Convenient slicing device

A slicing device and convenient technology, applied in metal processing and other directions, can solve the problems of inconvenient adjustment of slice thickness and unstable feeding force, and achieve the effect of simple and fast adjustment, reducing potential safety hazards and meeting the needs of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

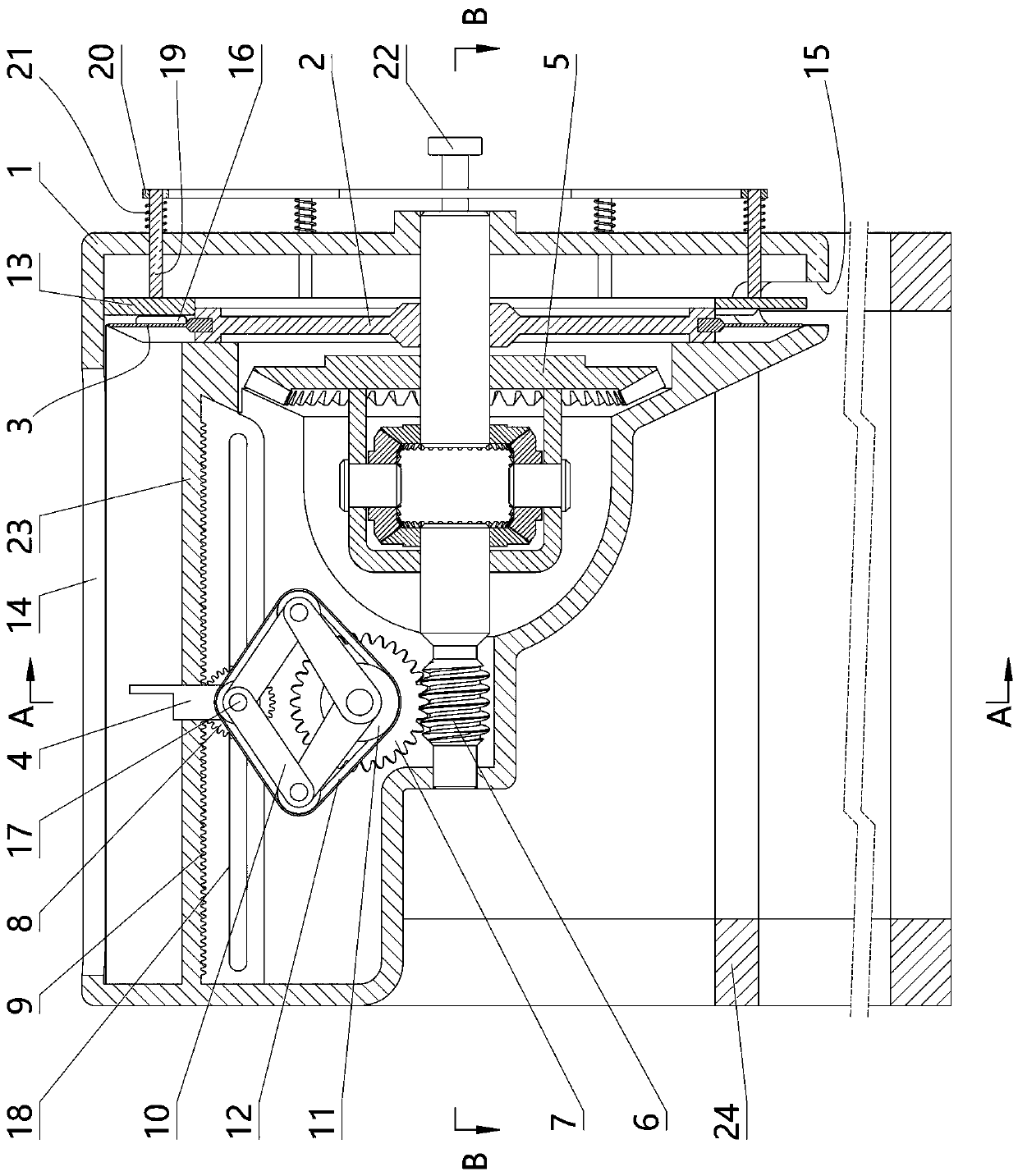

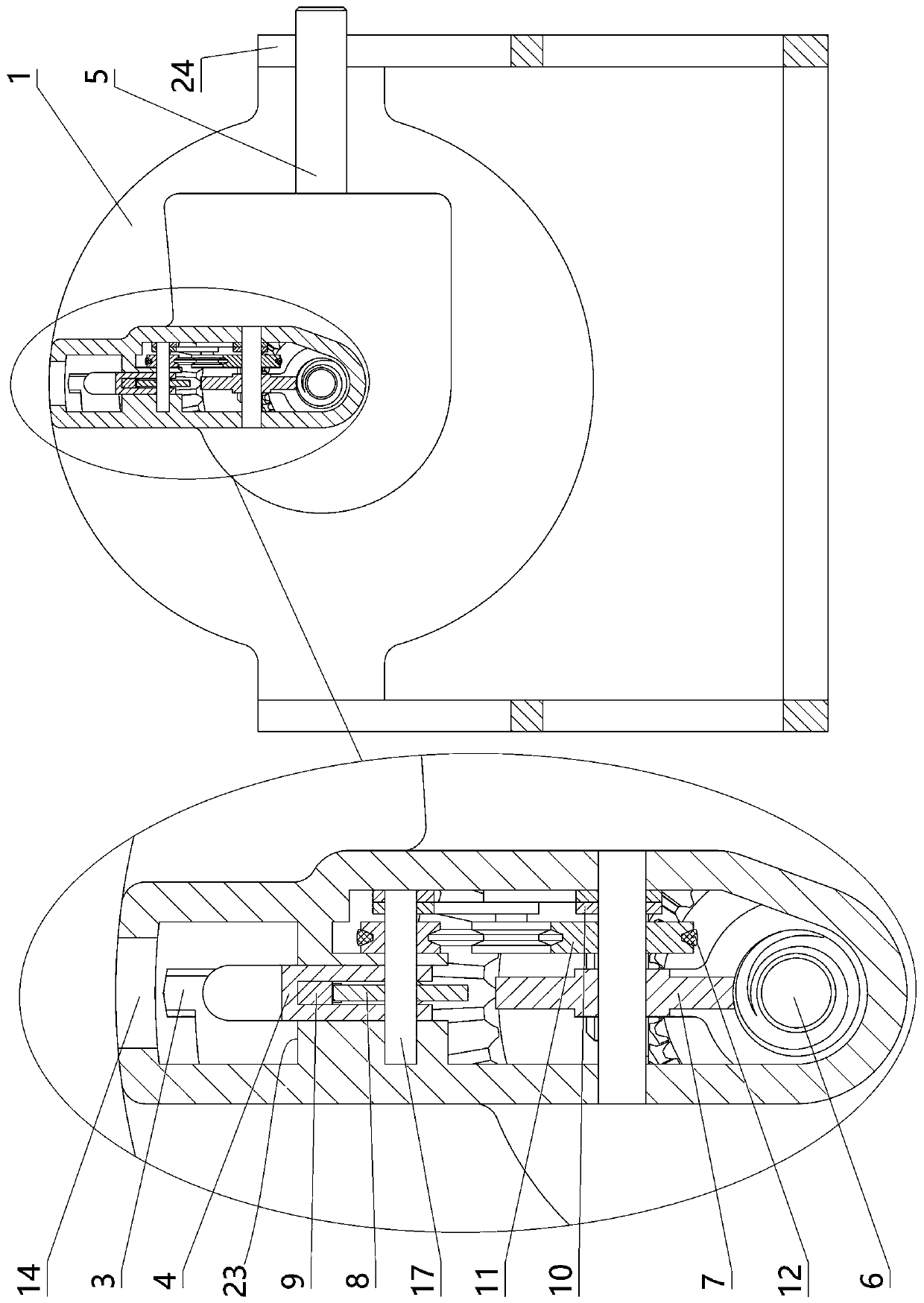

