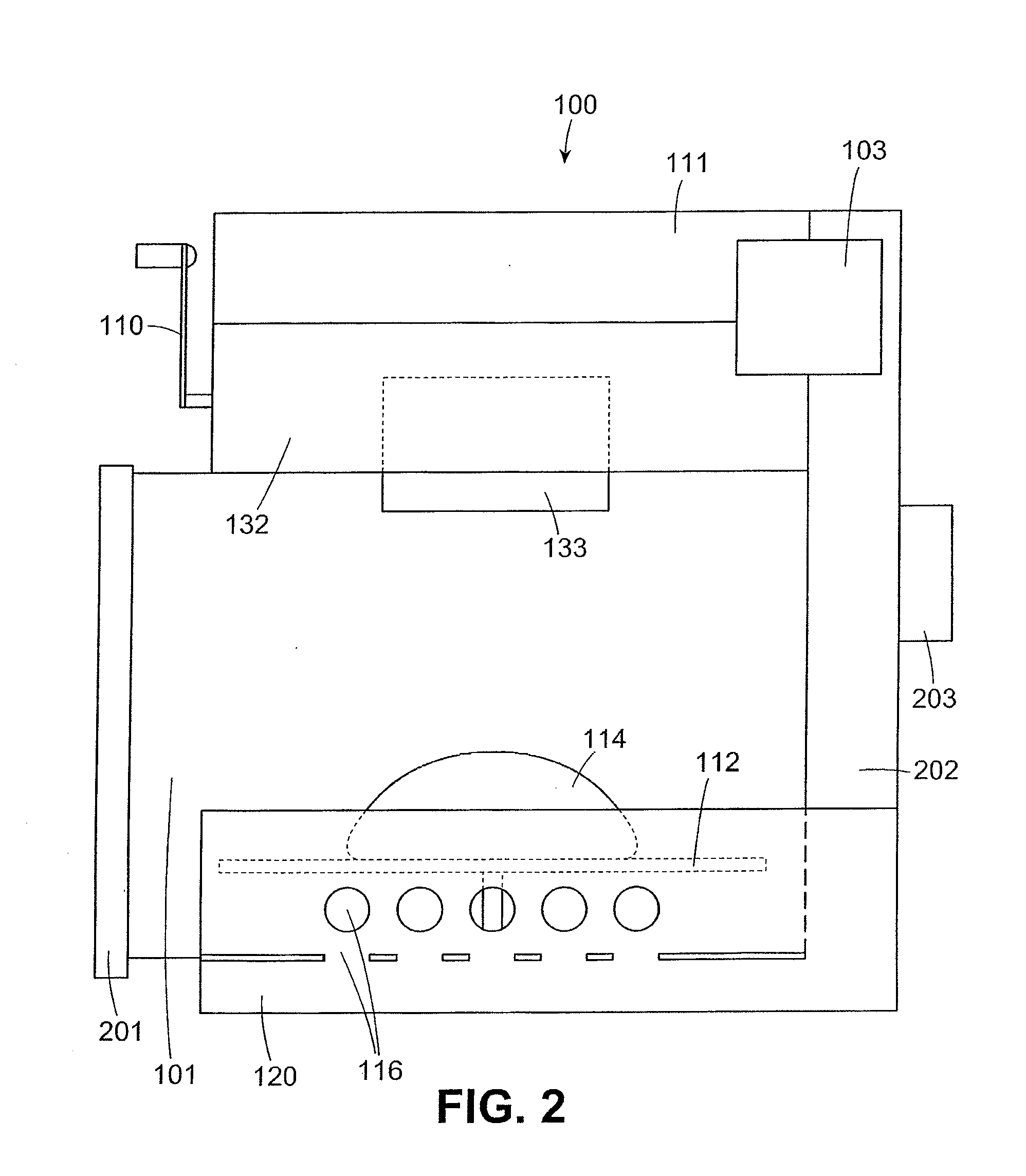

Ventilation system for malodorous air removal

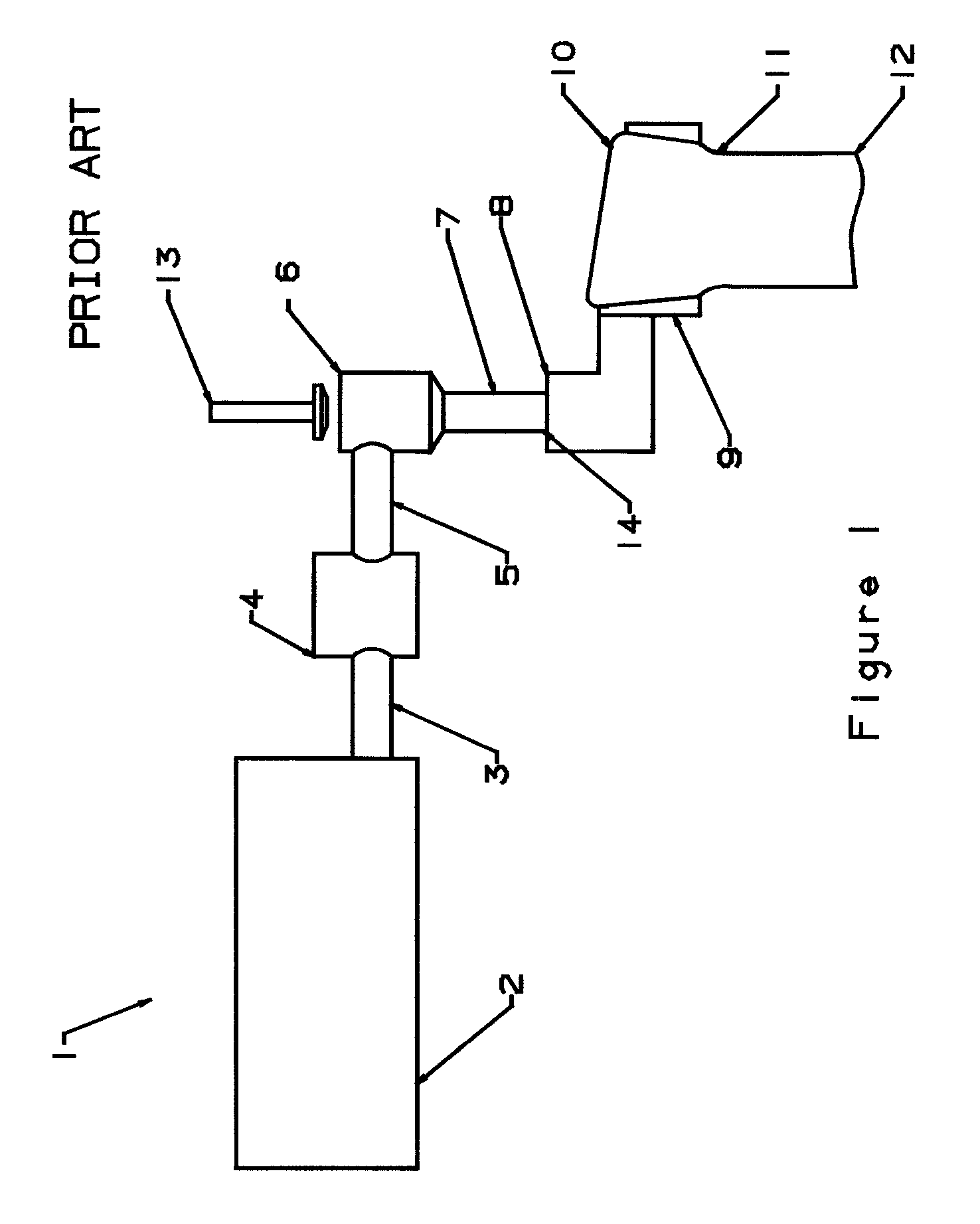

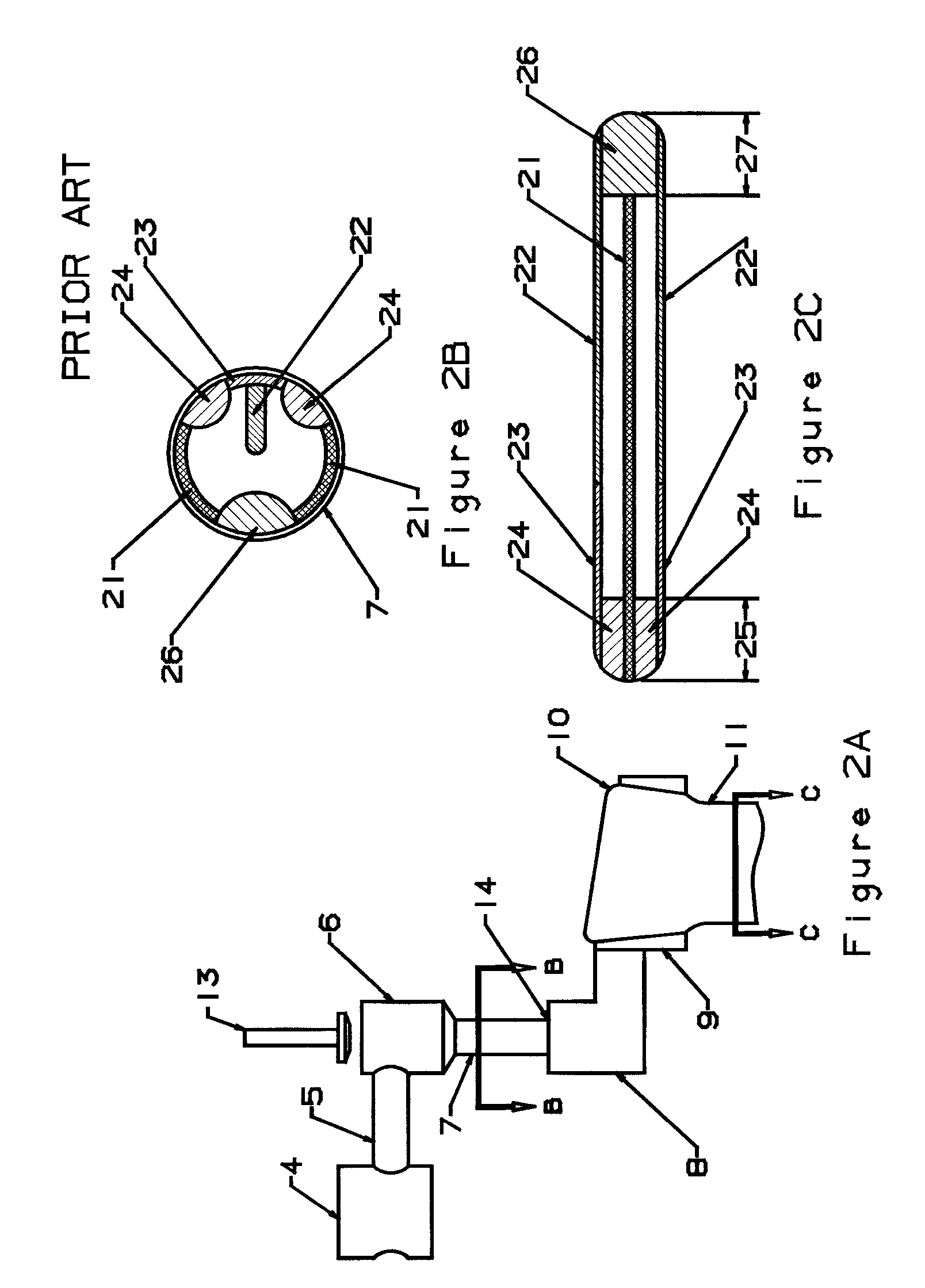

InactiveUS20020194670A1Minimize air leakageEfficient driveFlushing devicesLavatory sanitoryEngineeringFlush toilet

An odor evacuation and mitigation system for a bathroom space including a central evacuation fan system, an odor evacuation system for a toilet having a toilet bowl, an automatic flushing system, and a steam and moisture ventilation system. The fan system includes an enclosure having a motor and fan therein and connected to an exhaust hose for expelling odors. The odor evacuation system for a toilet includes a flush valve in communication with a pipe, connected to an external suction device for removal of odors, through an overflow pipe and an evacuation pipe. The automatic flushing system includes a sensor connected to a servomotor for rotation of an actuation lever connected to a flush valve. The steam ventilation system includes a manifold body disposed over a shower enclosure and having a grille through which air flows into the manifold body and outward through an externally extending hose.

Owner:HASHEMI AMIN H

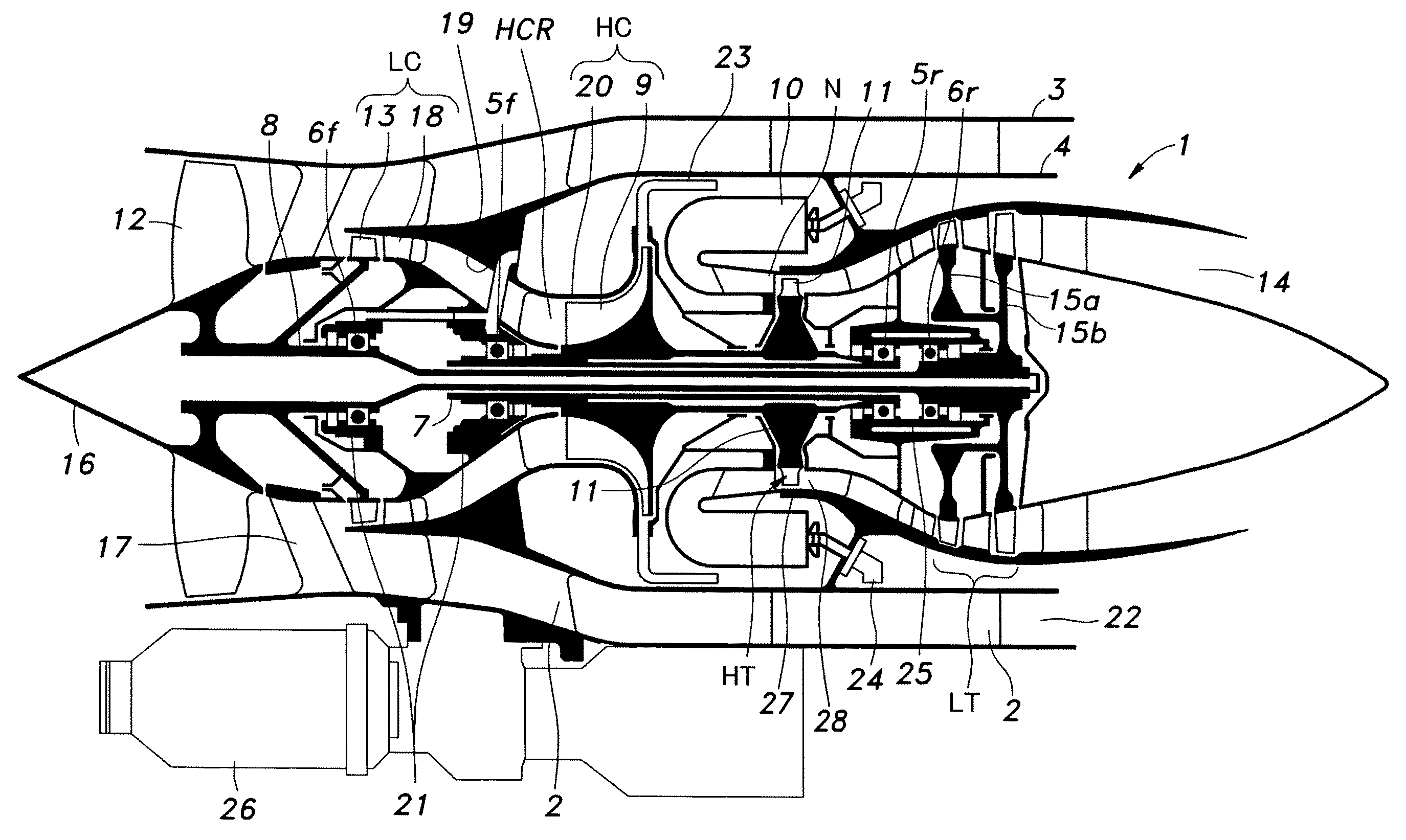

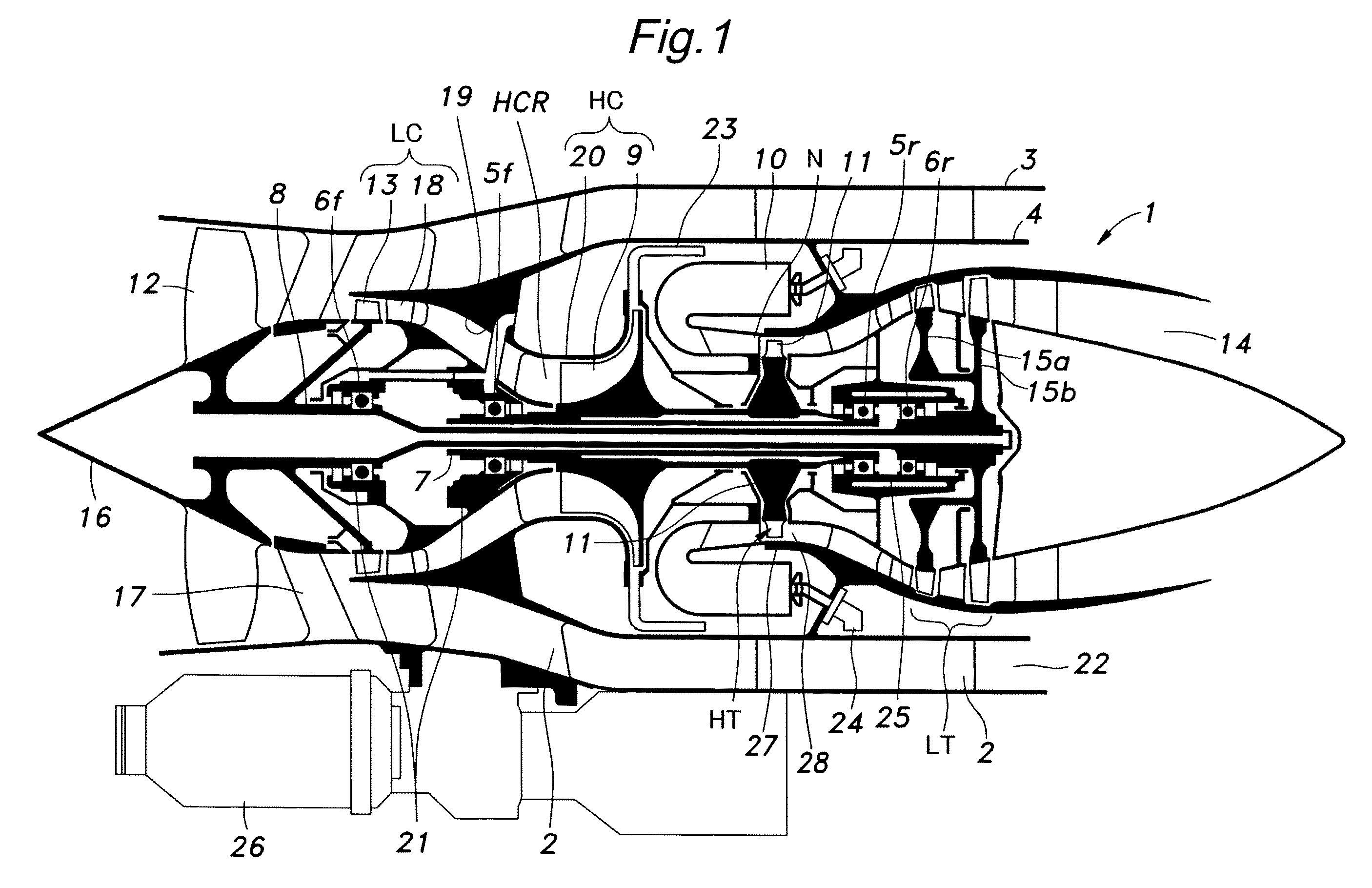

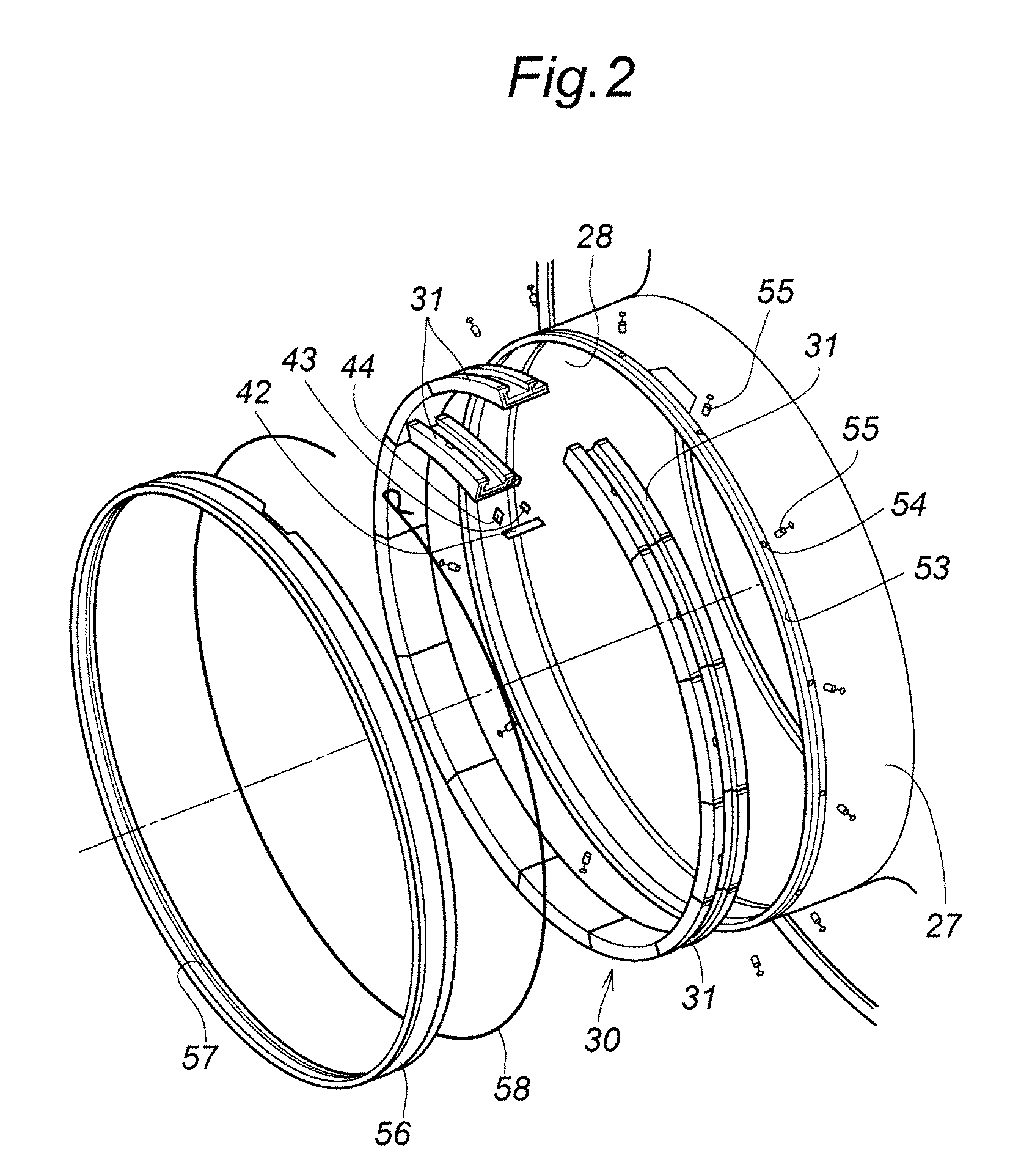

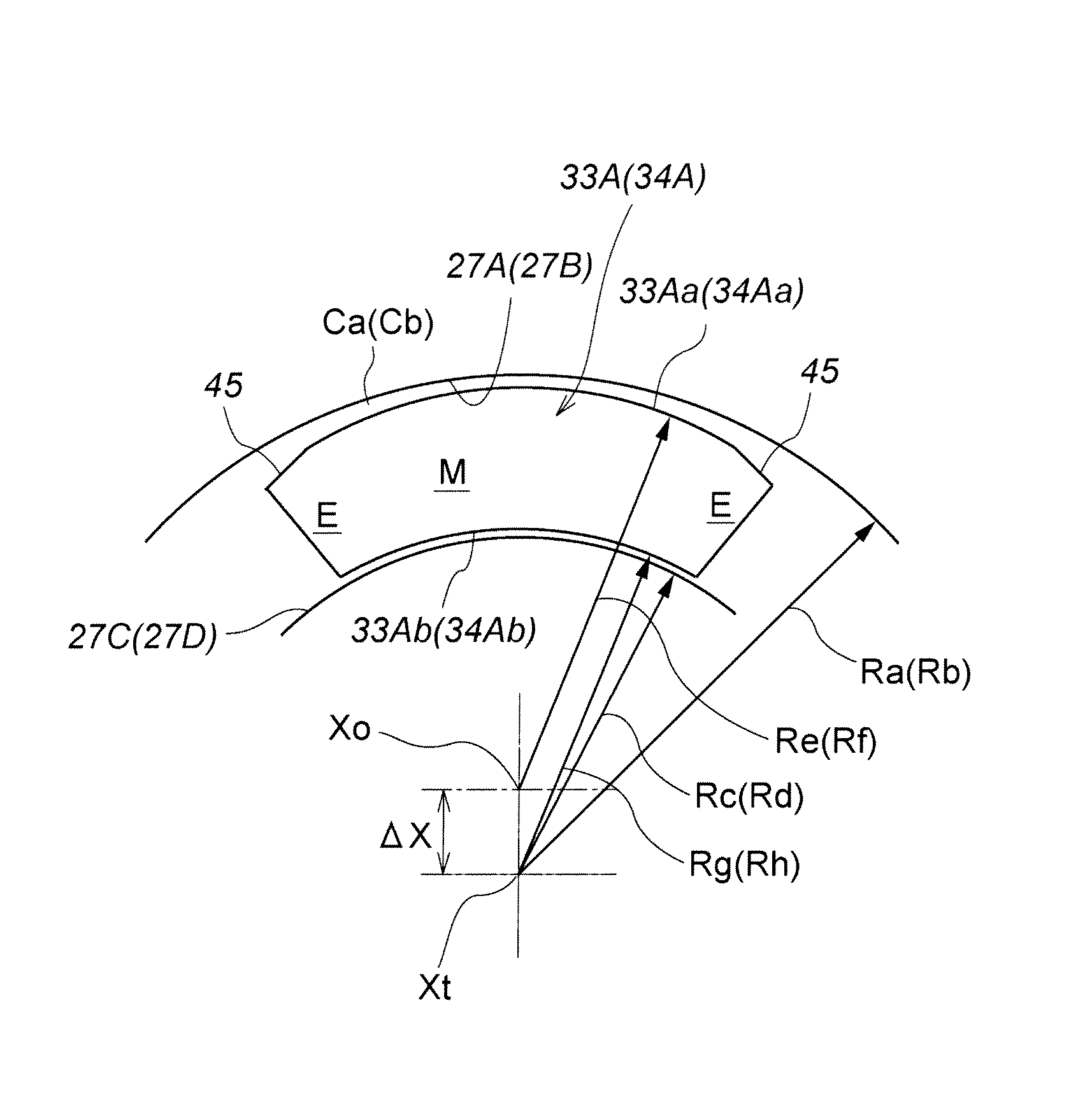

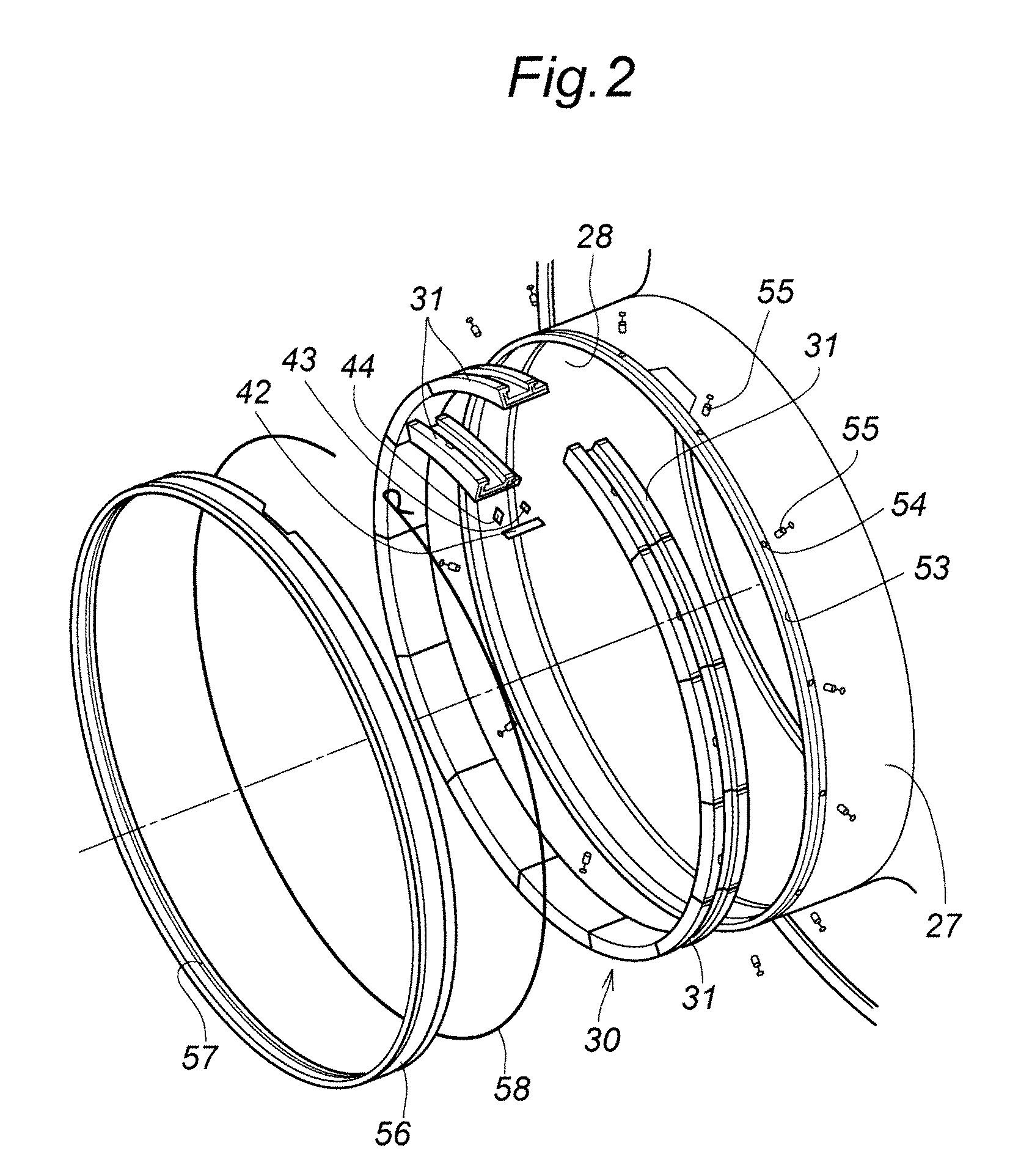

Turbine shroud

ActiveUS20100247298A1Minimize thermal stressReduce leakagePump componentsBlade accessoriesTurbine bladeThermal expansion

A turbine shroud (30) of a gas turbine engine comprises a plurality of arcuate shroud segments (31) combined into an annular configuration, each shroud segment including a main body (32) defining an inner circumferential surface opposing the tips of the turbine rotor blades (11a) at a small clearance and an engagement feature including an axial wall (33a, 34a) having a prescribed circumferential length and a prescribed axial length, the turbine casing including an axial slot (51, 52) extending coaxially around the center line of the engine and configured to receive the axially extending wall of each shroud segment. A clearance defined between each circumferential end part (E) of the axial wall and an opposing inner circumferential surface of the turbine casing is greater than that defined between a circumferentially middle part (M) of the axial wall and an opposing inner circumferential surface of the turbine casing under a cool condition of the engine. A radial temperature gradient that develops in each shroud segment when the engine is warmed causes a deformation of the shroud segment such that the clearance can be made substantially uniform over the entire circumference of the shroud segment and the cooling air leakage can be minimized while minimizing thermal stress that may be caused by the thermal expansion of the shroud segment.

Owner:HONDA MOTOR CO LTD

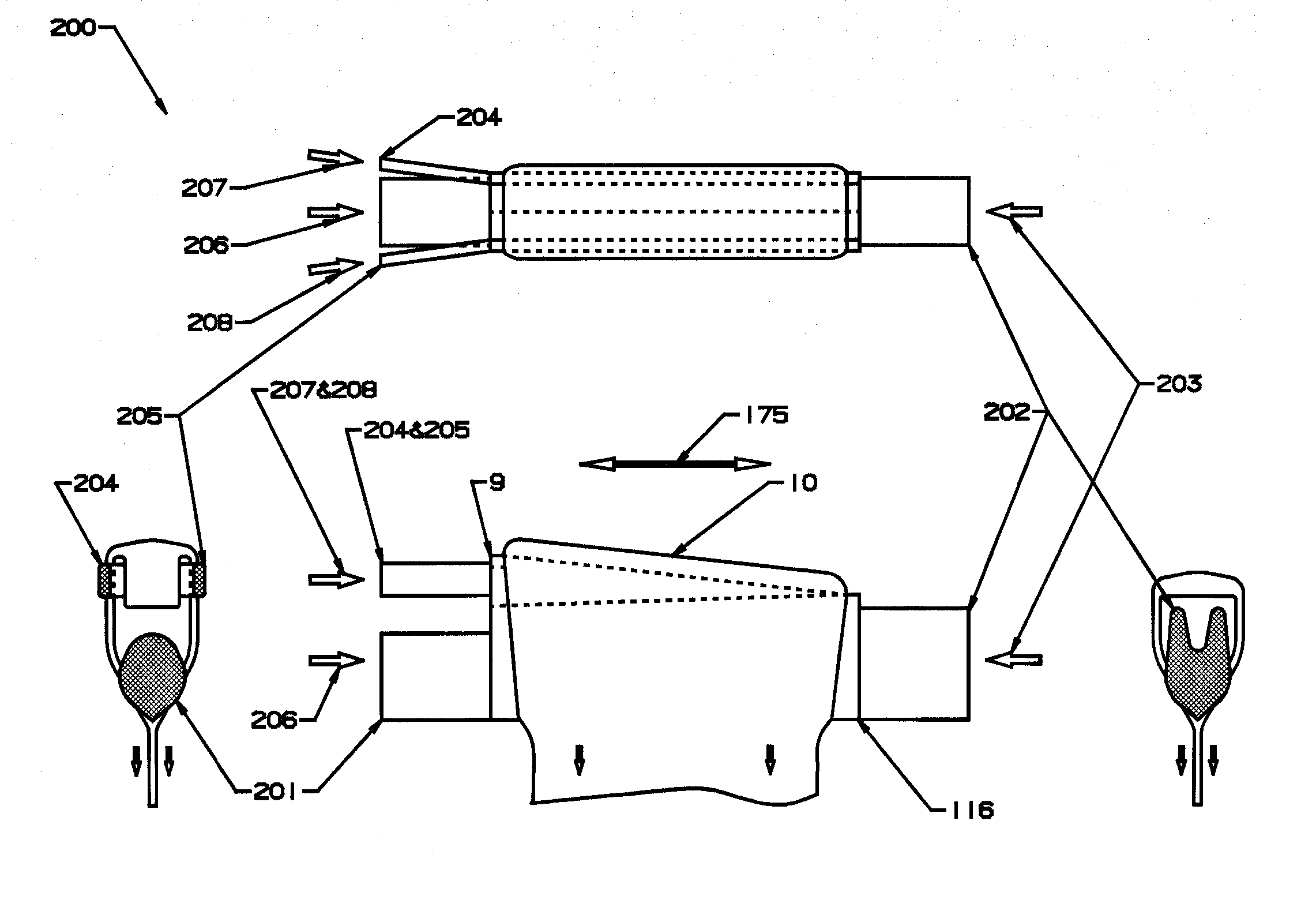

Overflow Downdraw Glass Forming Method and Apparatus

InactiveUS20070068197A1Reduce unevennessEfficient degradationBlowing machine gearingsGlass furnace apparatusFlat glassThermal creep

The present invention discloses improved methods and apparatus for forming sheet glass. In one embodiment, the invention introduces a counteracting force to the stresses on the forming structure in a manner such that the thermal creep which inevitably occurs has a minimum impact on the glass flow characteristics of the forming structure.

Owner:CORNING INC

Overflow downdrawn glass forming method and apparatus

InactiveUS6889526B2Reduce unevennessEfficient degradationGlass furnace apparatusGlass drawing apparatusThermal creepEngineering

Owner:CORNING INC

Overflow downdraw glass forming method and apparatus

InactiveUS7681414B2Reduce unevennessEfficient degradationBlowing machine gearingsGlass furnace apparatusFlat glassThermal creep

The present invention discloses improved methods and apparatus for forming sheet glass. In one embodiment, the invention introduces a counteracting force to the stresses on the forming structure in a manner such that the thermal creep which inevitably occurs has a minimum impact on the glass flow characteristics of the forming structure.

