Inward-outward double-bent soft steel transverse-wave vertical-bent buckle damper

A technology of damper and soft steel, which is applied in the direction of building components, building types, earthquake resistance, etc., can solve the problems of large aftershocks, long duration, and affecting the safety performance of the structure's seismic performance, and achieve the restoration of energy consumption and shock absorption and replacement The effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

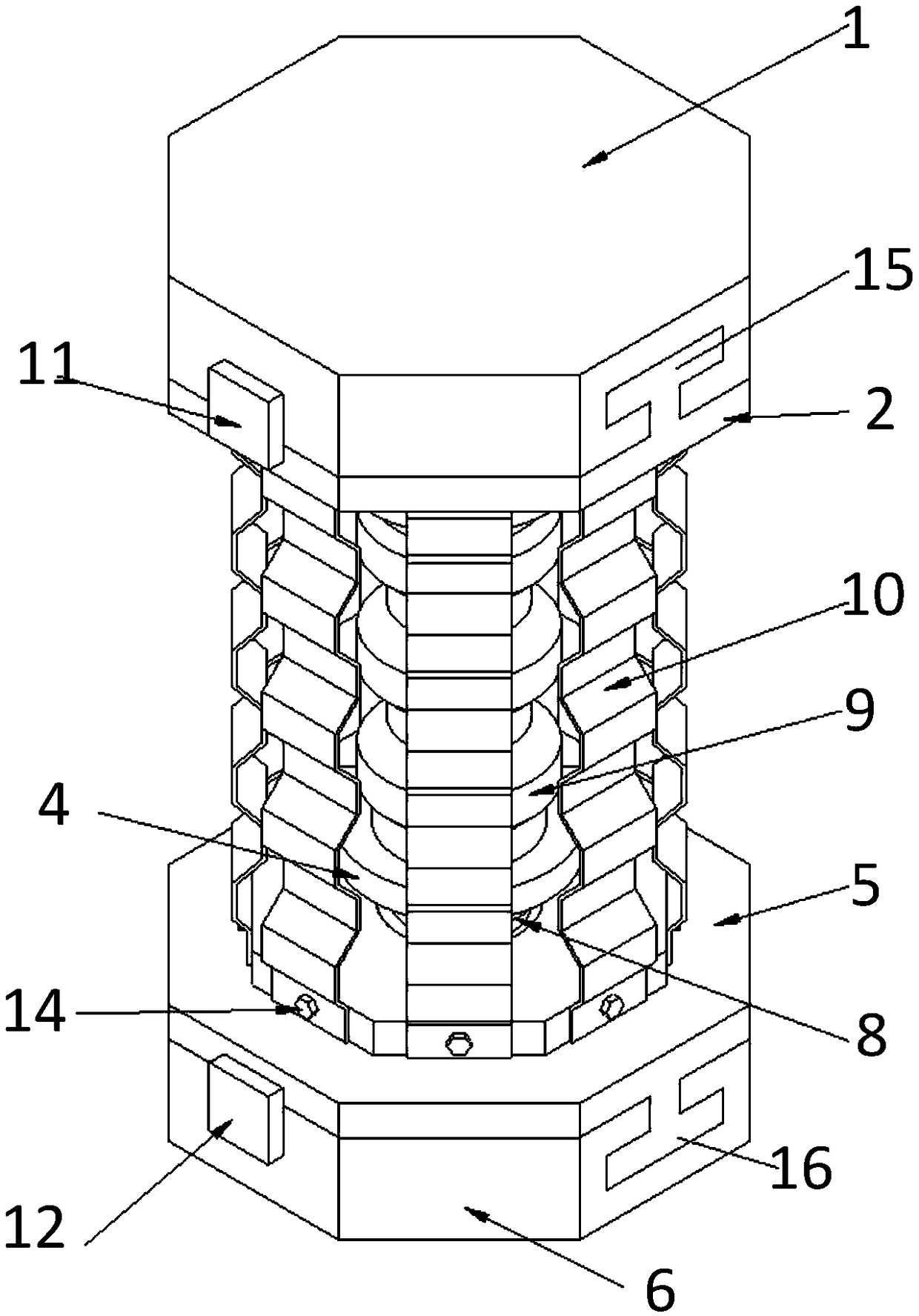