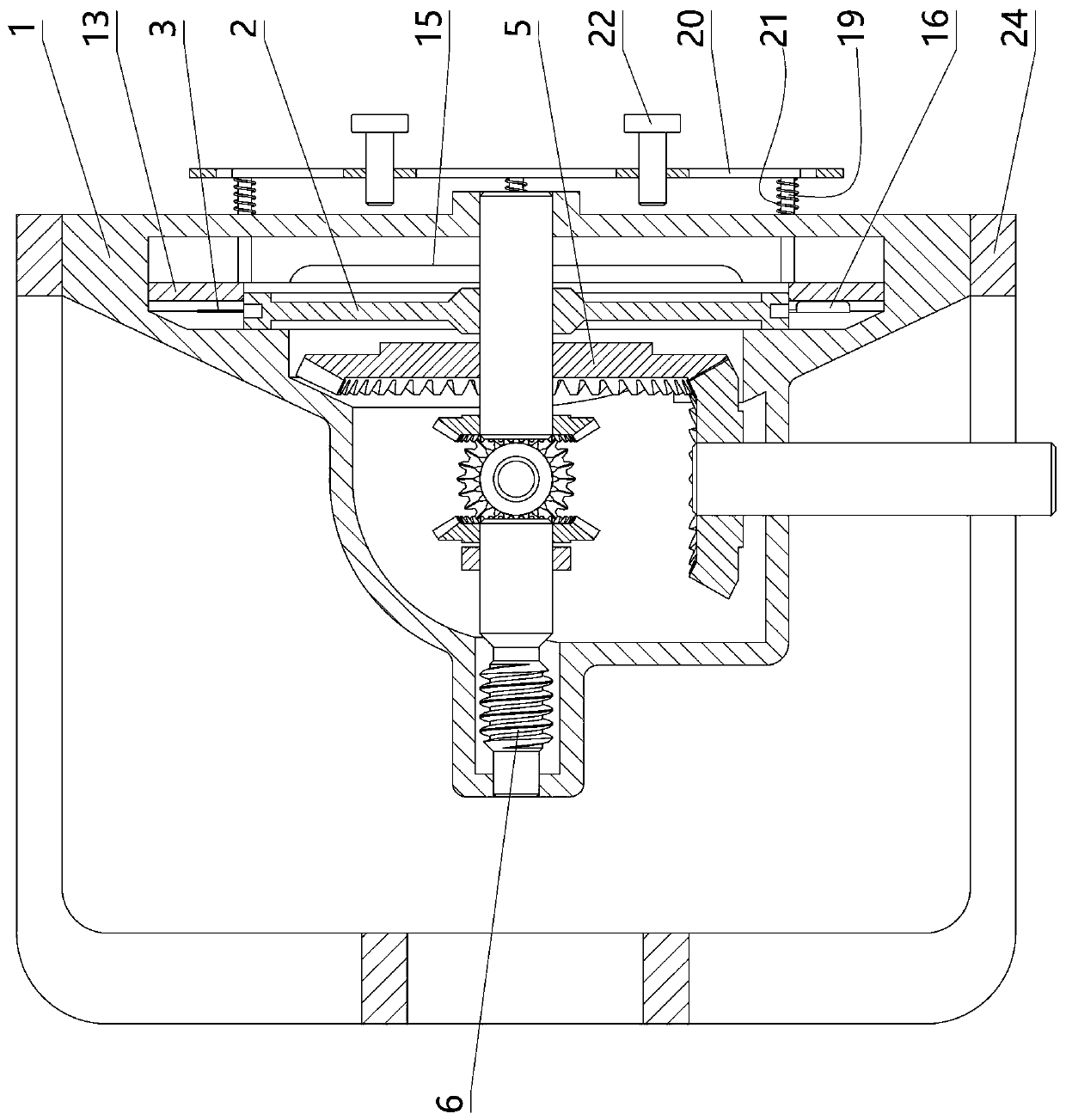

[0011] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0012] Depend on Figure 1 to Figure 5 Provide, the present invention comprises housing 1, the disc-shaped knife rest 2 that rotates on housing 1, is installed on the knife rest 2 and is perpendicular to the blade 3 of knife rest 2 axial directions and the feed that slides on housing 1 Slider 4, described blade 3 is placed on the outside of the circumference of tool holder 2, feed slider 4 is placed on one side of blade 3 and the sliding direction of feed slider 4 is arranged in parallel with the axial direction of tool holder 2; A differential 5, a worm 6 and a worm wheel 7 are arranged on the housing 1 described above, an output shaft of the differential 5 is coaxially connected with the tool holder 2, and another output shaft of the differential 5 is coaxially connected with the worm 6, The worm wheel 7 meshes with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com