Patents

Literature

122results about How to "Stable thrust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Input device

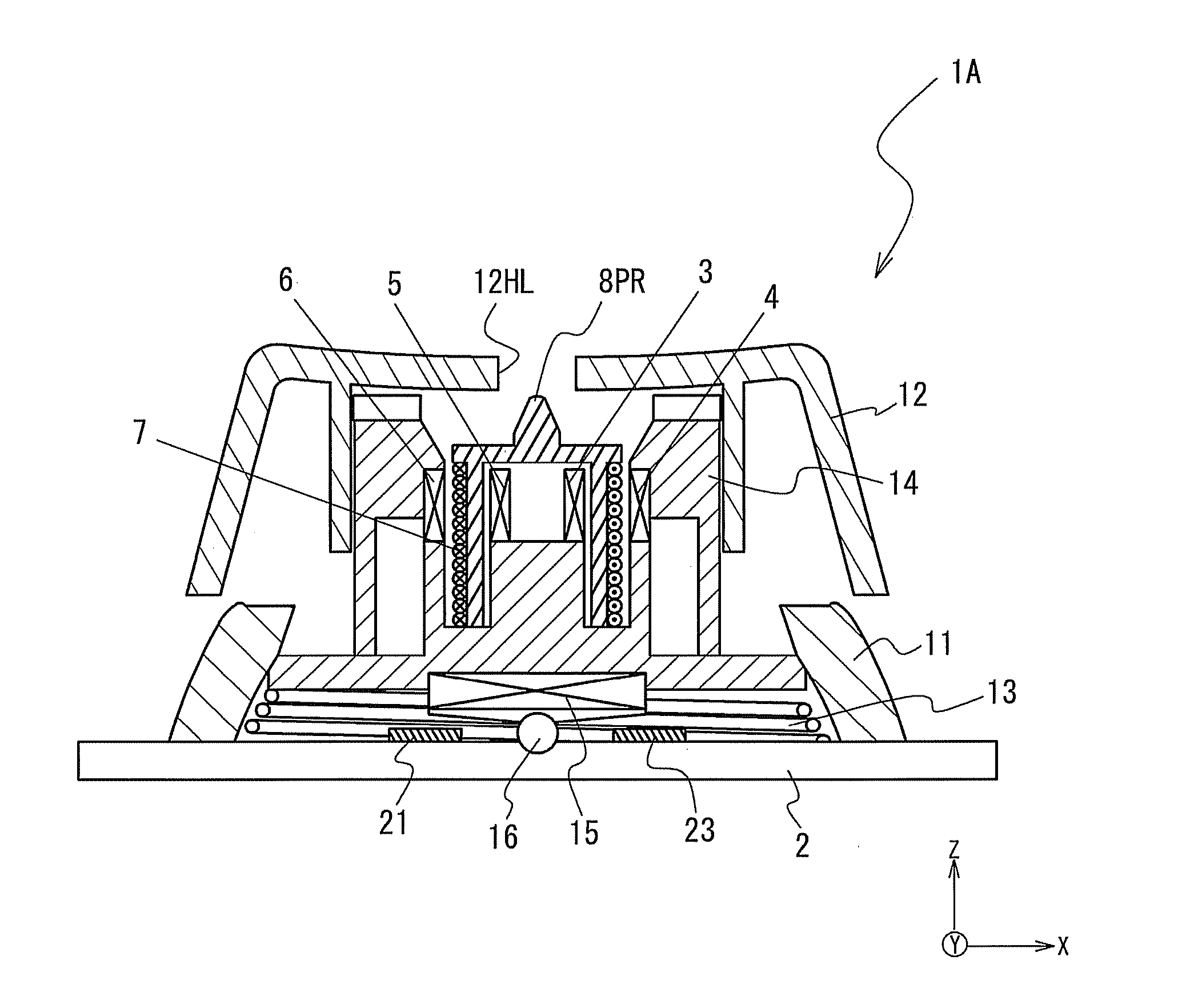

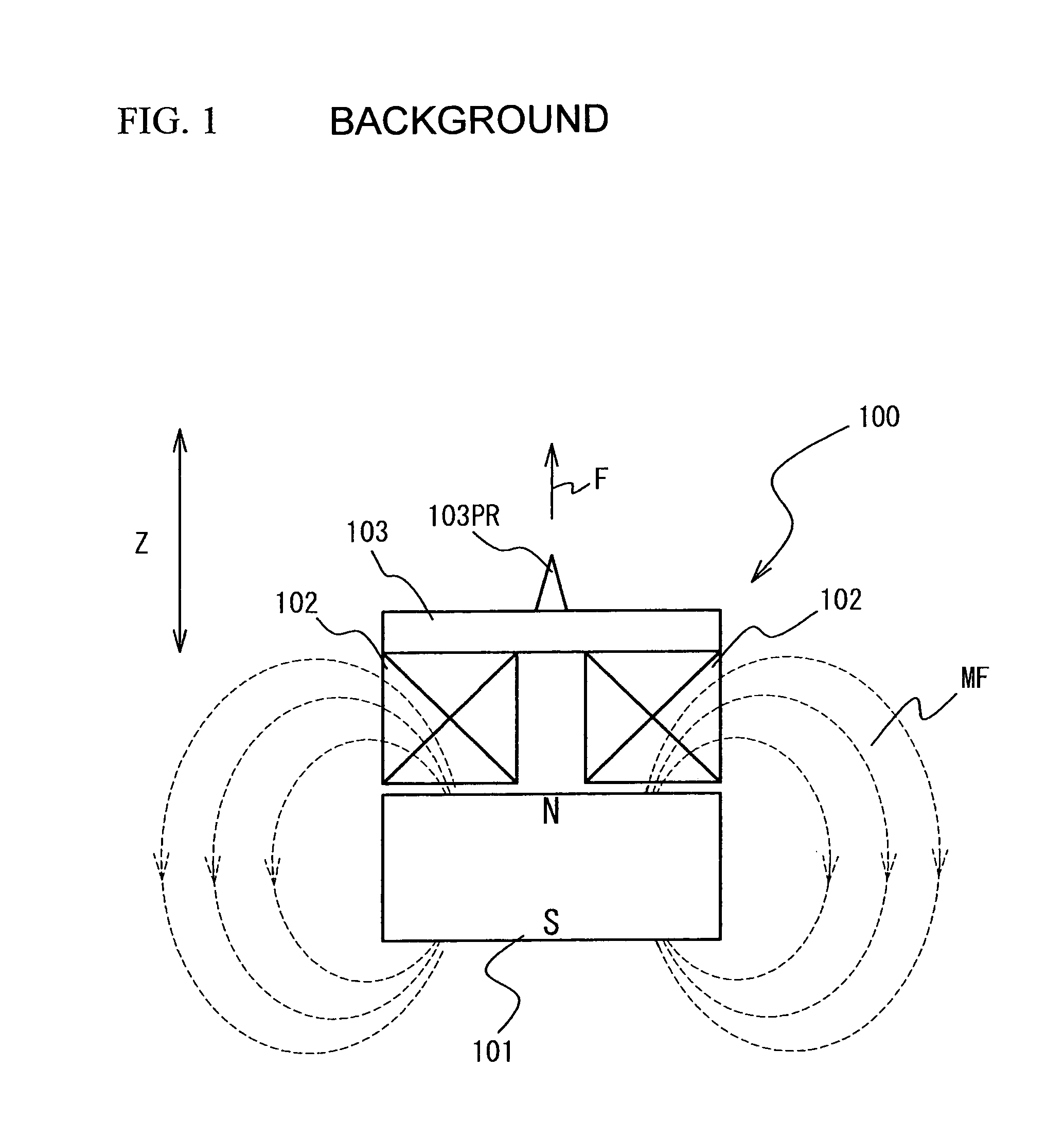

InactiveUS8681092B2Stable thrustCathode-ray tube indicatorsElectric switchesEngineeringMagnetic field

An input device including an operation portion to be operated by an external force, a signal generating portion that generates a signal according to a movement of the operation portion, and a tactile sense stimulus mechanism that applies a tactile sense stimulus to an object that applies the external force is provided. The tactile sense stimulus mechanism includes magnetic field generating portions, and a tactile sense stimulus member that is secured to a magnetic field generating portion.

