Hydraulic rock splitter

A splitting machine and hydraulic technology, applied in the field of rock hydraulic splitting machine, to achieve the effect of accurate return, good rigidity, and small wear and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

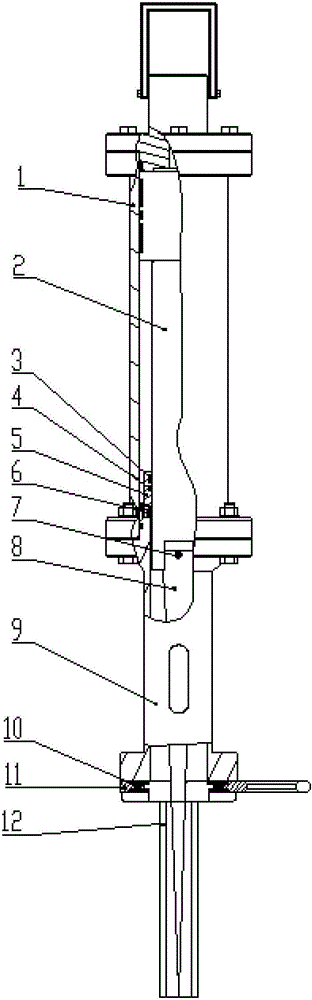

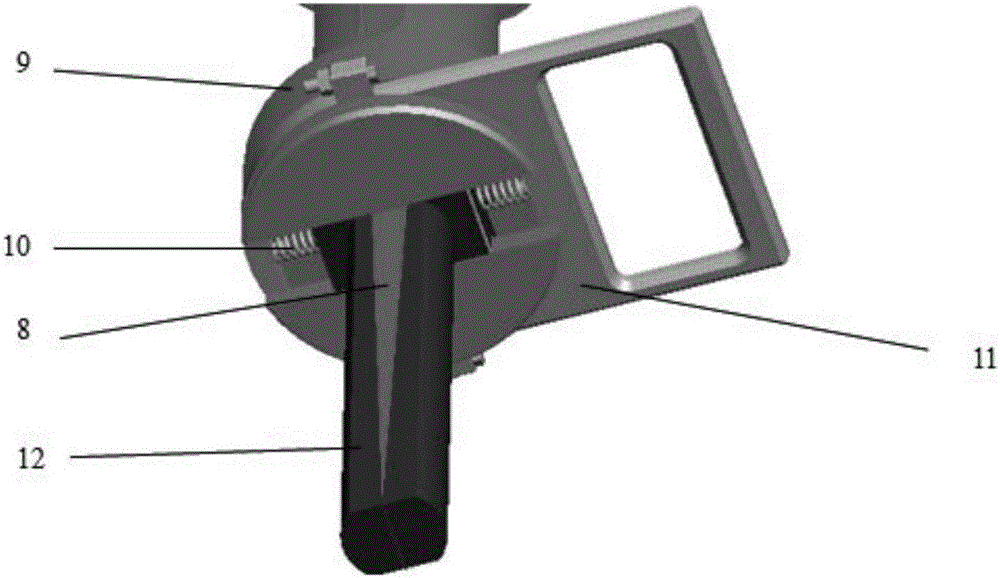

[0012] Such as figure 1 As shown, a hydraulic rock splitting machine includes a hydraulic cylinder 1, a piston rod 2, a sealing block 5, a connecting body 9, a splitting block 12, a wedge 8, a spring 10, and a handle 11. The cylinder 1 and the connecting body 9 are formed, and the two cooperate with each other and are equipped with sealing parts to realize sealing; the force transmission device of the splitter is composed of the rigid connection between the piston rod 2 and the wedge 8; the sealing of the piston rod 2 The guiding device is composed of a sealing block 5, a piston rod guide sleeve 3, an O-ring 4 and an ASW type dust-proof ring 6, which have a sealing and guiding function after being assembled and installed; The spring 10 and the splitting block 12 are assembled and fitted together; the spring 10 is installed on the pin shaft on the handle 11 and the splitting block 12 .

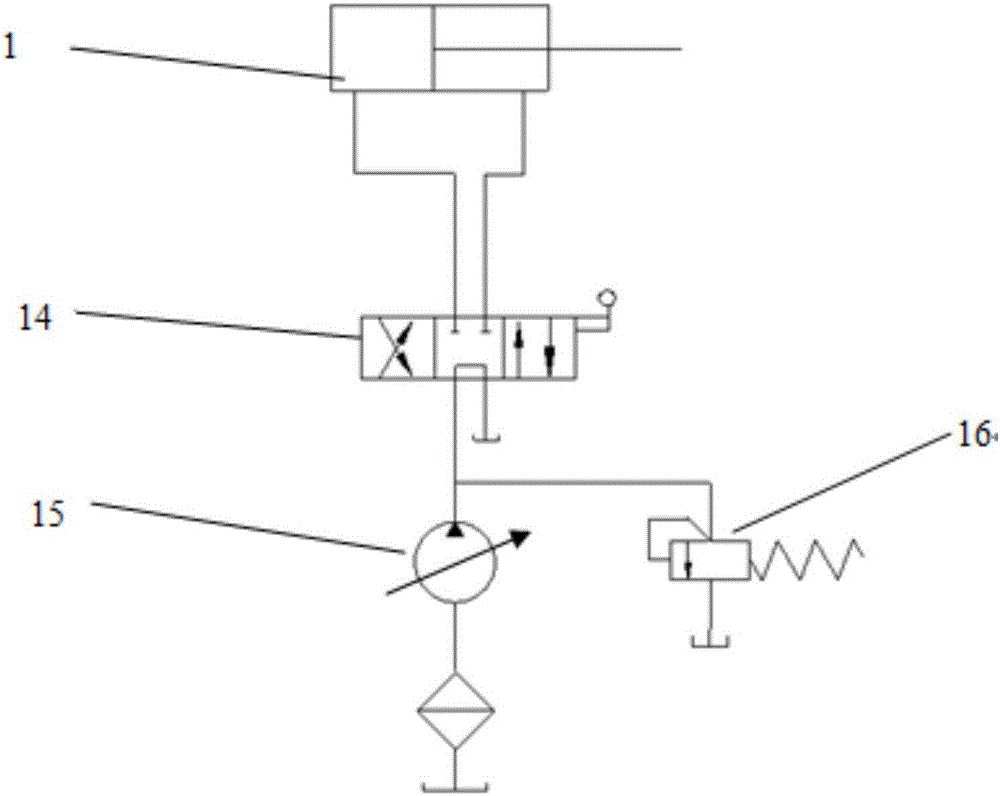

[0013] Such as image 3 As shown, a hydraulic system of a hydraulic rock splitting machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com