Absorbable magnesium alloy repairing system used for oral cavity guide bone/tissue regeneration

A repair system and tissue regeneration technology, applied in tissue regeneration, medical science, joint implants, etc., can solve the problems of fast degradation and poor biocompatibility of elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

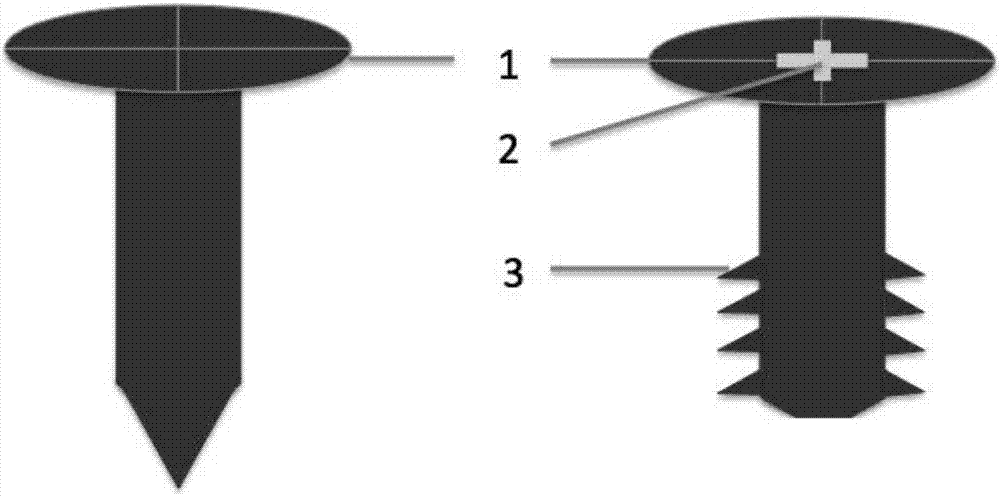

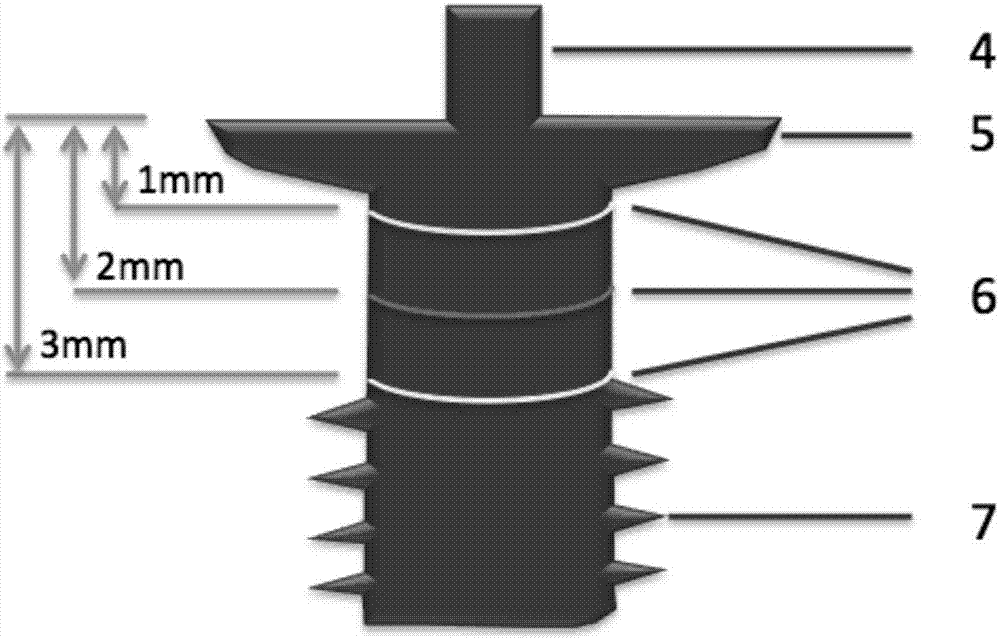

[0042] Figure 5 Schematic diagram of bone augmentation during implantation.

