Patents

Literature

419results about How to "Enough support" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

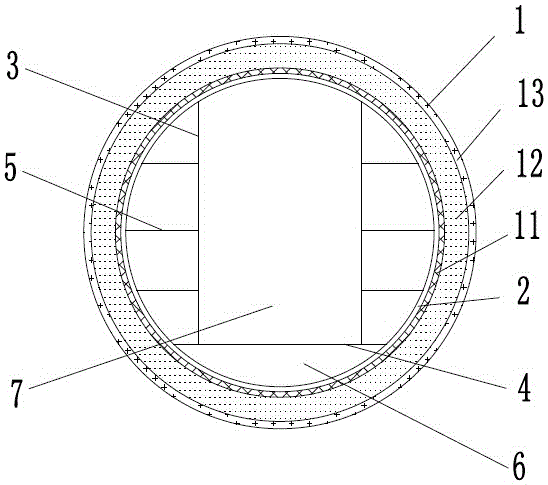

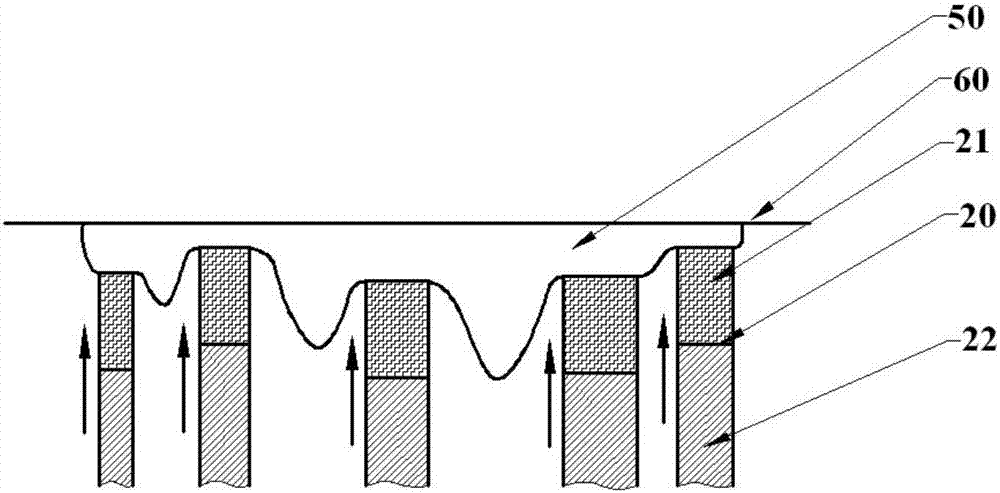

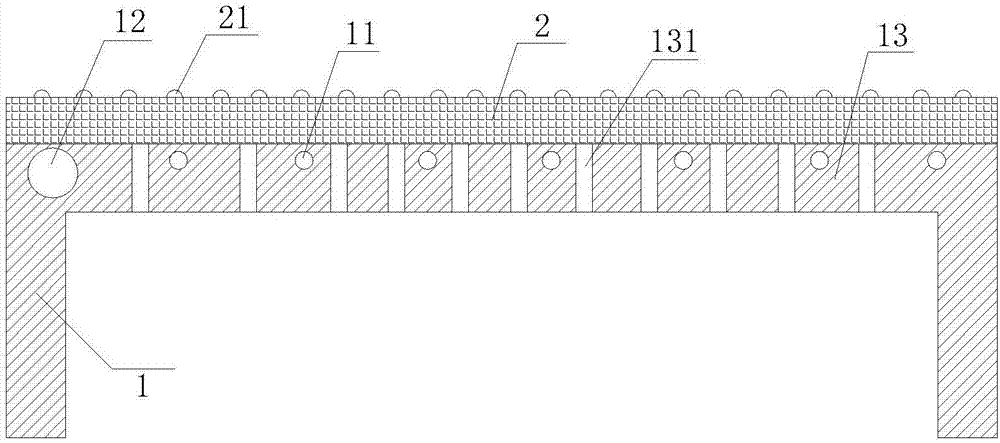

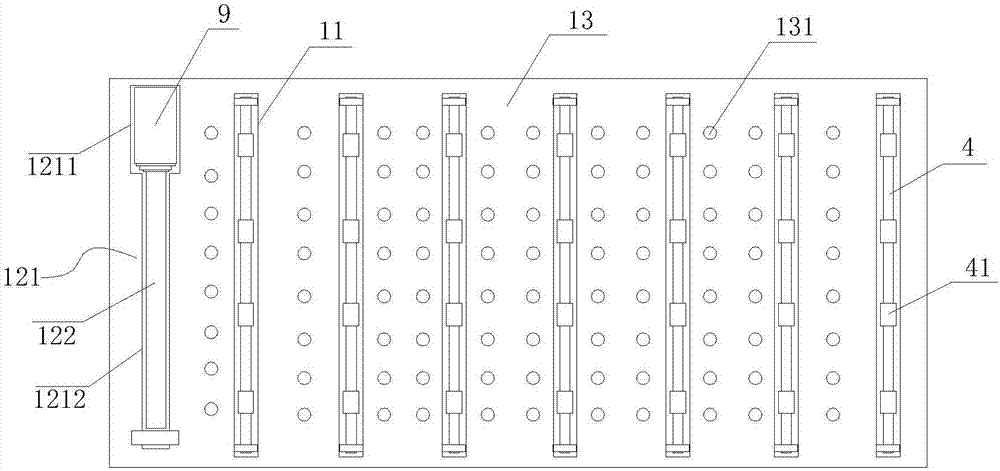

Prefabricated bamboo composite pipe gallery and manufacturing method thereof

InactiveCN105042213AReduce manufacturing costEnergy saving and environmental protection in the production processUnderwater structuresRigid pipesEngineeringWater soluble

The invention discloses a prefabricated bamboo composite pipe gallery, which is formed by connecting a plurality of prefabricated pipe joints, wherein each pipe joint comprises a pipe body, a force bearing mechanism, vertical supporting beams, a horizontal supporting beam and pipeline supports; the pipe body radially comprises a liner layer, a structure layer and an outer protection layer from inside to outside in sequence; the liner layer comprises flame-retarded resin and flame-retarded fabrics; the structure layer at least comprises a plurality of bamboo skin layers which are bonded with water soluble resin; the outer protection layer at least comprises flame-retarded resin; and the force bearing mechanism is fixed to the inner surface of the pipe body. The invention also discloses a method of manufacturing the prefabricated bamboo composite pipe gallery. The method comprises the manufacturing of the pipe body. The preparation method of the pipe body comprises the steps: (1) the liner layer is manufactured; (2) the structure layer is manufactured; and (3) the outer protection layer is manufactured. According to the invention, bamboo is utilized to manufacture a prefabricated pipe gallery, so that the intensity is good, the weight is light, the cost is low, the impermeability is good, the antiknock characteristic is strong, the construction is convenient, and the technical problems that the existing comprehensive pipe gallery consumes too many materials, the construction project amount is large, the construction period is long and the construction cost is high are solved.

Owner:ZHEJIANG XINZHOU BAMBOO BASED COMPOSITES TECH +1

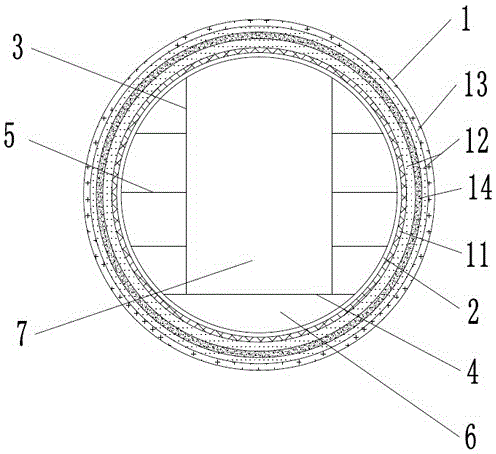

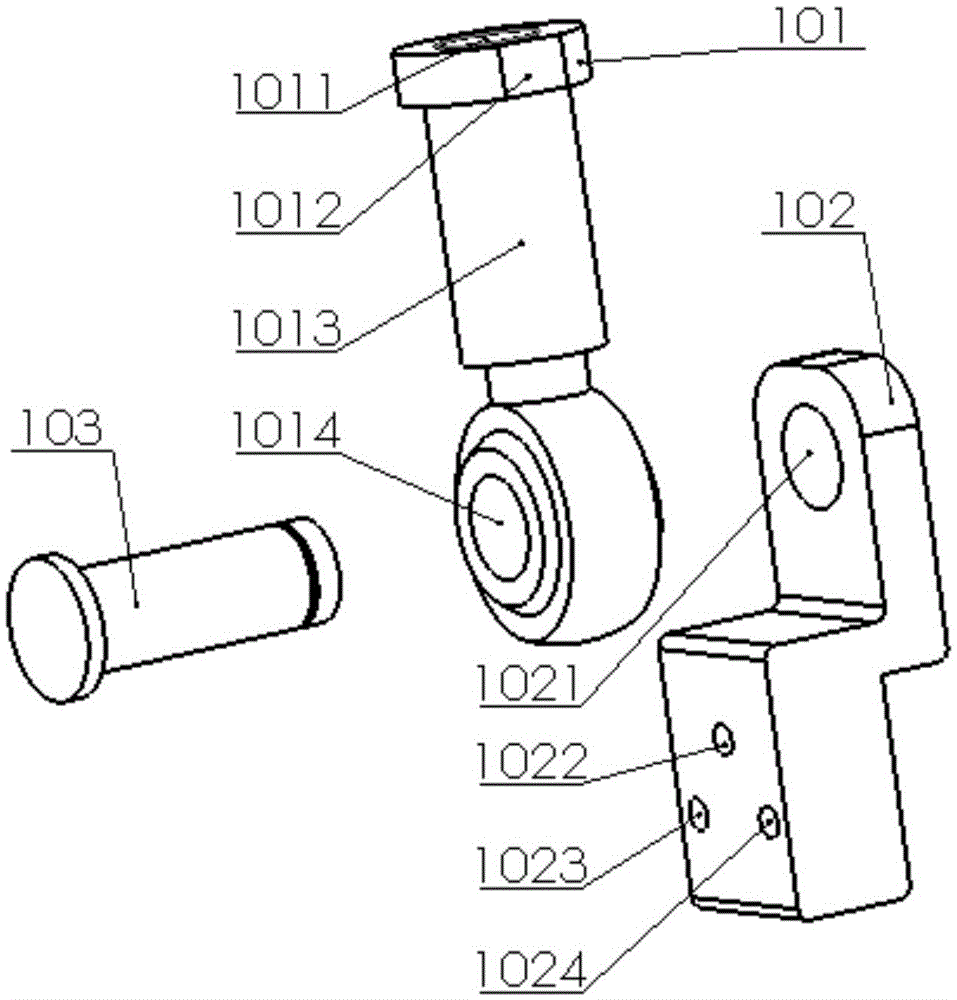

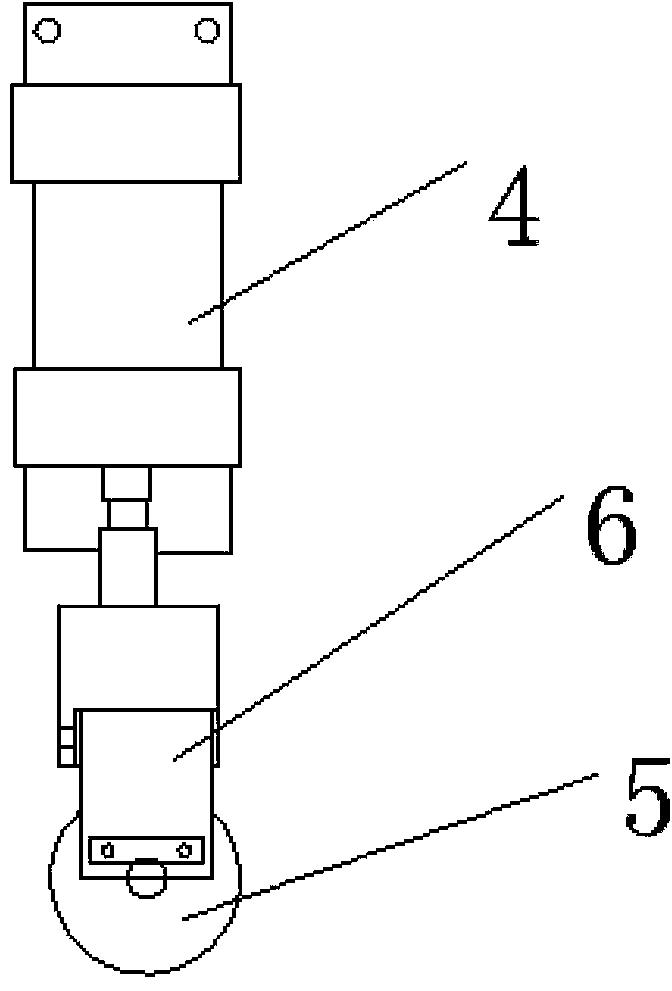

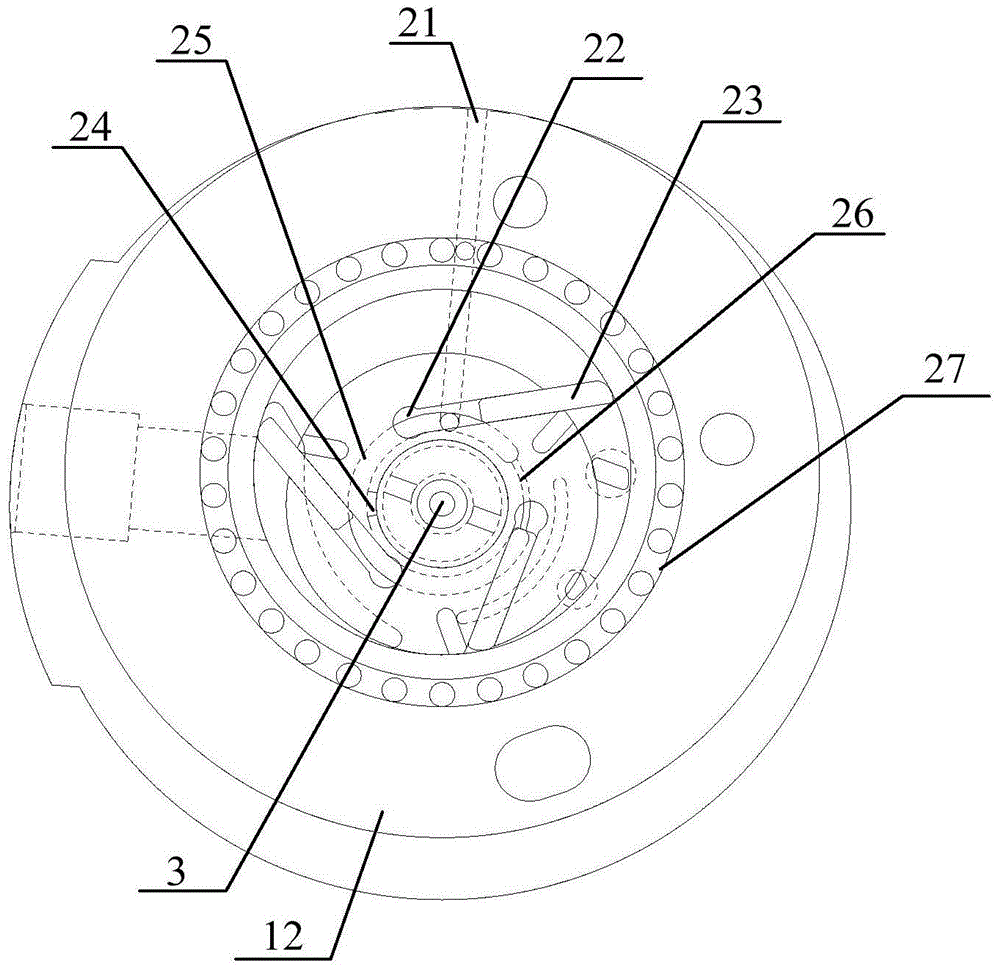

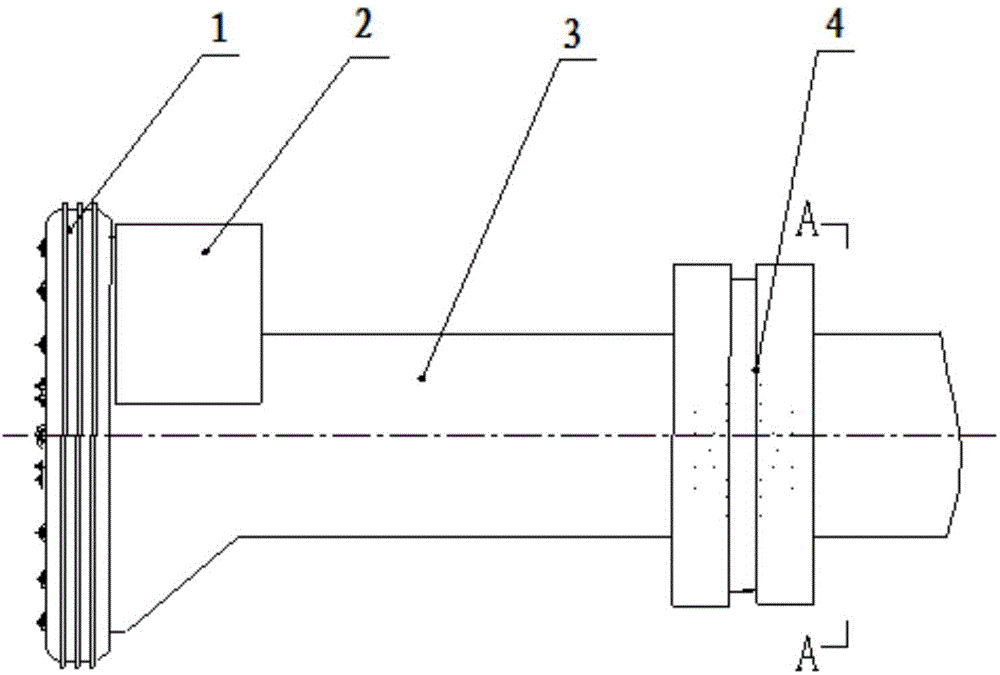

Spiral pipeline inner wall grinding and polishing robot suitable for different pipe diameters

ActiveCN106239284AGrinding muchLow costGrinding carriagesRevolution surface grinding machinesDrive wheelPipe fitting

The invention relates to a spiral pipeline inner wall grinding and polishing robot suitable for different pipe diameters, and belongs to the field of pipeline robots. A hub assembly and a cross-axis universal joint are mounted in a spline fit manner, three driving wheel grinding assemblies are arranged, two ends of drive shafts of the assemblies and a drive shaft support in the hub assembly are mounted in a matched manner through bearings, a motor and control and power assembly is mounted on a direction keeping mechanism, and a motor shaft of the assembly and the cross-axis universal joint are mounted in a spline fit manner. The spiral angles of the grinding assemblies relative to the cross section of a pipe fitting are adjusted in a self-adaptation manner, and therefore the aim that the position with the small pipe diameter and many impurities is ground much, and the position with the large pipe diameter and few impurities is ground little is achieved, the robot can be matched with multiple different-size grinding assemblies for use, the aim that one robot has multiple purposes is achieved, and the cost can be saved to a certain degree.

