Large-span steel box hybrid beam short combination section structure of high-speed rail

A steel-concrete combination and hybrid beam technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of long joint section, inconvenient construction, local self-heavyness, etc., to achieve enhanced stability, simple construction and installation, and improved force bearing and force transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

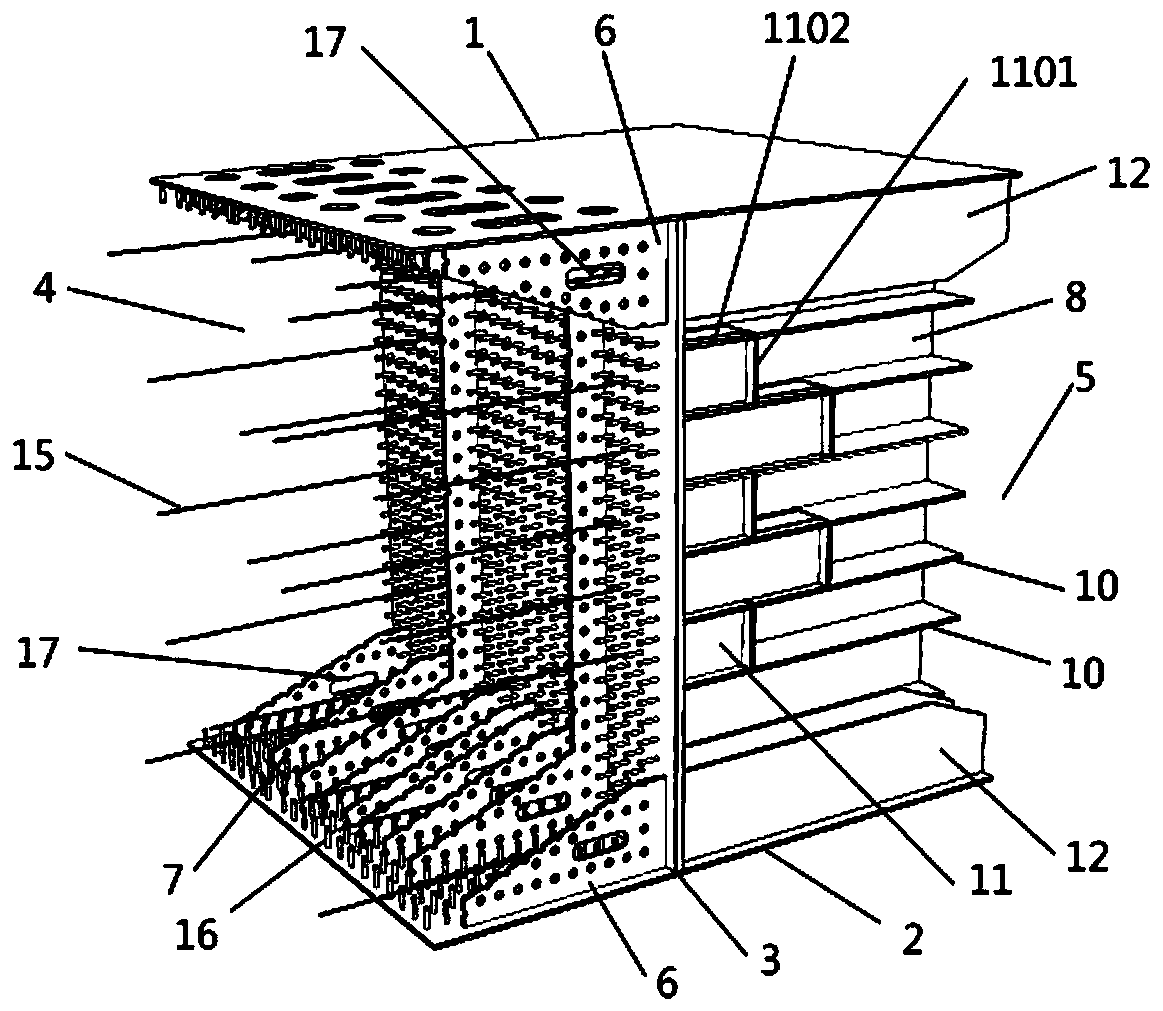

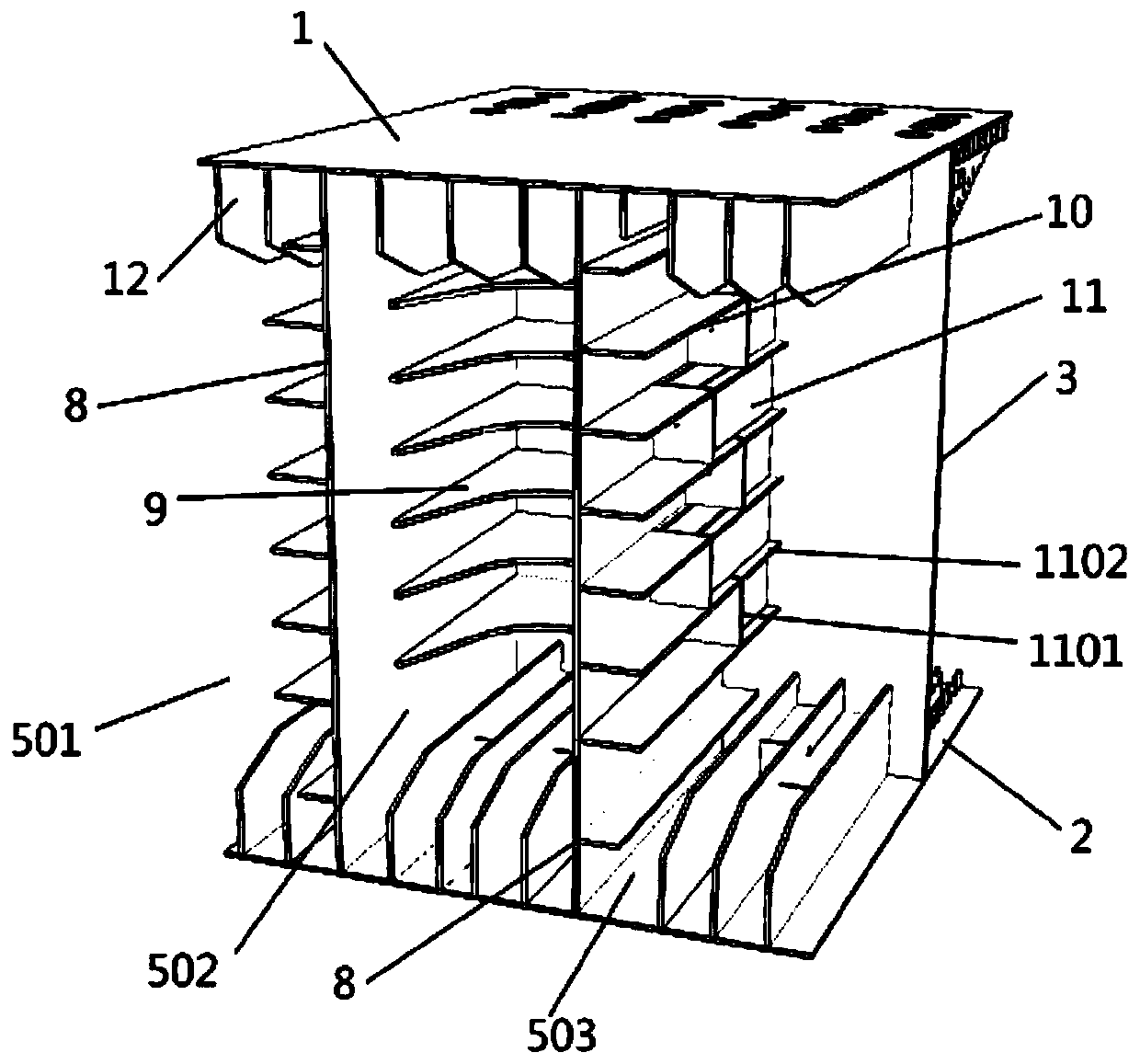