Owner:FUJITSU COMPONENENT LTD

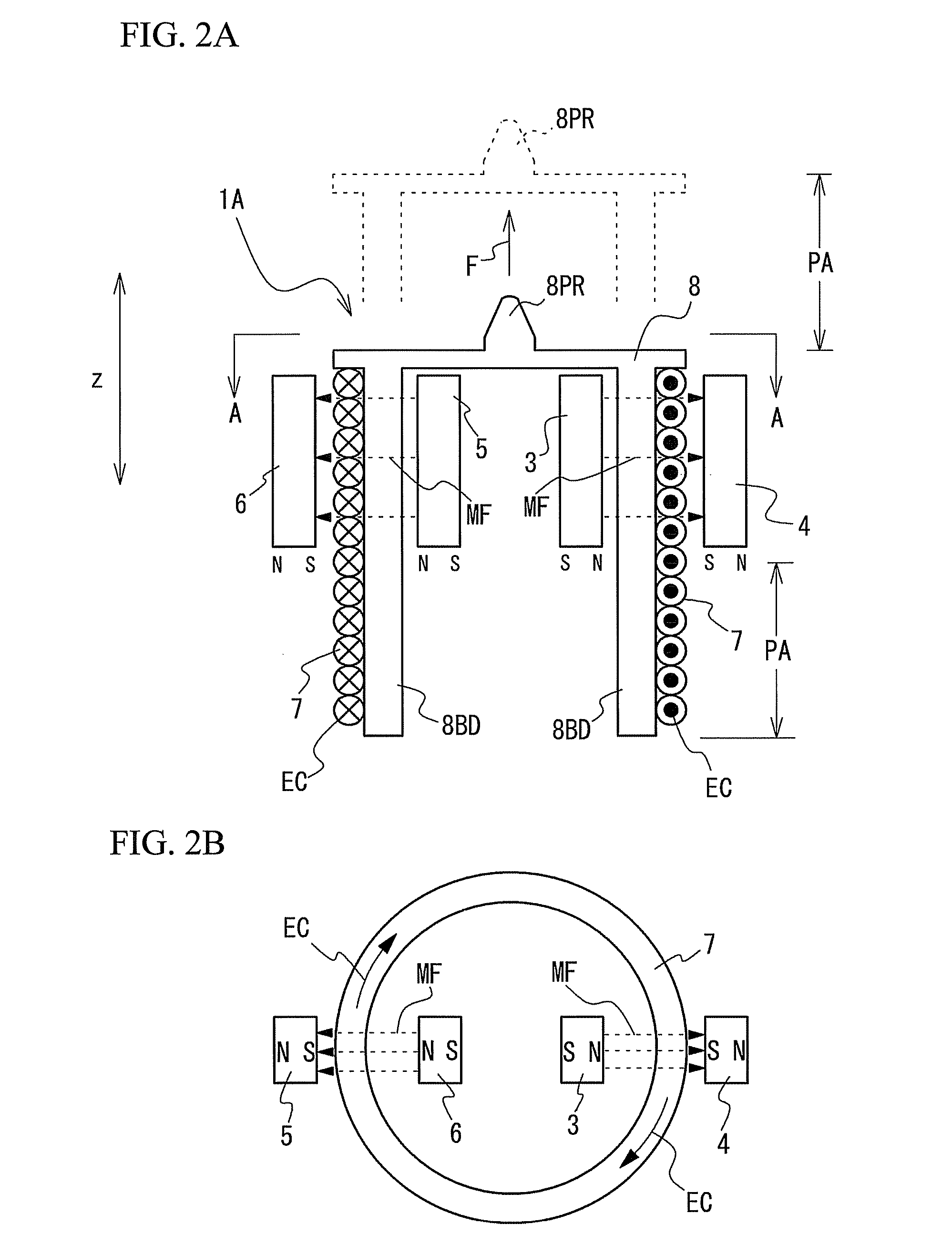

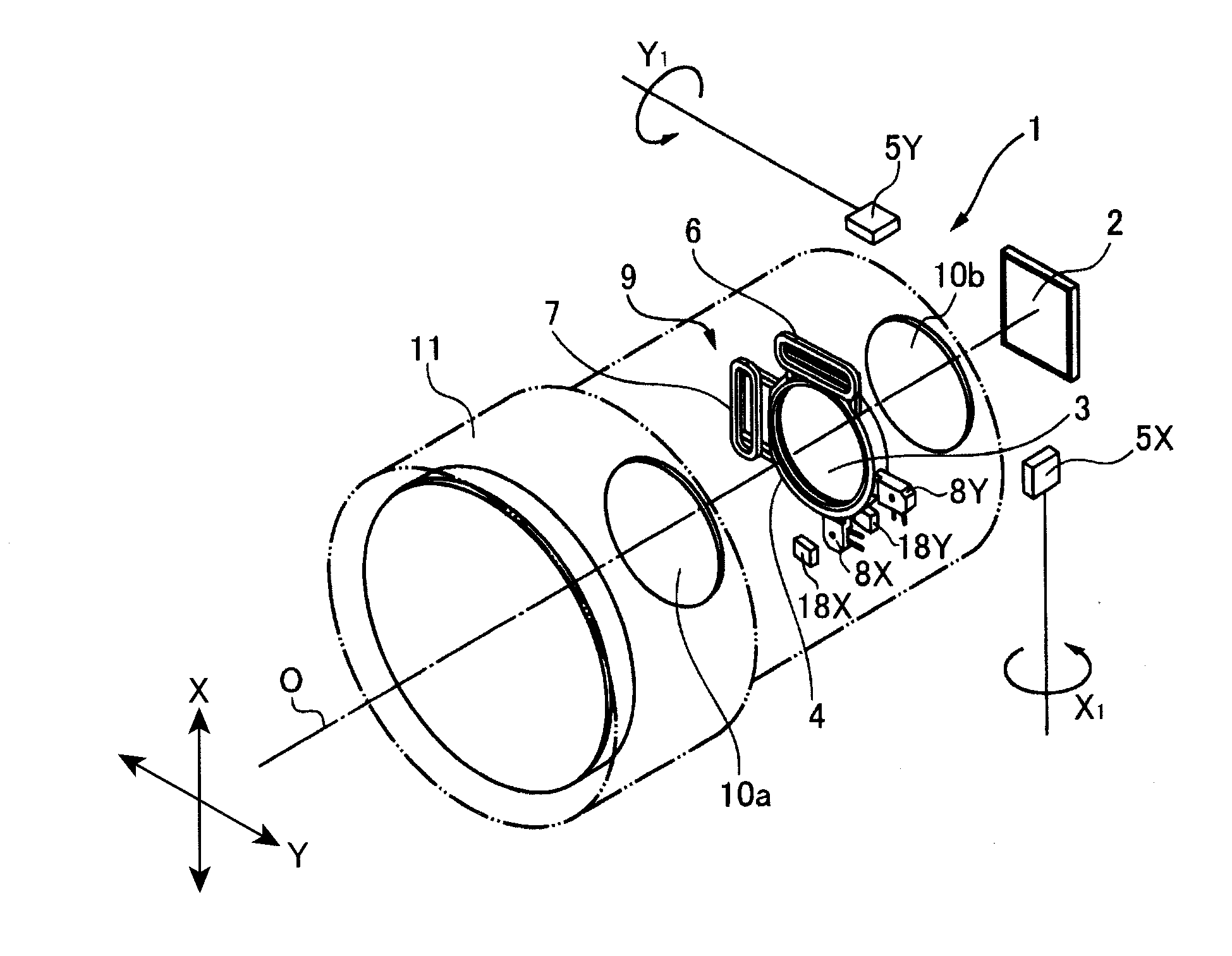

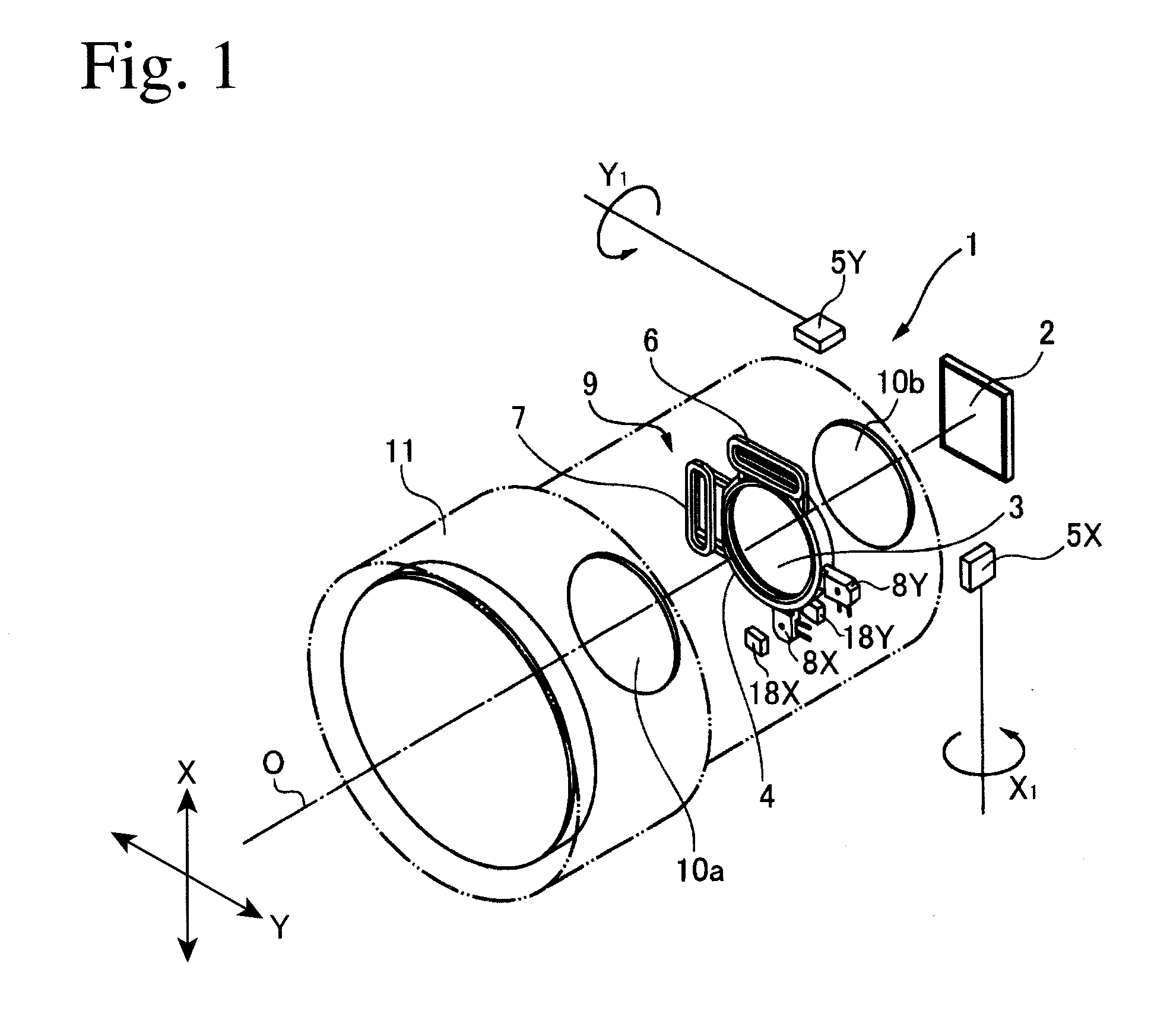

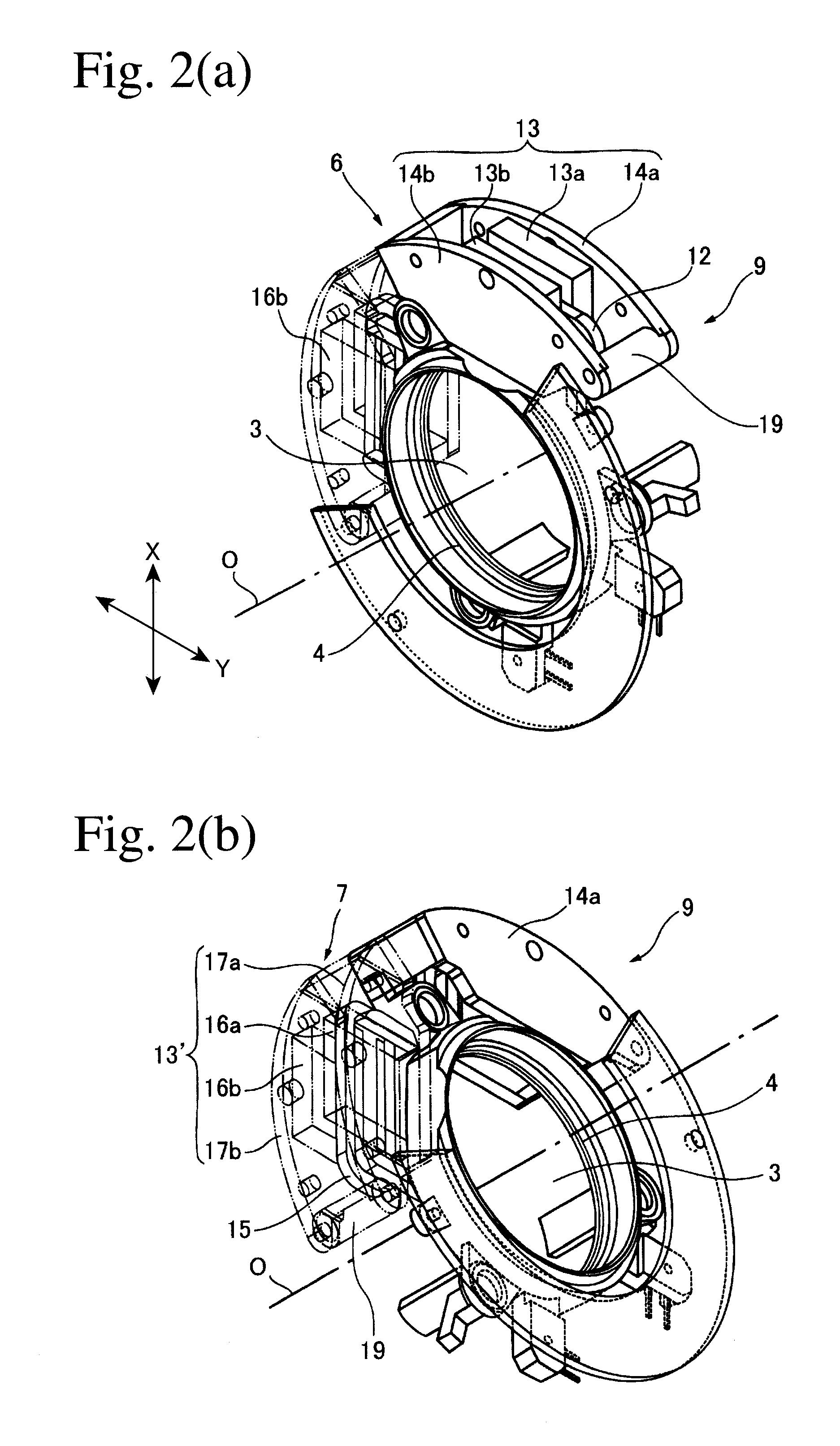

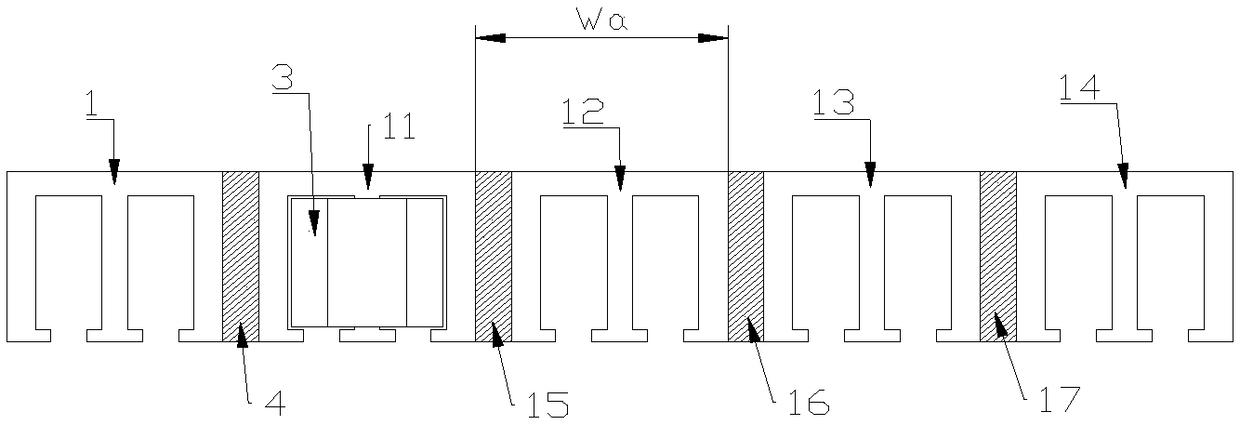

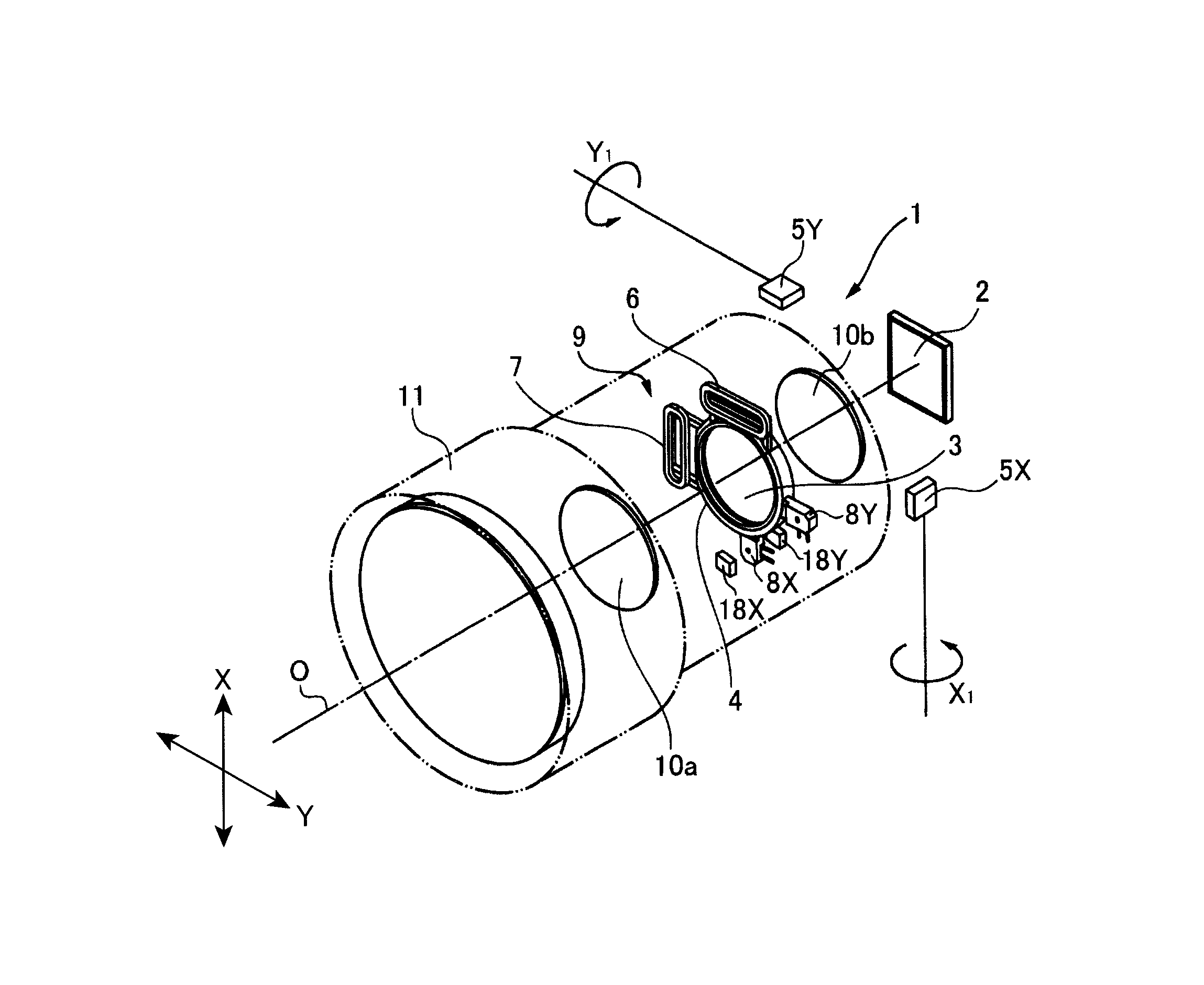

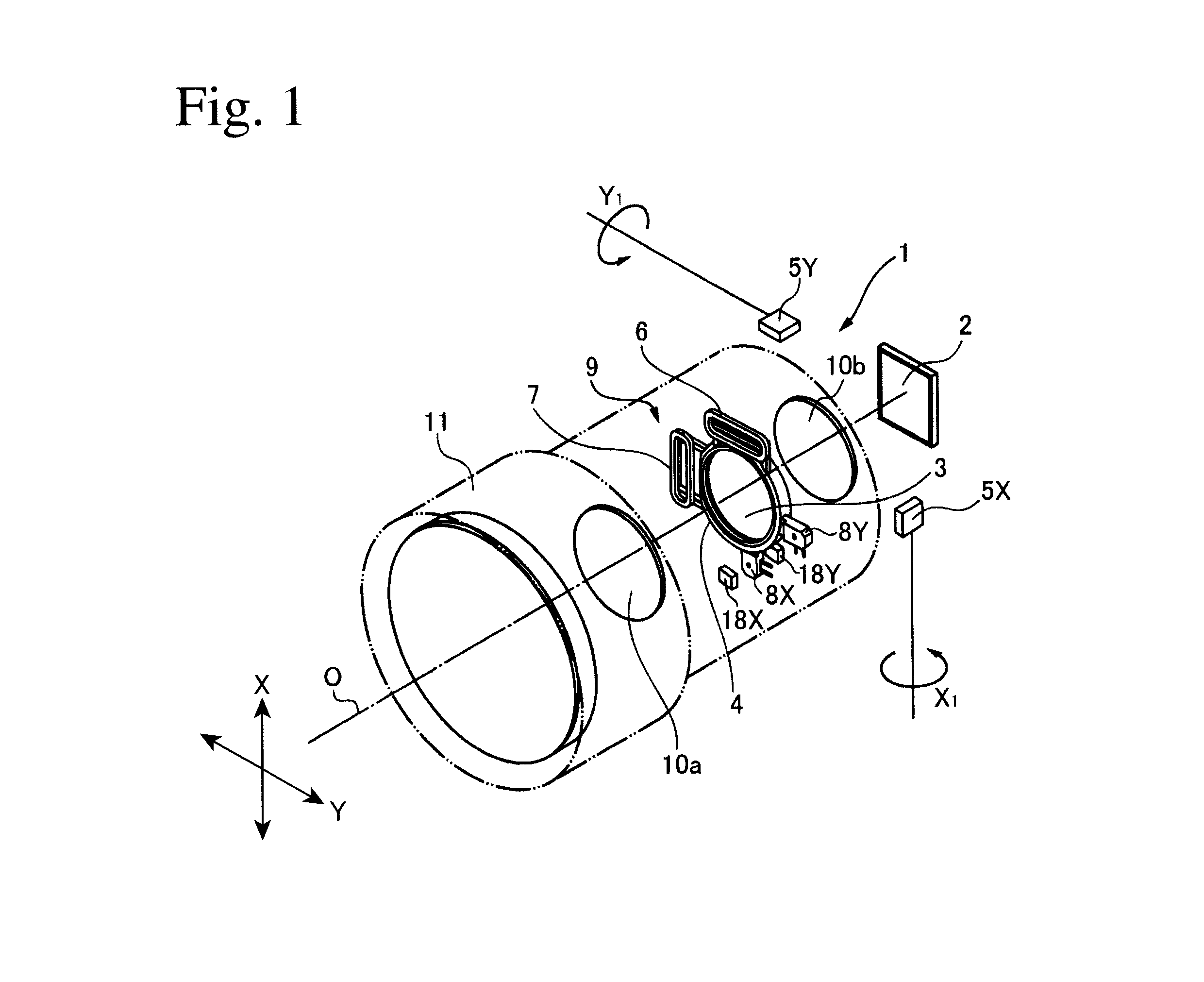

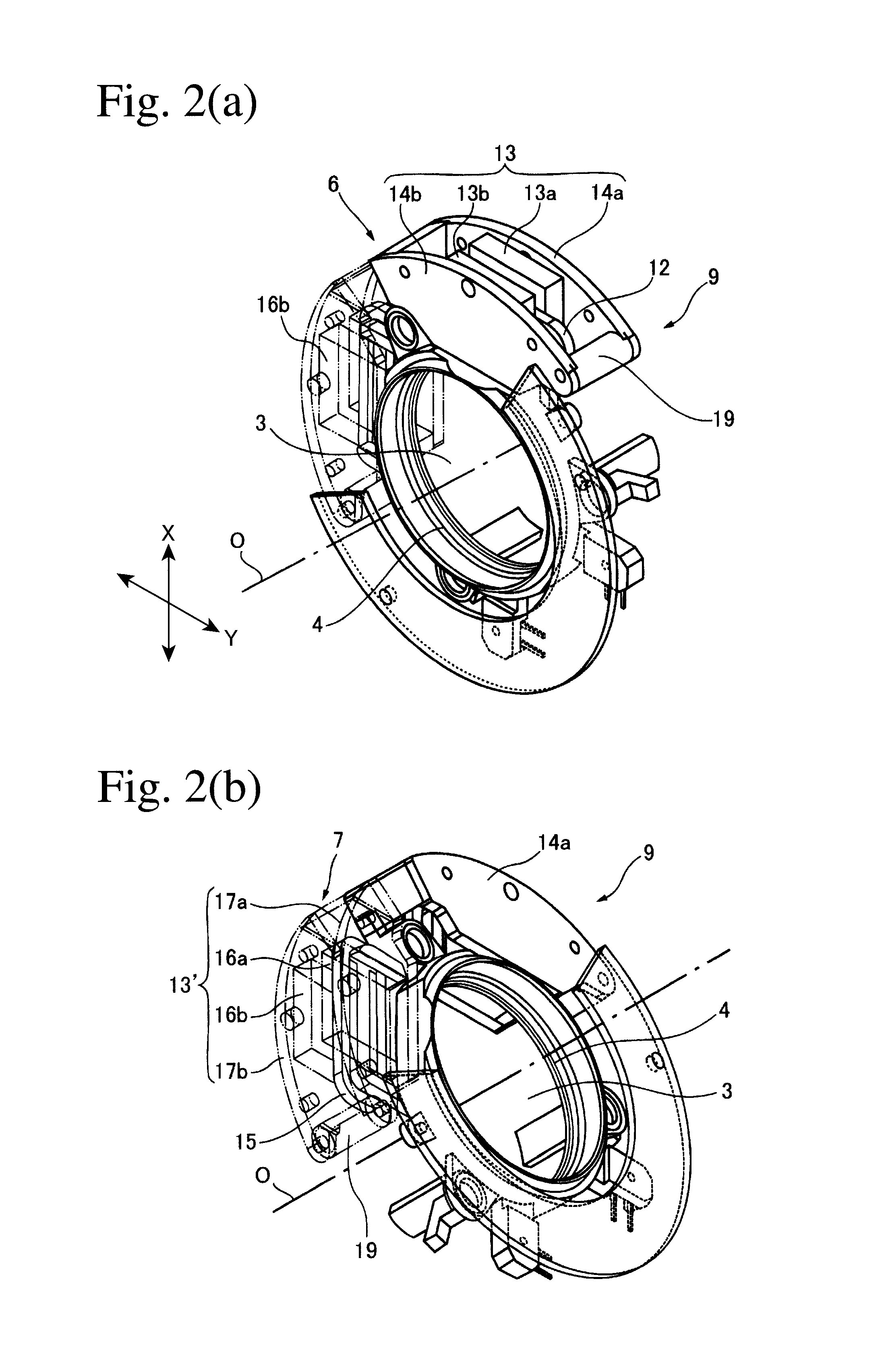

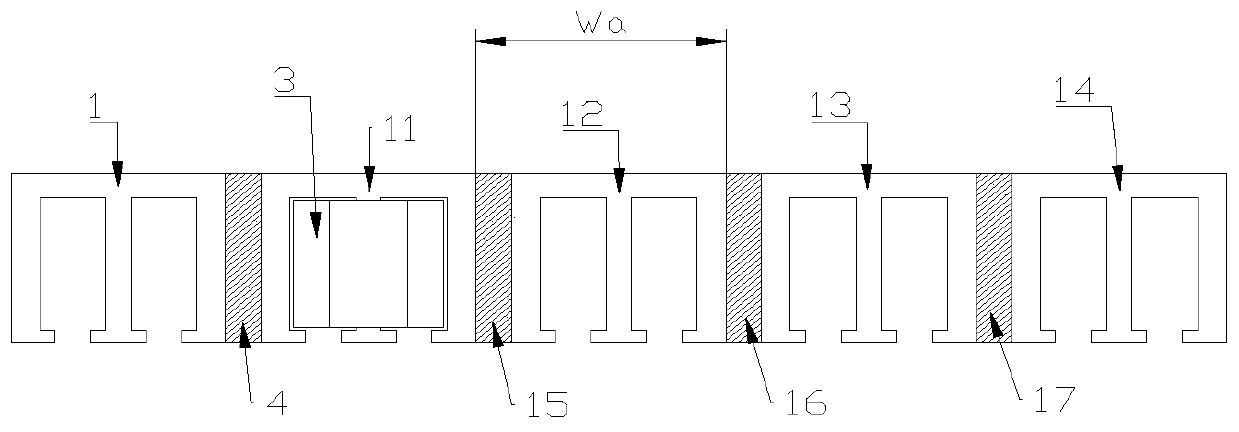

Correction-lens-moving voice coil motor, Anti-vibration device, interchangeable lens unit and optical apparatus

InactiveUS20110279899A1Reduce power consumptionStable thrustTelevision system detailsPrintersLinear motionElectrical conductor

A voice coil motor for moving a correction lens comprising a magnet unit comprising a pair of yokes and at least one permanent magnet for defining a magnetic gap, and a coil disposed in the magnetic gap, to cause the relative linear movement of the magnet unit and the coil by current supplied to the coil; the permanent magnet having different magnetic poles adjacent to each other along the movement direction on a surface opposing the magnetic gap; the width of the permanent magnet in the movement direction being two times the width Wm of the magnetic poles; the width Wa of the coil in the movement direction being smaller than the width 2Wm of the permanent magnet; and the effective conductor width Wb of the coil, the magnetic pole width Wm of the permanent magnet and the longest movement distance St of the correction lens meeting the conditions of Wm=(Wb+St)×K, wherein K is a constant meeting 1<K≦1.5.