Owner:CORNING INC

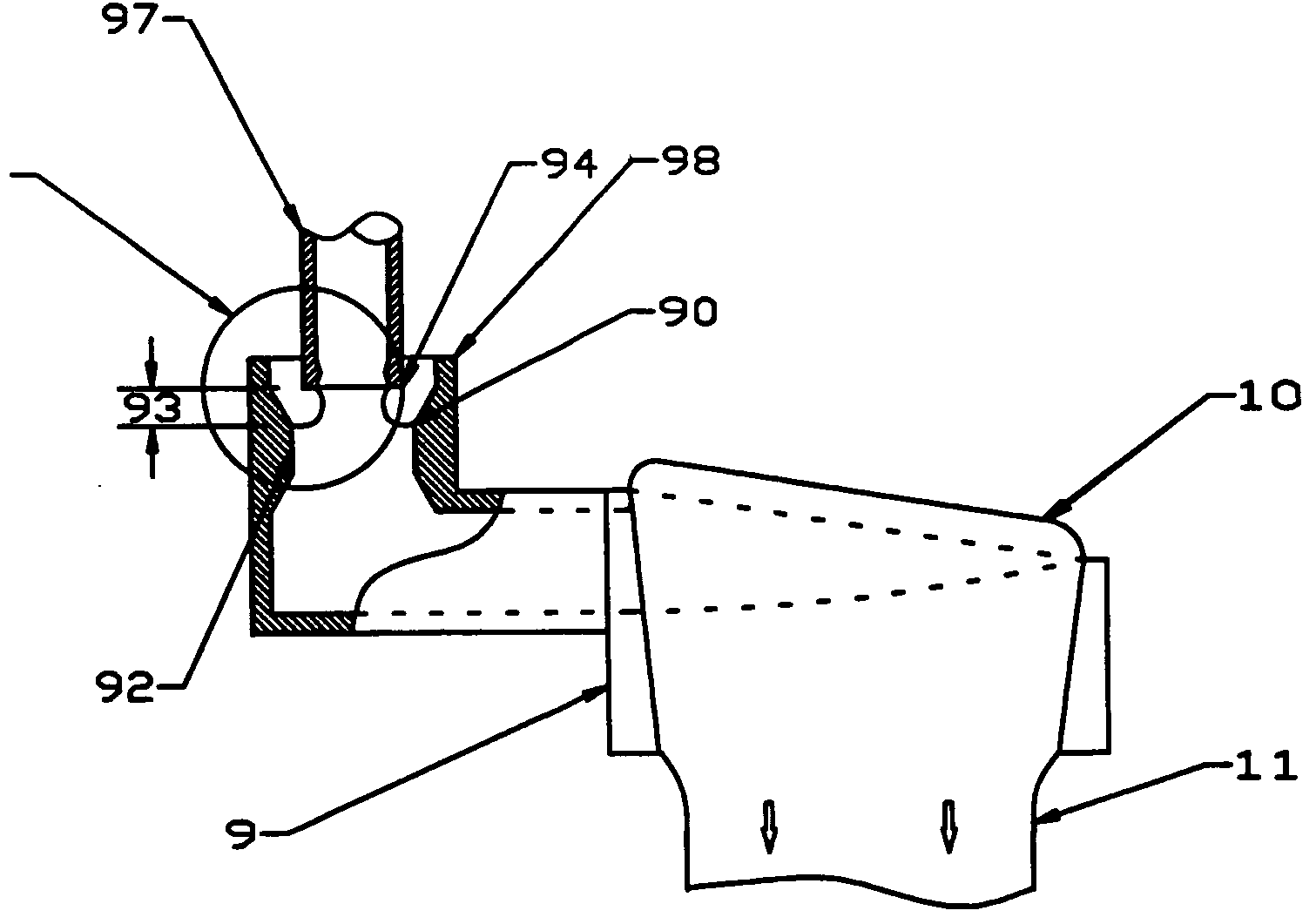

HVAC duct system

InactiveUS7393021B1Easy to installFirmly connectedThermal insulationSpace heating and ventilation detailsEngineeringGasket

A duct system generally comprises a flexible duct; a fitting having an end including either an in-turned circumferential lip or a plurality of circumferentially arranged tabs; a collar having a first end and a second end, the first end being adapted to be secured to the flexible duct, and the second end being adapted to be secured to the end of the fitting, such that, if the second end of the fitting includes an in-turned circumferential lip, the second end of the collar includes a plurality of circumferentially arranged tabs adapted to engage the in-turned circumferential lip, and if the end of the fitting includes a plurality of circumferentially arranged tabs, the second end of the collar includes an in-turned circumferential lip adapted to engage the plurality of circumferentially arranged tabs; and at least one gasket for forming a seal between the fitting and the collar.