Owner:JILIN UNIV

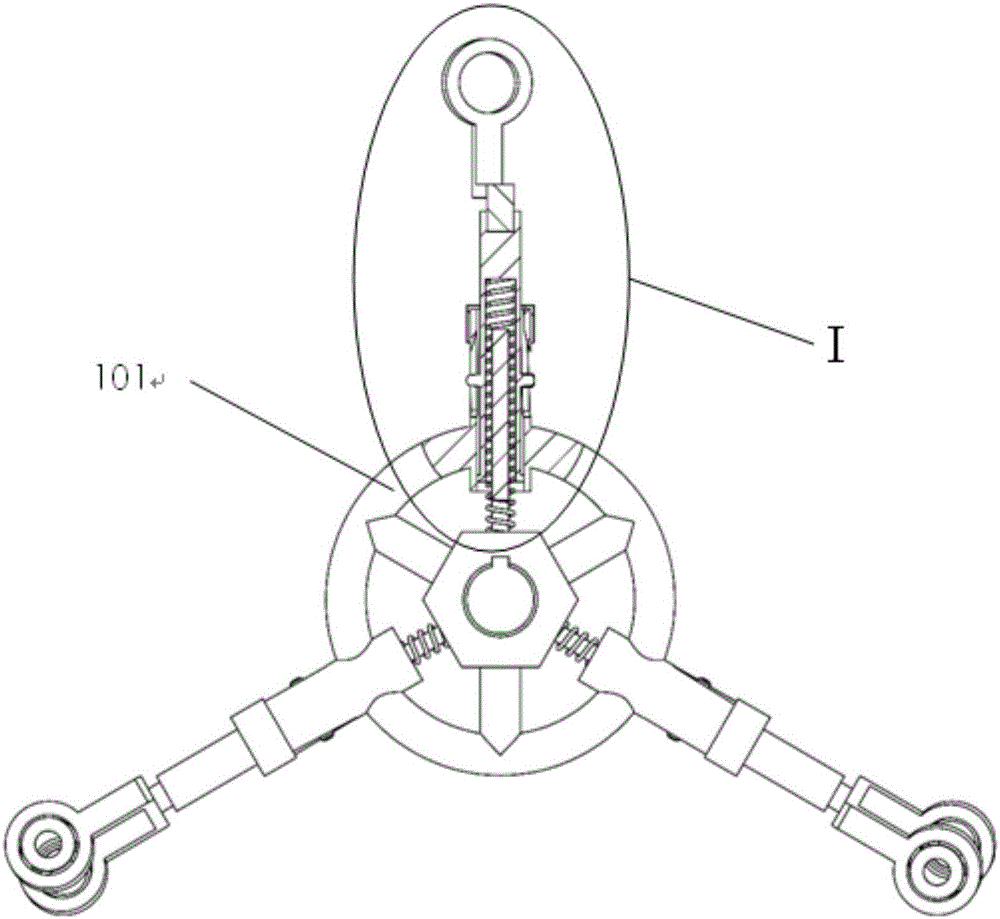

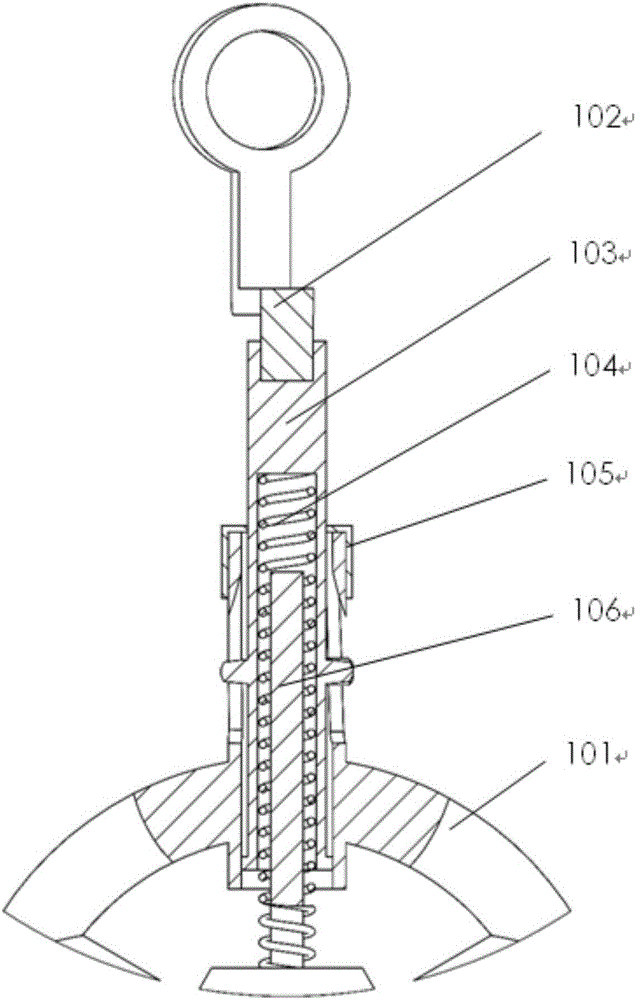

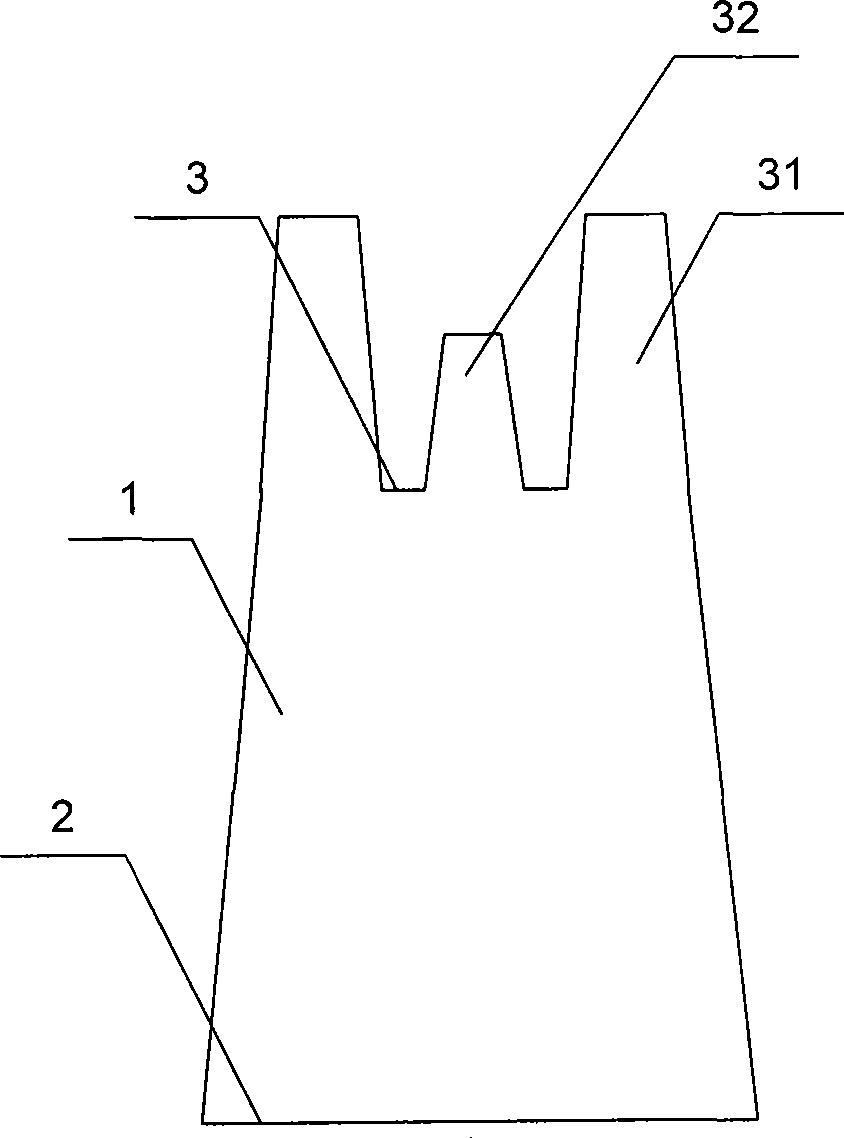

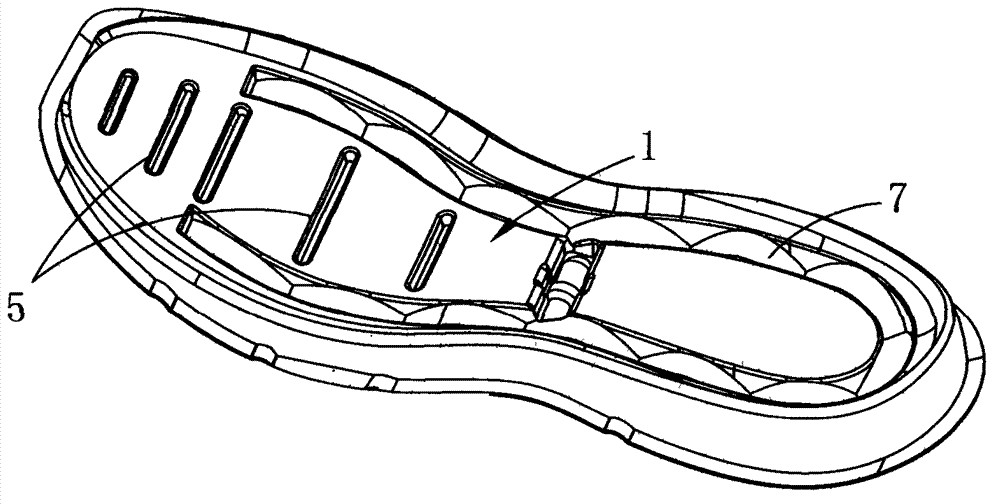

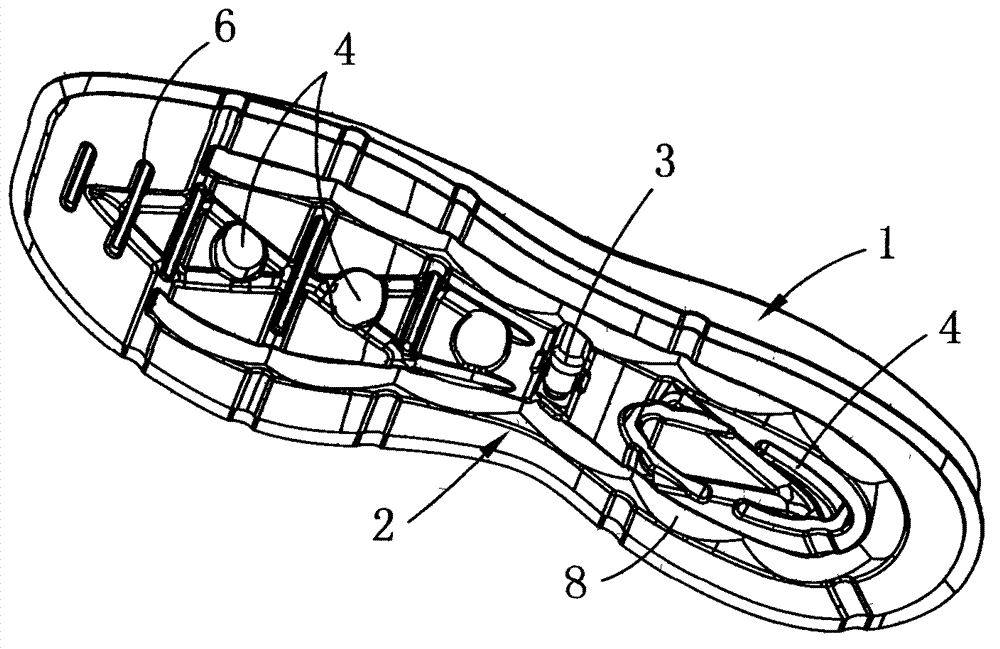

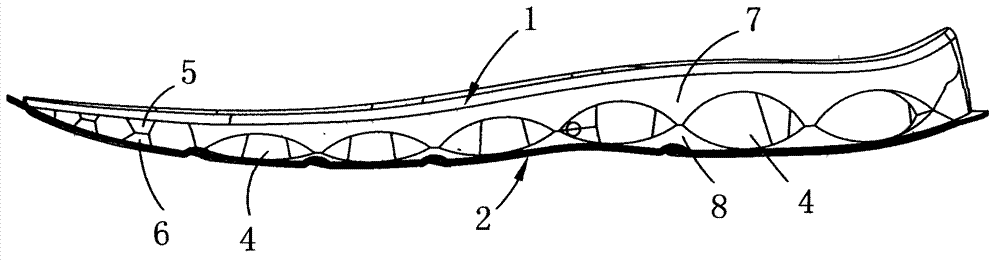

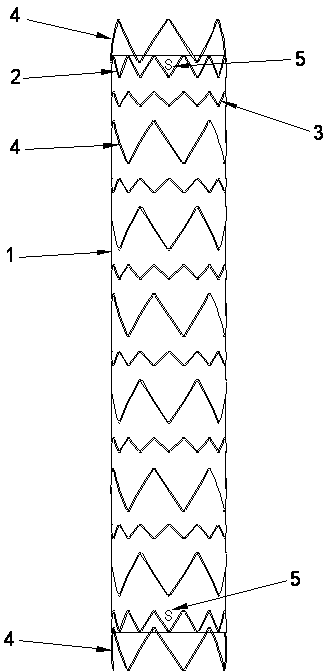

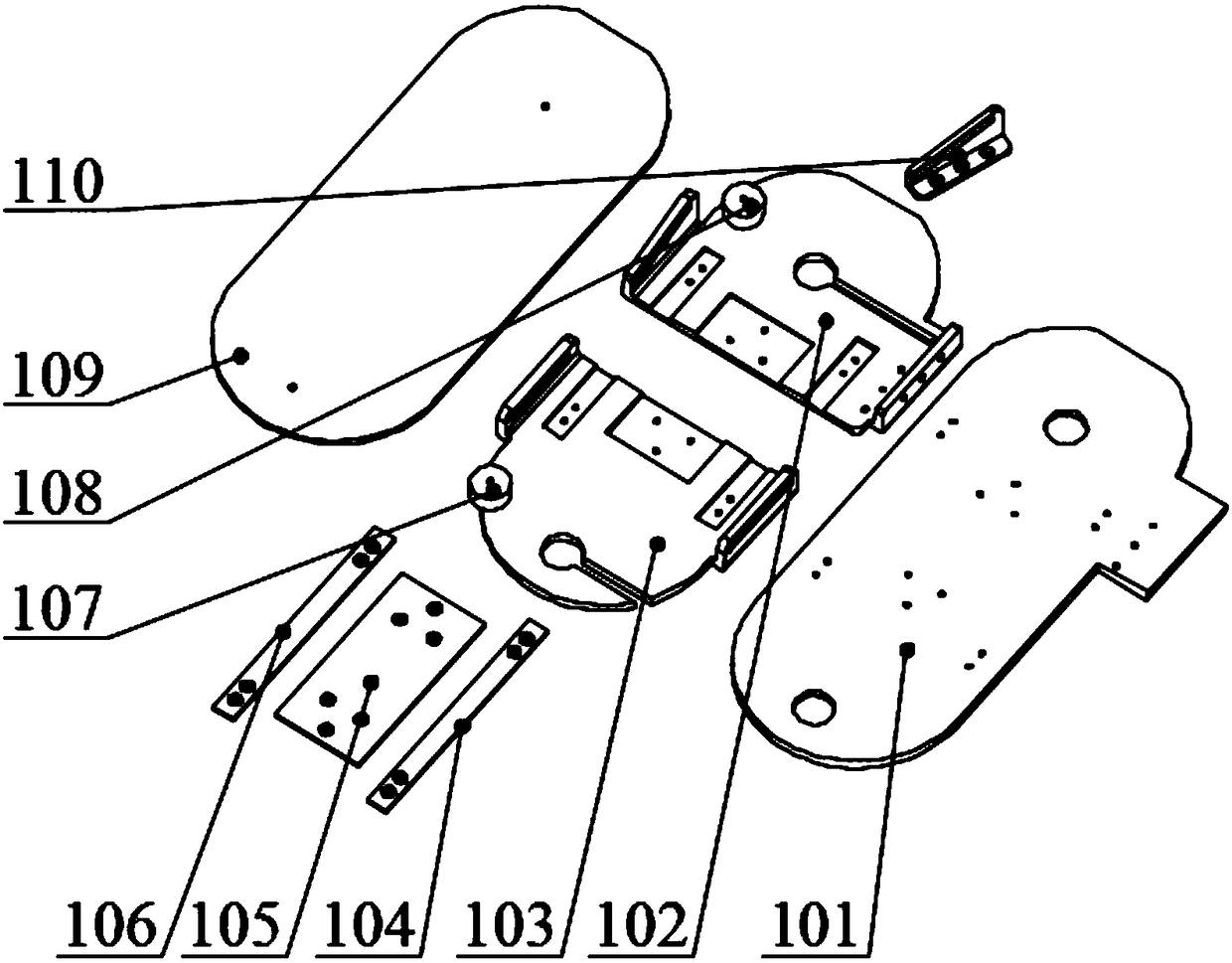

Passive energy storage foot mechanism for power assisting exoskeletons for lower limbs

ActiveCN105616113AMeet functional requirementsEnough supportProgramme-controlled manipulatorWalking aidsHuman bodyDorsal flexion

The invention discloses a passive energy storage foot mechanism for power assisting exoskeletons for lower limbs.The passive energy storage foot mechanism comprises an ankle joint unit, a foot side face plate, a foot sole unit, a binding unit and passive spring energy storage units.The ankle joint unit is connected with the foot sole unit by the foot side face plate; the foot sole unit is of a separation type flexible bending structure and comprises a rigid heel, a rigid front sole, a bottom plate spring, inner-side plate springs, outer-side plate springs, fixing mechanisms, a deformable adhesion plate and a rubber cushion; the passive spring energy storage units include a dorsal flexion passive spring energy storage unit and a plantar flexion passive spring energy storage unit and are connected with the ankle joint unit by a spring support unit, the foot side face plate is used as a fixing base for the passive spring energy storage units, and dorsal flexion and plantar flexion energy storage effects can be respectively realized during movement.The passive energy storage foot mechanism has the advantages that foot structures of human bodies and the weights and inertia effects of the human bodies and the exoskeletons are sufficiently utilized, accordingly, energy can be passively stored by ankle joints in walking procedures, ground pedaling actions of toes can be carried out in the walking procedures, states can be automatically restored in the walking procedures, a wearer can wear the passive energy storage foot mechanism comfortably, and the passive energy storage foot mechanism is high in practicality and low in energy consumption.

Owner:SOUTHEAST UNIV +1

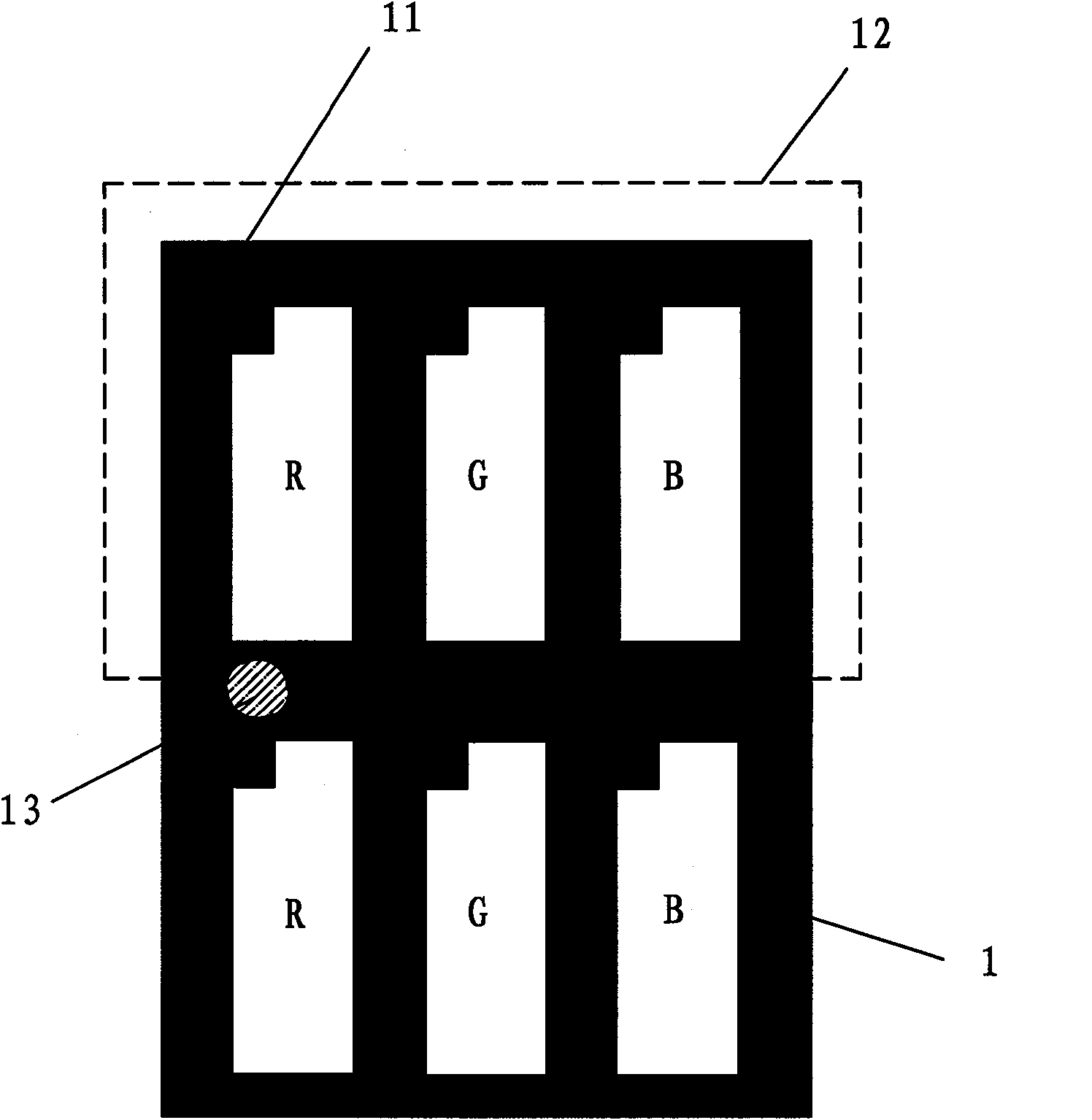

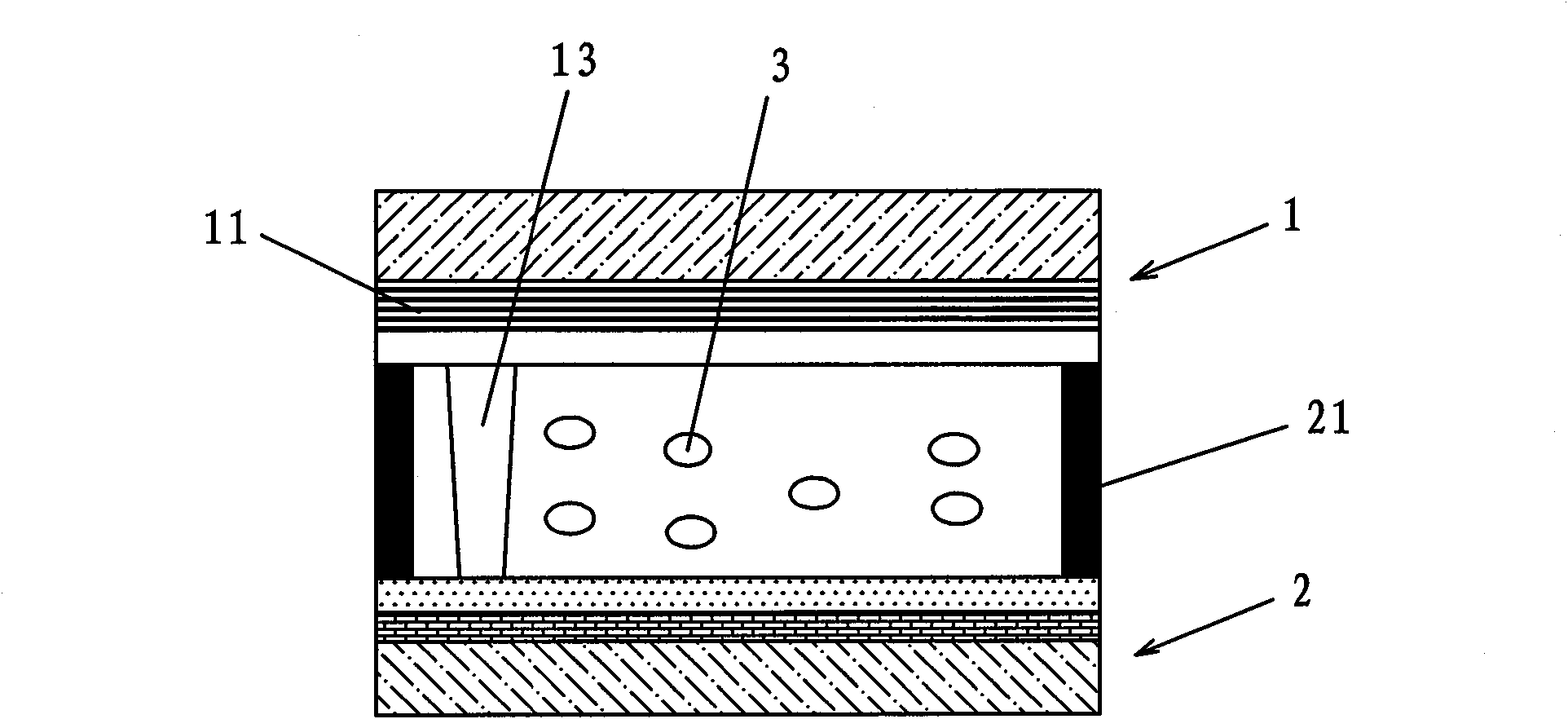

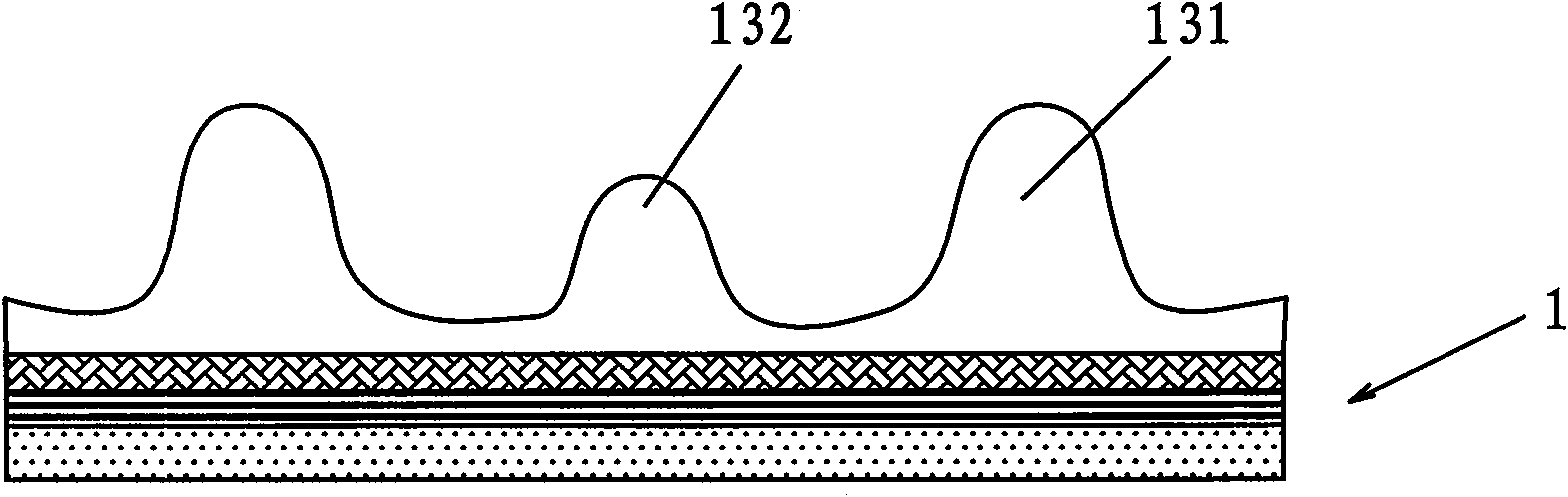

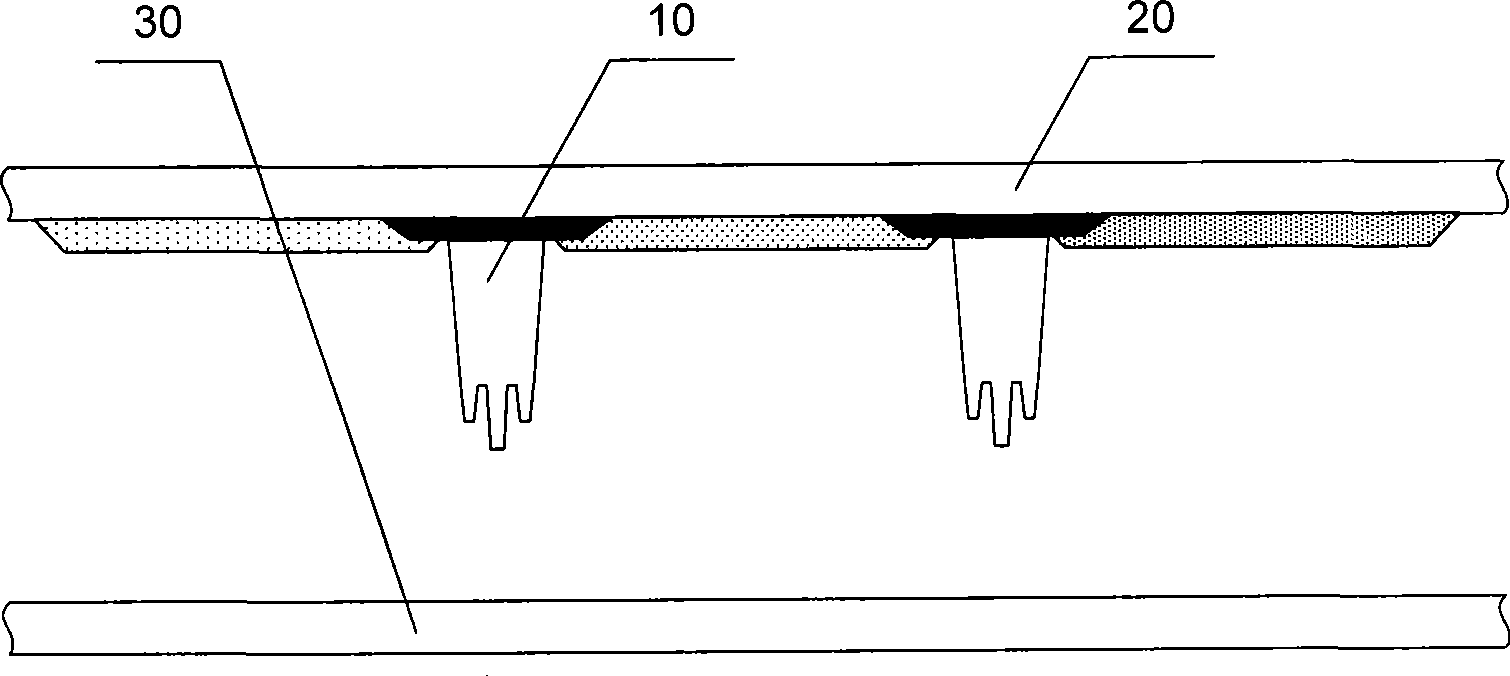

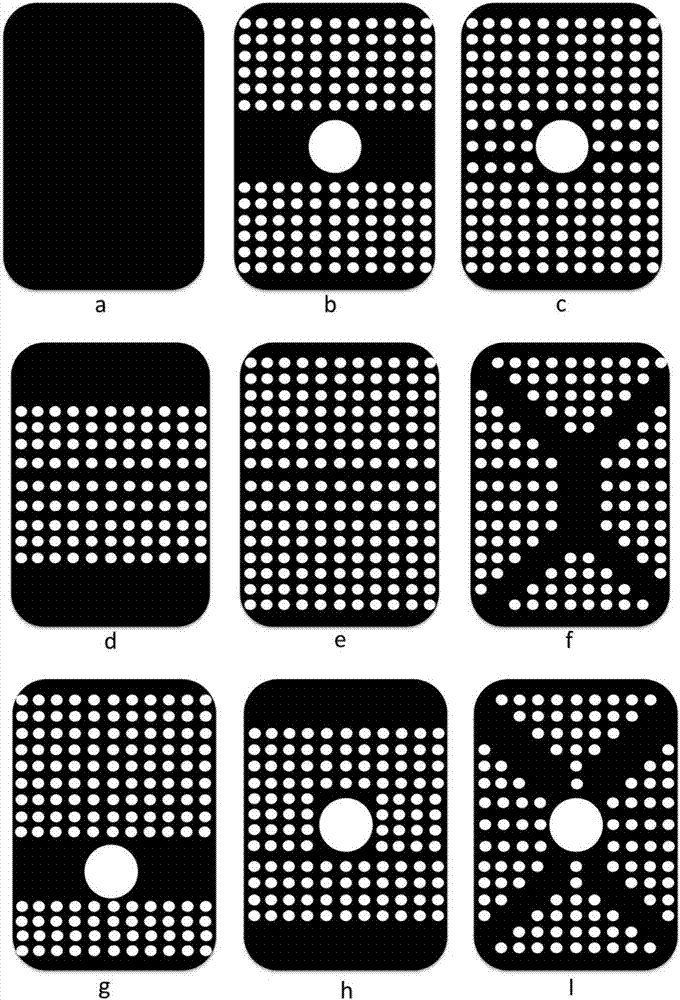

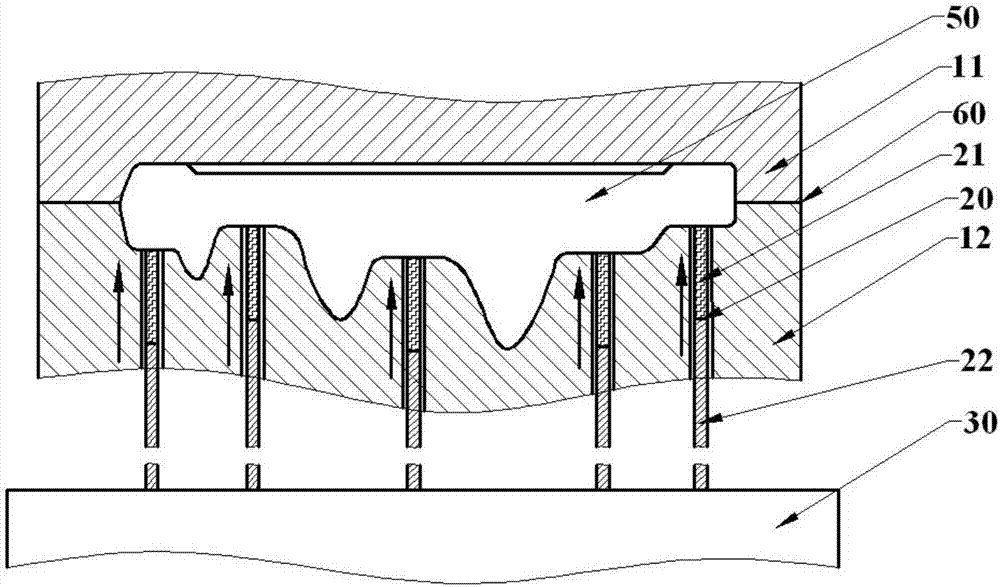

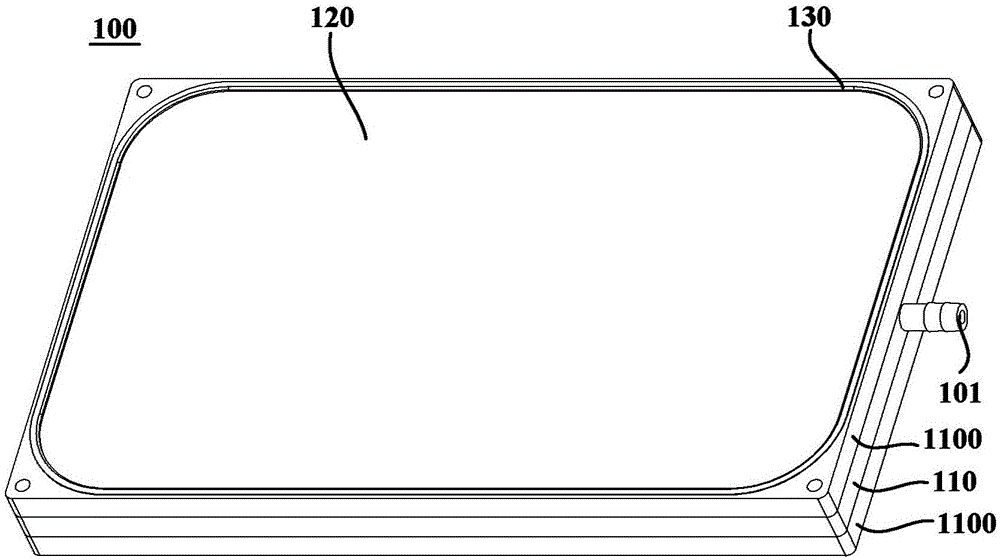

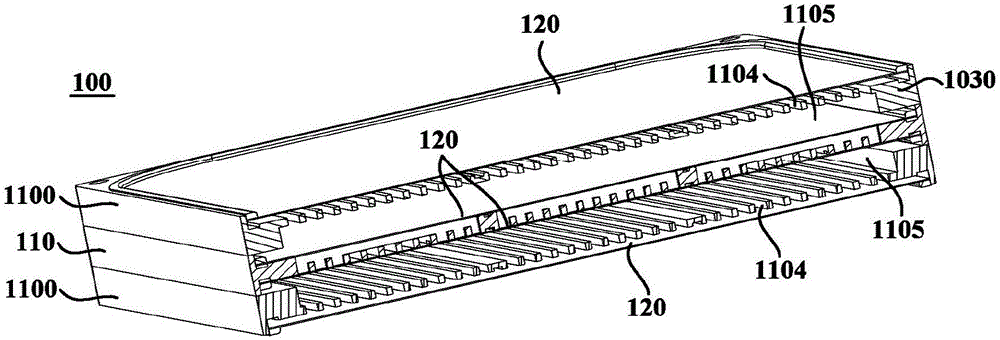

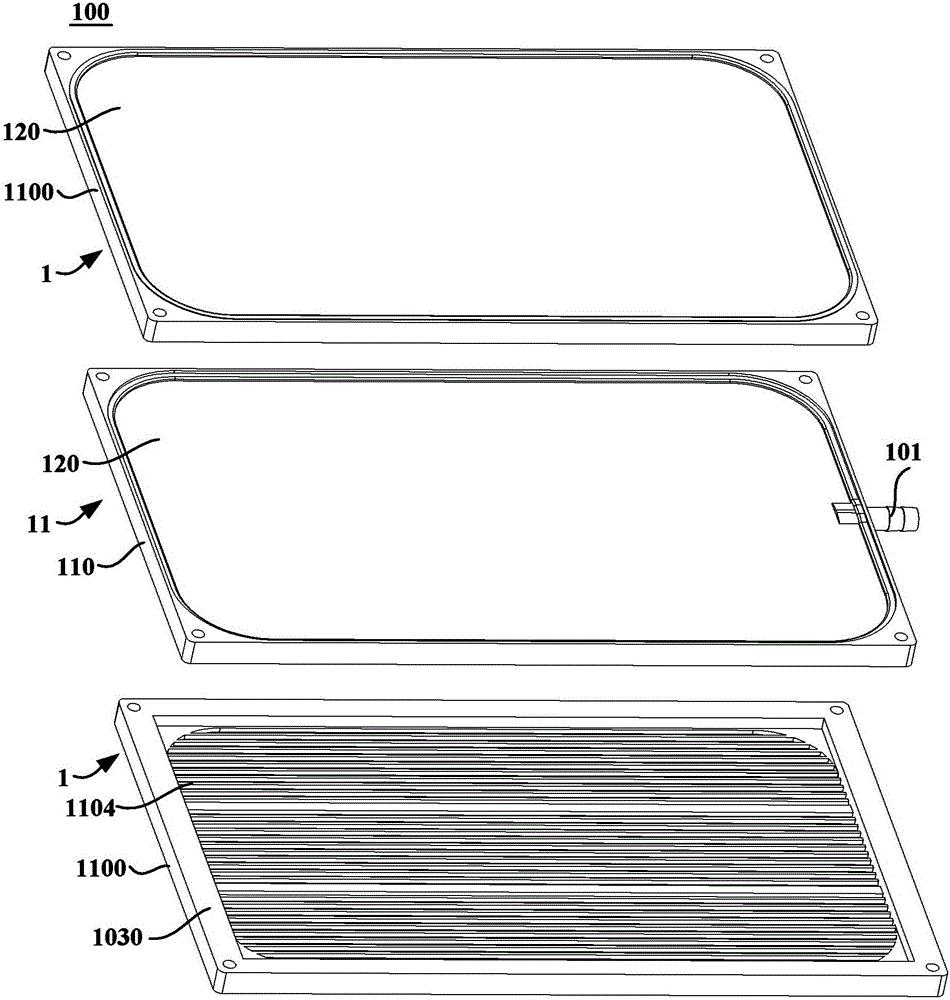

Colorful film substrate, manufacture method thereof and liquid crystal display panel

ActiveCN101806974AImprove display uniformityAvoid display unevennessPhotomechanical apparatusNon-linear opticsLiquid-crystal displayEngineering

The invention discloses a colorful film substrate, a manufacture method thereof and a liquid crystal display panel, relating to the field of liquid crystal displays and invented for improving the display uniformity of liquid crystal display panels. The liquid crystal display panel comprises the colorful film substrate and an array substrate which is in cassette-to-cassette arrangement with the colorful film substrate; liquid crystal is dropped between the colorful film substrate and the array substrate, wherein the colorful film substrate is provided with main column-shaped spacers and auxiliary column-shaped spacers at intervals, the main column-shaped spacers are higher than the auxiliary column-shaped spacers, and the main column-shaped spacers are connected with the auxiliary column-shaped spacers at bottoms. The manufacture method of the colorful film substrate comprises the following steps of: providing a glass substrate; and forming the main column-shaped spacers and the auxiliary column-shaped spacers connected at bottoms while forming a block array on the glass substrate. The colorful film substrate can be used for manufacturing liquid crystal displays.