Owner:KENKOTOKINA CORP

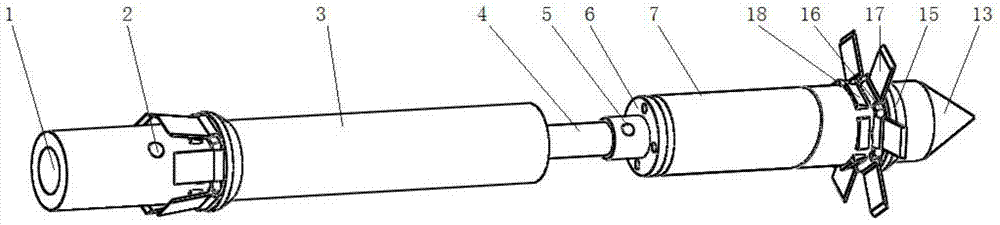

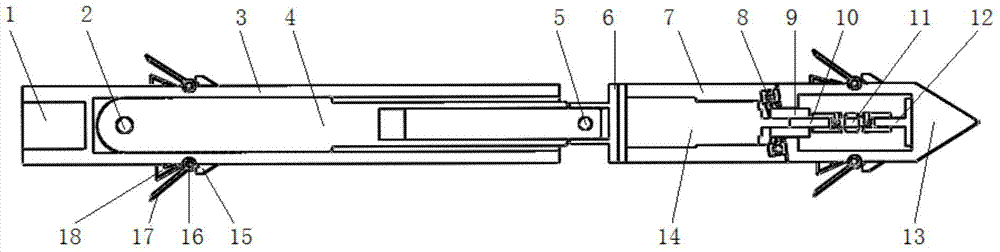

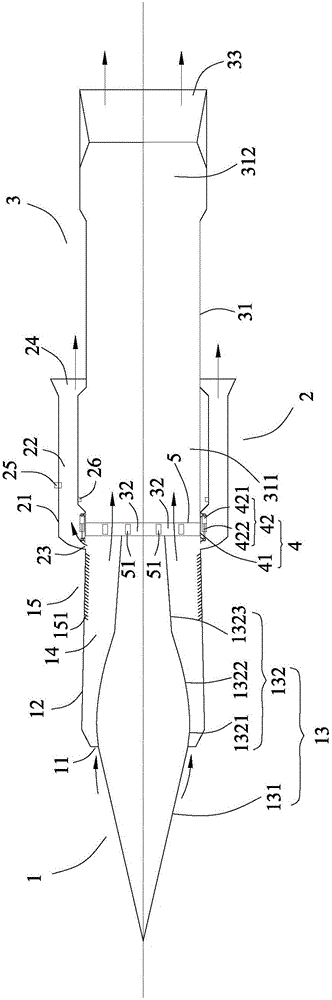

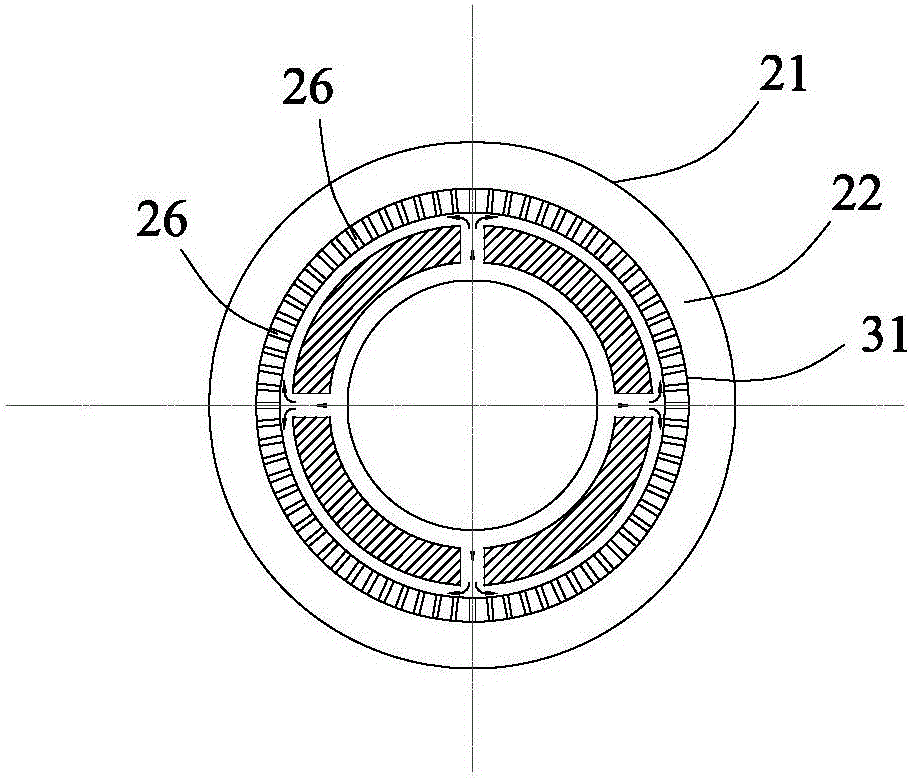

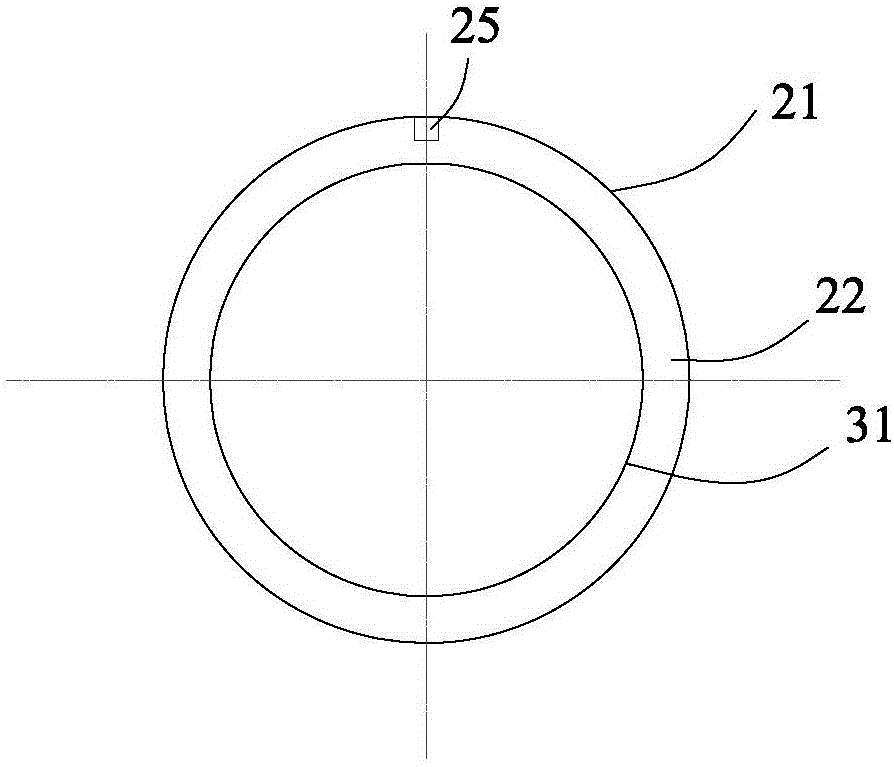

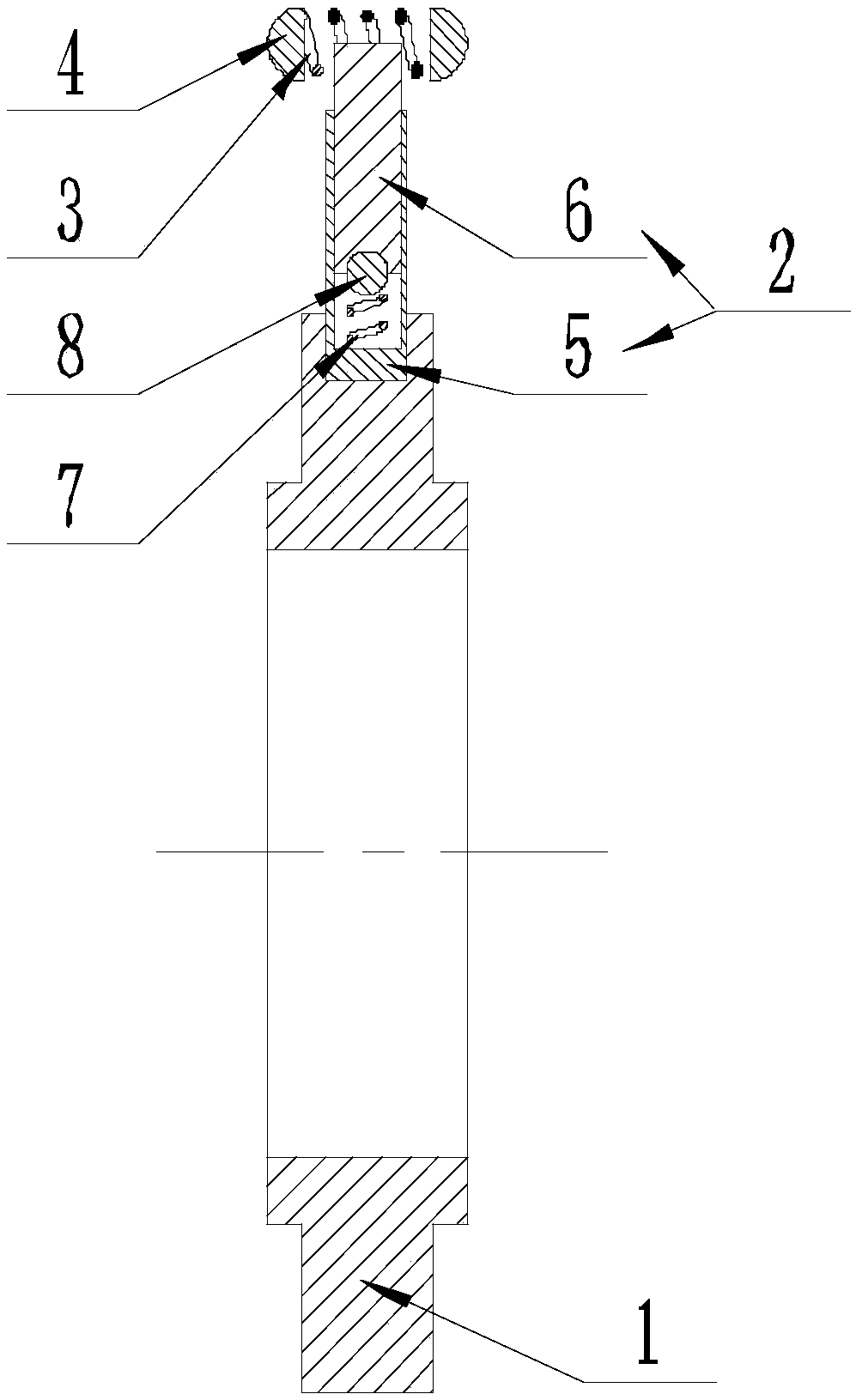

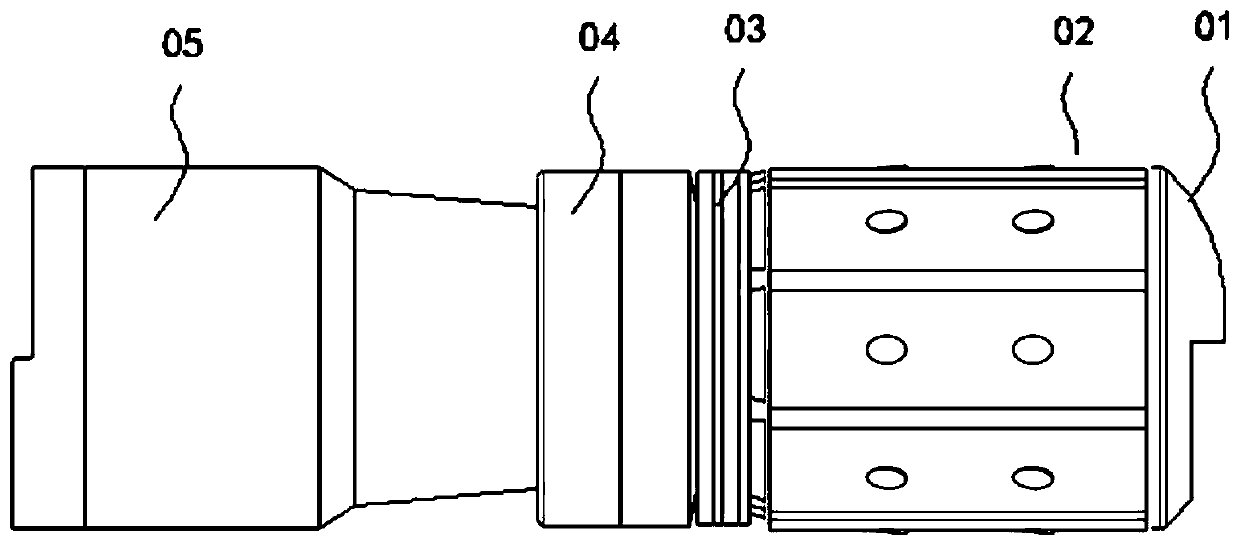

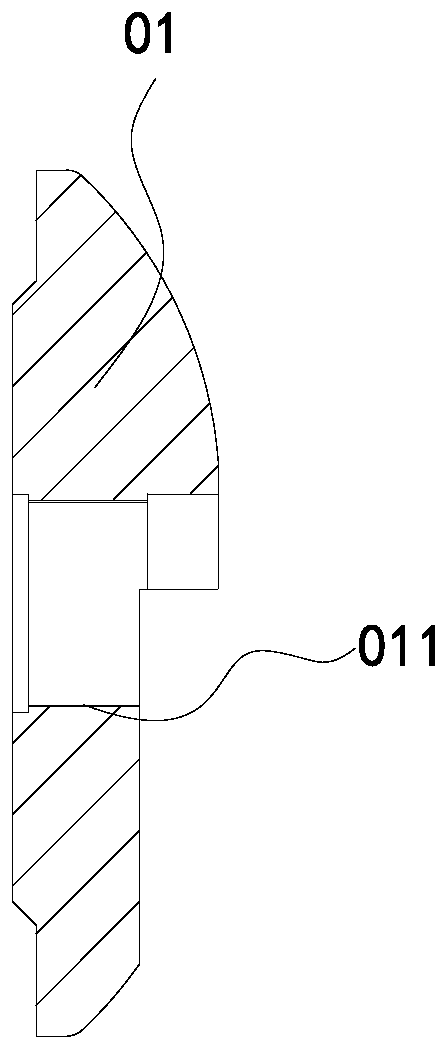

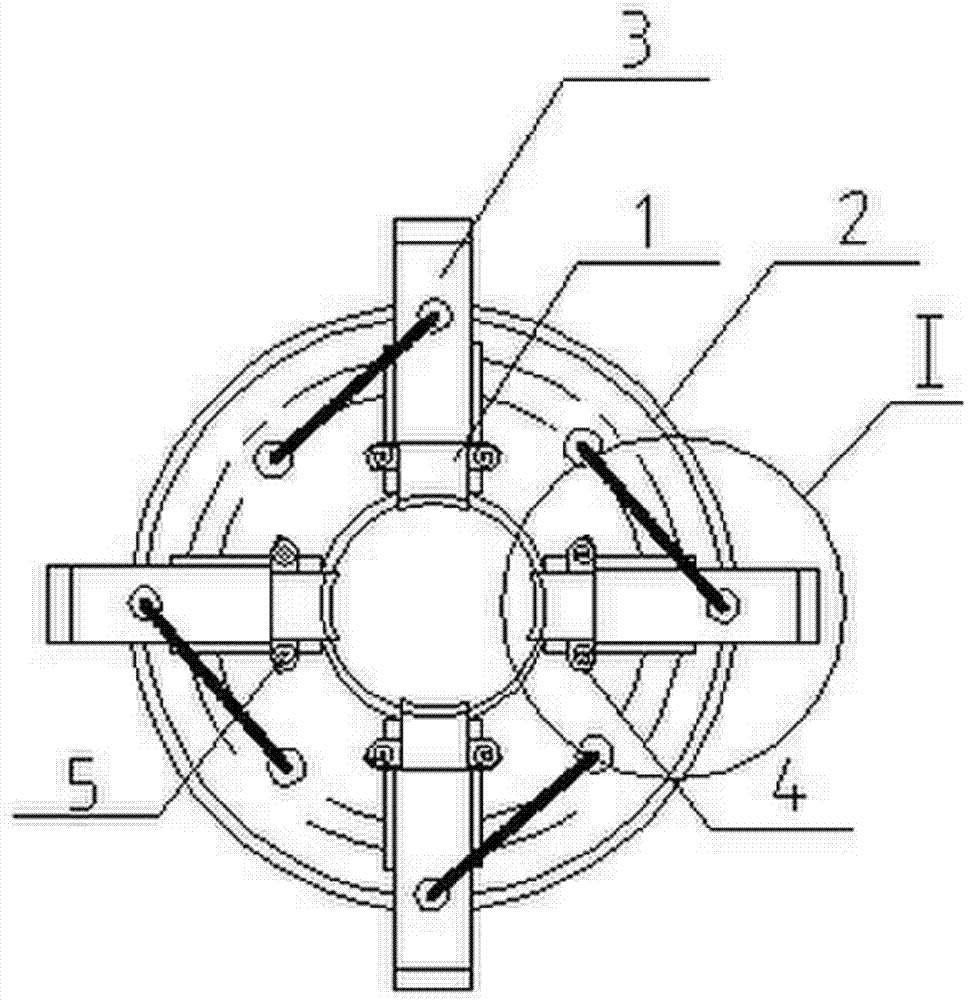

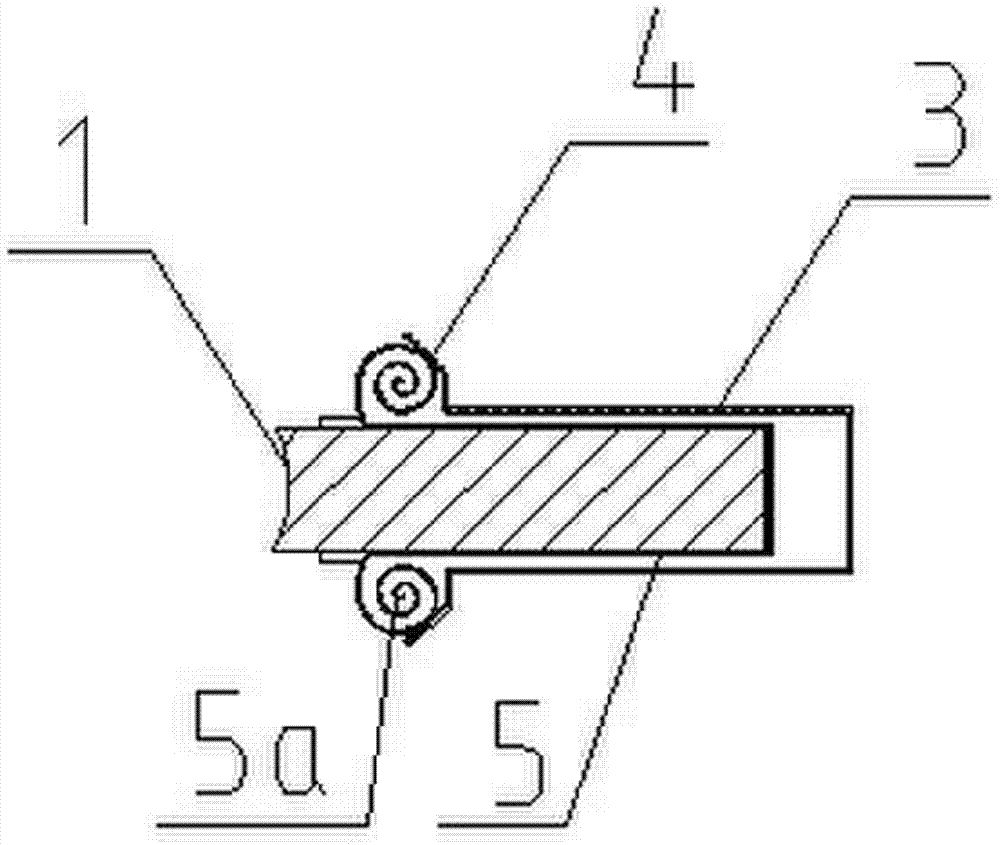

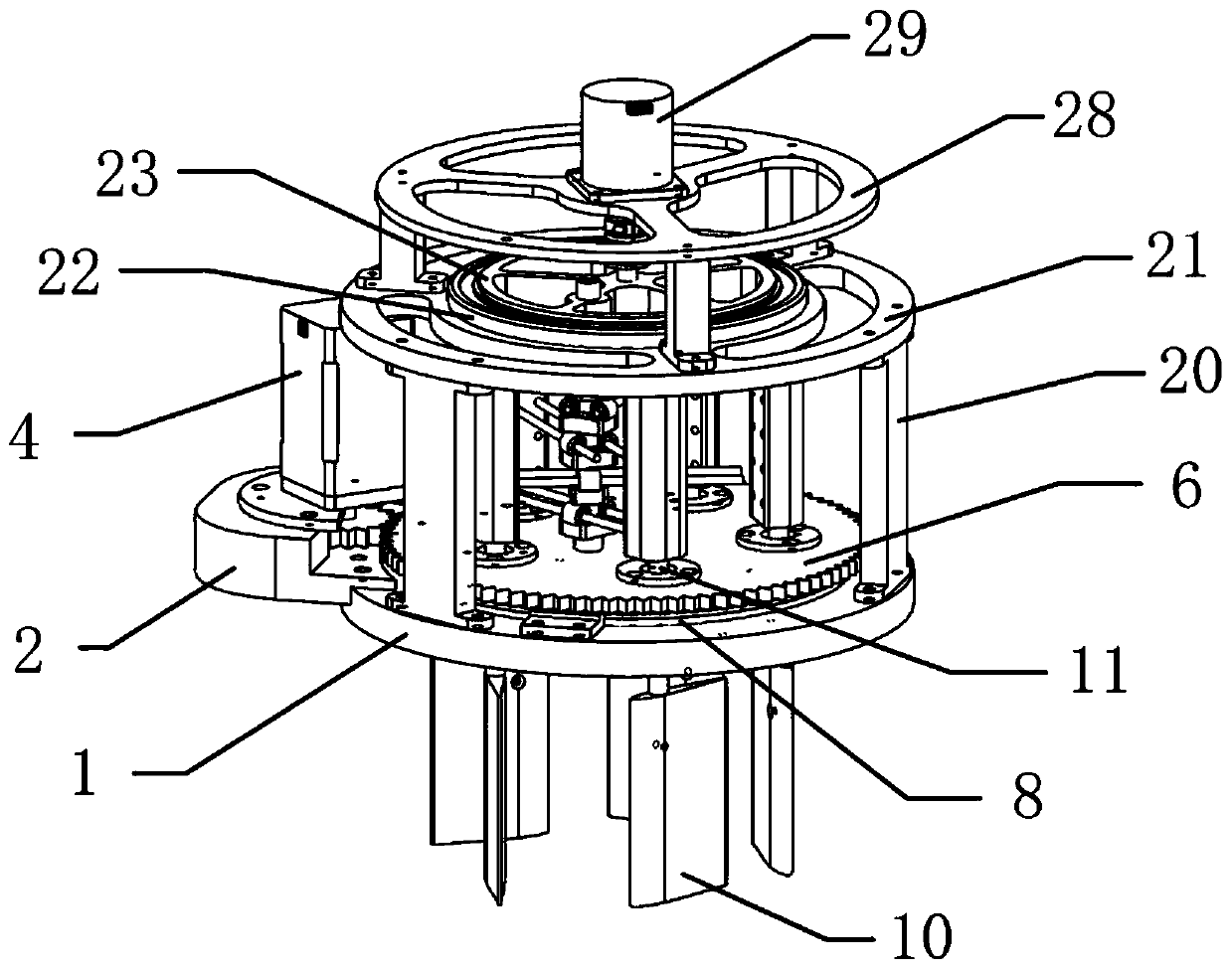

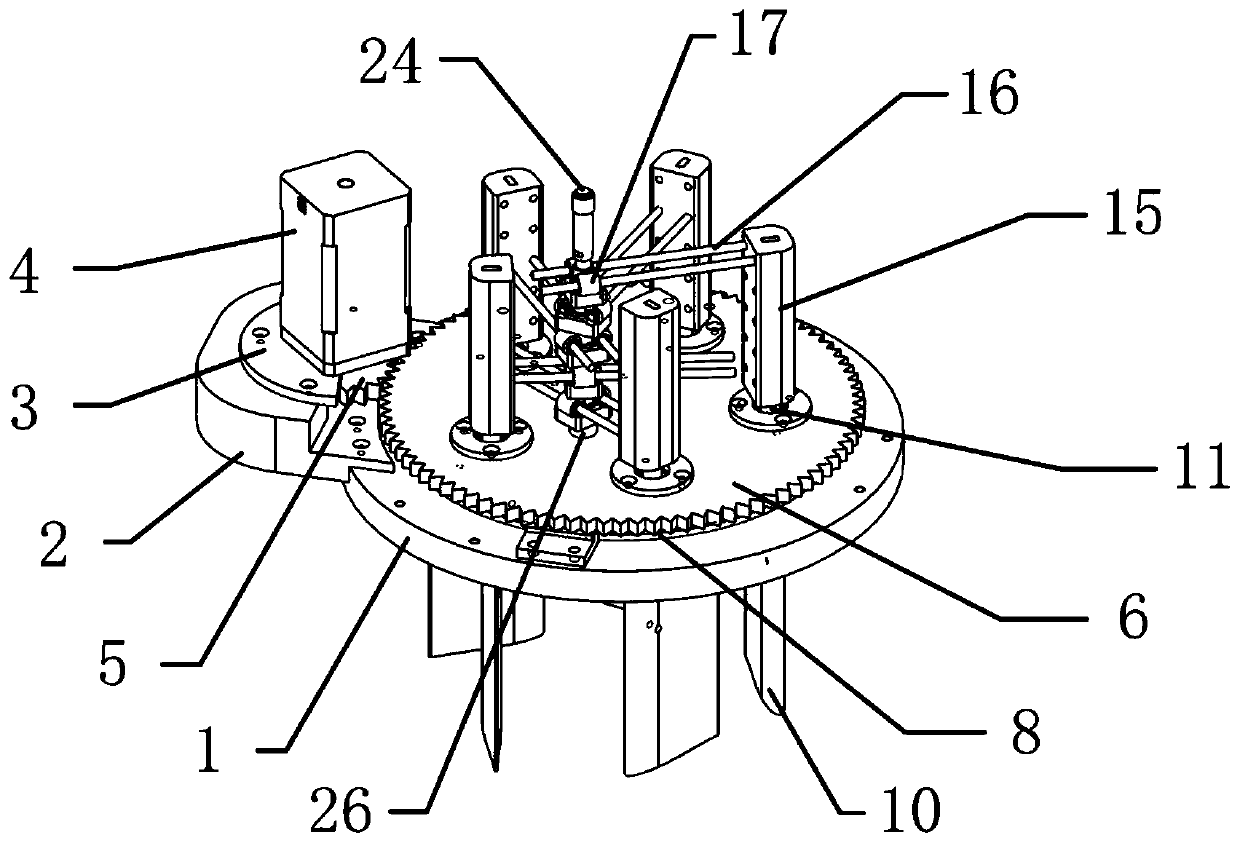

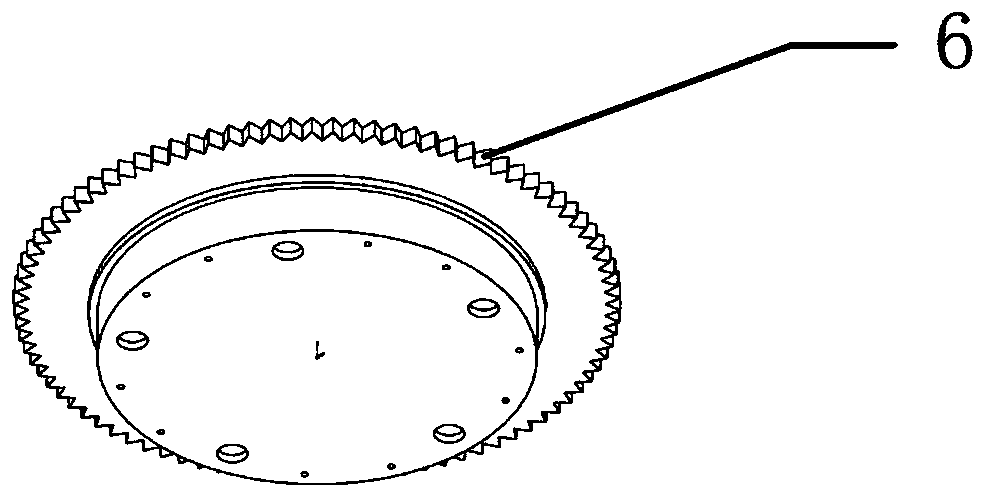

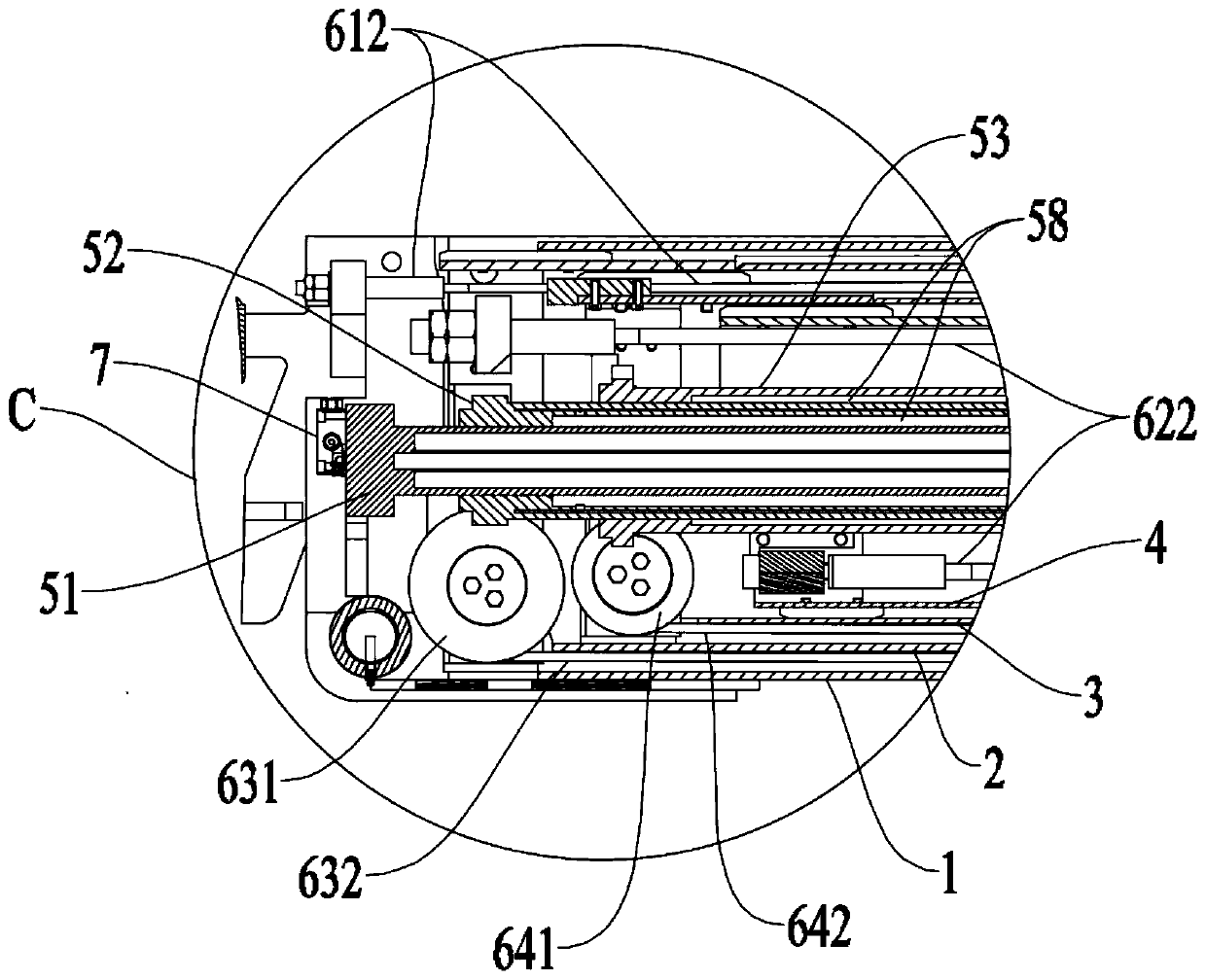

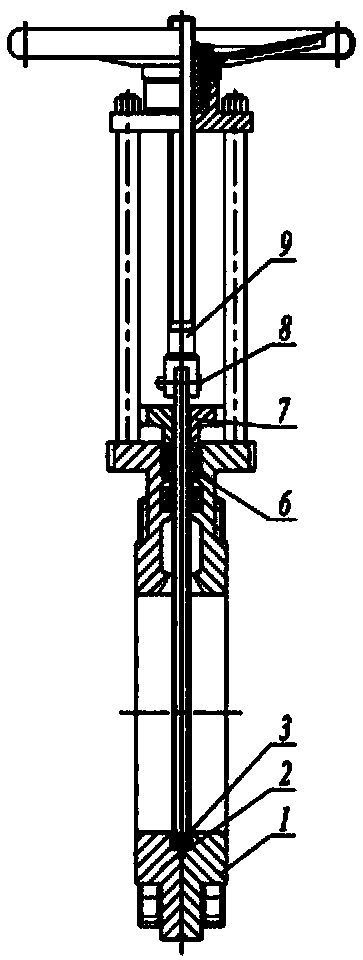

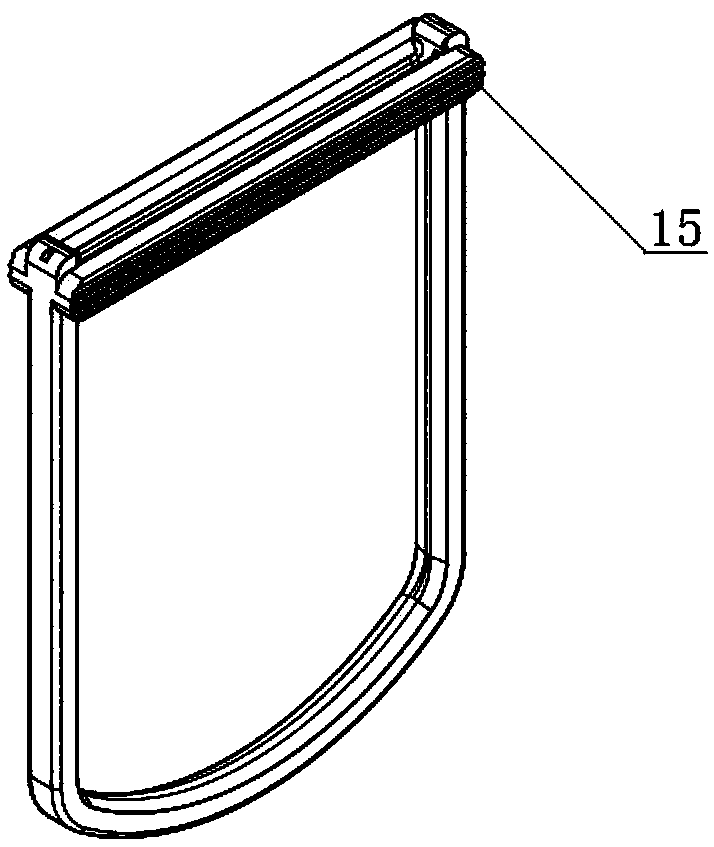

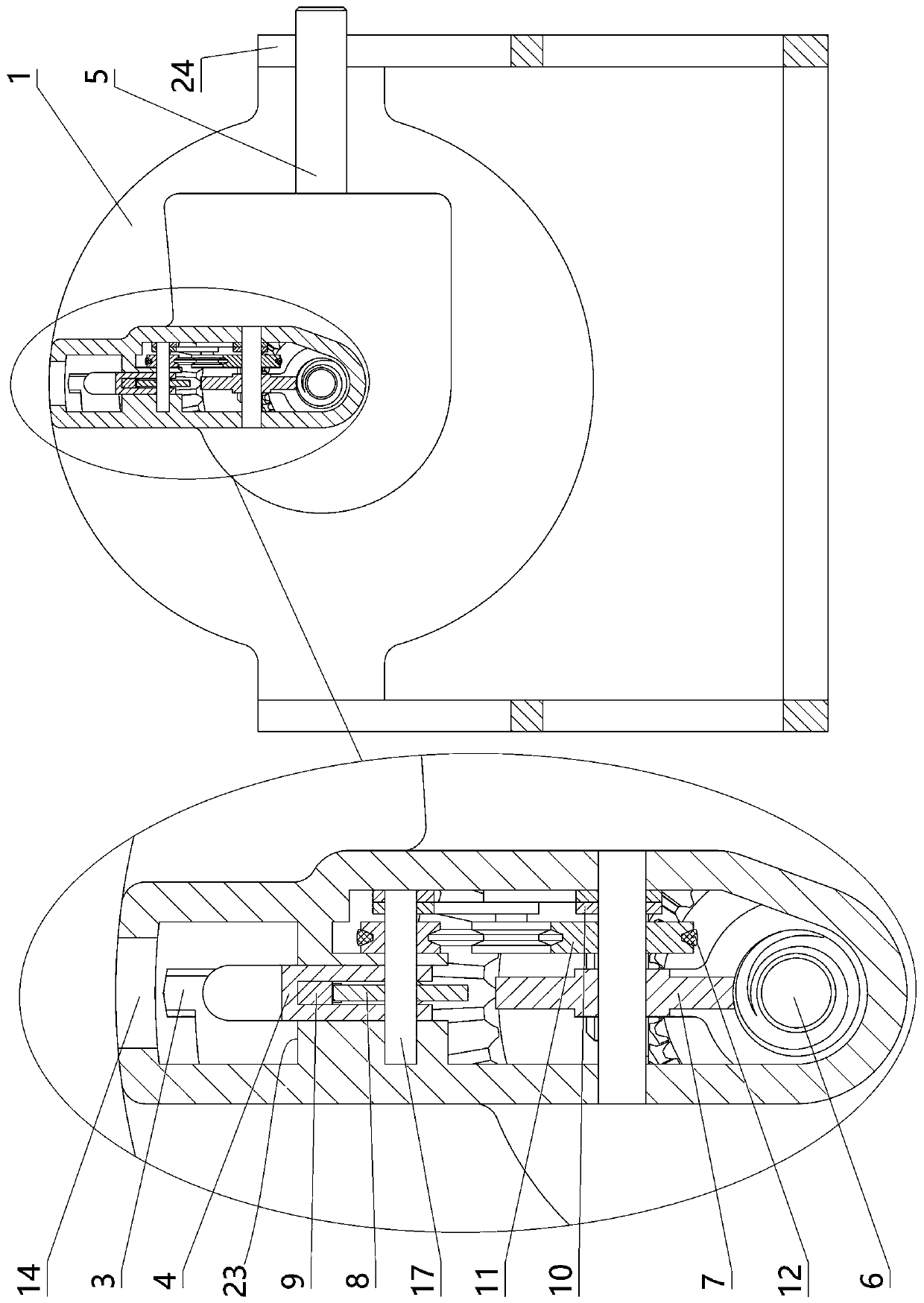

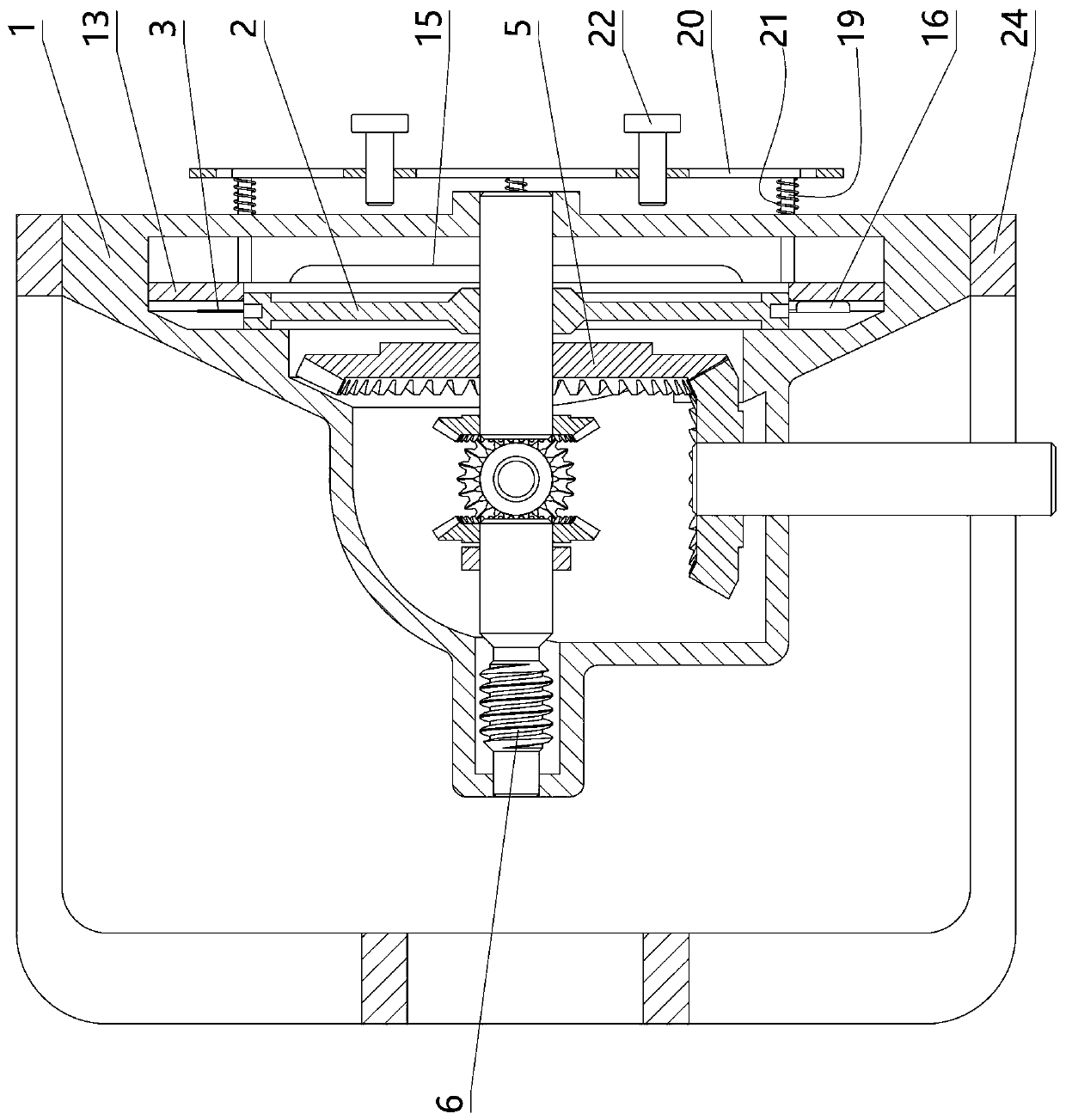

Creeping ground drilling robot

InactiveCN104727749AReduce resistanceStable thrustDrilling without earth removalEngineeringSearch and rescue

The invention relates to a creeping ground drilling robot which comprises an electric push rod mechanism, a motor steering mechanism and a drill bit mechanism which are sequentially connected. The outer wall of the electric push rod mechanism and the outer wall of the drill bit mechanism are each provided with a scale device capable of expanding and retracting, the electric push rod mechanism stretches and retracts periodically, each scale device expands or retracts under the action of soil body force and is used for providing supporting counterforce in the drilling direction, the motor steering mechanism adjusts steering of the drill bit mechanism, and a good platform is provided for the task that the robot is provided with a sensor to go deep into soil for geological prospecting, mine disaster search and rescue or soil sample collection in the future. Compared with the prior art, the robot has the advantages of being simple in structure, low in manufacturing cost, convenient to control and the like.

Owner:TONGJI UNIV

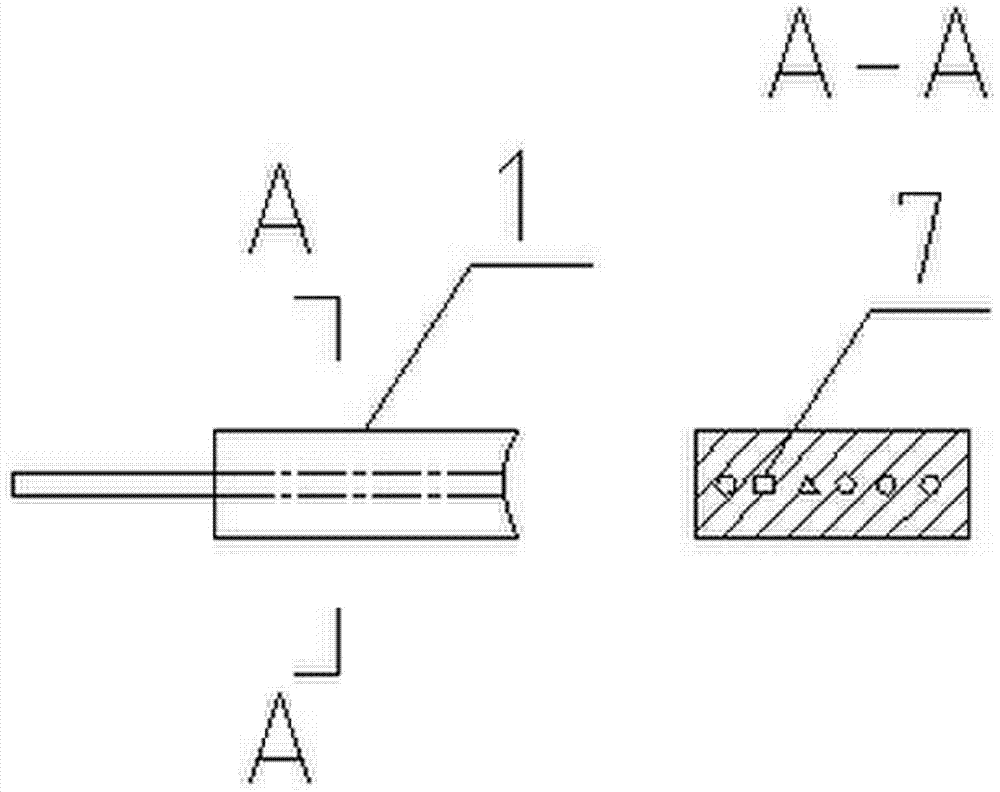

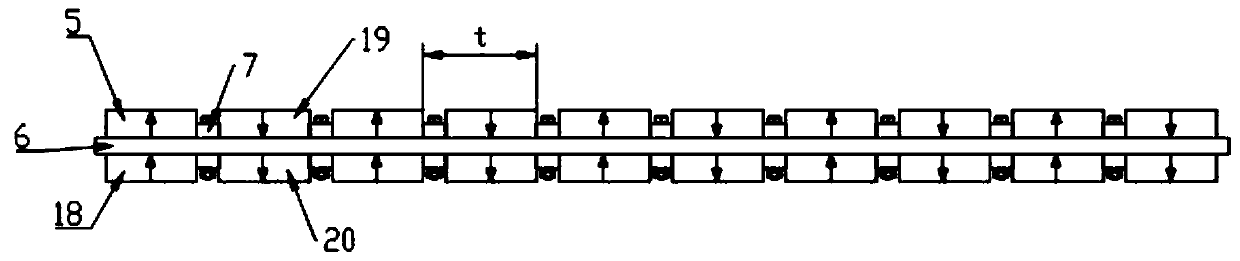

Double-foot driving piezoelectric linear motor and electric excitation mode

InactiveCN103427704AImprove efficiencyIncrease thrustPiezoelectric/electrostriction/magnetostriction machinesElectricitySignal on

The invention discloses a double-foot driving piezoelectric linear motor and an electric excitation mode. The motor is composed of two stator sets, a rotor / linear guide rail, a pre-pressing guide rail, a pre-pressing spring and a base. The two stator sets are distributed symmetrically along axes, and the ends of the two stator sets are fixedly connected with the pre-pressing guide rail. Under the action of elastic restoring force generated by elastic deformation of the pre-pressing spring, the two stator sets keep in contact with the rotor / linear guide rail, so that an outage self-locking function is provided for the piezoelectric linear motor. Each of the two stator sets is composed of piezoelectric actuation units, flexible connectors and a driving foot, wherein two ends of the piezoelectric actuation units are connected with the driving feet and the base through the flexible connectors. The piezoelectric actuation units serve as modular structures, so that the whole motor structure is simple, the motor assembly efficiency is improved, and batch production is facilitated. According to the double-foot driving piezoelectric linear motor and the electric excitation mode, the rotor / linear guide rail can be driven by the two stator sets alternately to perform rectilinear motion by imposing specific excitation voltage signals on laminated piezoelectric ceramic sets in the piezoelectric actuation units.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Combined cycle engine

ActiveCN105736178AImprove specific impulseImprove economyGas turbine plantsTurbine/propulsion air intakesDetonationTurbojet engine

The invention provides a combined cycle engine. The combined cycle engine comprises a supersonic air inlet mechanism, a continuous rotation detonation engine body and a turbojet engine body, wherein the supersonic air inlet mechanism is provided with a first gas inlet which communicates with the outside and is opened in the axial direction, and the continuous rotation detonation engine body and the turbojet engine body are fixedly connected to the lower portion of the supersonic air inlet mechanism. The continuous rotation detonation engine body and the turbojet engine body both communicate with the supersonic air inlet mechanism in a controlled mode in order to work in the mode that external gas is introduced into the continuous rotation detonation engine body and the turbojet engine body through the first gas inlet in the controlled mode. According to the combined cycle engine, mode transition can be completed within an operating envelope range, the stable thrust is provided for an aircraft, and then the aircraft hypersonically flies at 5.0 Mach or above in the atmosphere and can land and take off horizontally; in addition, the specific impulse of the engine is improved on the basis of adopting the continuous rotation detonation technique, the combustion heat efficiency is improved, and the economy and the reliability of the engine are improved.