Owner:LUKJAN M ZACK

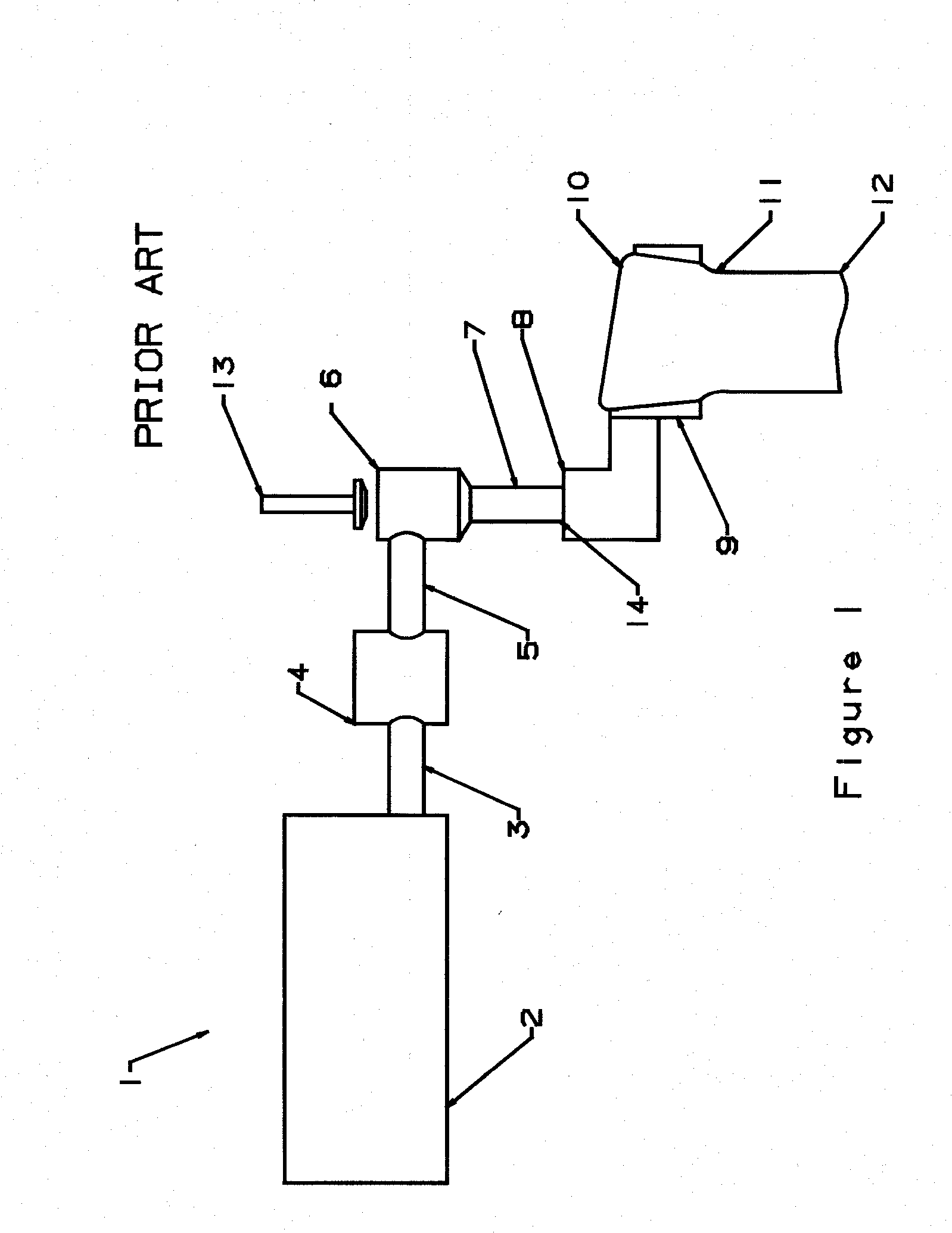

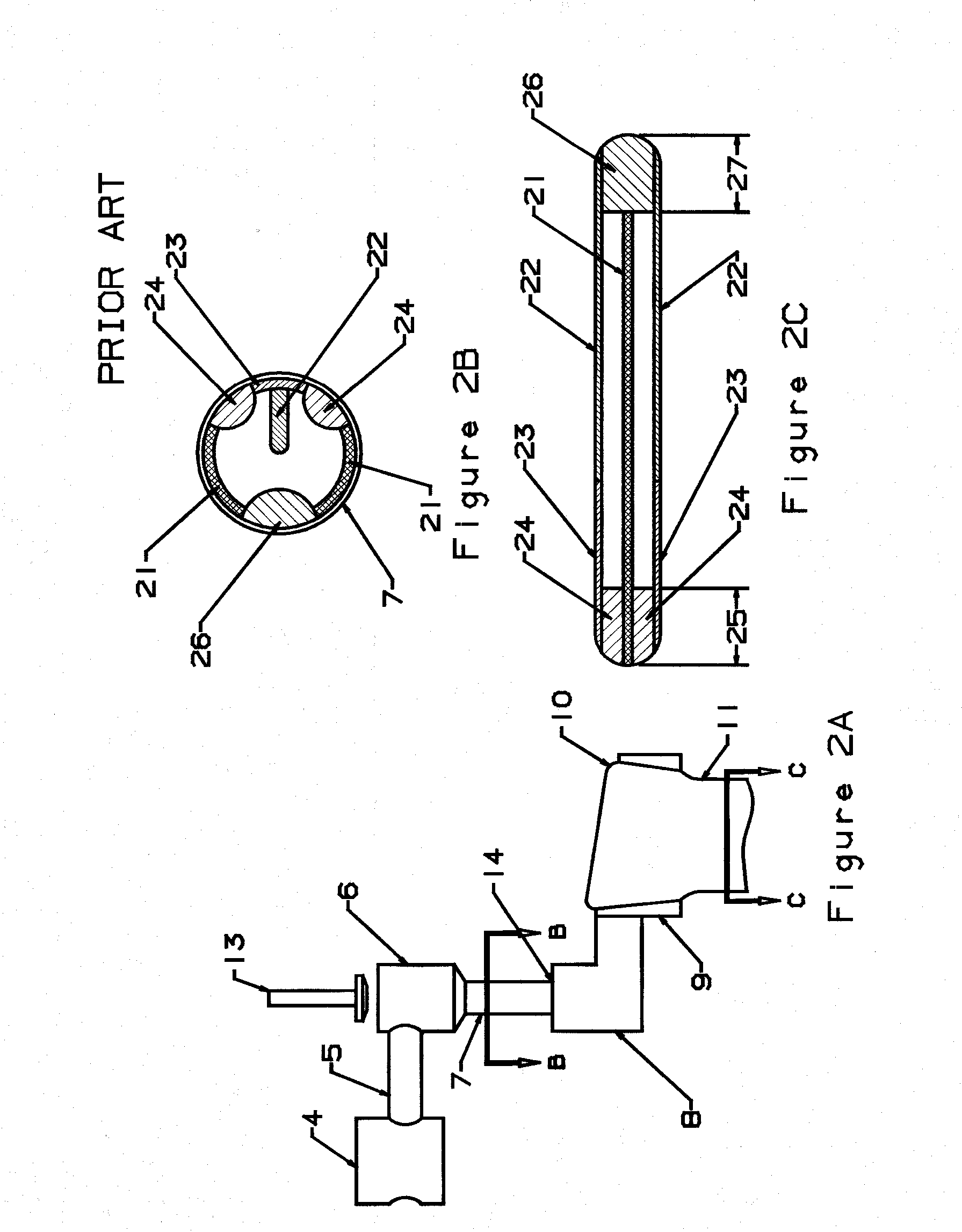

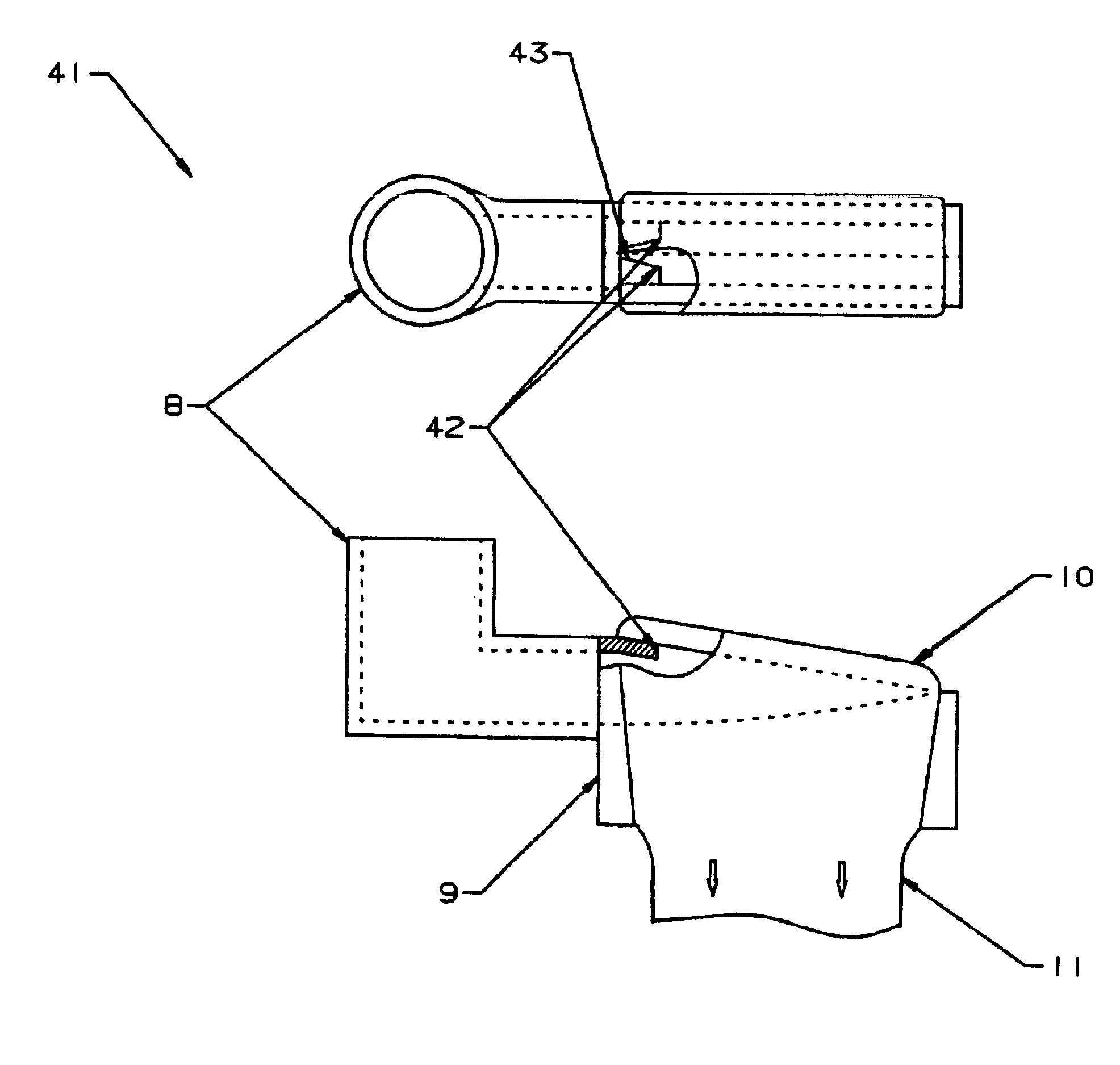

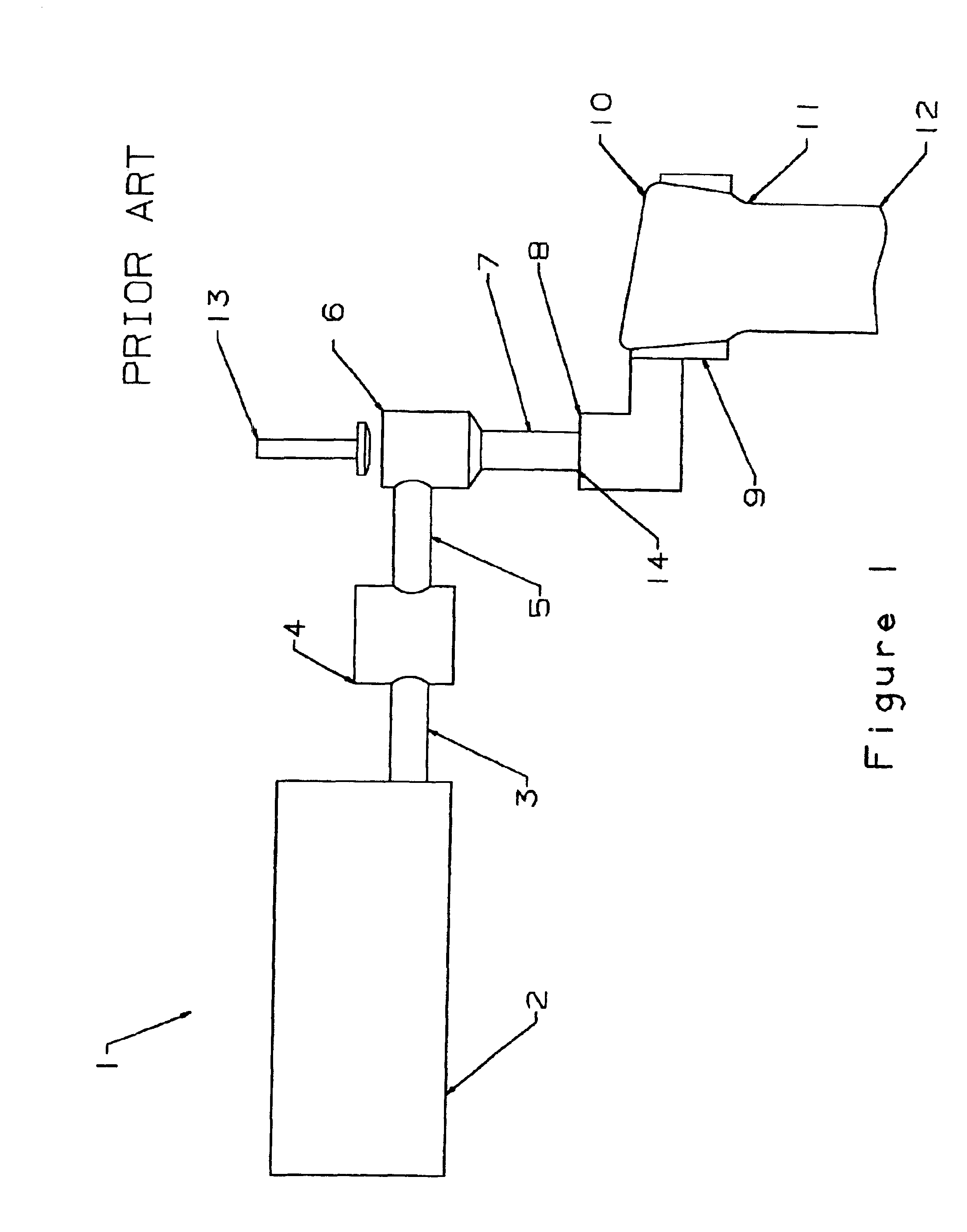

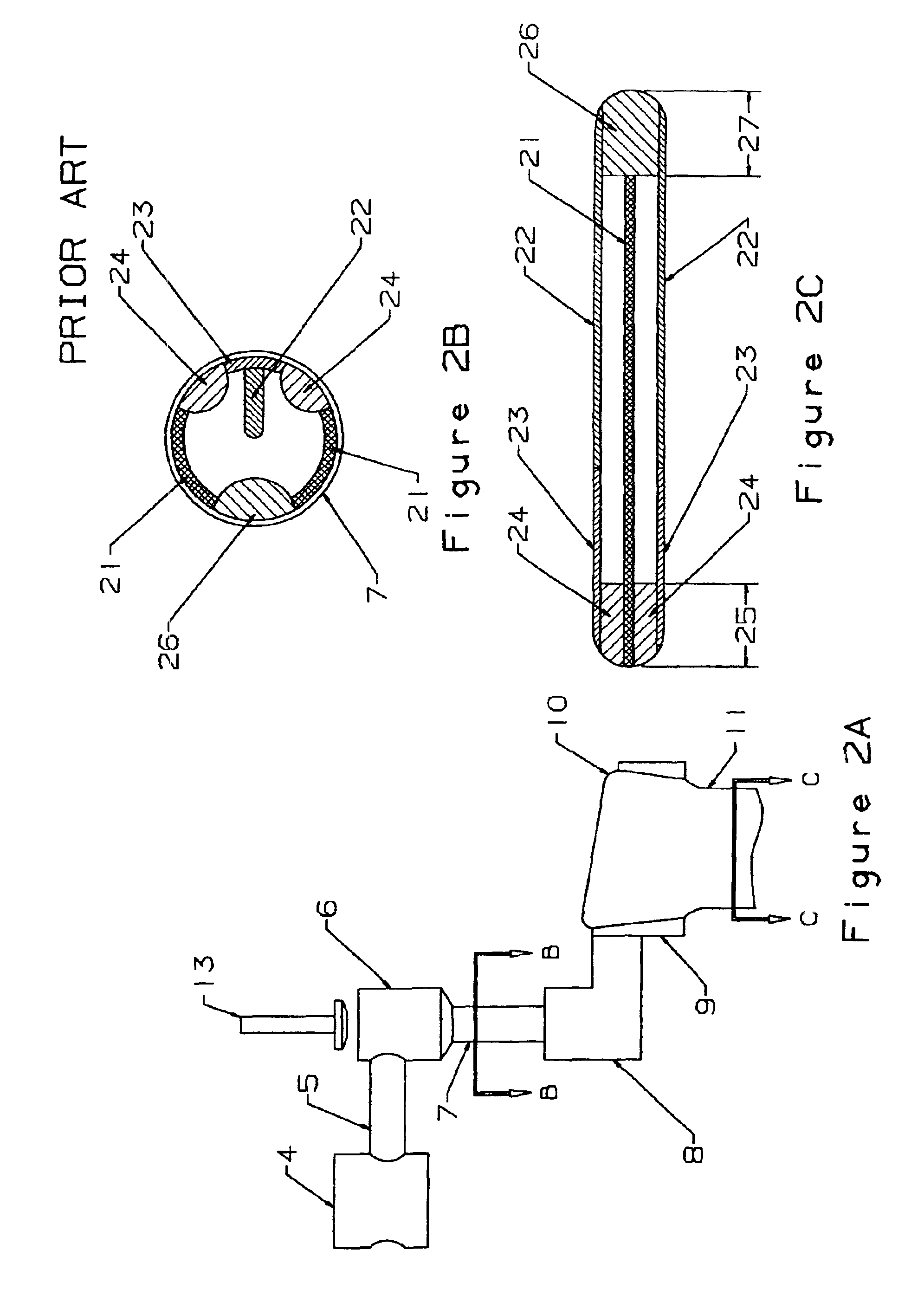

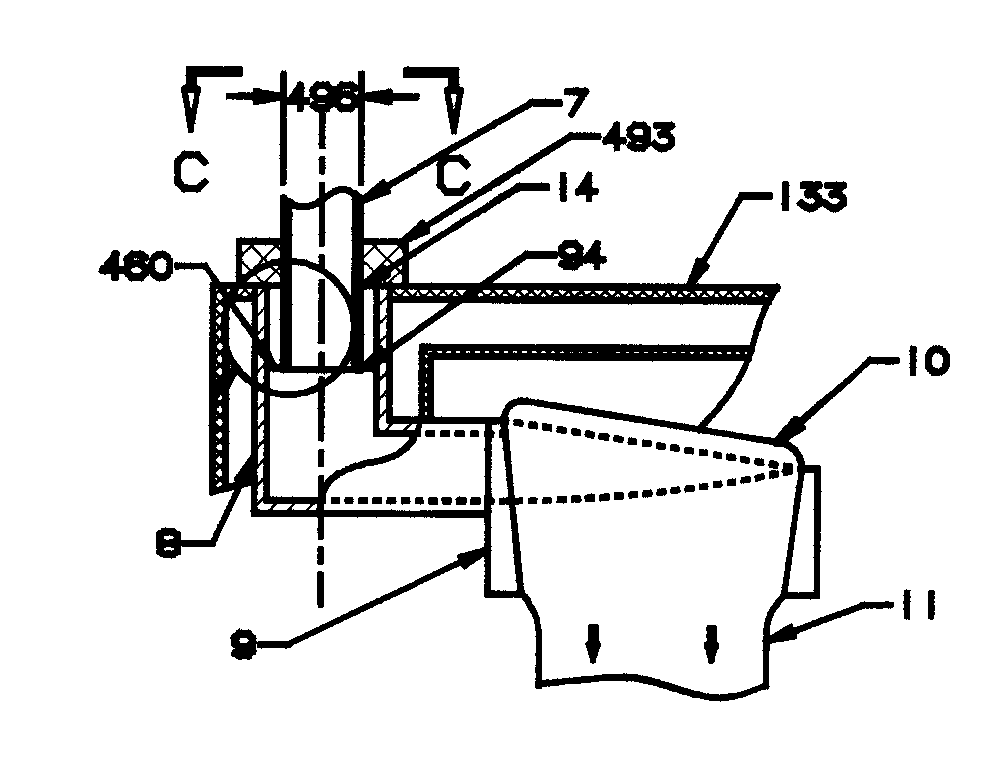

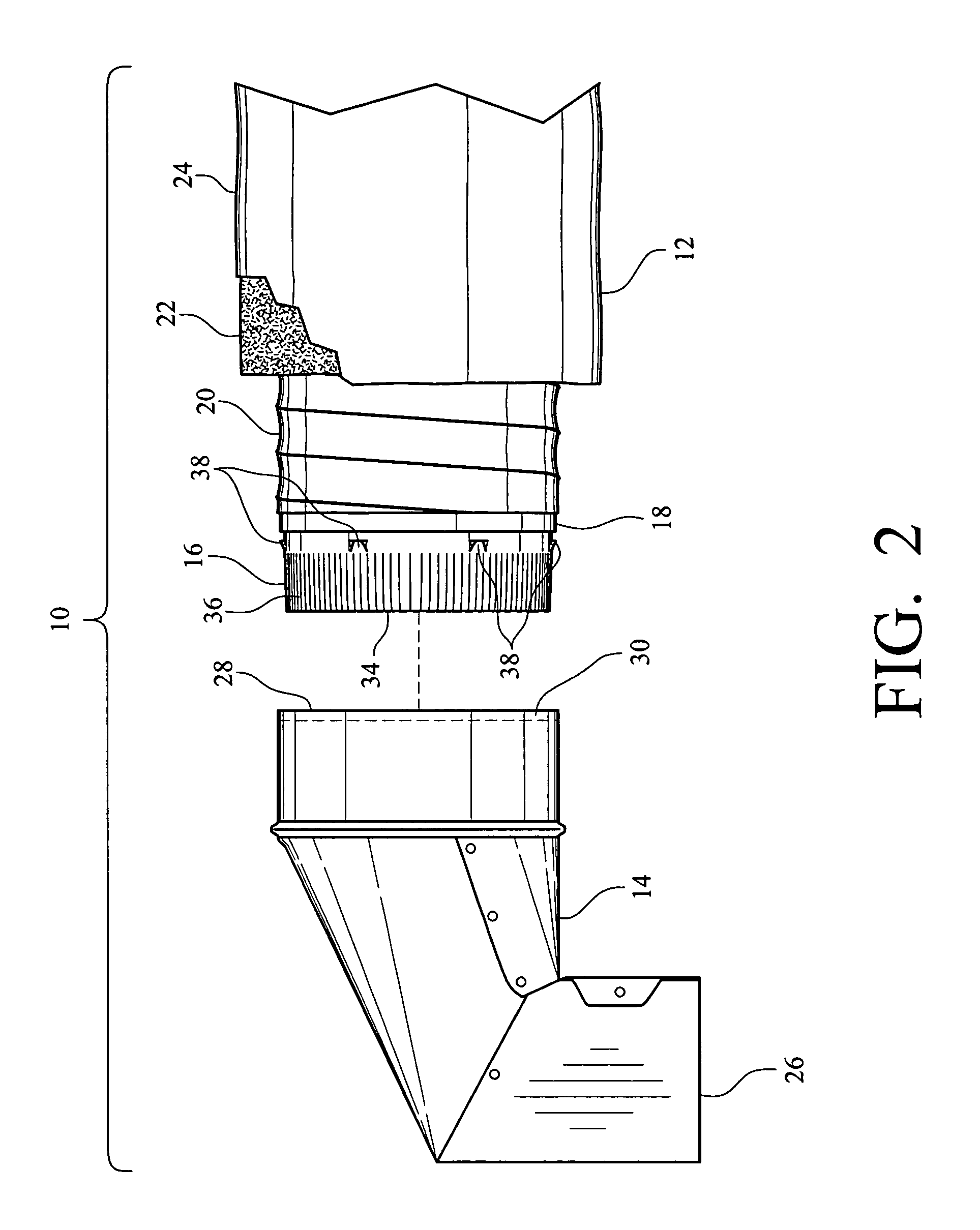

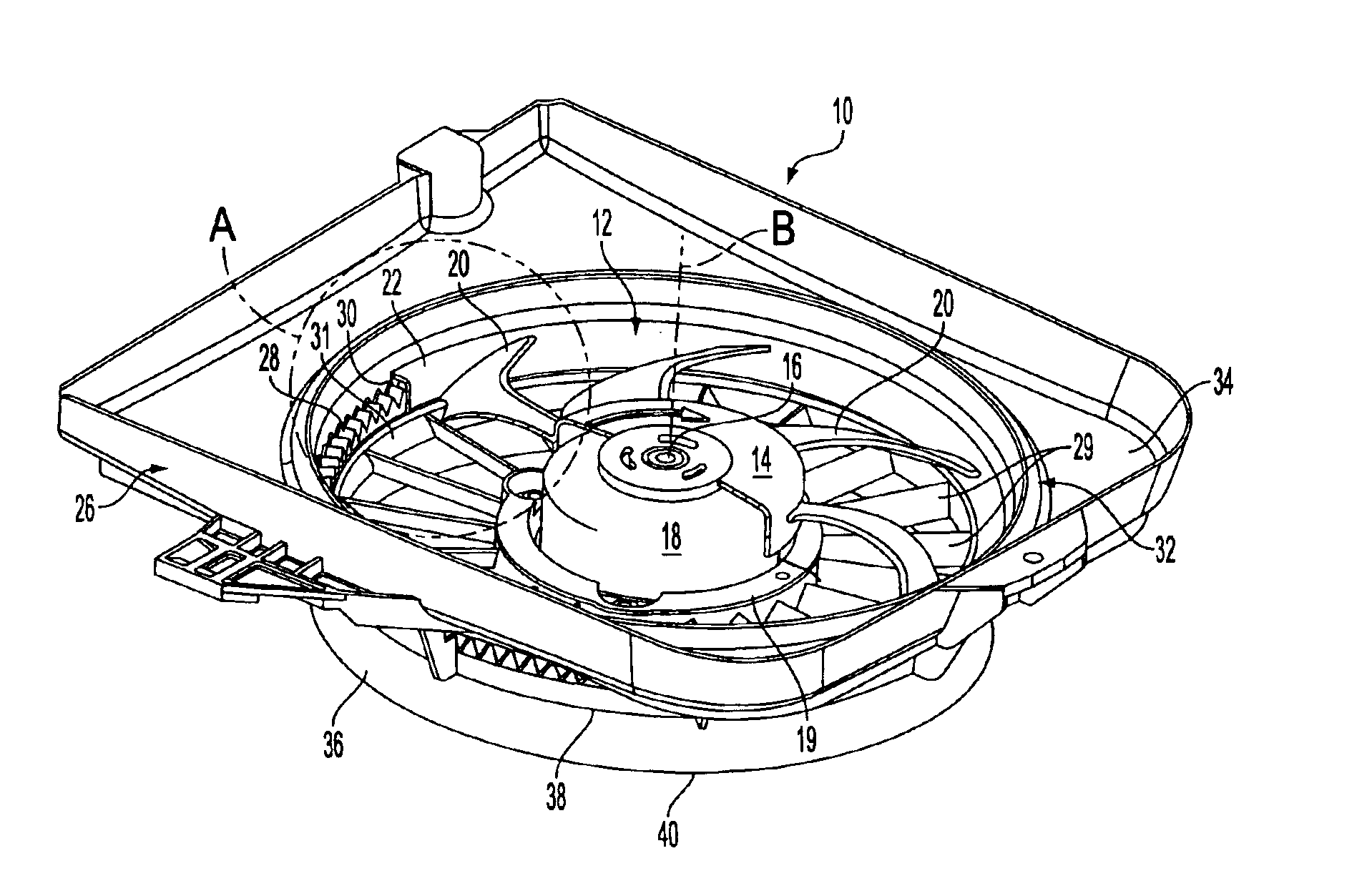

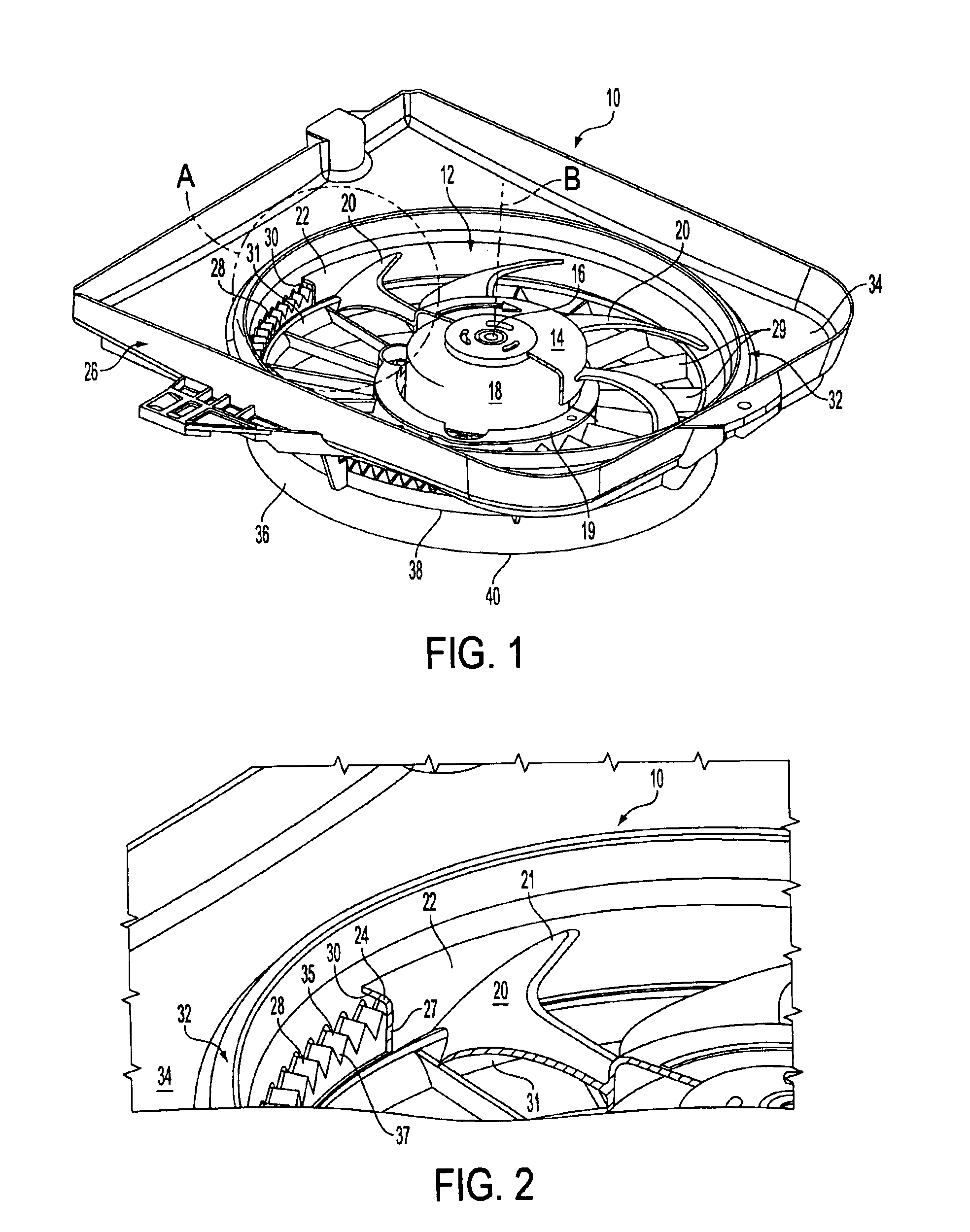

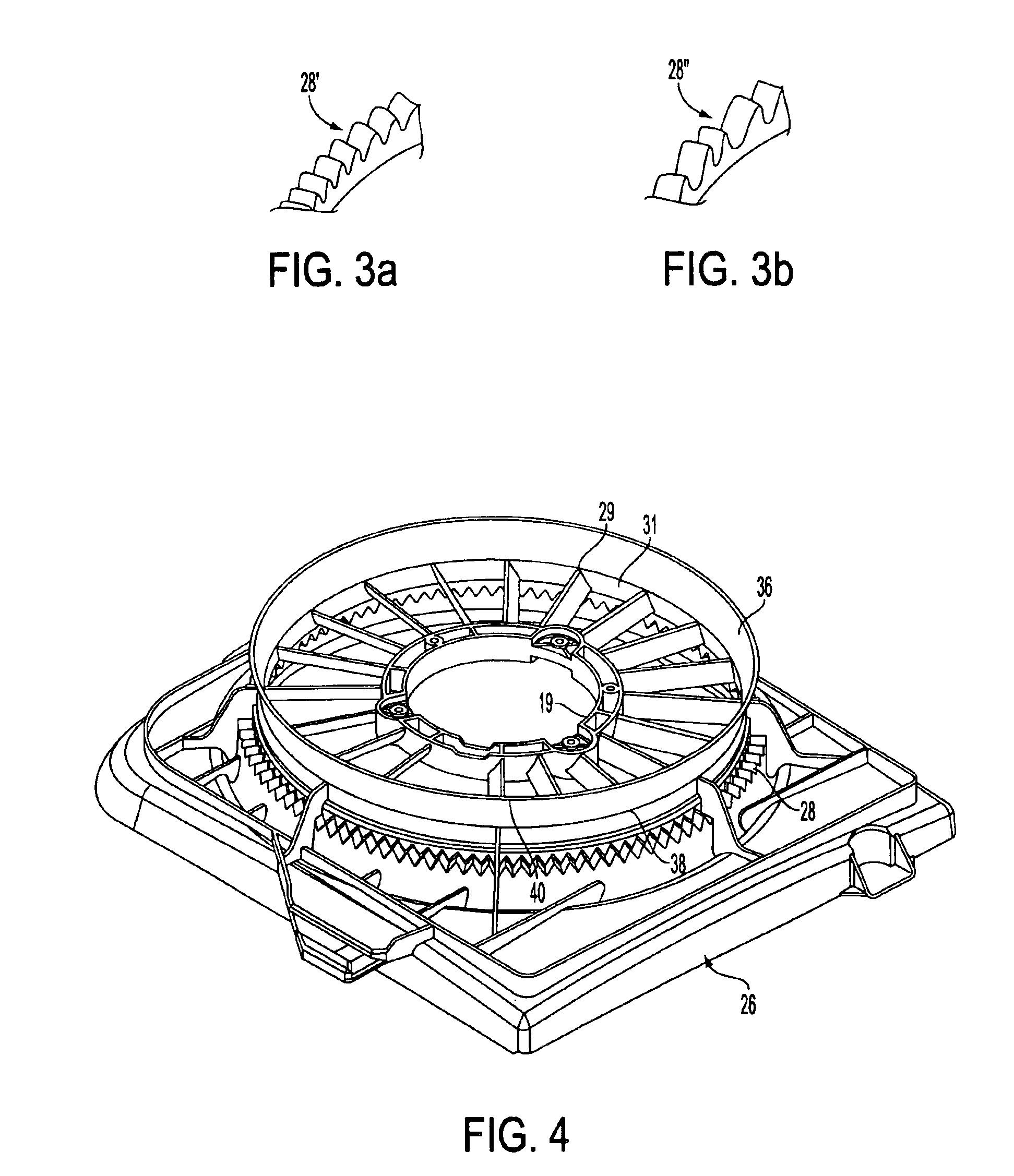

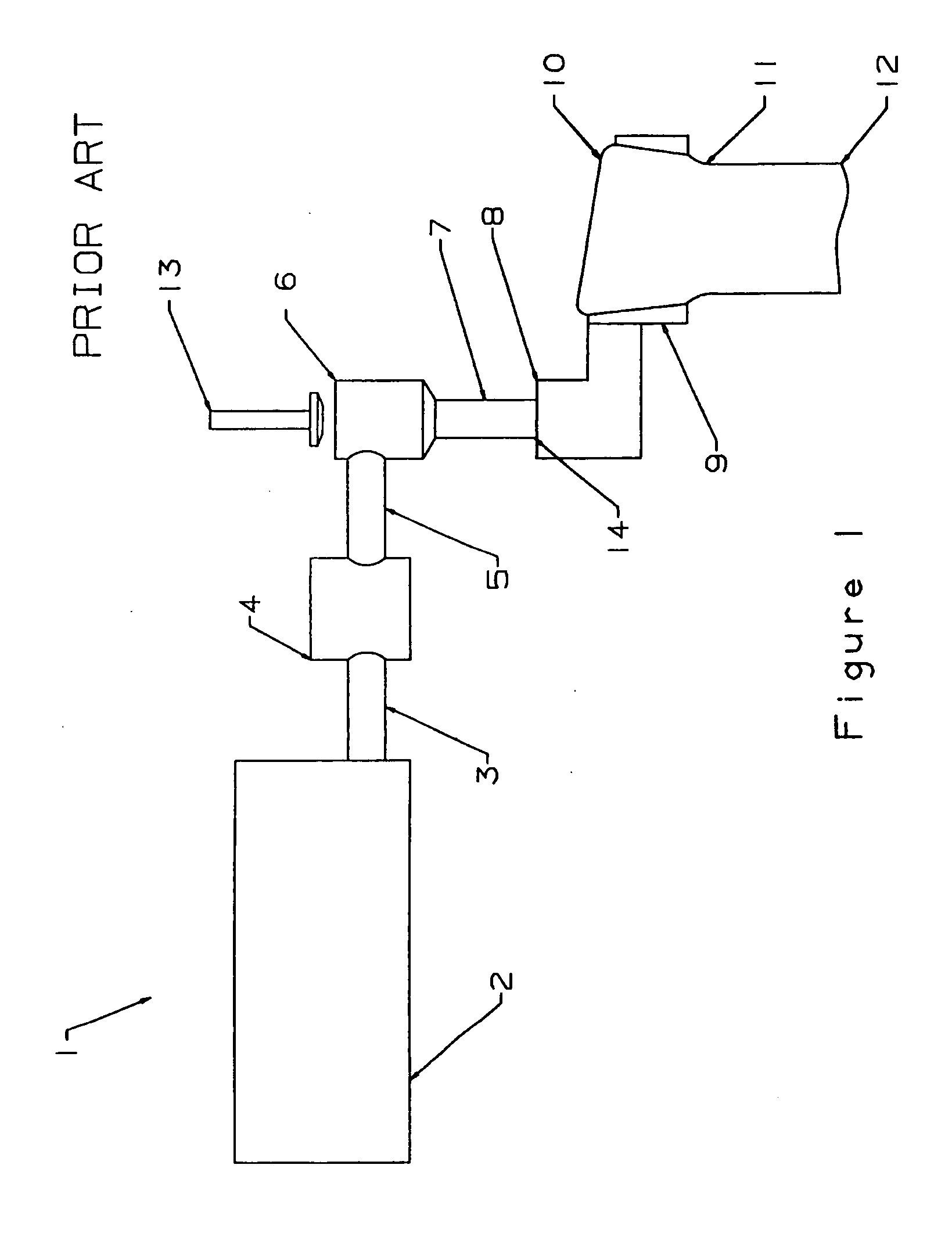

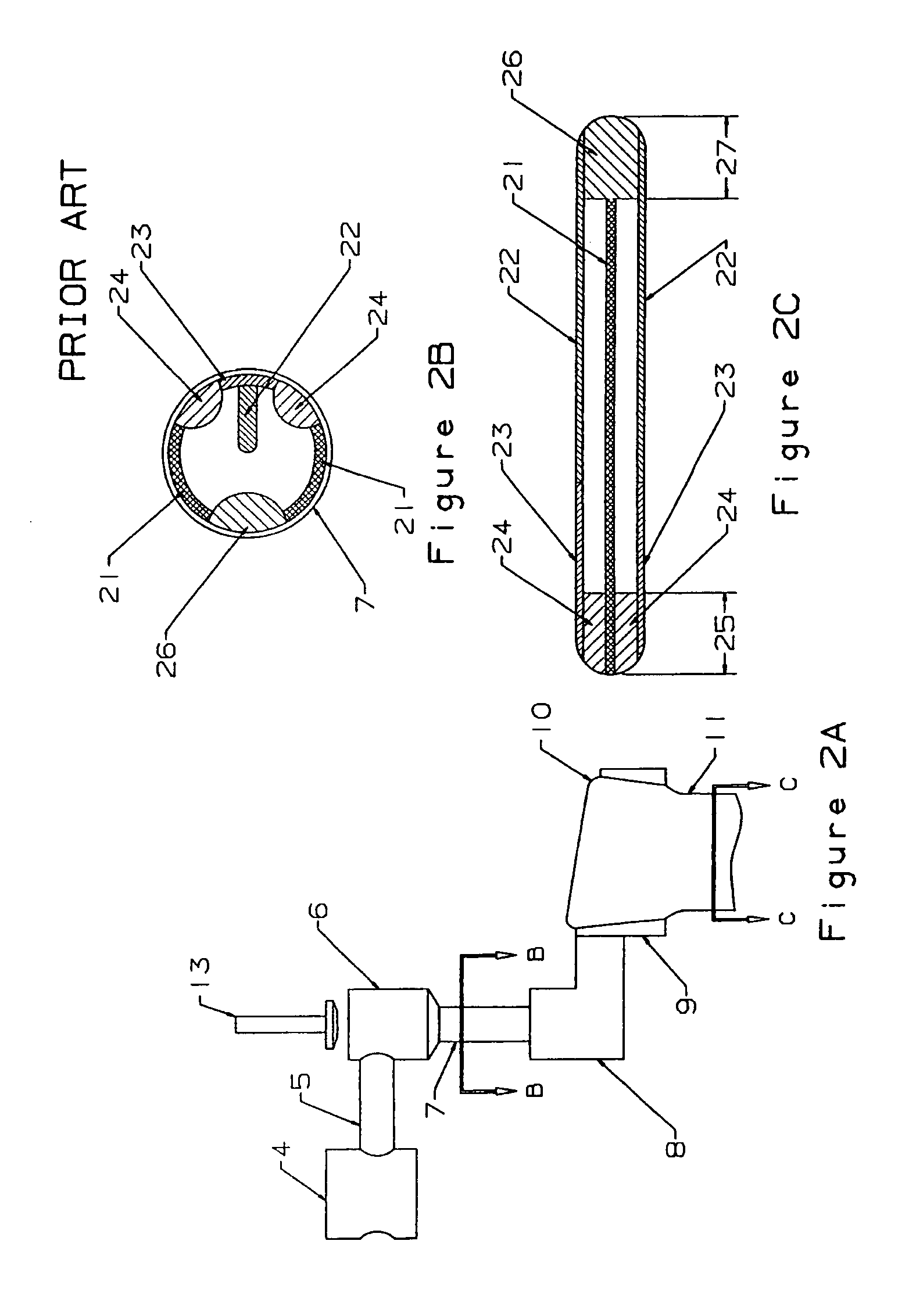

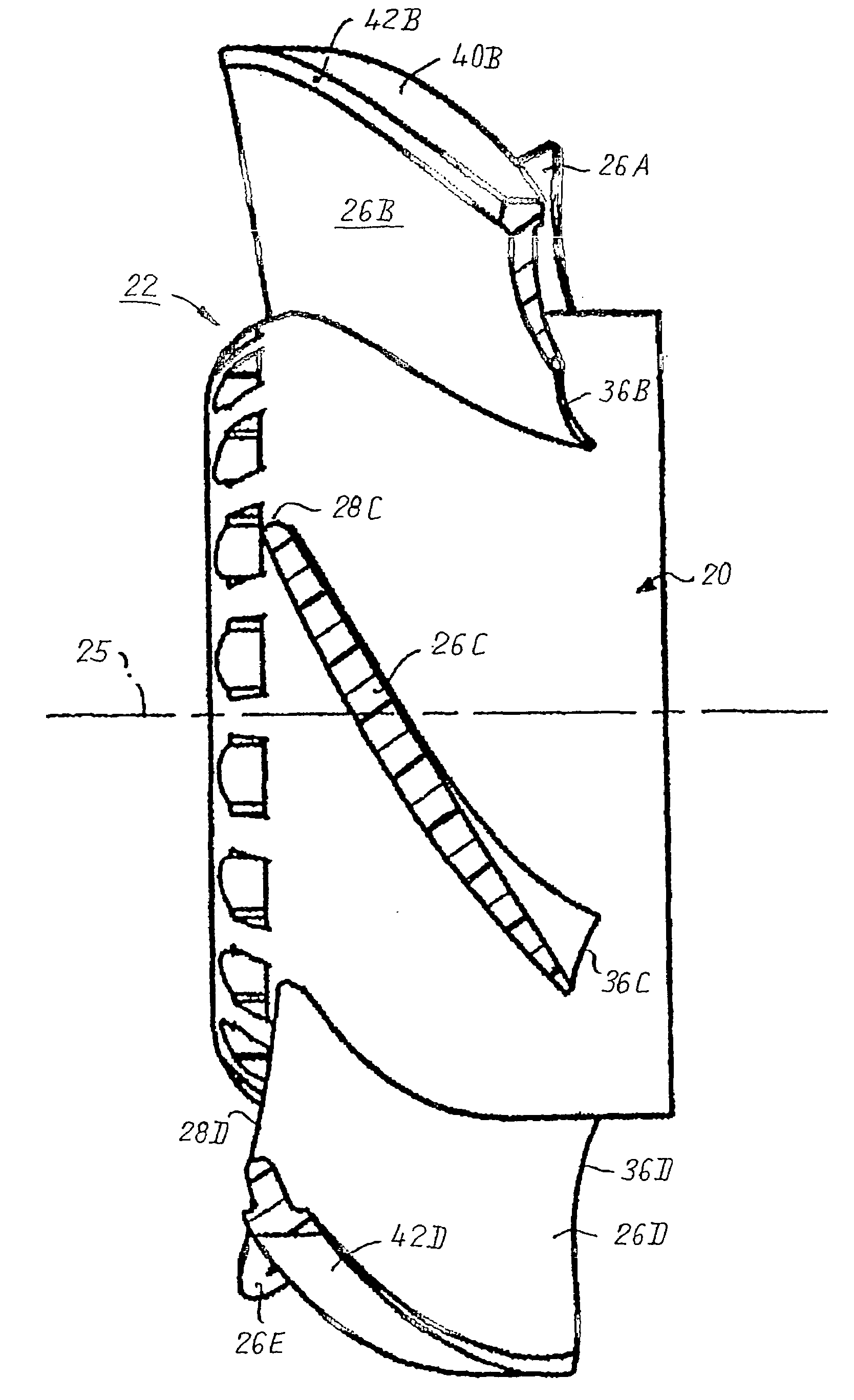

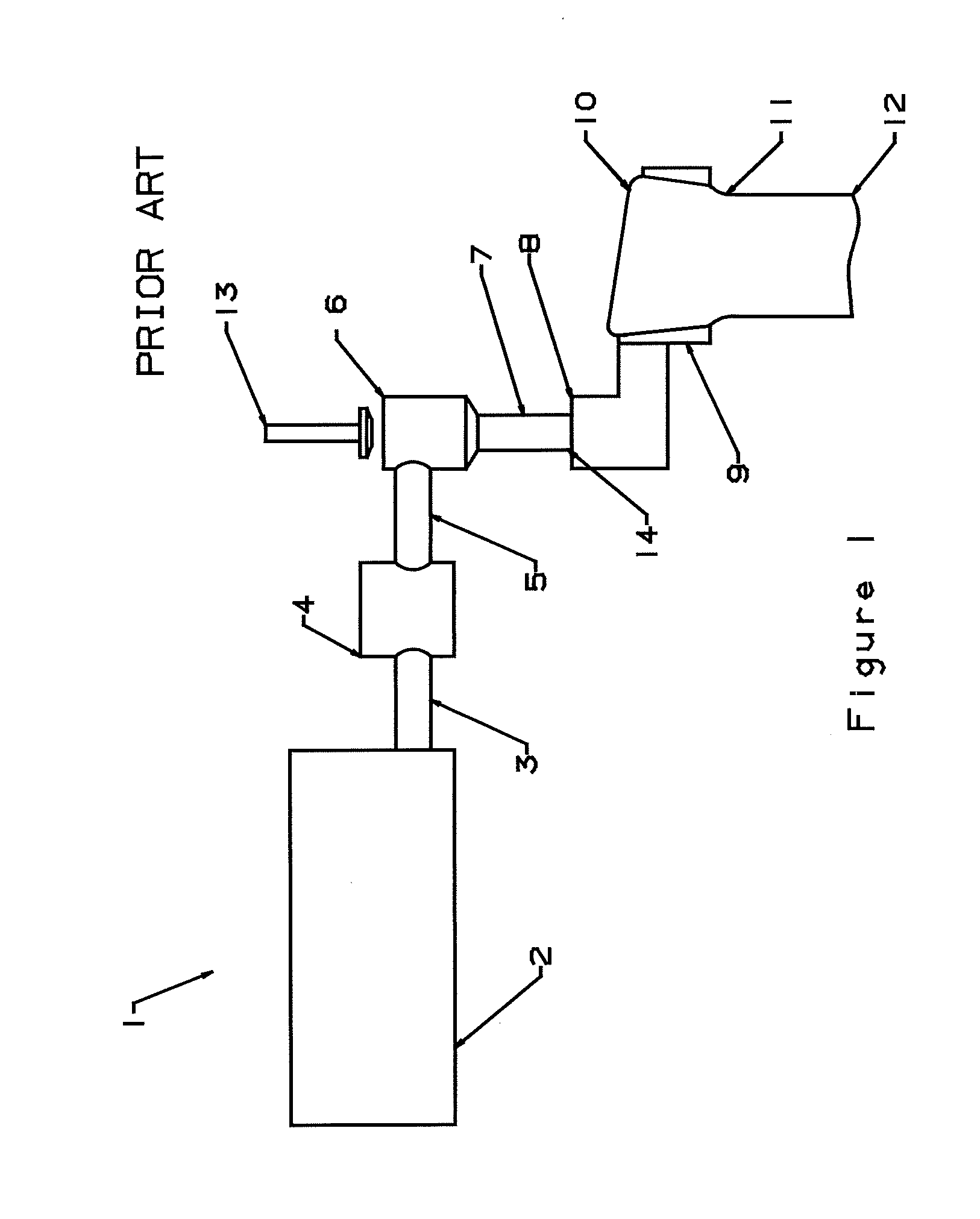

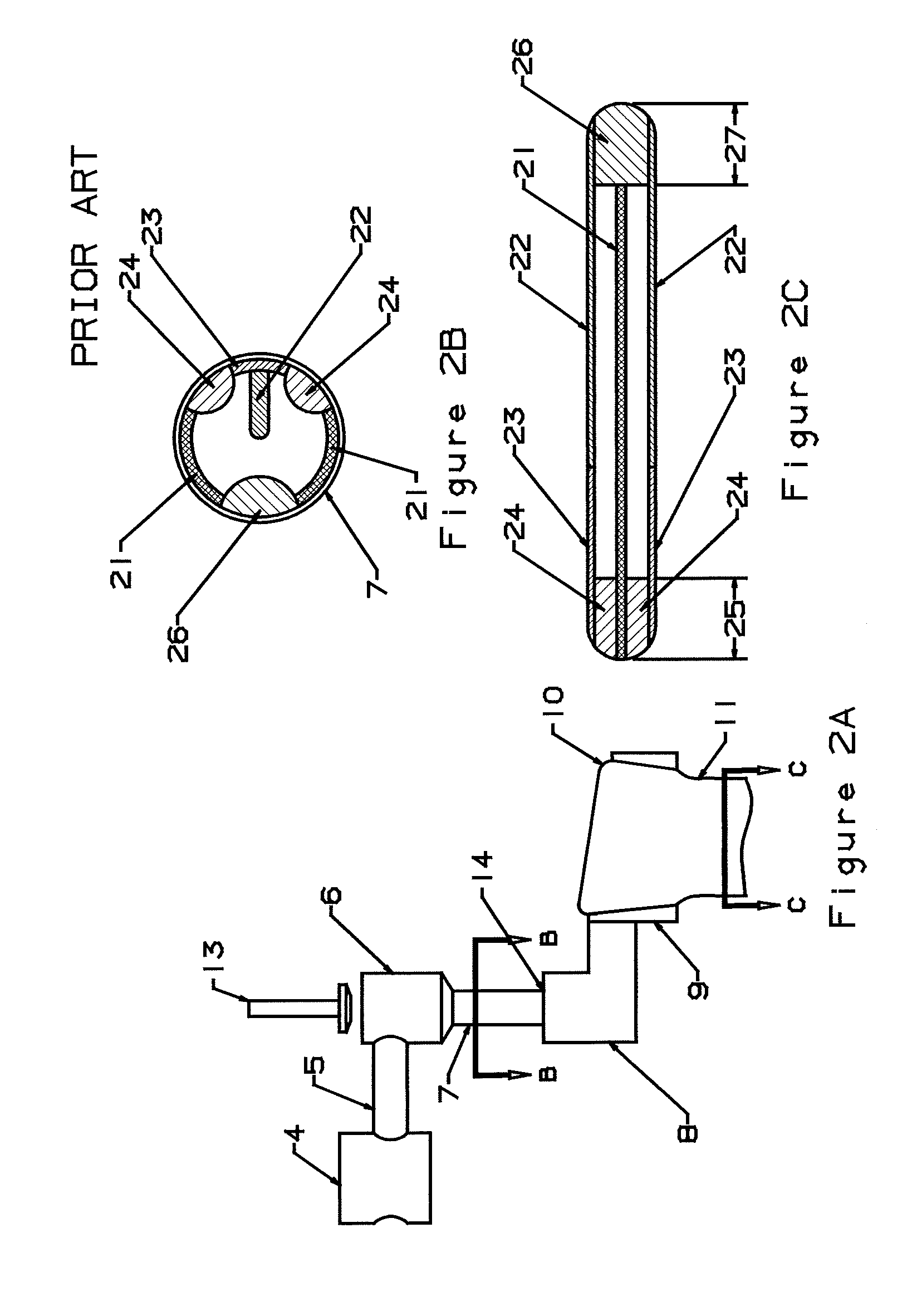

Integral tip seal in a fan-shroud structure

InactiveUS6874990B2Reduce noiseImprove fan efficiencyPropellersPump componentsEngineeringMechanical engineering

A fan-shroud structure 10 includes a fan 12 mounted for rotation about an axis B. The fan has a plurality of blades 20 with tips of the blades being coupled to an annular band 22. A shroud 26, including an annular labyrinth seal 28, is disposed generally adjacent to the annular band thereby defining a gap 30 between the annular band and the seal. The seal has a corrugated profile and is constructed and arranged to provide resistance to air flow as air swirls and flows back into the gap and to minimize air leakage across the gap.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

Tribologically improved design for variable stator vanes

InactiveUS6887035B2Increased durabilityFacilitate effectivenessWind motor controlPump componentsEngineeringPressure difference

A bushing and washer forming a bearing assembly at the outer radial end of a stator vane, the outer bearing assembly, and the bearing assembly at the inner radial end of the stator vane, the inner bearing assembly, that facilitate durability, effectiveness and reduced cost. Both the inner and outer bearing assemblies are designed to rotate relative to the vane shaft and the respective mating shroud or case to even out the wear around the circumference of the bushing. When a rotating bushing is used, a flange on the bushing is designed to be positioned on the inside of the case, so that a pressure differential across the case applies a force to the vane to move it outwardly against the flange and the flange against the case, thereby minimizing air leakage.

Owner:GENERAL ELECTRIC CO

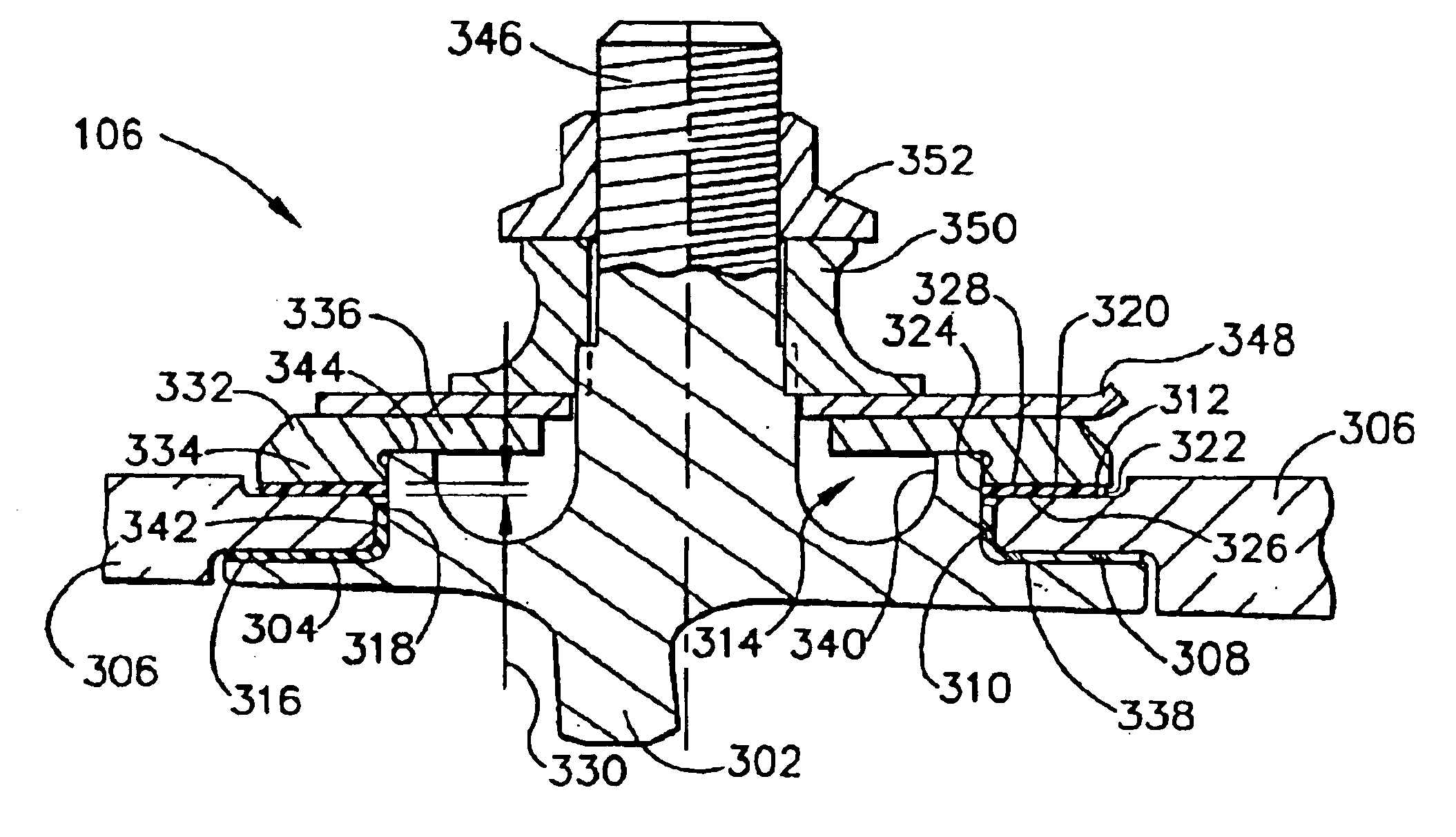

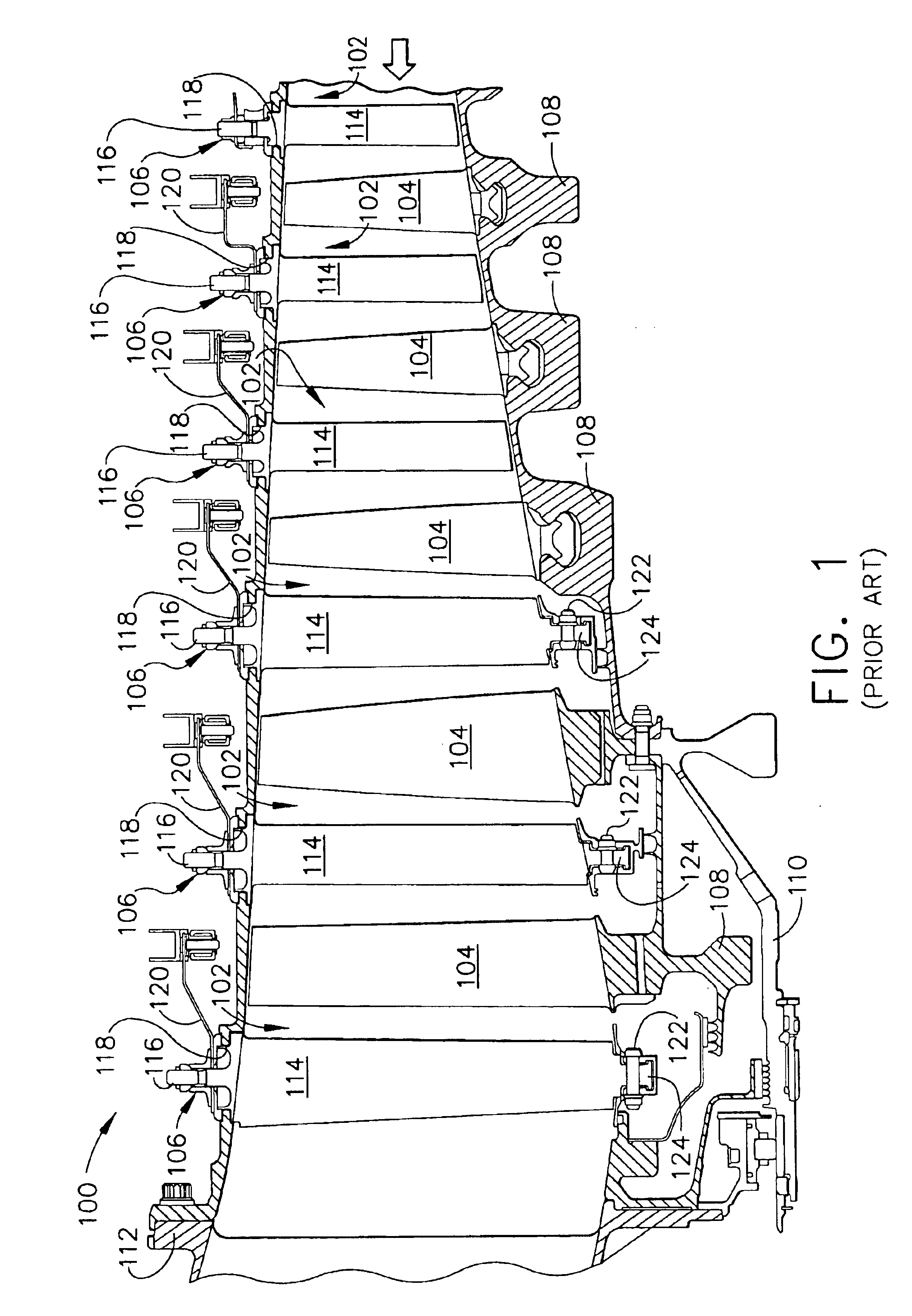

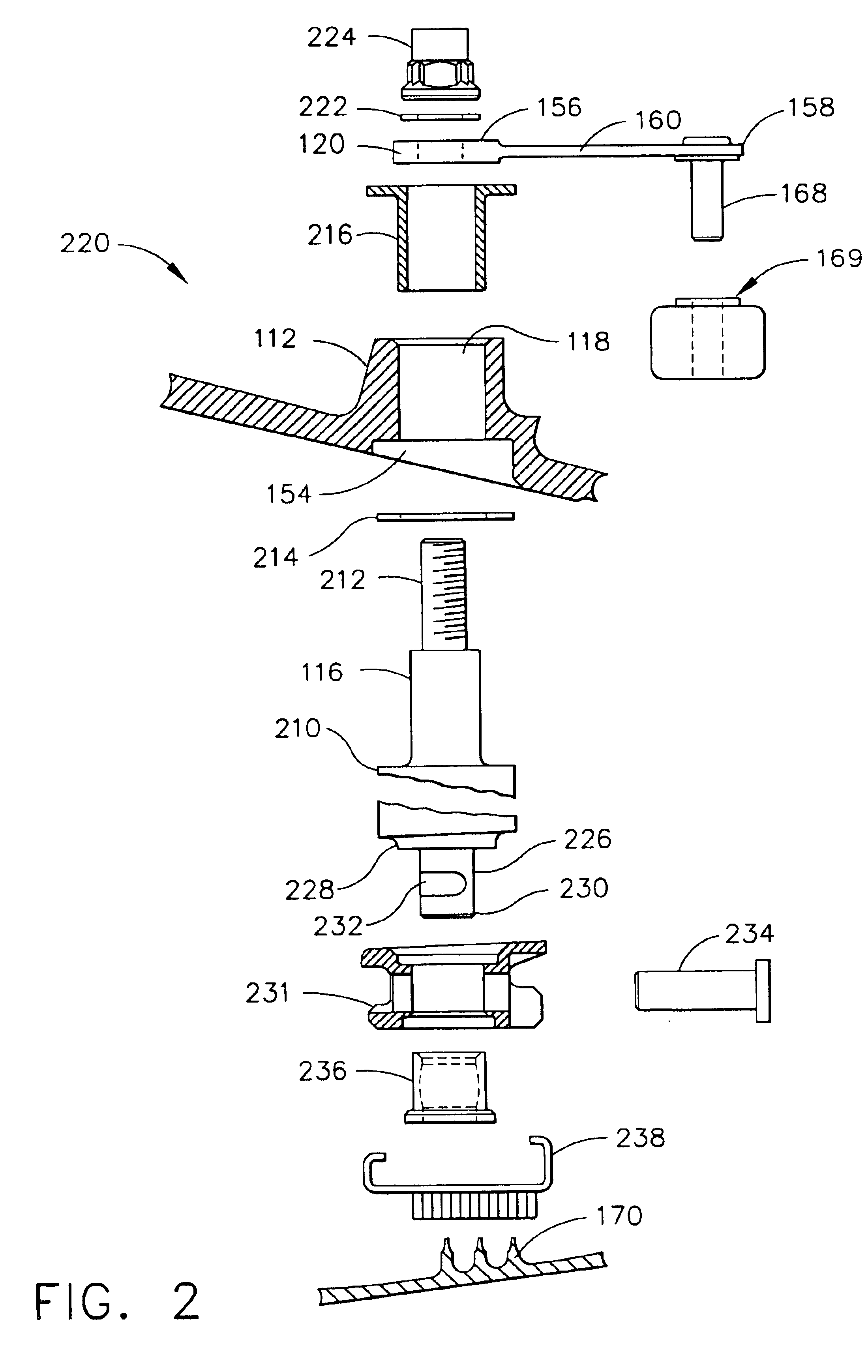

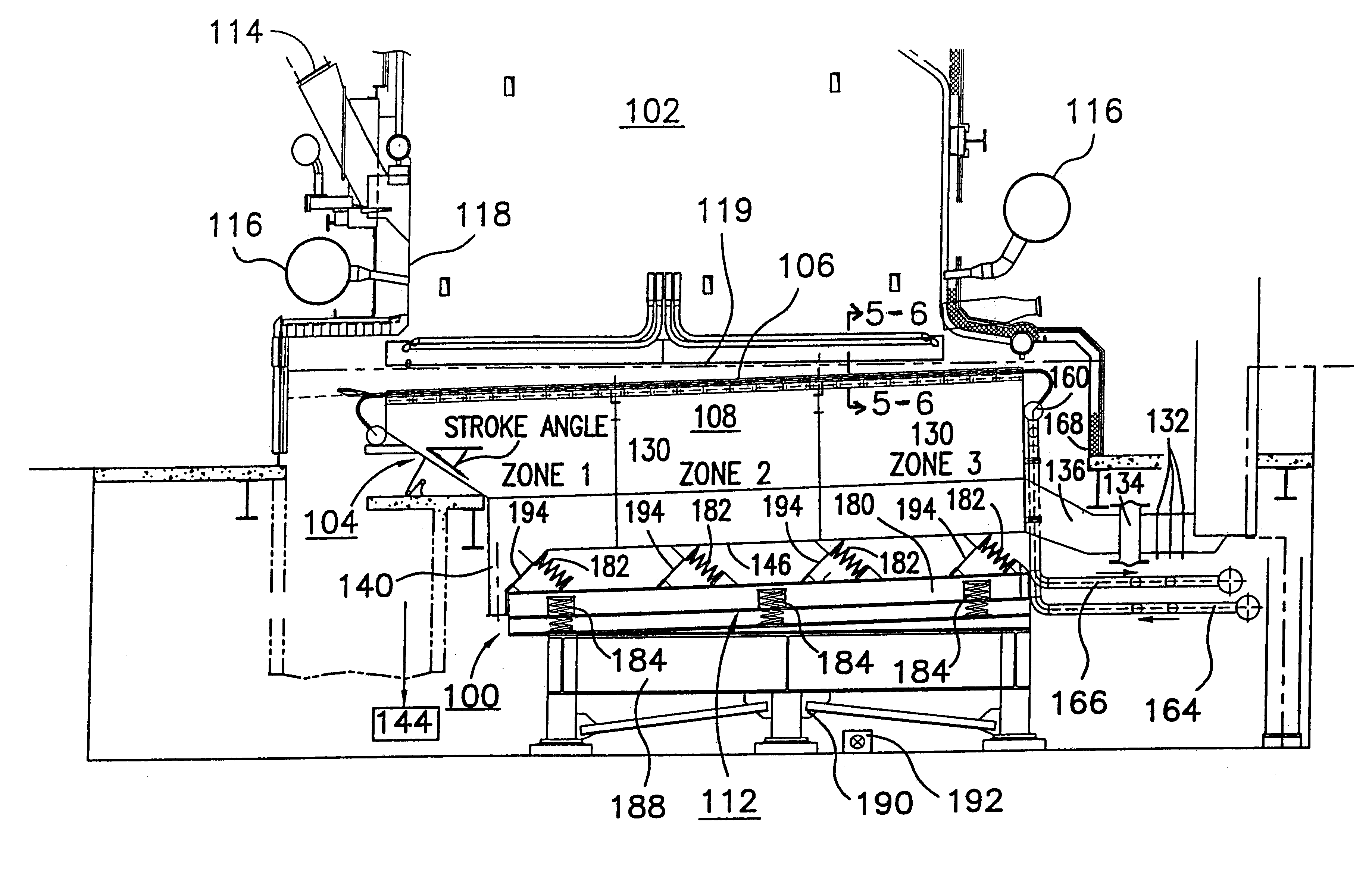

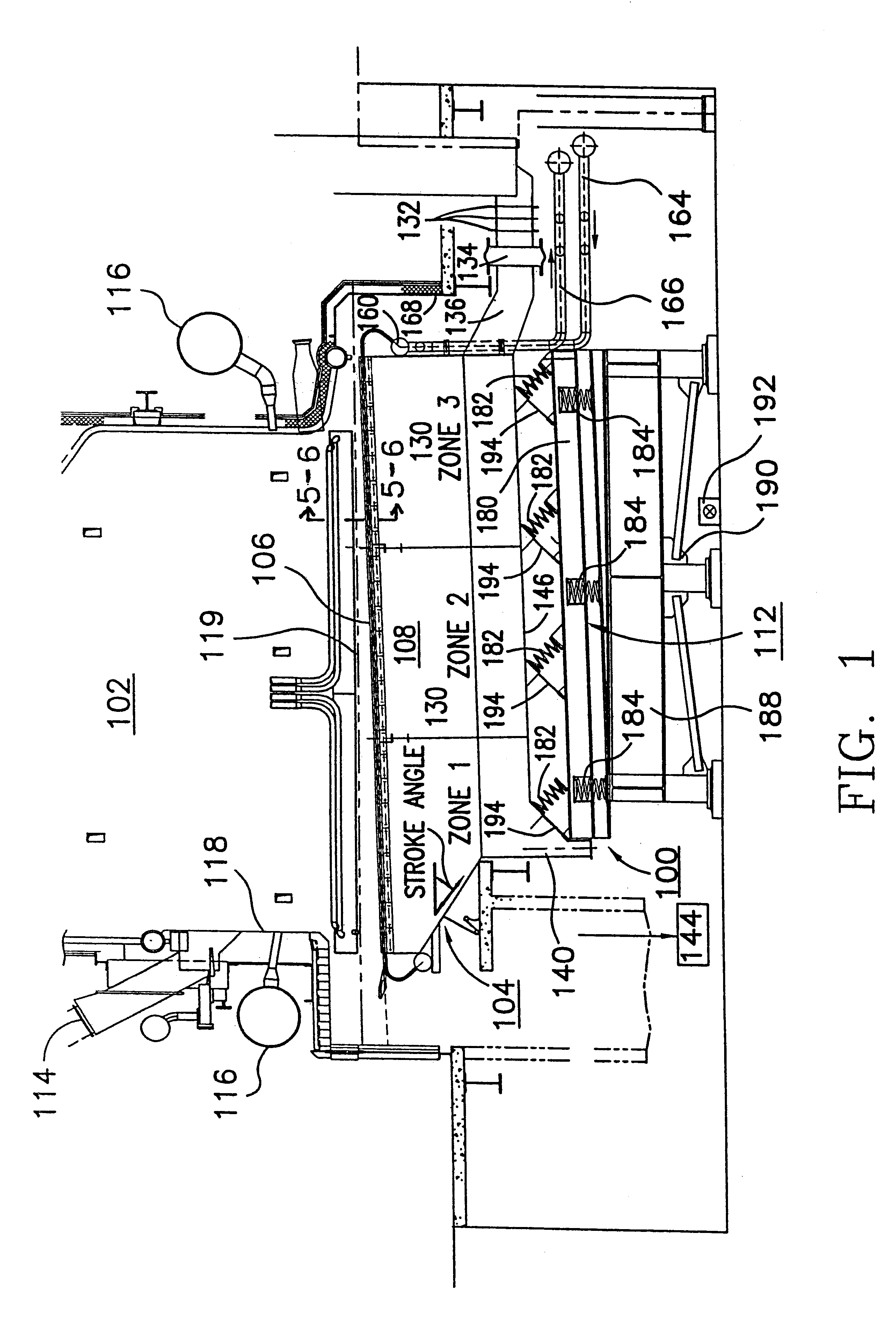

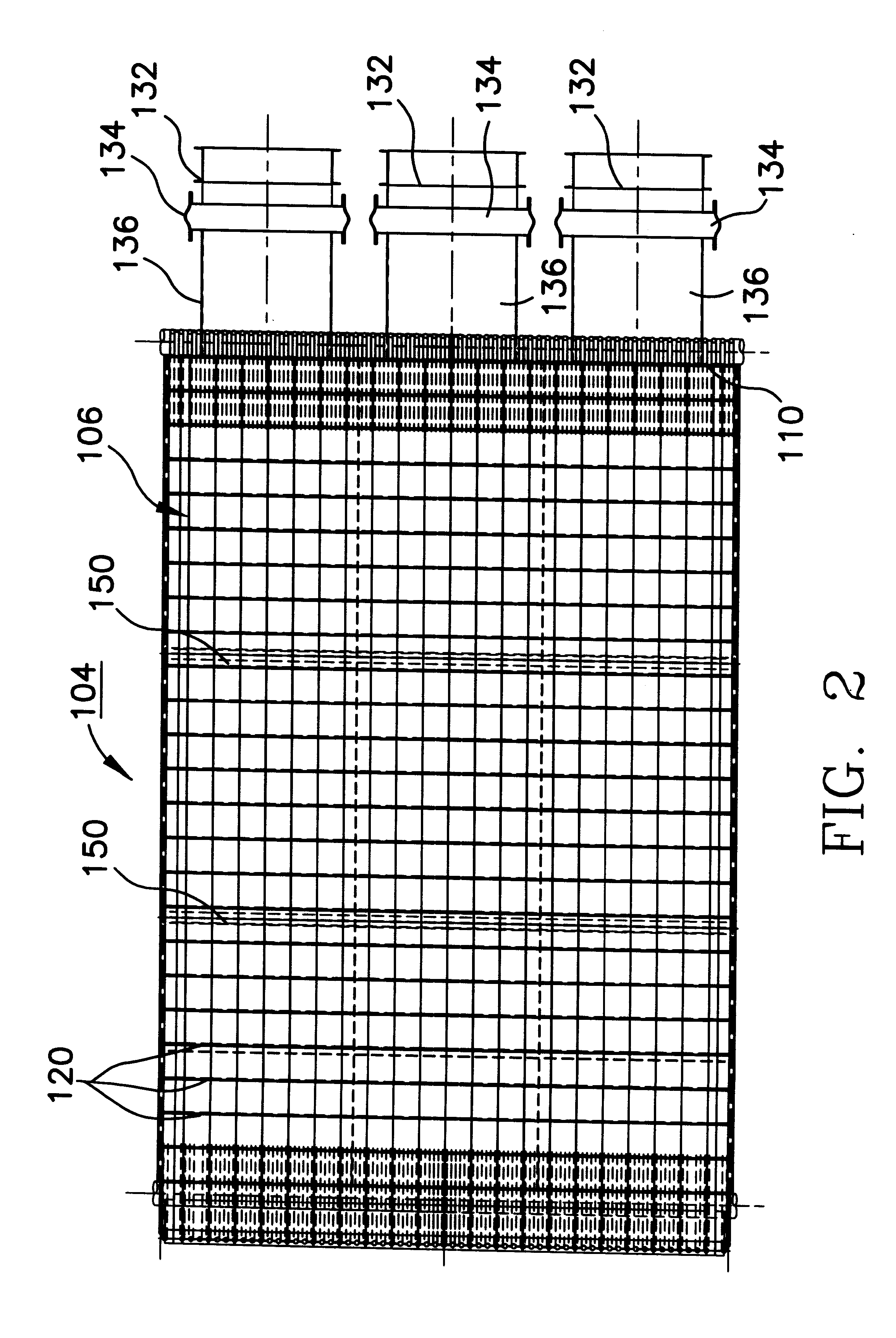

Water-cooled oscillating grate system

InactiveUS6220190B1Minimize under grate air leakageEffective and efficient and reliable operationHollow bar grateSpeed sensing governorsCombustionWater source

An integral water-cooled, air permeated, vibrating grate system for combusting biomass and other fuels in a boiler includes a grate top surface having air-flow apertures extending therethrough. The grate top surface is supported by a plurality of water-cooling pipes which arc coupled to a water supply. An enclosed air plenum unit is positioned under and attached directly to the grate top surface. The air plenum unit is coupled to an air supply for providing combustion air through the top grate surface air-flow apertures. The air plenum unit includes multiple zones, each of which zones has an associated air flow control damper so that the flow of combustion air can be controlled. Ash siftings formed on the grate top surface when the biomass or other fuel is combusted fall into the air plenum unit and flow toward at least one ash-siftings discharge opening at a discharge end of the air plenum when the grate top surface and the air plenum is vibrated. The grate top surface and the air plenum are vibrated together by a vibratory drive-isolation assembly which includes a longitudinally extending counterbalance member. A plurality of drive springs are supported by the counterbalance member. The drive springs are distributed across the width and the length of the top grate surface and at least one vibratory motor or mechanism is associated with the counterbalance member so that the vibration can be adjustably controlled.