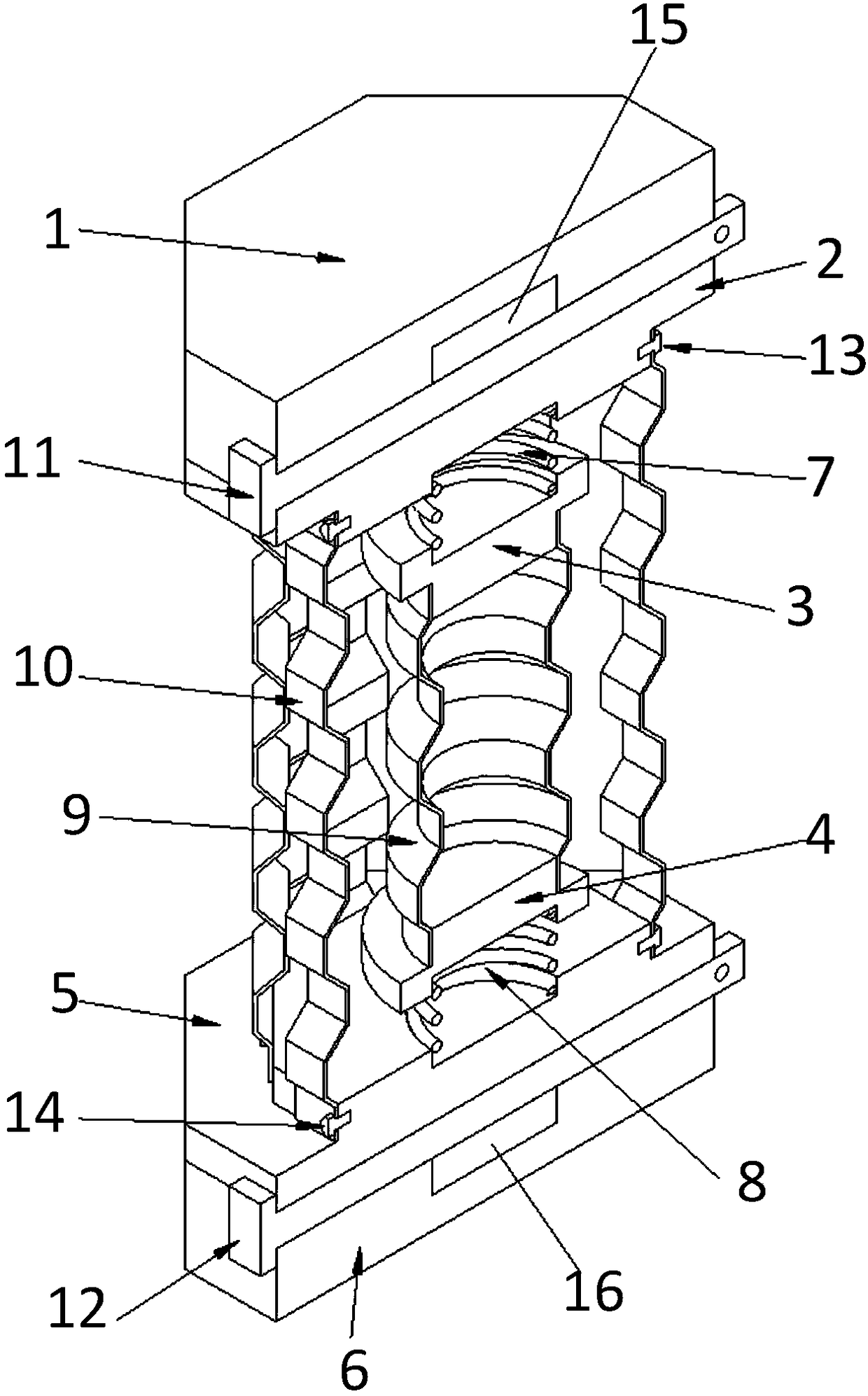

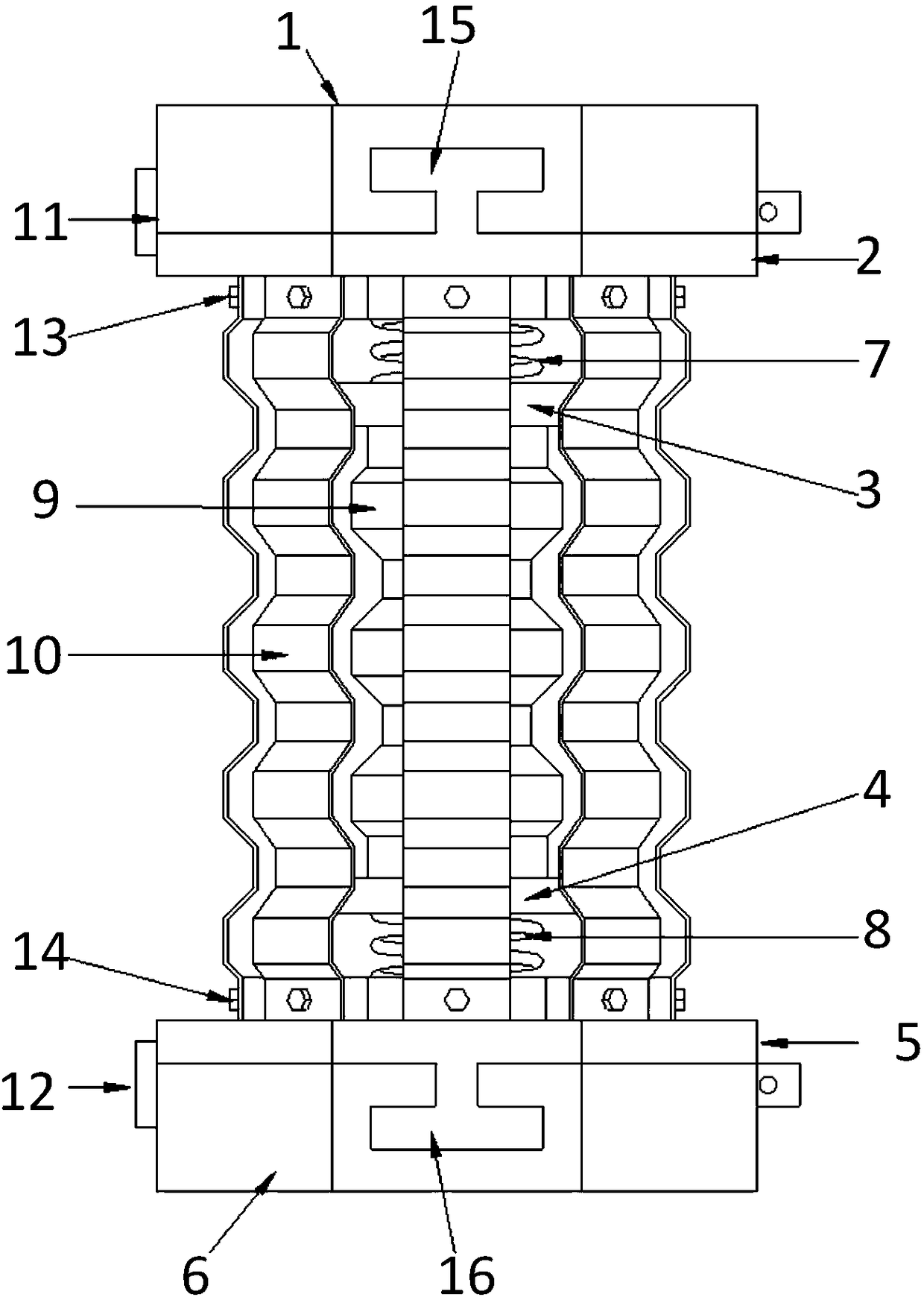

[0030] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0031] refer to Figure 1 to Figure 5 , the double-bending soft steel transverse wave vertical bending snap damper of the present invention includes an upper base 1, a first connecting plate 2, a first spring 7, a second connecting plate 3, a corrugated mild steel cylinder 9, a first Three connecting plates 4, a second spring 8, a fourth connecting plate 5, a lower base 6 and several corrugated steel plates 10; an upper base 1, a first connecting plate 2, a first spring 7, a second connecting plate 3, a corrugated mild steel circle The cylinder 9, the third connecting plate 4, the second spring 8, the fourth connecting plate 5 and the lower base 6 are distributed in order from top to bottom, and the first connecting plate 2 is fixed on the bottom of the upper base 1, and one end of the first spring 7 Connected with the bottom of the first connecting plate 2, the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com