Brush assembly

A brush and component technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems that the contact surface between the brush and the commutator is not ideal, the motor cannot run normally, and the service life of the motor is affected. The effect of brush consumption, suppression of discharge sparks, and improvement of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

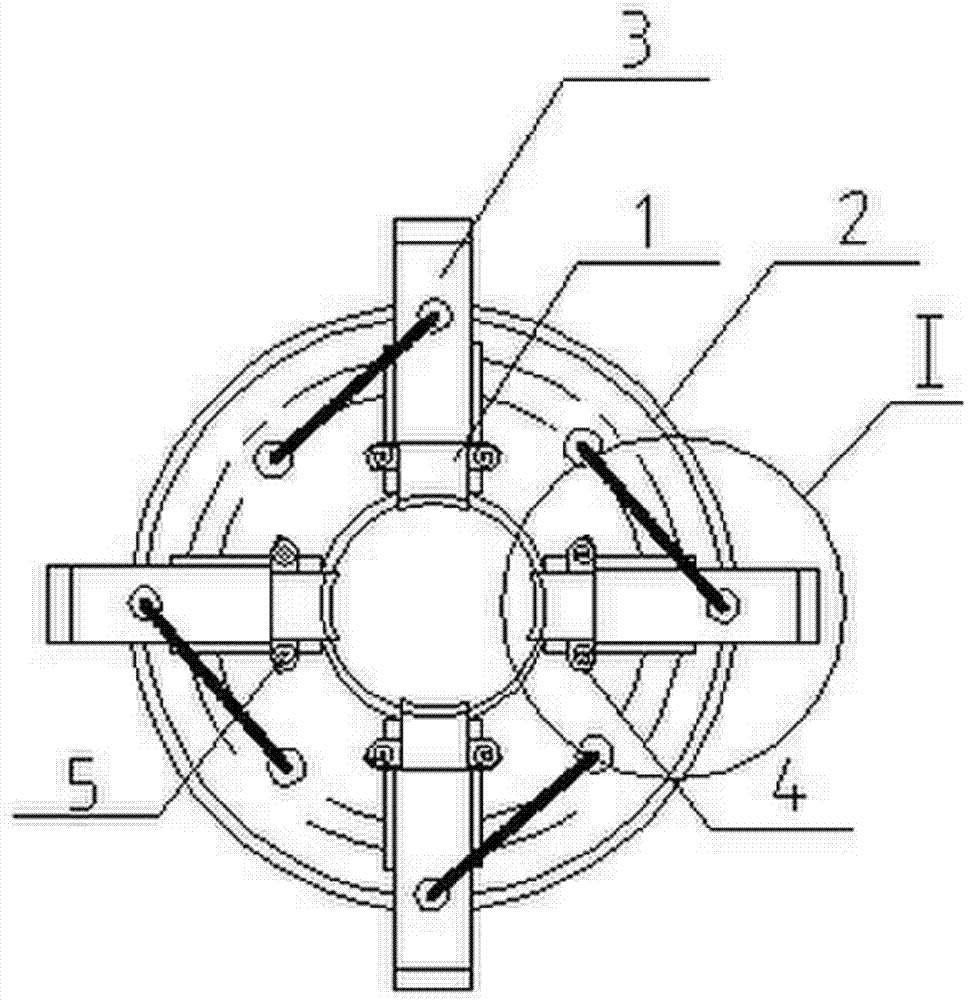

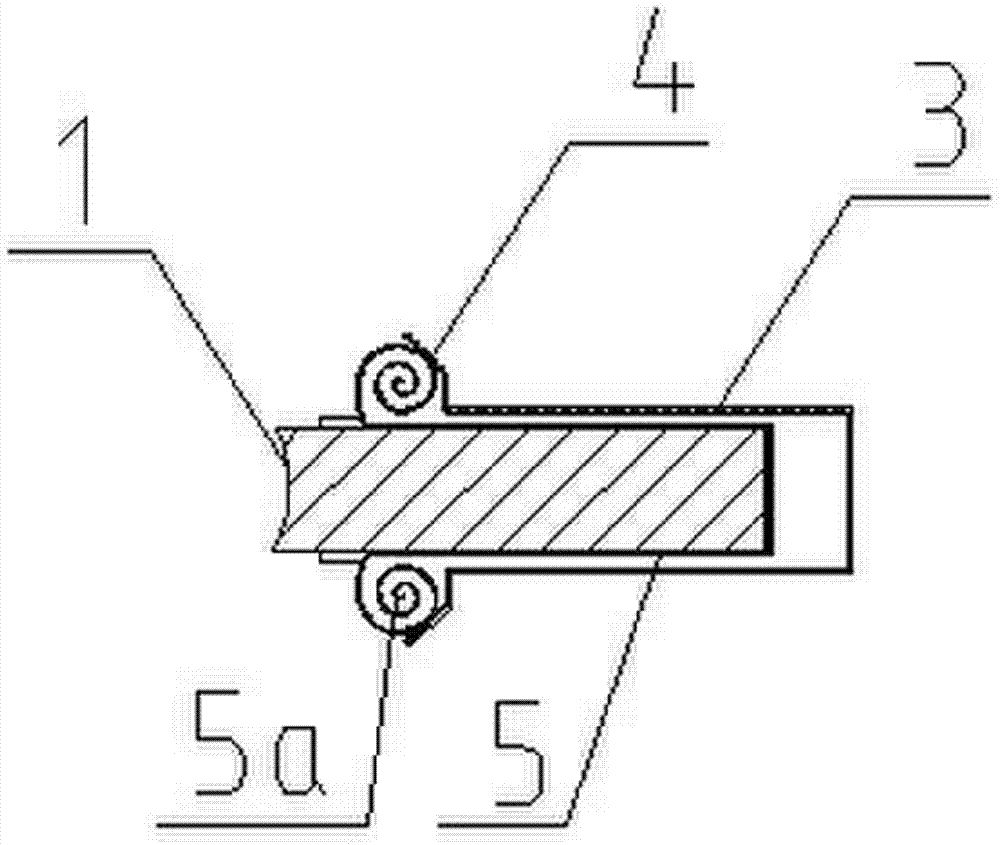

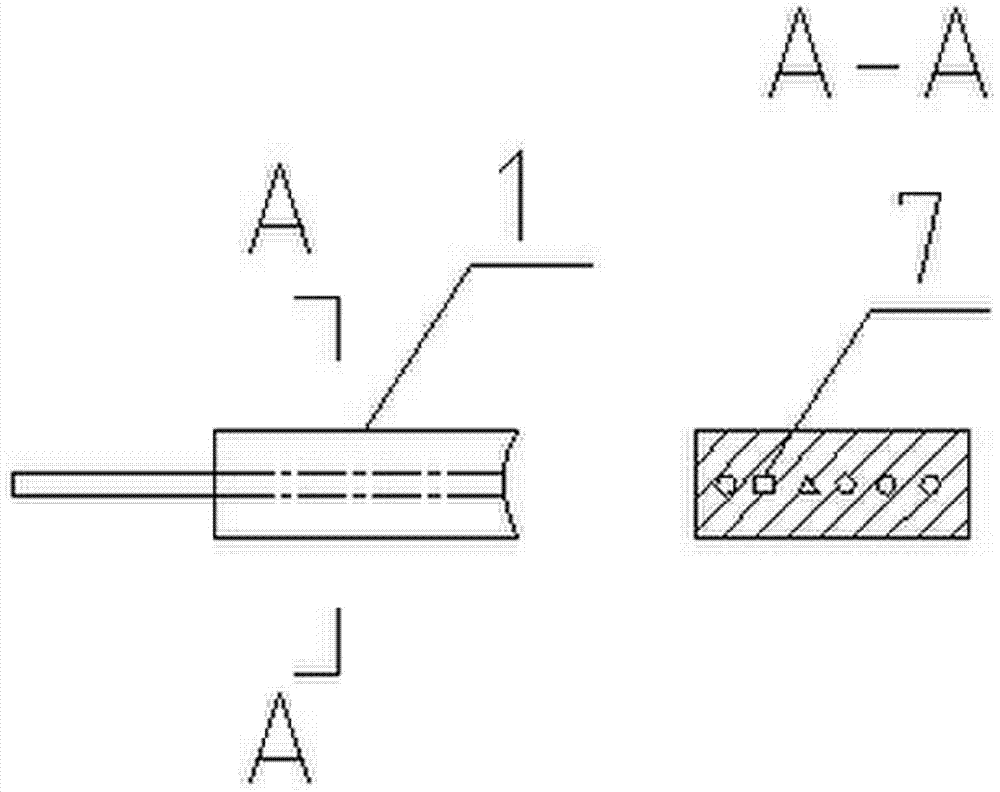

[0016] As shown in the figure: the present invention provides a brush assembly, including a brush holder 2, a brush holder 3, a brush 1, a constant force spring 5, and a bracket 4, and the brush holder 3 with a chute is fixed on the brush holder 2 Above, the cross-section of the brush holder 2 is conical, and the conical brush holder increases the contact area between the brush 1 and the commutator. In the limited internal space of the motor, the effective length of the brush 1 is increased, extending the To ensure the service life of the motor, the two card holders 4 are fixed on the two outer parts of the inner end of the brush holder 3, and the constant force spring 5 is a double-volume coil spring made of a spring steel strip with a thickness of 0.05 mm. There is a scroll 5a, the middle of which touches against the outer end of the brush 1 and is inserted into the notch at the inner end of the chute of the brush holder 3 together. The scrolls 5a at both ends are supported b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com