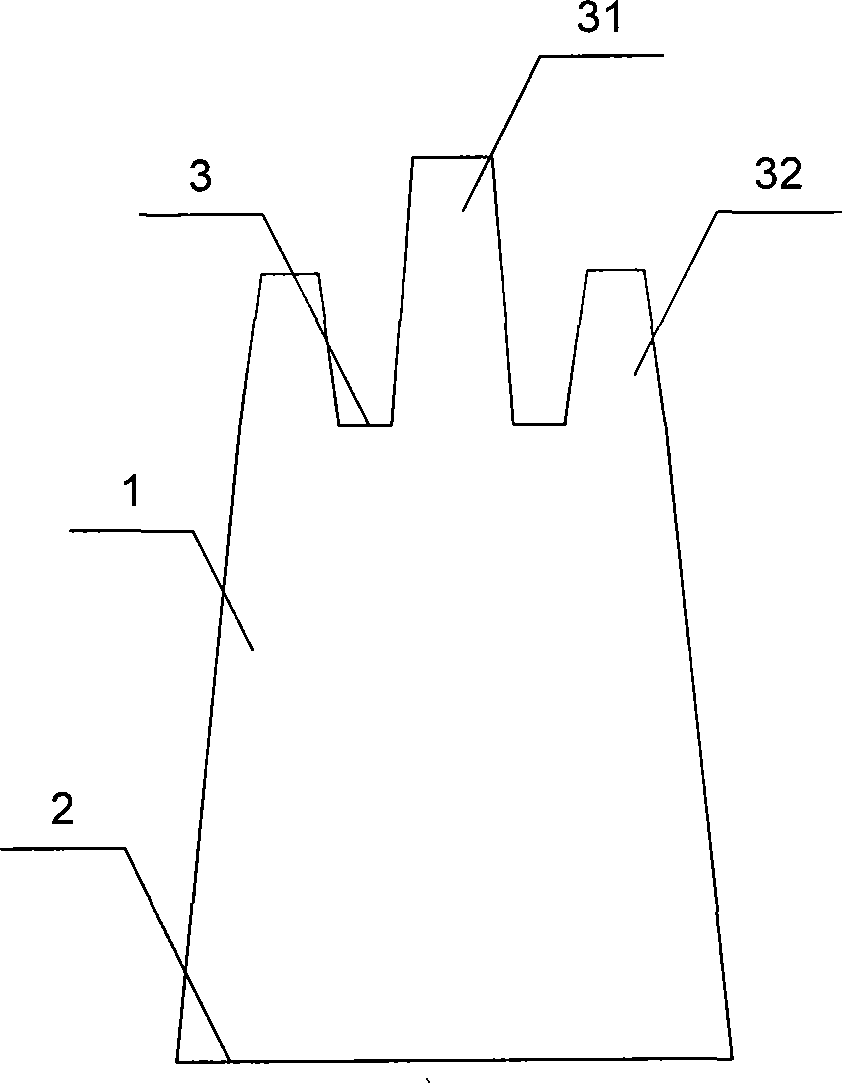

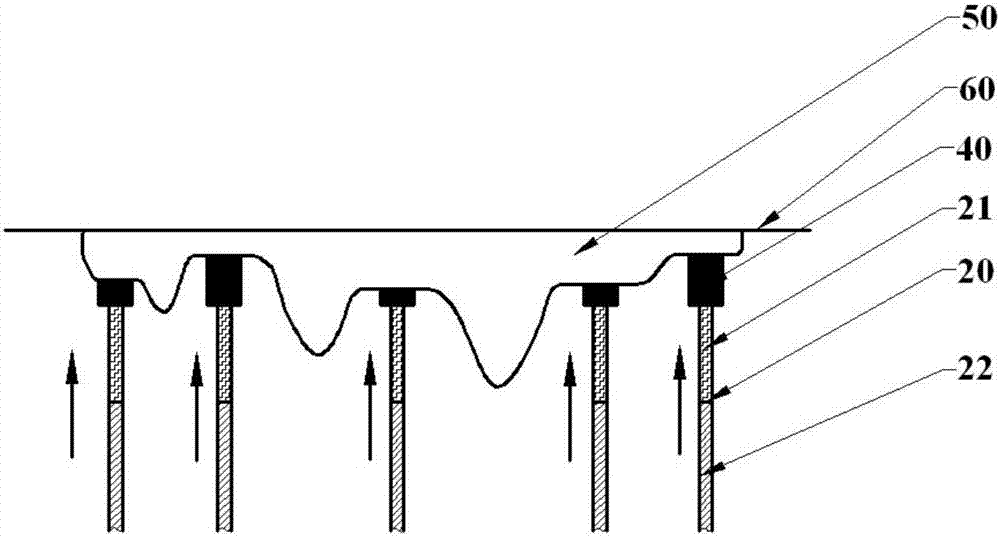

Column shaped spacer and LCD panel thereof

ActiveCN101452156AReduce processing requirementsImprove qualityNon-linear opticsLiquid-crystal displayLiquid crystal

The invention relates to a cylindrical spacer which comprises a cylindrical part that has a base end connected with a substrate of liquid crystal display panel and a top end supporting the other substrate of liquid crystal display panel. The top end of cylindrical part is a projection structure which is high at central part and low at external part, or a concave structure which is low at central part and high at external part. The invention also relates to a liquid crystal display panel which comprises a color film substrate and an array substrate, and a cylindrical spacer which has a base end connected with the color film substrate and a top end supporting the array substrate. The top end of cylindrical spacer is a projection structure or a concave structure which has larger preset deformation force and larger deformation allowance. The liquid crystal display panel according to the invention simultaneously increases the allowed filling high limit of liquid crystal and allowed filling lower limit of liquid crystal, can provide a liquid crystal layer allowance with larger range, reduce the technical requirement for the box, and increases the picture quality of liquid crystal display.

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

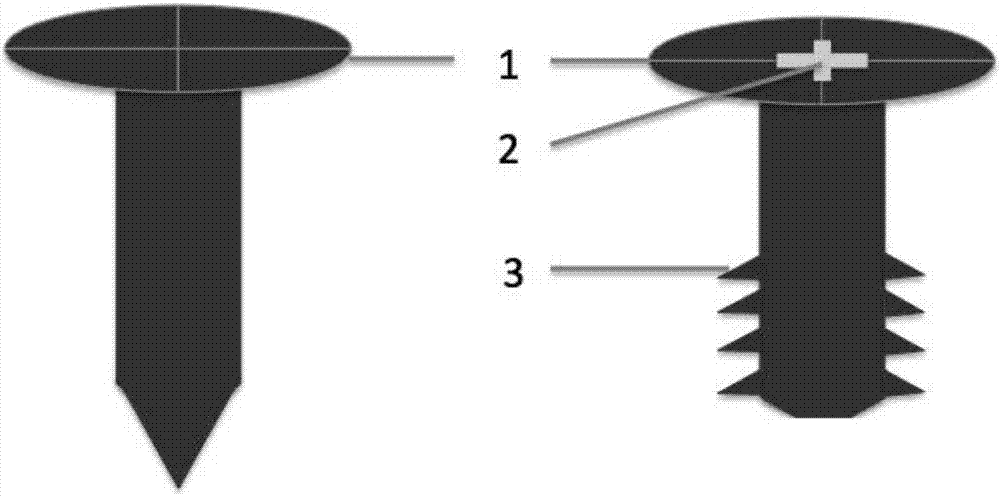

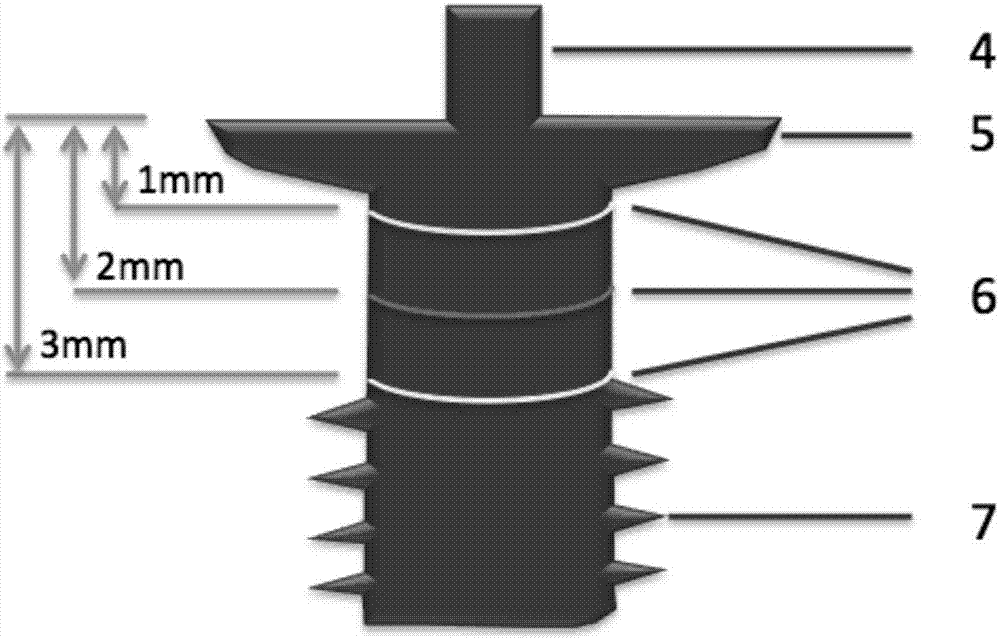

Absorbable magnesium alloy repairing system used for oral cavity guide bone/tissue regeneration

ActiveCN107164673AEnough supportJoint implantsTissue regenerationBarrier membraneMembrane configuration

The invention discloses an absorbable magnesium alloy repairing system used for oral cavity guide bone / tissue regeneration and belongs to the technical field of planting systems. A magnesium alloy containing silver is used for the repairing system. A supporting nail is additionally arranged in the repairing system, the whole supporting nail is in a nail shape, a protrusive cylinder structure which is arranged in the center of the upper surface of a supporting wing is a penetrating membrane, the lower end portion of a nail body is provided with a supporting nail thread, a barrier membrane can be better supported, and the repairing effect is improved.

Owner:浙江沣沅生物科技有限公司

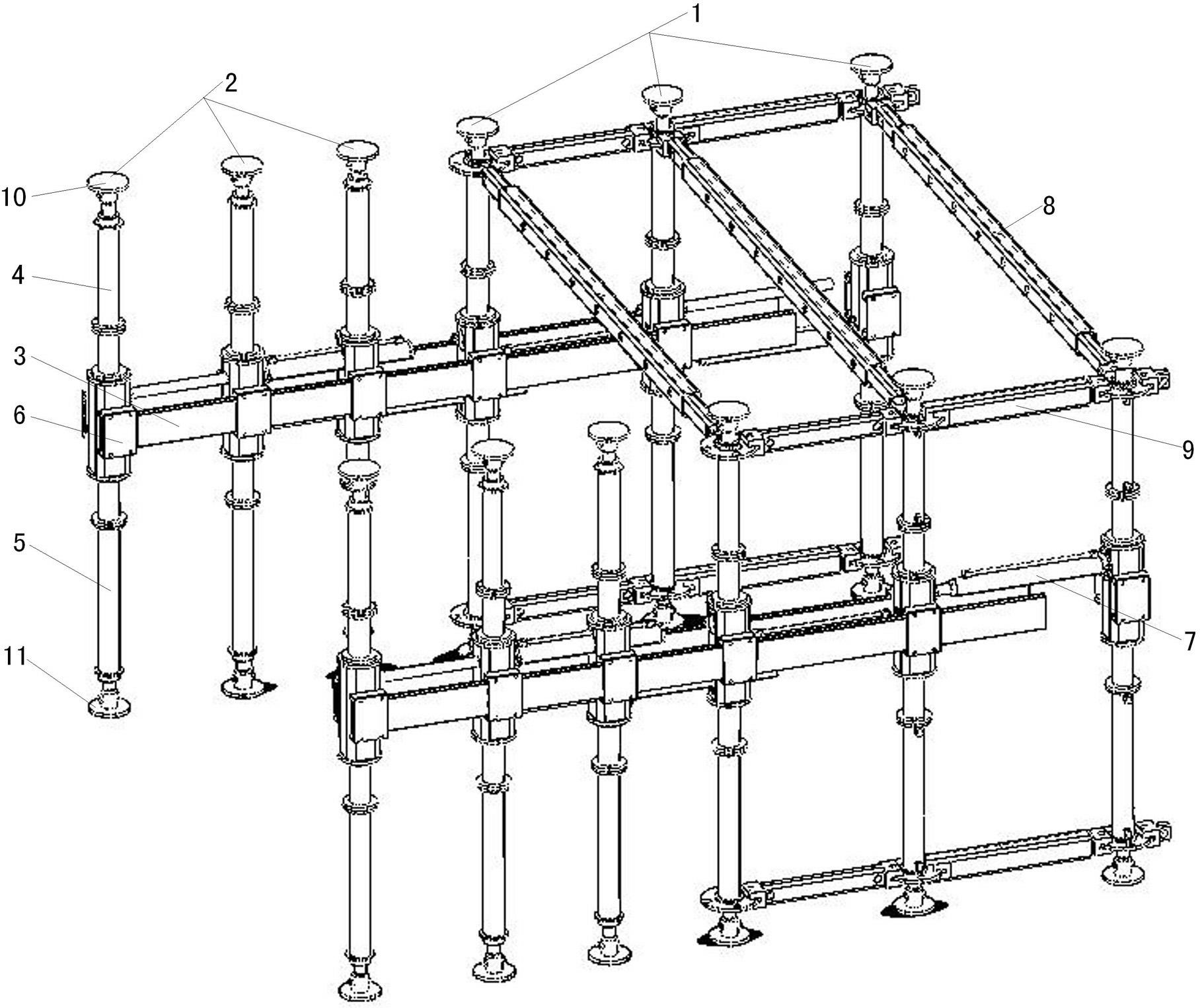

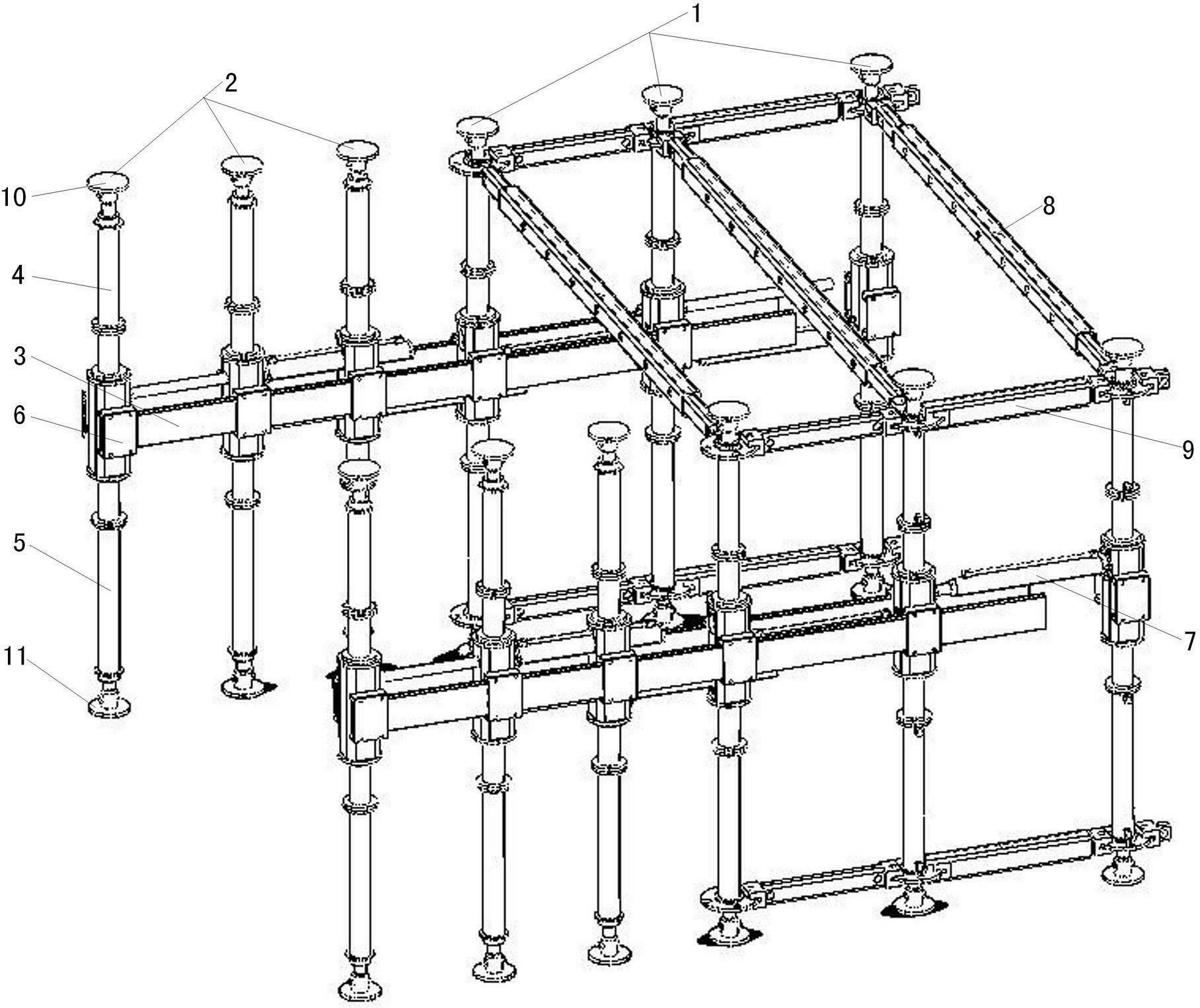

Hydraulic walking multi-level temporary supporting equipment for advancement of tunnel

InactiveCN102587945AImprove space utilizationEffective supportMine roof supportsSupport groupSingle support

The invention belongs to the technical field of equipment for advancement production of coal mines, and particularly relates to hydraulic walking multi-level temporary supporting equipment for advancement of a tunnel, which aims to realize safe and fast advancement of coal mine advancing tunnels. Single supports, which are located on the same side, of a walking support group and a temporary support group are serially connected onto a guide track and can slide relative to the guide track, and single supports located on the left side and the right side of the walking support group and single supports located on the left side and the right side of the temporary support group are connected with a pushing mechanism capable of pushing the single supports to move longitudinally. The hydraulic walking multi-level temporary supporting equipment has the advantages that safety of supporting operation is greatly improved; timely supporting of the supporting equipment can be guaranteed when the grade of the tunnel is changed; and the supporting equipment is an integral structure, runs independently and saves time, labor and space.

Owner:SHANXI DATONG UNIV

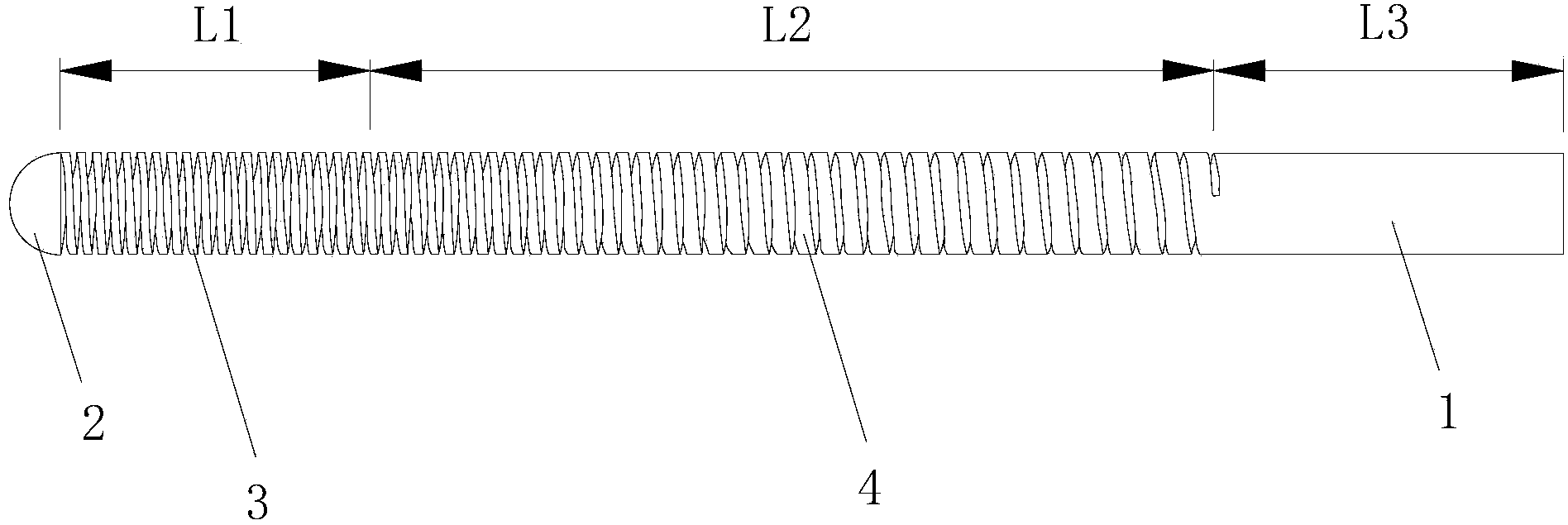

Titanium alloy guide wire for surgical interventional therapy

ActiveCN103623494ALarge range of performance adjustmentsSimple structureGuide wiresGroove widthInterventional therapy

The invention discloses a titanium alloy guide wire for interventional therapy. The titanium alloy guide wire comprises a titanium alloy small-diameter thin-wall tube and a noble metal end head which is distributed at the far end of the titanium alloy small-diameter thin-wall tube; the titanium alloy small-diameter thin-wall tube is divided into a guide wire far section, a guide wire middle section and a guide wire near section from far to near; a single spiral groove I is formed in the tube wall of the guide wire far section; a single spiral groove II is formed in the tube wall of the guide wire middle section; the single spiral slot I is an uniform-pitch spiral groove; the single spiral groove II is a variable-pitch spiral groove; the groove widths of the single spiral groove I and the single spiral groove II are same; the pitch of the single spiral groove II is gradually increased from far to near, and the pitch at the far end of the single spiral groove II is equal to that of the single spiral groove I; the groove depth of the single spiral groove I and the single spiral groove II is the same as the wall thickness of the titanium alloy small-diameter thin-wall tube. The titanium alloy guide wire disclosed by the invention is simple in structure, reasonable in design, simple and convenient to machine and manufacture, good in using effect, and capable of effectively solving the problems such as a complex machining process, high cost and poor adaptability of the existing titanium alloy guide wire.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Shock-absorption air cushion for shoe and manufacturing method for shock-absorption air cushion