Owner:清航空天(浙江)科技有限公司

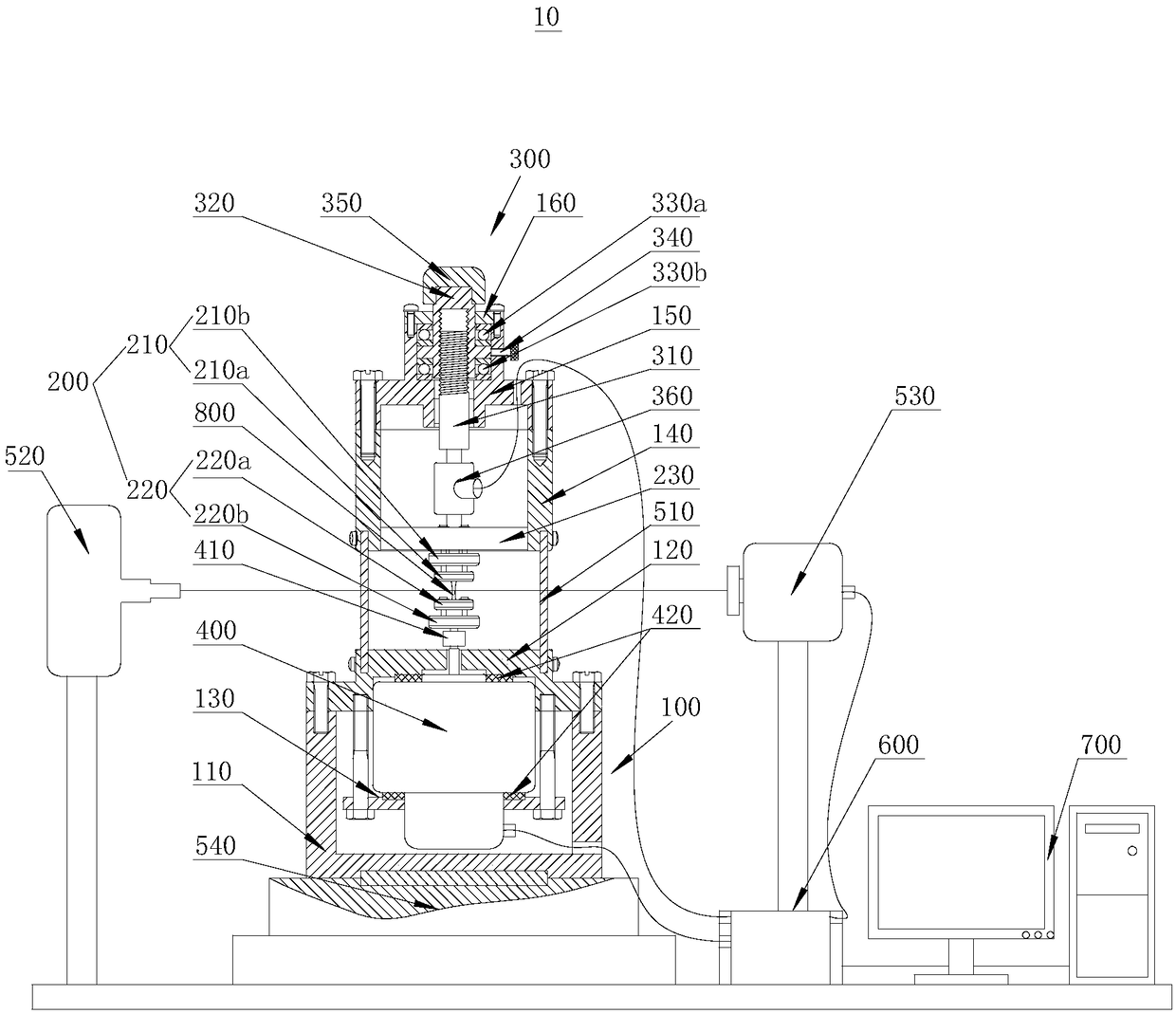

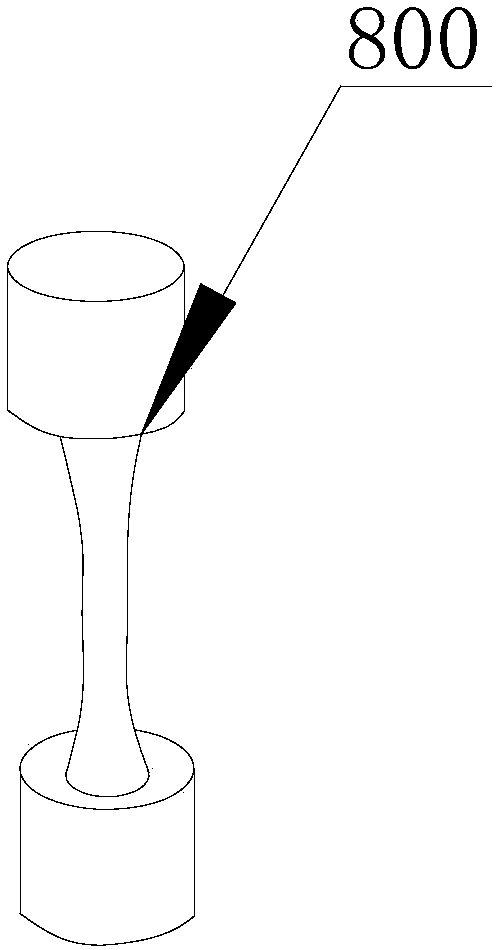

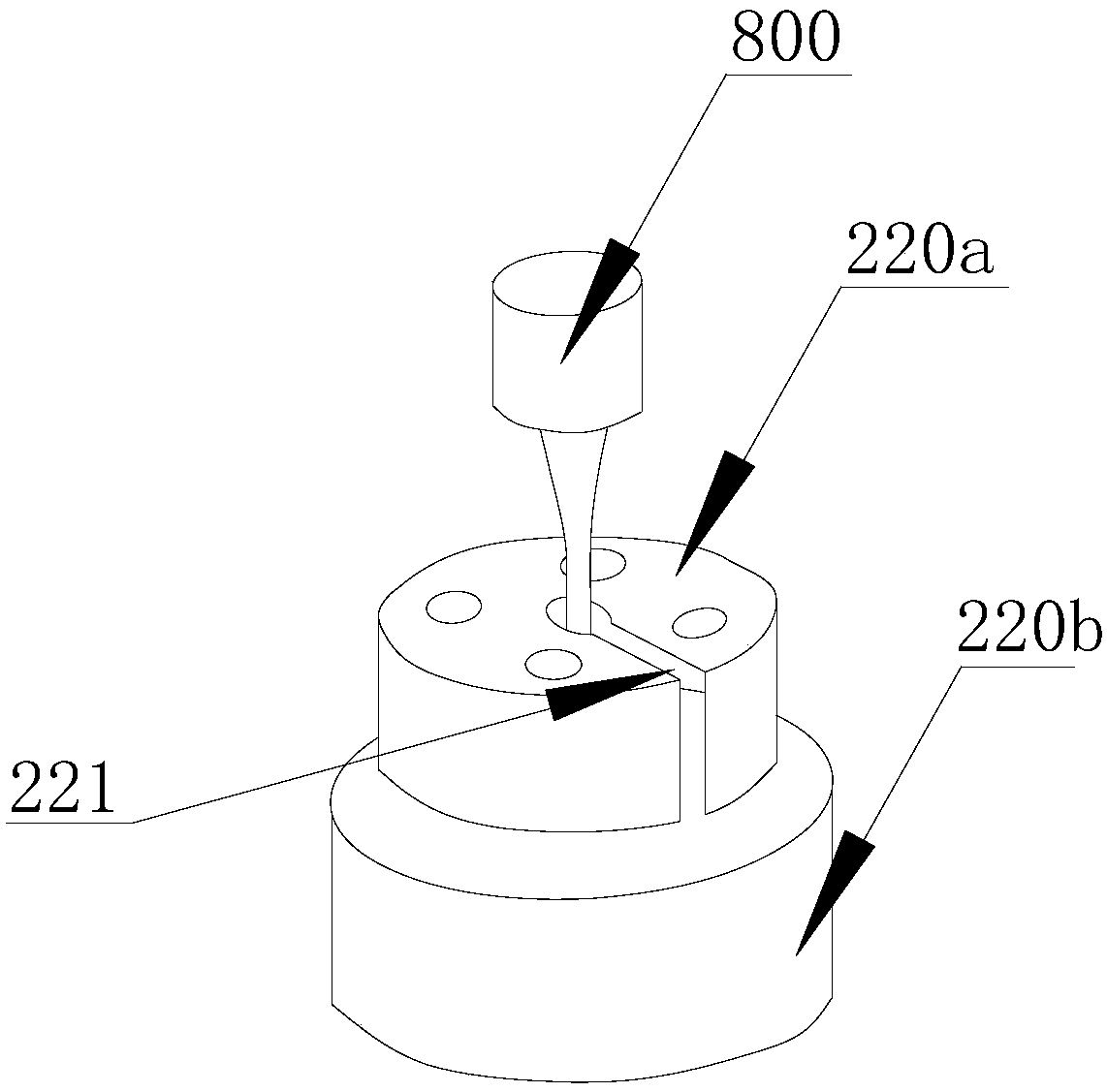

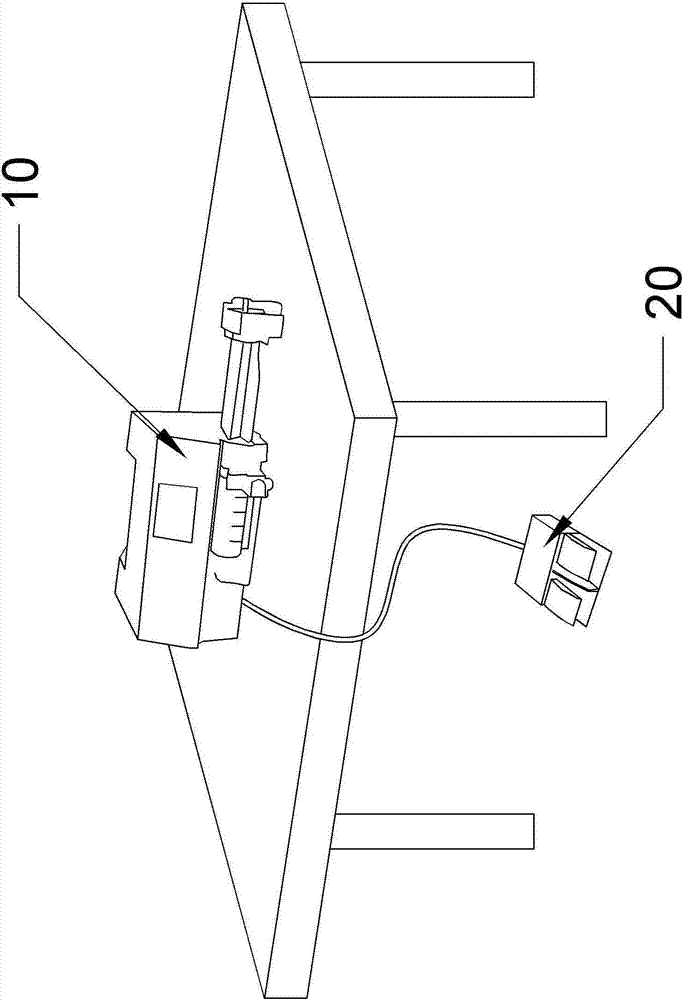

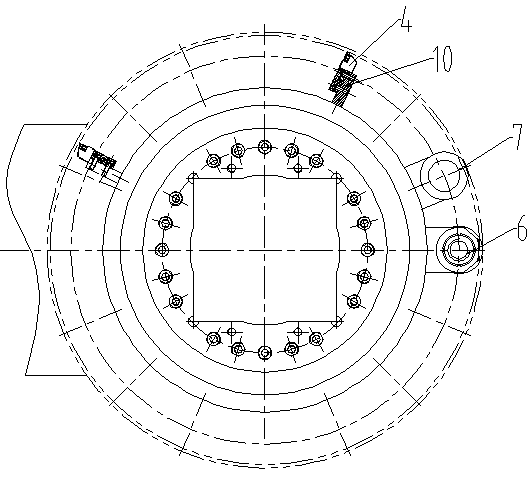

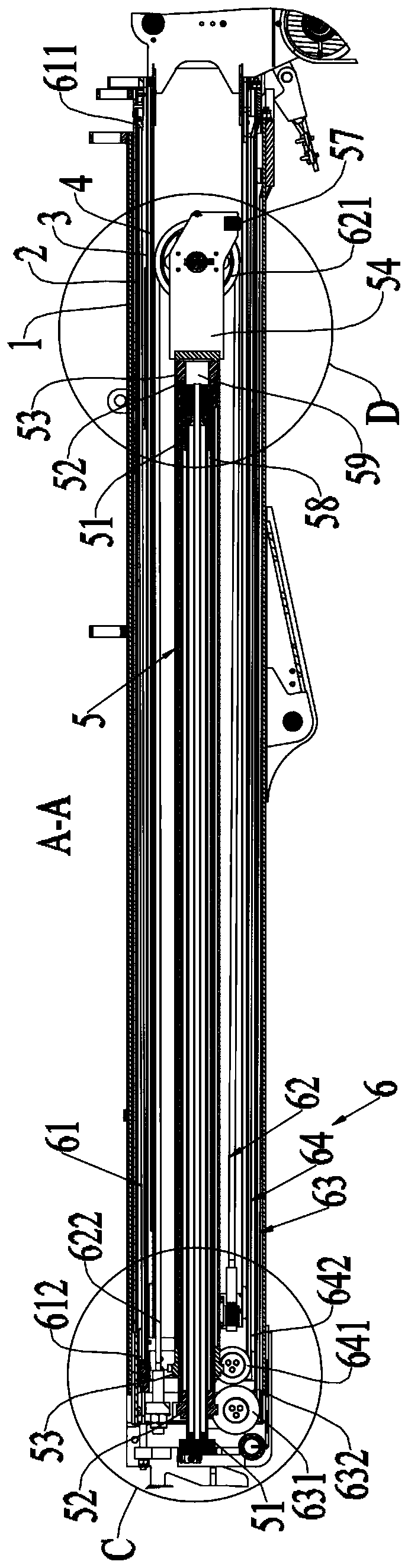

High-frequency in-situ imaging fatigue tester

PendingCN108562506AHigh frequencyHigh precisionMaterial strength using repeated/pulsating forcesMaterial analysis by transmitting radiationFatigue damageHigh energy

The invention relates to the technical field of material testing and particularly relates to a high-frequency in-situ imaging fatigue tester. The tester comprises a tester body, a test sample clampingmechanism, a preset force loading mechanism and a voice coil motor, wherein the test sample clamping mechanism is used for clamping and fixing a test sample, and the test sample clamping mechanism comprises a first clamping assembly and a second clamping assembly which are arranged oppositely; the preset force loading mechanism is arranged at one side of the first clamping assembly of the test sample clamping mechanism and is used for applying preset tension and pressure to the test sample; and the voice coil motor is fixedly connected to the tester body, and a moving shaft of the voice coilmotor is connected to the second clamping assembly. The voice coil motor is utilized for realizing high-frequency actuation to perform high-frequency fatigue on the test sample, and high-energy X-raysare utilized for performing three-dimensional imaging on fatigue damage inside materials, thereby researching the high-cycle and even ultra-high-cycle fatigue failure mechanism of the materials.

Owner:SOUTHWEST JIAOTONG UNIV

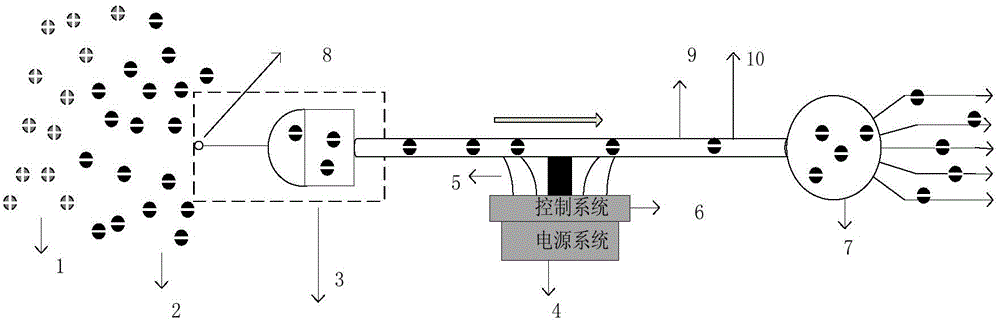

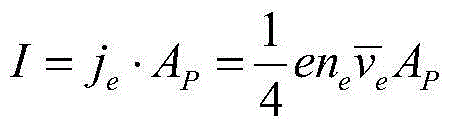

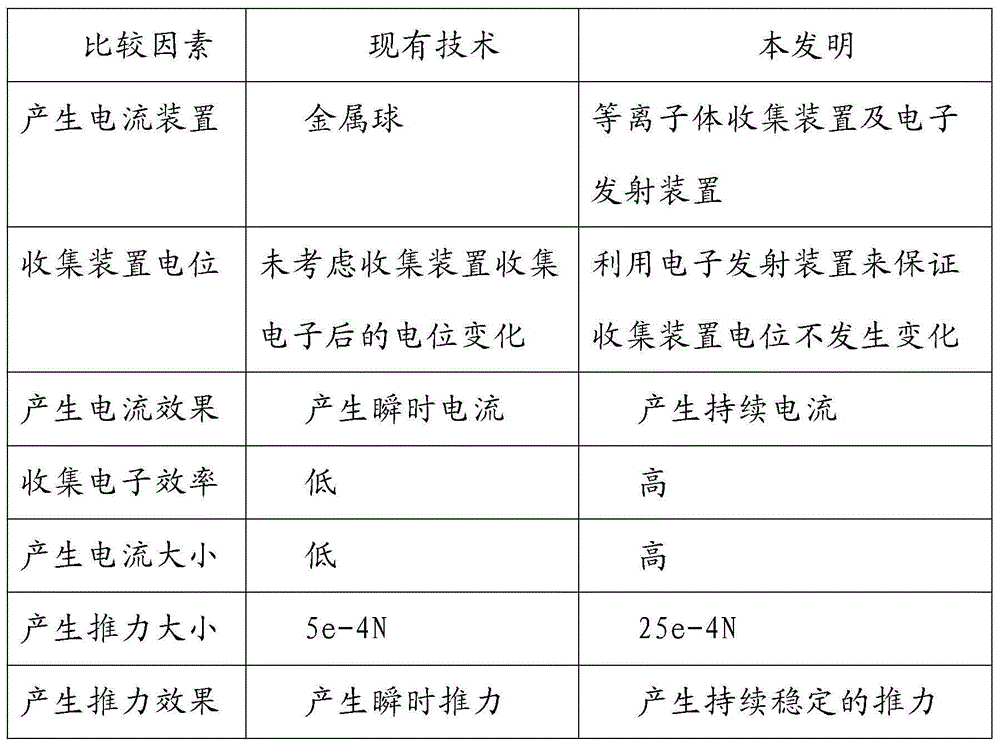

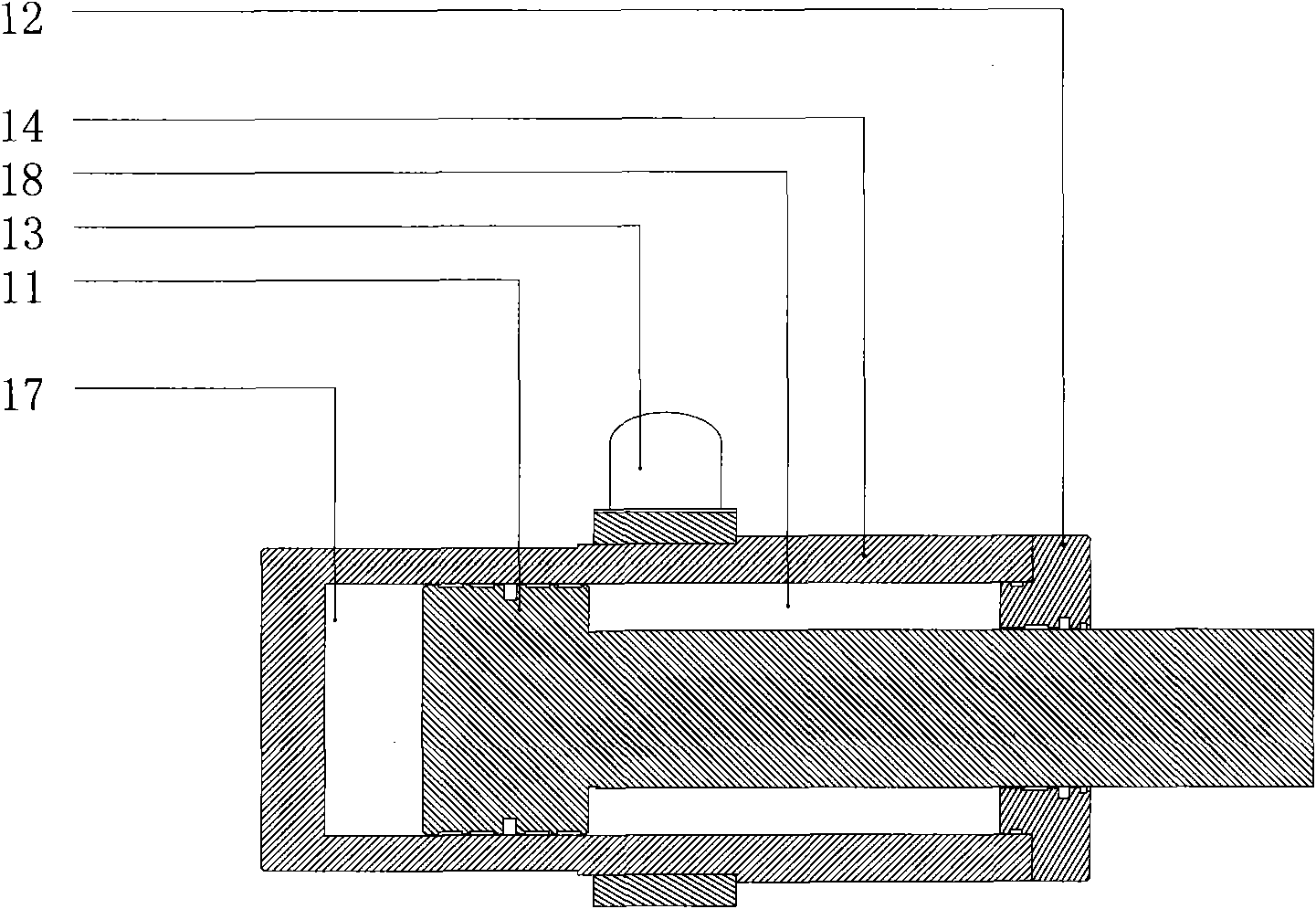

Spacecraft boosting system utilizing space plasmas and magnetic field action

InactiveCN103600854ALower launch costsIncrease collection currentCosmonautic vehiclesCosmonautic propulsion system apparatusFull life cycleControl system

The invention discloses a spacecraft boosting system utilizing space plasmas and magnetic field action. A long conducting rod of the spacecraft boosting system extends out of a spacecraft and is connected to the spacecraft by a control system, a space plasma collection device used for collecting electrons and an electron emission device used for emitting the plasmas in the long rod into the space are arranged at two ends of the long conducting rod respectively, a power supply system provides potential difference and working voltage for two ends of each of the space plasma collection device and the electron emission device, the collection device collects the plasmas from the space into the long conducting rod, the plasmas flow to the other end of the long conducting rod under the action of potential difference, and the emission device emits the electrons in the rod into the space to realize continuous generation and acting force of current. Compared with the prior art, the spacecraft boosting system has the great advantages that a working medium does not need to be carried, emission cost is lowered greatly, and in-orbit full-life-cycle working of the spacecraft is realized.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

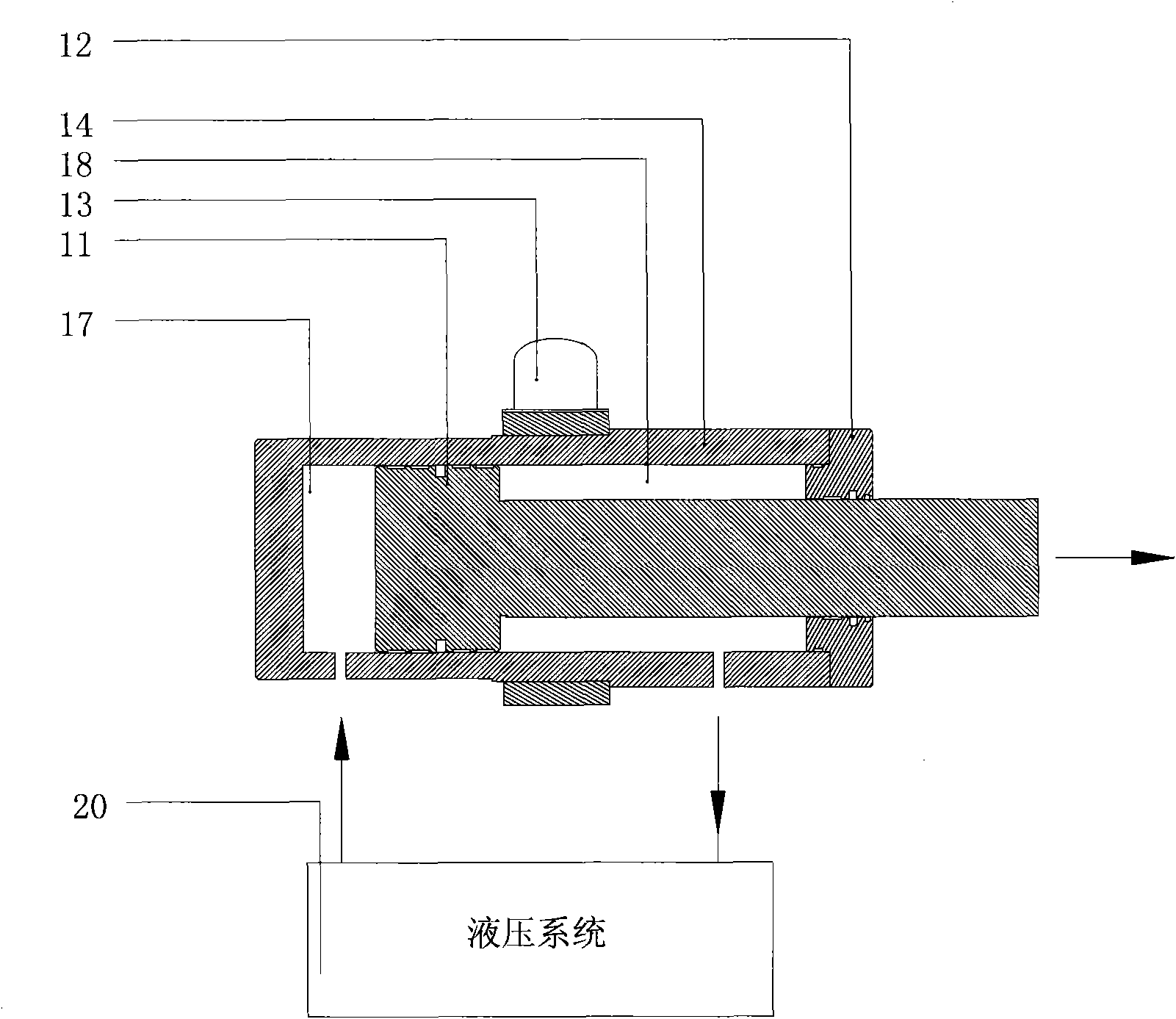

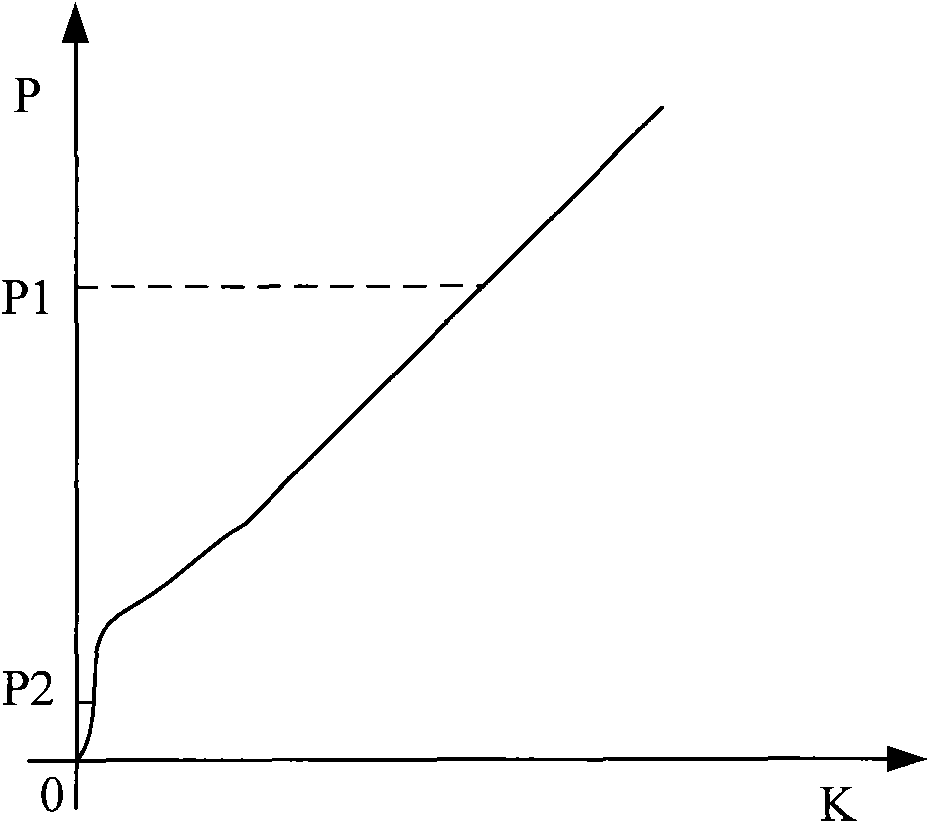

Hydraulic cylinder as well as method and system for controlling same

InactiveCN101655114AStable thrustThe output thrust is unstableFluid-pressure actuator componentsHydraulic cylinderControl system

The invention relates to a hydraulic cylinder which comprises a cylinder barrel and a guide seal sleeve, wherein the guide seal sleeve is fixed on the cylinder barrel; the cylinder barrel and the guide seal sleeve form a containing cavity; a big movable piston is arranged in the containing cavity; the containing cavity is divided into a rod cavity and a rod-free cavity by the big piston; a plungercavity is arranged on the big piston; one end of a small piston is tightly matched in the plunger cavity, the other end is fixed on the cylinder barrel, and the big piston can move relative to the small piston; and the plunger cavity is connected with a hydraulic system by a through hole arranged in the small piston. The invention also relates to a method and a system for controlling the hydraulic cylinder. The hydraulic cylinder with favorable applicability can output smaller or larger thrust under the condition of being communicated with pressure oil with higher pressure.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

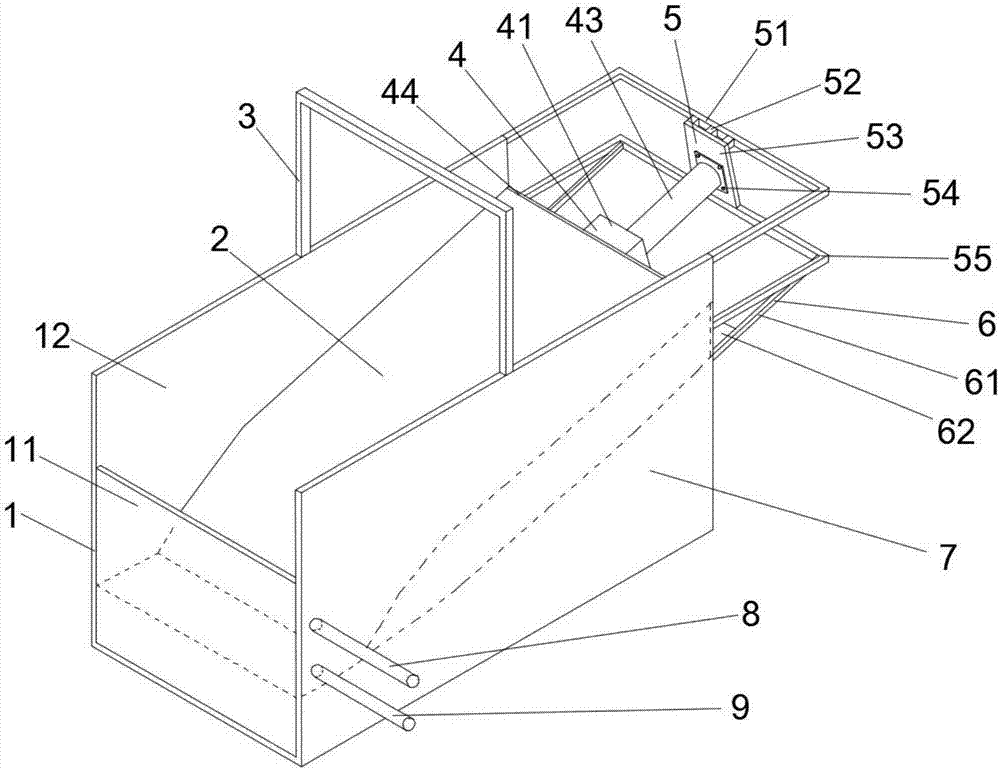

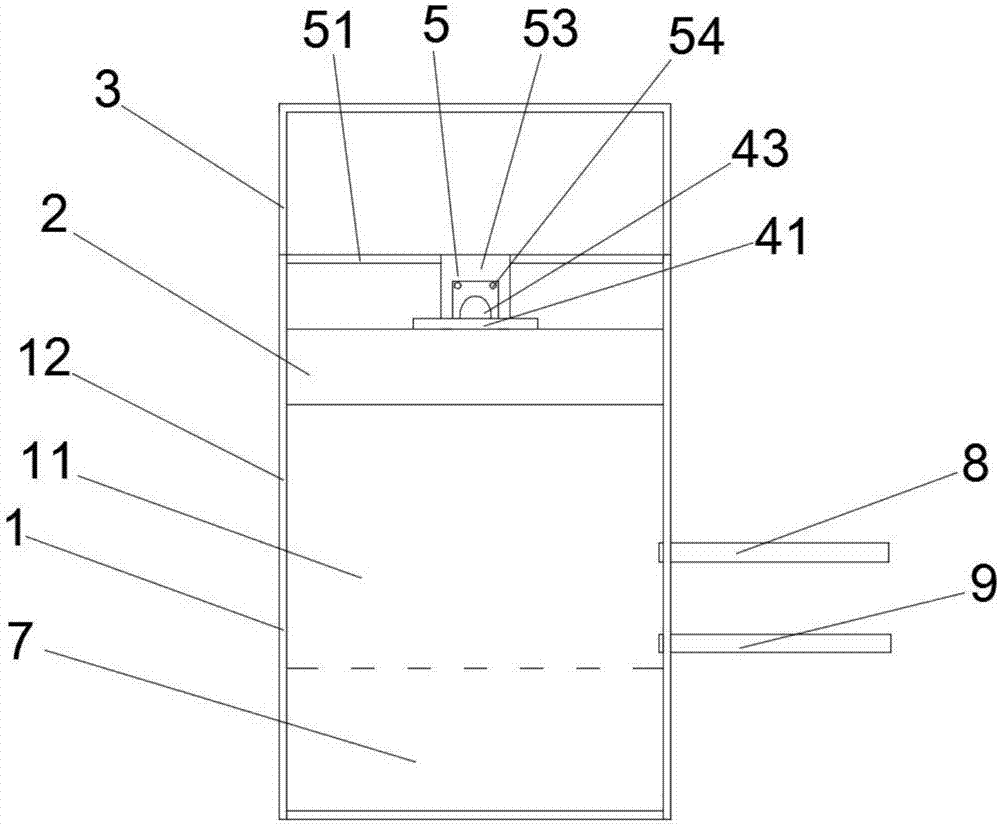

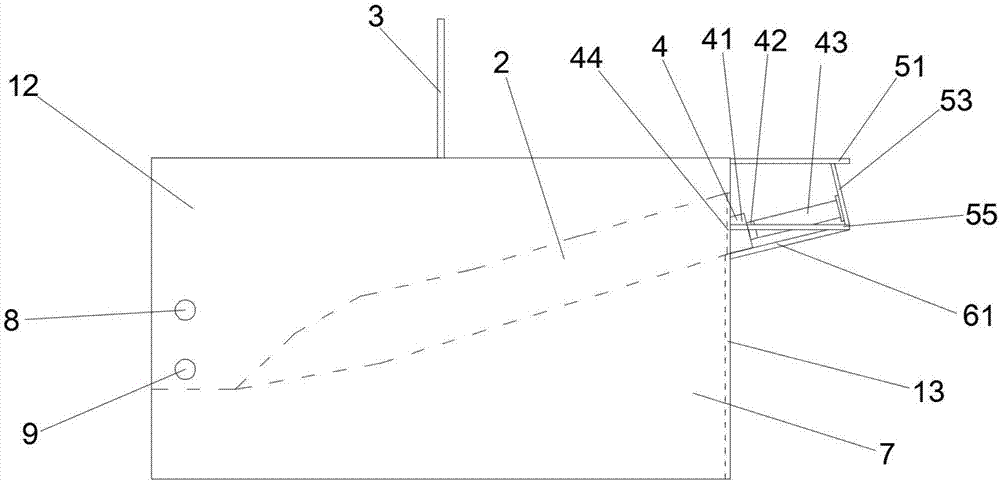

Self-reaction force type reservoir landslide model test device and test method

The invention relates to a self-reaction force type reservoir landslide model test device and test method. The device comprises a model groove, wherein a slide bed with the upper surface being inclined is arranged at the bottom of the model groove; the rear end of the slide bed is higher than the front end; a slip mass is arranged along the inclined surface on the slide bed; a water storage space is formed above the slide bed in the model groove; a water feeding pipe and a water draining pipe which are communicated with the water storage space are respectively arranged on the side wall of the model groove; a support component and a counterforce component are arranged along the inclined surface of the slide bed on the rear end face of the model groove in the form of backward stretching; a loading component is arranged on the support component; the loading component is clamped between the rear end face of the slip mass and the rear end of the counterforce component; the counterforce component is capable of pushing the slip mass to downwards slide along the inclined surface on the slide bed. According to the invention, the water feeding pipe and the water draining pipe are utilized to adjust the water level in the water storage space so as to simulate the practical running of reservoir; the loading component is utilized to apply force to the slip mass so as to simulate the whole process of the landslide evolution; the structure is compact and the operation is convenient.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

