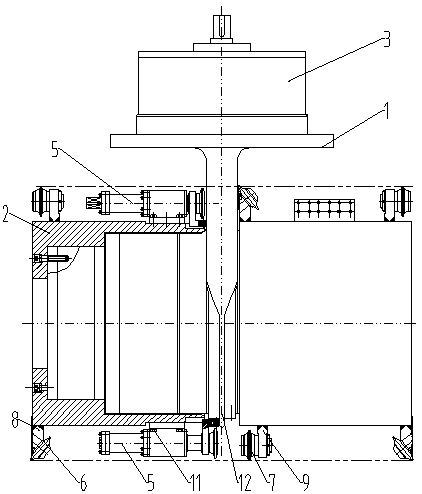

Rectangle hard rock shield cutter head

A cutter head, hard rock technology, applied in mining equipment, earth-moving, tunnels, etc., can solve the problems of cumbersome preparation work, low work efficiency, large impact force, etc., and achieves convenient operation, simple structure, and low impact and vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

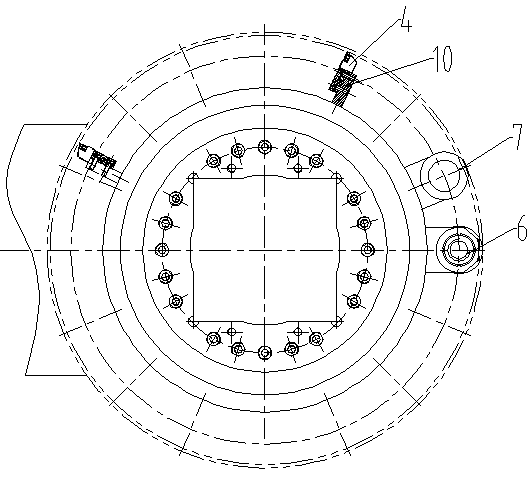

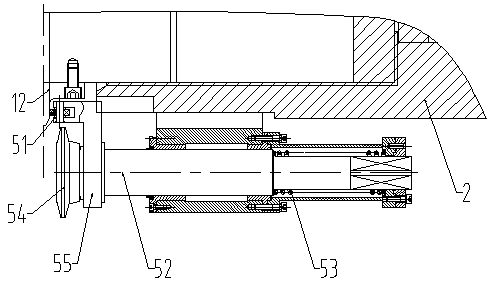

[0018] Embodiment 2, a rectangular hard rock shield cutting cutter head, the cutter 4 is connected with the drum cutter head 2 through the cutter seat 10, the cutter 4 is arranged on the cutter seat 10 in a strip shape, and the cutter uses a screw Fastened on the cutter seat, the cutter seat 10 is arranged on the drum cutter head 2 in the axial direction, and the cutter 4 is arranged in parallel with the drum cutter head 2 for peeling off floating rocks and taking away the peeled rocks. The height of the cutter 4 protruding from the drum cutter head 2 is lower than the height of the side hob 6 and the front hob 7 extending out of the drum cutter head 2, and the height of the cutter 4 extending out of the drum cutter head 2 is higher than the extension of the telescopic cutter 5 Out of the height of the drum cutter head 2, the hob distance of the side hob and the hob distance of the front hob are relatively small, which can effectively protect the cutter head from the impact of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com