Owner:DONGGUAN ZHANSHENG MOLD

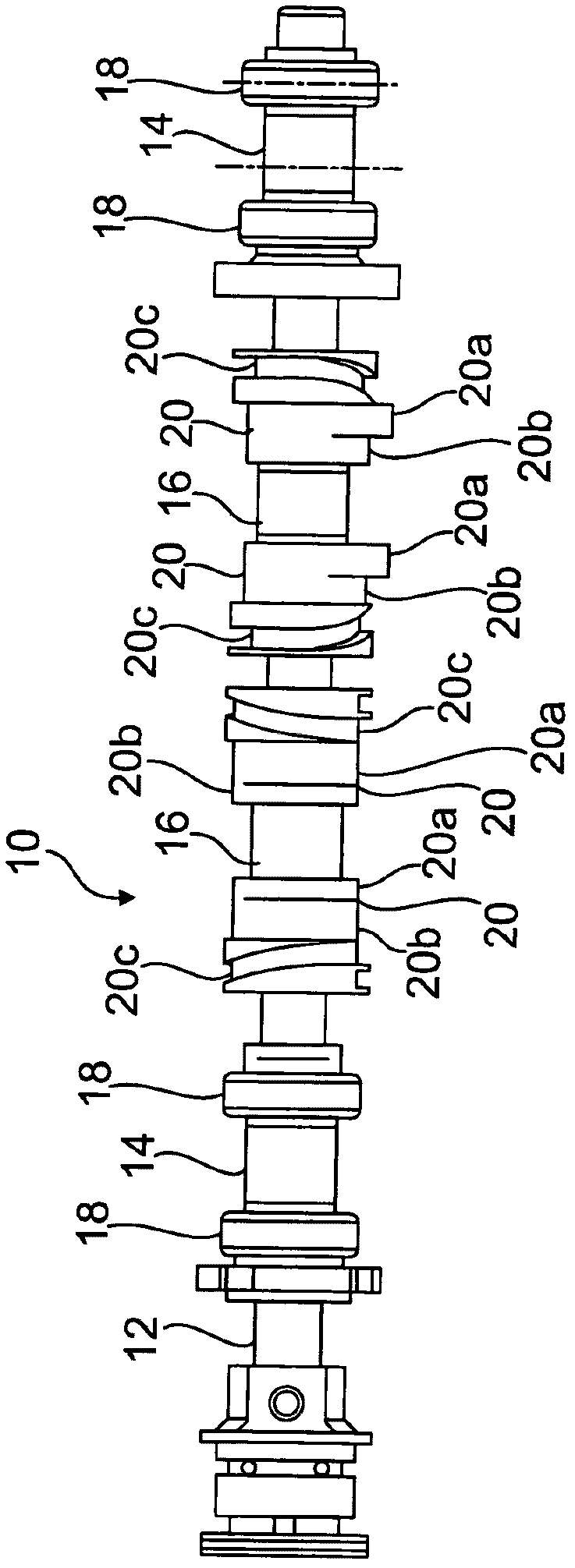

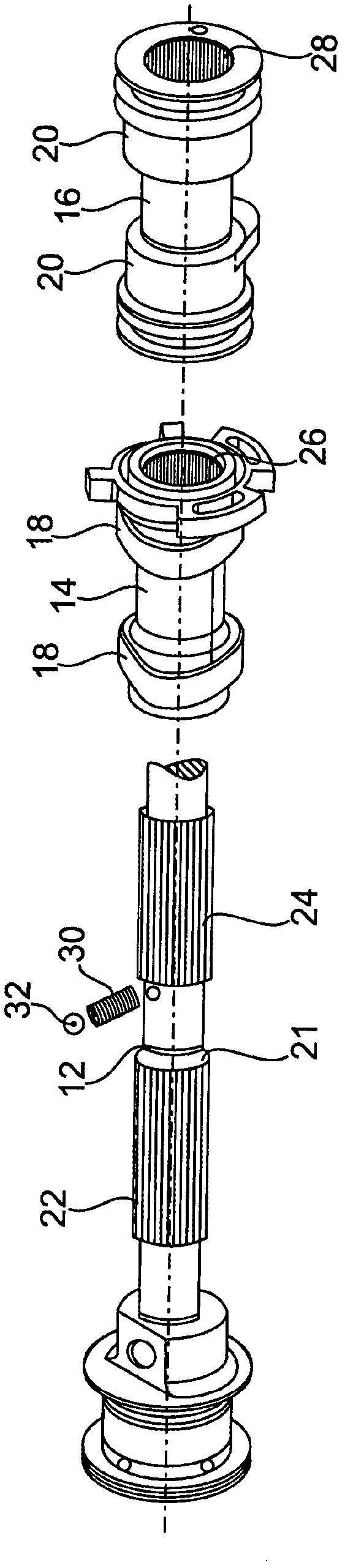

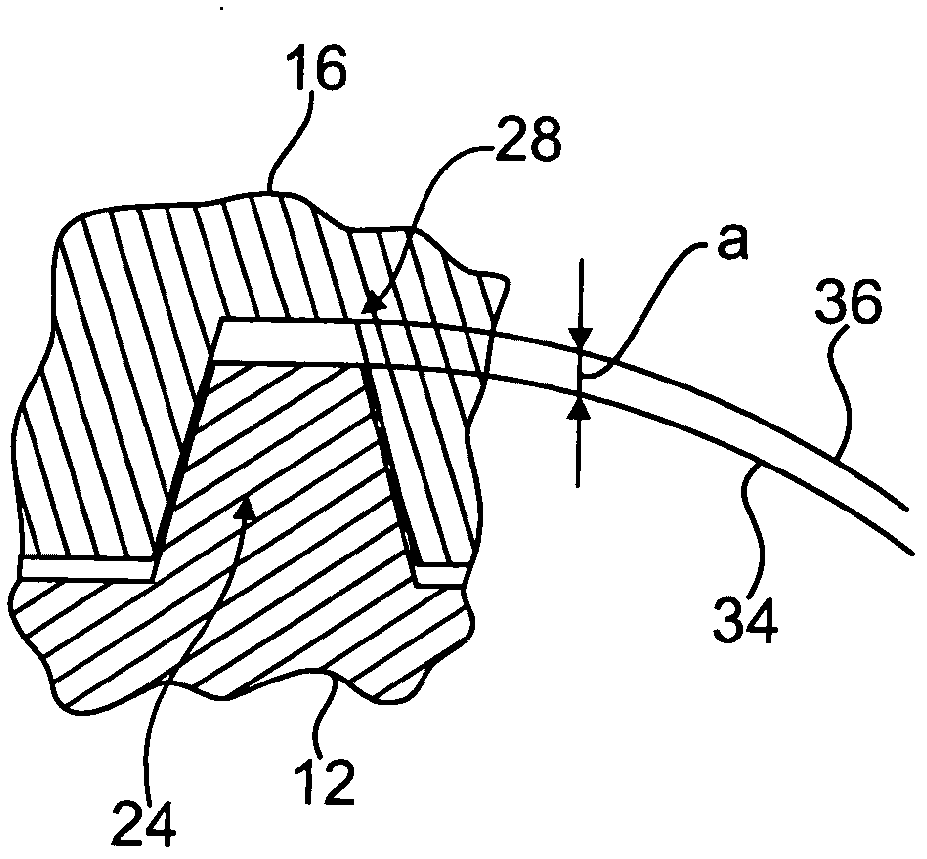

Constructed shaft element, particularly a constructed camshaft for valve controlled internal combustion engines

ActiveCN102459826AAdd supportReduce noise emissionsValve arrangementsCouplings for rigid shaftsCombustionInternal combustion engine

The present invention relates to a constructed shaft element, particularly a constructed camshaft for valve controlled internal combustion engines, wherein a hub body comprising at least one functional part, particularly at least one cam, is held on a shaft by a form fit connection by means of insertion teeth in the circumferential direction, wherein the insertion teeth comprise shaft teeth formed on the shaft and interacting with hub body teeth formed in a hub body recess. According to the invention, the at least one hub body (14) is held in addition to the circumferential form fit connection by a fixed seat on the shaft (12) implemented by a press fit between a tooth circle of the shaft teeth (22) and a root circle of the hub body teeth (26). The invention further relates to a method for producing a constructed camshaft for valve controlled internal combustion engines.

Owner:AUDI AG

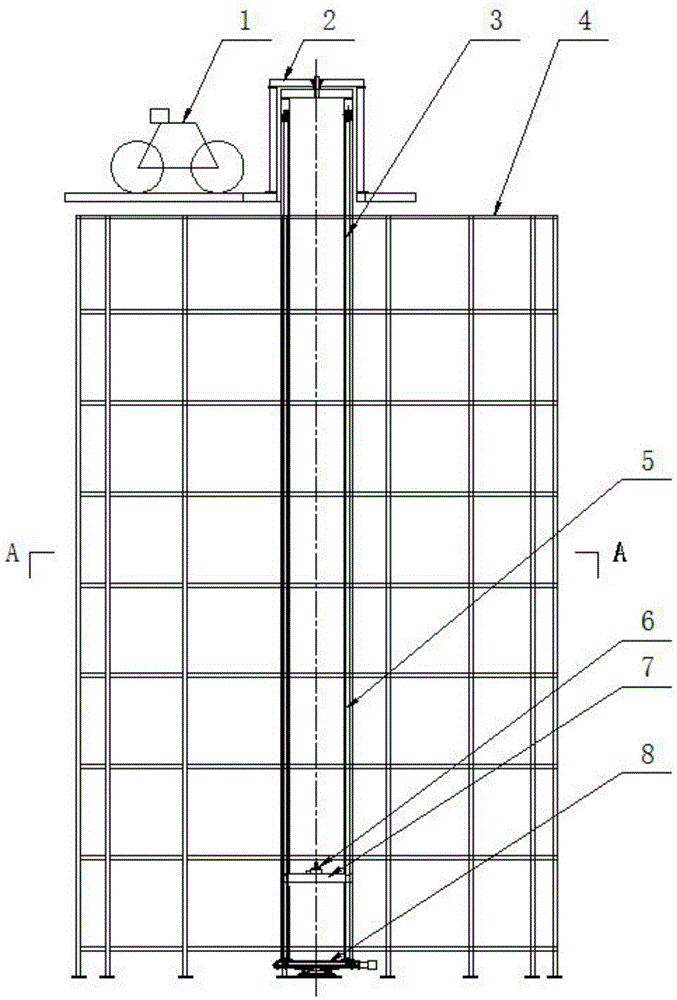

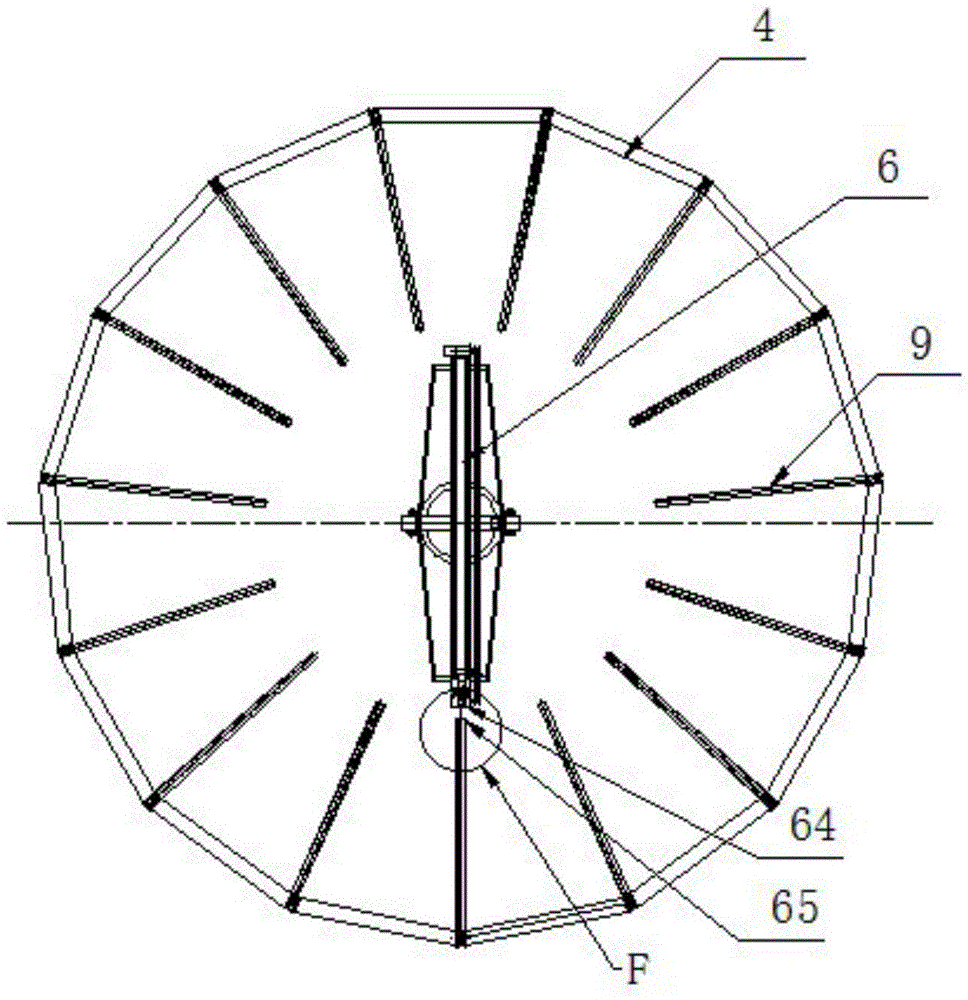

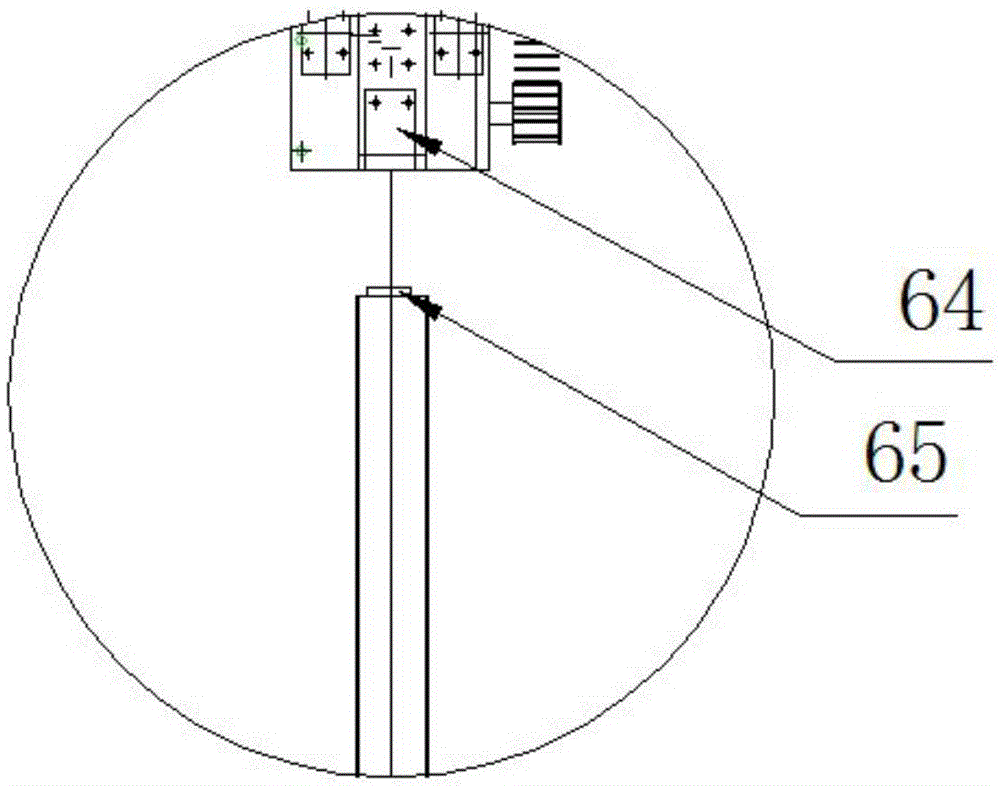

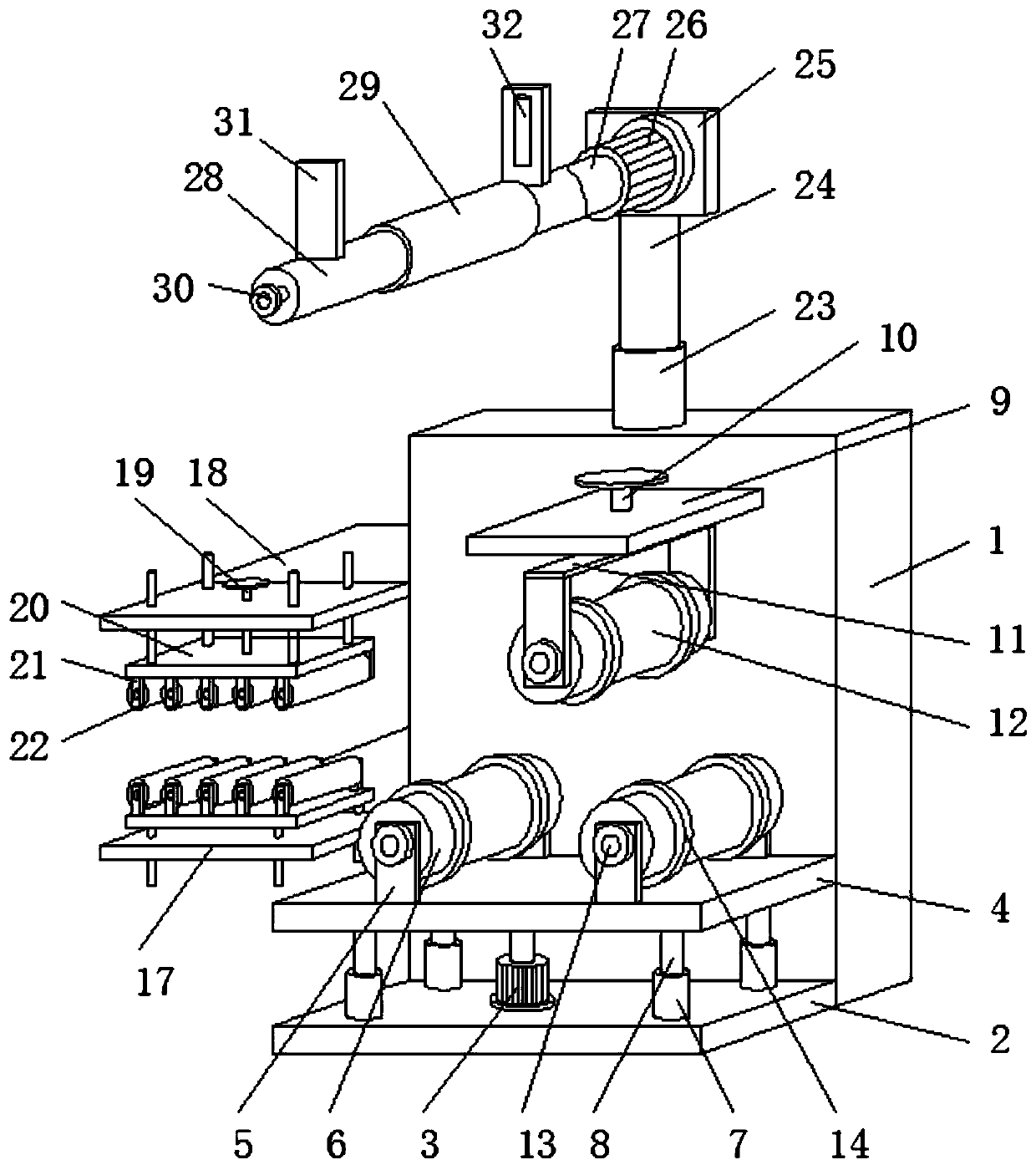

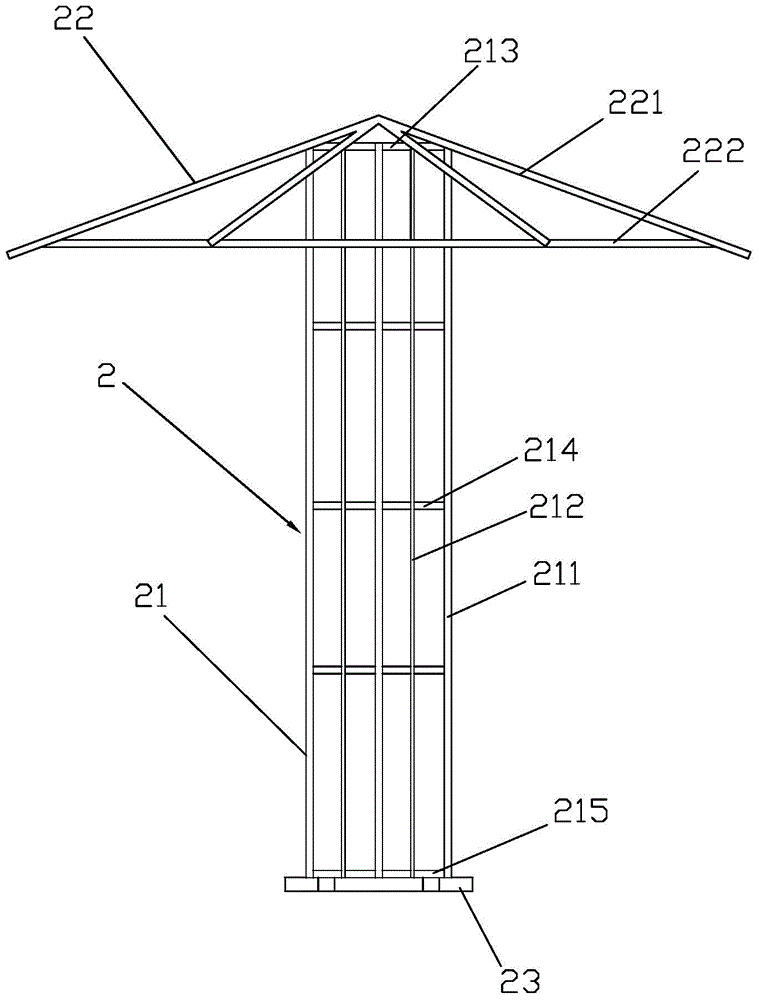

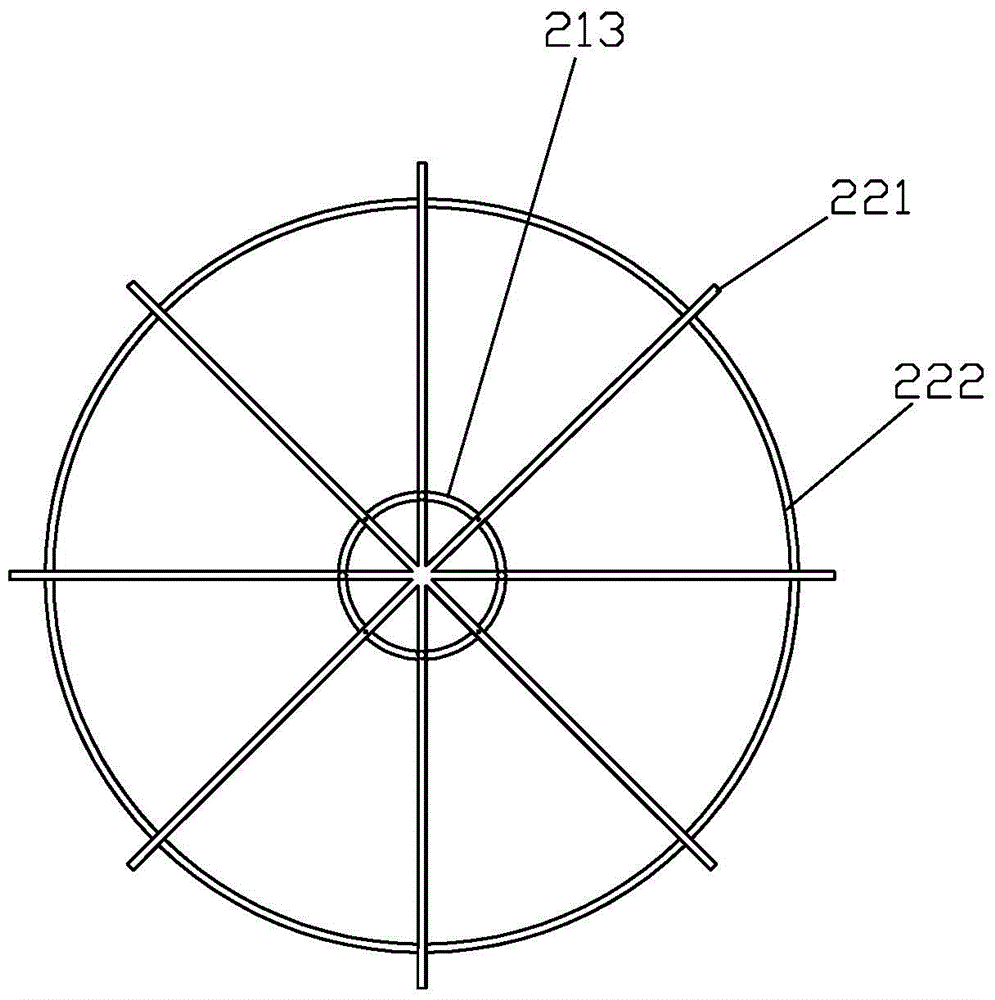

Underground bicycle garage for rotating mechanism at accurately controlled angle

The invention relates to an underground bicycle garage for a rotating mechanism at an accurately controlled angle. The underground bicycle garage comprises an assembling type supporting unit and a central conveying unit, wherein the assembling type supporting unit is composed of a cage type barrel and a plurality of layers of bicycle storage racks peripherally arranged on the inner wall of the cage type barrel facing an axial center position; the central conveying unit is mounted at the axial center position of the assembling type supporting unit, the central conveying unit is composed of parallel rotating guide rails, a synchronous belt type lifting mechanism, a shaft support type rotating mechanism and a conveying table, a laser distance measuring sensor is fixedly mounted at one side end part of the conveying table, a reflecting plate is mounted at the end part of each bicycle storage rack, and the signal output end of the laser distance measuring sensor is connected to a control system. The underground bicycle garage can complete grabbing, lifting, accurate rotation and pushing of bicycles, the bicycles can be placed on the bicycle storage racks at right positions, the quantity of the stored bicycles is large, the ground space is saved, and the underground bicycle garage is reasonable in structure, good in safety and stable and efficient in operation.

Owner:TIANJIN YUANZHUO TECH DEV CO LTD

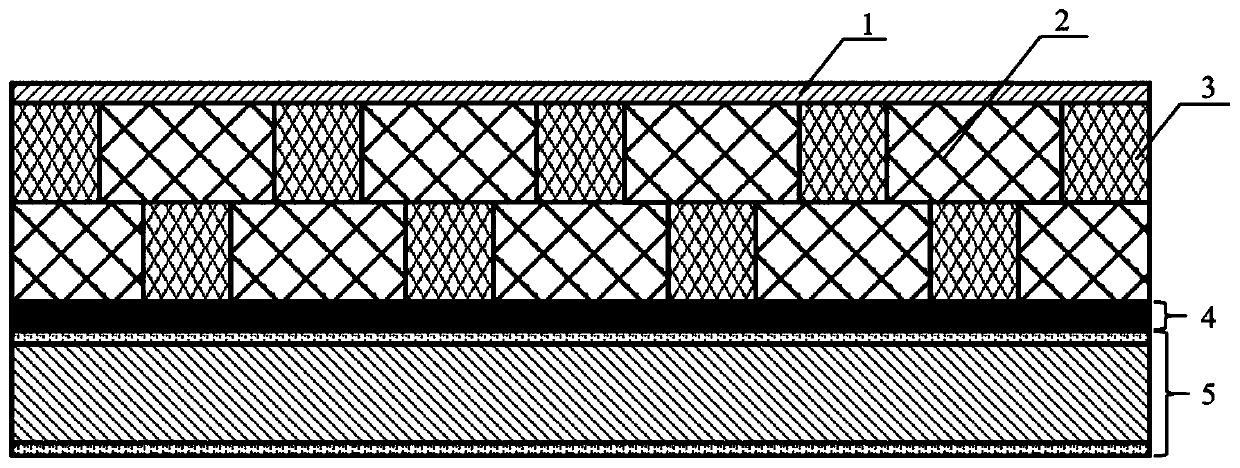

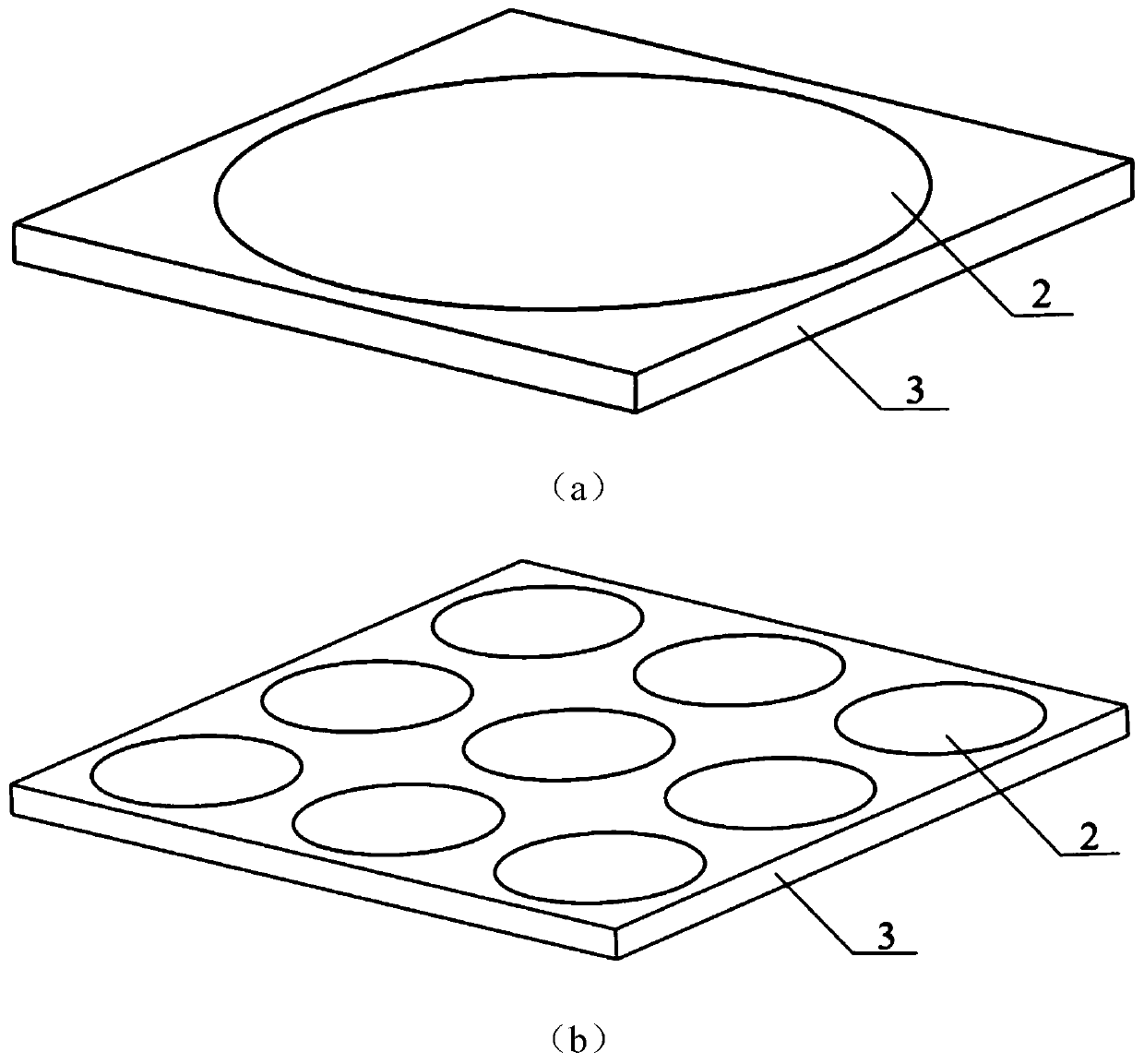

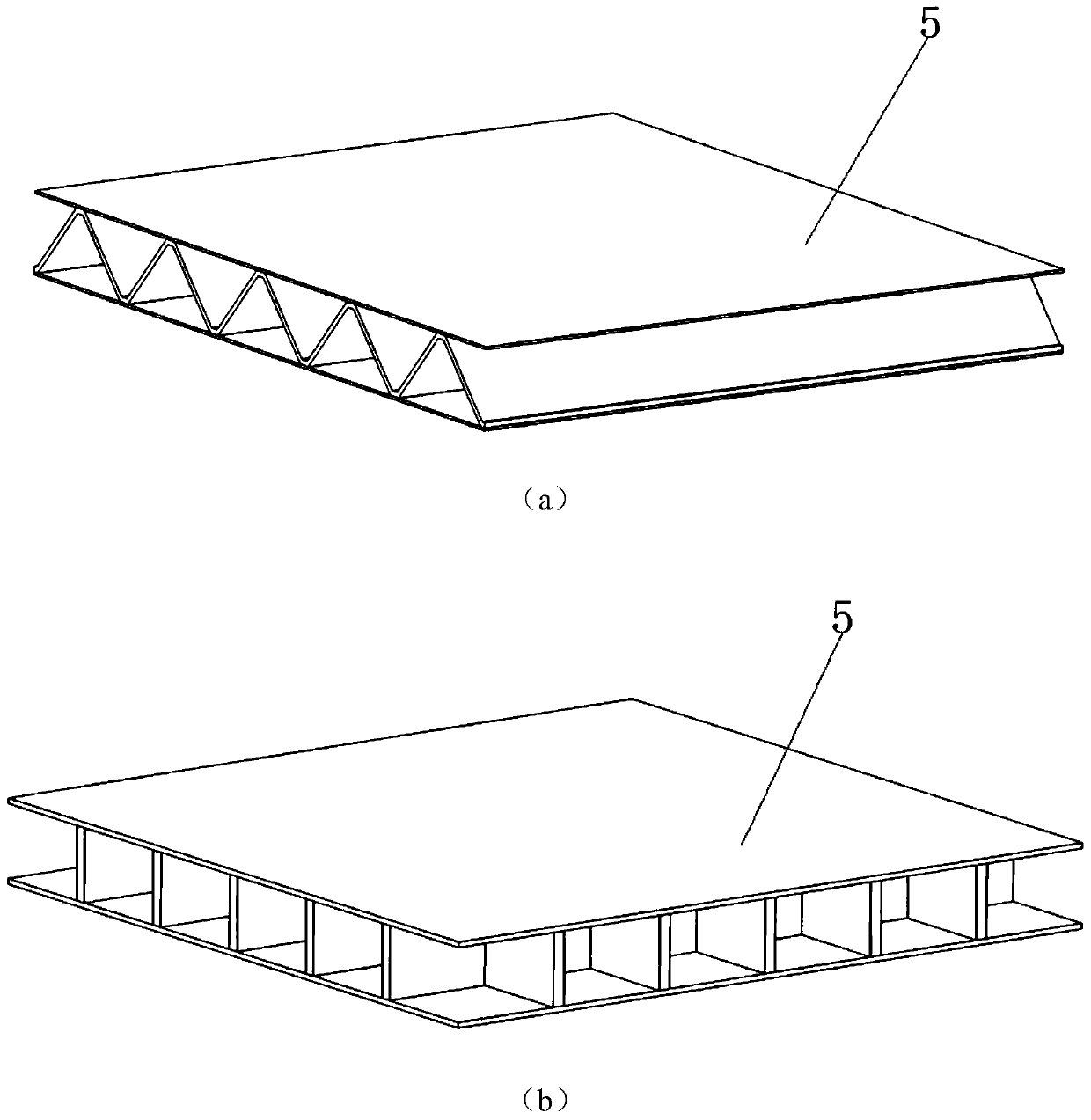

Composite bulletproof armor plate and preparation method thereof

ActiveCN109855473AHigh compressive strengthIncrease elasticitySynthetic resin layered productsLaminationInterference fitCeramic composite

The invention discloses a composite bulletproof armor plate and a preparation method thereof. The composite bulletproof armor plate comprises a protective cover plate, ceramic plates, metal restraining plates, a fiber metal laminated plate and a porous metal sandwich plate; and the ceramic plates and the metal restraining plates are assembled and connected in an interference fit mode, the ceramicplates are supported through the fiber metal laminated plate and the porous metal sandwich plate, and the bullet resistance of a bulletproof armor plate is improved. The preparation technology is simple, the cost is low, compared with a traditional ceramic composite armor plate, the composite bulletproof armor plate is higher in impact resistance at a time and has the multi-time impact resistance,and the composite bulletproof armor plate has the wide application prospects in the bulletproof fields of armed helicopters, armored cars, vessels and the like.