Owner:RILEY STOKER

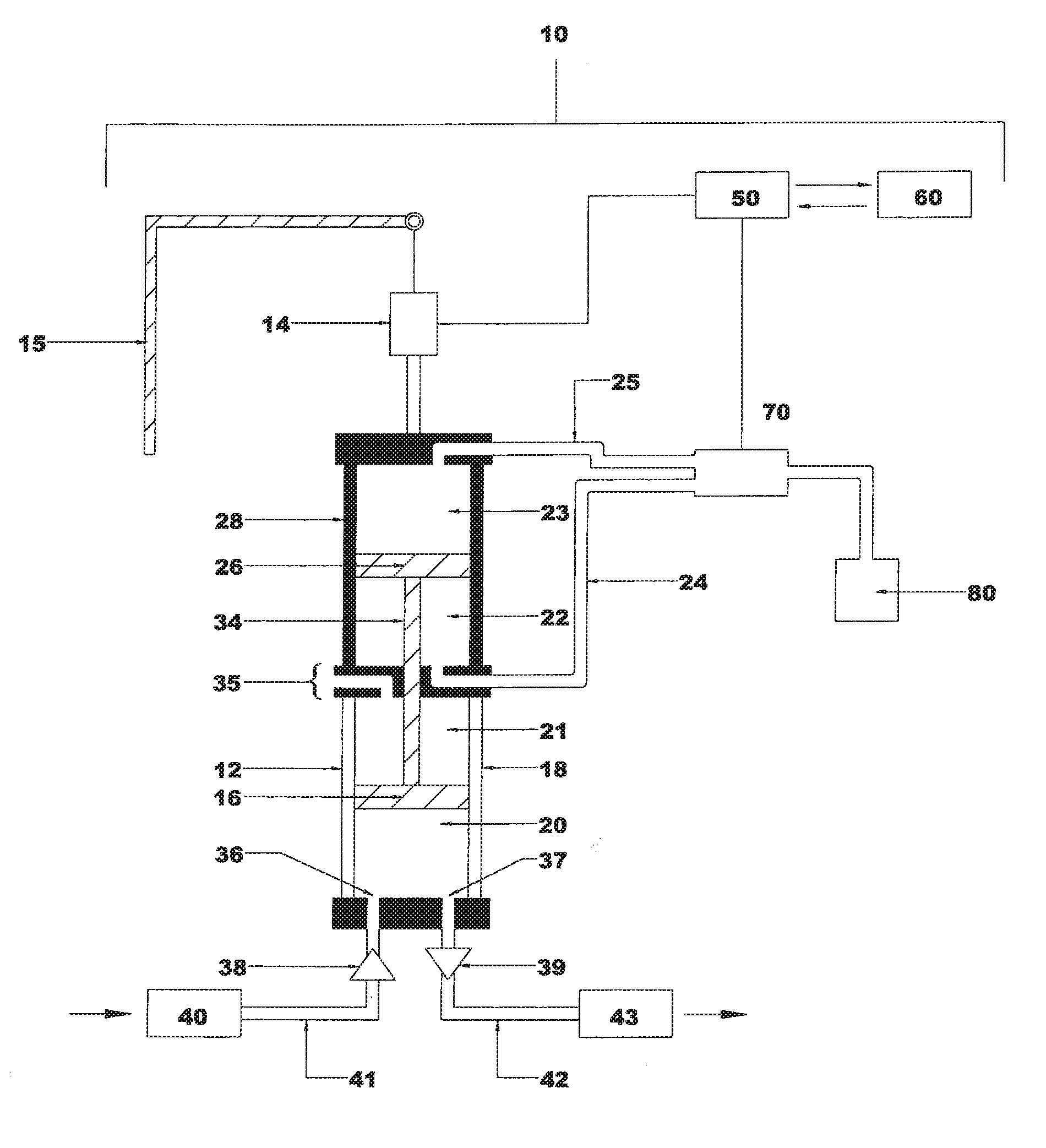

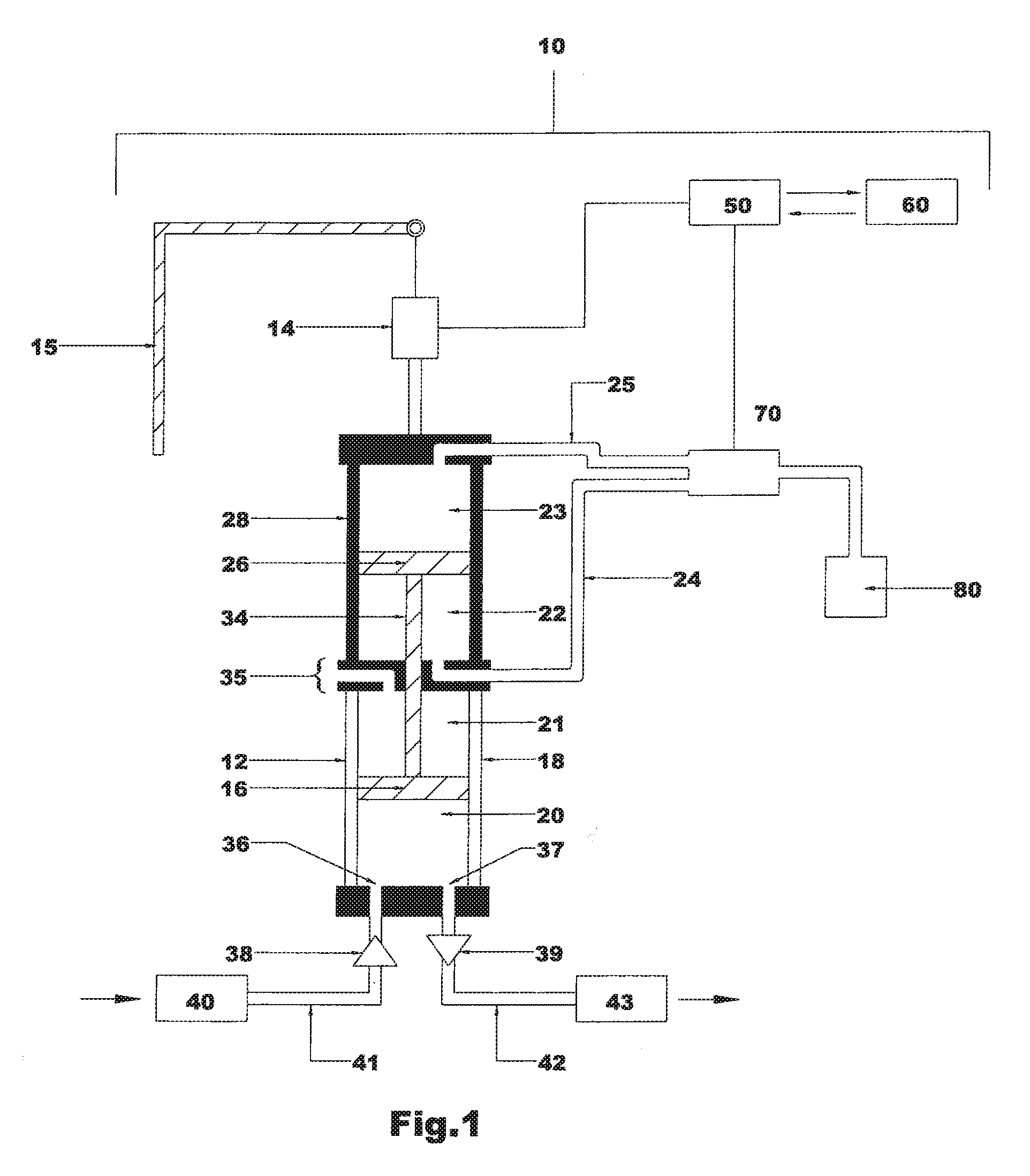

Double-action fluid weighing and dispensing process and system

ActiveUS20090026220A1High precision measurementEasy to measurePower operated devicesLarge containersPistonMechanical engineering

Apparatus and process for dispensing fluids, such as chemical concrete admixtures, using an air-operated pump and load cell for supporting and measuring at least substantially 100% of the weight of the pump and fluid dispensed through the pump. A double-action, dual piston design of the air-operated pump allows positive air pressure to be used during both fluid-filling and fluid-expelling phases.

Owner:GCP APPL TECH INC

Sheet glass forming apparatus

InactiveUS20050092027A1Minimize air leakageReduce unevennessGlass furnace apparatusGlass drawing apparatusFlat glassInternal pressure

One embodiment of the present invention is an improved sheet glass forming apparatus. In another embodiment, a precise thermal control system redistributes the flow of molten glass at the weirs to counteract the degradation of the sheet forming apparatus which inevitably occurs during manufacturing. In yet another embodiment, the invention introduces a counteracting force to the stresses on the trough in a manner such that the thermal creep which inevitably occurs has a minimum impact on the glass flow characteristics of the forming trough. Another embodiment creates a variable external cross-section which provides hydraulic stresses that are in opposition to the surface tension and body force stresses and thus, reduces the influence of surface tension and body forces. In an alternative embodiment, the glass is preferentially cooled across its width to create forming stresses during solidification, which ensures that the glass sheet drawn is inherently flat. In an additional embodiment, the internal pressure is adjusted in each of the major components of the forming apparatus such that the pressure difference across any leakage path to the forming zone is essentially zero. Therefore, air leakage in the apparatus is minimized even though the cracks and openings exist during initial operation and develop during manufacturing.

Owner:CORNING INC

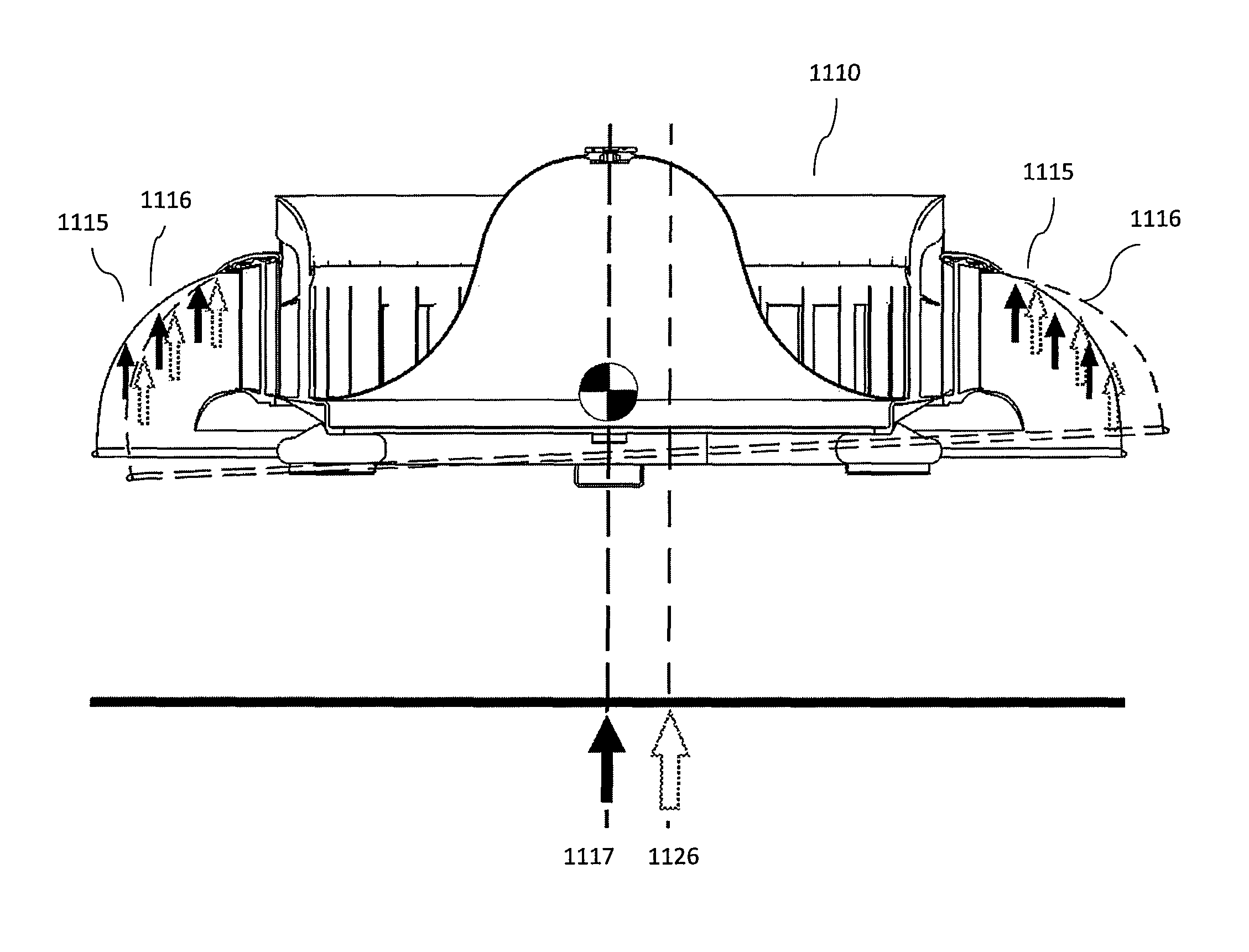

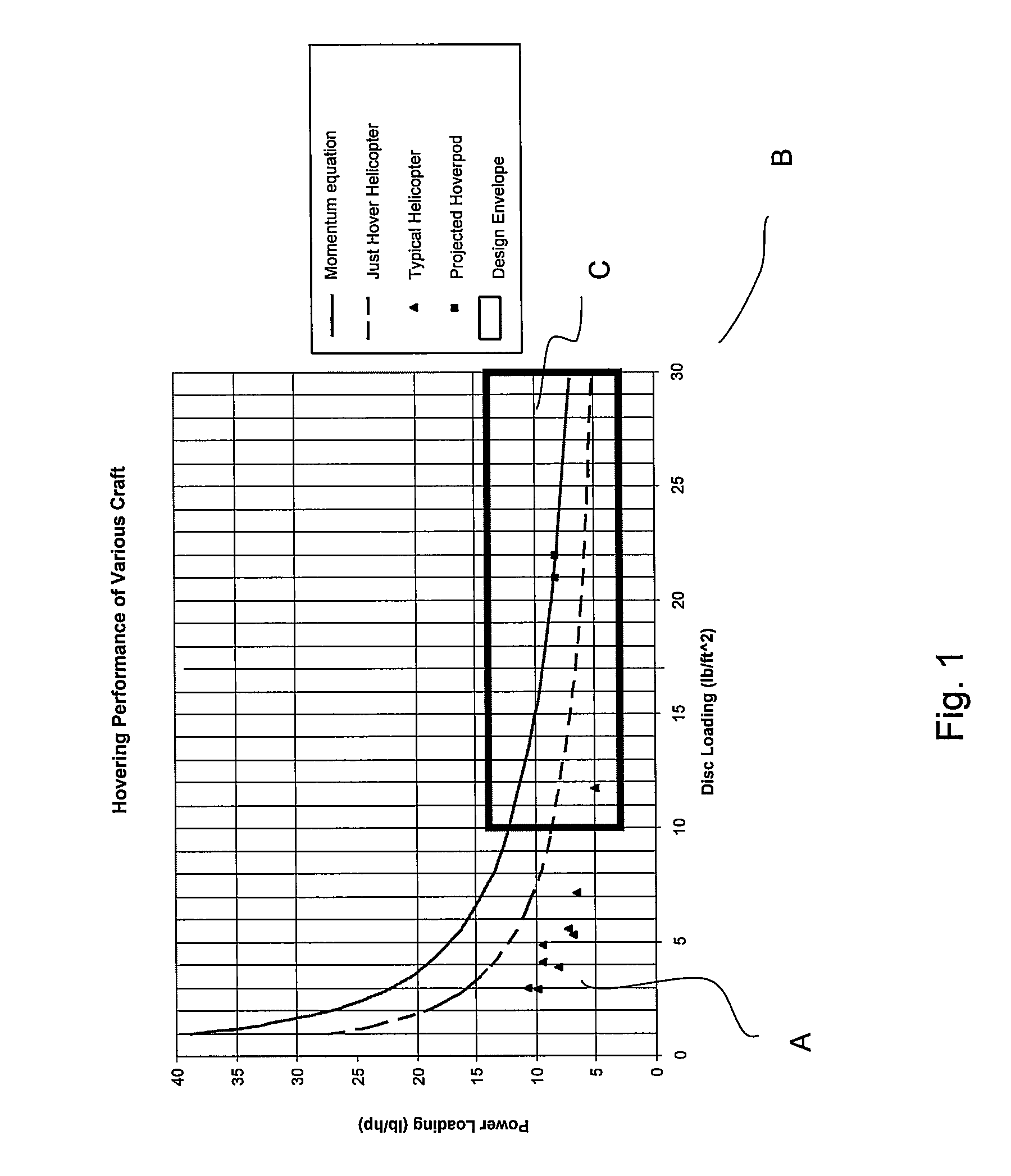

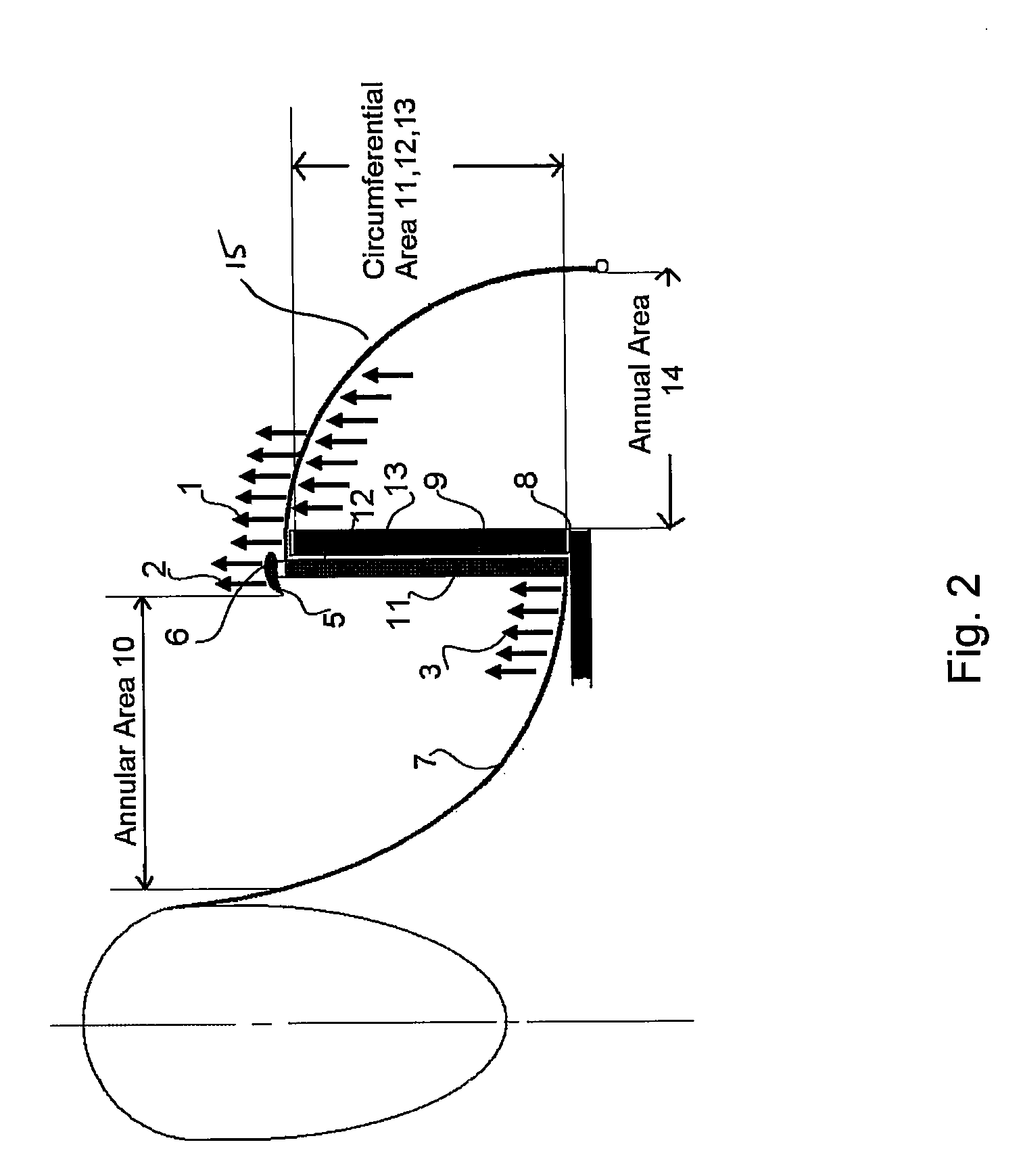

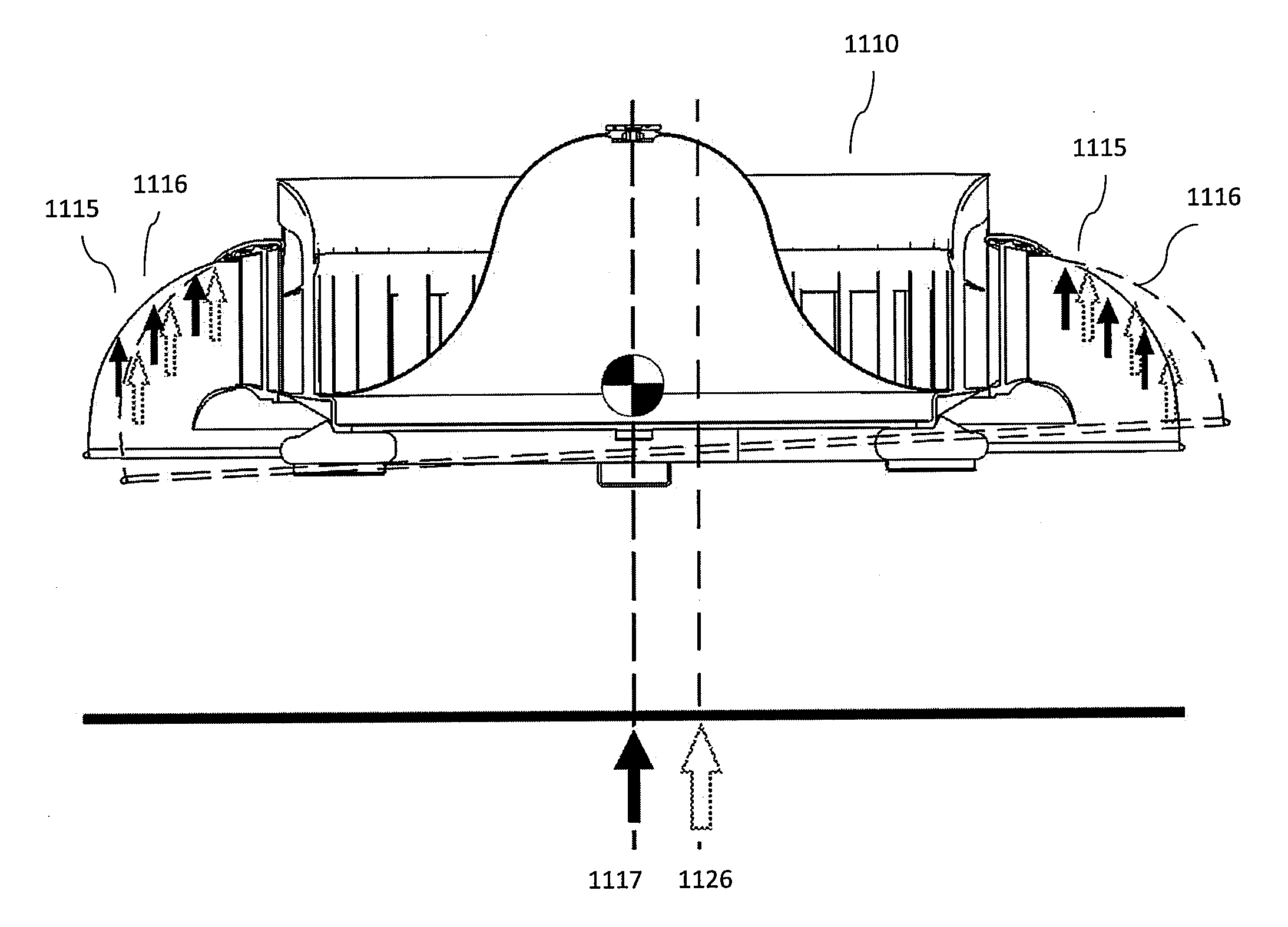

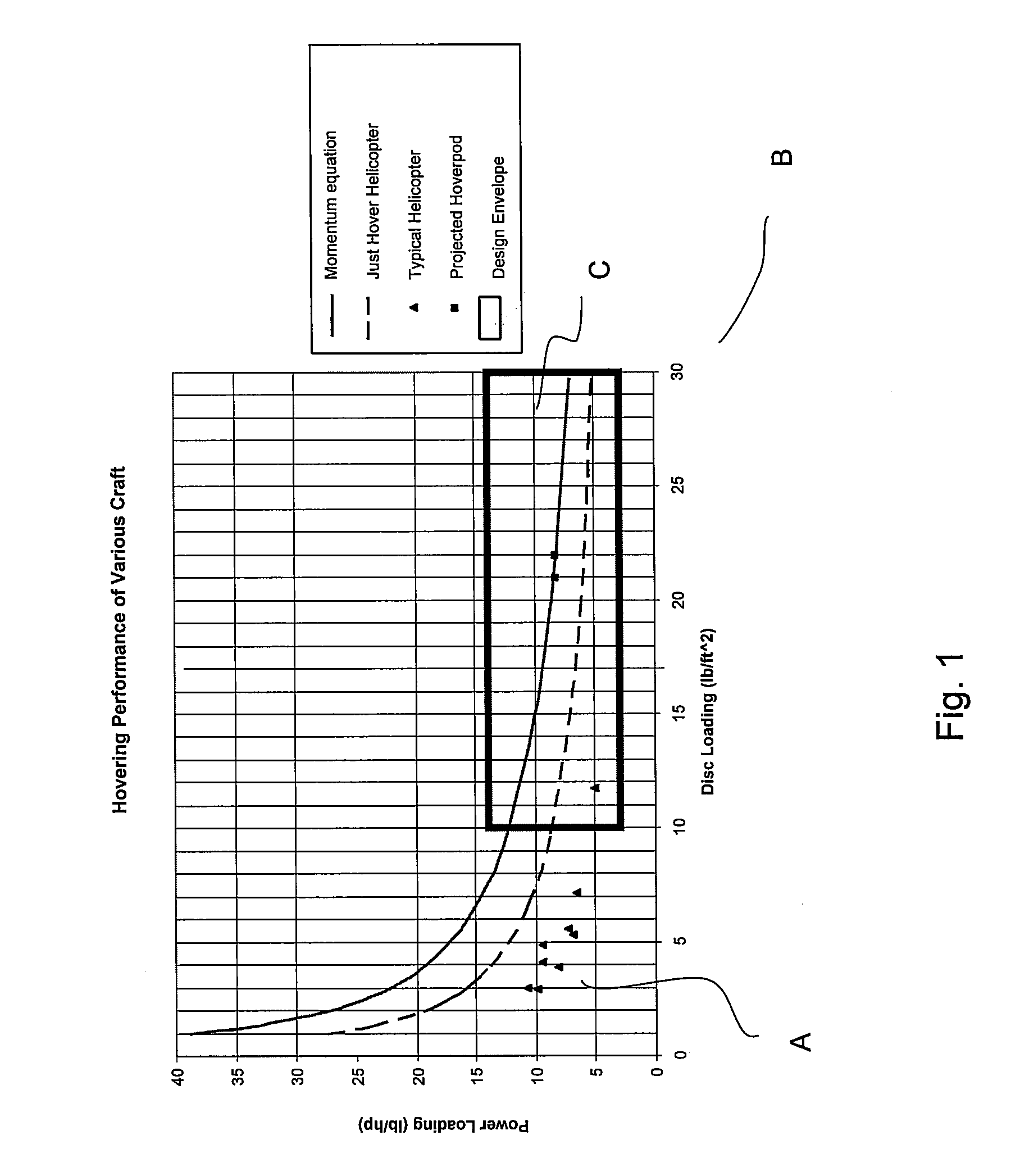

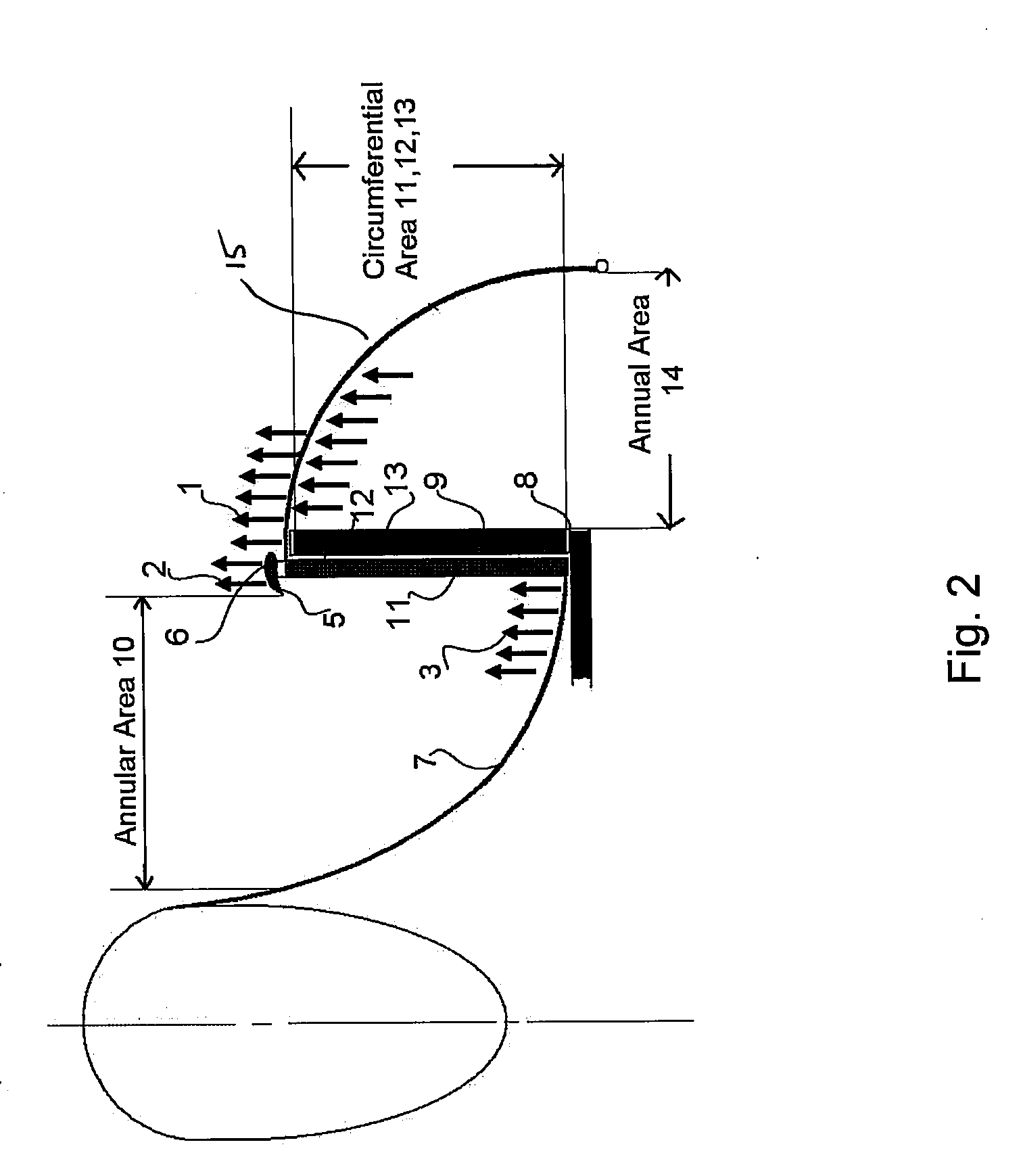

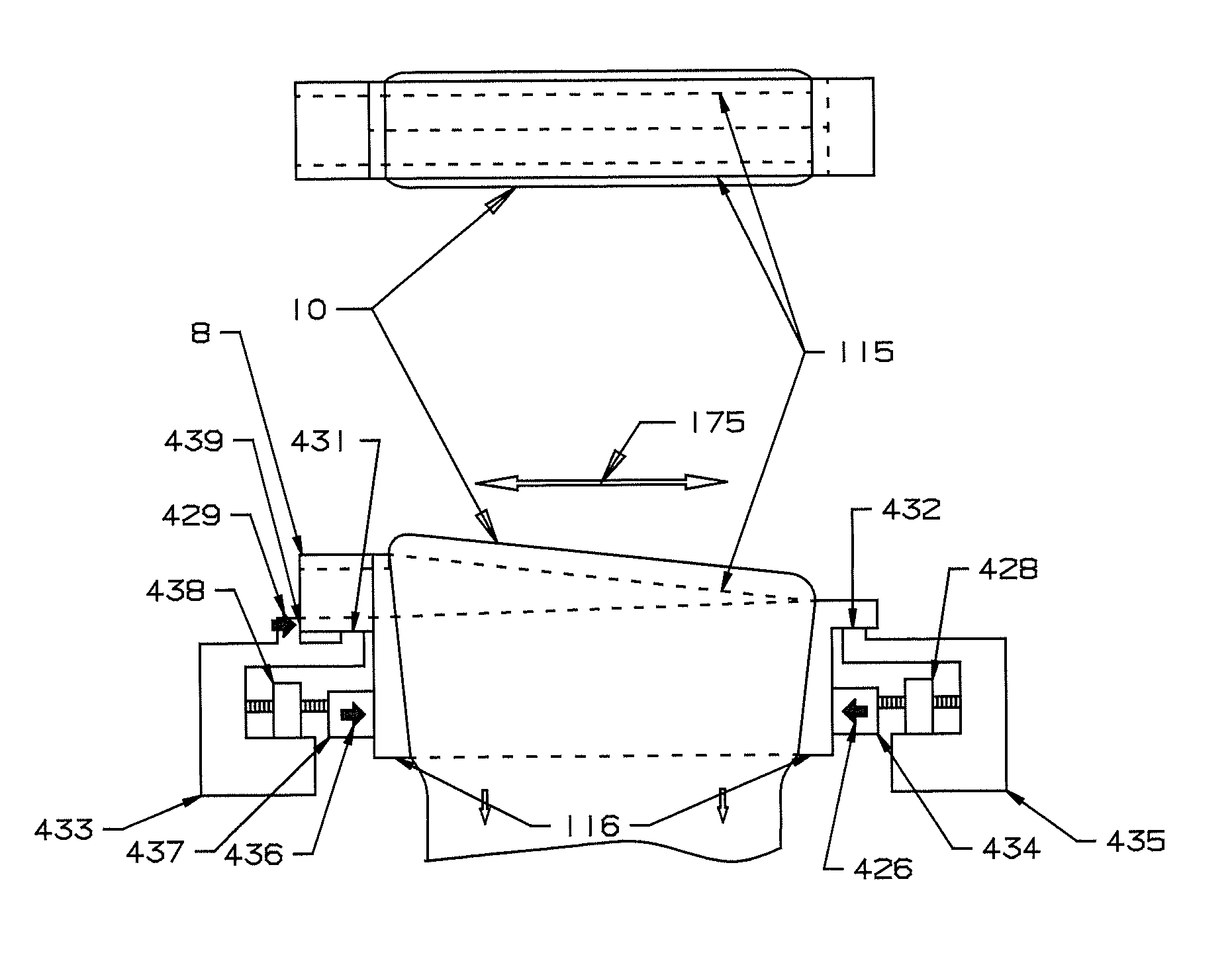

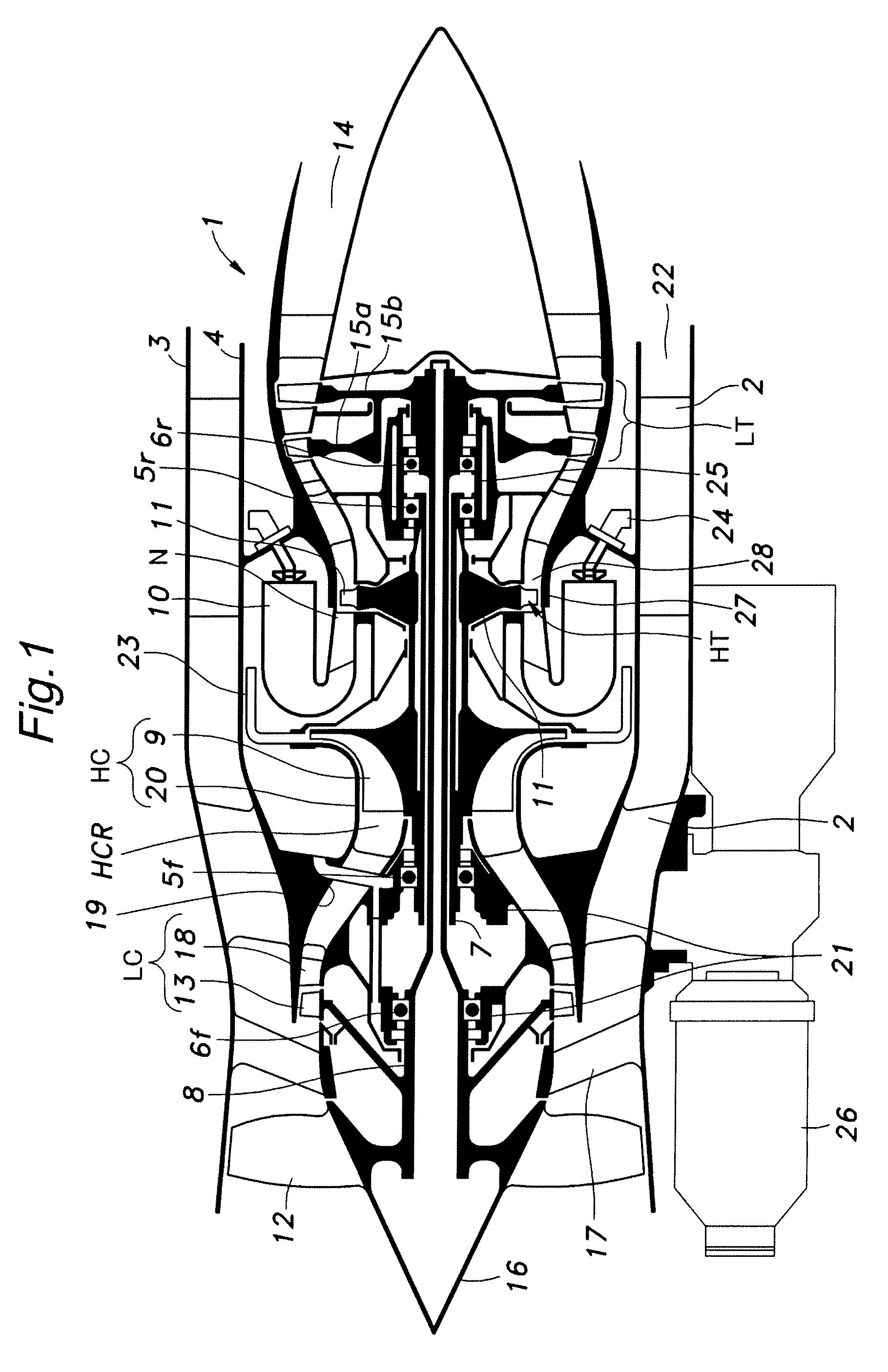

Aerodynamic lifting device and airborne craft

ActiveUS8181902B2Prevent leakageLow powerAircraft navigation controlPropellersRotational axisFlight vehicle

An airborne craft is provided comprising an aerodynamic lifting device having a radial drum fan and a thrust vectoring shroud. The radial drum or vertical axis fan comprises a fan with a rotor, the rotor having a rotational axis and comprising a plurality of rotor blades disposed in an annular ring about the rotational axis and a driving means for the rotor such that, on operation of the driving means, lift is generated.