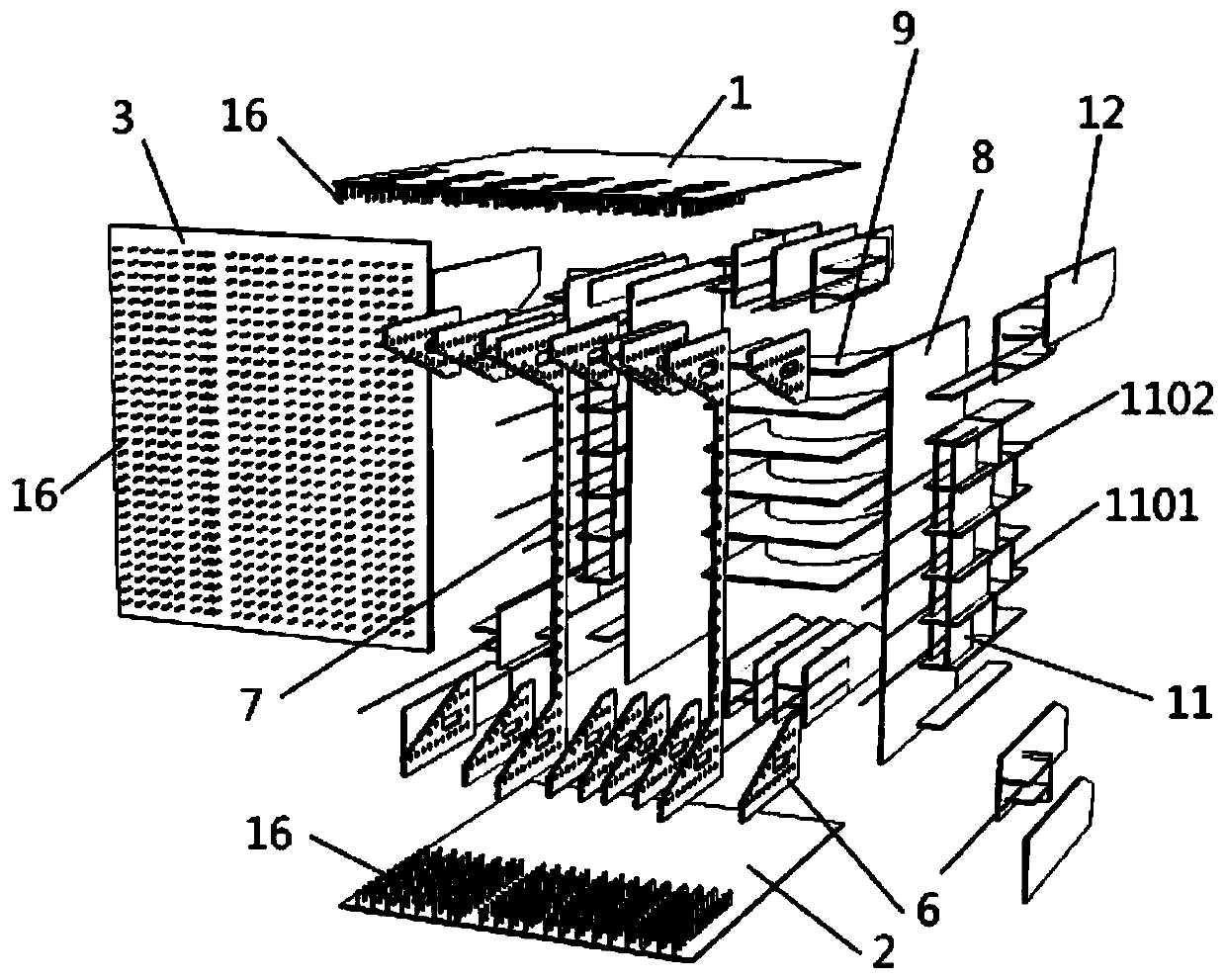

[0034] refer to Figure 1-10 , the present invention provides a technical solution:

[0035] Please refer to Figure 1-3 and Image 6 , a high-speed rail long-span steel box mixed beam short joint section structure, including a steel top plate 1, a steel bottom plate 2 and a pressure bearing plate 3, and the pressure bearing plate 3 is sandwiched between the steel top plate 1 and the steel bottom plate 2 And in the longitudinal bridge direction, the short joint section of steel box composite girder is divided into steel-concrete joint section 4 and steel beam transition section 5;

[0036] Both ends of the steel top plate 1 and the steel bottom plate 2 in the steel-concrete joint section 4 are equipped with PBL perforated steel plates 6 parallel to the longitudinal bridge direction, and between the PBL perforated steel plates 6 at both ends of the steel top plate 1 and the steel bottom plate 2 Multiple C-shaped perforated steel plates 7 are installed between the PBL perfora...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com