Owner:XI AN JIAOTONG UNIV

Online longitudinal cutting machine for thick glass

ActiveCN104058583AIncrease productivityReduce labor intensityGlass severing apparatusGlass productionTool marksEngineering

Owner:ZHANGZHOU KIBING GLASS +1

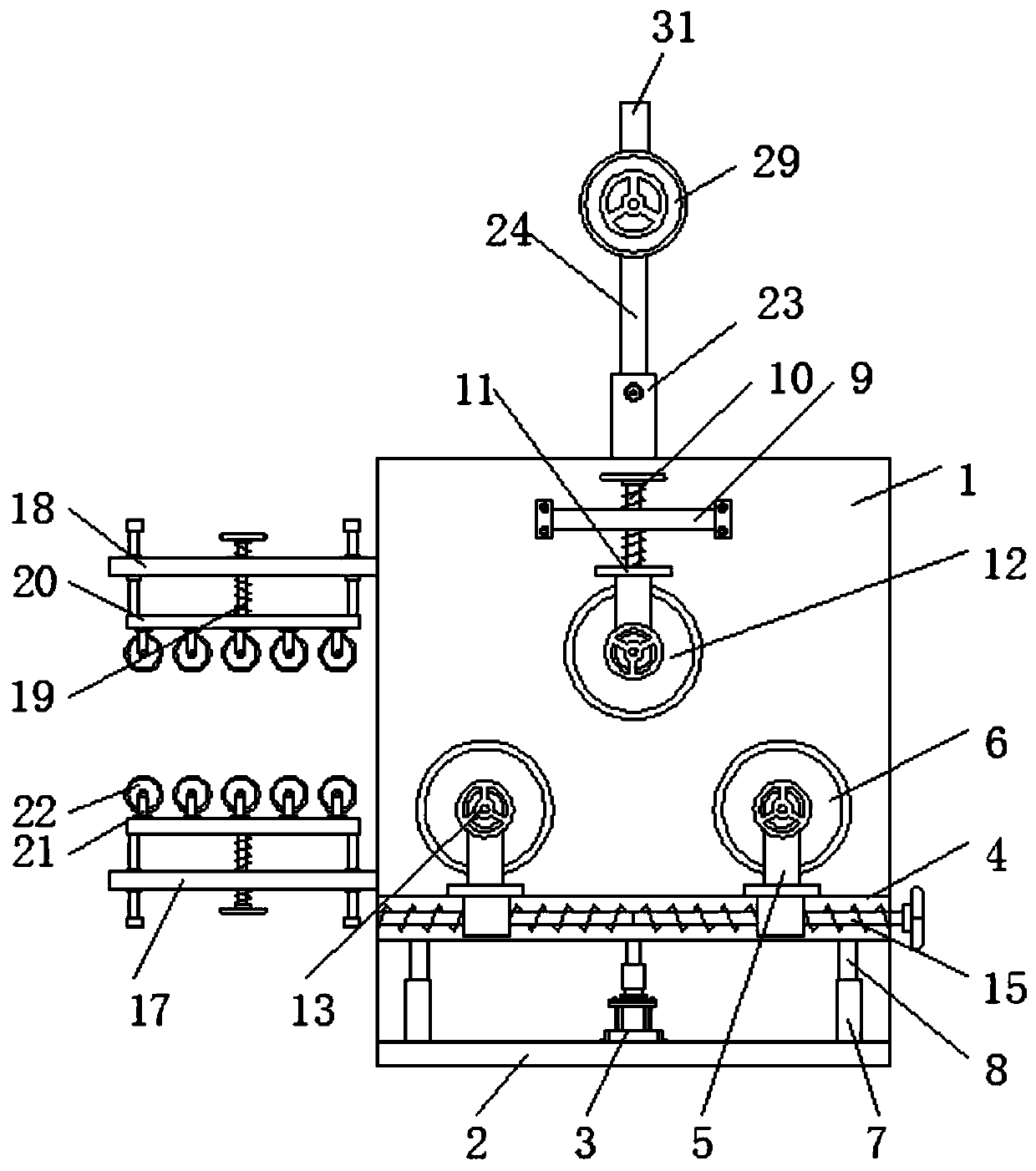

Multi-angle building pipe bending device capable of conducting discharging conveniently

InactiveCN110479817AAvoid offsetIncreased bend rangeMetal-working feeding devicesPositioning devicesArchitectural engineeringFuselage

The invention discloses a multi-angle building pipe bending device capable of conducting discharging conveniently. The multi-angle building pipe bending device comprises a device body; a base is arranged on the outer wall of one side of the device body, and the center of the top of the base is fixedly connected with a first air cylinder through bolts; the top end of the first air cylinder is connected with a lifting platform through a telescopic rod, and a second lead screw is arranged in the lifting platform; and the outer side of one side of the second lead screw is in screwed connection with a first supporting frame through a thread. The multi-angle building pipe bending device capable of conducting discharging conveniently can meet the pipe bending demands of different pipes through two horizontal moving pipe bending rollers, thus the demand for the angles of the different pipes on a building are met, the pipe bending range of the different pipes is expanded, adjustment can be conducted according to the diameters of the different pipes through roller rings with adjusting spacing on the pipe bending rollers, thus the multi-angle building pipe bending device adapts to machining of the pipes of different specifications conveniently, and the problem that operation wastes the time and labor due to pipe bending die replacement is avoided.

Owner:马鞍山致青工业设计有限公司

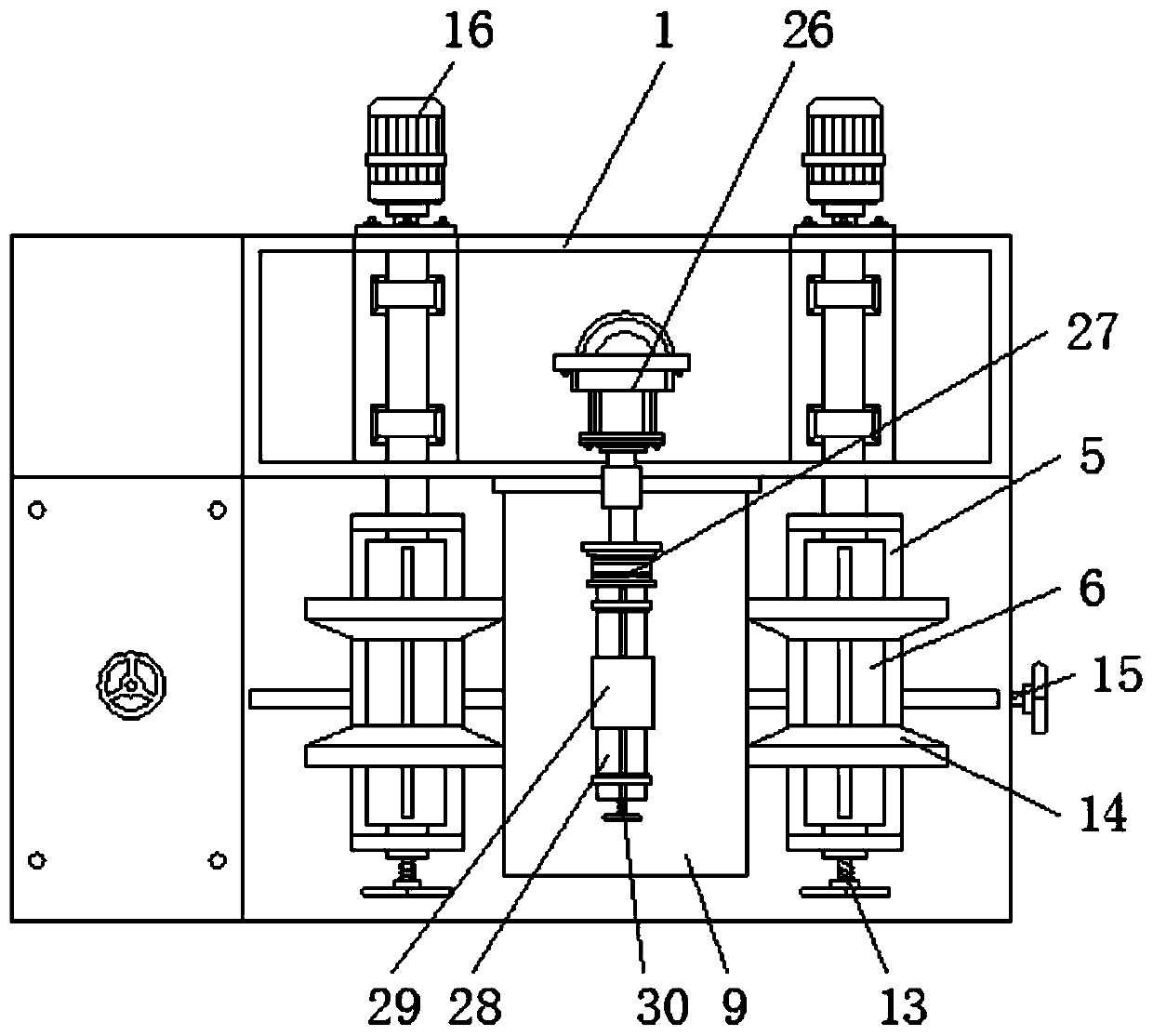

Flexible die releasing method of closed die forging large irregular profile structure forge piece

ActiveCN106975722AEject evenlyReduce contact areaForging/hammering/pressing machinesPush upsEngineering

The invention discloses a flexible die releasing method of a closed die forging large irregular profile structure forge piece. The flexible die releasing method comprises the steps that an upper forging die is taken out firstly and then force is applied to pushing rods to push up the large irregular profile structure forge piece in a lower forging die; flexible sections of each pushing rod are compressed to the elastic limit, and the compression amount is equal; when push-out force of a certain pushing rod is larger than frictional resistance of the position, located on the pushing rod, of the forging piece and a die mold cavity, the position of the forging piece loosens firstly and produces certain displacement, the pushing rod is not separated from the forging piece, the situation same with the just pushing rod occurs gradually on the other one pushing rod or the other multiple pushing rods, and the process occurs randomly and is conducted continuously; and when the total push-out force of all the pushing rods is larger than the total frictional resistance of the forging piece, the forging piece loosens overall, bears relatively-even force and is steadily pushed out of the die mold cavity. According to the flexible die releasing method, the die releasing process of the forging piece becomes steadier and is not liable to damage, and the flexible die releasing method is mainly used for die releasing after forging of forging pieces such as large aircraft structural pieces.

Owner:贵州锆石科技发展有限责任公司

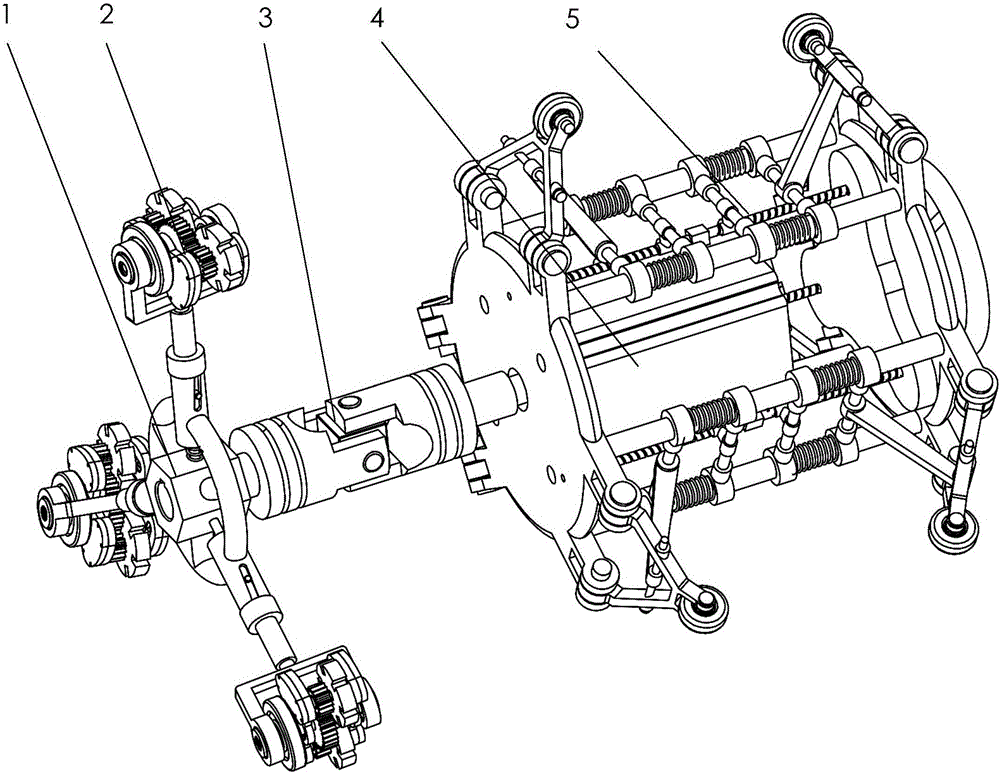

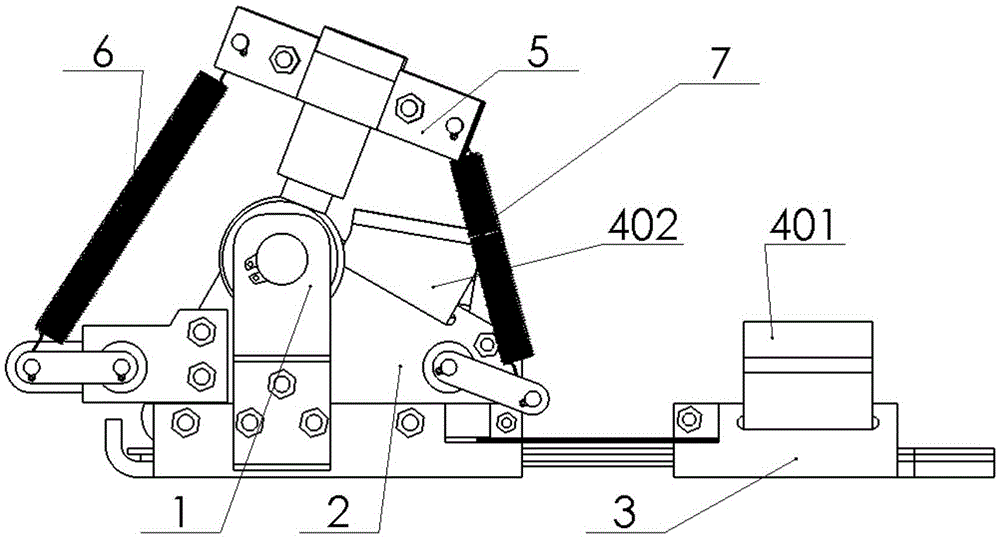

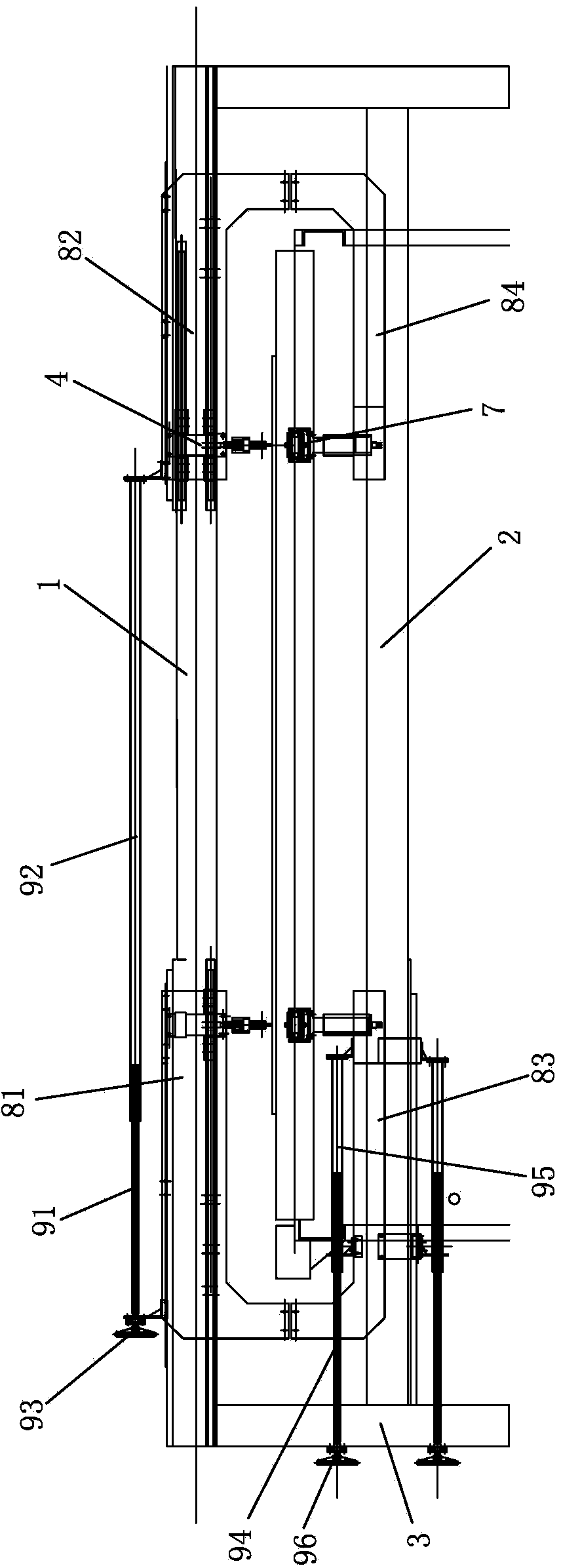

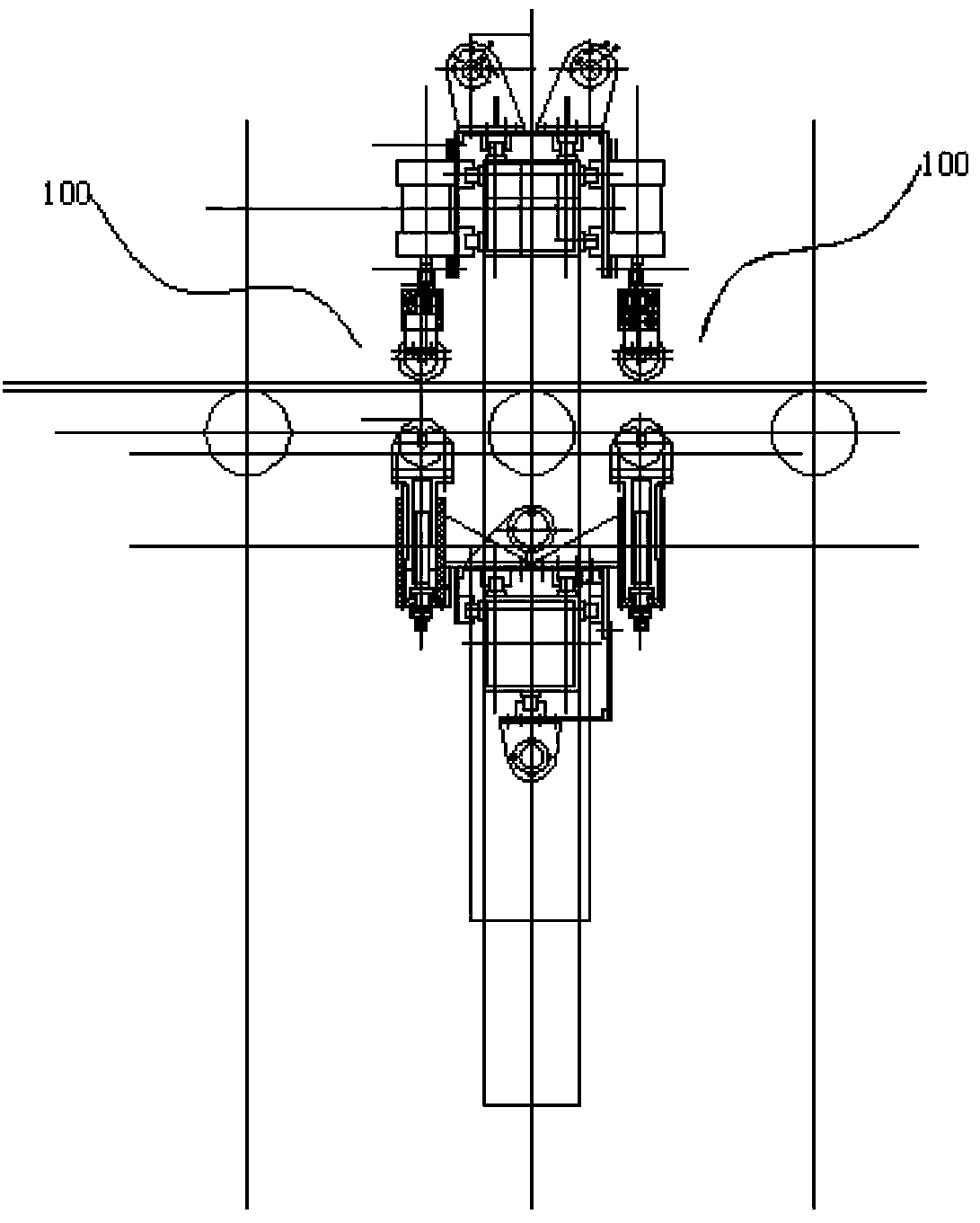

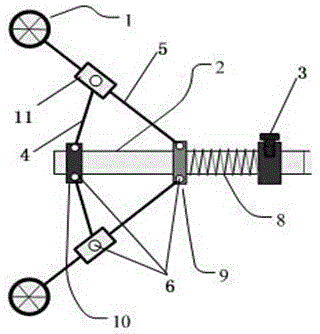

Main mechanism of pipeline crossing device for preventing track deviation and device

The invention discloses underground pipeline detection techniques and provides a main mechanism of a pipeline crossing device for preventing track deviation and the device. The main mechanism comprises a sliding mechanism arranged on a linear guide rail and a supporting hinge mechanism hinged to the sliding mechanism. The sliding mechanism is connected with an elastic piece arranged on the linear guide rail. The other end of the elastic piece is fixed to the linear guide rail. The supporting hinge mechanism comprises three or more supporting rods and limiting rods, wherein the supporting rods are hinged to the sliding mechanism, and the limiting rods are hinged to the supporting rods. The supporting rods are evenly arranged on the sliding mechanism with the linear guide rail as the center. The other end of each limiting rod is hinged to the linear guide rail. The device comprises two main mechanisms which are connected through a universal coupling. The device can be adapted to detection of underground pipelines with different diameters; in addition, the situation that the pipelines deviate from pipeline center lines under the influences of the factors such as the gravity can be avoided, so that the accuracy of detection data is greatly improved, and safety use of the pipelines is guaranteed.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