Owner:ENTECHO (PTY) LTD

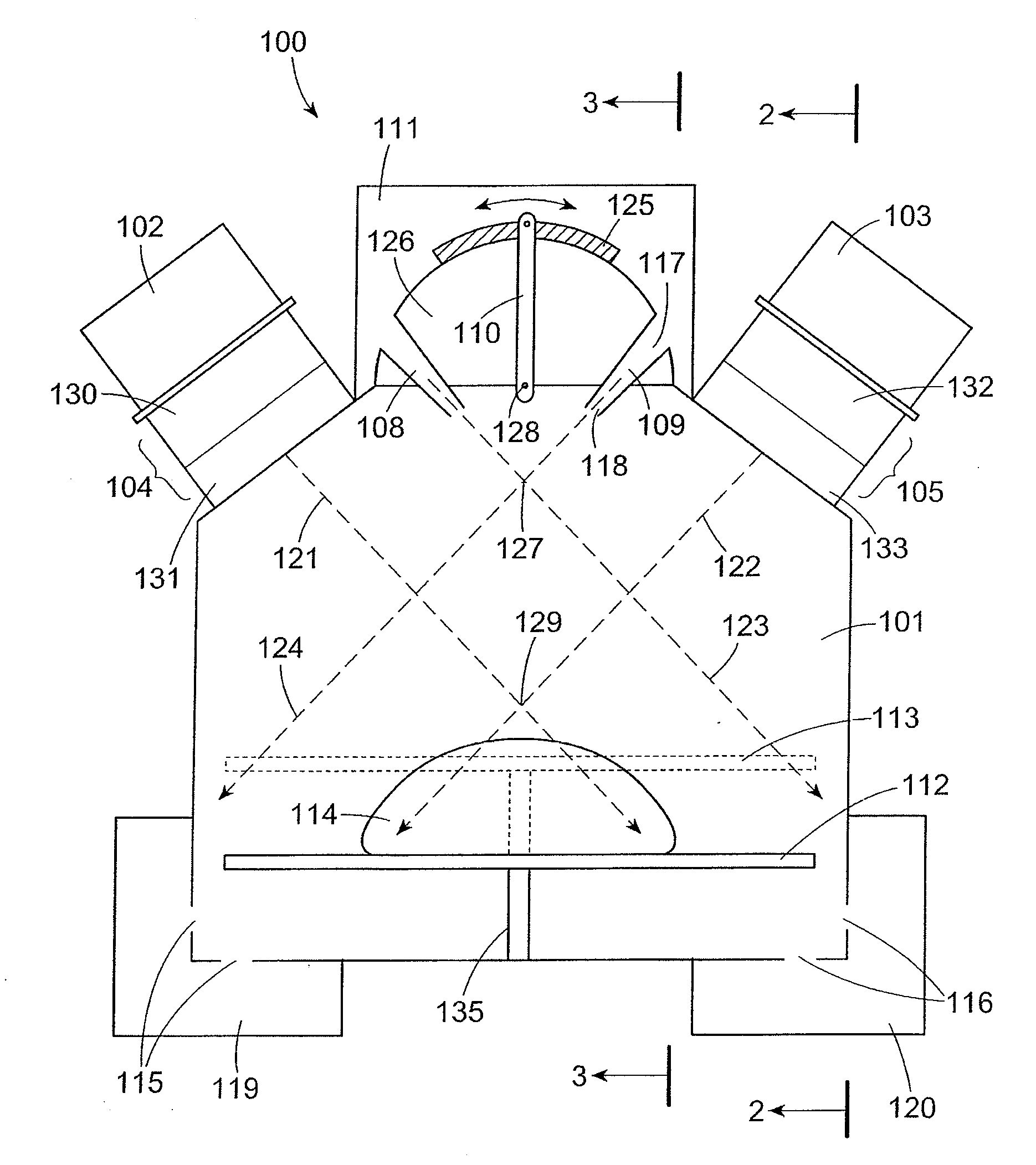

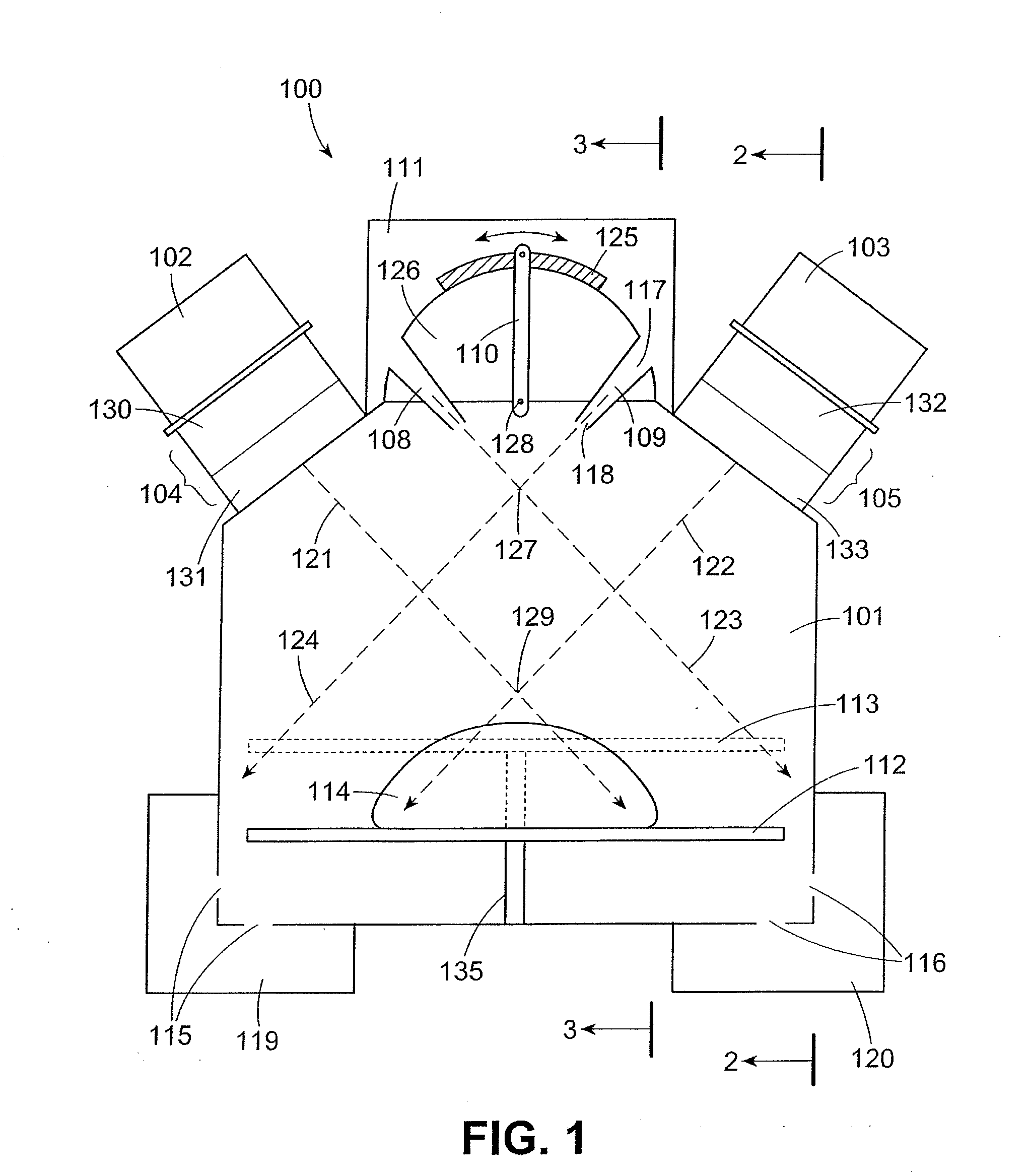

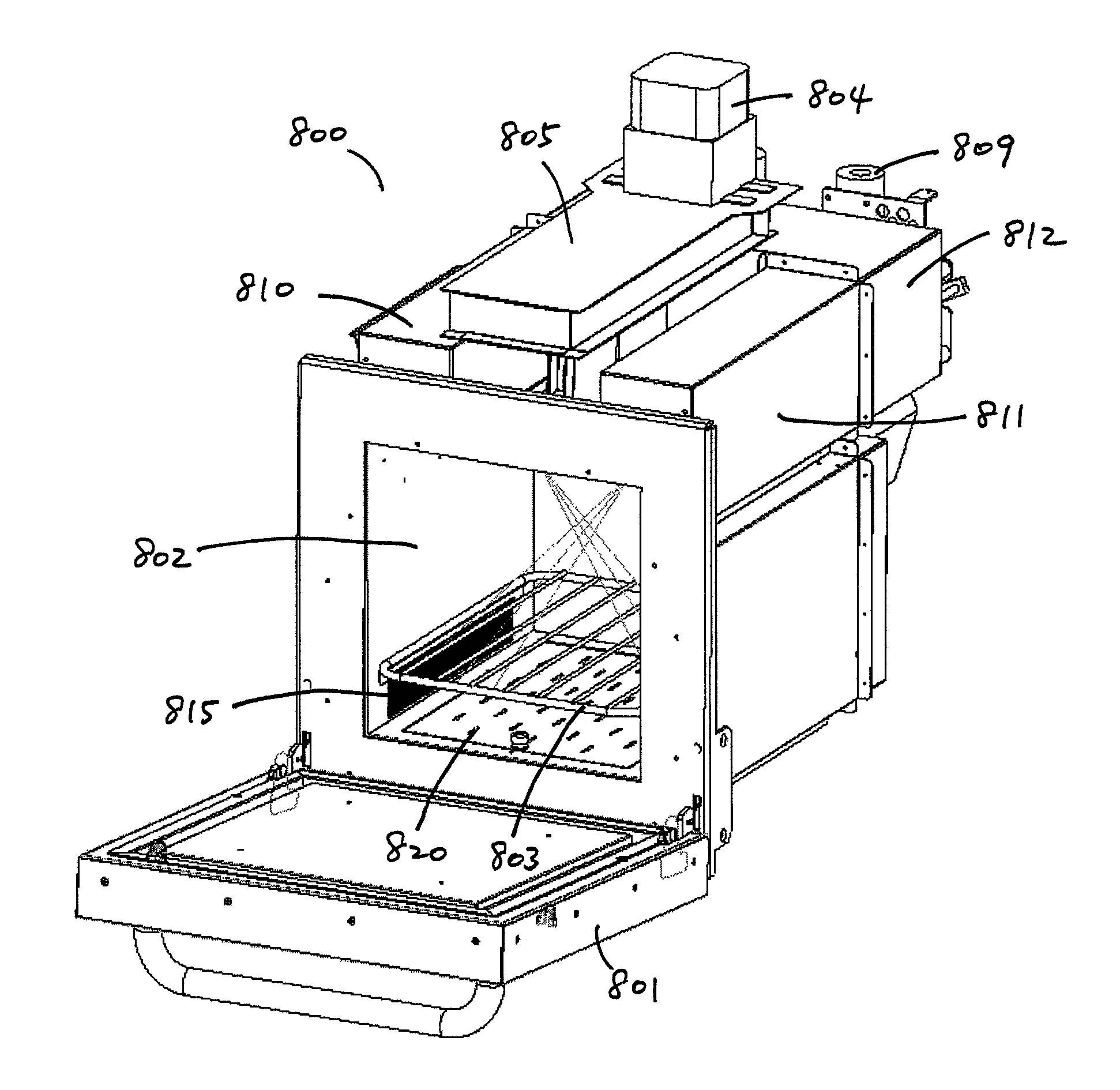

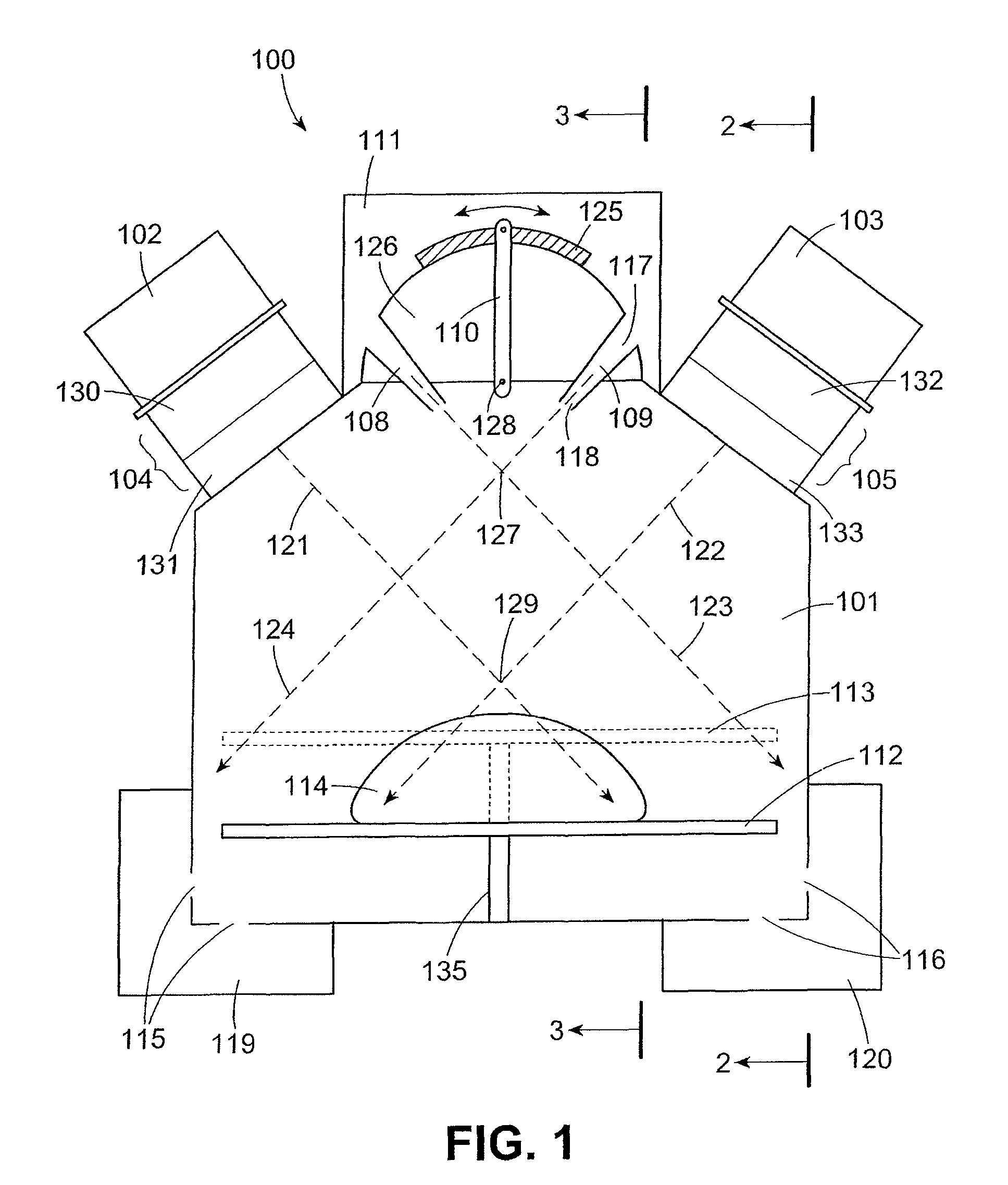

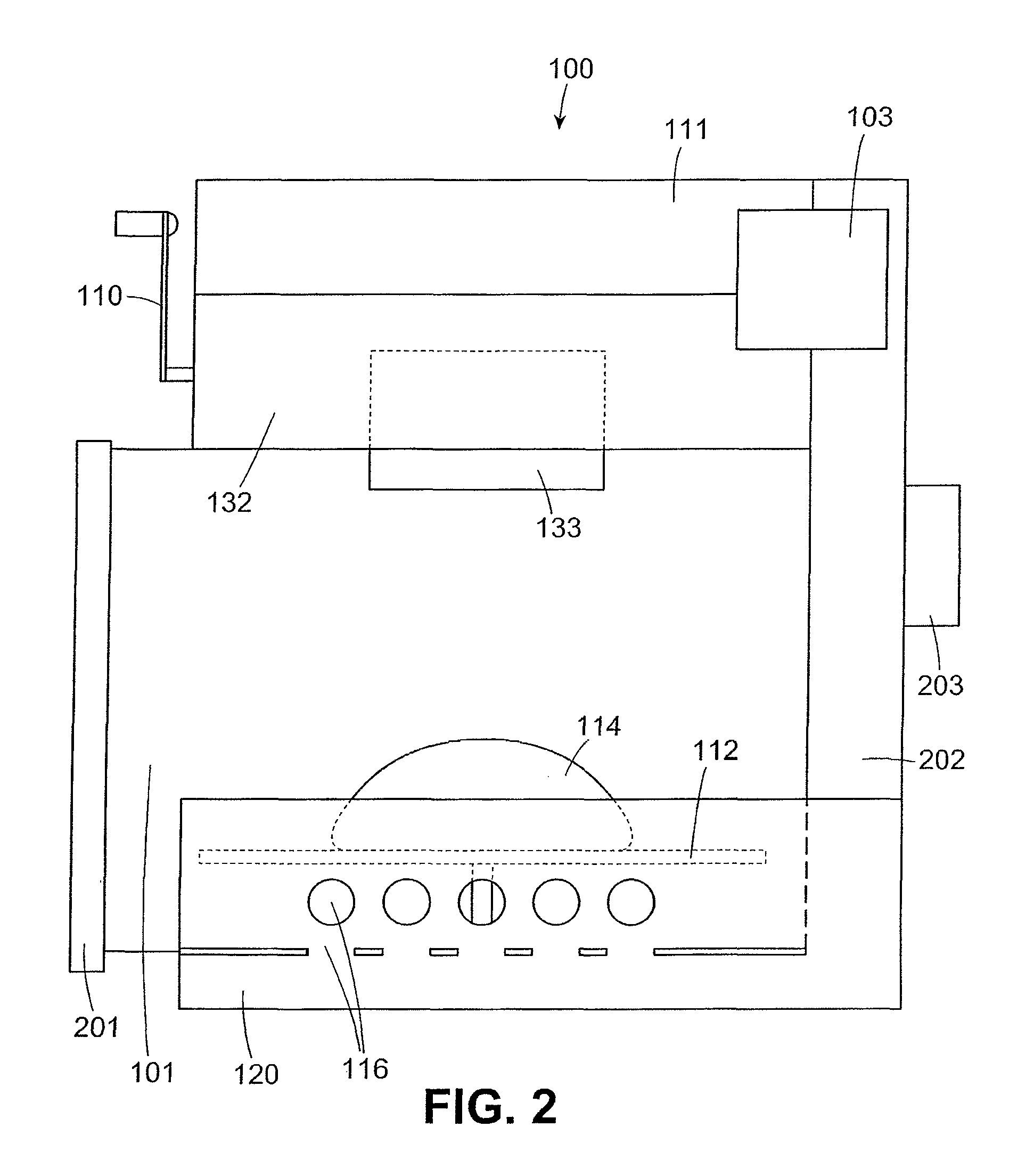

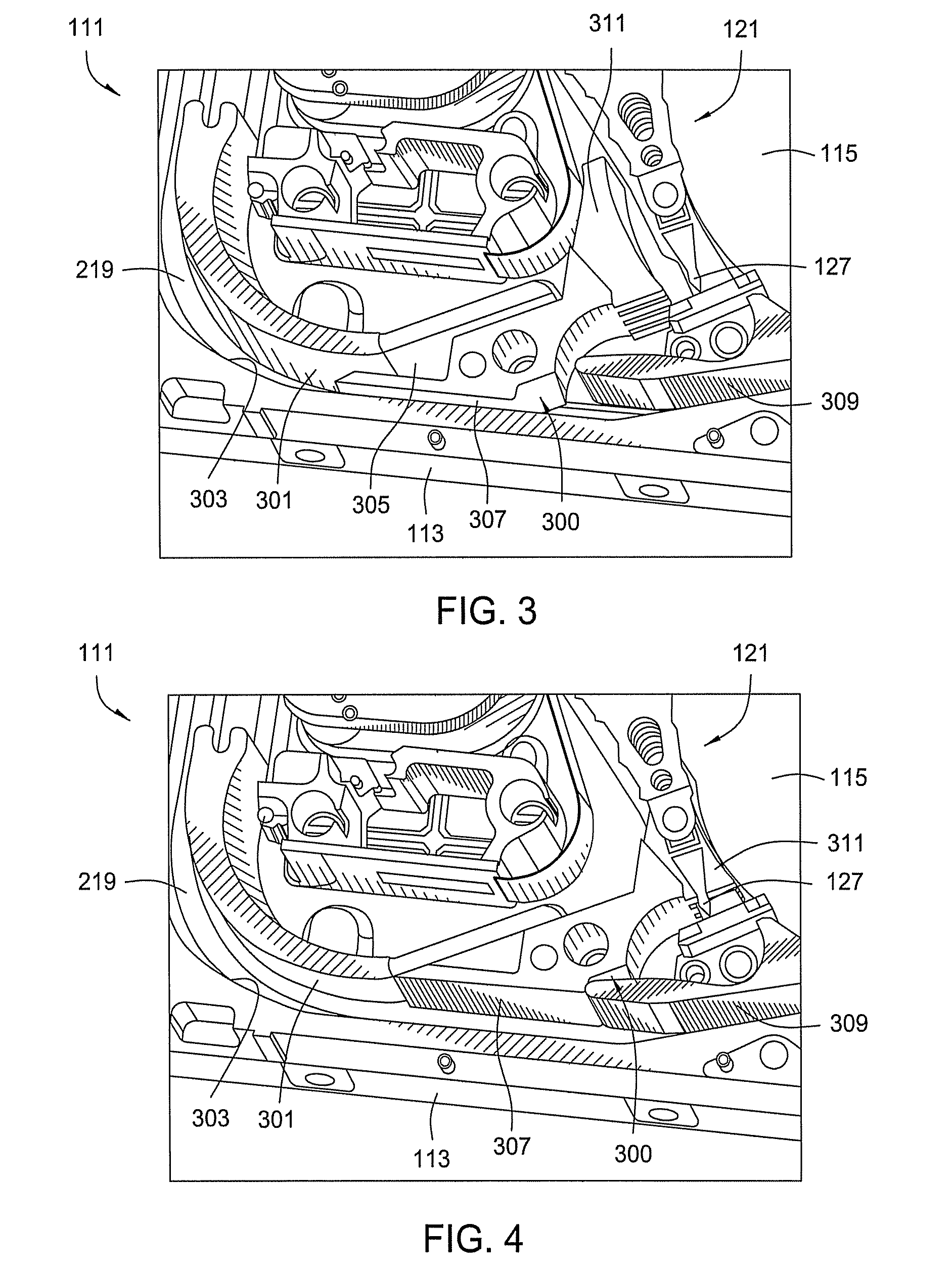

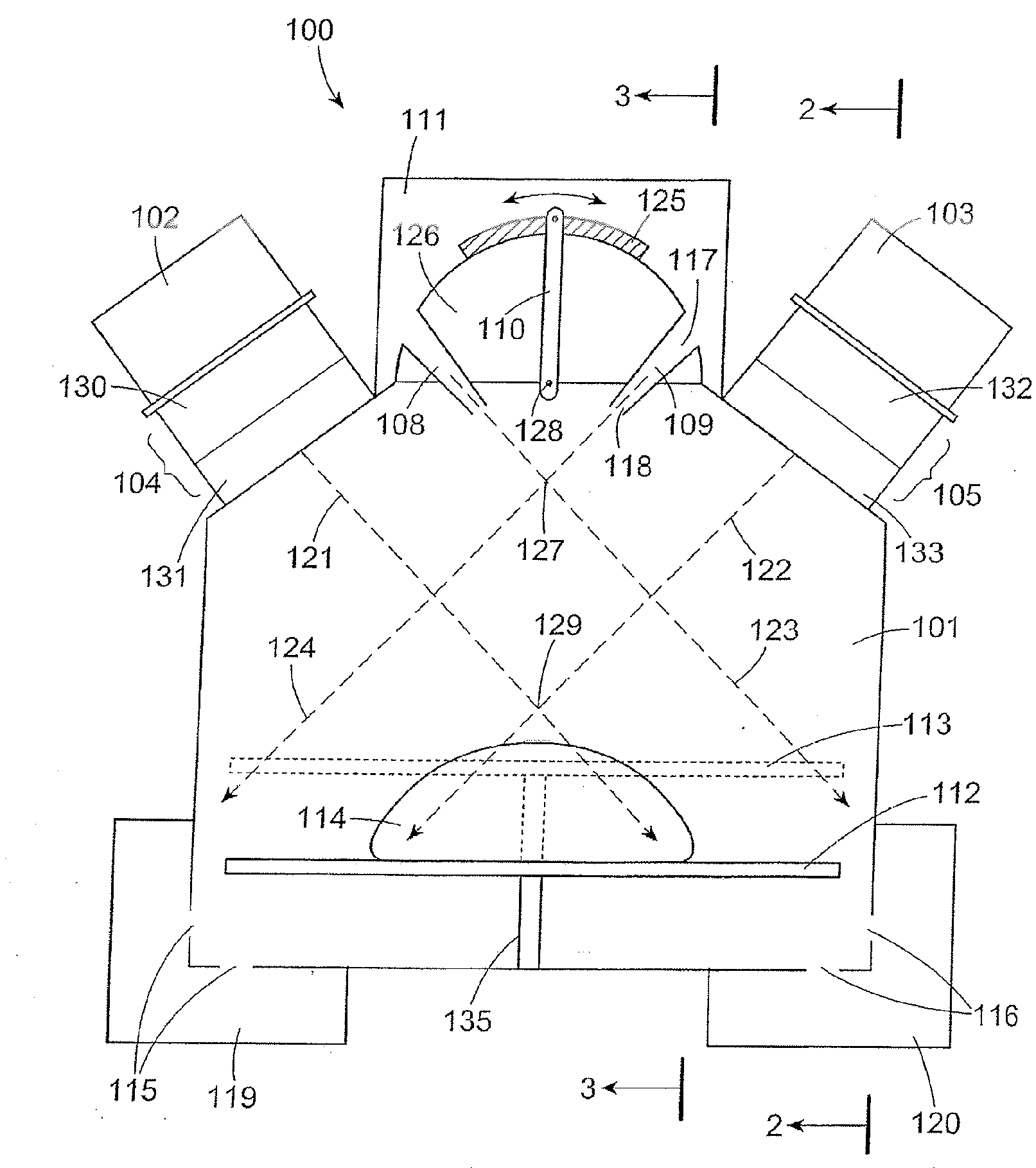

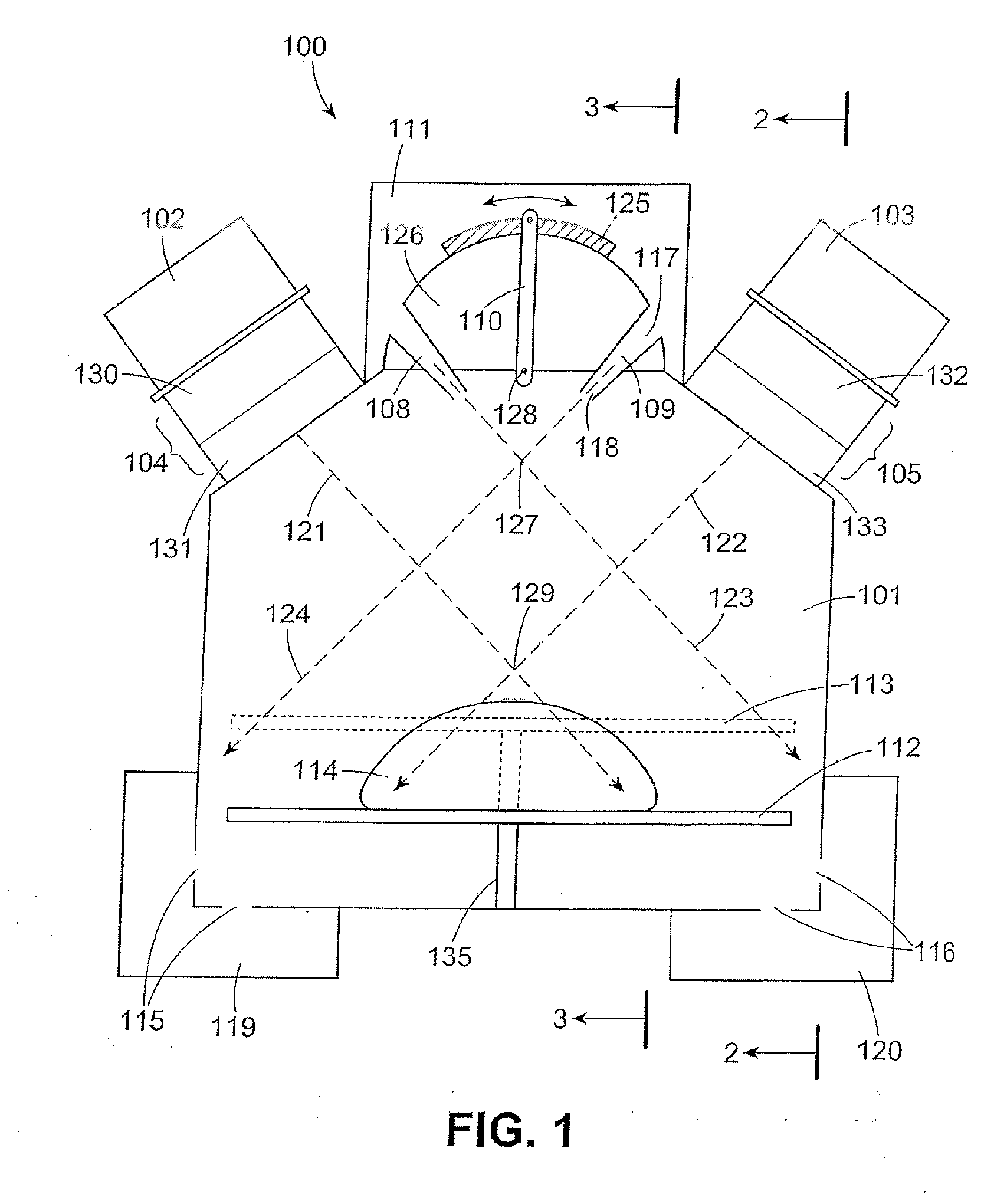

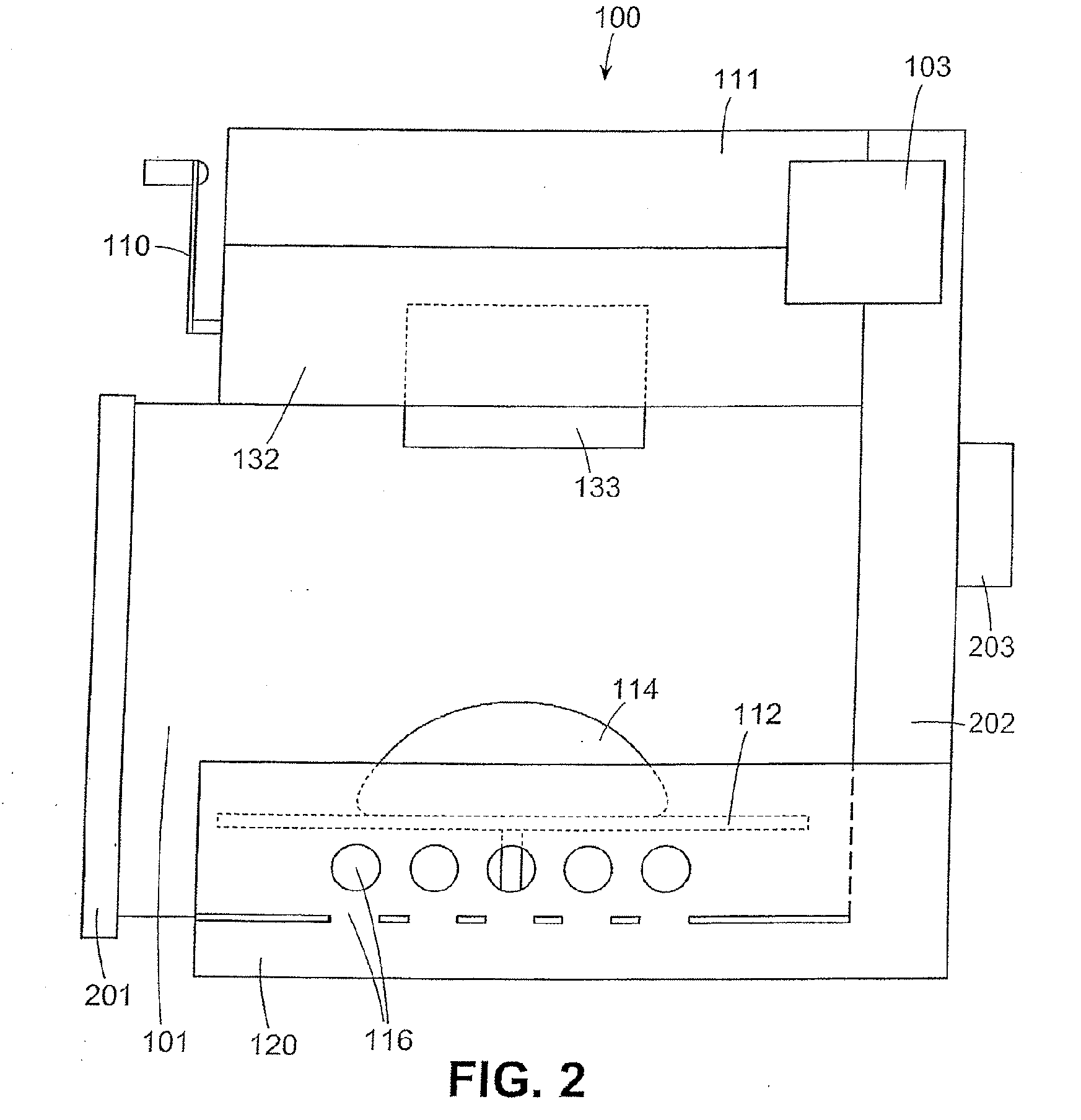

High-speed cooking oven with optimized cooking efficiency

InactiveUS20080283519A1Eliminate and reduce some of inefficiencyIncrease flow rateDomestic stoves or rangesLighting and heating apparatusMicrowaveProcess engineering

The present invention is directed to improving the conventional high-speed cooking oven based on a combination of hot air impingement and microwave heating by providing a time-dependent spatial variation in the net air impingement and / or net microwave energy applied to the food product in the oven. This is aimed at optimizing heat transfer and microwave efficiencies in a high-speed cooking oven, thereby enabling the oven to deliver an optimal cooking efficiency in comparison to the conventional high-speed cooking oven. In addition, under the present invention, the cooking efficiency may be further optimized by dimensioning the nozzles for hot air impingement to tighten impingement plumes, subject to the space constraint of the oven's cooking chamber, and dimensioning the cooking chamber of the oven in integer multiples of the wavelength of the microwave energy to match the microwave load. With the optimized cooking efficiency provided by the present invention, the high speed cooking technology may now be extended to ovens operating on a power supply based on a voltage less than 220 volts, preferably between 110 and 125 volts, with more productive results, so that the high-speed cooking technology may find a wider applicability and customer base.

