Hinge joint structure with composite shear keys and precast slab bridge thereof

A shear key and prefabricated plate technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as damaged concrete, unclear mechanics concept, and difficulty in finding steel bars, so as to improve the ability to transmit loads and solve shear resistance problems. Insufficient strength and the effect of improving the force transmission performance of hinge joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

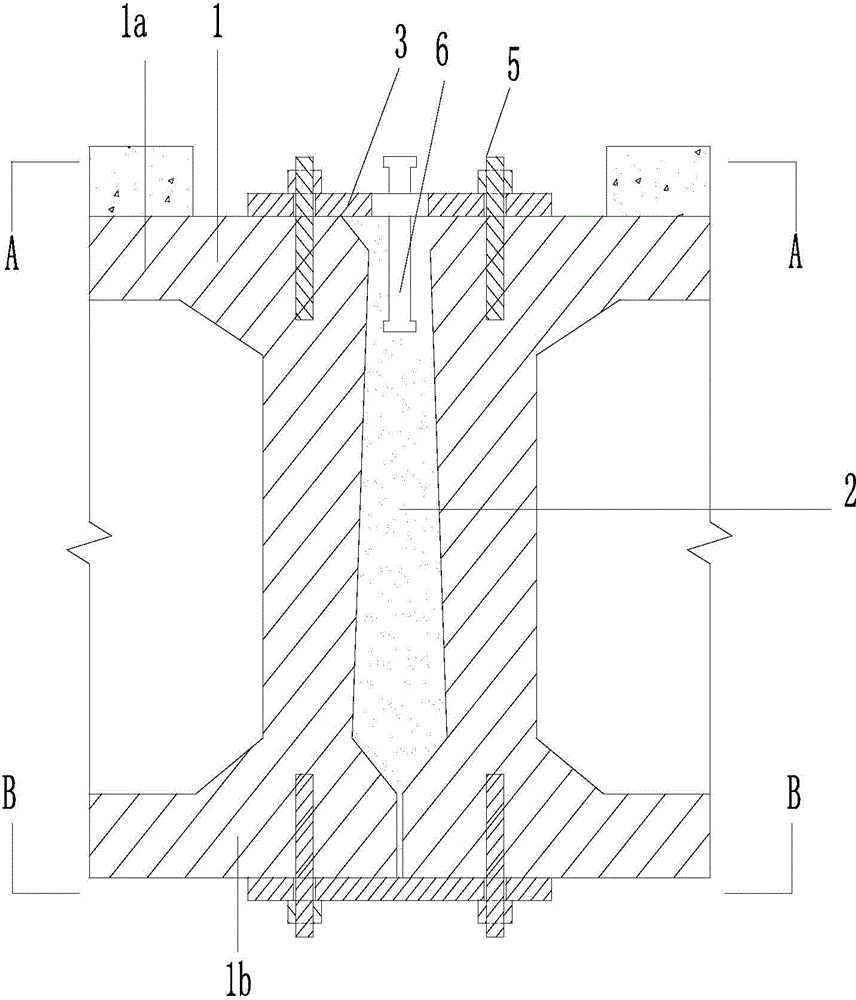

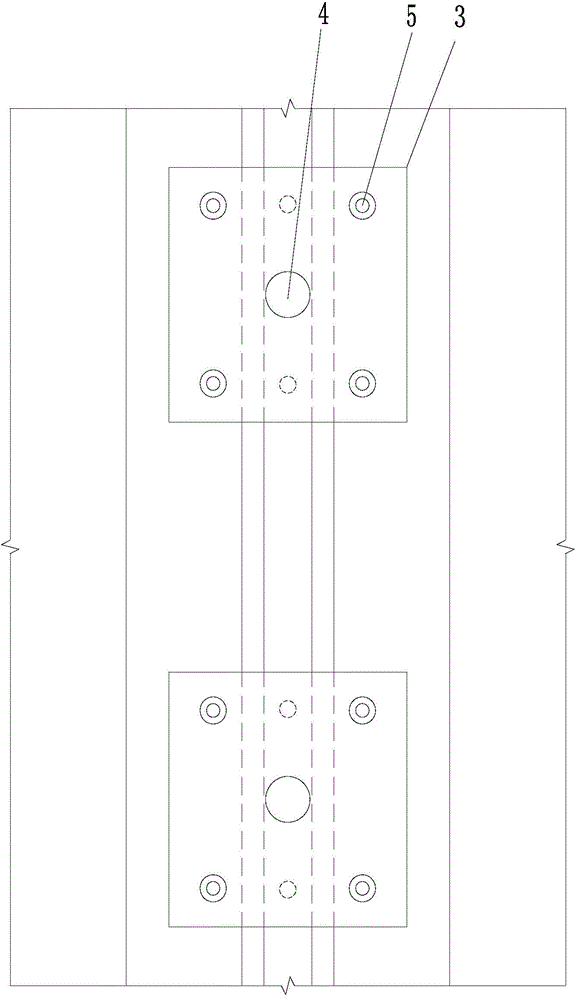

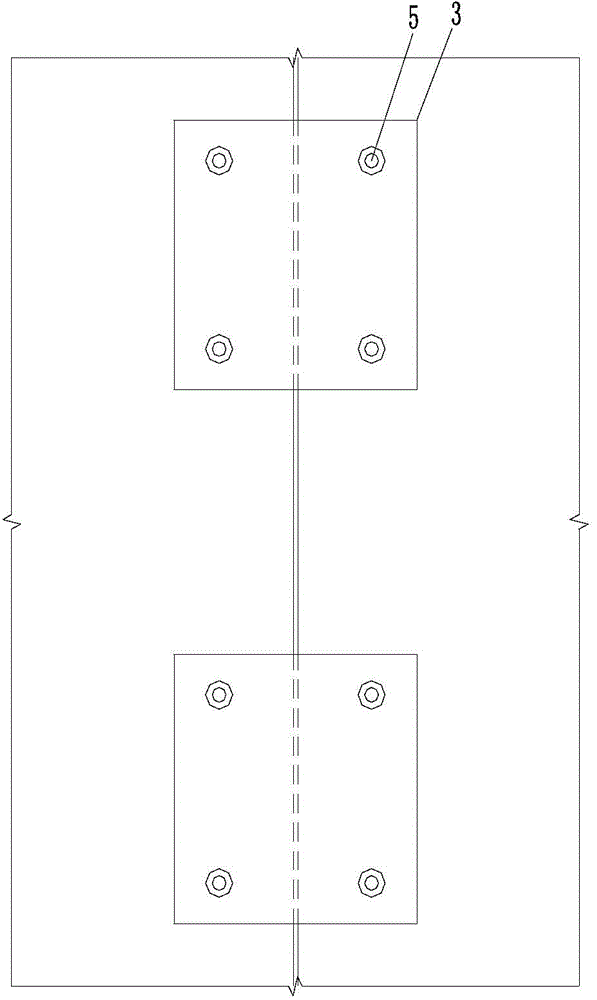

[0023] figure 1 It is a schematic diagram of the structure of the hinged joint of the hollow slab; figure 2 for figure 1 A schematic diagram of the A-A structure;

[0024] image 3 for figure 1 Schematic diagram of the B-B structure; Figure 4 It is a schematic diagram of the construction process of the hinged joint structure of the hollow slab during maintenance and reinforcement; Figure 5 It is a schematic diagram of the construction process of the hollow slab hinge joint structure in the new bridge; Image 6 It is a schematic diagram of the construction process of the slot plate hinge joint structure in the new bridge construction; Figure 7 It is a schematic diagram of the construction process of the hinged slot structure in bridge reinforcement and maintenance; Figure 8 for Image 6 A'-A' structural schematic diagram in the structural schematic diagram; Figure 9 for Image 6 Schematic diagram of the B'-B' structure in the structural diagram.

[0025] As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com