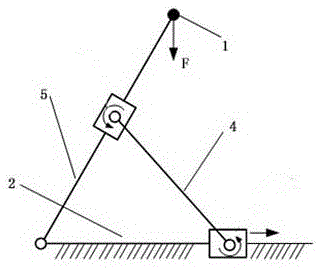

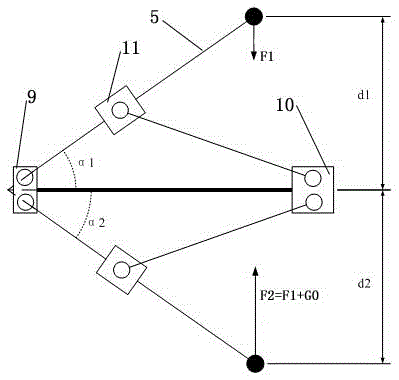

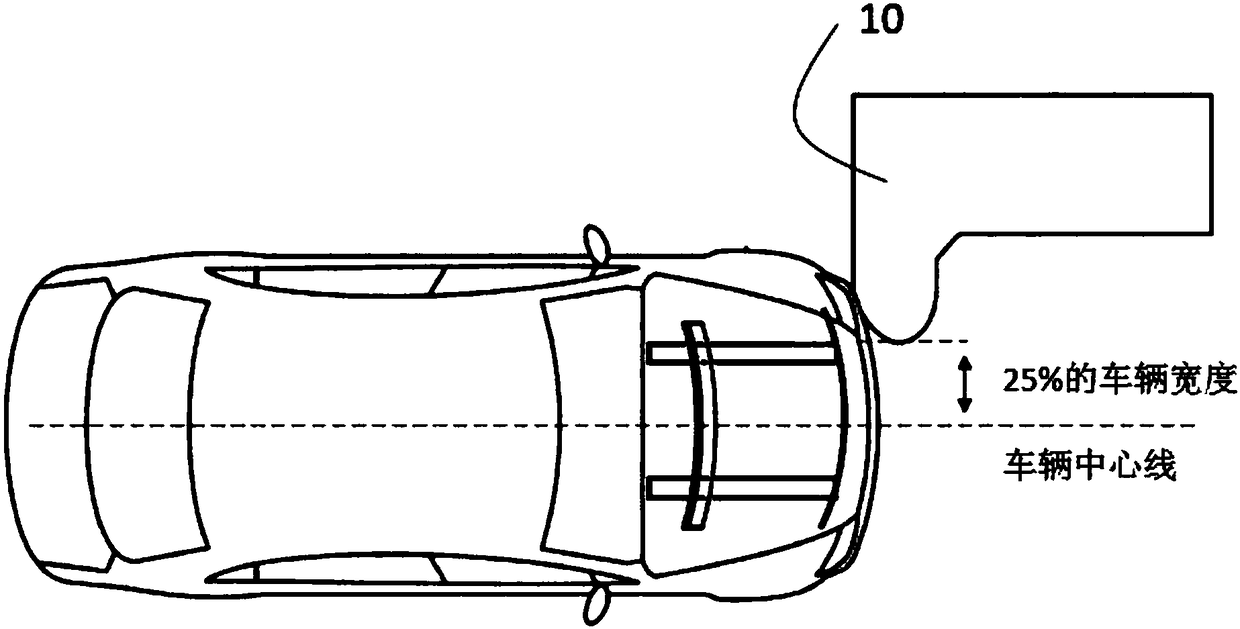

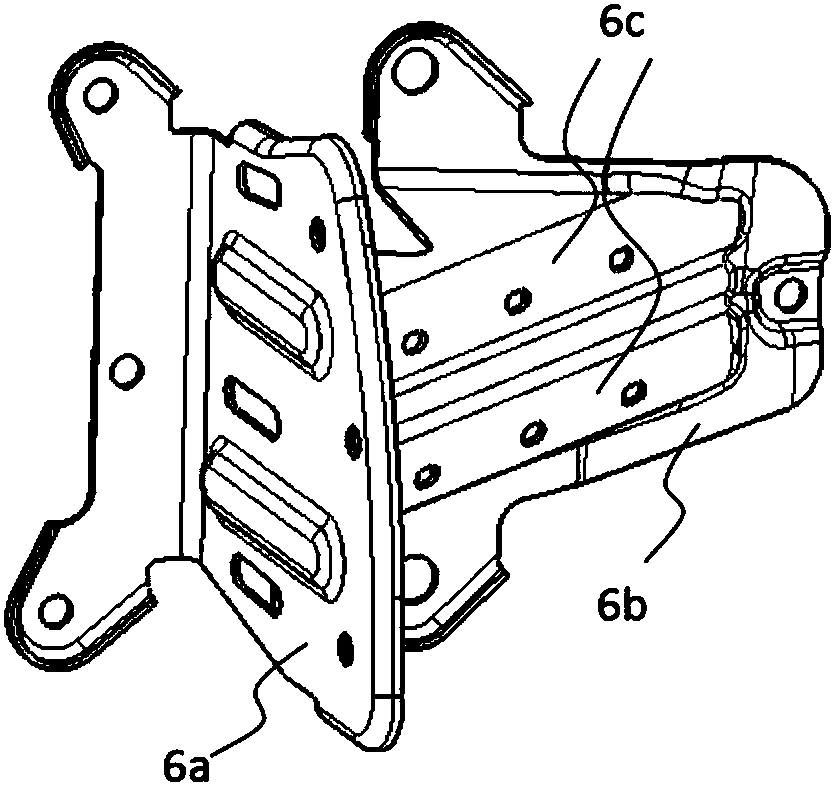

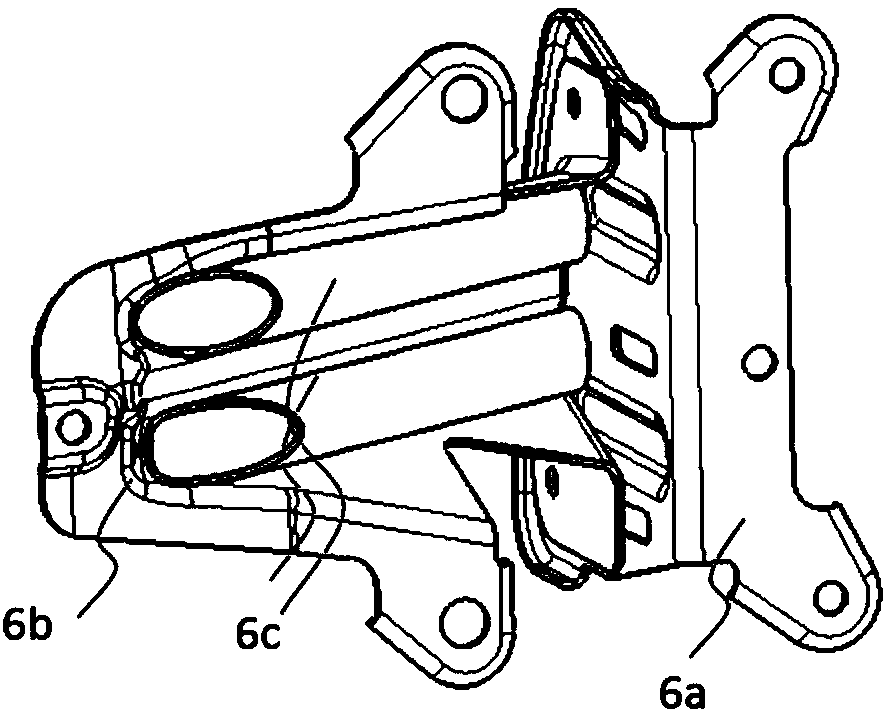

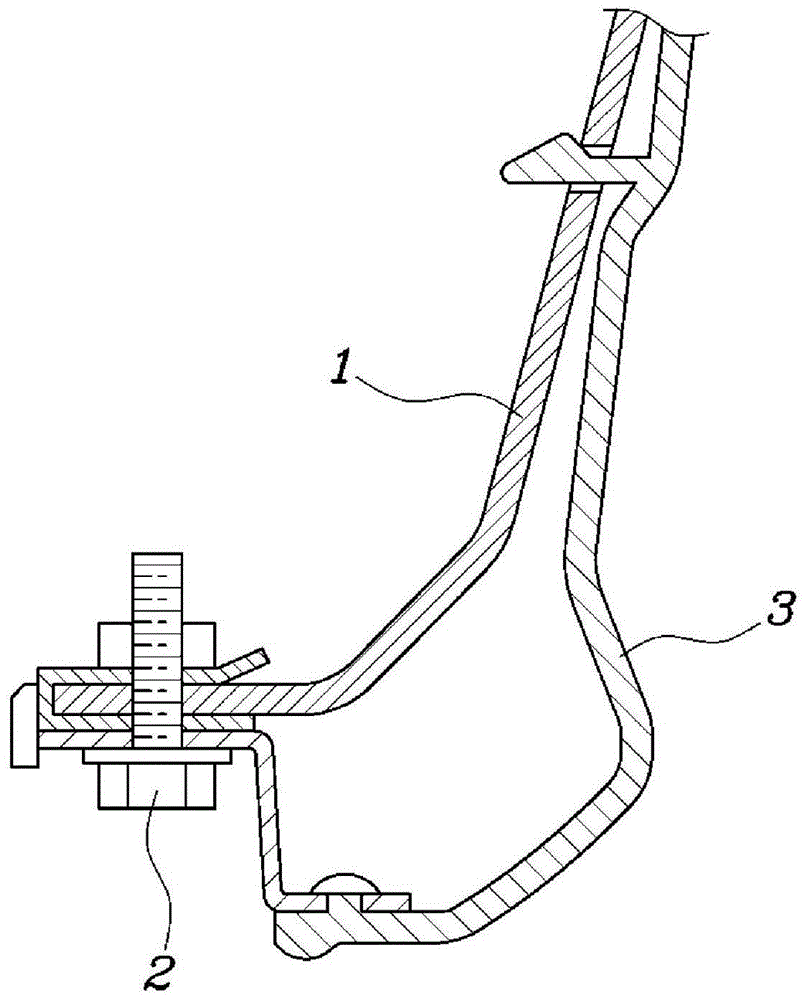

Engine room force transfer structure dealing with automobile small offset crashes

InactiveCN108248533AEnough supportImprove power transmissionUnderstructuresSuperstructure subunitsEnergy absorptionEngineering

The invention relates to an engine room force transfer structure dealing with automobile small offset crashes. The structure comprises a front anti-collision beam assembly, an engine room longitudinalbeam assembly and a force transfer component which is positioned and connected to the engine room longitudinal beam assembly and corresponds to the front anti-collision beam assembly; the front anti-collision beam assembly comprises an anti-collision beam and an energy absorption box; the structure is characterized in that the force transfer component is formed by connecting a stress component, asupporting component and a main force transfer component, and the whole structure is in a triangular shape. When small offset crashes of automobiles happen, the engine room longitudinal beam sufficiently participates in deformation and energy absorption, and the automobile body kinetic energy is lowered; a power assembly is forced to move in the reverse direction of the crash side, crash impact force on the crash side is timely and effectively transferred to the non-crash side through the power assembly, the longitudinal crash impact force of the automobile body is greatly reduced, the passenger compartment deformation amount is reduced, and life safety of passengers is ensured.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

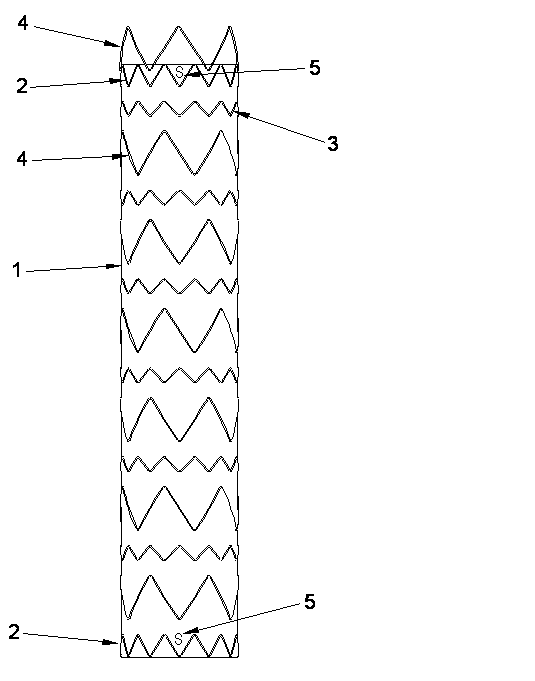

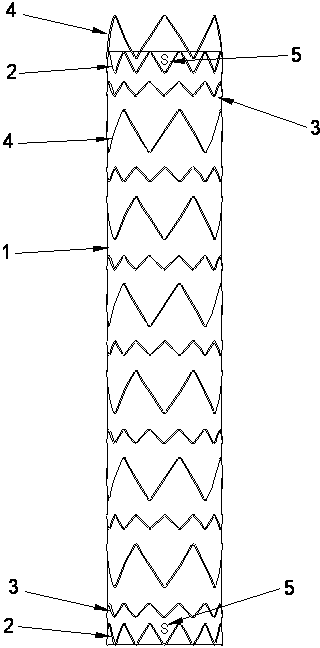

Thoracic aorta covered stent

ActiveCN102824237AImprove flexibilityNot easy to twistStentsBlood vesselsThoracic aortaCovered stent

The invention relates to a thoracic aorta covered stent, which is used for treating aneurysm of thoracic aorta and dissecting aortic aneurysm in minimally invasive surgeries. The thoracic aorta covered stent comprises a cover and a stent composed of a plurality of cylindrical single rings, wherein the cover is adhered to the stent to form a tubular cover; the plurality of cylindrical single rings are in wave patterns; a supporting frame is arranged at the near end of the stent; and each cylindrical single ring comprises a first type cylindrical single ring and a second type cylindrical single ring which are distributed at intervals on the tubular cover; the amount of the waveforms of the first type cylindrical single ring is not less than that of the second type cylindrical single ring; and the waveform of the first type cylindrical single ring is less than that of the second type cylindrical ring.

Owner:BEIJING PERCUTEK THERAPEUTICS CO LTD

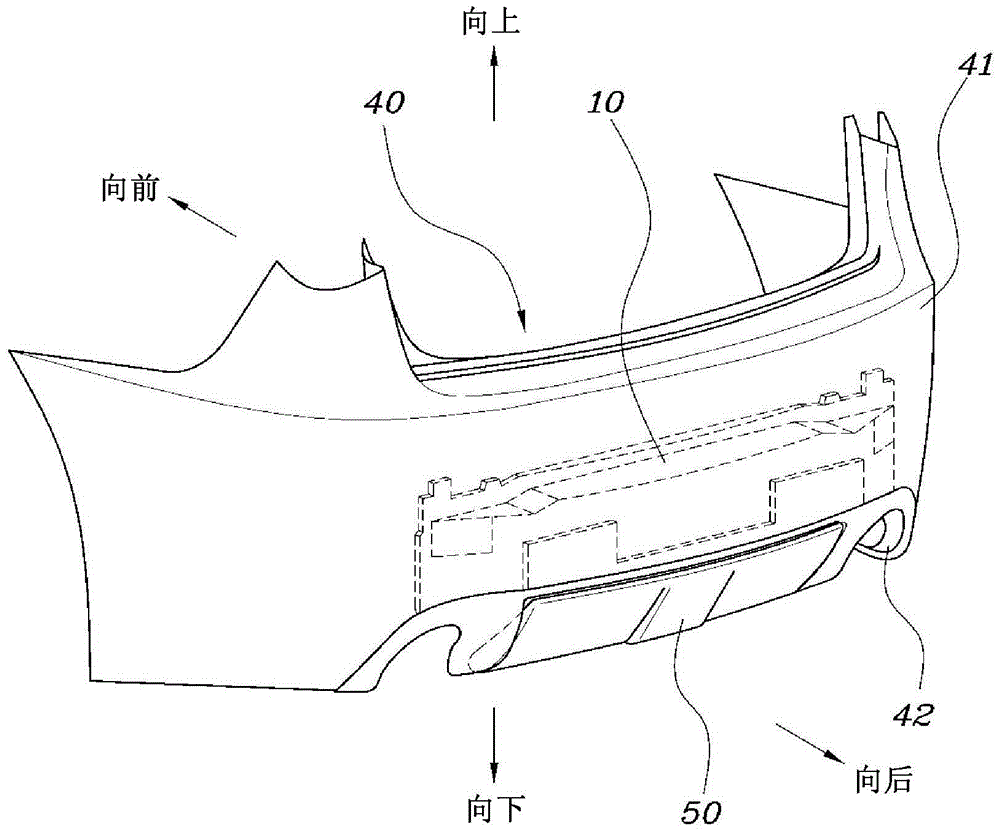

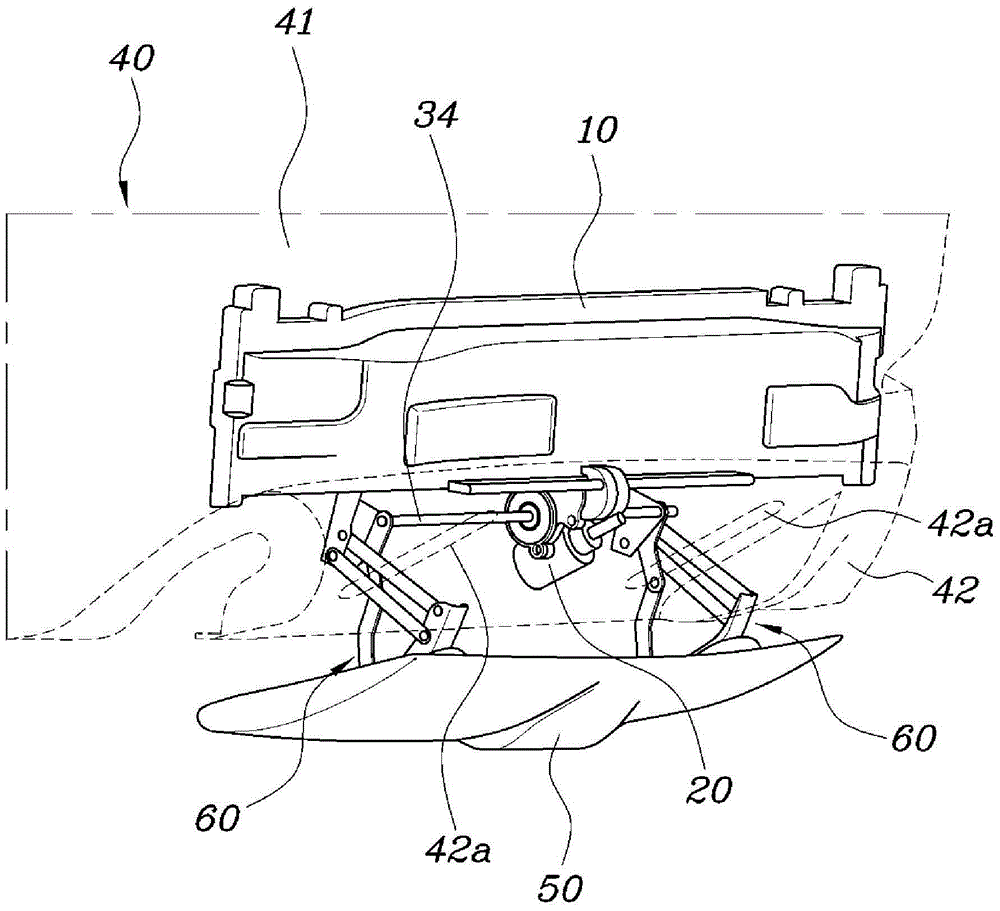

Variable spoiler device for rear bumper of vehicle

InactiveCN106515880AImprove aerodynamic performanceEnough supportVehicle body stabilisationAerodynamics improvementEngineeringMechanical engineering

A variable spoiler device may include a spoiler panel, which closely contacts a rear bumper in a retracted state, to perform a rear bumper function, and protrudes downwards from the rear bumper in a protruded state, to perform a spoiler function. Link mechanisms, which enable retraction and protrusion operations of the spoiler panel, continuously secure support force withstanding wind pressure in a protruded state of the spoiler panel.

Owner:HYUNDAI MOTOR CO LTD

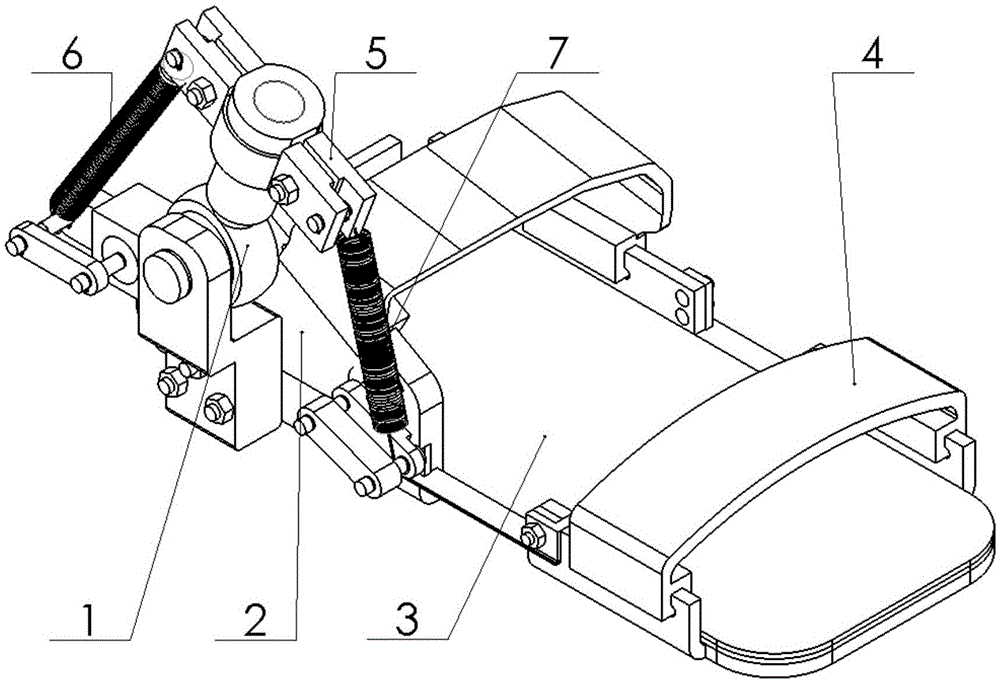

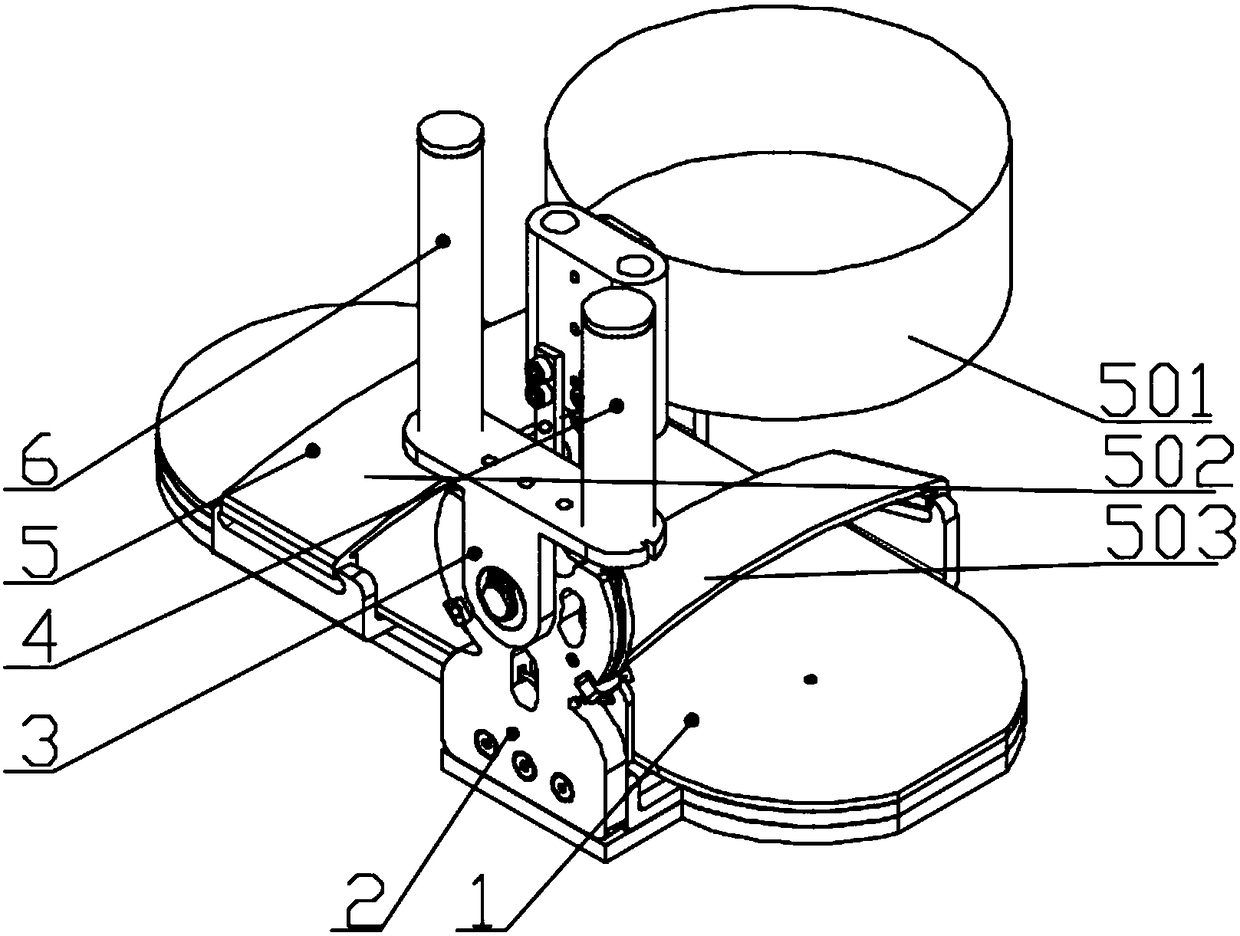

Multi-DOF (degree of freedom) energy-storing foot mechanism

InactiveCN108186287AReduce energy lossLarge transmission torqueChiropractic devicesEnergy lossExoskeleton

The invention discloses a multi-DOF (degree of freedom) energy-storing foot mechanism, comprising a sole unit, a side plate unit, an ankle unit and a binding unit. The ankle unit is releasably connected with the sole unit through the side plate unit; the binding unit is releasably connected with both the sole unit and the ankle unit; the ankle unit includes an ankle support that includes a supportterrace and a hanger lug that are integrated; the hanger lug is provided with a through hole; an ankle toe-flexure dorsal-flexure spindle and a bearing are mounted in the through hole so that the ankle support may be rotationally fitted to the side plate unit; the support is releasably connected with an energy-storing unit. The multi-DOF energy-storing foot mechanism has the advantages that energy loss can be effectively decreased, a multi-direction DOF is achieved, the structure is simple, wearing is facilitated, comfort is better for a wearer, parts are convenient to manufacture and mount,the multi-DOF energy-storing foot mechanism is highly transplantable and may be used with any limb-assistant exoskeleton, and the production cost may be greatly reduced since no drive and control system is provided.