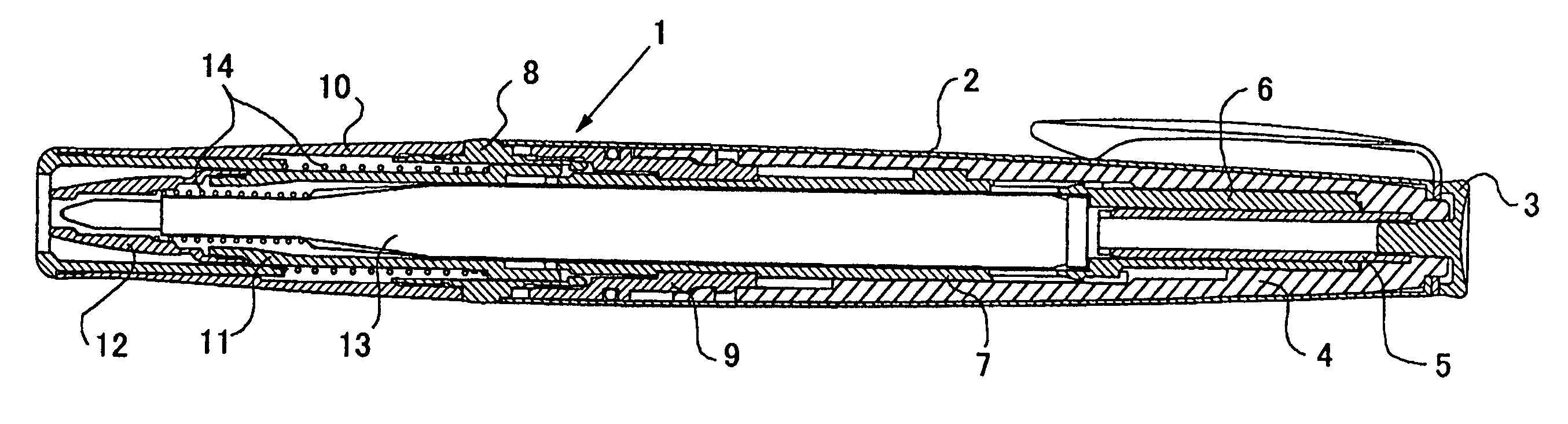

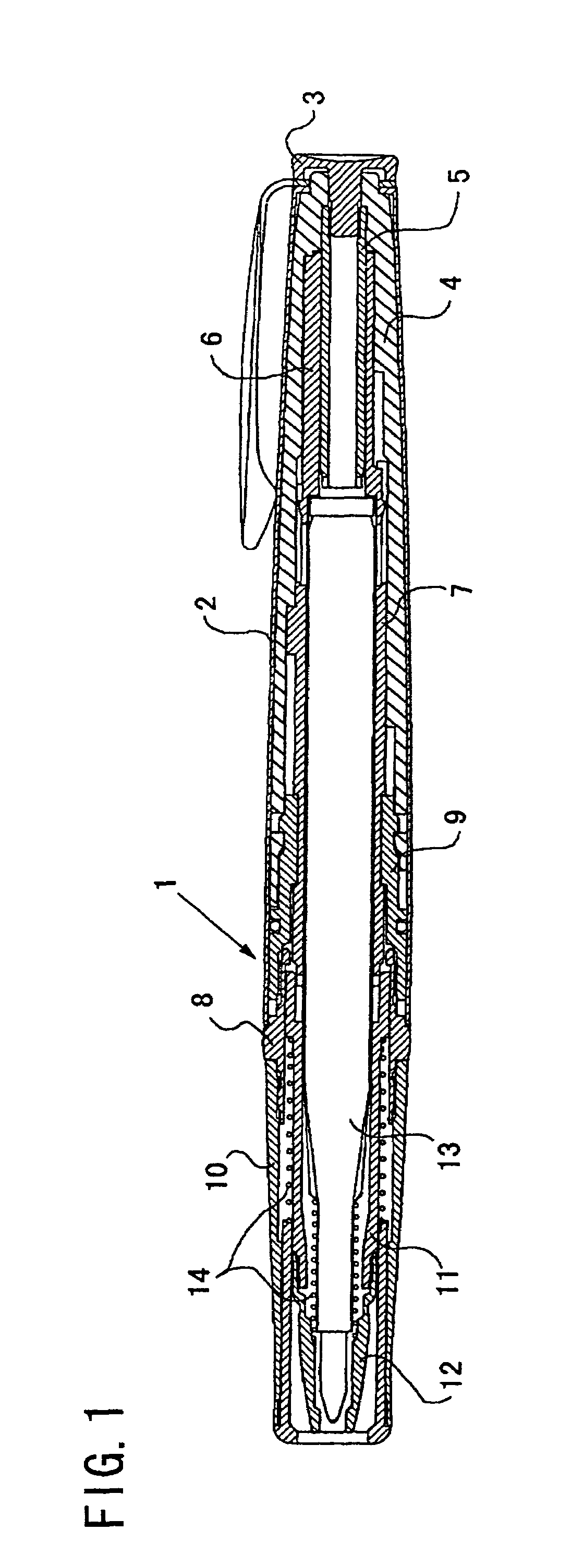

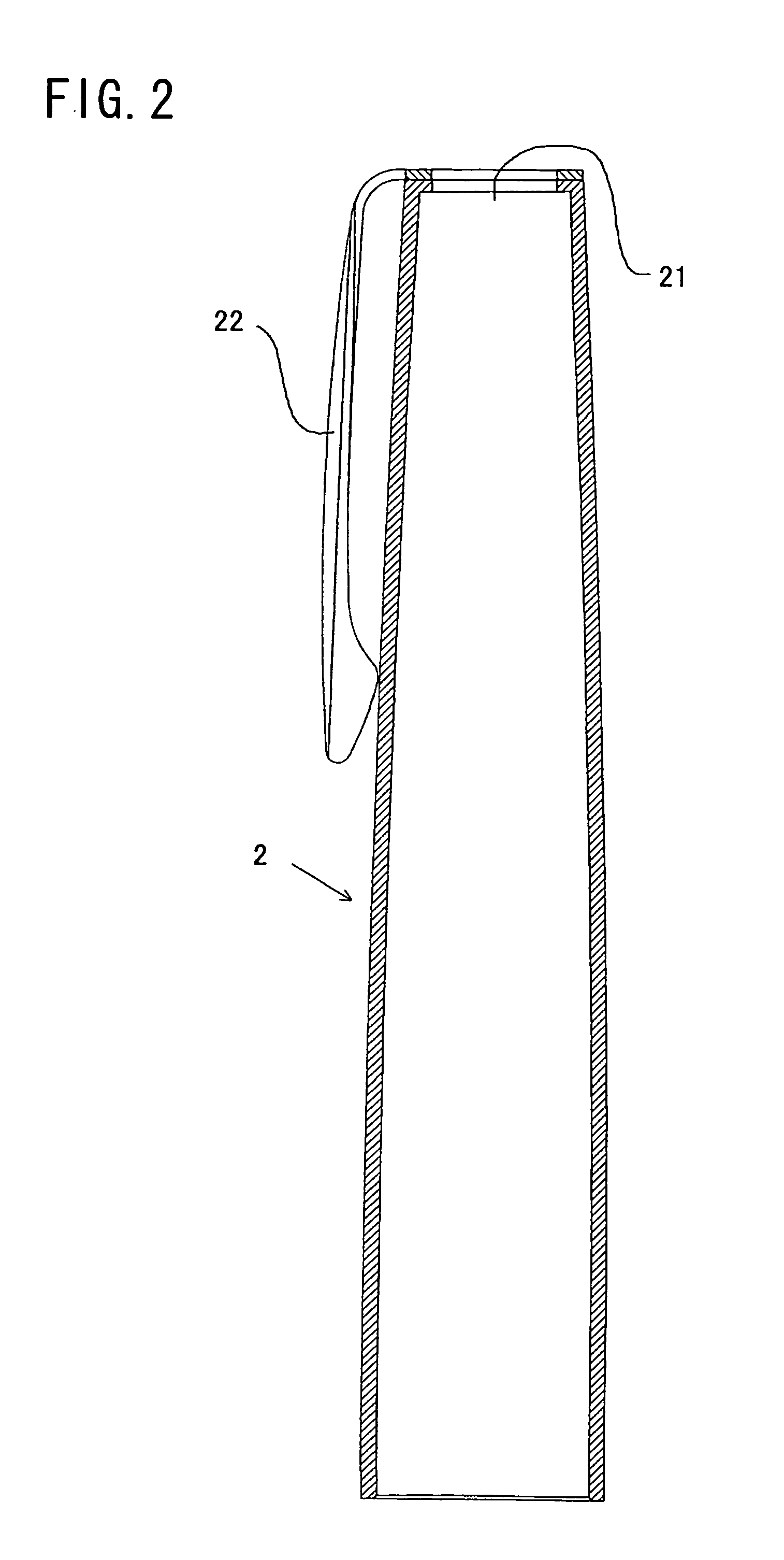

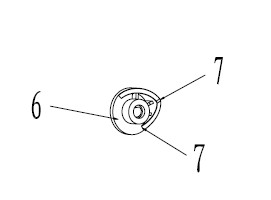

Rotating retractable writing instrument

The present invention relates to a rotating retractable writing instrument, which is constituted in a simpler way and can thrust a mouthpiece and a writing core element smoothly to positions ready for writing. The writing instrument by the present invention comprises a rear outer cylinder 2, an inner sheath 4 unrotatably accommodated in the rear outer cylinder 2, a front outer cylinder 10 from which a mouthpiece 12 and a writing core element 13 can be thrust. A protrusion 45 for restraining rotating range, a refill sliding cam 42 and a mouthpiece sliding cam 43 are formed in the inner sheath 4. A refill sliding element 6 and a mouthpiece sliding element 7 are accommodated in the inner sheath 4. The mouthpiece sliding element 7 is connected to the refill sliding element 6. Further a connecting element 9 is connected to the inner sheath 4. In the writing instrument constituted in the above-mentioned way, when the rear outer cylinder 2 is rotated in one direction relative to the connecting element 9, the mouthpiece and the writing core element are thrust out of an opening of the front outer cylinder 10. When the rear outer cylinder is further rotated, a tip of the writing core element is thrust out of an opening on a front face of the mouthpiece.

Owner:NOVITA +1

Damping assembly for preventing damage of film membrane and filtering membrane assembly utilizing damping assembly

PendingCN107899425AReduce jitter amplitudeReduce stressUltrafiltrationWater/sewage treatment bu osmosis/dialysisMechanical engineeringPhysics

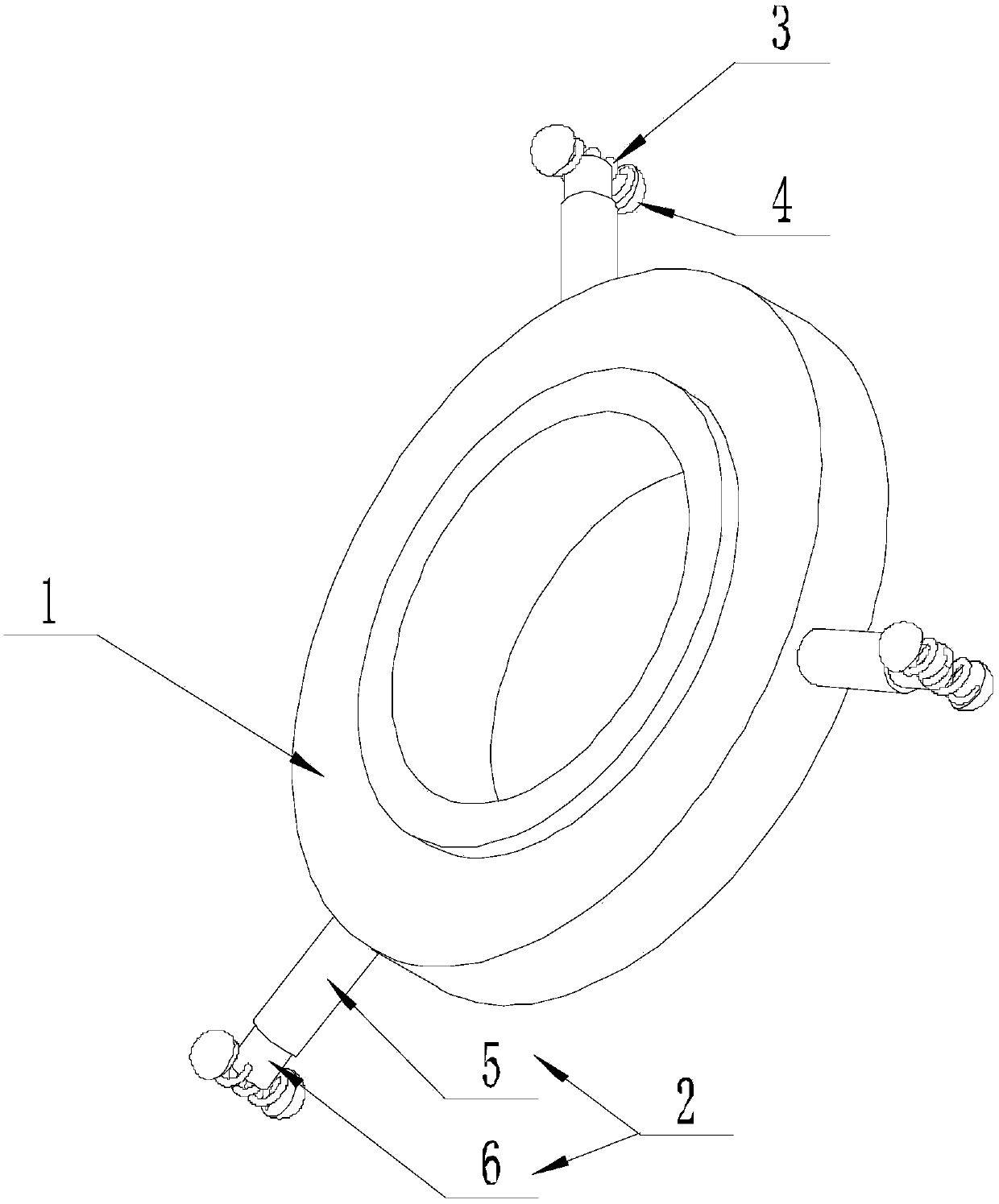

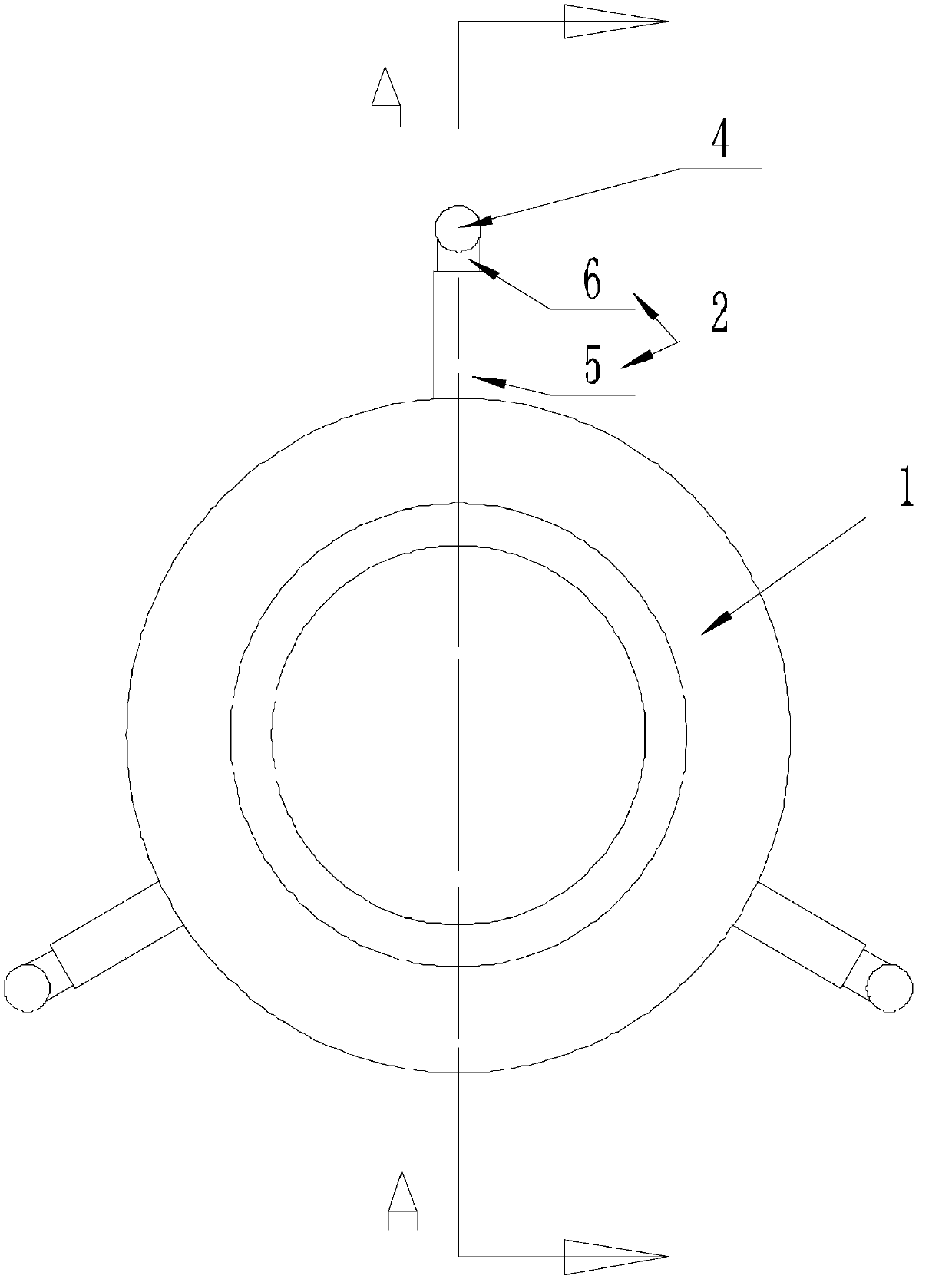

The invention discloses a damping assembly for preventing damage of a film membrane and a filtering membrane assembly utilizing the damping assembly. The damping assembly comprises a positioning ring,wherein the side wall of the positioning ring is provided with a damping assembly body, the damping assembly body comprises a telescopic rod and two elastic assemblies which are successively connected with each other, one end of the telescopic rod is connected with the outer wall of the positioning ring, the other end of the telescopic rod is connected with the elastic assembly, the two elastic assemblies are coaxial, one end of each elastic assembly is connected with the telescopic rod, and a telescopic axis of the elastic assembly is parallel to the axis of the positioning ring. When a filmmembrane jitters, due to the arrangement of the elastic assemblies, the jittering amplitude of a part, close to the positioning ring, of the film membrane is alleviated and buffered, the stress applied to the part, clamped by the positioning ring, of the film membrane is reduced, and the strength quality of the clamped part of the film membrane is improved, so that the film membrane can successfully filter water, and the sealing performance between the positioning ring and the film membrane is improved.

Owner:中欧兴华膜技术(成都)有限公司

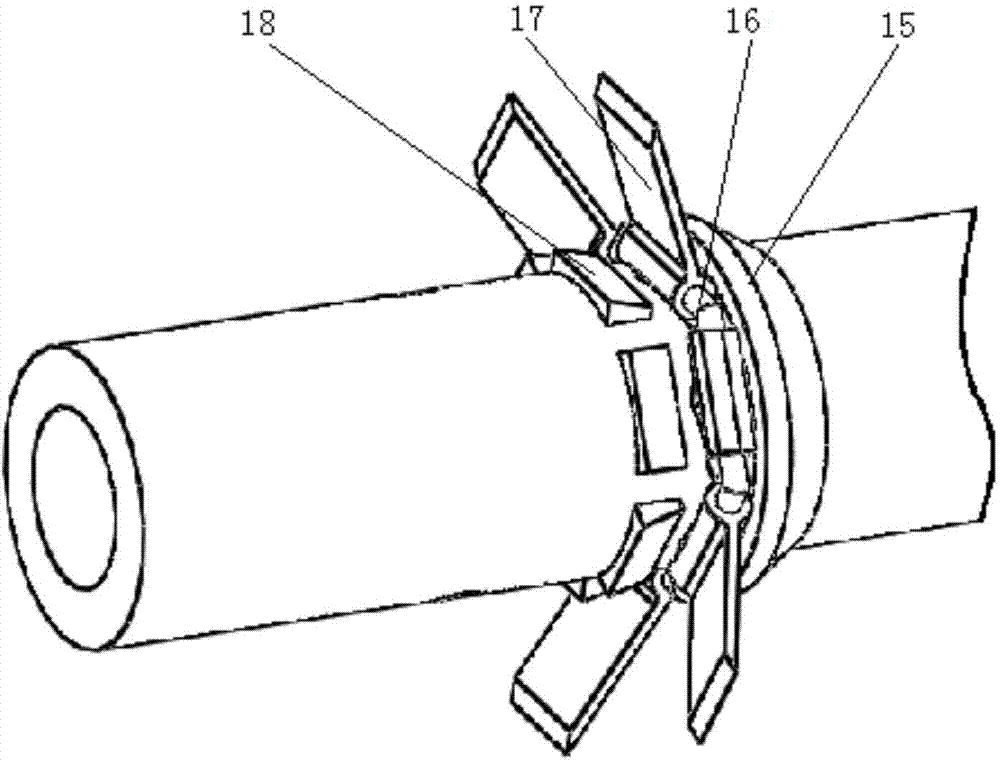

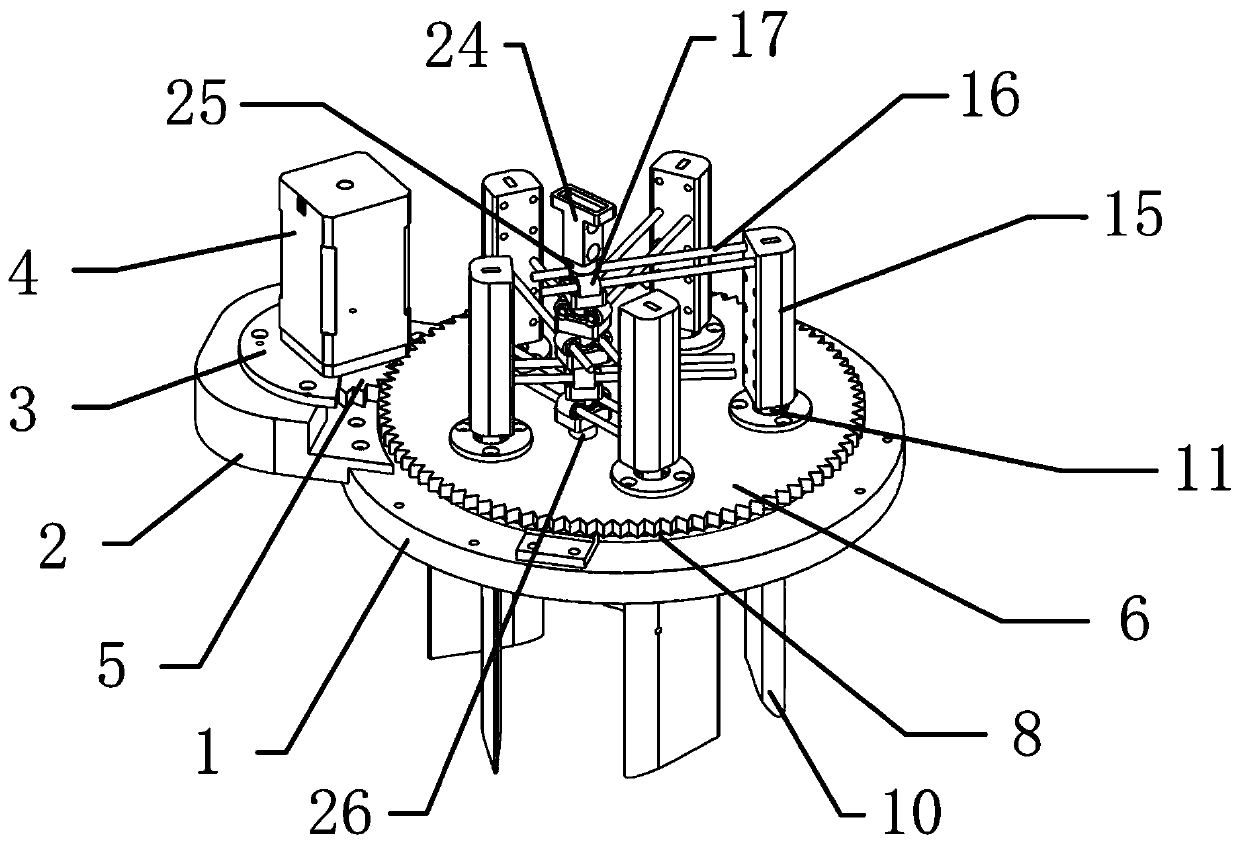

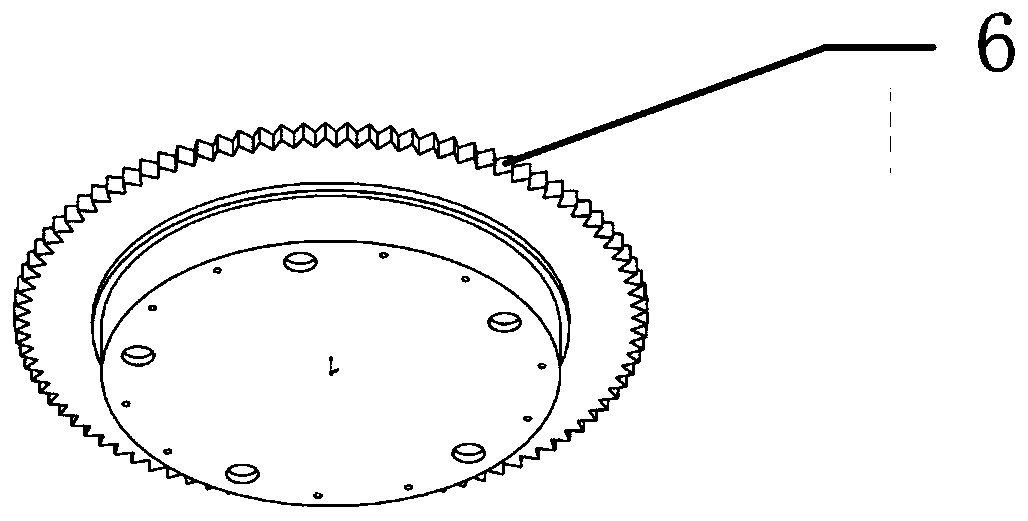

Slide-rod cycloidal paddle propeller with adjustable maximum attack angle

InactiveCN110466725AAngle of attack controlChange thrust directionPropulsive elements of rotary typePropellerAngular degrees