[0043] Figure 5 a) When the width of the bone is not enough, the implant placement causes part of the implant to be exposed or the residual bone wall is too thin, which is easy to be absorbed, cover the surface of the exposed implant or the surface of the thin residual bone wall with absorbable magnesium alloy barrier film, and in the barrier film gingival The side or mesio-distal are fixed with retaining screws, and the coronal side of the barrier film is placed on the edge of the implant, or it completely covers the surface of the implant and falls on the lingual edge, which can be fixed with cover screws, between the barrier film and the implant filled with bone material.

[0044] Figure 5 b and Figure 5 c is that when the bone width and bone height are insufficient, the implant cannot be fully embedded in the bone, resulting in the exposure of the upper end of the implant. Pre-formed or n...

Embodiment 2

[0046] Image 6 and Figure 7 Respectively, the schematic diagram of the application of the extraction socket site preservation after tooth extraction, and the schematic diagram of horizontal or vertical bone augmentation repair.

[0047] Its usage is the same as Example 1

Embodiment 3

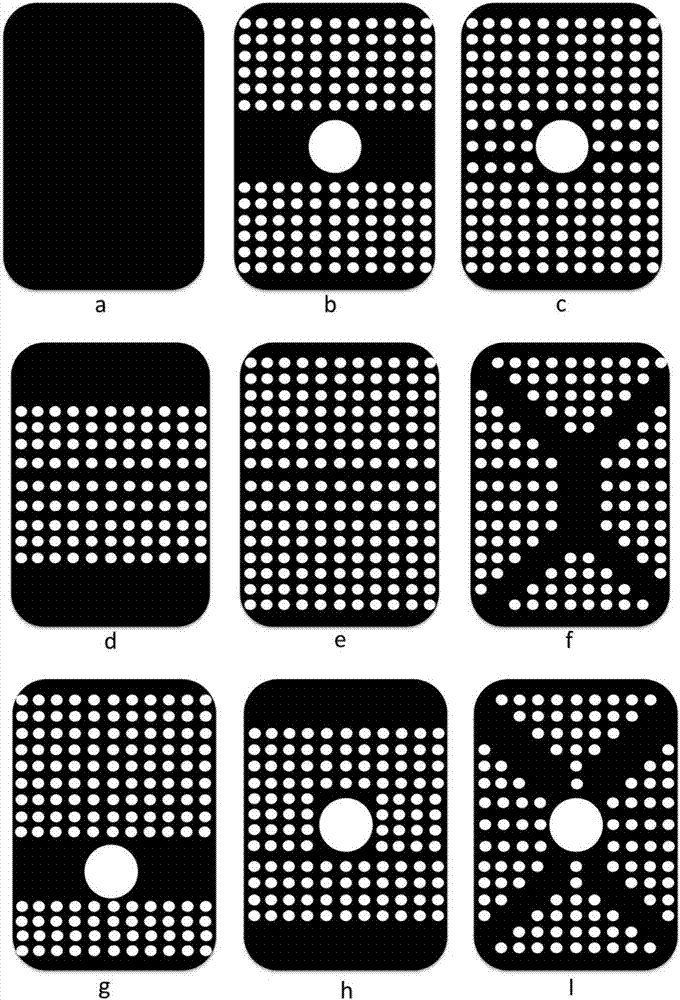

[0049] Figure 8 It is a schematic diagram of periodontal guided tissue regeneration repair;

[0050] Figure 8 a: After the basic treatment of the periodontal pocket, the periodontal pocket is filled or not filled with bone graft material, and the opening of the periodontal pocket is covered with a barrier film, which can be fixed with or without fixation, and tightly sutured. Figure 8 b is to trim the barrier film to an appropriate size according to the size of the periodontal pocket, and pack the barrier film in the periodontal pocket, which can be retained by the elasticity of the barrier film. In the process of degradation of magnesium alloy, an alkaline environment is generated, which is beneficial to the control of periodontal microorganisms, promotes the recovery of periodontal infection, and promotes bone regeneration, which makes up for the gap that the current GTR membrane materials do not have bacteriostatic and osteogenic effects. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com