Owner:SOUTHEAST UNIV

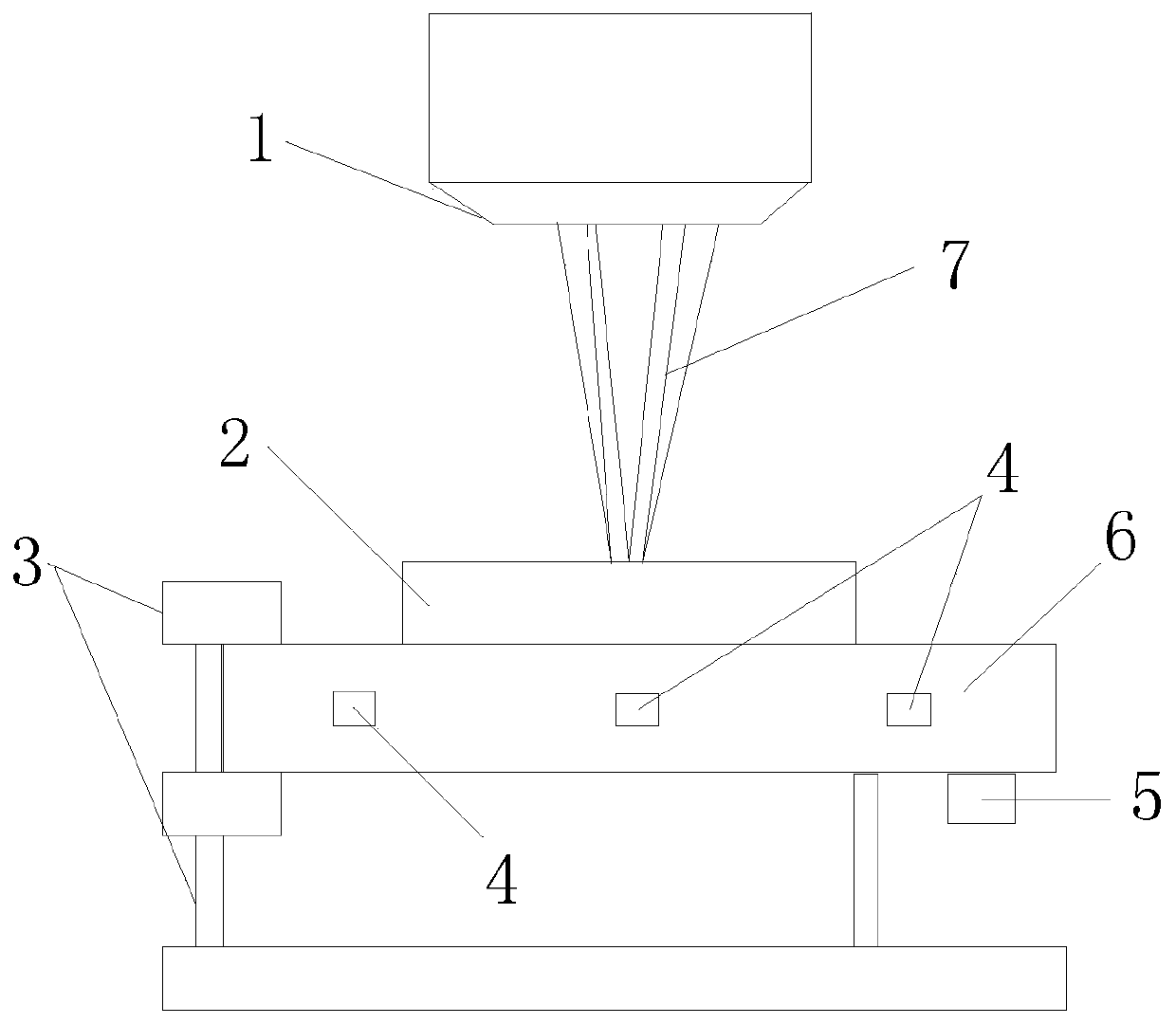

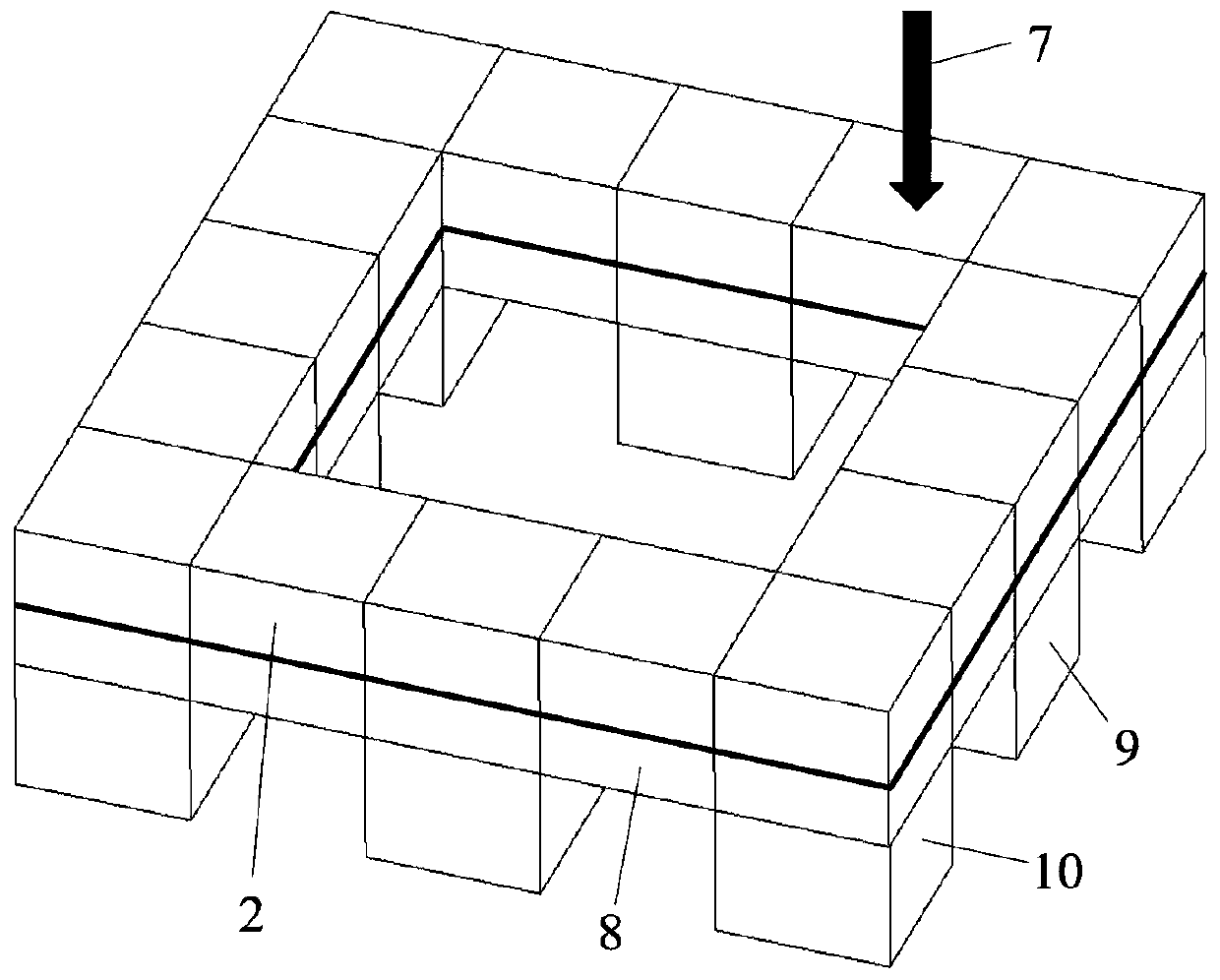

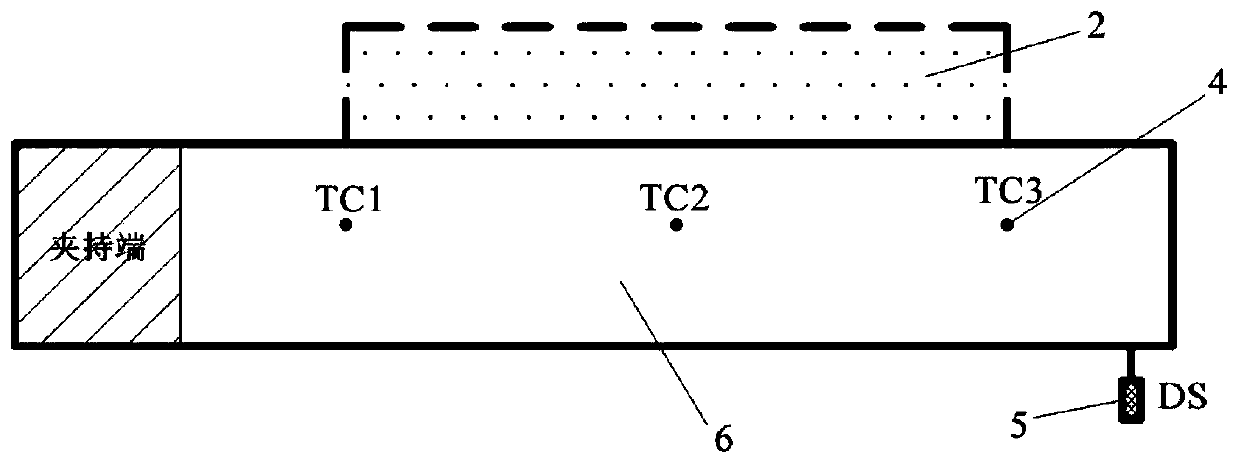

Method for reducing additive manufacturing residual stress and unsteady state by optimizing substrate

ActiveCN109746444AReduce mechanical constraintsReduce deliveryAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingMaximum temperature

The invention discloses a method for reducing additive manufacturing residual stress and the unsteady state by optimizing a substrate. In the method, the shape of the substrate is directly optimized,the substrate only keeps the shape of the contact face of a target part, it is guaranteed that enough supporting force can be given to an additive manufacturing part on the aspect of thickness, and mechanical constraints of the substrate to a forming part in the part manufacturing process are reduced; and the substrate is designed to be of a hollowed structure, the maximum temperature gradient inthe additive manufacturing process is adjusted and controlled, and finally the residual stress of the additive manufacturing part and the unsteady state stage in the forming process are reduced. The method can be used for metal additive manufacturing processes, including laser stereoscopic forming, selective laser melting, electronic beam fuse wire deposition and the like, with various high-energybeams (lasers, electronic beams, plasma beams, arcs) as hot sources.

Owner:RES & DEV INST OF NORTHWESTERN POLYTECHNICAL UNIV IN SHENZHEN +1

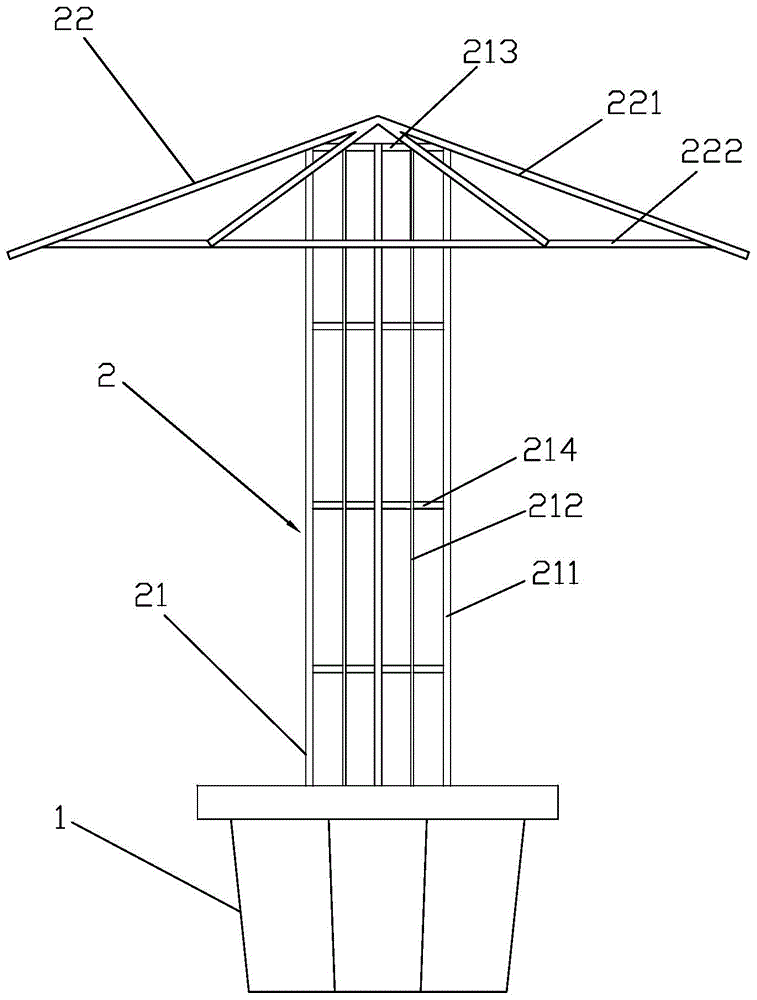

Cultivation method for bougainvil-lea-spp rapid forming

InactiveCN105981545AImprove the landscape effectGood drainage and fertilizer retentionPlant supportsNitrogen richOrganic fertilizer

The invention discloses a cultivation method for bougainvil-lea-spp rapid forming. The cultivation method includes the following steps that a flowerpot with a specific flower-shelf structure is provided; a bougainvil-lea-spp plant is selected; a culture medium is filled in the flowerpot bottom, and bougainvil lea spp is transplanted; maintaining is carried out for half a month to one month, shading, plant leaf surface spraying and medium completely pouring are carried out within the maintaining period; after the maintaining period is completed, full exposure is given, nitrogen-rich organic fertilizer is applied, and sucker-growth branches of the bougainvil lea spp are initiated; the sucker-growth branches are guided to climb a flower shelf by curling, binding, pinching and bending, and the clambering branches are evenly bound on the flower shelf and closely attached to the flower shelf by curling and binding till complete forming is carried out. By means of the cultivation method, the bougainvil lea spp can be rapidly formed and subjected to scenery forming in half a year to one year, and after the bougainvil lea spp is formed, the flower and the shape are played, the landscape effect is good, and the cultivation method is a brand-new innovative mode of an application of the bougainvil lea spp.

Owner:周群

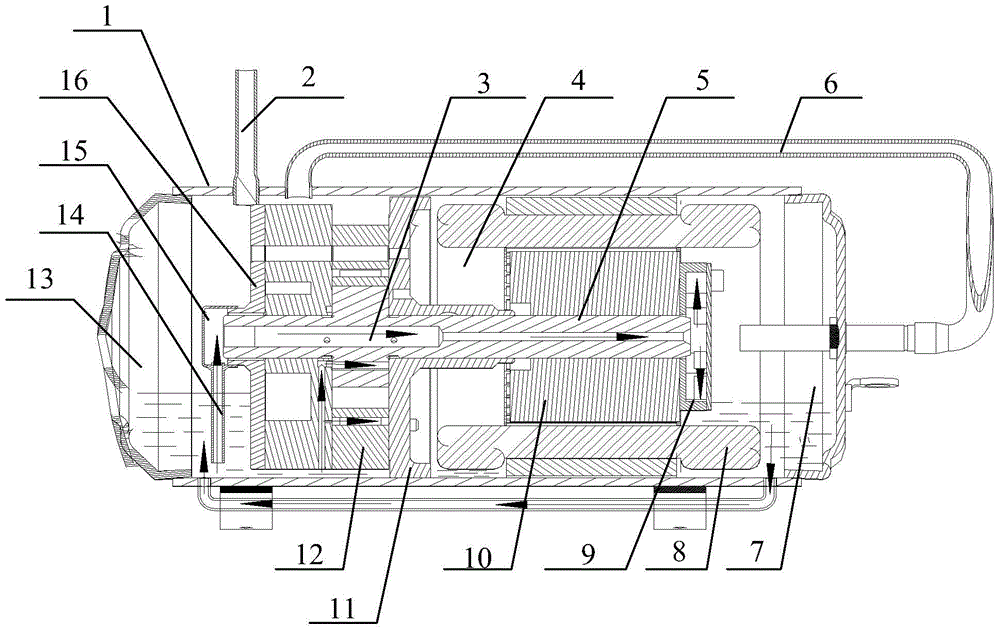

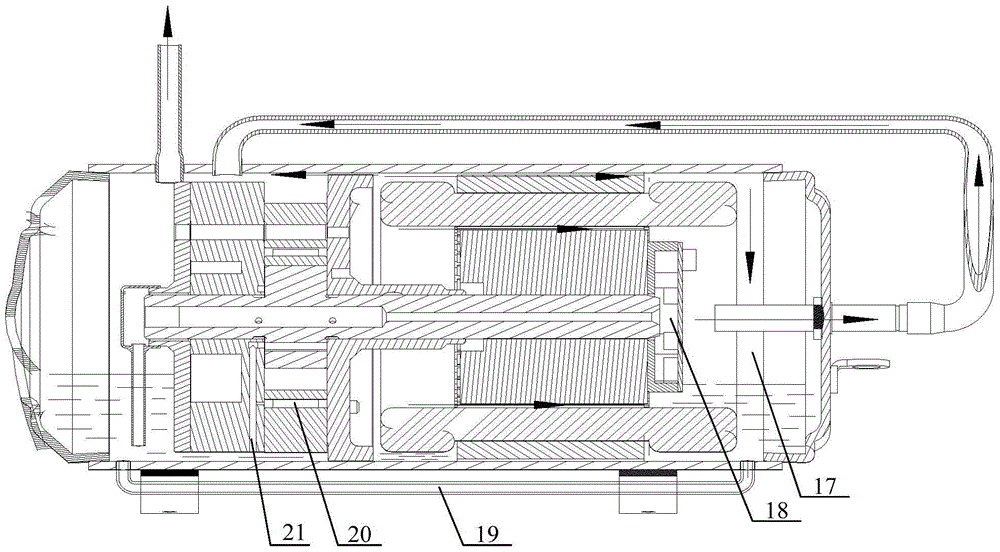

Horizontal compressor and temperature adjusting device

ActiveCN106481555AStretch out smoothlyEnough supportRotary piston pumpsRotary piston liquid enginesBack pressureOil storage

The invention relates to a horizontal compressor which comprises a shell, a lower flange, an air cylinder, an upper flange and a motor. The lower flange, the air cylinder, the upper flange and the motor are sequentially arranged in the shell. An oil storage cavity is formed by the lower flange and the shell. A rotor is rotationally arranged in the air cylinder through a main shaft. The horizontal compressor further comprises a center oil hole penetrating the main shaft, a radial hole formed in the main shaft and communicating with the center oil hole, an oiling pipe fixedly connected to the end, located in the oil storage cavity, of the main shaft and communicating with the center oil hole, a lower flange back pressure groove formed in the lower flange and communicating with a sliding piece installation groove of the rotor, a groove for communicating the lower flange back pressure groove and the radial hole of the main shaft, an exhaust cavity communicating with an exhaust hole of the air cylinder and the center oil hole of the main shaft, and a fan installed at the other end of the fan, wherein the bottom end of the oiling pipe is close to the bottom of the oil storage cavity. According to the horizontal compressor, smooth stretching-out of a sliding piece during starting of the compressor and attachment between the sliding piece and the air cylinder during normal running of the compressor are effectively ensured. The invention further discloses a temperature adjusting device comprising the horizontal compressor.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI +1

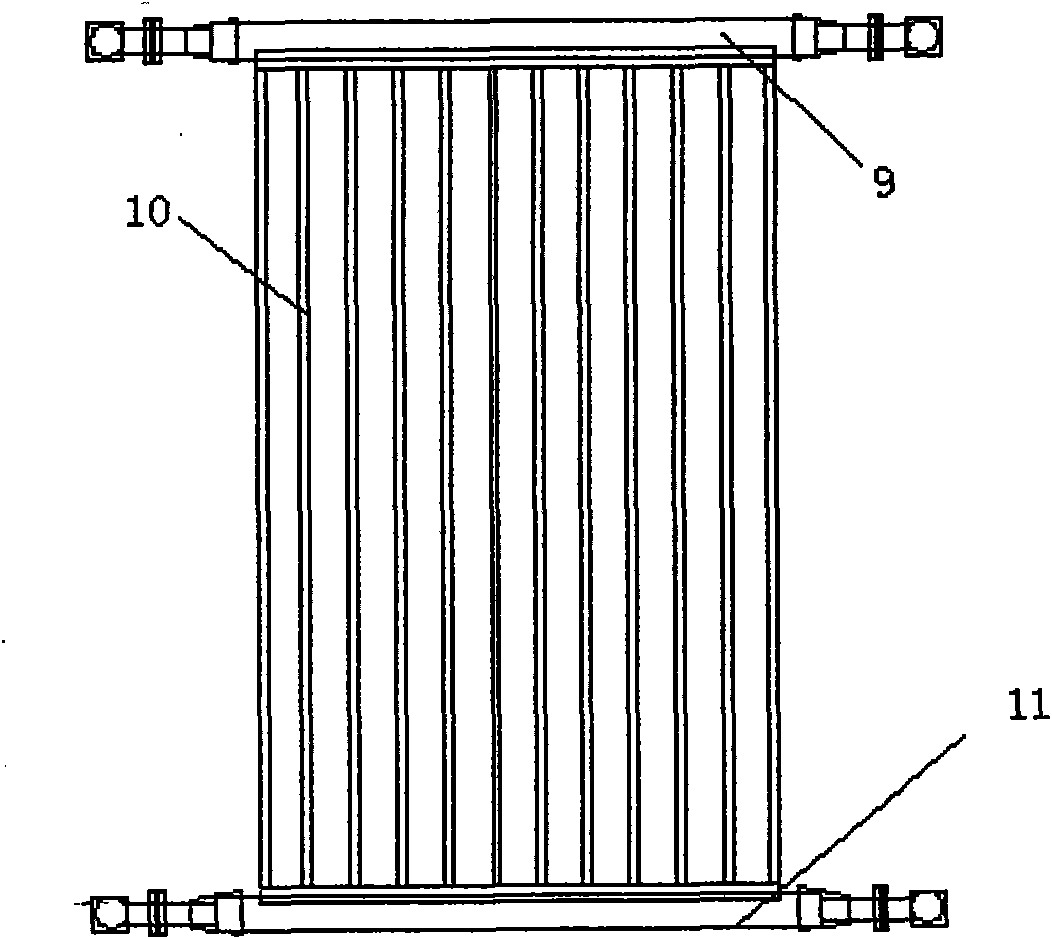

Air separation apparatus and refrigerating freezing apparatus

ActiveCN106582216AHigh purityEasy to manufactureLighting and heating apparatusDomestic refrigeratorsAir separationAirflow

The invention provides an air separation apparatus and a refrigerating freezing apparatus. The air separation apparatus comprises: a base frame in which an enriched gas collection cavity is defined and which has at least one base support surface communicated with the enriched gas collection cavity; at least one stacking frame each having a stacking support surface which forms a channel, wherein each stacking frame is releasably stacked to the outer side of the base support frame of the base frame; and a plurality of air separation membranes that are spread to the base support surface and the stacking support surfaces respectively, wherein each air separation membrane is configured such that more specific gas in air flow in the peripheral space of the air separation apparatus permeates the air separation membranes into the enriched gas collection cavity than other gases therein. By assembling the base frame and the stacking frames, more layers of air separation membranes are permeated by the outside air before entering the enriched gas collection cavity, and the purity of separated air is enhanced.

Owner:HAIER SMART HOME CO LTD

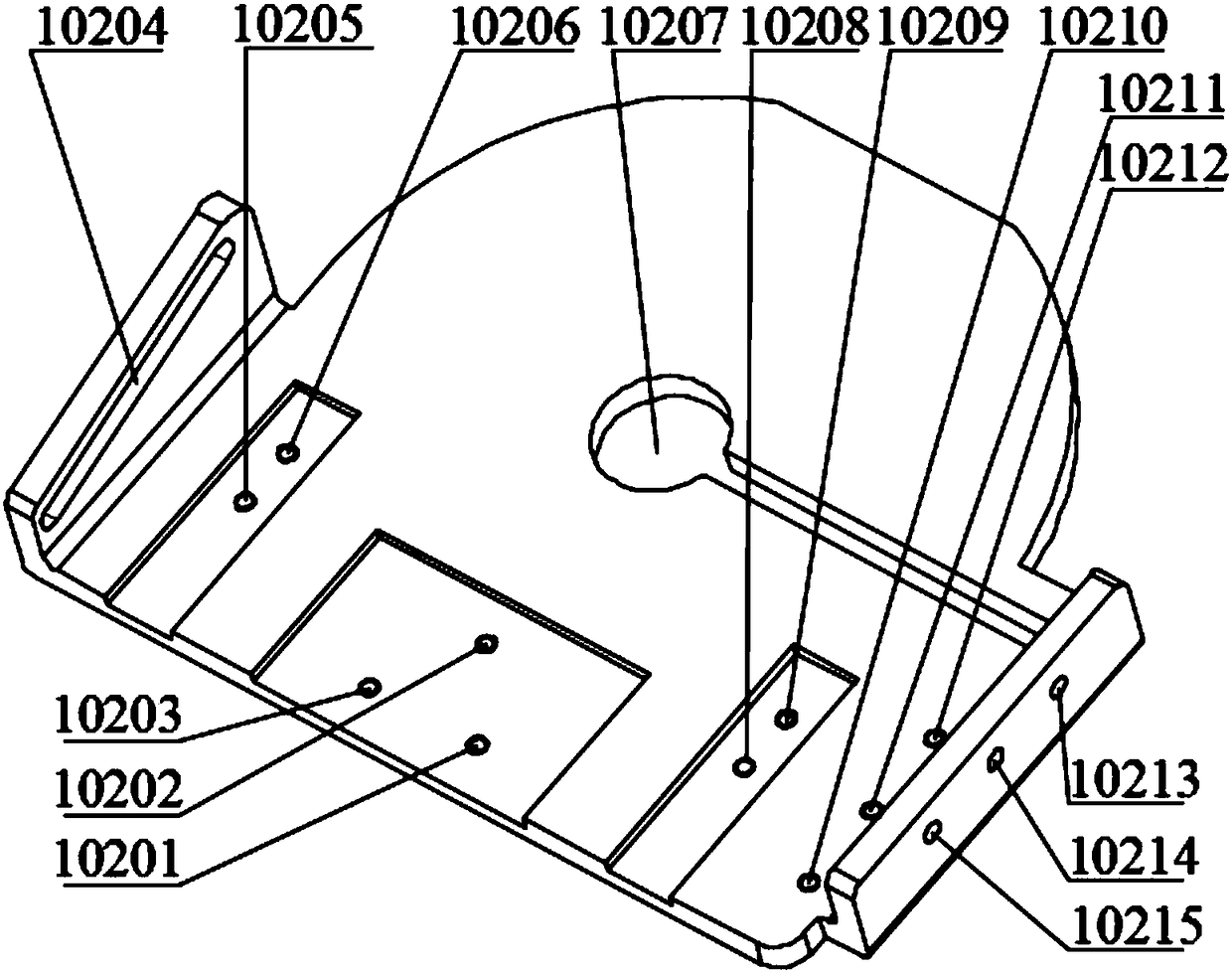

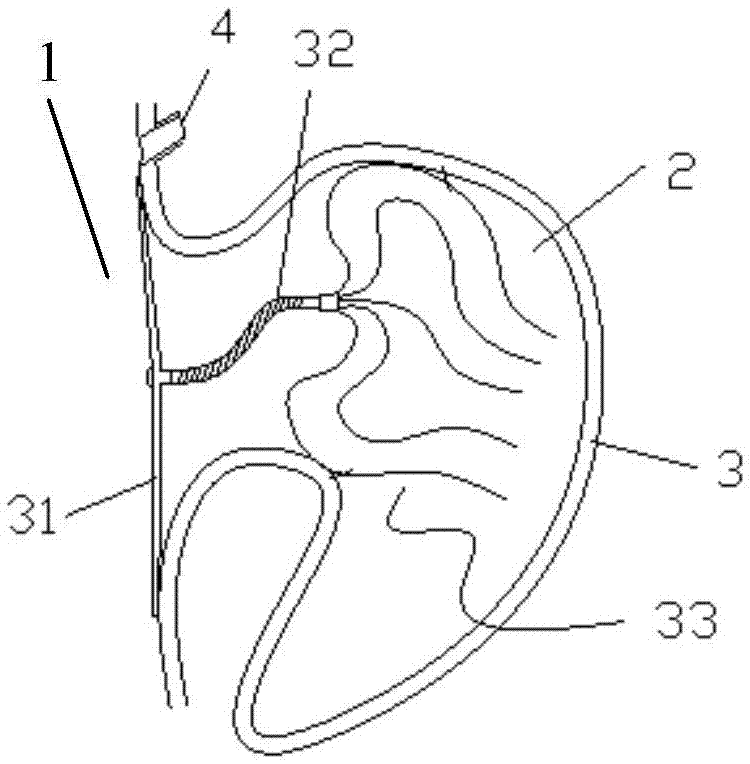

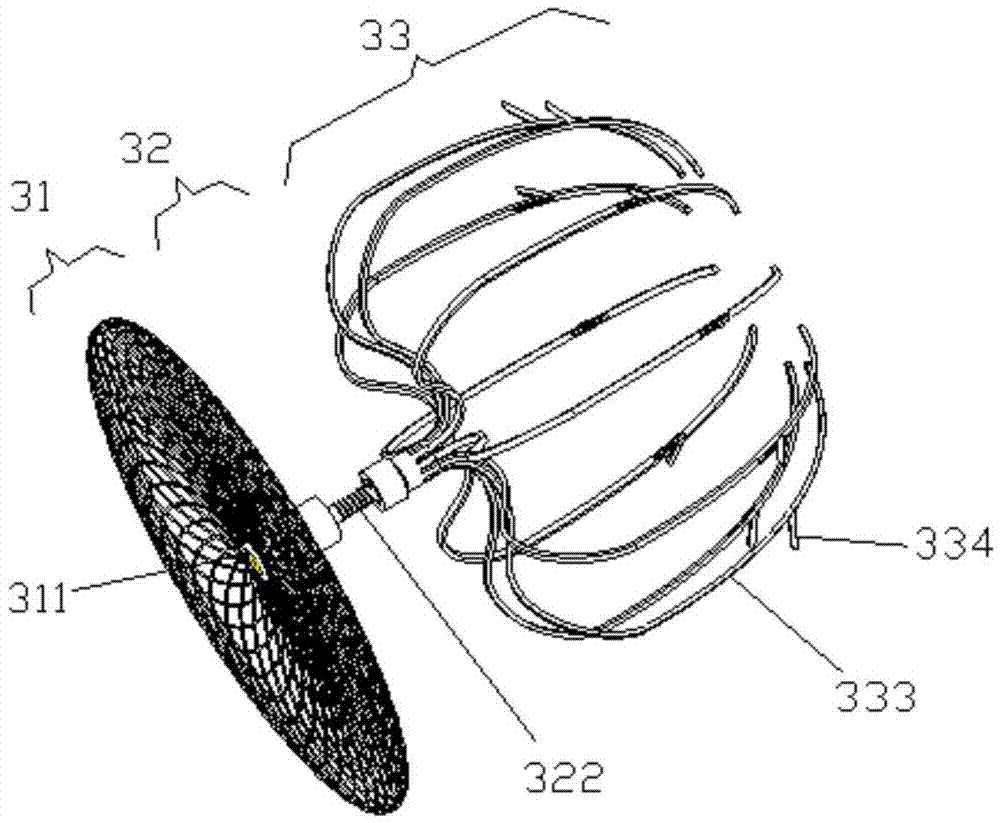

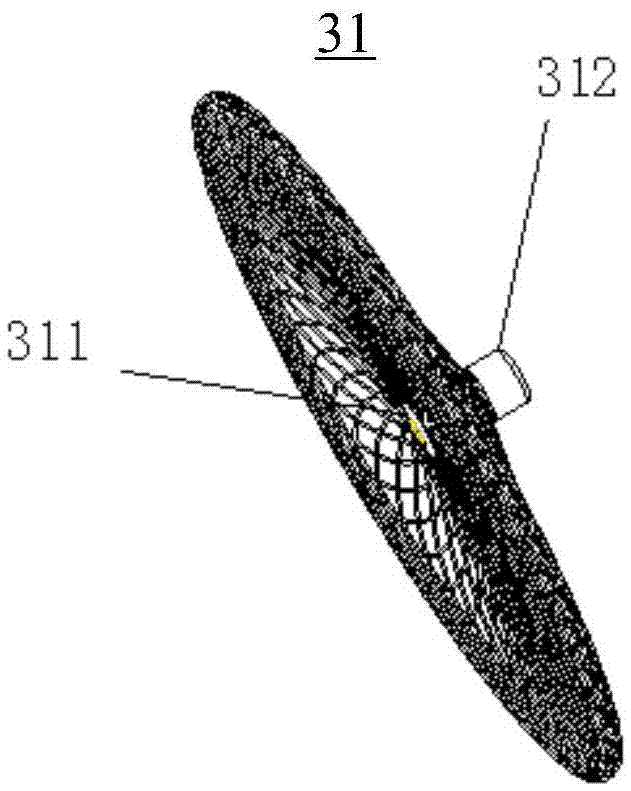

Left auricle occluder

The invention relates to a left auricle occluder. The left auricle occluder comprises a sealing disc and a fixing rack located on one side of a far end of the sealing disc. The left auricle occluder further comprises a connecting part connecting the sealing disc with the fixing rack. The fixing rack comprises a framework structure. The framework structure comprises a near-end side surface and a support peripheral surface which is connected to the near-end side surface and extends towards the far end. The connecting part is connected with the near-end side surface. The left auricle occluder has the following beneficial effects: the fixing rack is configured to be in the structure with one enclosed end and an opened end composed of at least two support rods; therefore, enough support force for the fixing rack is ensured while each support rod is independent of each other; support rods can maintain good pasting and covering performance of a cavity wall of a left auricle; stability and fixation performance of the fixing rack in the left auricle are enhanced; and the fixing rack can be fixed in the left auricle without needing to set an anchor thorn so that damage to the cavity wall of the left auricle is avoided.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

Dynamic magnetic health mattress

InactiveCN107157189AHelp microcirculationPromote sleep health regimenStuffed mattressesSpring mattressesEngineeringMotor shaft

The present invention discloses a dynamic magnetic health mattress, which comprises a frame bridge, wherein the surface layer of the frame bridge is provided with a latex pad, the frame bridge interior close to the upper surface is provided with a plurality of circular cylinder holes perpendicular to the length direction of the frame bridge and at least a power installation hole, a magnet connection rod is arranged in the circular cylinder hole, a cylindrical magnet penetrates through the rod body of the magnet connection rod, a PVC plastic pipe is arranged in the power installation hole, a direct current motor is fixed on one end in the PVC plastic pipe and is connected to a controller, the motor shaft of the direct current motor is connected to a magnetic bar, the upper surface of the frame bridge is provided with a magnetic force penetration hole, the upper surface of the latex pad is provided with spherical and projecting massage points distributed in an array manner, and the frame bridge, the latex pad and the bottom plate are integrally wrapped with a mattress sleeve. According to the present invention, by controlling the direct current motor to rotate, the magnet on the magnet connection rod is driven by the magnetic bar to perform rotation movement, such that the dynamic magnetic field is generated on the surface of the mattress so as to help the microcirculation of the human body and promote the sleep health preserving.