The invention relates to a slide-rod cycloidal paddle propeller with an adjustable maximum attack angle. The slide-rod cycloidal paddle propeller with the adjustable maximum attack angle is composed of a drive mechanism and an attack angle control mechanism. A gear of a drive motor of the drive mechanism is engaged with a gear of a paddle drive disc, the paddle drive disc is enabled to drive paddles to rotate, and power is provided for the cycloidal paddle propeller. Each paddle shaft is capable of freely rotating in a hole position, connected together with an attack angle control hinge through a slide rod, and used for controlling the attack angles of the paddles at different positions. A control shaft in the attack angle control mechanism changes a phase angle of an attack angle change period of each paddle by controlling a rotation angle of a control disc, and then changes a thrust direction of the paddle. A distance between the axis of the control disc and the control shaft is adjusted by an axial stepper motor, and the maximum attack angle adjustment is realized. The slide-rod cycloidal paddle propeller with the adjustable maximum attack angle has the following beneficial effects: the slide-rod cycloidal paddle propeller with the adjustable maximum attack angle is provided with few specially-shaped members and reasonable in layout, and has the characteristics of being simple and reliable in structure, and convenient to maintain; and the slide-rod cycloidal paddle propeller with the adjustable maximum attack angle is not provided with a friction pair in a working process, has few transmission links, and has the characteristic of being low in mechanical loss.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

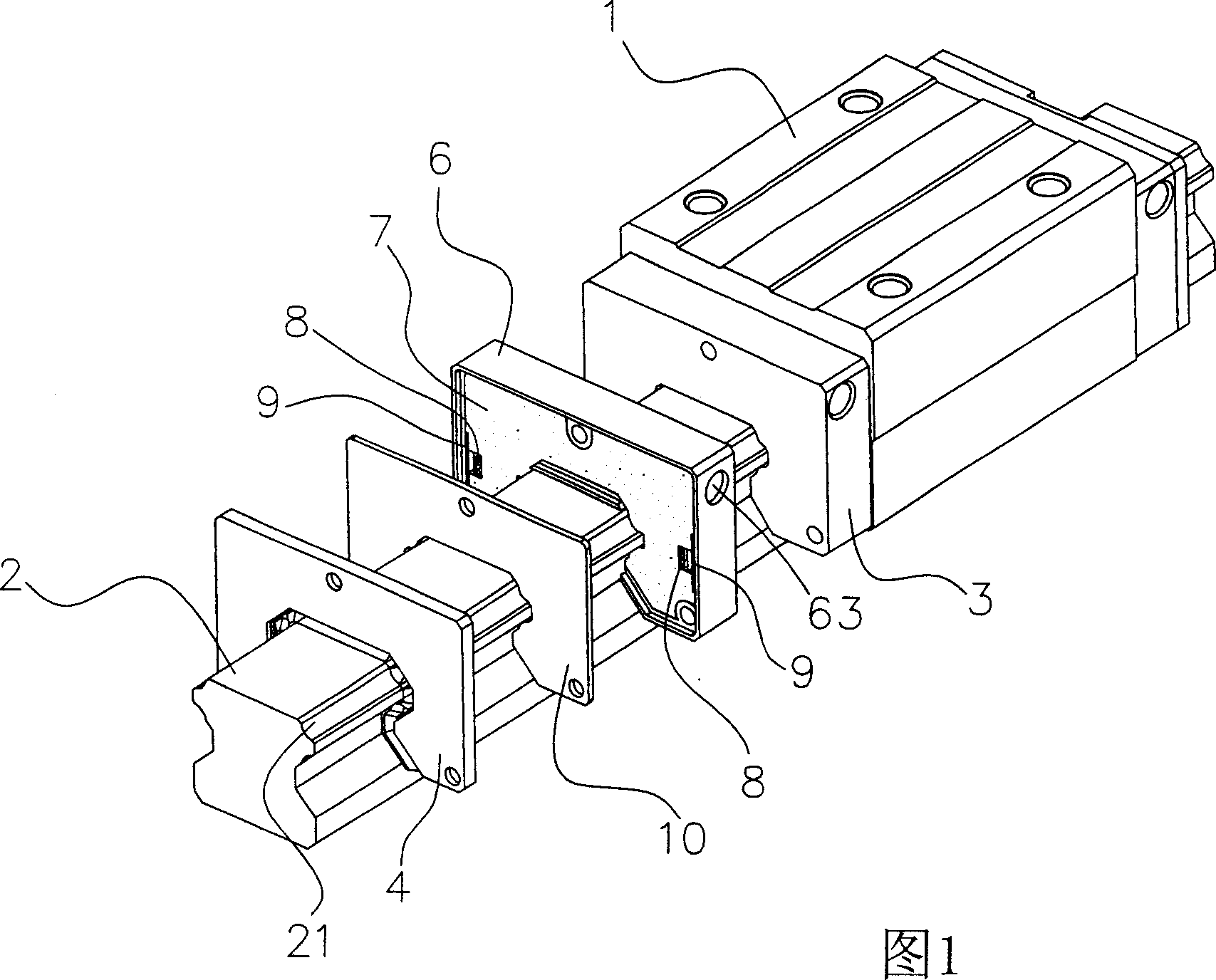

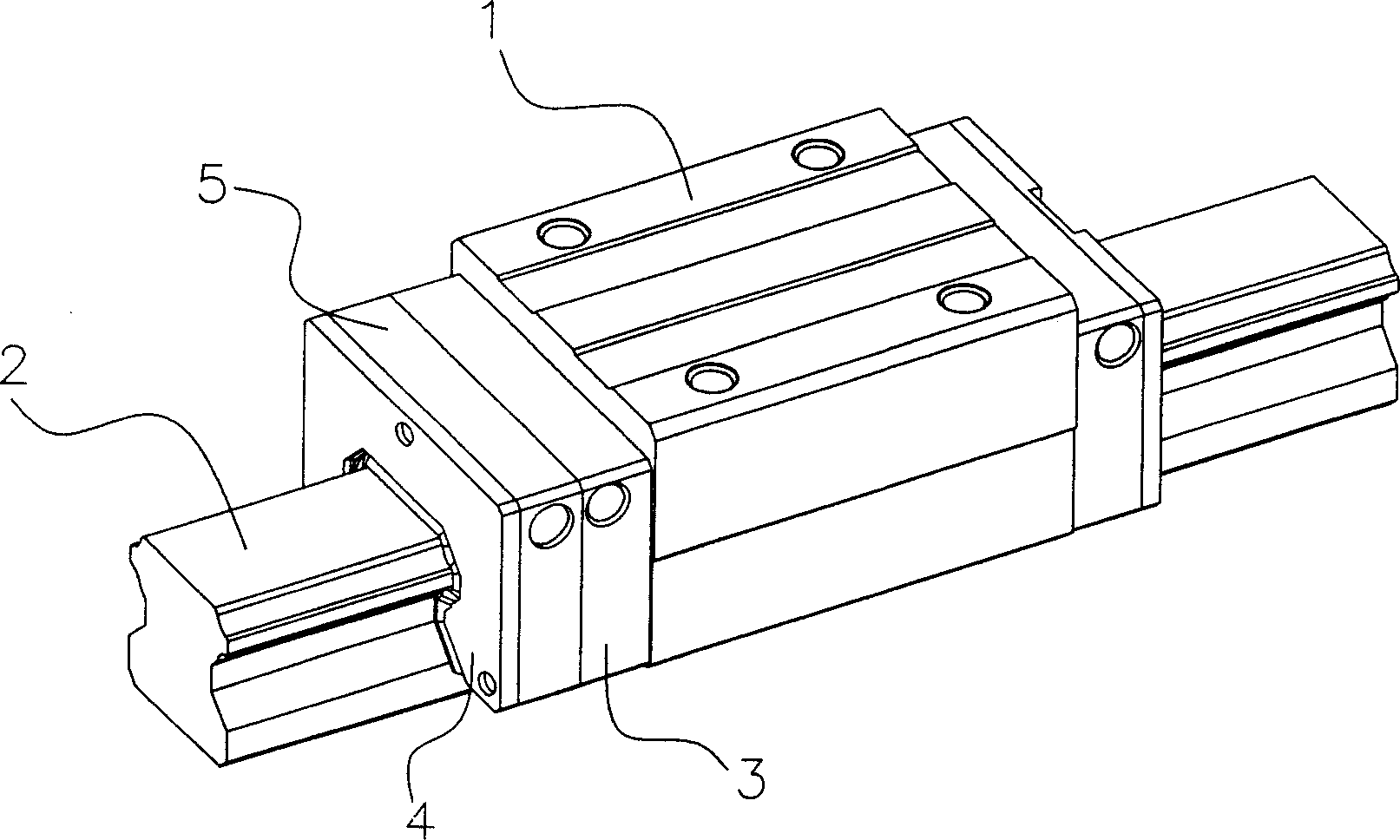

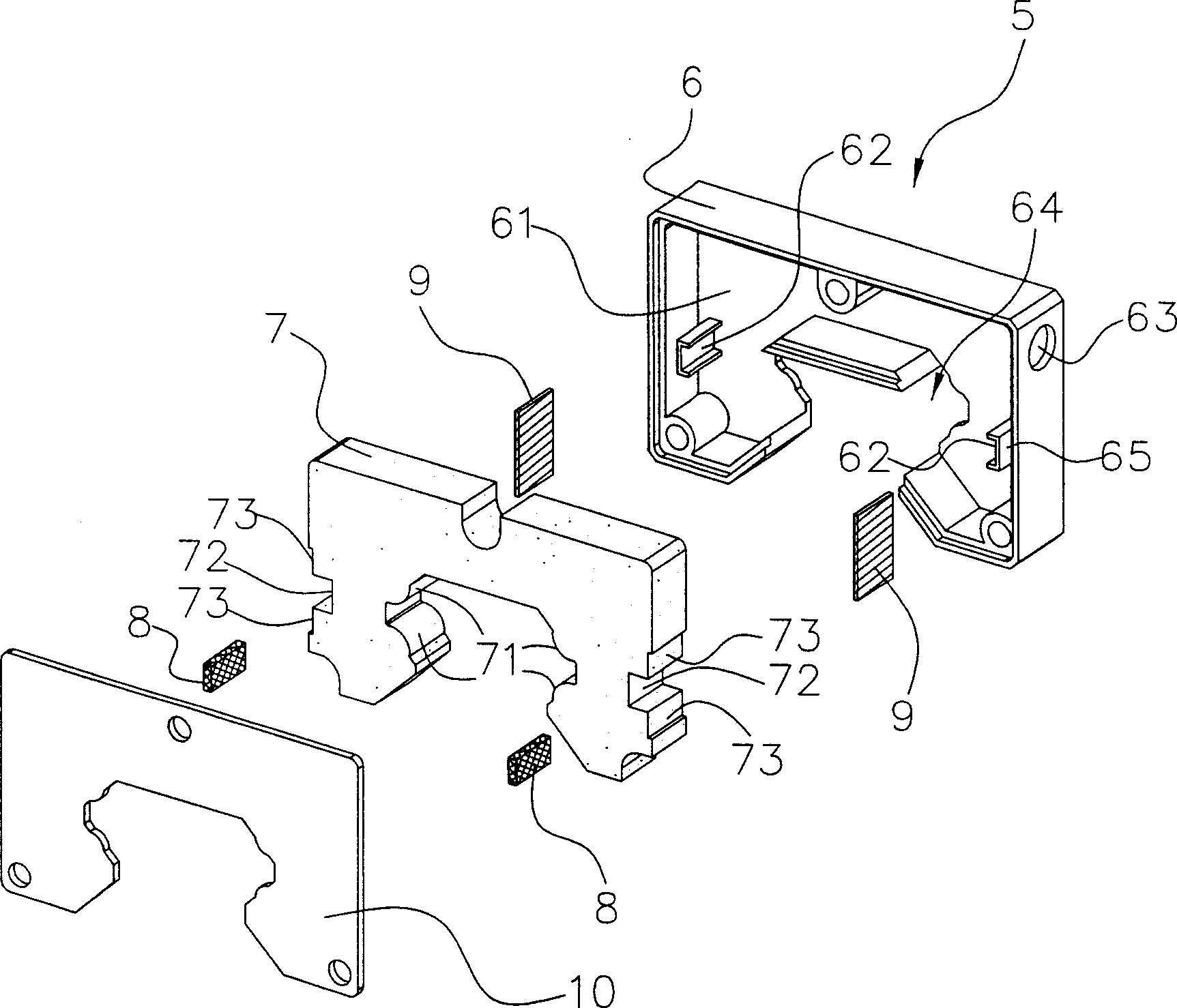

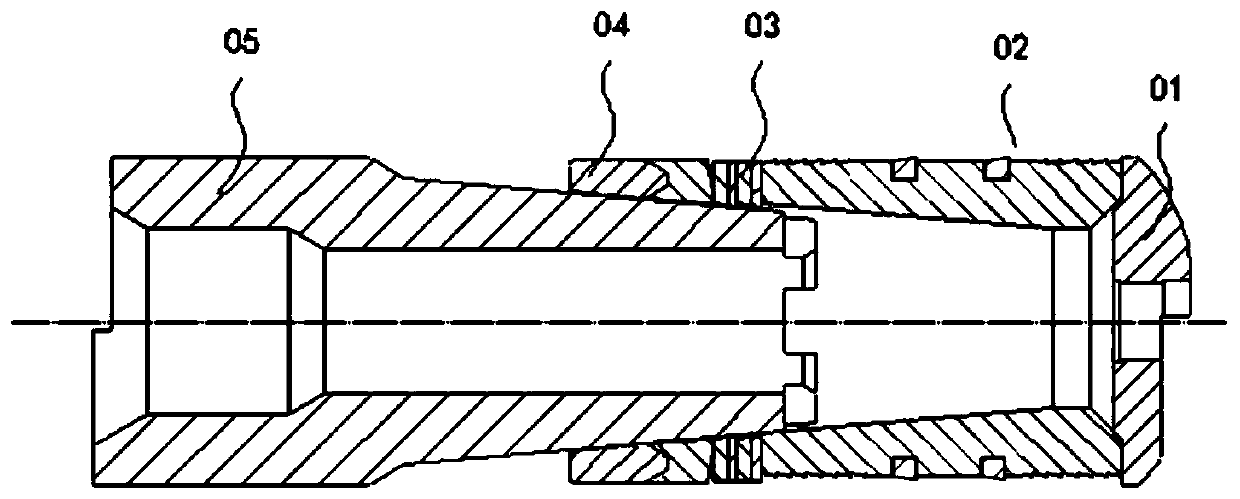

Linear sliding rail containing lubricating retaining device

The invention is a truly original linear sliding rail comprising lubrication holder, applied in the lubricating device at the end of a slide block, and it comprises: casing, lubrication-containing component, magnetic piece and magnet, and uses the magnet to produce attraction corresponding to the magnetic piece (such as metallic magnetic piece and metallic sliding rail) to make the magnet or magnetic piece to push the lubricant-containing component so as to keep contact energy between the lubricant-containing component and the sliding rail, thus able to continuously supply lubricant from the lubricant-containing component to the surface of ball groove of the sliding rail to solve the problem of bad lubrication caused by abrasion of the lubricant-containing component and achieve a long-term maintenance-free effect

Owner:HIWIN TECH

Lightweight ball seat

PendingCN109944571AShorten the overall lengthImprove drilling efficiencyFluid removalWell/borehole valve arrangementsHardnessEngineering

The invention provides a lightweight ball seat. The seat comprises a lower joint, a slip, a sealing member and a central tube, the central tube is in a truncated cone shape, the sealing member and theslip sequentially sleeve the outer side of one end with a smaller outer diameter of the central tube in a direction in which the outer diameter of the central tube is reduced, one end of the sealingmember abuts the one end of the slip, and the end of the one end with a smaller outer diameter of the central tube is located in the slip; the end of the lower joint abuts the other end of the slip, and the lower joint is internally provided with a sealing tool connecting structure; the sealing member adopts a two-stage structure, and the hardness of the first-stage sealing member is smaller thanthe hardness of the second-stage sealing member. The ball seat is provided with the two-stage sealing member, and improves the reliability of the sealing during work, the design of the ball seat is compact and short, the material is a lightweight magnesium-lithium alloy material, the drilling efficiency is improved, after the work is finished, it is easy to return out, and the risk of clogging a wellbore is eliminated.

Owner:VERTECHS OIL & GAS TECH CO LTD

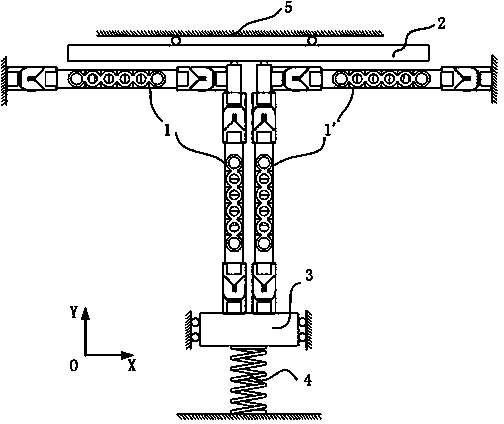

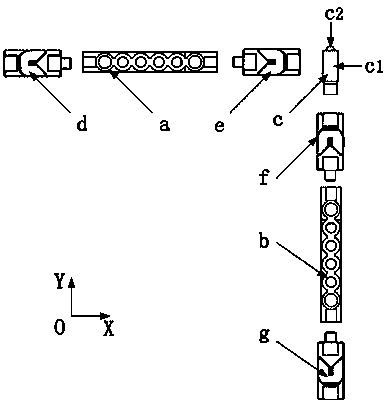

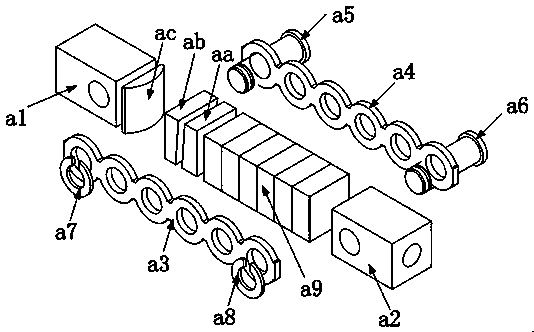

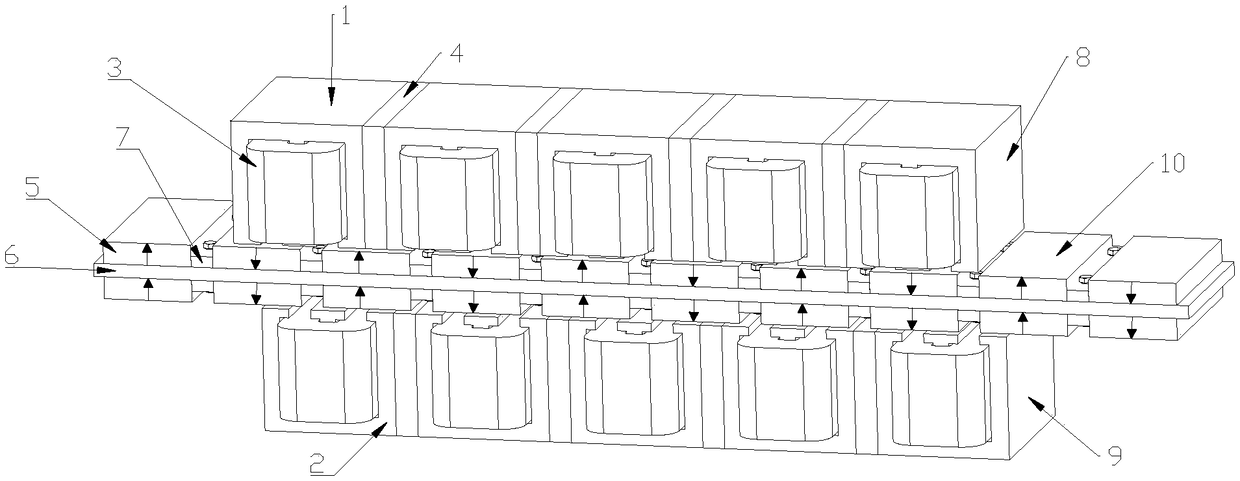

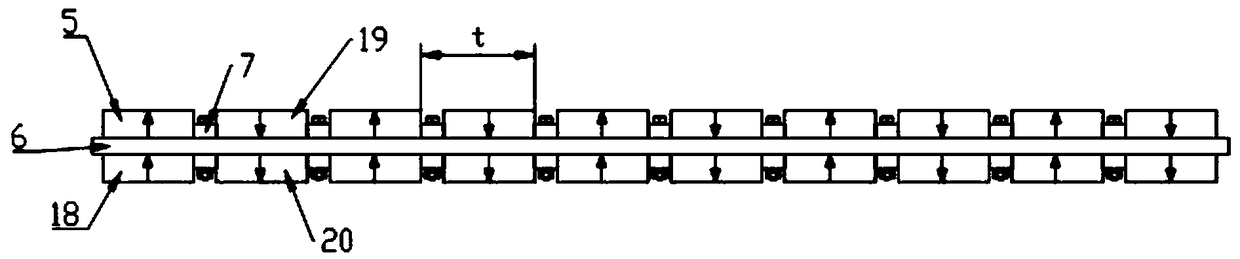

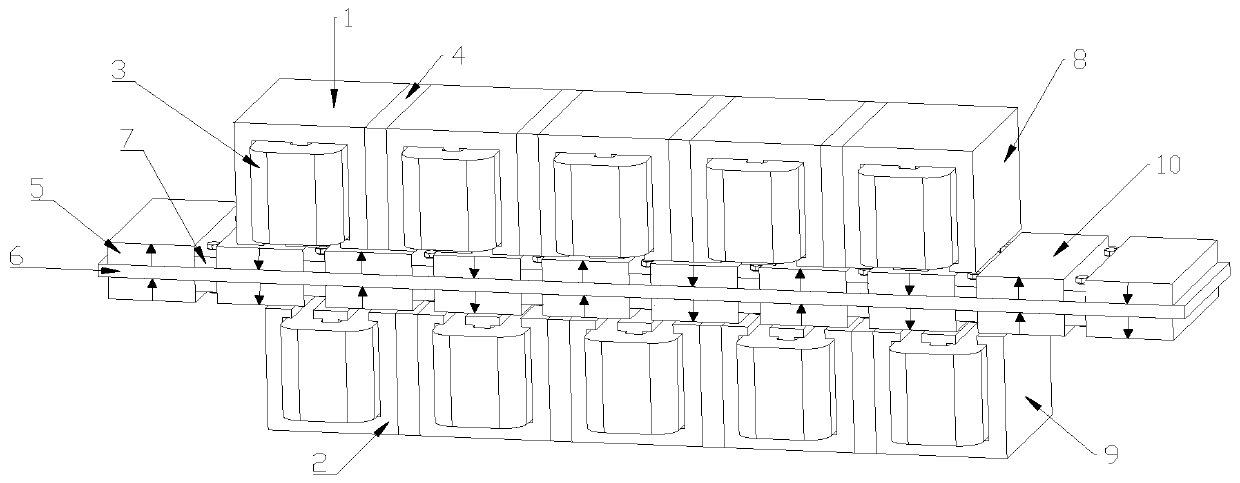

A dual-rotor modular permanent magnet linear motor capable of differential operation

The invention discloses a dual-mover modular permanent magnet linear motor capable of differential operation. The motor comprises an upper-layer rotor module, a lower-layer rotor module and a stator module; the stator module is arranged between the upper-layer rotor module and the lower-layer rotor module; the upper-layer rotor module includes a plurality of first E-shaped iron cores, and the opening direction of the first E-shaped iron cores faces the stator module; a magnetic isolation block is arranged between two adjacent first E-shaped iron cores; the lower-layer rotor module comprises aplurality of second E-shaped iron cores, the second E-shaped iron cores have the same structure as the first E-shaped iron cores, the opening direction of the second E-shaped iron cores faces the stator module, and a magnetic isolation block is arranged between two adjacent second E-shaped iron cores; the first E-shaped iron cores and the second E-shaped iron cores are both provided with windings;and the stator module comprises a permanent magnet group and a stator core. The modular structure of the invention facilitates expansion of the thrust range of the motor, weakens the thrust fluctuation of the motor, simplifies the maintenance difficulty of the motor and shortens the maintenance period.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

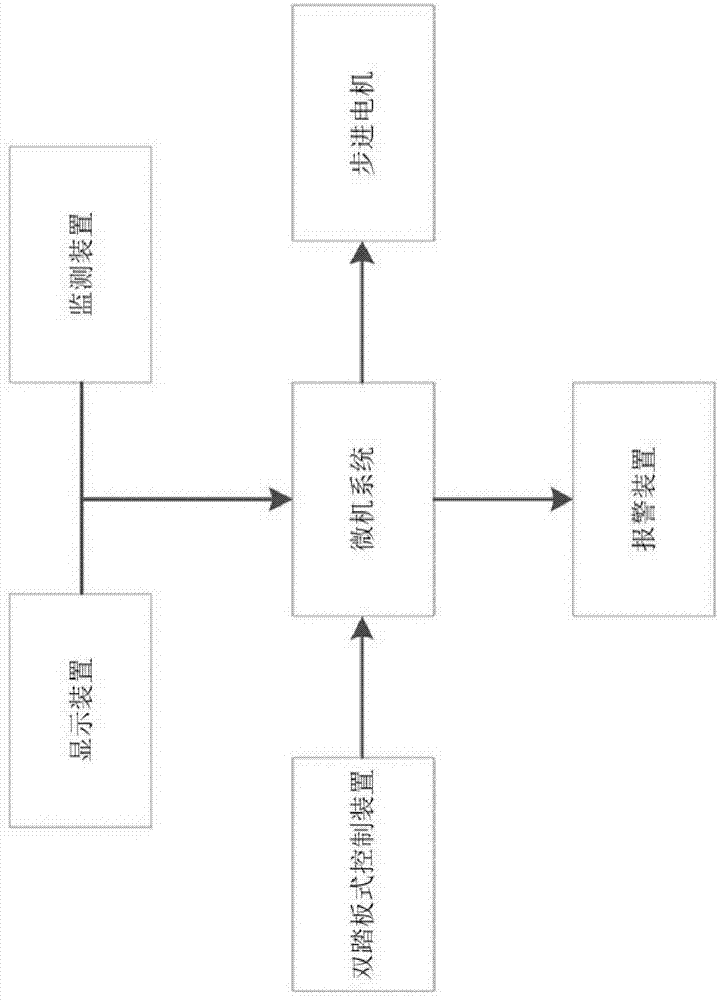

Syringe pump for nerve block anesthesia

InactiveCN107693895APrevent stray entryRetraction implementationAnaesthesiaSurgical needlesMicrocomputer systemDisplay device

The invention belongs to the field of medical appliances, and discloses a syringe pump for nerve block anesthesia and having a suction function in order to solve the technical problem that the conventional nerve block operations are completed by many workers. The syringe pump includes an infusion pump body; the infusion pump body includes a microcomputer system, a pump device, a detection device,an alarm device, and a display device; the pump device is used for providing power for infusion and pumping-back; the microcomputer system is used for controlling a working state of the pump device; the detection device is used for detecting the flow speed and the flow amount of liquid, the blocking pressure, leakage and bubbles and feeding the signals back to the microcomputer system; the alarm device is used for sending an alarm according to a command of the microcomputer; a dual-pedal type control device includes a pumping-back pedal and an infusion pedal; the pumping-back pedal is connected to a first signal input device for sending a pumping-back signal to the microcomputer system; and the infusion pedal is connected to a second signal input device for sending an infusion signal to the microcomputer system.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

Correction-lens-moving voice coil motor, anti-vibration device, interchangeable lens unit and optical apparatus

InactiveUS8817375B2Reduce power consumptionStable thrustTelevision system detailsPrintersElectrical conductorMagnetic poles

Owner:KENKOTOKINA CORP

Brush assembly

InactiveCN104753259AIncrease contact areaExtended service lifeSupports/enclosures/casingsConstant forceCoil spring

The invention relates to the technical field of a DC motor and particularly relates to a brush assembly. The brush assembly comprises brushes, a brush rack, brush holders and constant-force springs, and the brush holders are arranged on the brush rack. The brush assembly is characterized in that the cross section of the brush rack is cone-shaped, the brushes are provided with through holes, the through holes are communication holes which penetrate using surfaces of the brushes and surfaces opposite to the using surfaces, the brush holders are provided with slide grooves, a clamping support is fixed to two outer side positions of an inner end of each brush holder, each constant-force spring is a double-scroll coil spring with two ends provided with scrolls, middle parts of the constant-force springs abut against outer ends of the brushes, the middle segment of each spring and the outer end of the corresponding brush are sleeved in the slide groove of the corresponding brush holder, and two ends of each spring are supported by the corresponding clamping support. According to the brush assembly, the service life of the brushes is effectively prolonged, and the noise of the motor is reduced.