Owner:APPLIANCE SCI

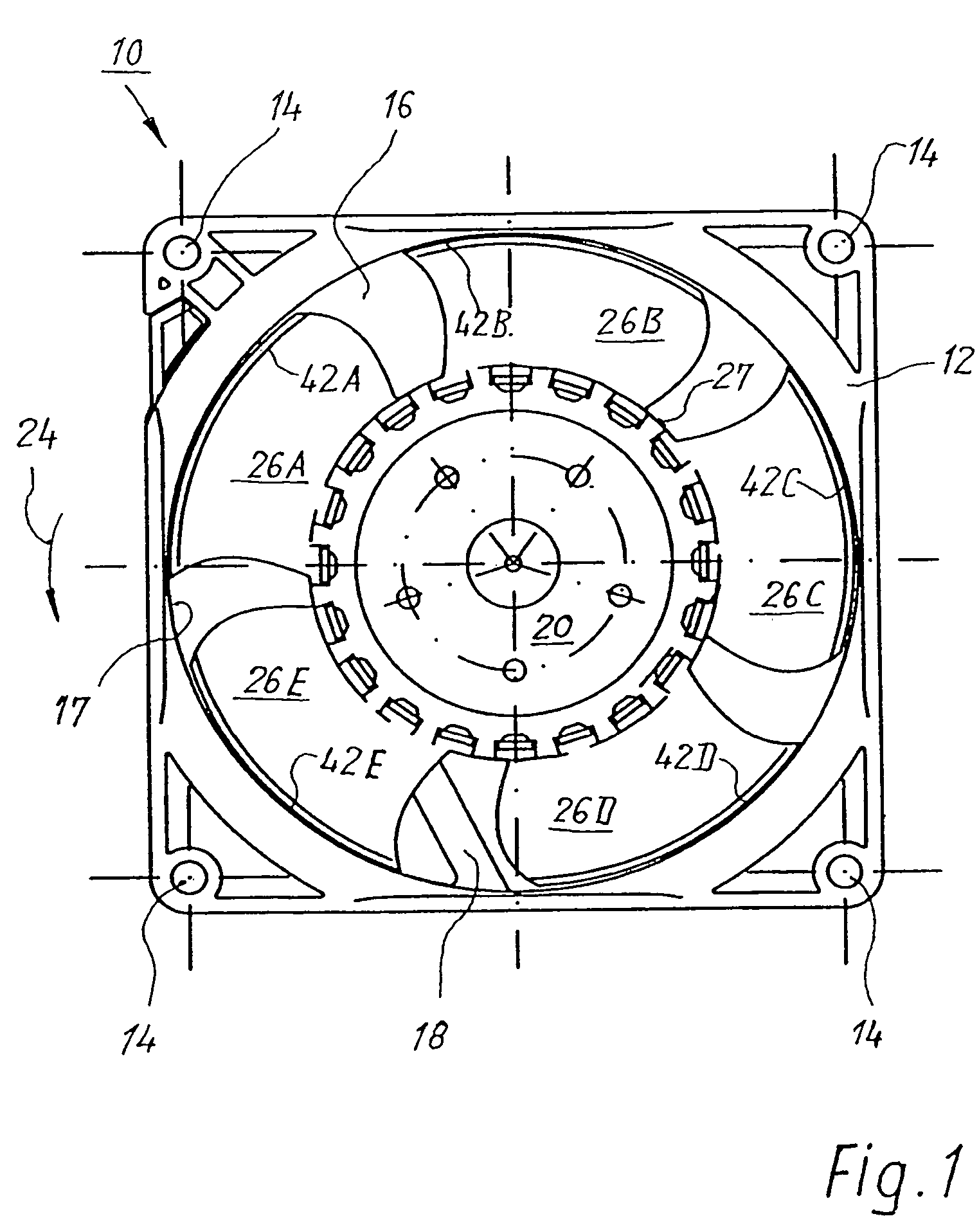

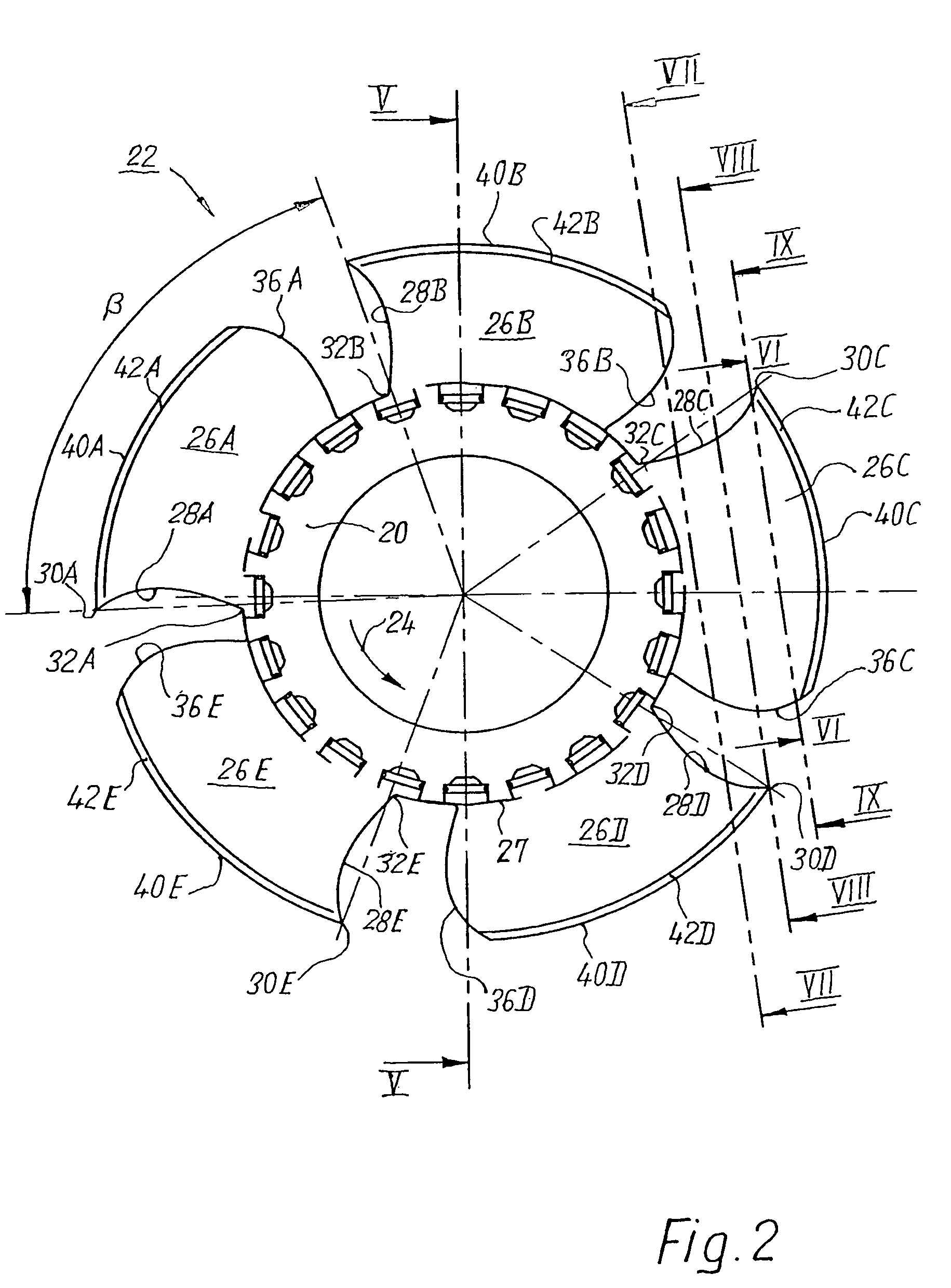

Fan

A fan has an air conveying conduit (16) and a fan wheel (22) arranged therein, which wheel is rotatable about a central axis (25) and is formed with a central hub (20; 120) having an outer periphery (27) on which fan blades (26) are mounted. These extend with their radially outer rims (40) as far as a surface (17) that is substantially coaxial with the central axis (25) and delimits the air conveying conduit (16) externally. The blades (26) have a profile similar to an airfoil profile. A flow element (42) is provided along the radial outer edge (40) of a fan blade and serves as an obstacle to a compensating flow proceeding around that radial outer edge (40) from the delivery side to the intake side, and likewise has, in cross section, an airfoil profile.Adjacent the front edge (28) and rear edge (36) of a blade (26), it has substantially the same outline as the adjacent part of the associated blade (26), and in a middle region (48) between the front and back edge is wider, by an approximately constant amount, than the adjacent part of the blade (26).

Owner:EBM PAPST ST GEORGEN & -

Aerodynamic lifting device and airborne craft

ActiveUS20080223979A1Less noisePrevent leakageAircraft navigation controlVertical landing/take-off aircraftsFlight vehicleRotational axis

An airborne craft is provided comprising an aerodynamic lifting device having a radial drum fan and a thrust vectoring shroud. The radial drum or vertical axis fan comprises a fan with a rotor, the rotor having a rotational axis and comprising a plurality of rotor blades disposed in an annular ring about the rotational axis and a driving means for the rotor such that, on operation of the driving means, lift is generated.

Owner:ENTECHO (PTY) LTD

Overflow downdraw glass forming method and apparatus

ActiveUS9233869B2Reduce unevennessEfficient degradationGlass drawing apparatusGlass forming apparatusFlat glassThermal creep

The present invention discloses improved methods and apparatus for forming sheet glass. In one embodiment, the invention introduces a counteracting force to the stresses on the forming structure in a manner such that the thermal creep which inevitably occurs has a minimum impact on the glass flow characteristics of the forming structure.

Owner:CORNING INC

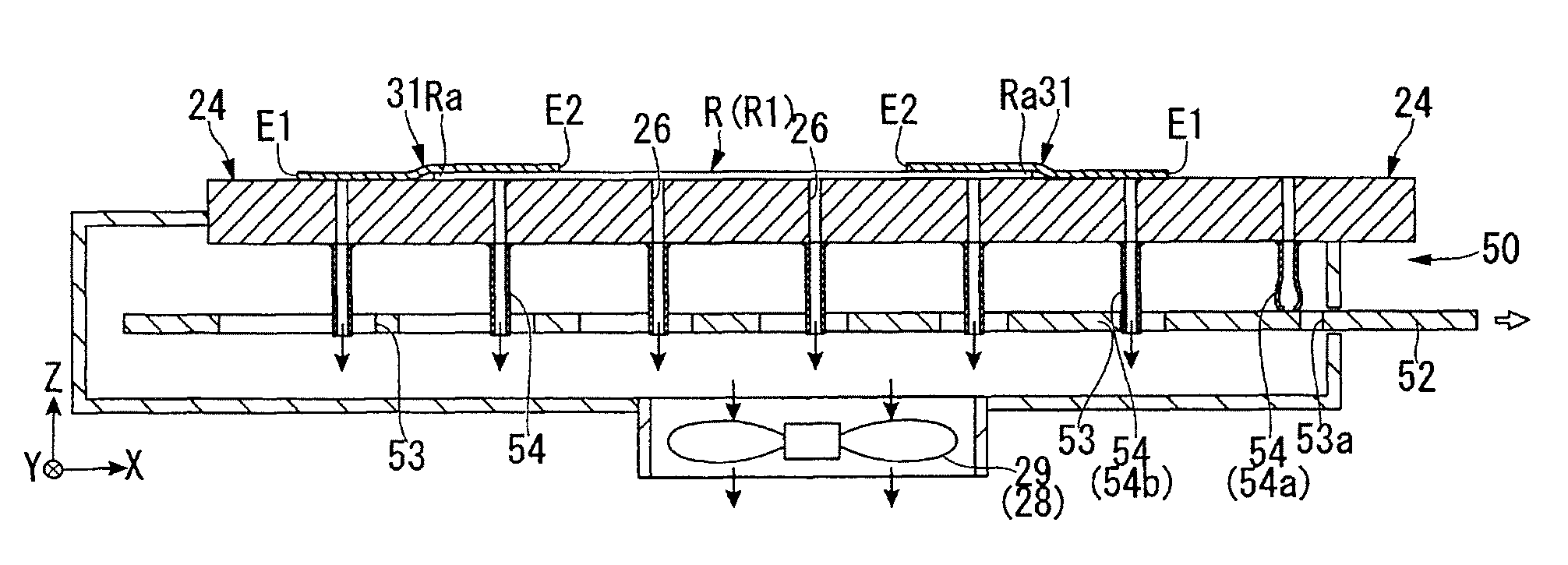

Turbine shroud

ActiveUS8641371B2Reduce leakageUndue thermal stressPump componentsBlade accessoriesTurbine bladeThermal expansion

A turbine shroud (30) of a gas turbine engine comprises a plurality of arcuate shroud segments (31) combined into an annular configuration, each shroud segment including a main body (32) defining an inner circumferential surface opposing the tips of the turbine rotor blades (11a) at a small clearance and an engagement feature including an axial wall (33a, 34a) having a prescribed circumferential length and a prescribed axial length, the turbine casing including an axial slot (51, 52) extending coaxially around the center line of the engine and configured to receive the axially extending wall of each shroud segment. A clearance defined between each circumferential end part (E) of the axial wall and an opposing inner circumferential surface of the turbine casing is greater than that defined between a circumferentially middle part (M) of the axial wall and an opposing inner circumferential surface of the turbine casing under a cool condition of the engine. A radial temperature gradient that develops in each shroud segment when the engine is warmed causes a deformation of the shroud segment such that the clearance can be made substantially uniform over the entire circumference of the shroud segment and the cooling air leakage can be minimized while minimizing thermal stress that may be caused by the thermal expansion of the shroud segment.

Owner:HONDA MOTOR CO LTD

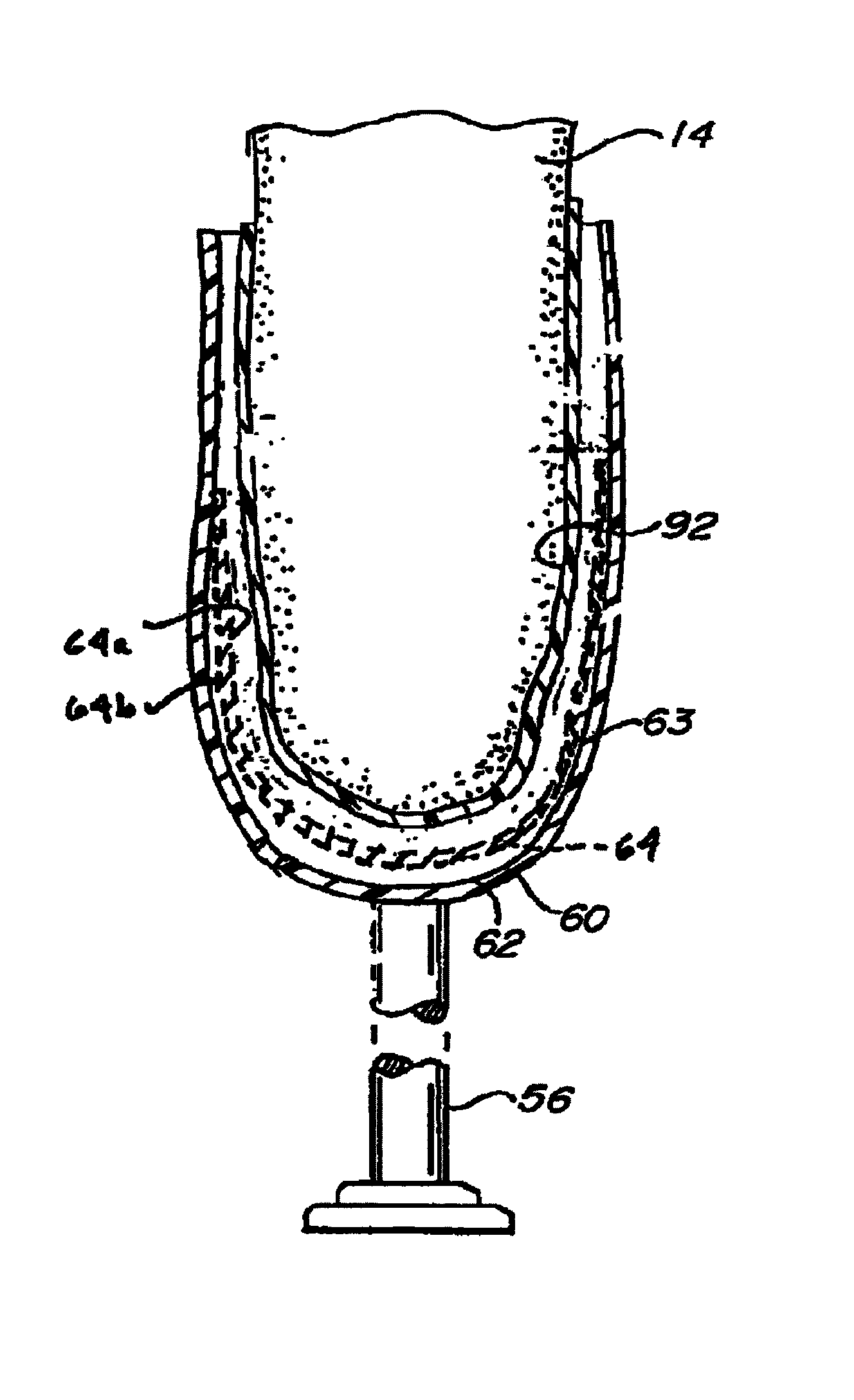

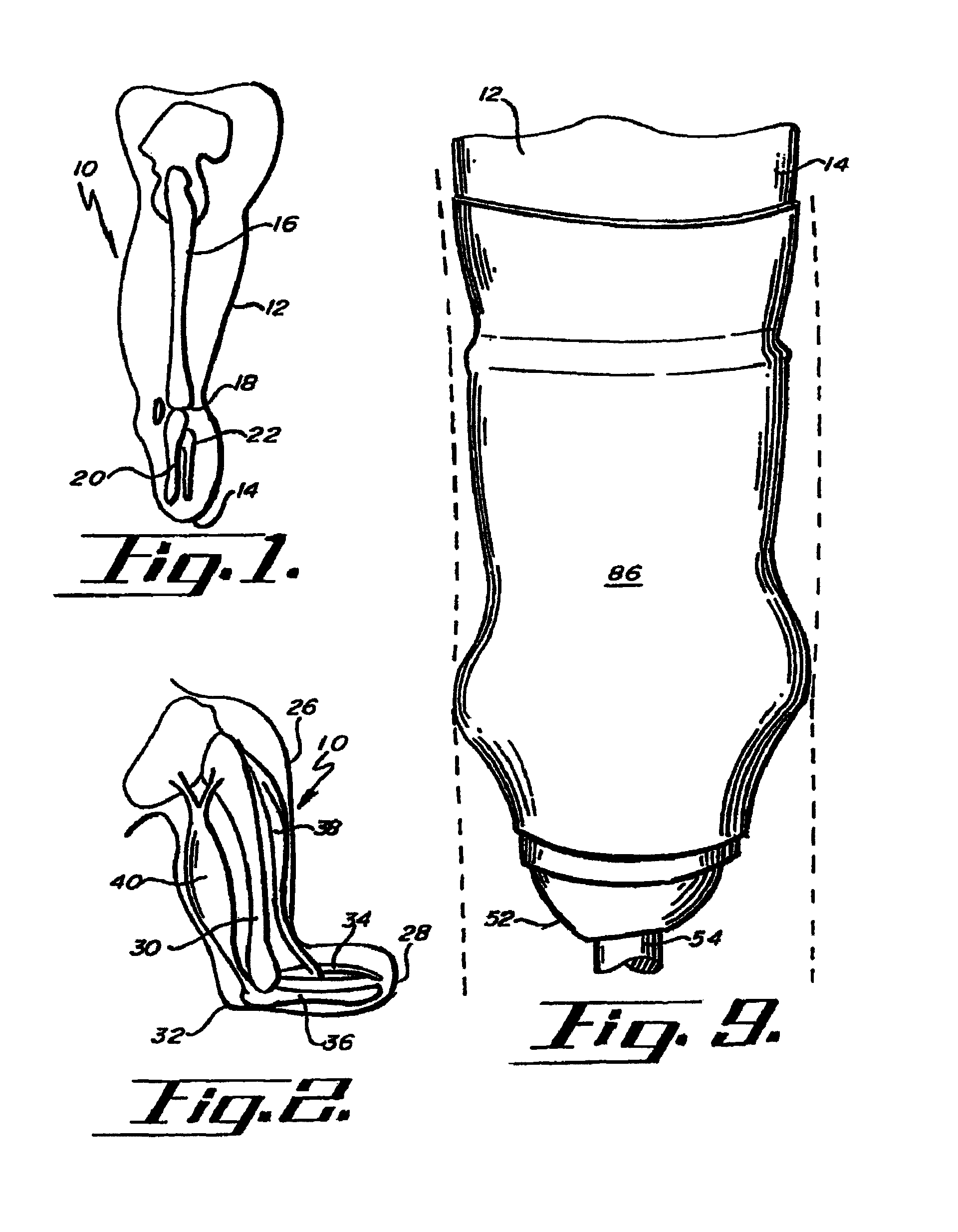

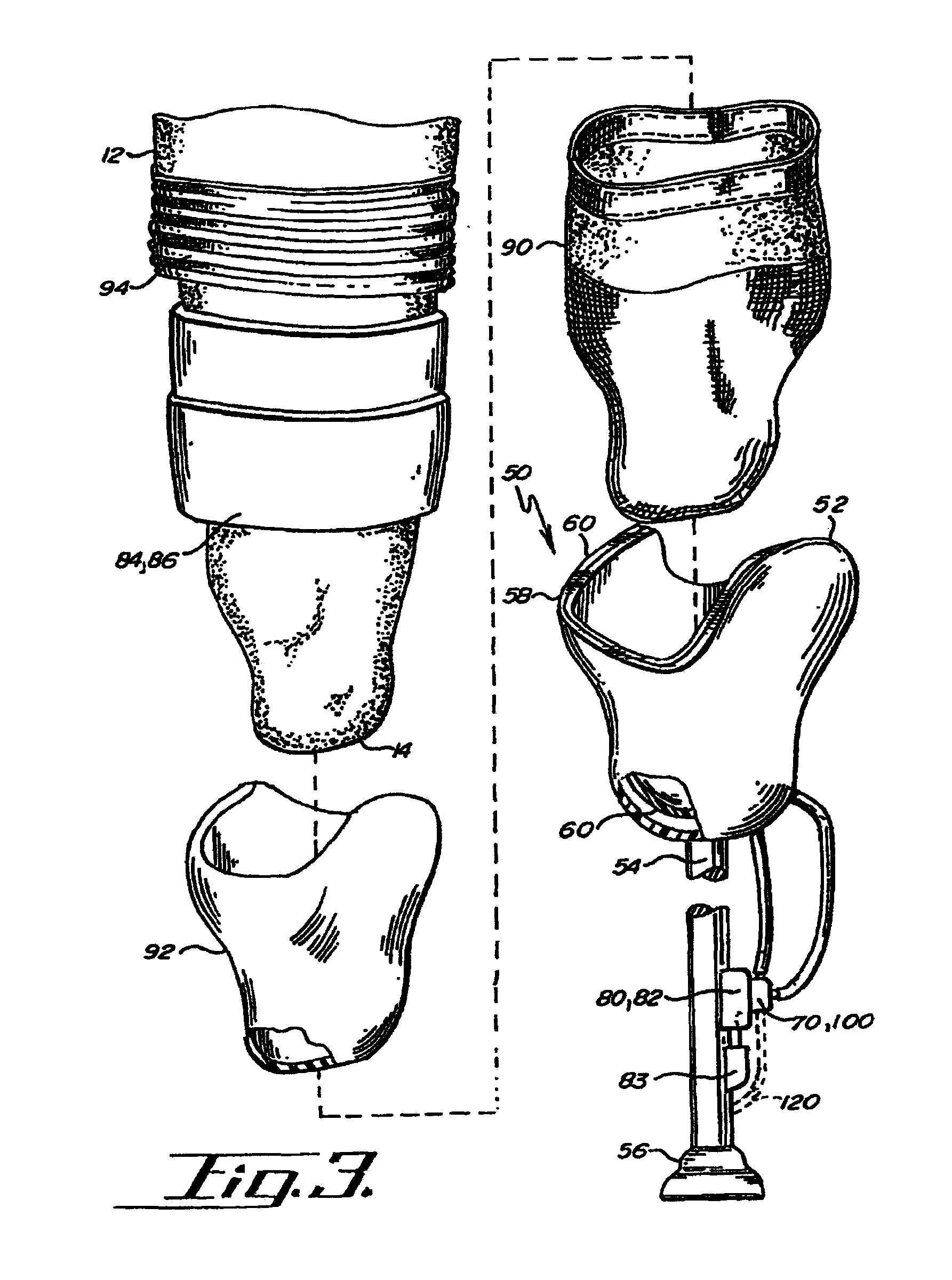

Socket liner for artificial limb

A hypobarically-controlled artificial limb for amputees includes a single socket with a volume and shape to receive a substantial portion of the residual limb. A sealed cavity is formed between the socket and the residual limb. The wearer may use a liner over the residual limb for comfort. A vacuum source is connected to a vacuum valve connected to the cavity to suspend the artificial limb from the residual limb and to control and minimize volumetric and fluid changes within the residual limb. A liner for a hypobarically-controlled socket for an artificial limb, with a liner interface bonding the liner to the socket and forming a seal between the liner and the socket. The liner may be permanently attached to the socket or the liner may be removed from the socket for replacement.