Owner:李爱平

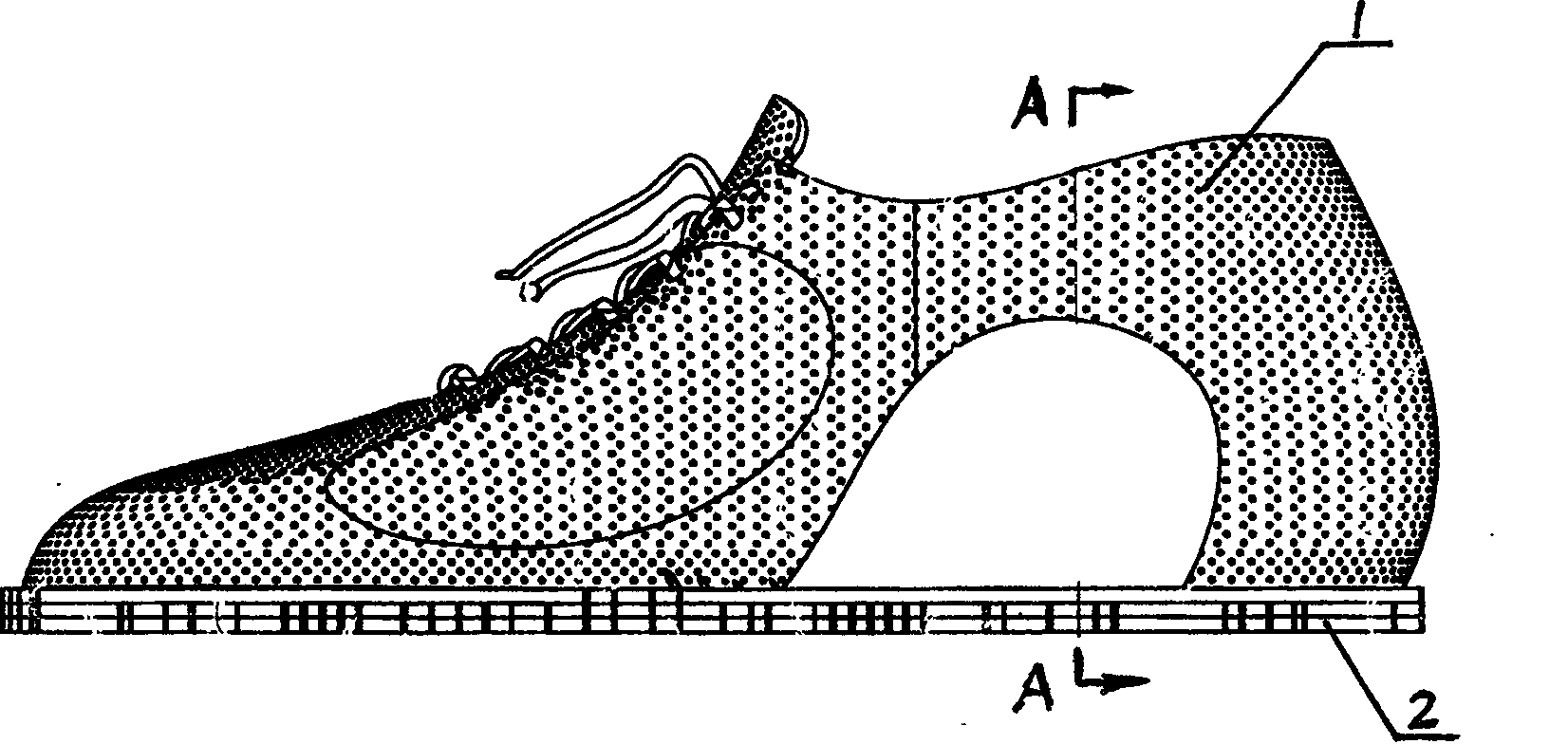

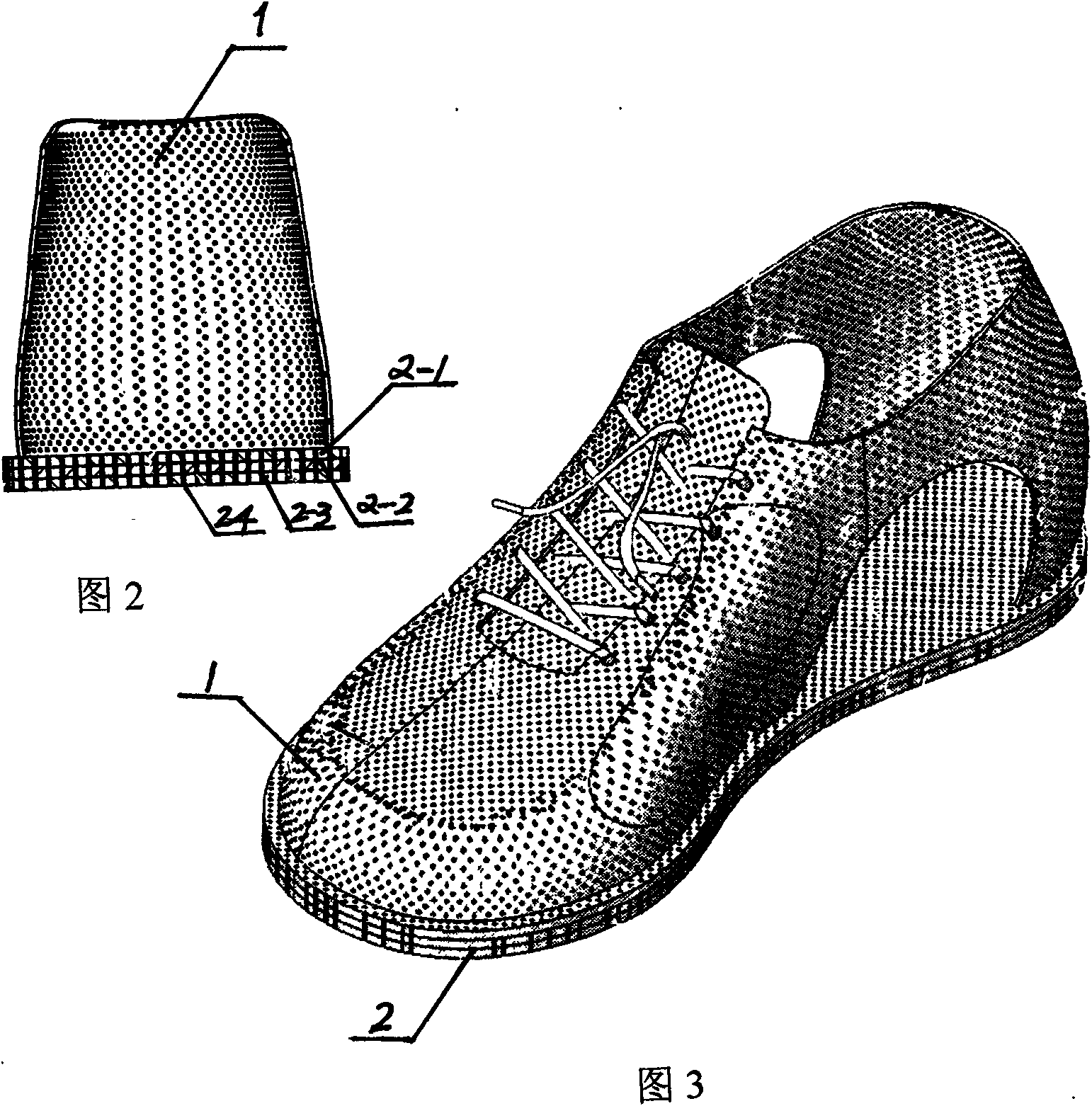

Treadmill shoe

The invention discloses a treadmill shoe, which is composed of a sole and an upper, wherein the sole is provided with a full shoe heel or a front-half shoe heel, the sole is formed by bonding an outsole, an insole and an upper base in a successive arrangement mode, the outsole arranged at the lower part of the sole is prepared by fiber material reinforced rubber, and the underside of the outsole is provided with abbatre; the insole is prepared by rubber foamed plastics; the upper base is prepared by fluffy and soft fiber fabrics or leathers; and a complex composed of the insole and the outsole is evenly provided with a group of vertically arranged breathers which run through the complex. When a user wearing the shoes runs on the treadmill, the shoes ensure the enough bearing for the human body, and can preferably buffer and absorb the impact force generated by running. In addition, sweat generated in the running process can be discharged timely, the shoes can ensure feet to be dry and comfortable and have the obvious effects of safety, comfortableness and enjoyment.

Owner:吴小凤

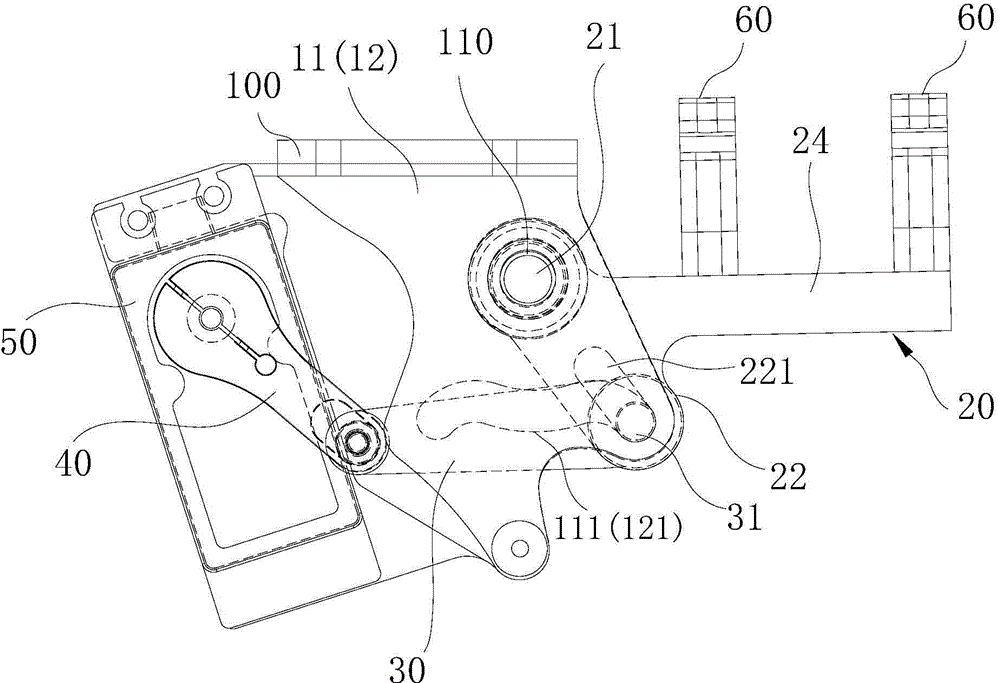

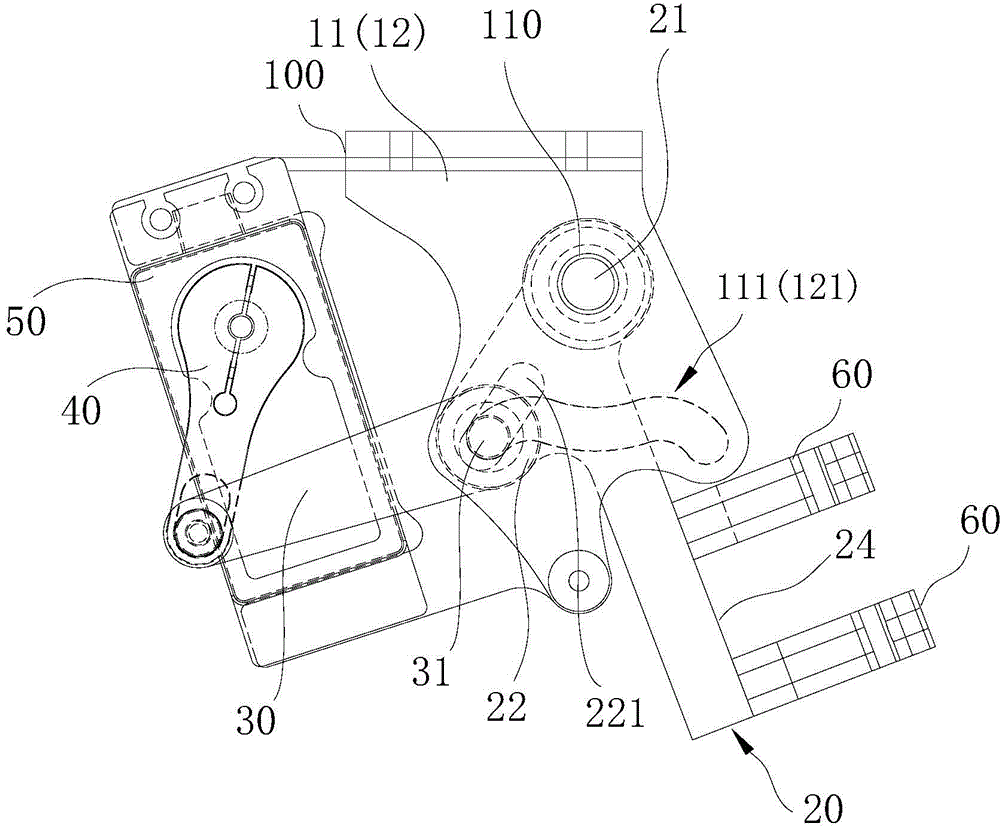

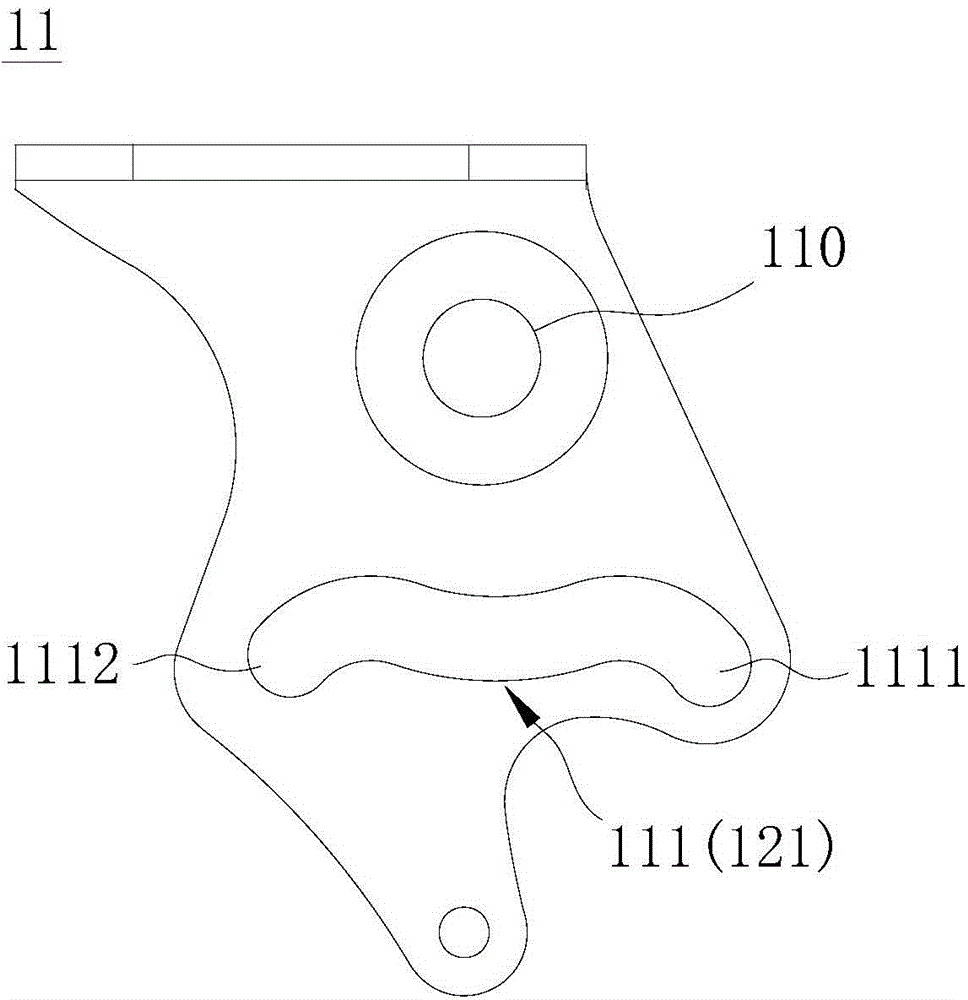

Aircraft undercarriage driving device, aircraft undercarriage and aircraft

ActiveCN104787308AEnsure normal and safe landingPrecise positioningWeight reductionUndercarriagesFlight vehicleEngineering

The invention discloses an aircraft undercarriage driving device, an aircraft undercarriage and an aircraft. The aircraft undercarriage driving device comprises a first support arm plate, a second support arm plate, an undercarriage seat, a driven arm and an actuating arm, wherein the first support arm plate and the second support arm plate are fixedly connected below a rack, a first chute is formed in the first support arm plate, and a second chute is formed in the second support arm plate; the undercarriage seat can be rotationally arranged between the first support arm plate and the second support arm plate through a rotating shaft, and a hinged part is bulged on the undercarriage seat; one end of the driven arm is hinged to the hinged part through a hinged shaft, and two ends of the hinged shaft are glidingly clamped to the first chute and the second chute respectively; one end of the actuating arm is hinged to the other end of the driven arm, and the other end of the actuating arm is connected with an actuator. The aircraft undercarriage can be stably and accurately positioned in retracting and deploying positions.

Owner:ZEROTECH (BEIJING) INTELLIGENCE TECH CO LTD

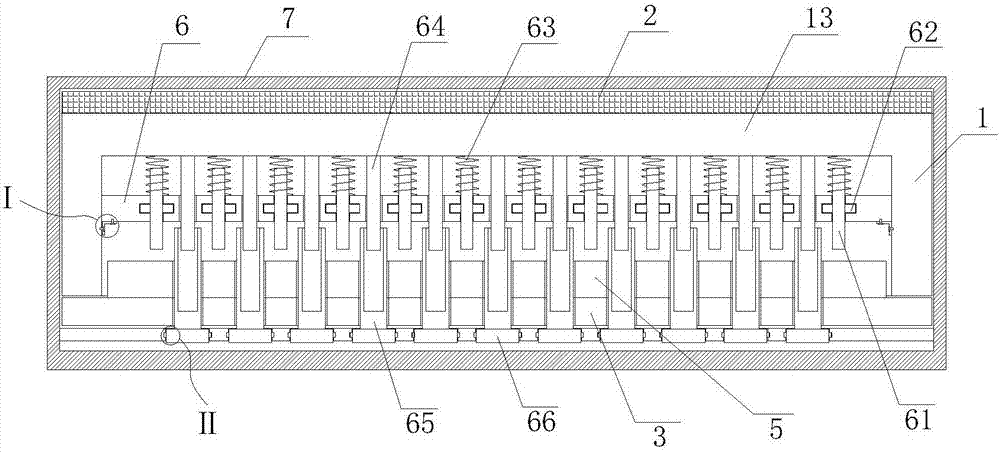

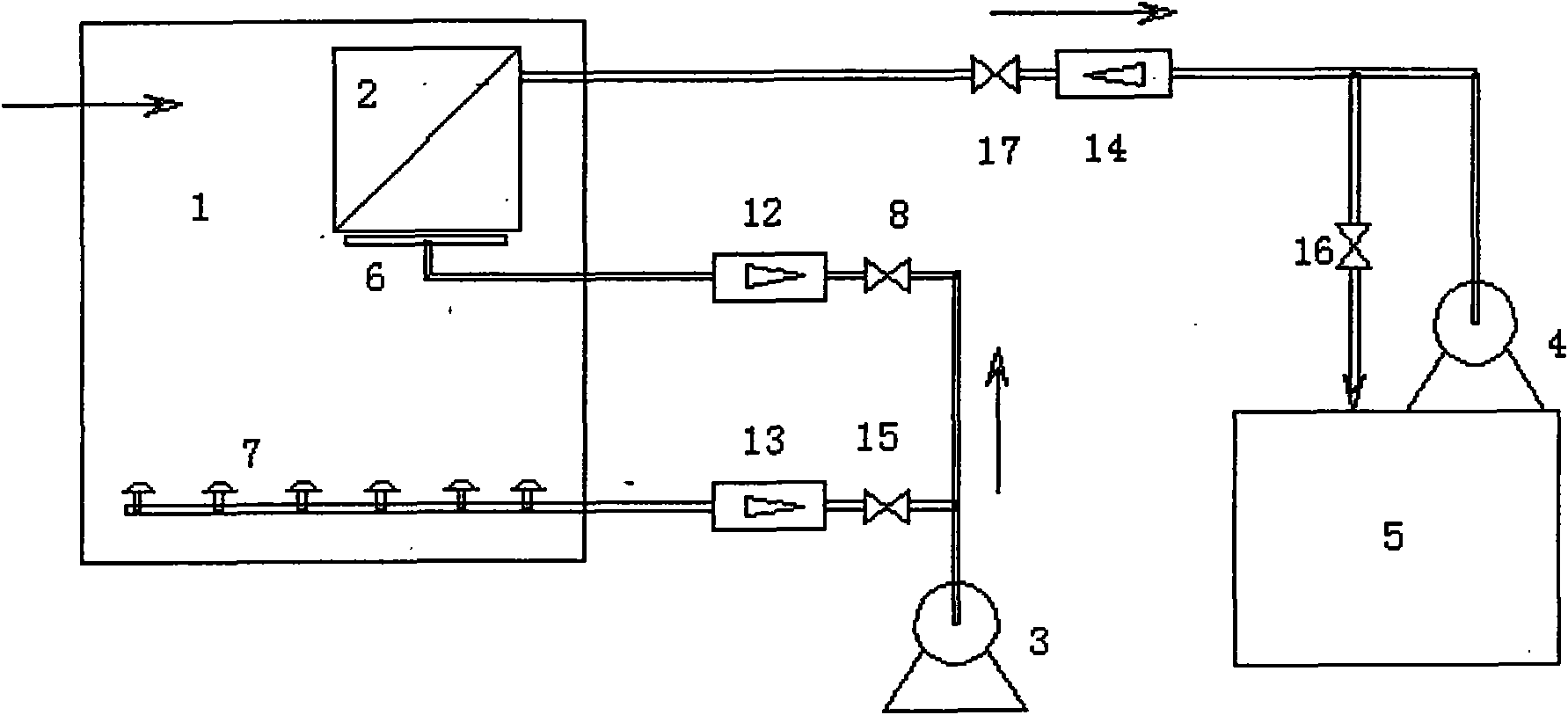

Low energy-consumption integrative membrane bioreactor

InactiveCN101648763AReduce energy consumptionIncrease profitWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentFiltrationWater quality

The invention relates to a low energy-consumption integrative membrane bioreactor which leads a biological reaction tank and a membrane bio-filter to be integrated; sewage fully reacts with sludge inan integrative biological reaction tank (1) in the reaction tank after entering in the integrative biological reaction tank (1) under the aeration of a micropore aerator pipe (7), and then clean waterflows out to a clean water tank (5) from a membrane component (2) through the filtration of the membrane component (2). In the invention, a micropore aerator device and a perforation aerator device are effectively combined, so as to effectively utilize oxygen and improve the treatment effect of the reaction tank when treating the same water quality and water quantity compared with a way using a single aeration way; in addition, the needed energy consumption for processing sewage is the lowest when the water quality reaches to standard.

Owner:JIANGSU HUANFA ENVIRONMENTAL ENG

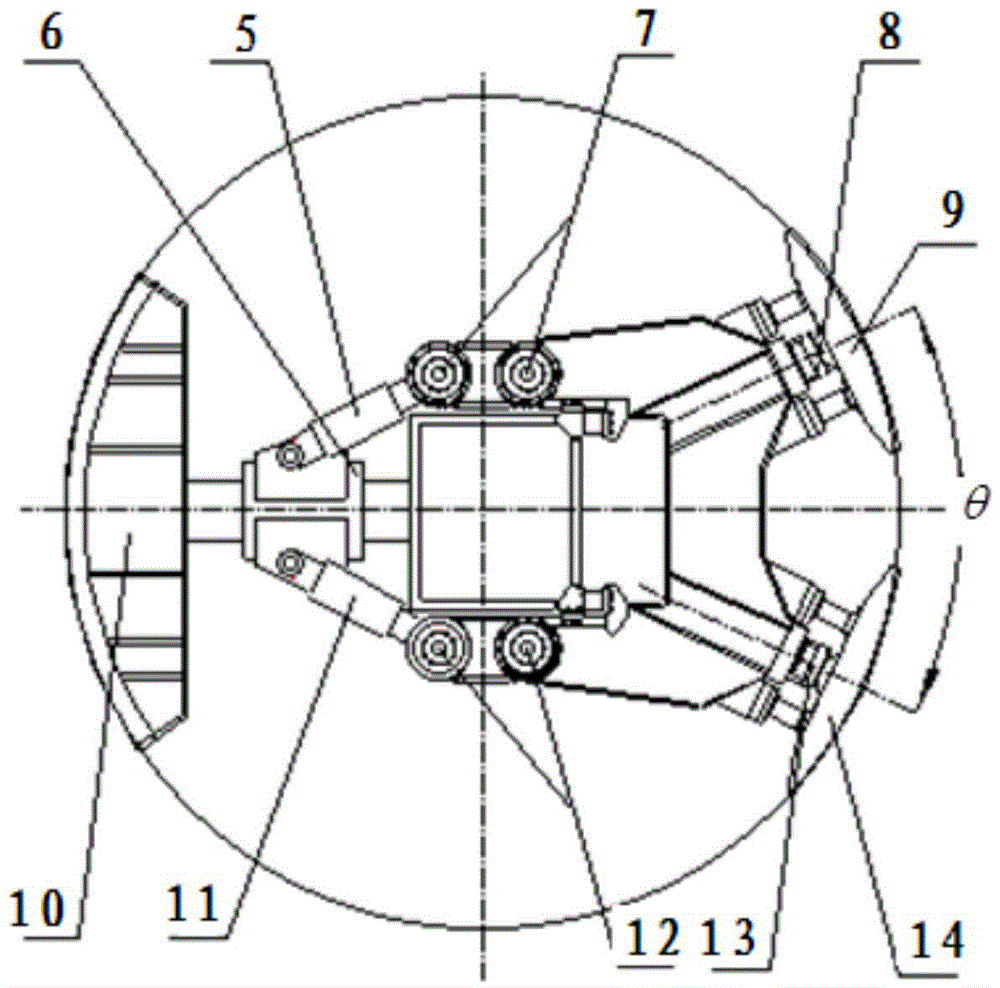

Method for designing Y-shaped support shoe structures of full-face rock tunnel boring machines

The invention belongs to the field of boring technologies for full-face rock tunnel boring machines, relates to a tunnel rock boring machine, and particularly relates to a method for designing Y-shaped support shoe structures of full-face rock tunnel boring machines. The method includes analyzing instability geological characteristics; primarily selecting included angles between first oblique support shoes and second oblique support shoes of right half portions of Y-shaped support shoes according to the geological characteristics; analyzing the stability of the right half portions by the aid of software ANSYS, judging whether the right half portions are stable or not and adjusting the right half portions until the right half portions are stable if the right half portions are not stable; determining left half portion structures and forming the Y-shaped support shoe structures. The method has the advantages that stable support effects can be realized under instable geological conditions, the probability of rock burst and collapse of surrounding rock at support shoe positions in rock burst regions and surrounding rock broken strata can be effectively reduced, and the adaptability and the boring efficiency of equipment of the TBM (tunnel boring machines) in the rock burst regions and the surrounding rock broke strata can be obviously improved.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com