Owner:常州时代精工刃具有限公司

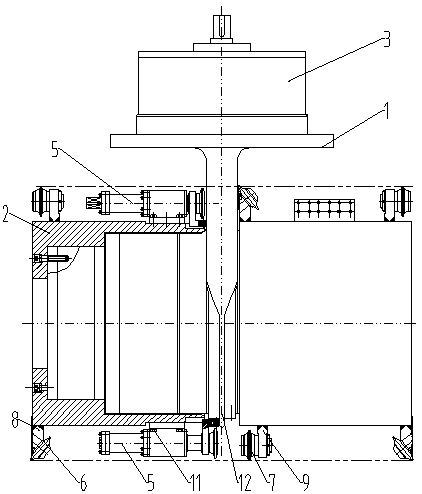

Rectangle hard rock shield cutter head

The invention discloses a rectangular hard rock shield cutter head. The cutter head solves the problems that in the prior art, cutter heads applied to rectangular tunnel construction are complex in structure, complicated in preparation work, large in impact force and the like. According to the technical scheme, the rectangular hard rock shield cutter head comprises a supporting frame, a roller cutter head body and a cutter set, the roller cutter head body is connected with a deceleration device mounted on the supporting frame, and the cutter set is mounted on the roller wall of the roller cutter head body; the cutter set comprises a hobbing cutter, a cutter and retractable cutters, the hobbing cutter is circumferentially arranged on the roller wall of the roller cutter head body, the cutter is radially arranged on the roller wall of the roller cutter head body, and the retractable cutters are symmetrically arranged on the roller wall of the roller cutter head body. According to the rectangular hard rock shield cutter head, the propulsion force and the cutting rotation power are relatively low, the fluctuation angle of the cutting force is small, and impact and vibration on equipment are weak. By adjusting the axial length of the cutting equipment and the supporting mode of a bracket, the cutter head can adapt to tunneling of partial sections and a whole section.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

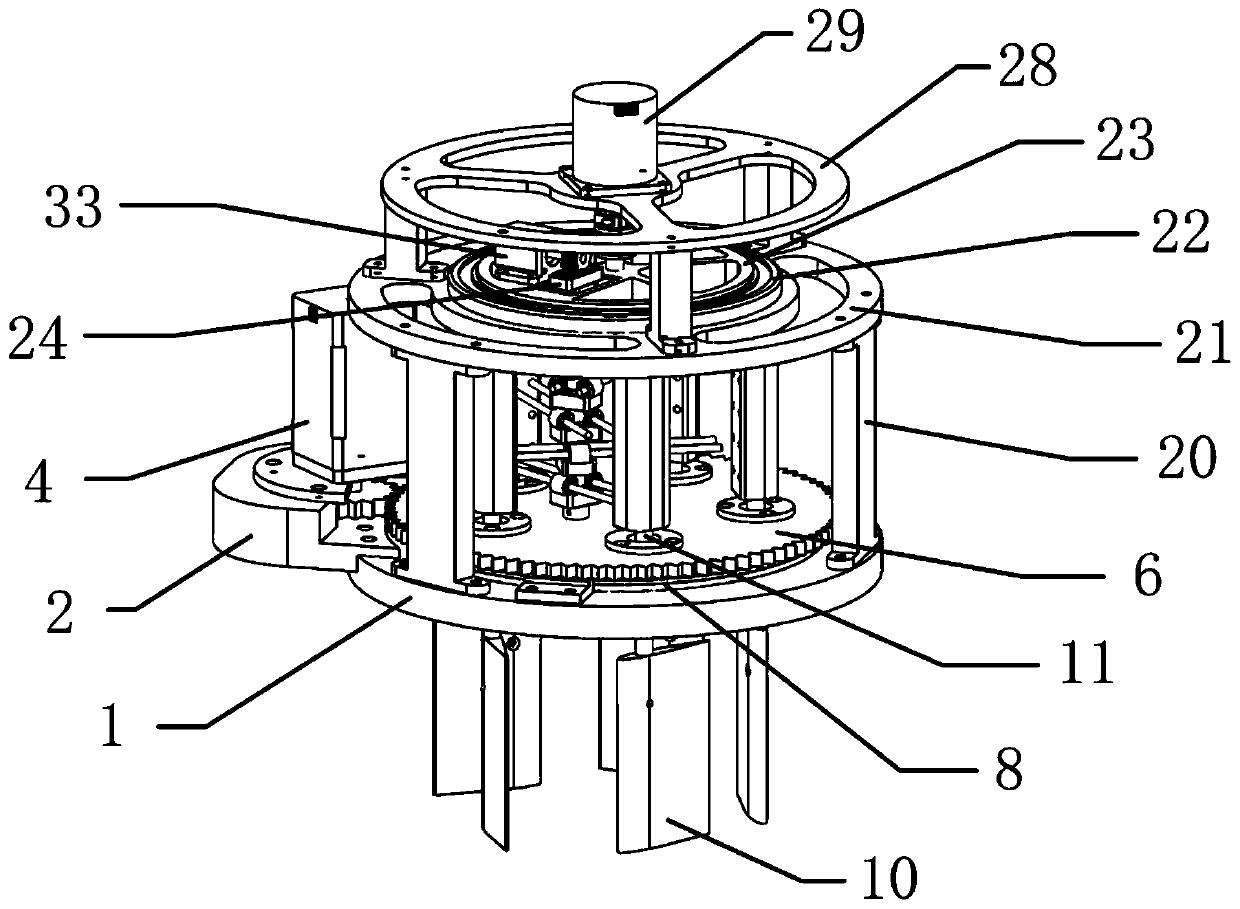

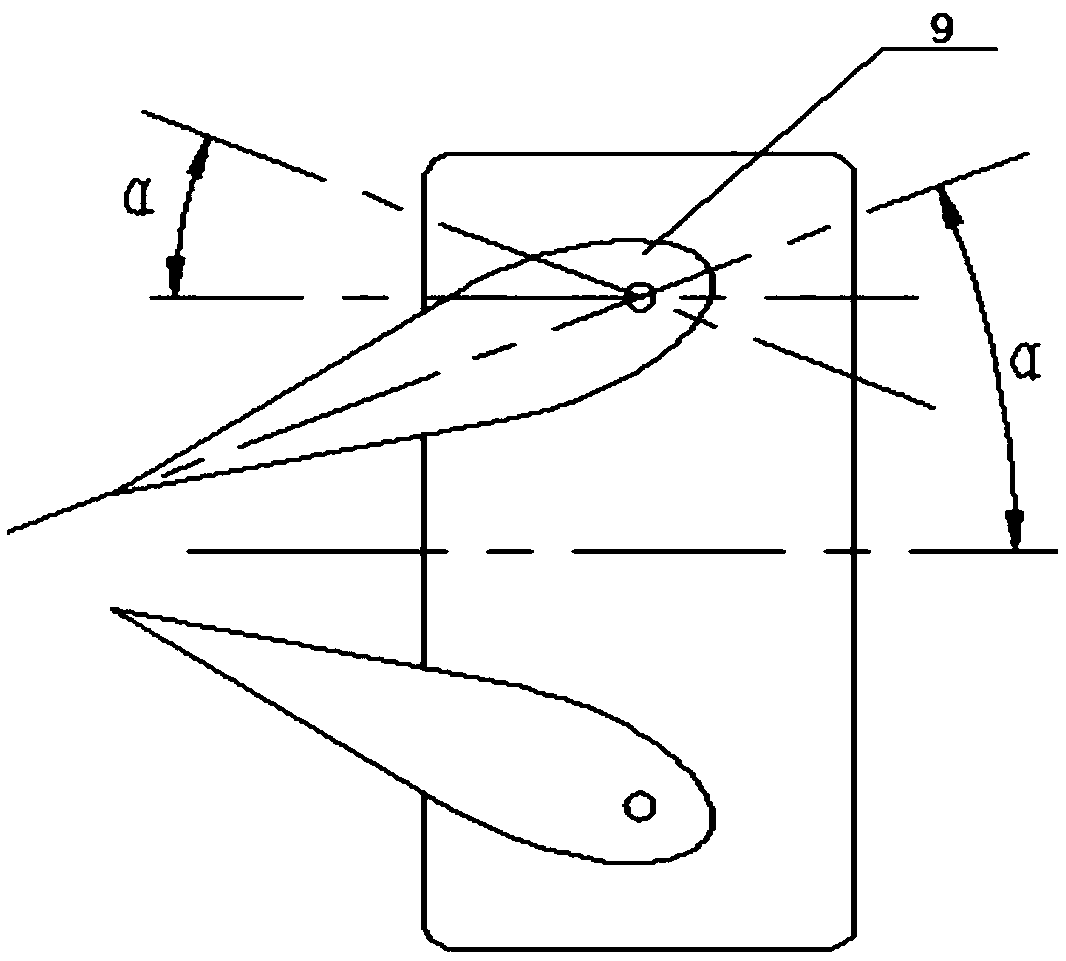

Sliding lever type cycloidal propeller

InactiveCN110386240AEasy to controlQuick responsePropulsion power plantsPropulsive elements of rotary typePropellerControl theory

The invention relates to a sliding lever type cycloidal propeller. The sliding lever type cycloidal propeller consists of a driving mechanism and an attack angle control mechanism. A gear of a drivingmotor of the driving mechanism is engaged with a gear of a propeller blade driving disc so that the propeller blade driving disc drives propeller blades to rotate to provide power for the cycloidal propeller. Each propeller blade shaft can freely rotate within a hole position and is connected with an attack angle control hub through a sliding rod to control the attack angles of each propeller blade in different positions. A control shaft in the attack angle control mechanism changes a phase angle of a propeller blade attack angle changing period according to a rotating angle of a control discso as to change thrust directions of the propeller blades. The sliding lever type cycloidal propeller has the beneficial effects that separate control of a rotation speed and a phase angle of the cycloidal propeller is realized, the moving rules of different propeller blades of the cycloidal propeller are completely as same as each other, and the integral thrust is stable; the sliding lever typecycloidal propeller has the characteristics of less special members, reasonable layout, simple and reliable structure and convenient maintenance; and the sliding lever type cycloidal propeller has thecharacteristics of no friction pair and less transmission links in the working process and small mechanical loss.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

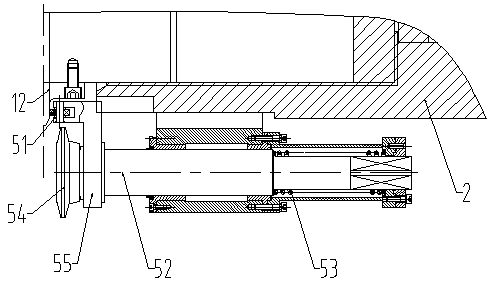

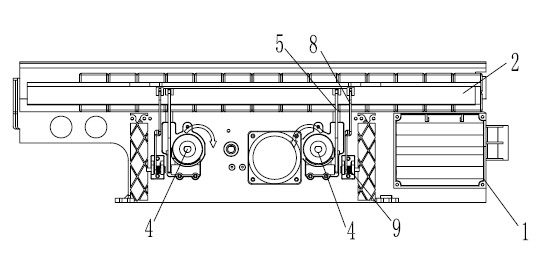

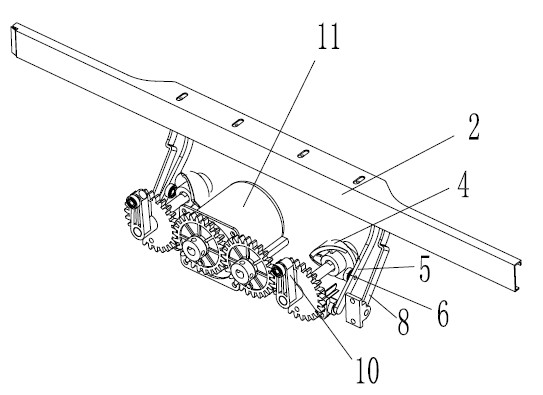

Pushing-elevating mechanism for full-automatic mahjong machine

The invention relates to a pushing-elevating mechanism for a full-automatic mahjong machine. The pushing-elevating mechanism comprises an pushing-elevating main body frame, a mahjong push plate, an elevating platform, a driving device, at least two peach-shaped wheels and active oscillating bars with the same number as the peach-shaped wheels, wherein the elevating platform is arranged on the pushing-elevating main body frame in a manner that the elevating platform can slide upwards and downwards; the contact surface of each peach-shaped wheel comprises a bottom plane and two sloping surfacesformed on the bottom plane and connected with each other at a highest position; the at least two peach-shaped wheels are bilaterally symmetrically arranged below the mahjong push plate; one end of each active oscillating bar is hinged with the pushing-elevating main body frame while the other end is fixedly connected with the mahjong push plate; a bearing is rotatably arranged in the middle of the active oscillating bar and is pressed against the contact surface of the peach-shaped wheel; and the at least two peach-shaped wheels are in transmission connection with the driving device. Inclination of mahjong pushing can be avoided and action stability can be improved.

Owner:杭州赛峰电子机械制造有限公司

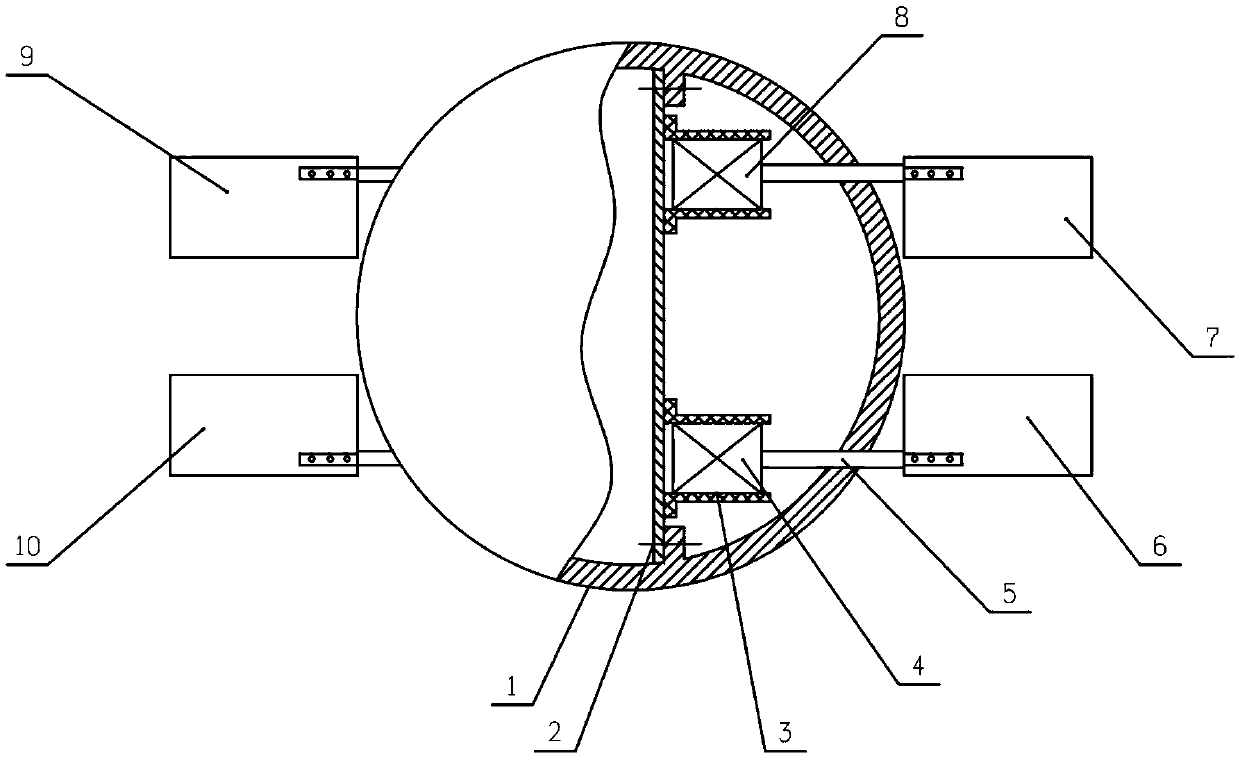

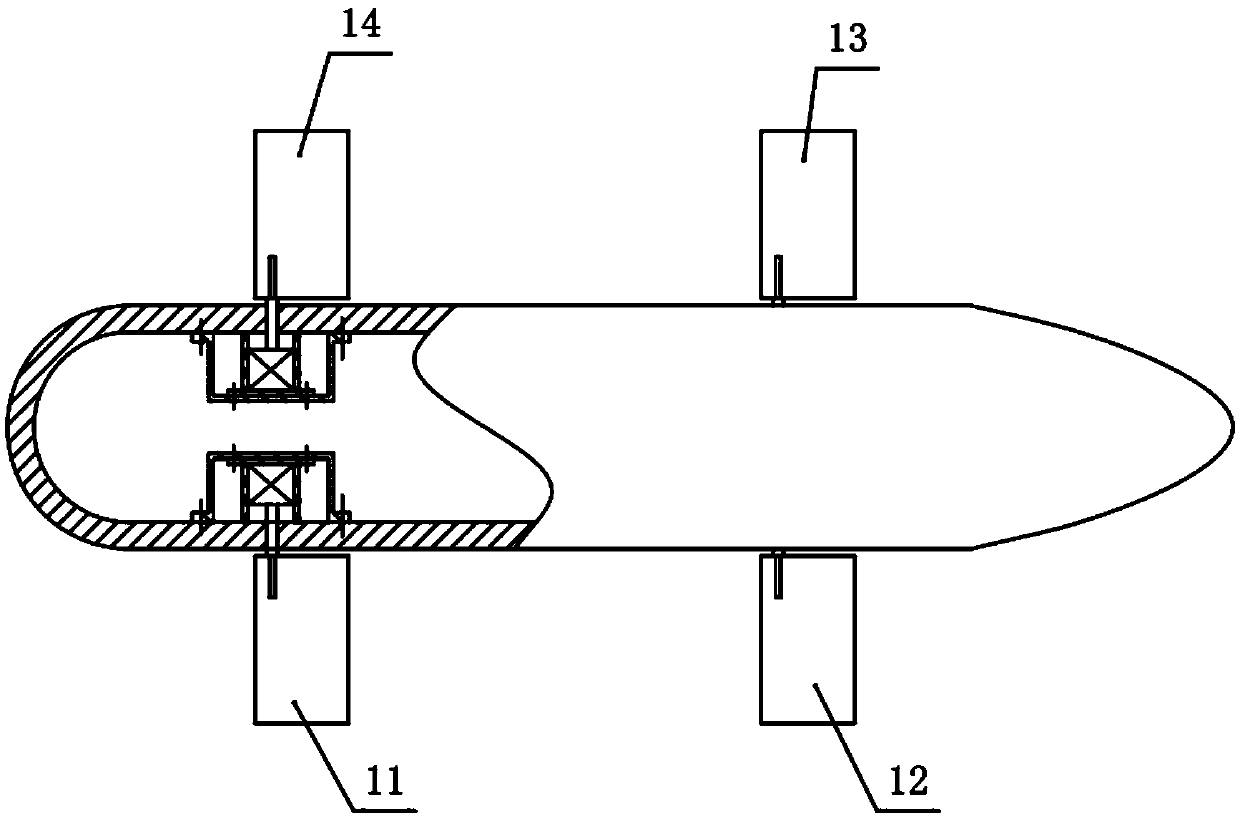

Underwater double-flapping-wing propeller

InactiveCN105584608ASimple structureStable thrustPropulsive elements of non-rotary typeAerospace engineeringPhase angle

The invention discloses an underwater double-flapping-wing propeller. The underwater double-flapping-wing propeller is composed of motors, flapping wings, flapping wing propeller bodies and an underwater vehicle body. The four sets of identical flapping wing propeller bodies are installed on the underwater vehicle along the central axis in a pairwise symmetry mode, rotary shafts of each set of upper and lower flapping wings are located on the same vertical line, the included angles between the rotary shafts of the upper and lower flapping wings and the center axial plane of the underwater vehicle are + / -30 degrees, the motors are fixed to installation plates of the flapping wing propeller bodies respectively through motor sleeves, output shafts of the motors are connected with rotary shafts of the flapping wing propeller bodies through couplers, and the motors drive the flapping wings. When the underwater vehicle moves, the flapping wings of the flapping wing propeller bodies conduct opposite beating motion at the same water beating frequency and up-and-down motion amplitude and opposite phase angles, and then the underwater vehicle can go straight, make a turn, float, descend and turn over. The double-flapping-wing propeller is simple in structure, flexible in motion, more stable in generated thrust and high in energy utilization rate, and has wide application prospects.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

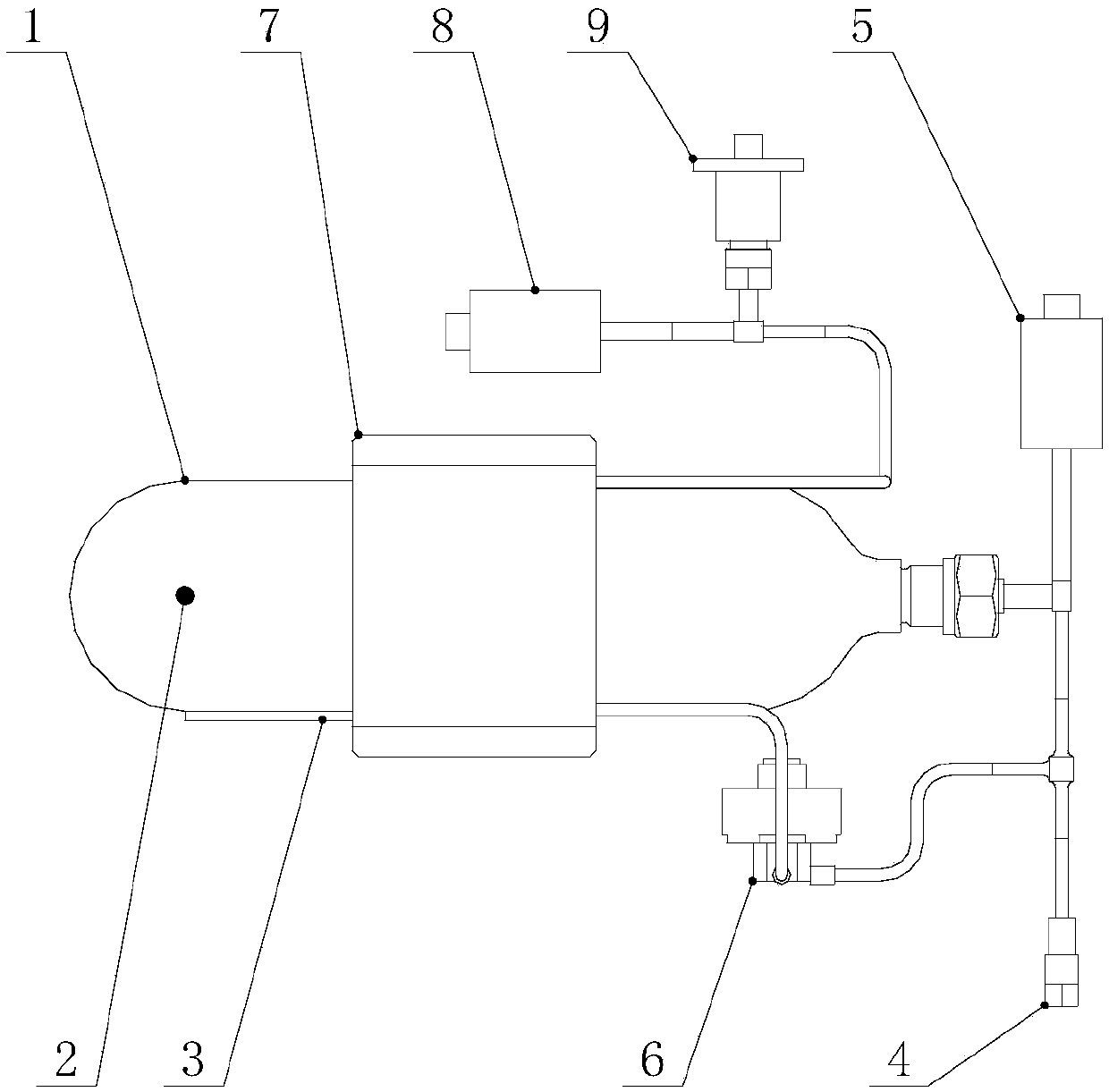

Small satellite liquefied gas constant pressure propulsion system and method

ActiveCN106564623BAchieve vaporizationImprove specific impulseCosmonautic propulsion system apparatusArtificial satellitesHigh pressureSatellite attitude control

The invention provides a system and method for liquefied gas constant-pressure propulsion of a small satellite. The system comprises a storage box, wherein ammonia is stored in the storage box in a gas-liquid two-phase form; a temperature sensor is installed on a shell of the storage box, and a high-pressure sensor is installed at an outlet pipe of the storage box and used to detect temperatures and pressures in the storage box; a heater is installed on the storage box and used to increase the storage box temperature and adjust the pressure of a propellant in the storage box; the storage box outlet pipe is equipped with a filling valve, and the filling valve is used to fill an ammonia propellant into the storage box; an output pipeline of the storage box is connected to a pressure reduction valve and used for throttling and temperature reduction of liquidated ammonia as well as stabilization of the downstream pressure; an output pipeline of the pressure reduction valve is connected to an evaporator, and the evaporator is installed on the storage box, is used for heat exchange with the high-temperature liquidated ammonia inside the storage box, and ensures that the gaseous propellant exists at an engine entrance; a low-pressure sensor is installed on an output pipeline of the evaporator and used to detect the pressure at the engine entrance; and an air-conditioning engine installed on the output pipeline of the evaporator provides push force and impulse needed by the satellite so as to satisfy demands for demands of functions including satellite attitude control and orbit control.

Owner:SHANGHAI INST OF SPACE PROPULSION

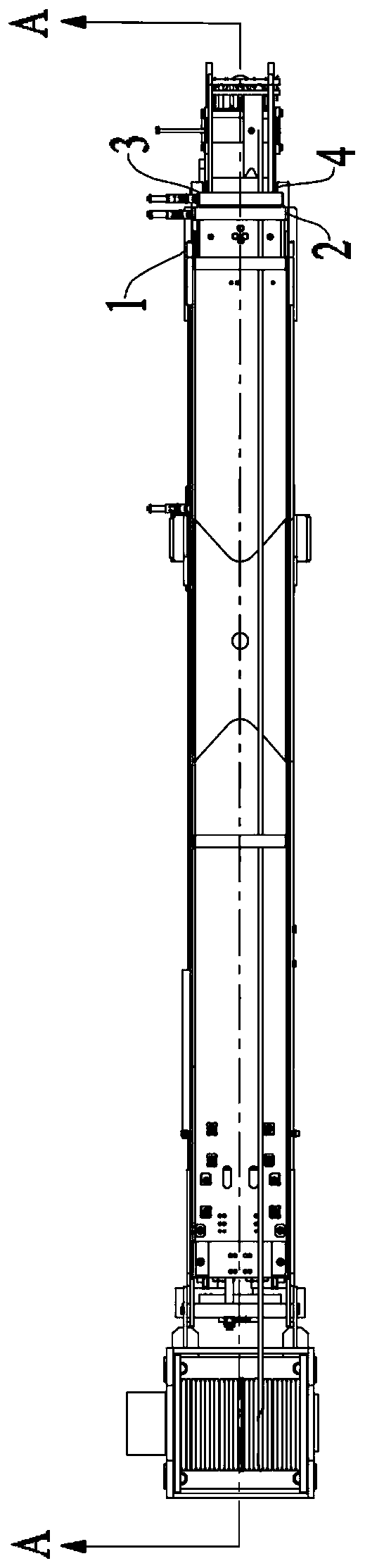

Synchronous telescopic mechanism of truck-mounted crane

The invention provides a synchronous telescopic mechanism of a truck-mounted crane. The synchronous telescopic mechanism comprises a basic arm, a first telescopic arm, a second telescopic arm, a thirdtelescopic arm, a multi-stage telescopic cylinder and a rope row mechanism, and the first telescopic arm, the second telescopic arm, the third telescopic arm, the multi-stage telescopic cylinder andthe rope row mechanism are sequentially connected into the basic arm in a sleeved manner; the rope row mechanism includes a first arm stretching rope assembly, a second arm stretching rope assembly, afirst arm shrinking rope assembly and a second arm shrinking rope assembly; the multi-stage telescopic cylinder includes a piston rod, a first-stage cylinder barrel, a two-stage cylinder barrel and abracket arranged at the end, far away from the first-stage cylinder barrel, of the two-stage cylinder barrel; and the first arm stretching rope assembly comprises a first arm stretching wheel and a first arm stretching rope, the second arm stretching rope assembly comprises a second arm stretching wheel and a second arm stretching rope, the first arm shrinking rope assembly comprises a first armshrinking wheel and a first arm shrinking rope, and the second arm shrinking rope assembly comprises a second arm shrinking wheel and a second arm shrinking rope. The synchronous telescopic mechanismhas the characteristics of being simple in structure and convenient to install.

Owner:HUNAN SHUANGDA ELECTROMECHANICAL CO LTD

A dual mover modular permanent magnet linear motor capable of differential operation

ActiveCN109004805BStable thrustStable outputPropulsion systemsElectric machinePermanent magnet linear motor

The invention discloses a dual-mover modular permanent magnet linear motor capable of differential operation. The motor comprises an upper-layer rotor module, a lower-layer rotor module and a stator module; the stator module is arranged between the upper-layer rotor module and the lower-layer rotor module; the upper-layer rotor module includes a plurality of first E-shaped iron cores, and the opening direction of the first E-shaped iron cores faces the stator module; a magnetic isolation block is arranged between two adjacent first E-shaped iron cores; the lower-layer rotor module comprises aplurality of second E-shaped iron cores, the second E-shaped iron cores have the same structure as the first E-shaped iron cores, the opening direction of the second E-shaped iron cores faces the stator module, and a magnetic isolation block is arranged between two adjacent second E-shaped iron cores; the first E-shaped iron cores and the second E-shaped iron cores are both provided with windings;and the stator module comprises a permanent magnet group and a stator core. The modular structure of the invention facilitates expansion of the thrust range of the motor, weakens the thrust fluctuation of the motor, simplifies the maintenance difficulty of the motor and shortens the maintenance period.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