Owner:OTTO BOCK HEALTHCARE IP GMBH & CO KG

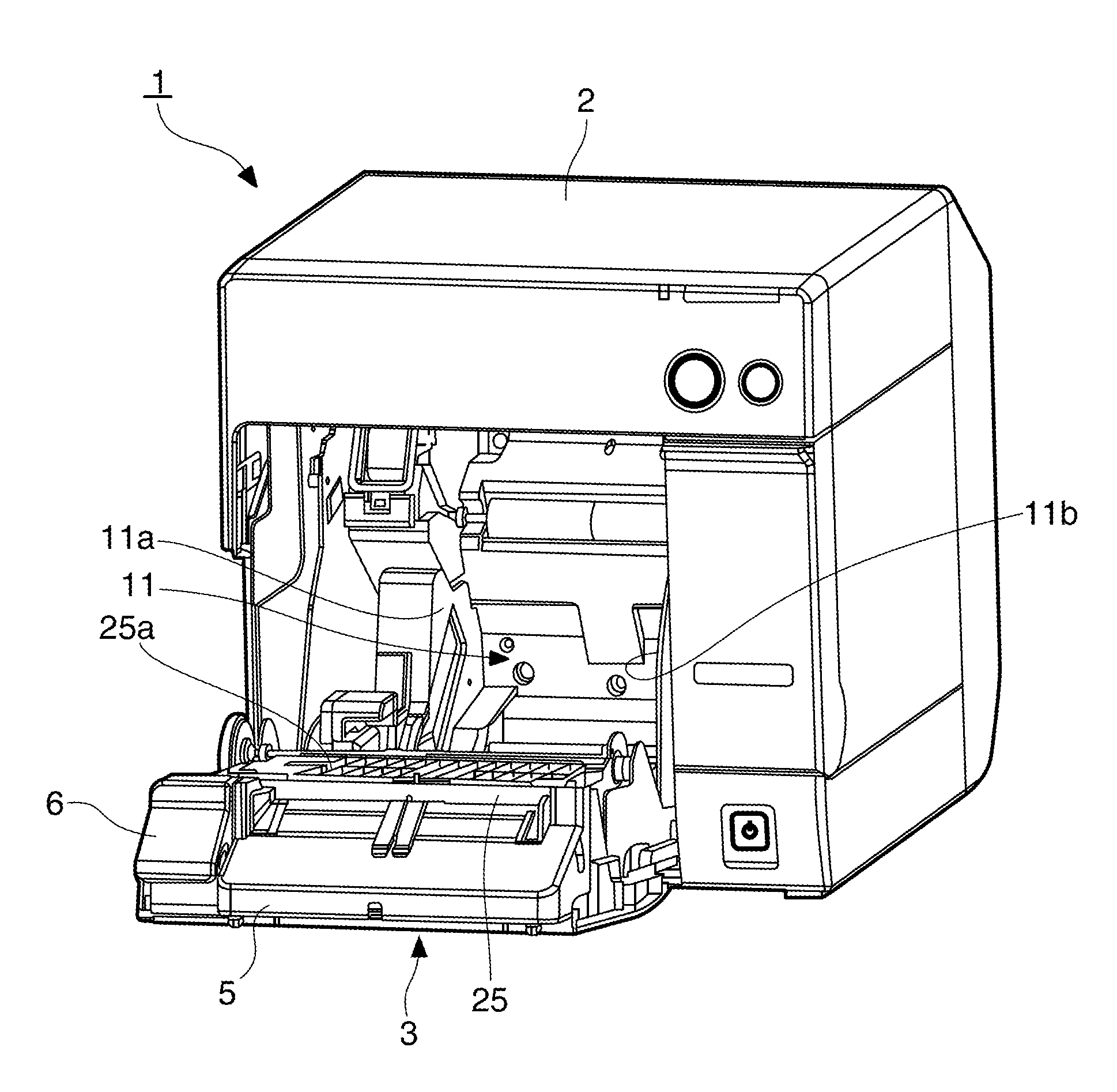

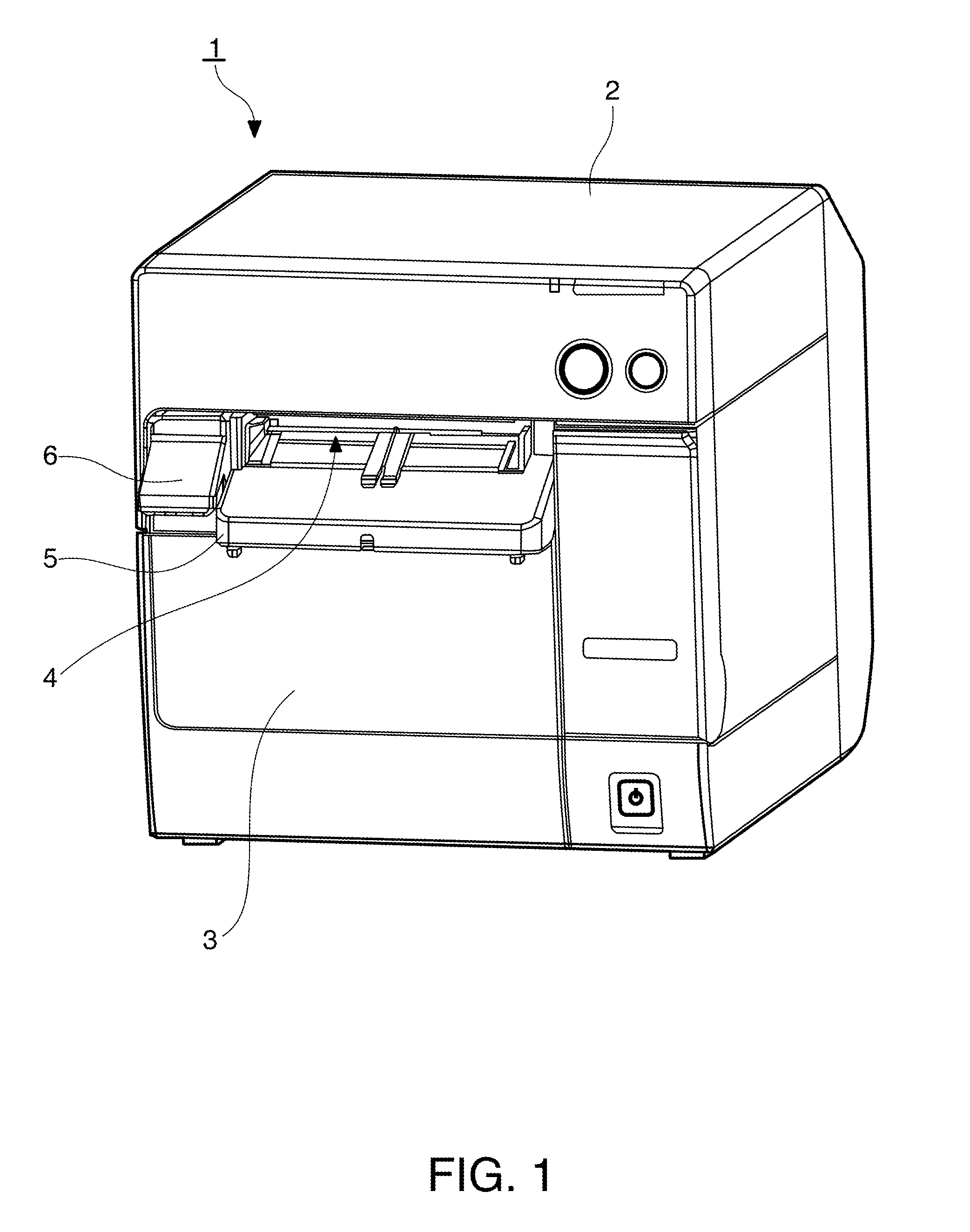

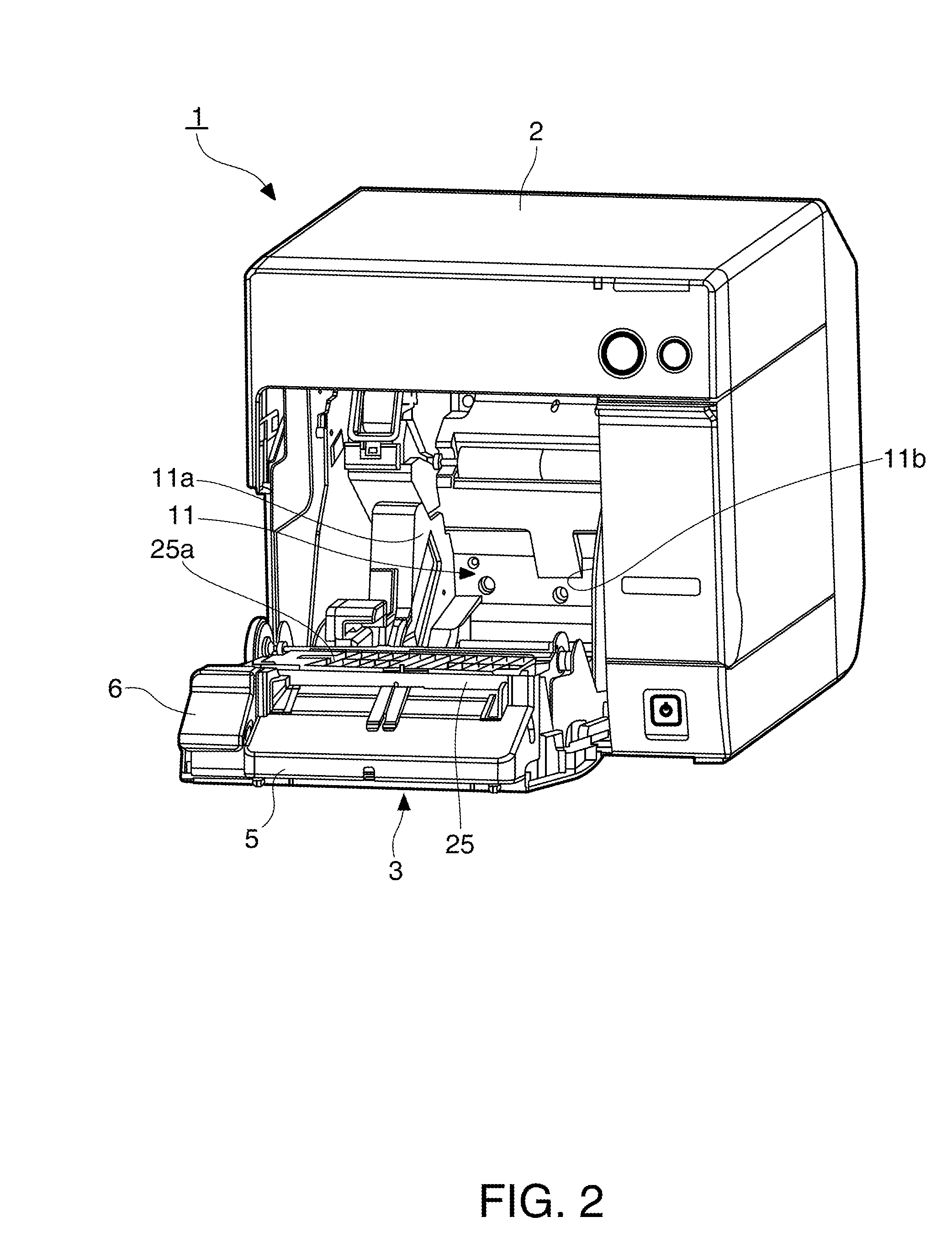

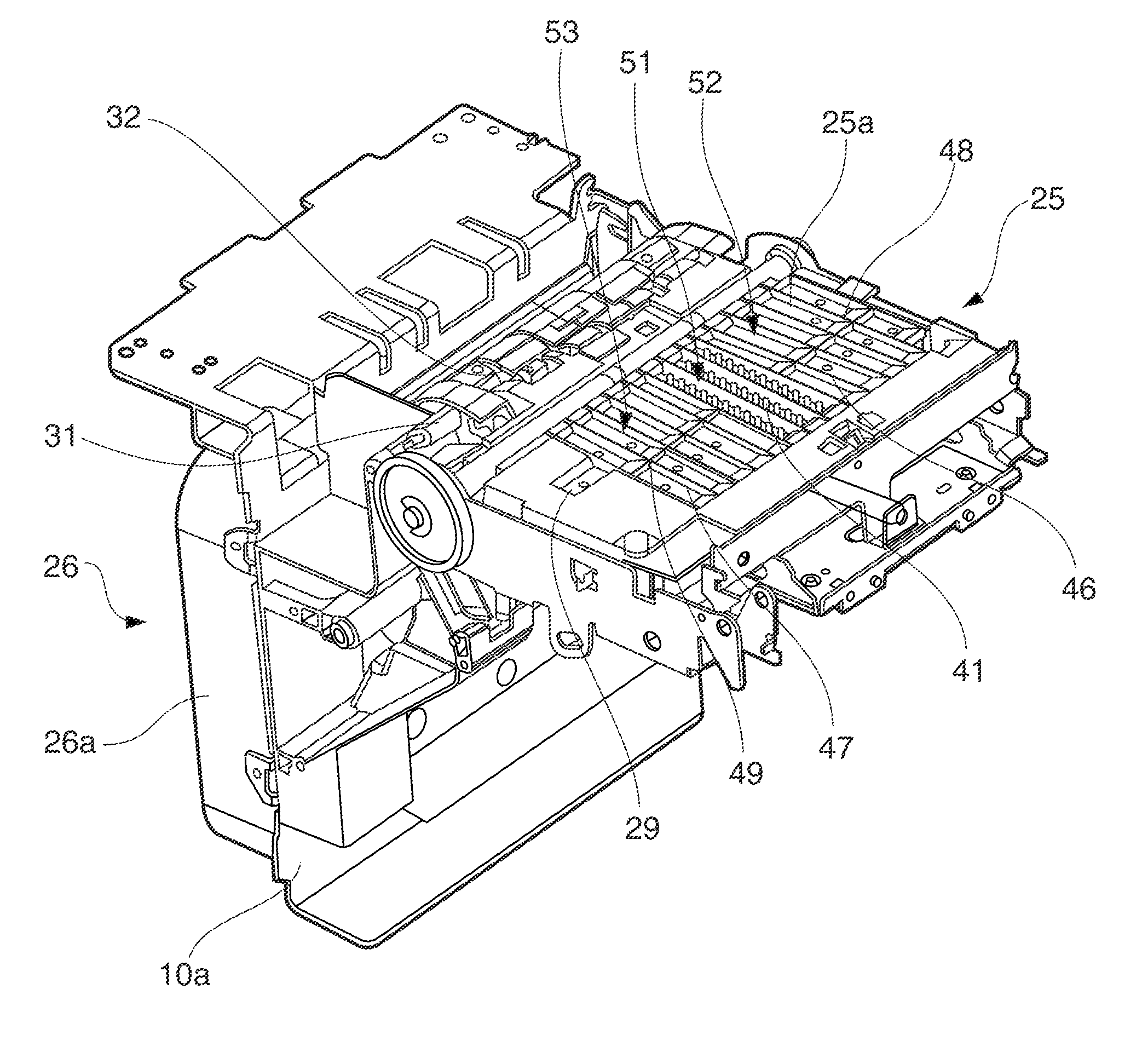

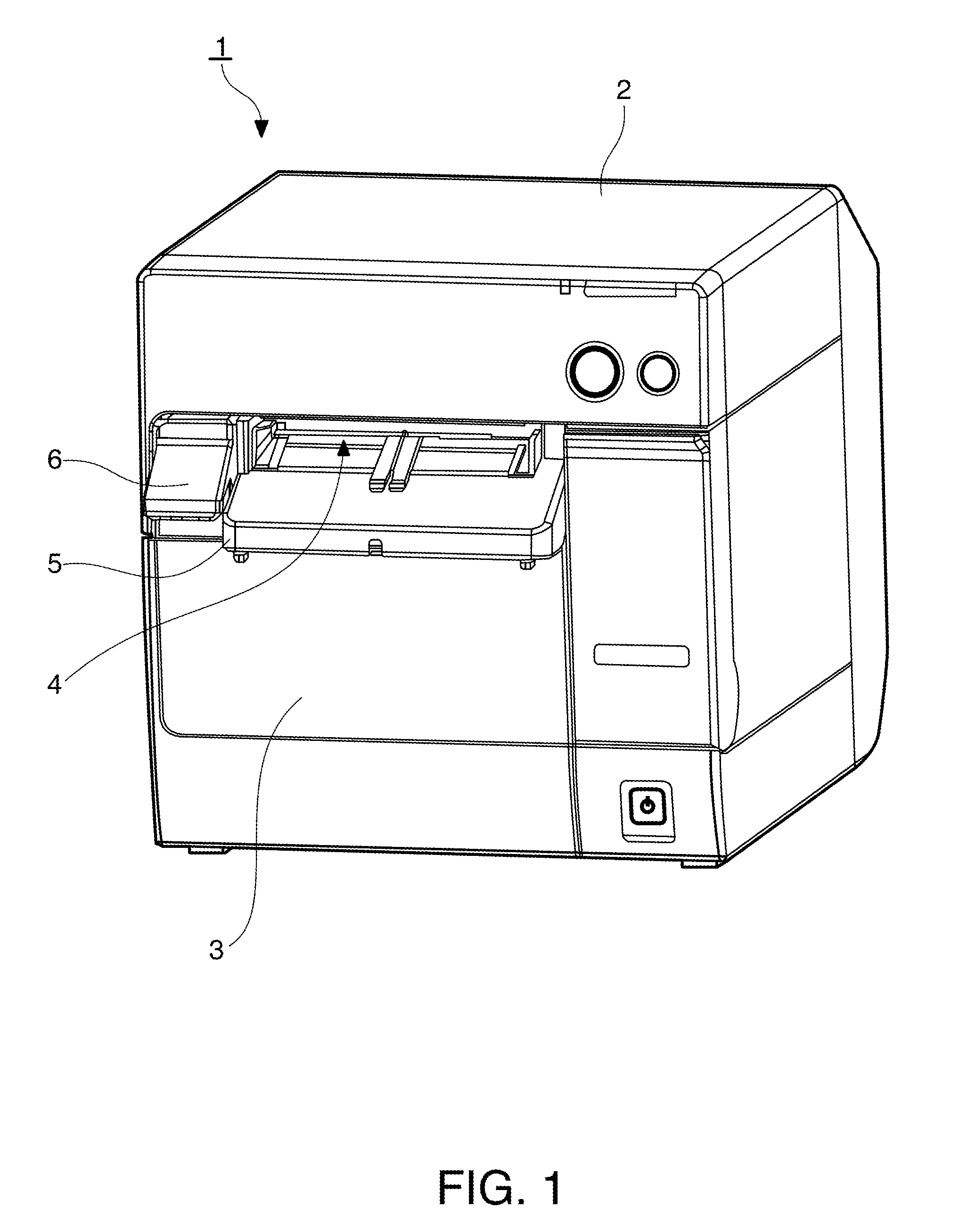

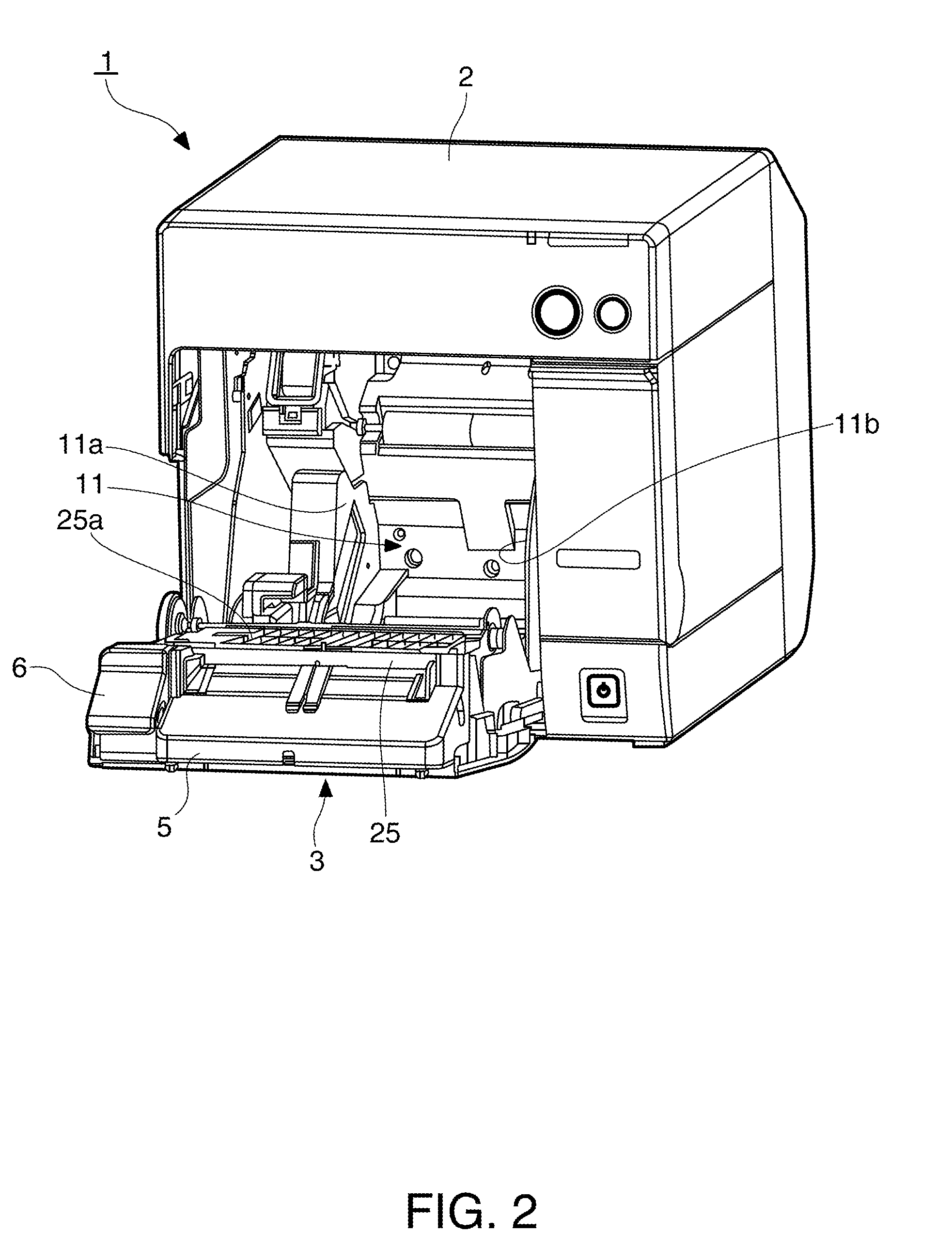

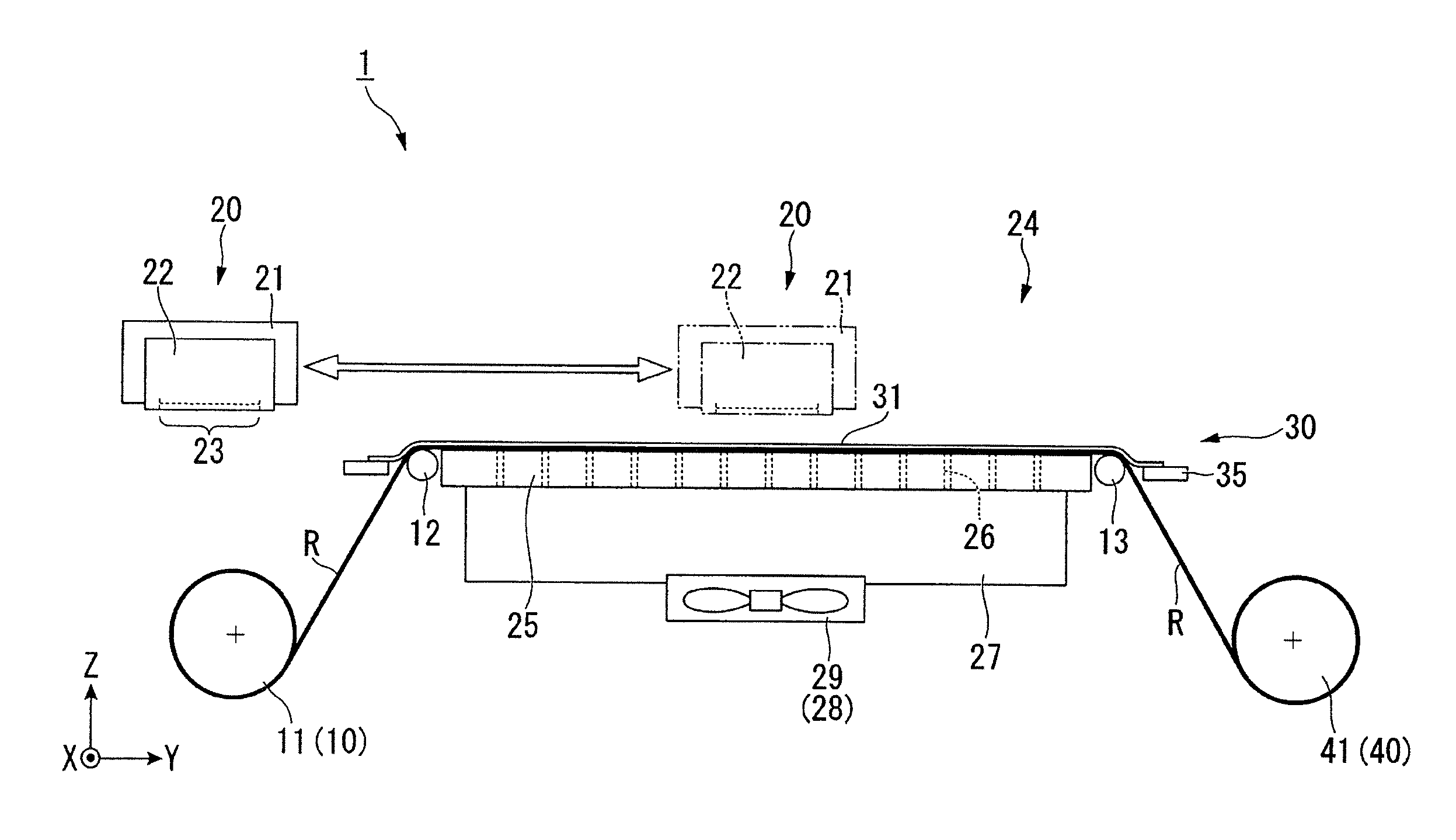

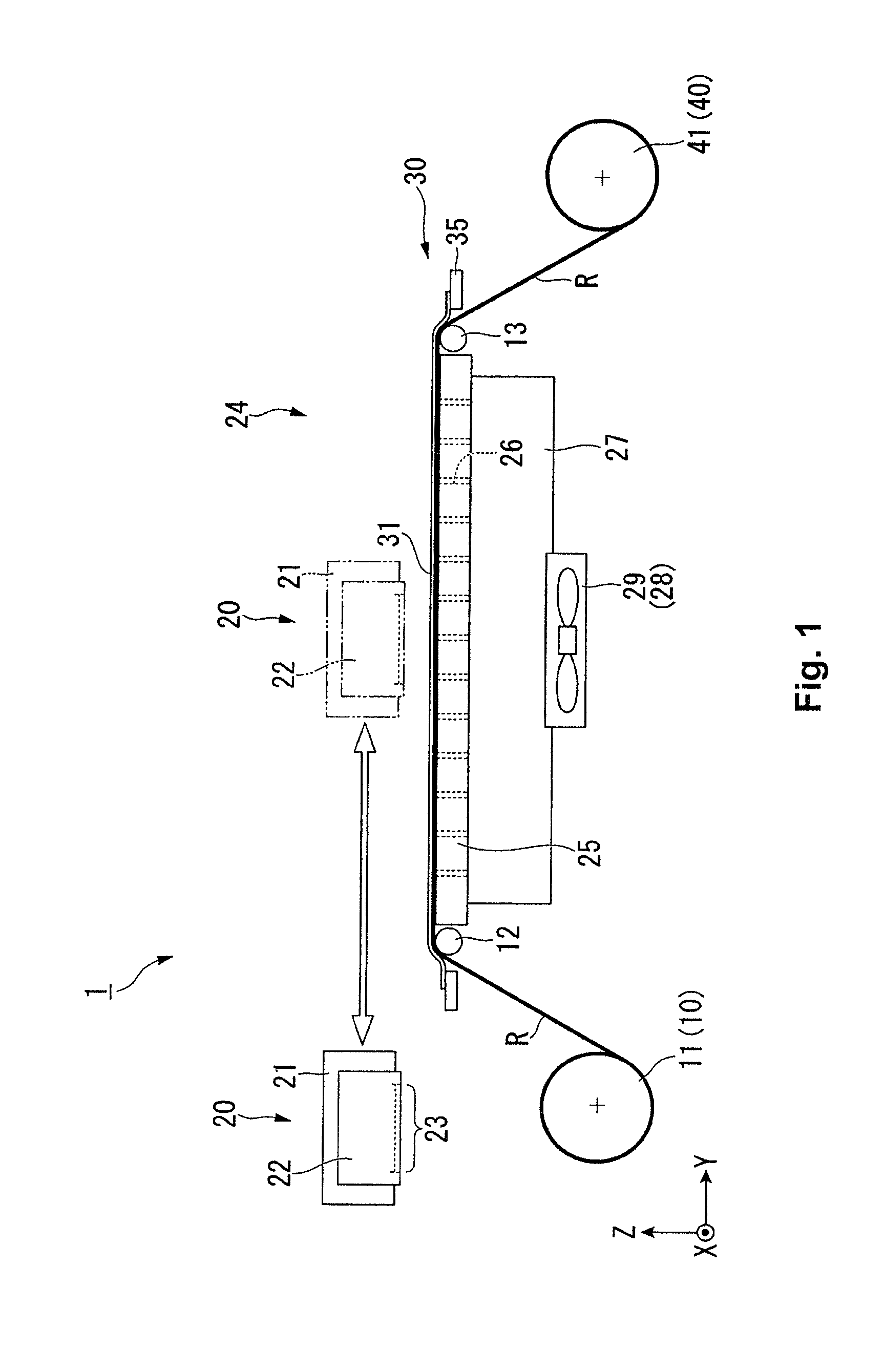

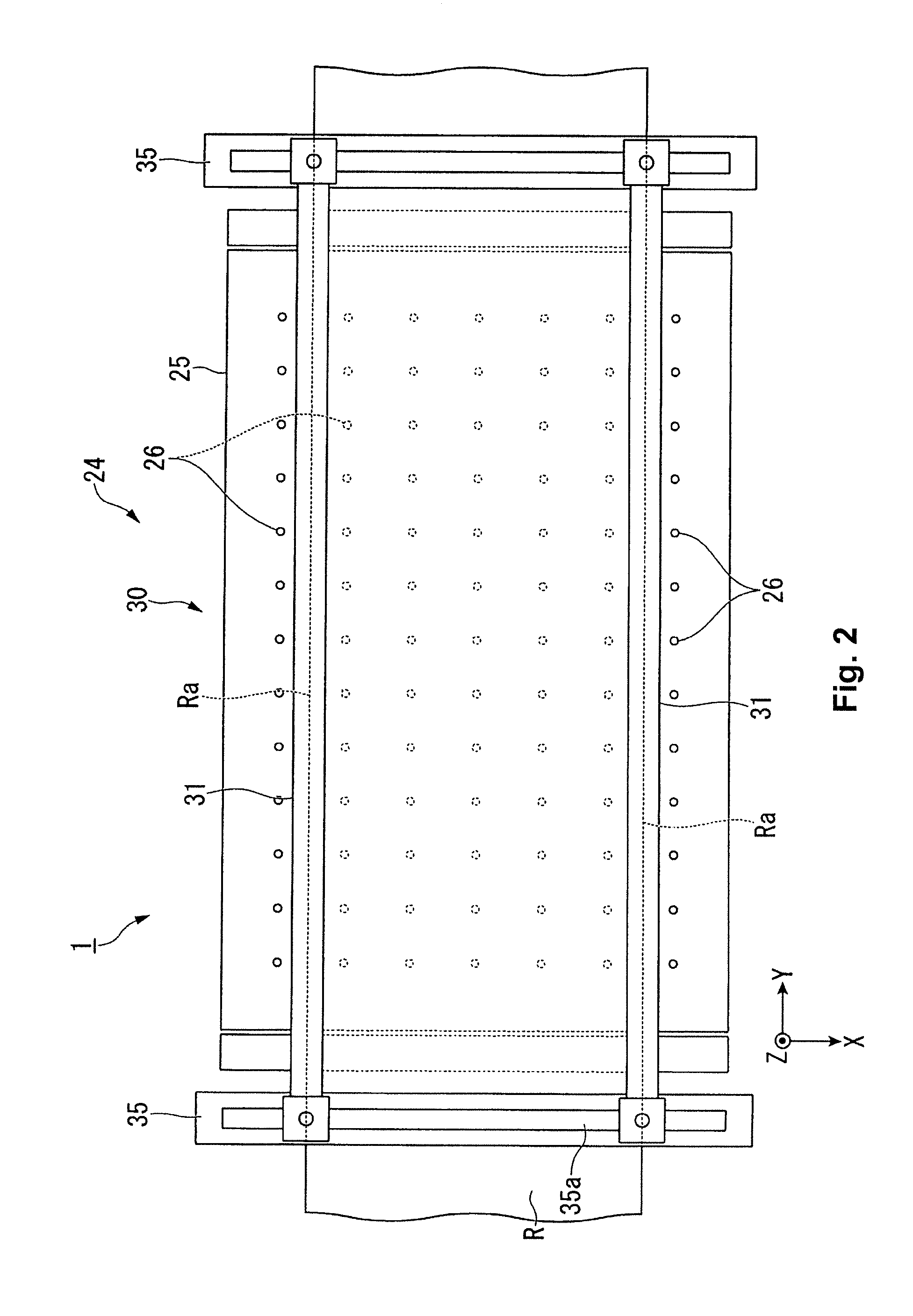

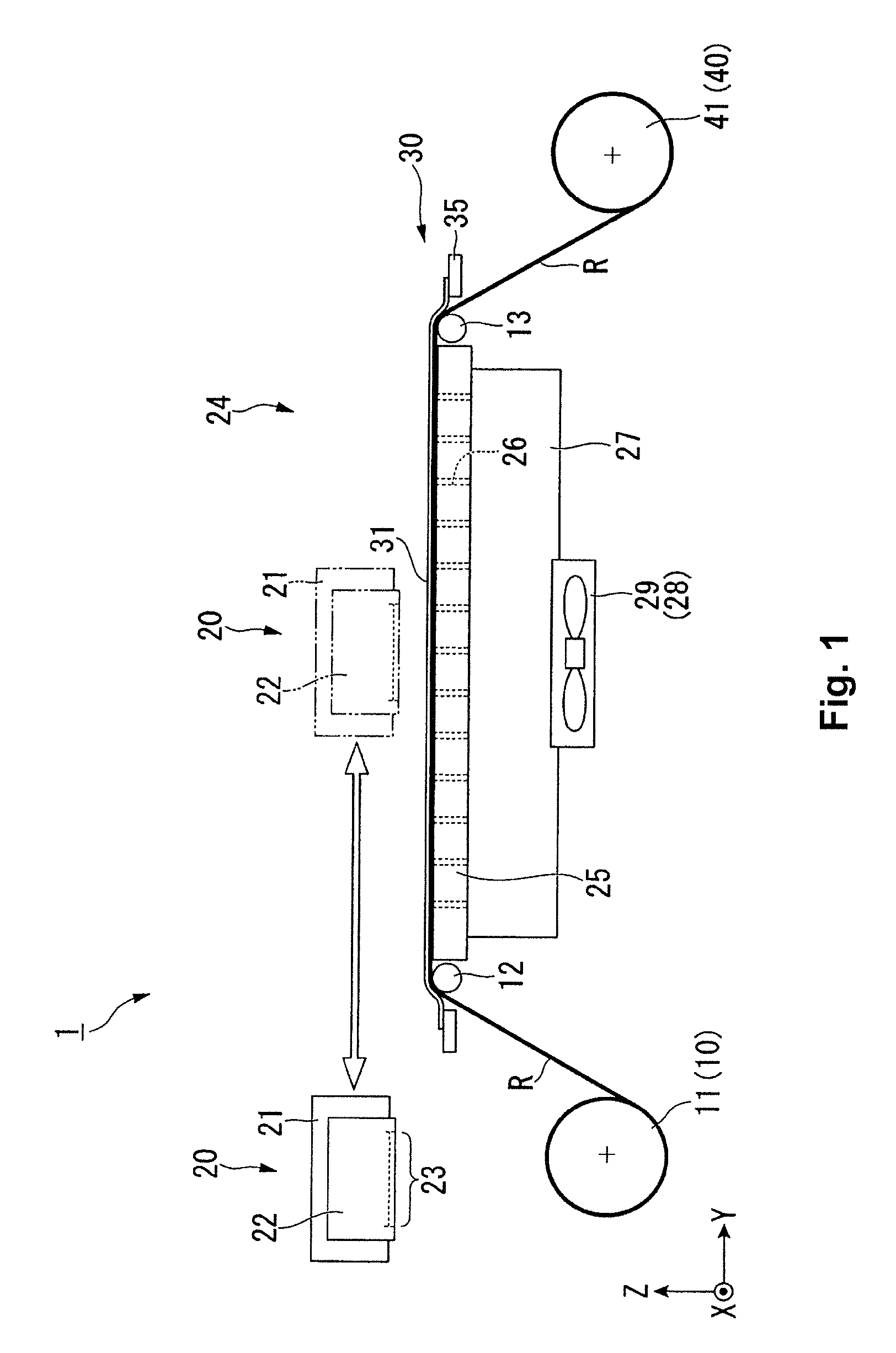

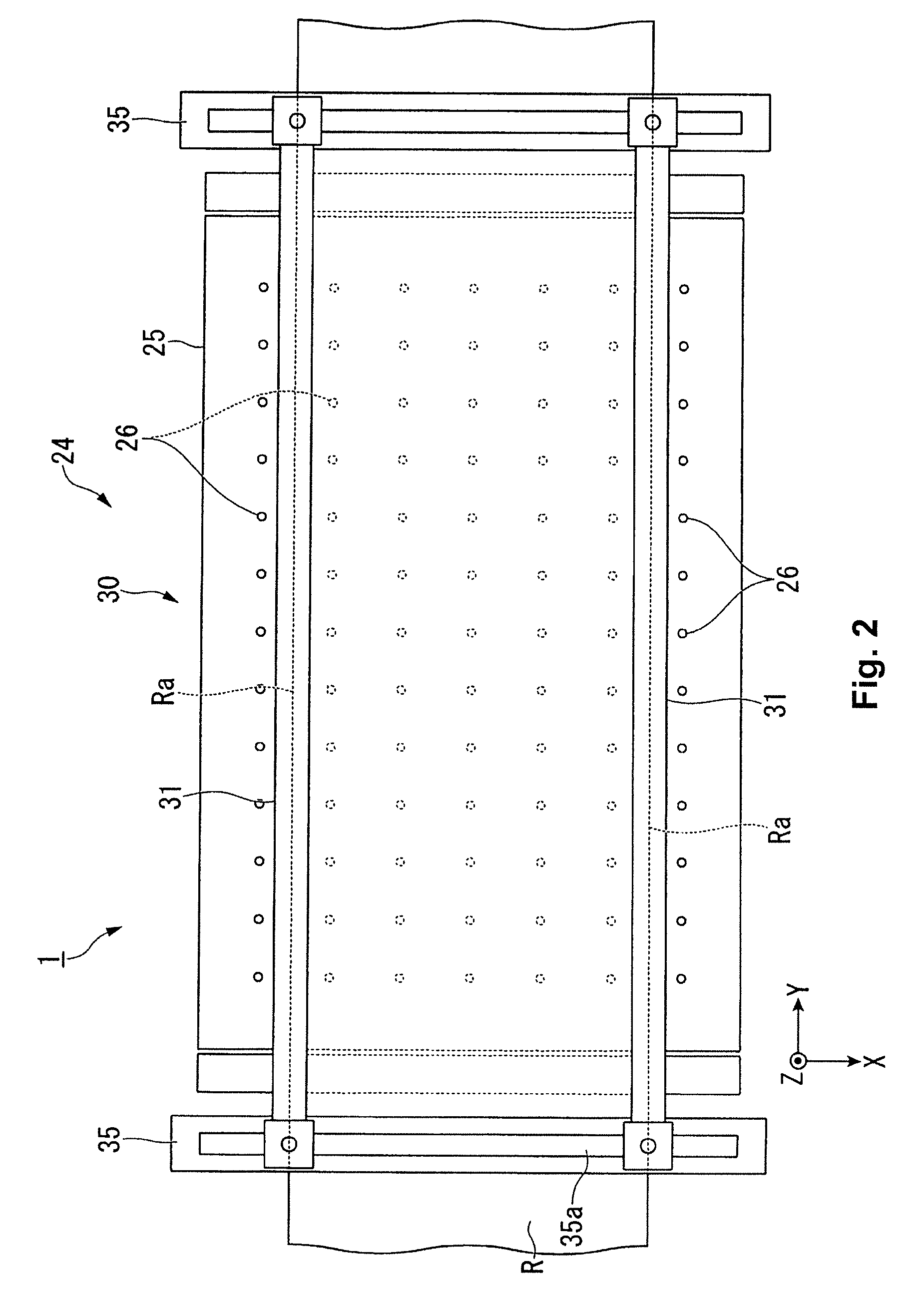

Vacuum Platen Mechanism and Fluid Droplet Discharge Device

ActiveUS20120218341A1Increase opening ratioStrong suctionOther printing apparatusVacuum pressureEngineering

Mechanism for producing vacuum pressure and air flow for drawing recording paper of various widths to the platen surface of a printer enables such pressure and air flow to be held in a suitable range without adjusting the suction. A first suction area of specified width is disposed width-wise in the middle of the platen surface that opposes the inkjet head of the printer, and second suction areas are disposed on the left and right sides of the first suction area, the front edge of which is offset from the front edge of the second suction areas. The first suction area is divided to form first chambers, each having a first suction hole that communicates with a vacuum channel. The second suction areas are segmented to form second chambers, some, but not all, of which are formed with second suction holes that are spaced from the first suction holes.

Owner:SEIKO EPSON CORP

Vacuum platen mechanism and fluid droplet discharge device

ActiveUS8152296B2Increase opening ratioStrong suctionWork holdersOther printing apparatusVacuum pressureFront edge

Mechanism for producing vacuum pressure and air flow for drawing recording paper of various widths to the platen surface of a printer enables such pressure and air flow to be held in a suitable range without adjusting the suction. A first suction area with the same width as the minimum width of the recording paper is disposed width-wise in the middle of the platen surface that opposes the inkjet head of the printer, and second suction areas are disposed on the left and right sides of the first suction area. The first suction area is divided into a grid by intersecting ribs to form first chambers, each having a first suction hole formed in a bottom thereof that communicates with a vacuum channel. The second suction areas are also segmented to form second chambers. Second suction holes are selectively formed in some, but not all, of the second chambers and are appropriately spaced from the first suction holes. The front edge of the first suction area is offset slightly from the front edge of the second suction areas.

Owner:SEIKO EPSON CORP

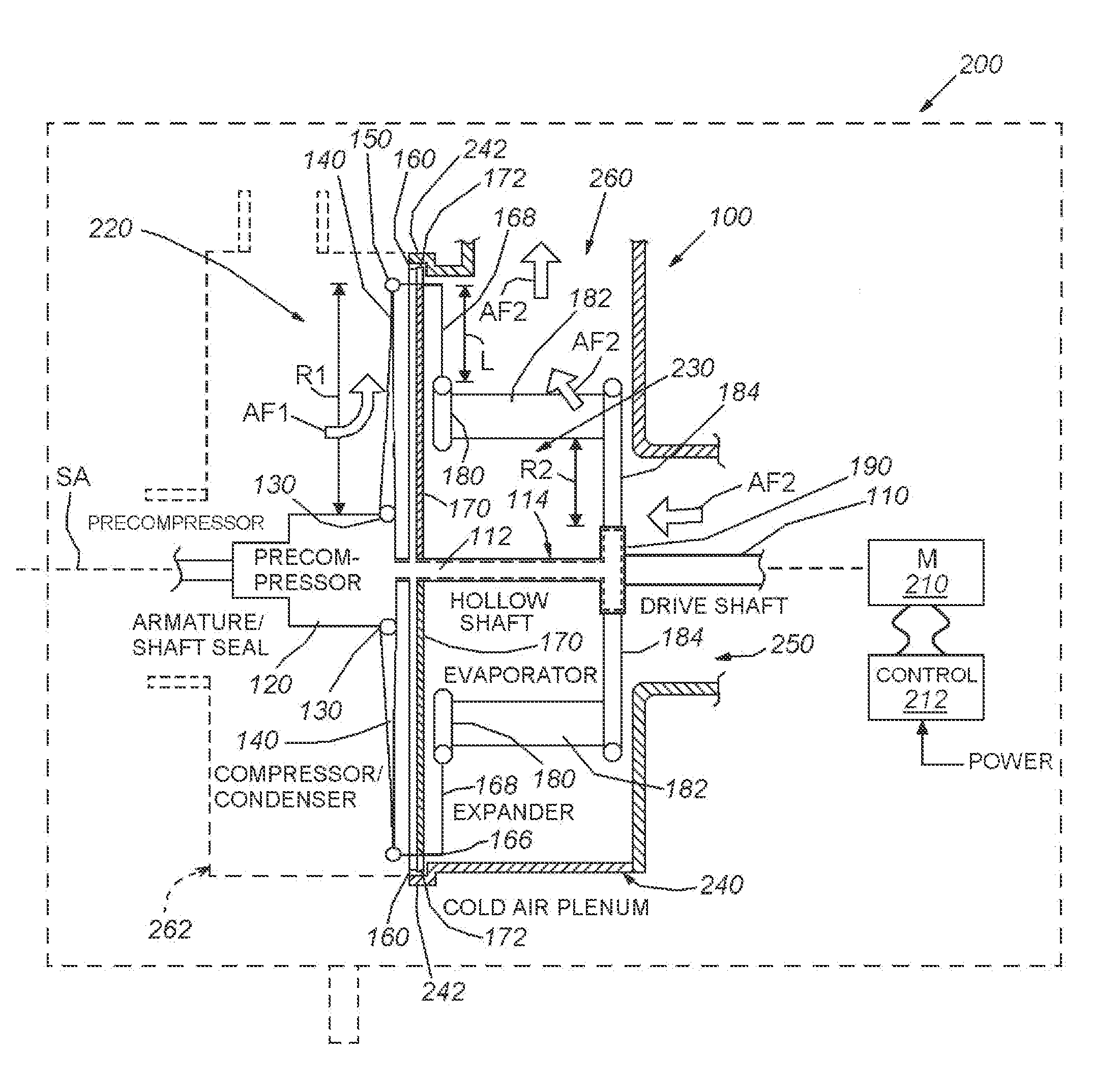

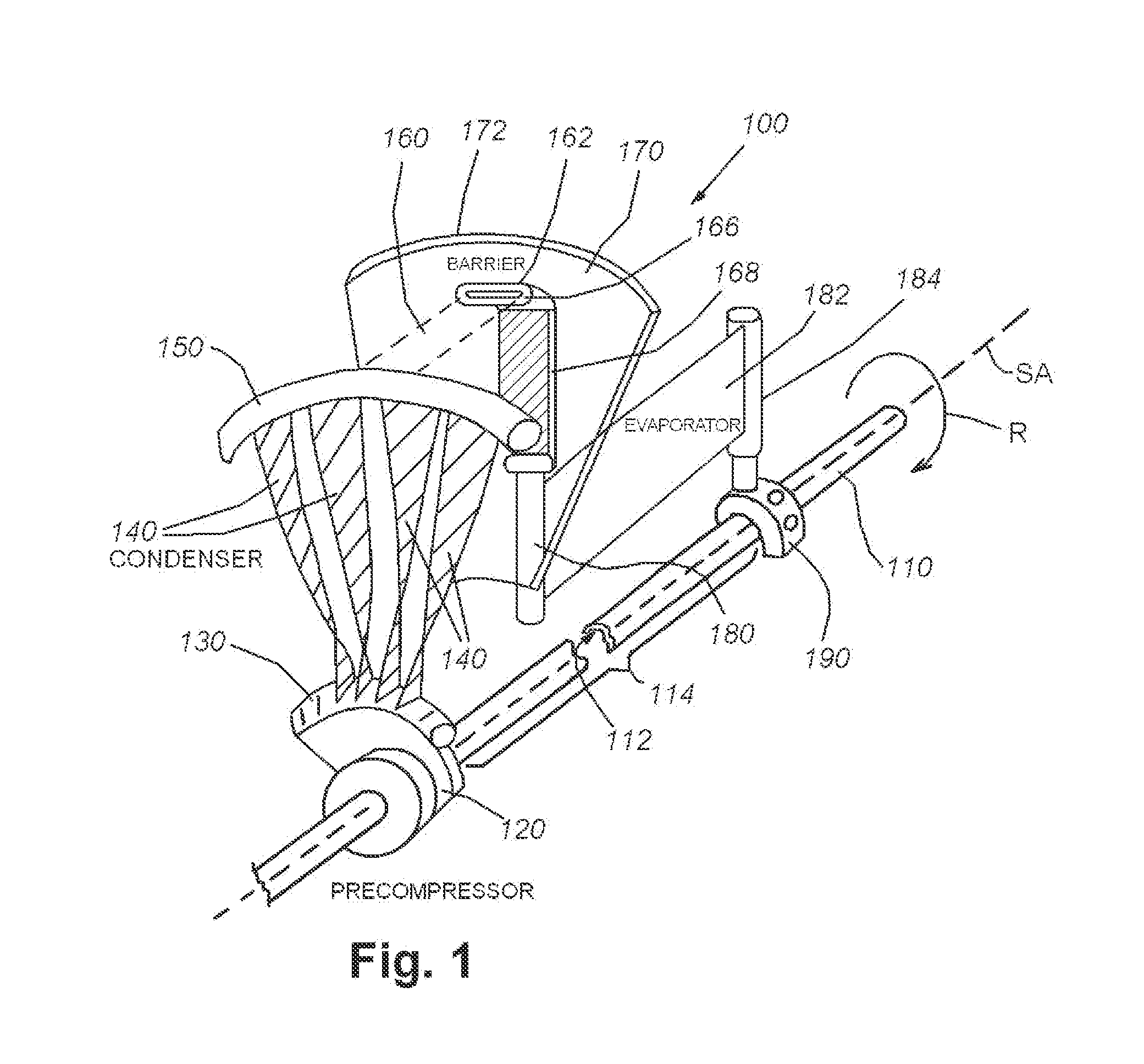

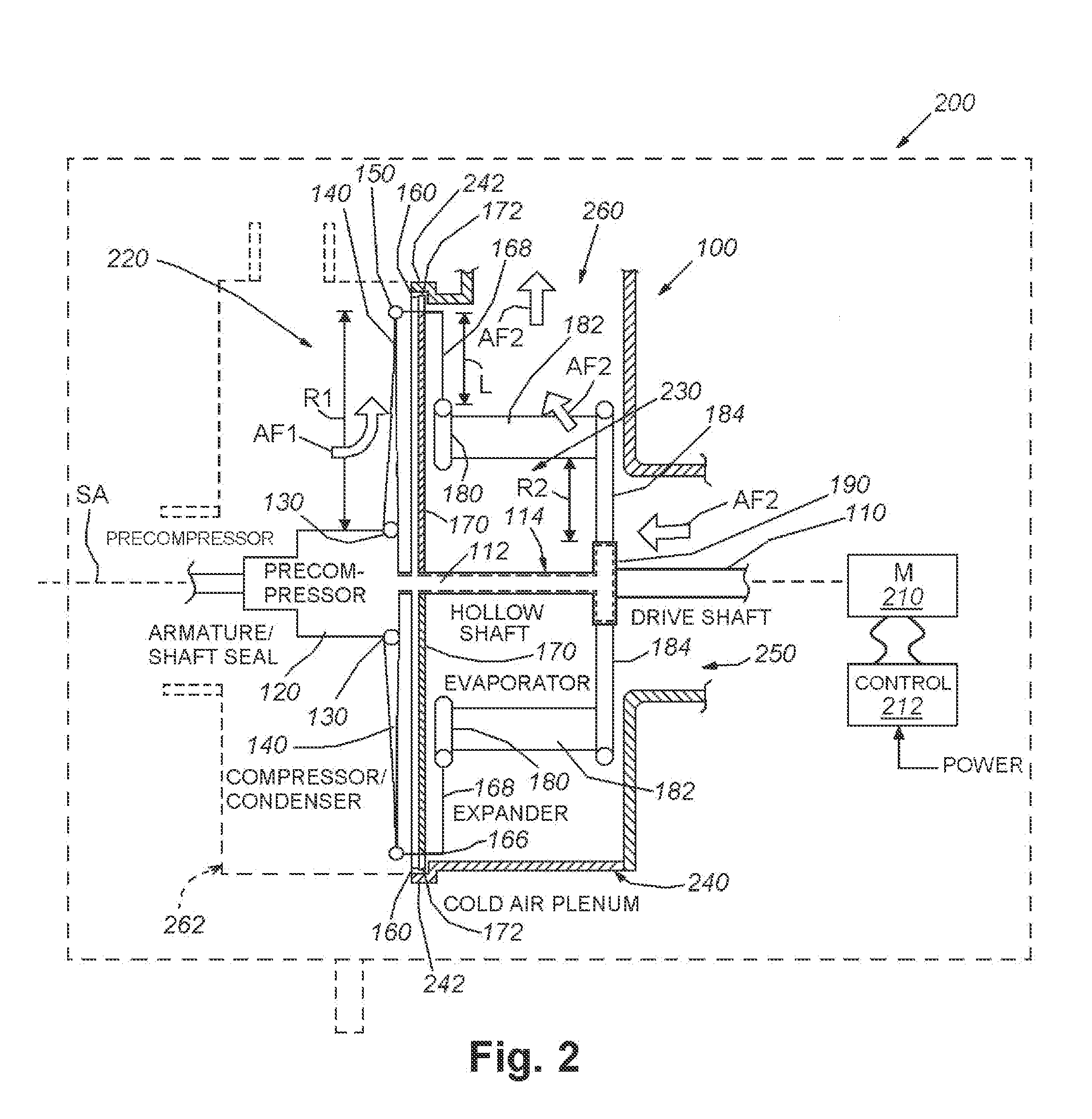

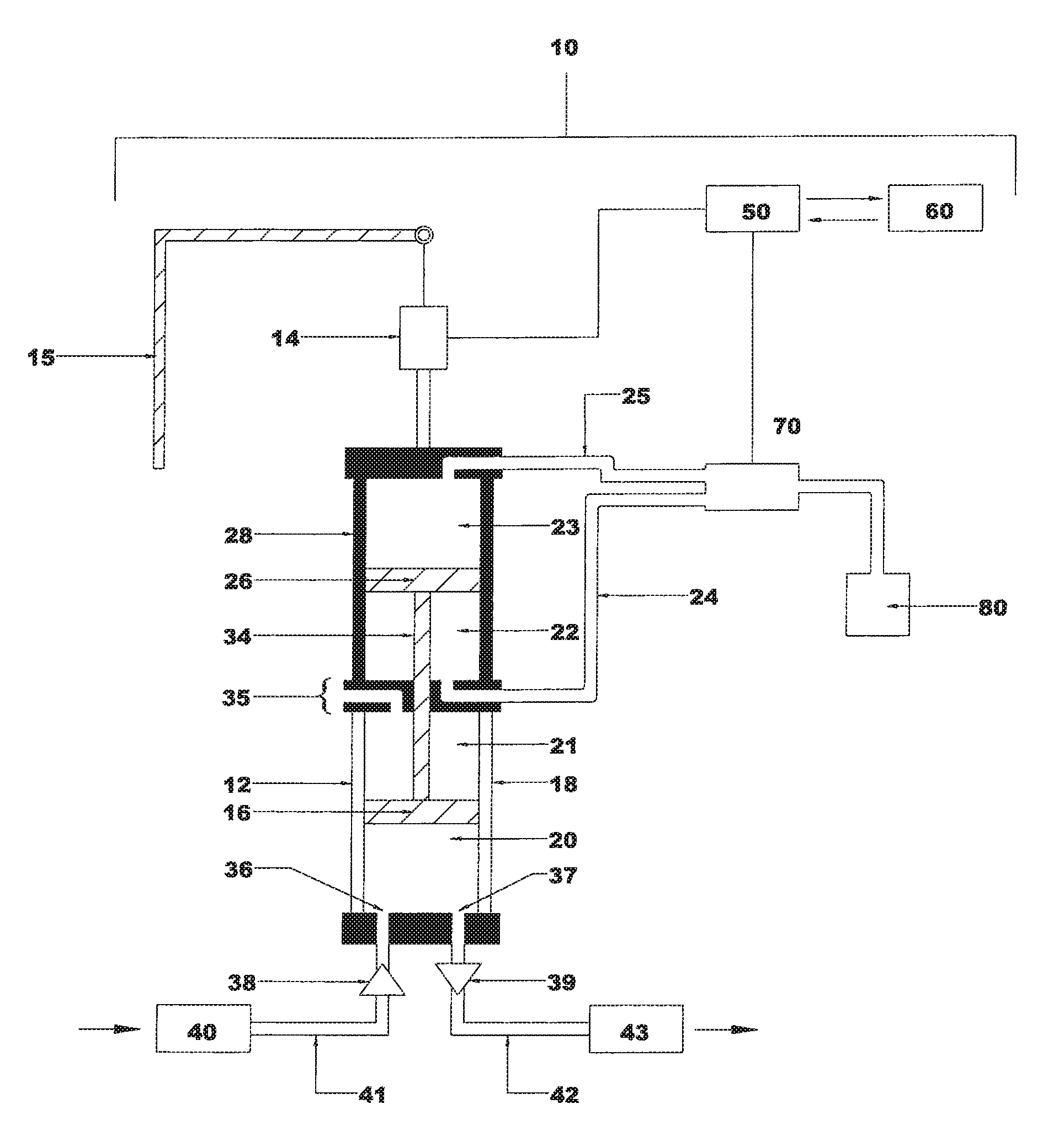

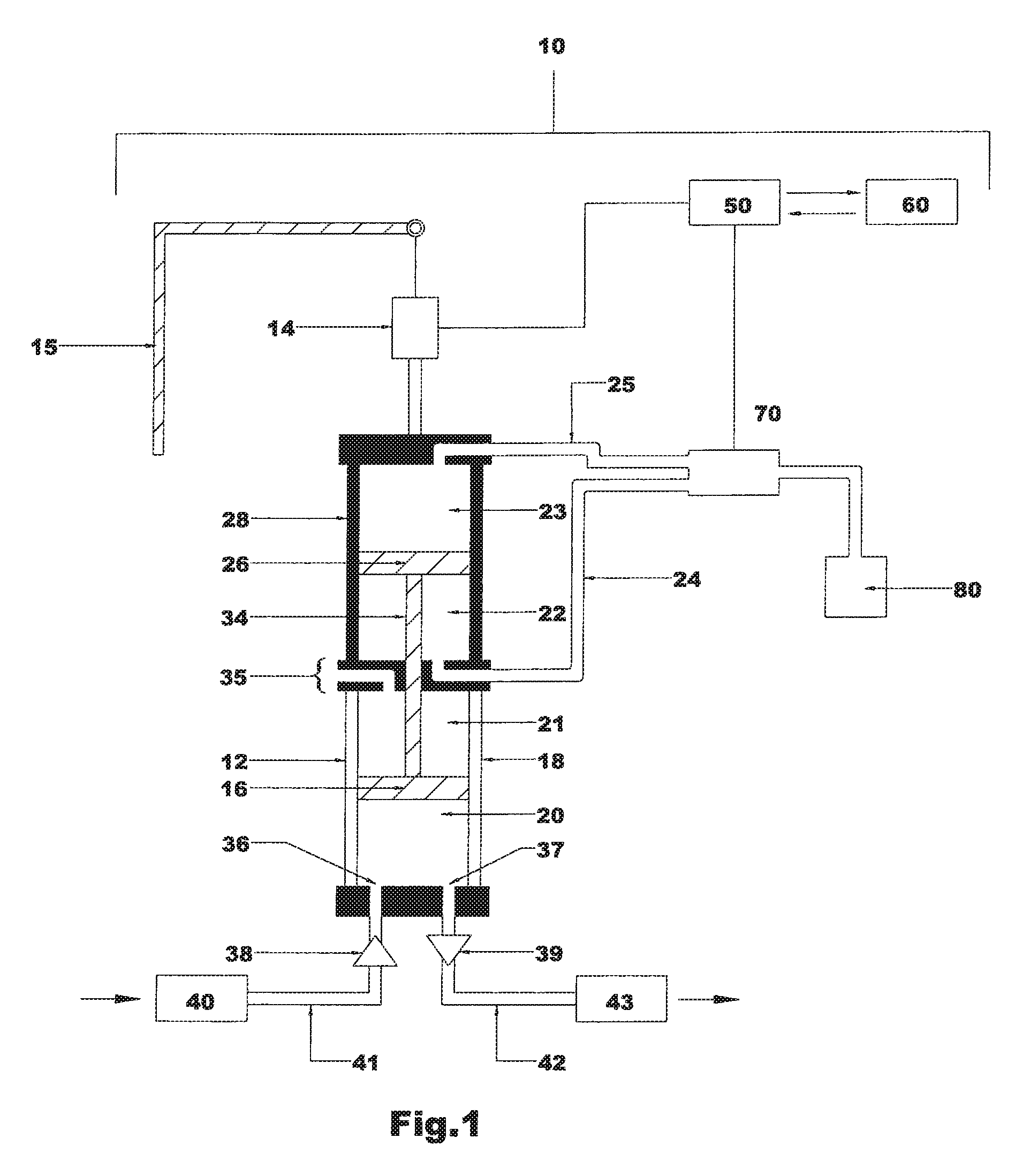

Isothermal-turbo-compressor-expander-condenser-evaporator device

InactiveUS20160138815A1Minimize air leakageSelf-contained rotary compression machinesCompression machines with non-reversible cycleEvaporationEngineering

This invention provides an isothermal turbo-compressor-expander-condenser-evaporator in a single integral arrangement that is suitable for a variety of compact arrangements, such as a window air-conditioner and / or automotive-based unit. This arrangement avoids the use of rotary fluid joints and maintains the entire fluid cycle, including compression, condensation, expansion and evaporation within a single rotating shaft-based structure, with the compressor / condenser section and the expansion / evaporator section separated from each other in separate spaces and / or plena by a rotating, insulated barrier disc and associated seal.

Owner:APPOLLO WIND TECH

Medium suction support device and medium conveying device

ActiveUS20110253763A1Satisfactory conveyingReliable holdWork holdersStands/trestlesEngineeringSupport surface

A medium suction support device includes a medium support table, a suction unit, a plurality of flexible tube members and a sliding member. Through-holes are formed in the medium support table to pass through the medium support table. The suction unit is disposed on a side of the back surface to suction the recording medium disposed on the medium support surface via the through-holes. One opening end of each of the flexible tube members surrounds a corresponding one of the through-holes on the back surface. The sliding member is configured to move in parallel along the back surface. The sliding member has openings formed in an opposing surface facing the back surface with each of the openings being configured to respectively accommodate the other opening end of a corresponding one of the flexible tube members. The openings have different lengths in a parallel movement direction of the sliding member.

Owner:SEIKO EPSON CORP

High-speed cooking oven with optimized cooking efficiency

InactiveUS8026463B2Increase flow rateAvoid enteringFood processingOhmic-resistance heatingMicrowaveSpray nozzle

The present invention is directed to improving the conventional high-speed cooking oven based on a combination of hot air impingement and microwave heating by providing a time-dependent spatial variation in the net air impingement and / or net microwave energy applied to the food product in the oven. This is aimed at optimizing heat transfer and microwave efficiencies in a high-speed cooking oven, thereby enabling the oven to deliver an optimal cooking efficiency in comparison to the conventional high-speed cooking oven. In addition, under the present invention, the cooking efficiency may be further optimized by dimensioning the nozzles for hot air impingement to tighten impingement plumes, subject to the space constraint of the oven's cooking chamber, and dimensioning the cooking chamber of the oven in integer multiples of the wavelength of the microwave energy to match the microwave load. With the optimized cooking efficiency provided by the present invention, the high speed cooking technology may now be extended to ovens operating on a power supply based on a voltage less than 220 volts, preferably between 110 and 125 volts, with more productive results, so that the high-speed cooking technology may find a wider applicability and customer base.

Owner:APPLIANCE SCI

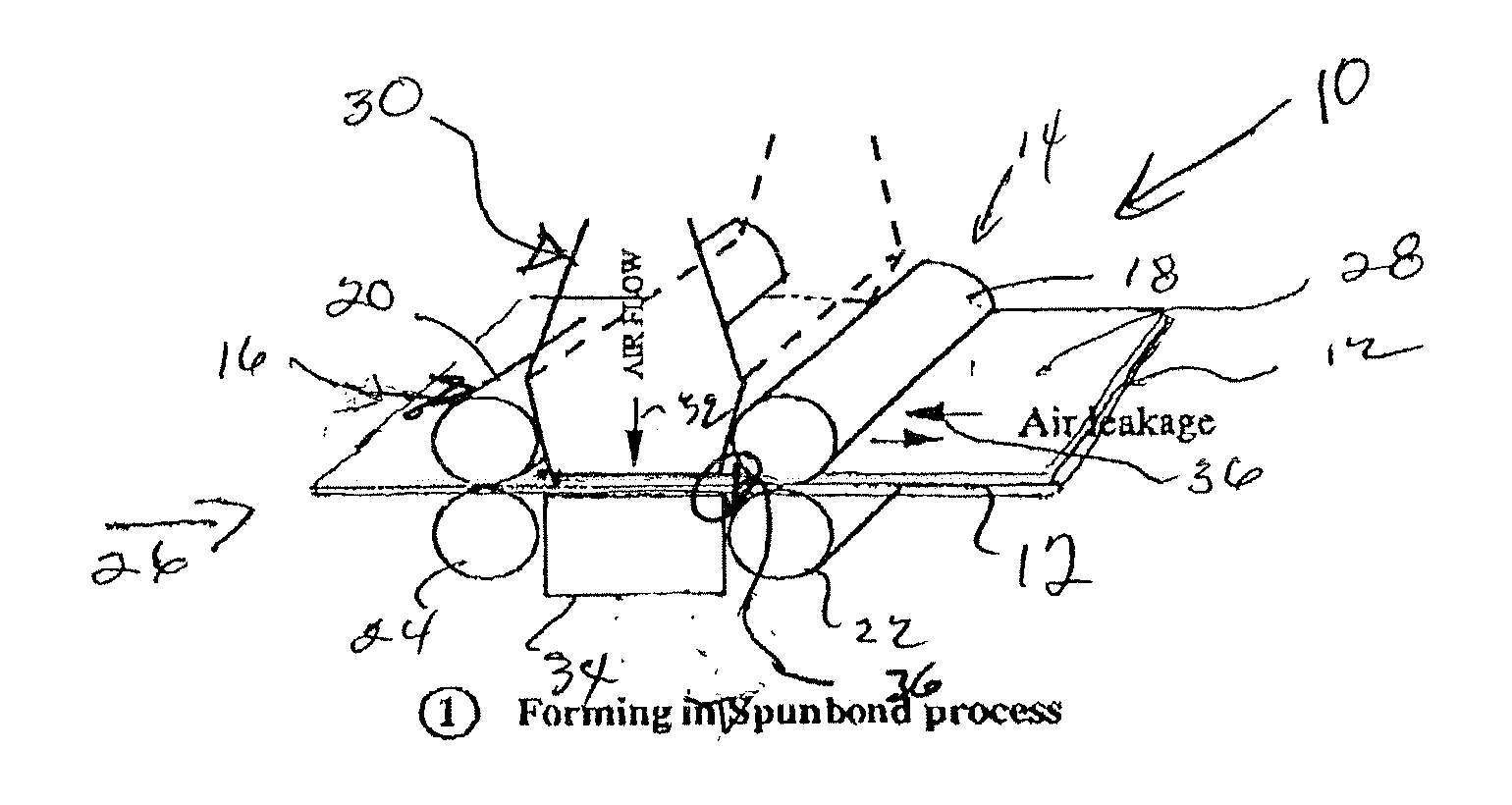

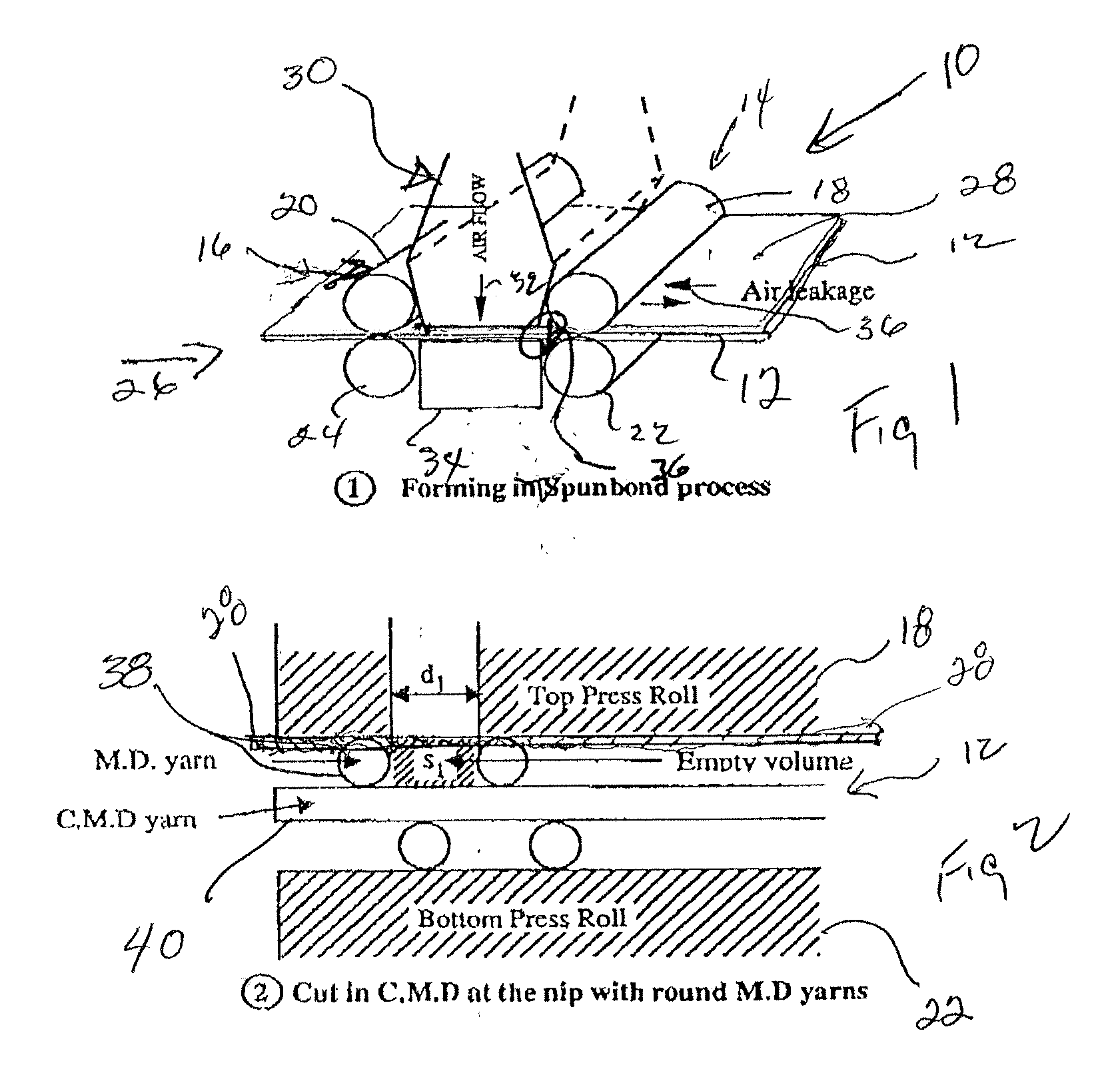

Fabric Comprising Shaped Conductive Monofilament Used in the Production of Non-Woven Fabrics

InactiveUS20110121481A1Minimize air leakageMinimizes and eliminates web flutterLiquid surface applicatorsCeramic shaping apparatusYarnBonding process

In an apparatus for the production of a non-woven web, structure, or article using a spun-bonding process in combination with a forming fabric which is woven having flat CMD yarns, flat MD yarns or both with some or all of such yarns being conductive so as to dissipate static electricity.

Owner:MONNERIE JEAN LOUIS +1

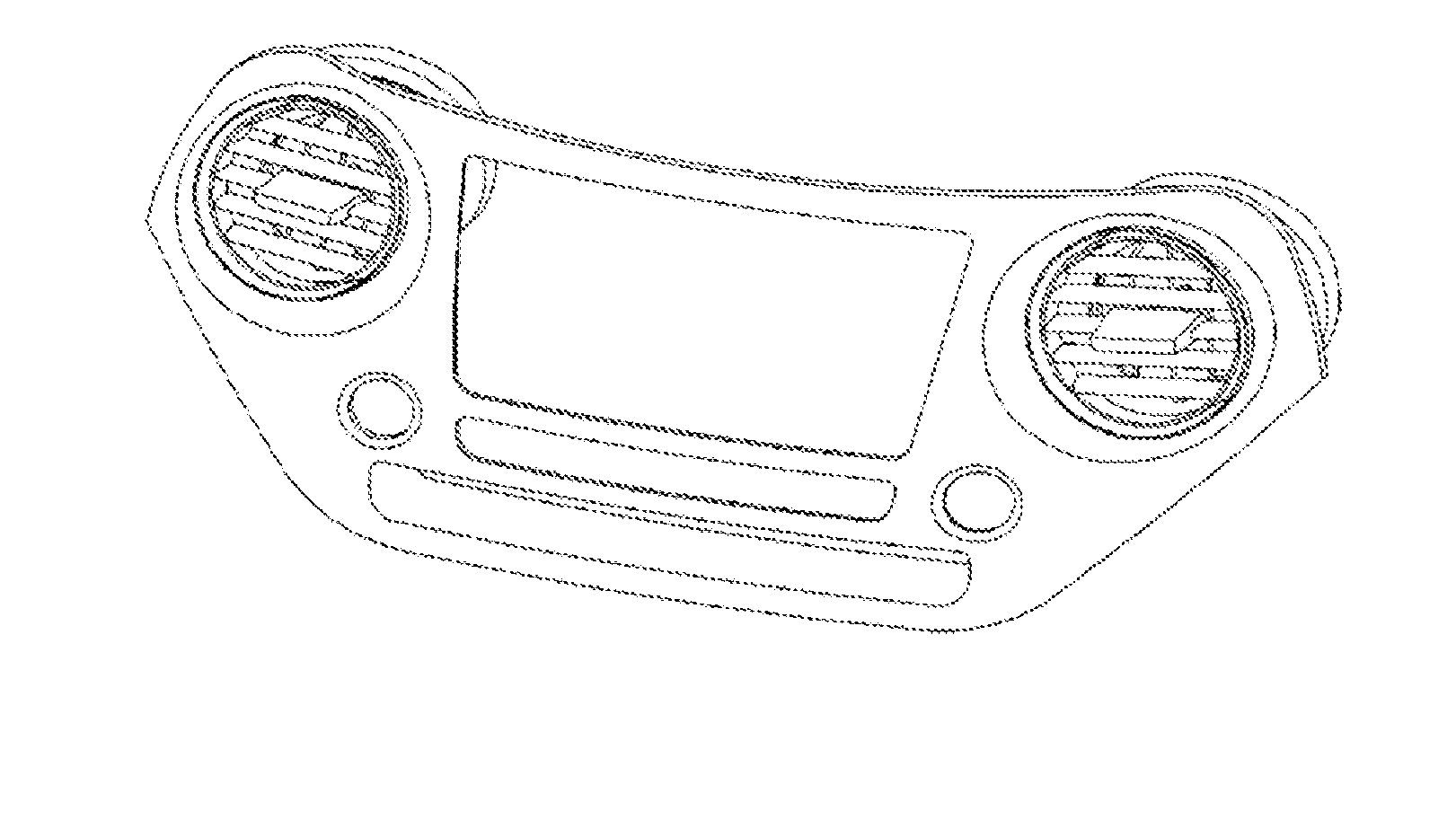

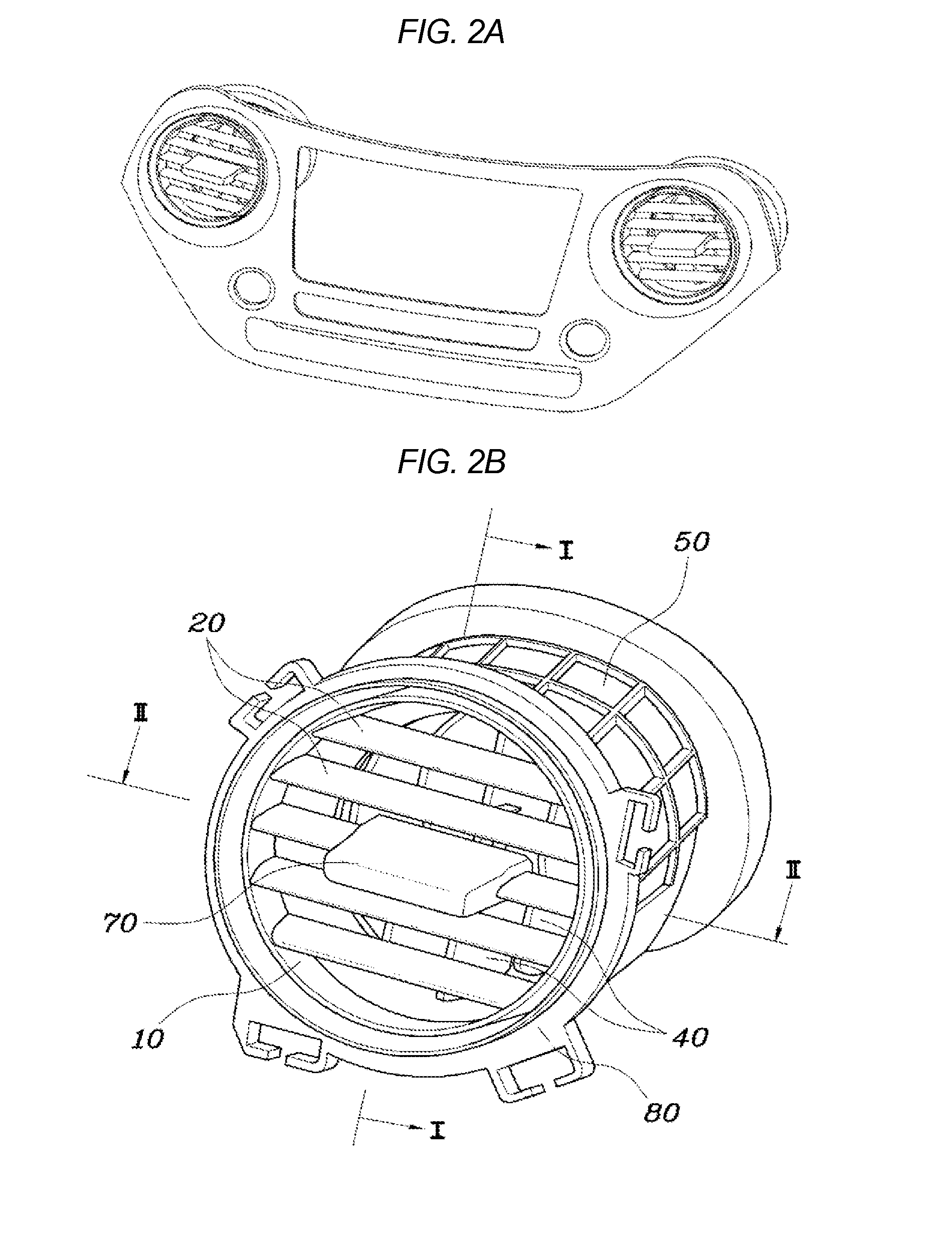

Air vent apparatus for vehicle

InactiveUS20150183300A1Reduce the number of partsLow costAir-treating devicesVehicle heating/cooling devicesNozzle

An air vent apparatus for a vehicle may include an outer wing integrated with a wing nozzle, a plurality of inner wings coupled to each other via a wing link, a spacer to which the wing nozzle may be fixedly coupled, the inner wings being rotatably coupled to the spacer, the spacer being rotatably coupled to the duct, and a knob coupled to the inner wings while being fitted to the outer wing, thus rotating the inner wings relative to the spacer.

Owner:HYUNDAI MOTOR CO LTD +1

Double-action fluid weighing and dispensing process and system

ActiveUS7963422B2Easy to measureMinimize air leakagePower operated devicesLarge containersEngineeringLoad cell

Apparatus and process for dispensing fluids, such as chemical concrete admixtures, using an air-operated pump and load cell for supporting and measuring at least substantially 100% of the weight of the pump and fluid dispensed through the pump. A double-action, dual piston design of the air-operated pump allows positive air pressure to be used during both fluid-filling and fluid-expelling phases.

Owner:GCP APPL TECH INC

Medium suction support device and medium conveying device

ActiveUS8505890B2Minimizes suctionMinimize air leakageWork holdersStands/trestlesSupport surfaceRecording media

A medium suction support device includes a medium support table, a suction unit, a plurality of flexible tube members and a sliding member. Through-holes are formed in the medium support table to pass through the medium support table. The suction unit is disposed on a side of the back surface to suction the recording medium disposed on the medium support surface via the through-holes. One opening end of each of the flexible tube members surrounds a corresponding one of the through-holes on the back surface. The sliding member is configured to move in parallel along the back surface. The sliding member has openings formed in an opposing surface facing the back surface with each of the openings being configured to respectively accommodate the other opening end of a corresponding one of the flexible tube members. The openings have different lengths in a parallel movement direction of the sliding member.

Owner:SEIKO EPSON CORP

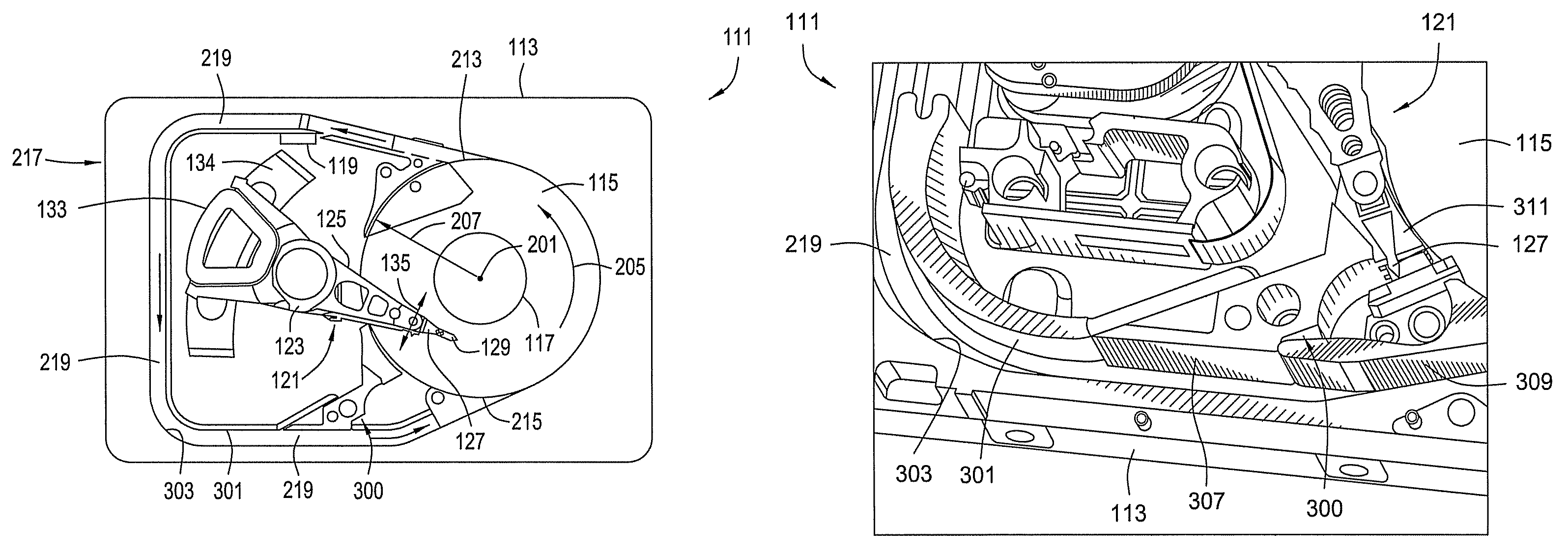

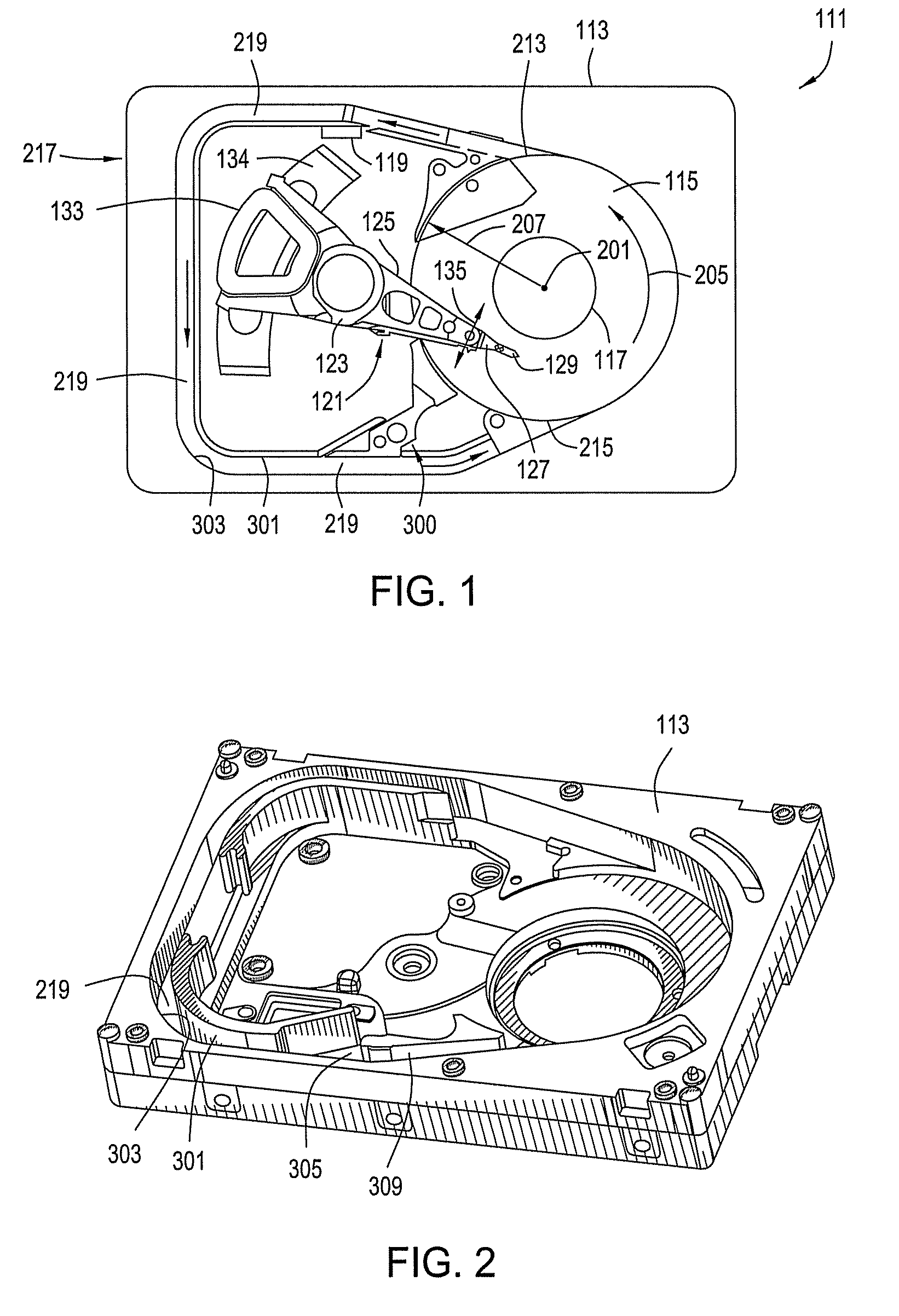

System, method, and apparatus for slit shroud with integrated bypass channel wall feature for disk drive applications

InactiveUS7898764B2Reduce discontinuityIncrease the areaUndesired vibrations/sounds insulation/absorptionRecord information storageEngineeringGuide tube

Owner:WESTERN DIGITAL TECH INC

High-speed cooking oven with optimized cooking efficiency

InactiveUS20090095739A1Increase flow rateAvoid enteringDomestic stoves or rangesLighting and heating apparatusProcess engineeringVoltage

An improved oven is aimed at optimizing heat transfer and delivering an optimal cooking efficiency in comparison to conventional high-speed cooking ovens. The oven includes tubes that generate plume arrays of a heated gas and introduce them into a cooking chamber of the oven. The tubes may be removably located at the bottom of the cooking chamber of the oven. The tubes are dimensioned for hot air impingement to tighten impingement plume arrays, subject to the space constraints of the oven's cooking chamber. With the optimized cooking efficiency provided by the present invention, high-speed cooking technology may now be extended to ovens operating on a power supply based on a voltage less than 220 volts, preferably between 110 and 125 volts, with more productive results, so that the high-speed cooking technology may find wider applicability and a broader customer base.

Owner:APPLIANCE SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com