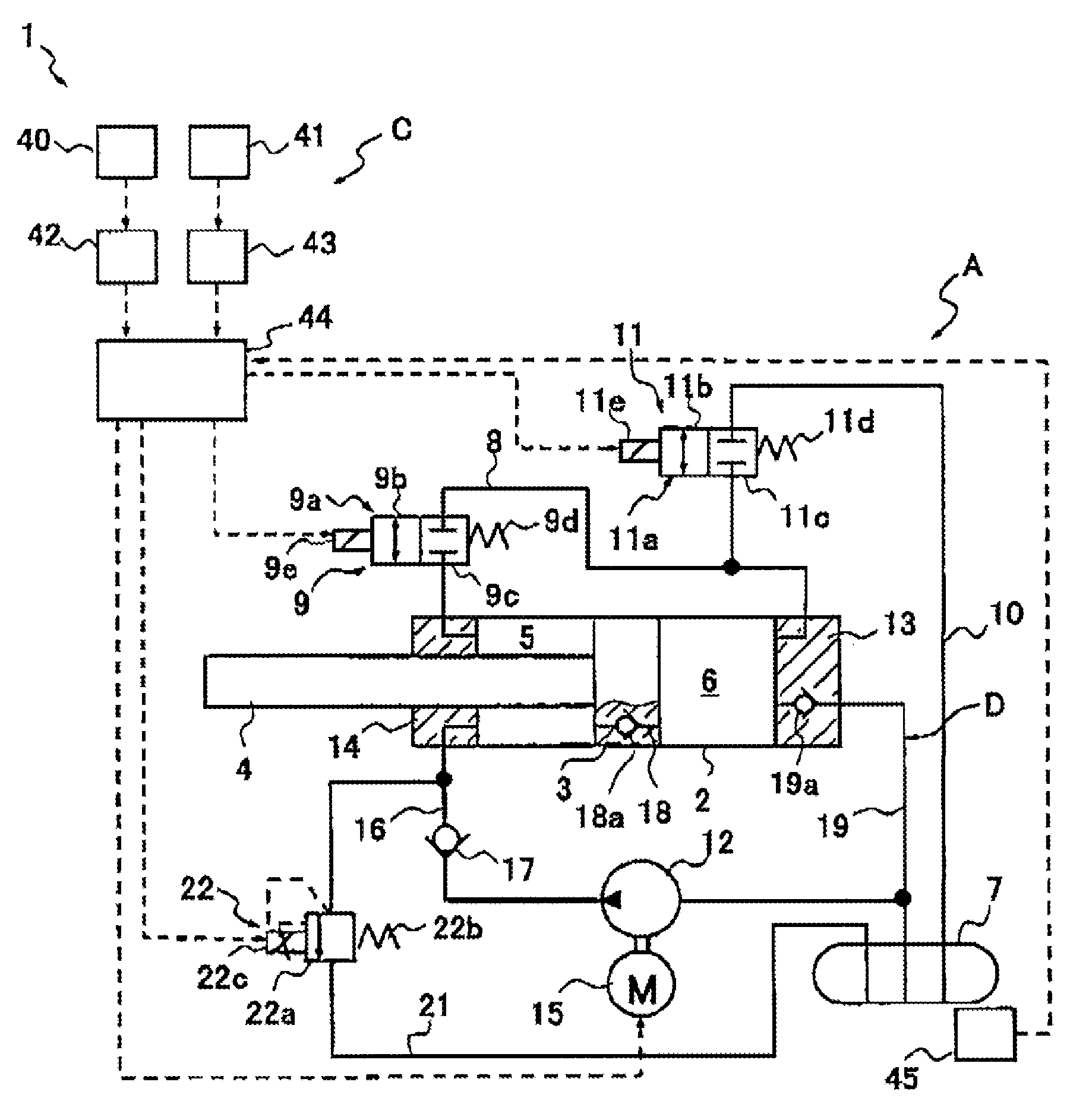

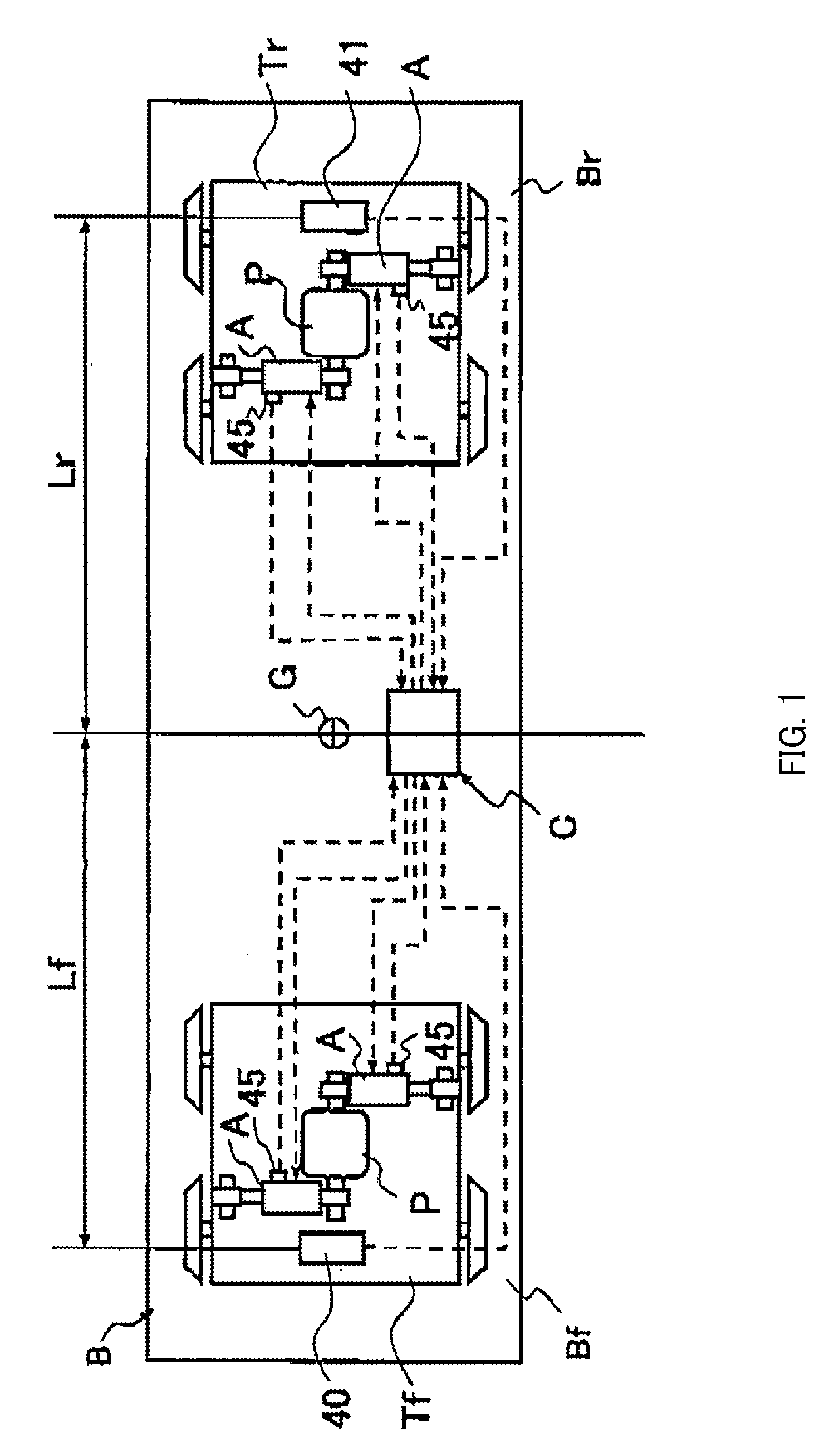

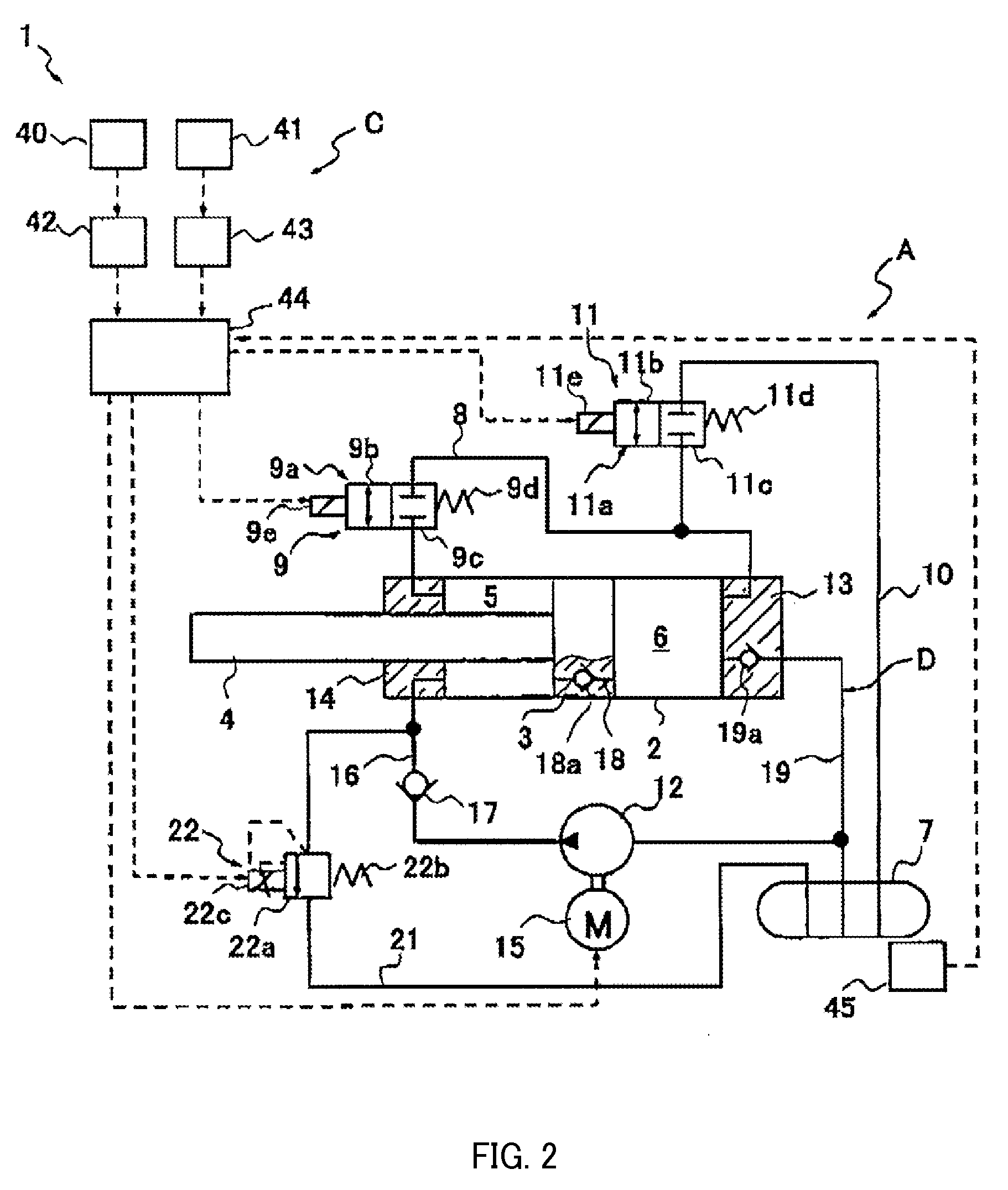

Vibration damping device for railway vehicle

ActiveUS9328789B2Vibration of the body may be aggravatedImprove deviationSpringsServomotorsHydraulic fluidActuator

A vibration damping device for railway vehicle includes an actuator and a damper circuit that causes the actuator to function as a damper. The actuator includes a cylinder coupled to a truck of a railway vehicle, a piston, a rod coupled to the piston and a body, a rod-side chamber and a piston-side chamber inside the cylinder, a first on-off valve for a first passage that communicates between a rod-side chamber and a piston-side chamber, a second on-off valve for a second passage that communicates between the piston-side chamber and a tank, and a pump that supplies a hydraulic fluid into the rod-side chamber. The hydraulic fluid has such kinematic viscosity-temperature characteristics that a kinematic viscosity of the hydraulic fluid ranges from 7 mm2 / s to 50 mm2 / s in a temperature range of from 20° C. to 60° C.

Owner:KYB CORP

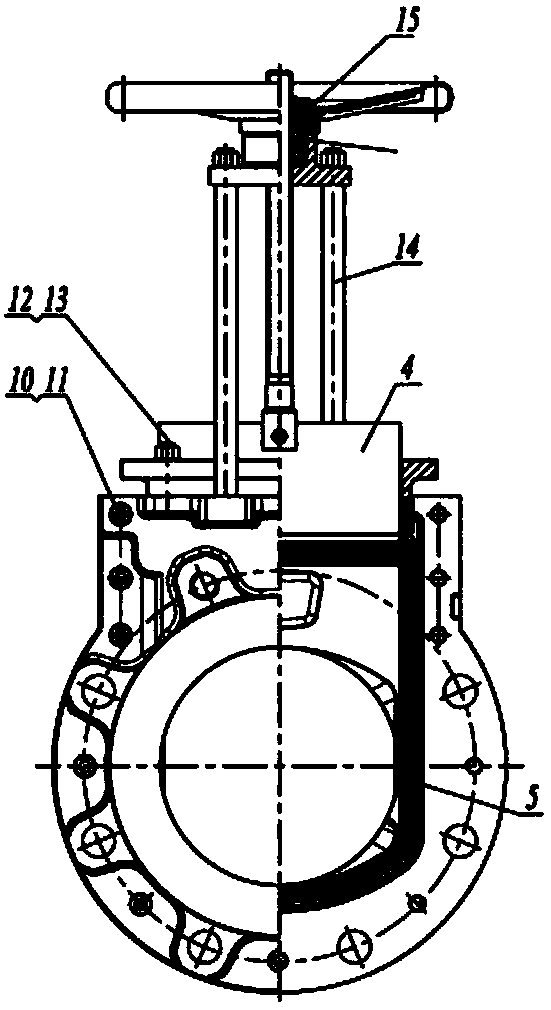

Flashboard periphery sealed knife gate valve

PendingCN108547988AOpening and closing thrust is smallWon't pile upSpindle sealingsSlide valveEngineeringPressure difference

The invention relates to a flashboard periphery sealed knife gate valve. The flashboard periphery sealed knife gate valve comprises a valve body. The top of the valve body is fixedly connected with asupport. An operating device is fixed to the top of the support. The two sides of the valve body are provided with a left valve body and a right valve body. An elastic special-shaped valve seat is clamped and fixed between the left valve body and the right valve body. The special-shaped valve seat is in a U shape. A flashboard slides in the special-shaped valve seat in a sliding mode. The two sides of the top end of the special-shaped valve seat are provided with transverse cleaning scraping plates correspondingly. The space between the top end of the left valve body and the top end of the right valve body is filled with packing. The packing is fastened and pressed tightly through a packing bushing. A valve rod is arranged in the support. The top of the flashboard is connected with the bottom of the valve rod. The top of the valve rod is fixedly connected with the operating device. According to the flashboard periphery sealed knife gate valve, the valve body with the grooves is adoptedto clamp the elastic special-shaped valve seat to press the periphery of the flashboard for sealing; the sealing performance is goo; the thrust of the valve is stable, and the opening thrust cannot be increased due to rising of the pressure differential pressure of the valve.

Owner:云峰科技(北京)有限公司

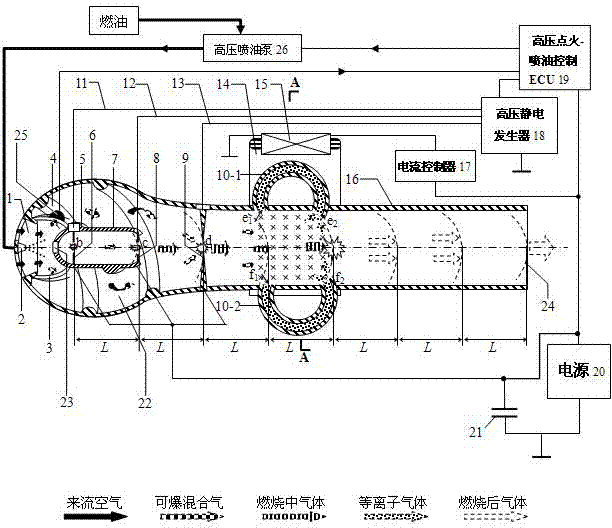

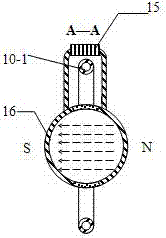

Detonation-wave-front high-voltage electric plasma gas relay coupling ignition detonation engine

The invention relates to a detonation-wave-front high-voltage electric plasma gas relay coupling ignition detonation engine which is formed by a pre-detonation burning pipe (7), a high-voltage ignition head c (8), a high-voltage ignition head, a plasma flow guide pipe (10), an annular face magnetic pole plate (14), a field coil (15), a detonation spraying pipe (16), a current controller (17), a high-voltage ignition-oil injection control ECU (19), a fuel and air premixing chamber (22), an air velocity transducer (25) and a high pressure oil spraying pump (26). Through multi-stage high-voltage ignition and plasma gas discharge, after a tiny pulse detonation wave is subject to three-stage relay coupling ignition, energy is amplified continuously, the best energy is achieved finally, the energy is sprayed out from a fuel gas spraying opening (24), and generation of detonation is guaranteed. The detonation-wave-front high-voltage electric plasma gas relay coupling ignition detonation engine has the beneficial effects that (1) the detonation, control and quick holding of the knock can be solved, and the pulse detonation wave can be gradually amplified; (2) atomization, jetting and doping of liquid fuel and an oxidizing agent can be achieved; (3) stable pushing force can be generated, low frequency to high-frequency continuous work can be achieved; and (4) pulse knock engine power adjustment can be achieved.

Owner:江苏知聚知识产权服务有限公司

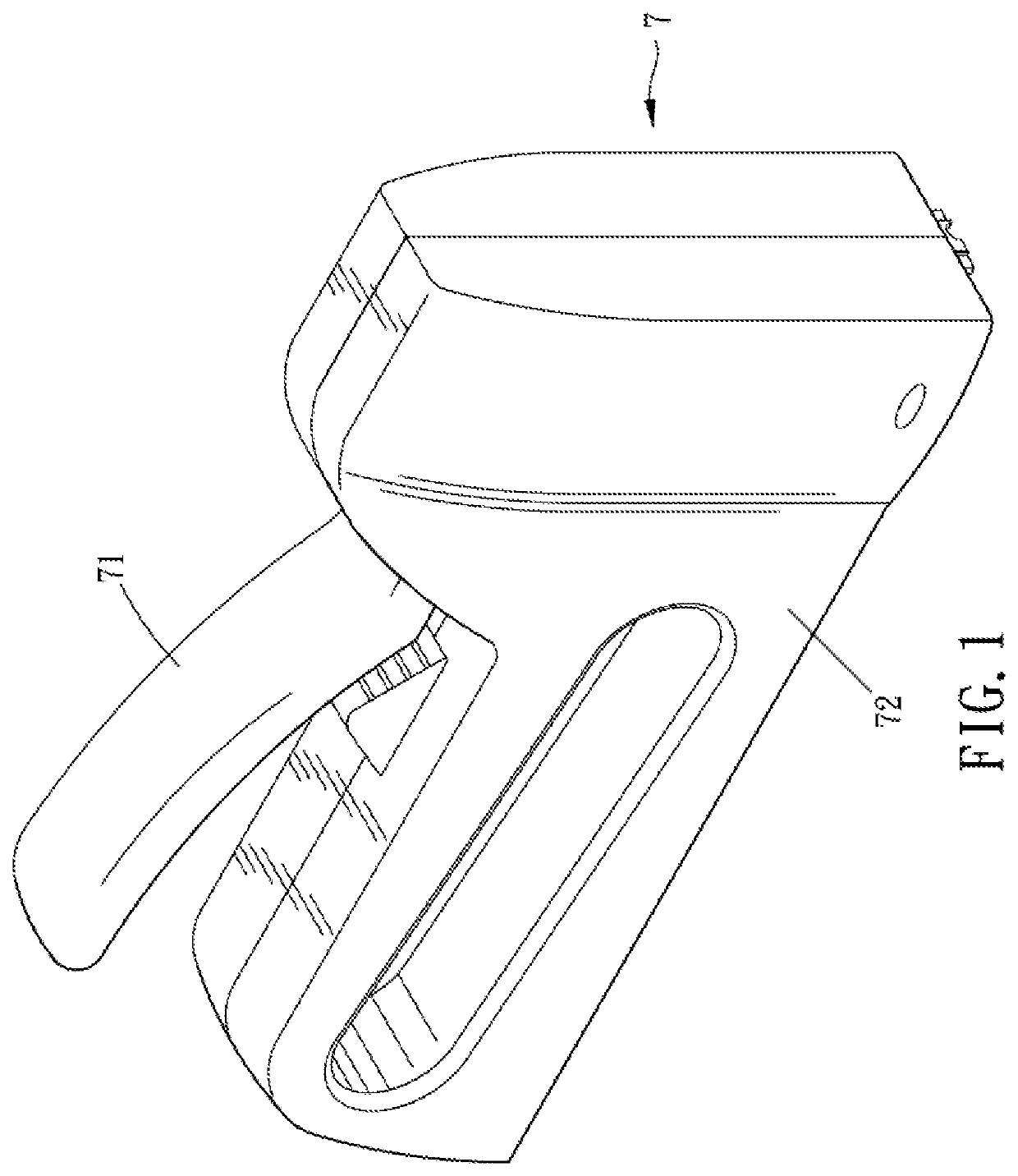

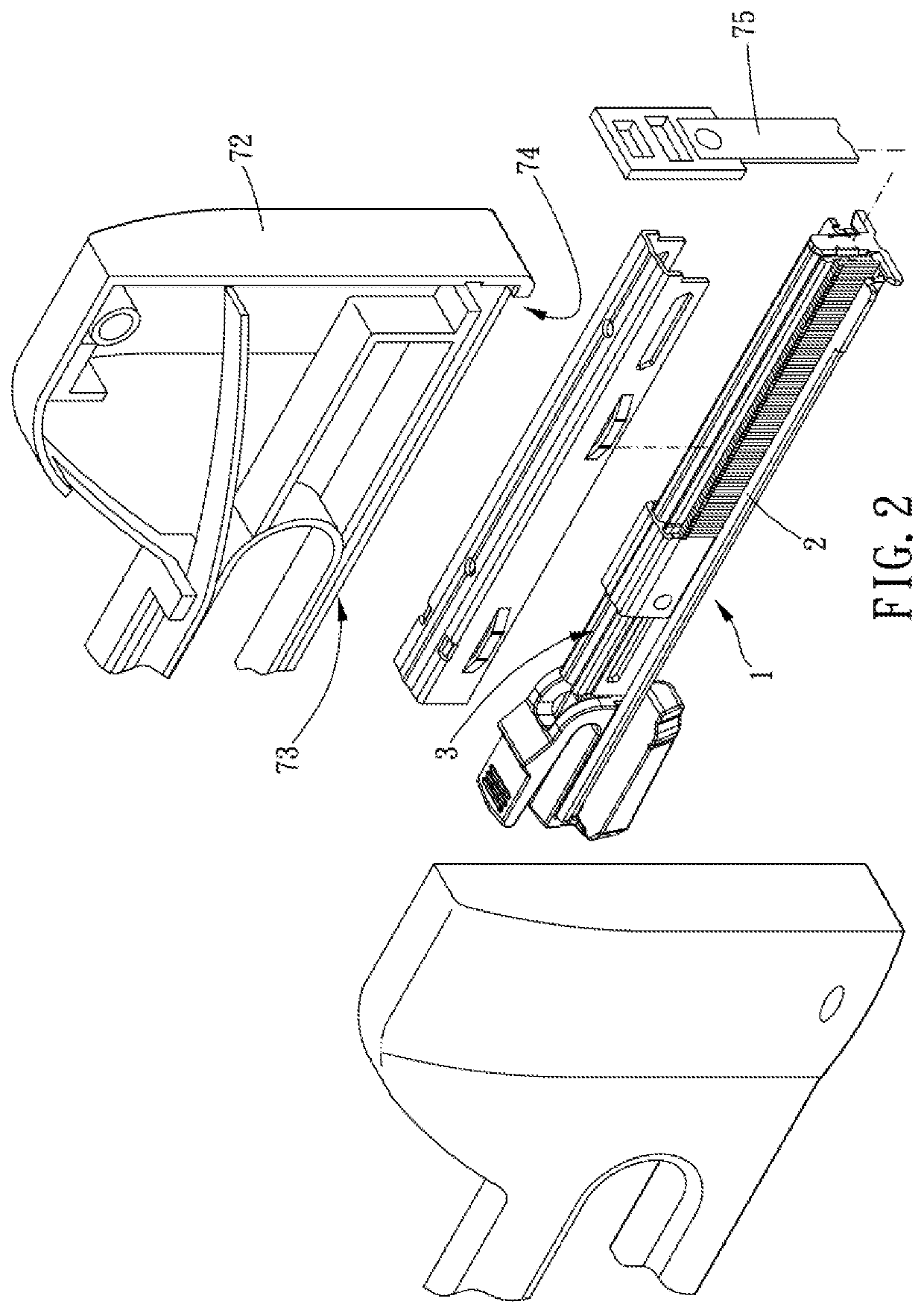

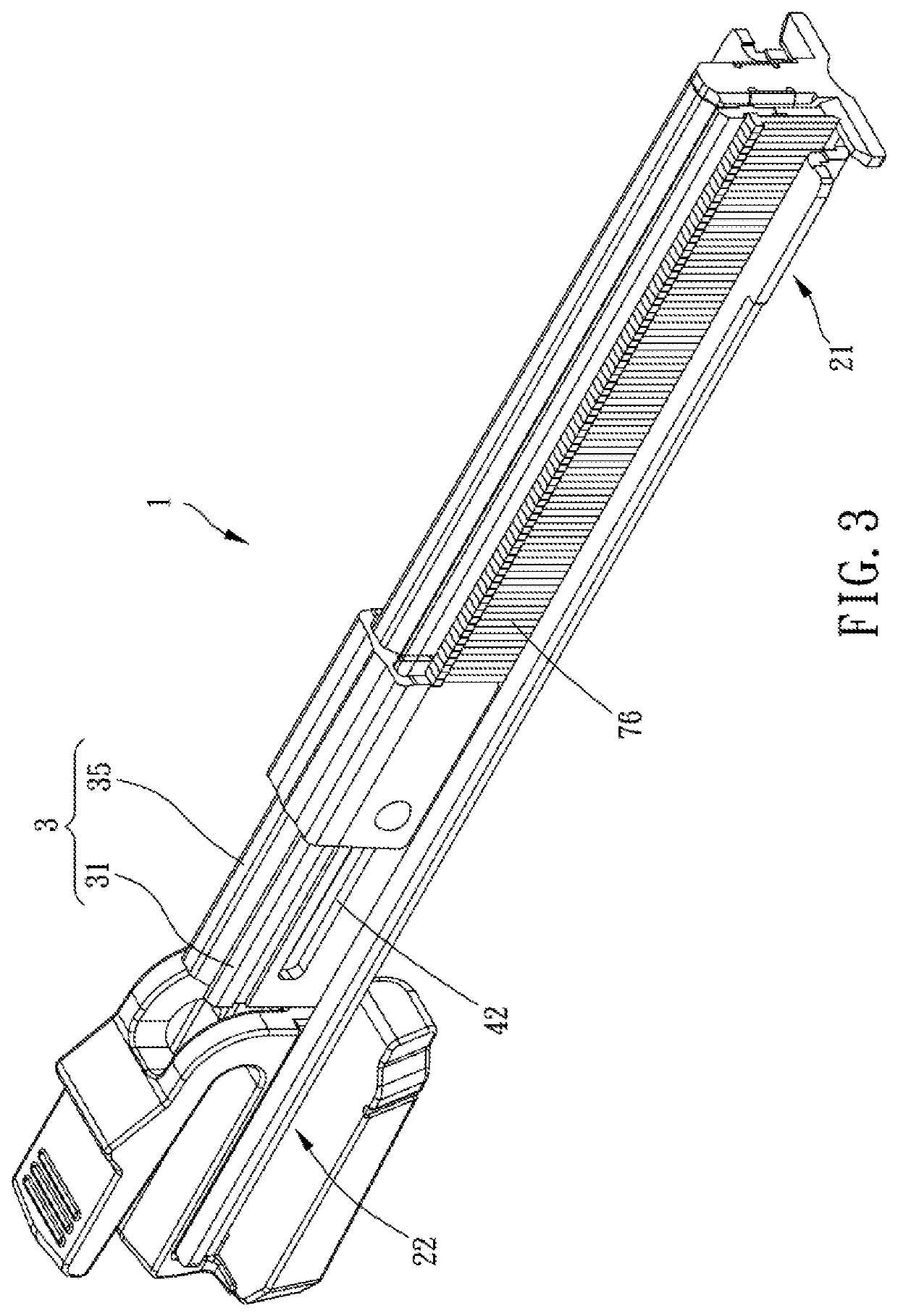

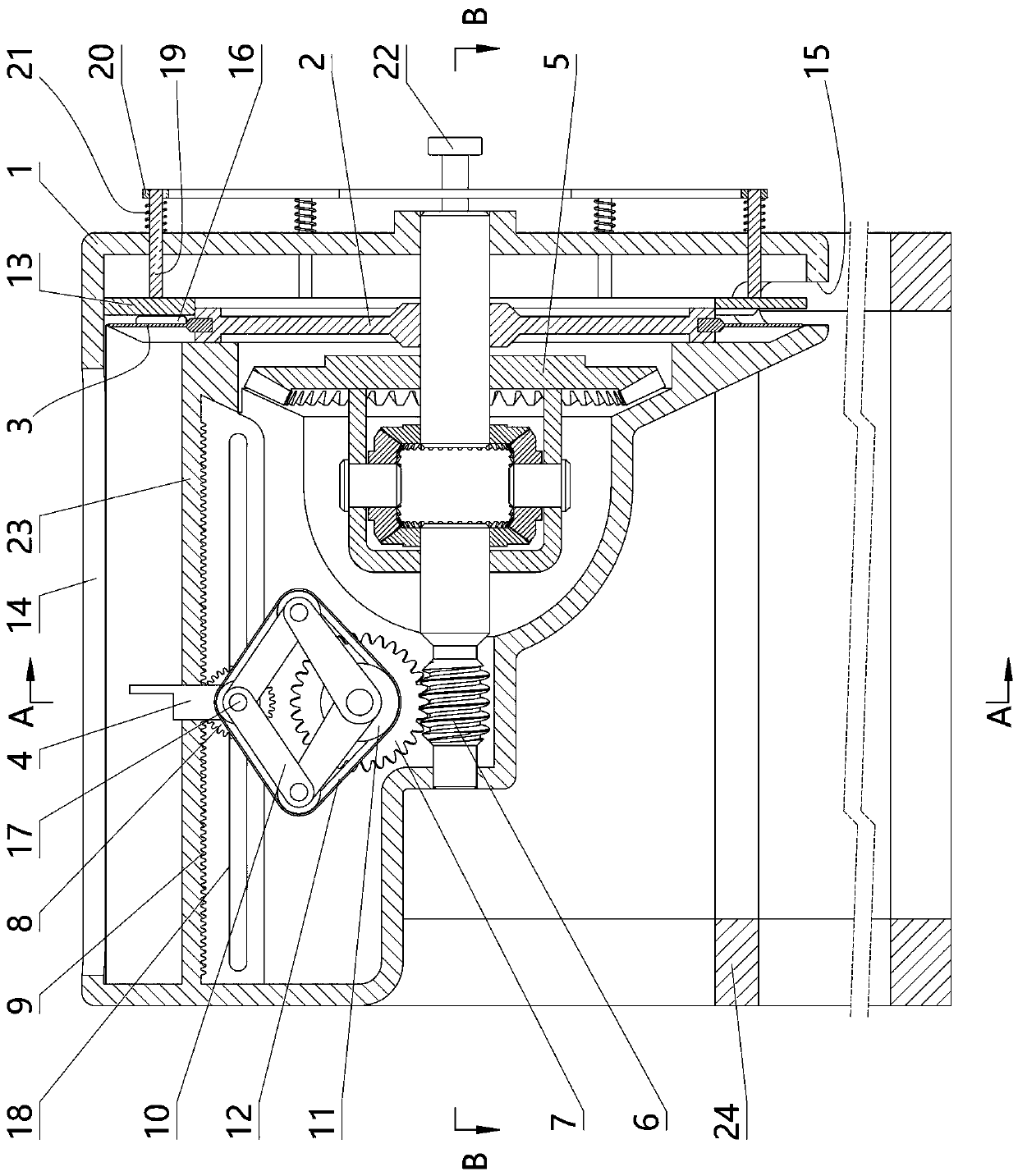

Magazine assembly and stapler including the same

A magazine assembly and a stapler including the same are provided. The magazine assembly includes a main body and a staple-pushing mechanism. The main body has a seat body and at least one rail, the seat body has a first end portion and a second end portion, a connection of the first and second end portions is defined as a moving path, and the at least one rail is disposed on the seat body. The staple-pushing mechanism is arranged on the main body, the staple-pushing mechanism includes a staple-pushing member and a constant force spring, and the staple-pushing member is driven to move toward the first end portion via the constant force spring.

Owner:APEX MFG

Convenient slicing device

ActiveCN110014472AGuaranteed continuityEasy to adjustMetal working apparatusMechanical engineeringParallelogram

The invention relates to a convenient slicing device. The device comprises a shell, a tool rest rotating on the shell, a blade on the tool rest and a feeding sliding block sliding on the shell, wherein the blade is arranged on the outer side of the circumference of the tool rest, the feeding sliding block is arranged on one side of the blade, and the sliding direction of the feeding sliding blockis parallel to the axial direction of the tool rest; a differential mechanism, a worm and a worm gear are arranged on the shell, one output shaft of the differential mechanism is coaxially connected with the tool rest, the other output shaft of the differential mechanism is coaxially connected with the worm, and the worm gear is meshed with the worm; the device further comprises a gear connected with the feeding sliding block in a rotating mode, a rack parallel to the sliding direction of the feeding sliding block is arranged on the shell, the gear is meshed with the rack, the worm gear and the gear are arranged in parallel in the axial direction and are connected through a parallelogram connecting rod mechanism, two hinge parts on any diagonal line of the connecting rod mechanism are hinged to the worm gear and the gear respectively, the four hinge parts of the connecting rod mechanism are coaxially hinged with belt wheels respectively, and the four belt wheels are connected through belts; a baffle plate arranged on the other side of the blade is arranged on the shell; and a feeding opening and a discharging opening are formed in the shell.

Owner:博兴兴业智能新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com