Low energy-consumption integrative membrane bioreactor

A technology of membrane bioreactor and bioreaction tank, which is applied in biological water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc. It can solve the problem that membrane modules cannot be effectively cleaned and oxygen cannot be contained in water. Effective distribution, reducing sewage filtration efficiency and other issues, to achieve the effect of reducing aeration energy consumption, improving oxygen utilization rate, and improving treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

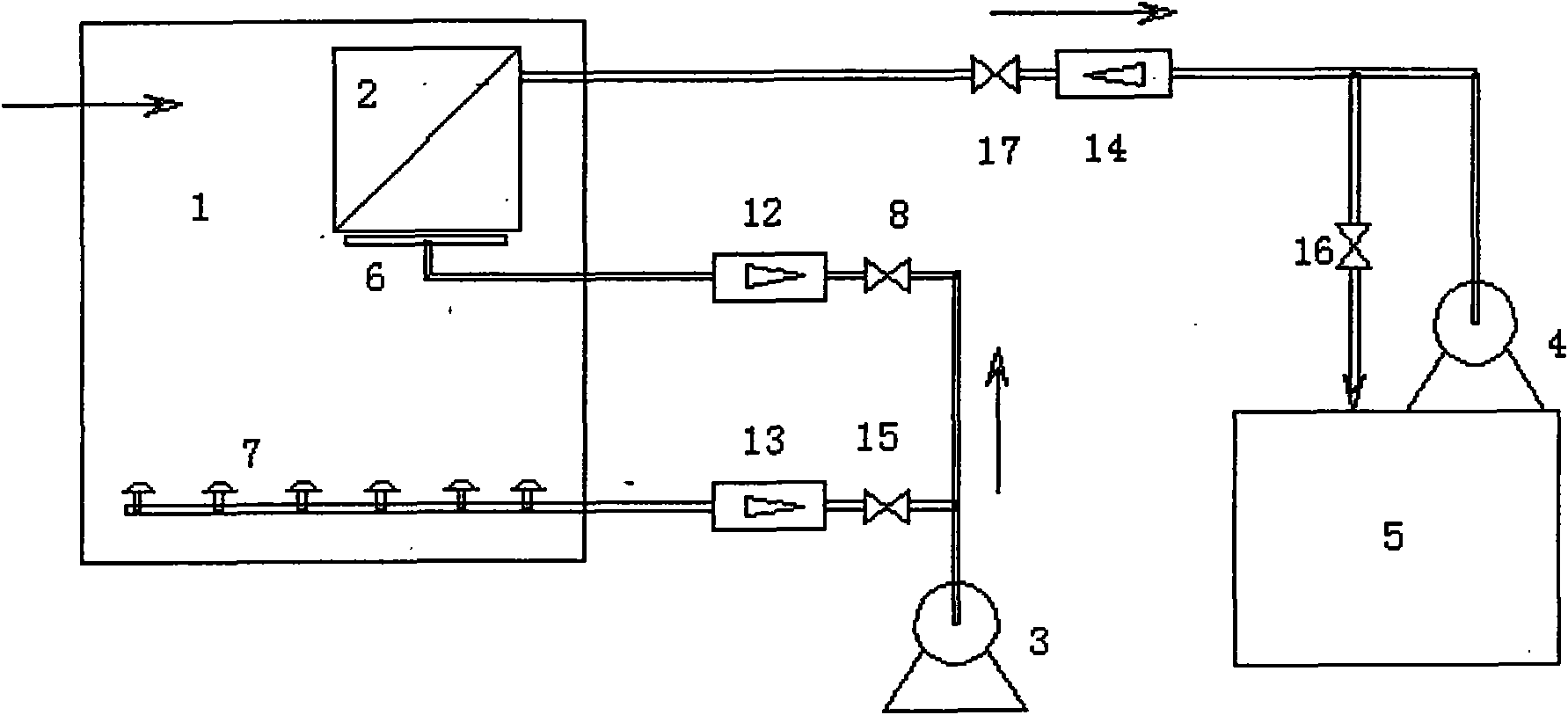

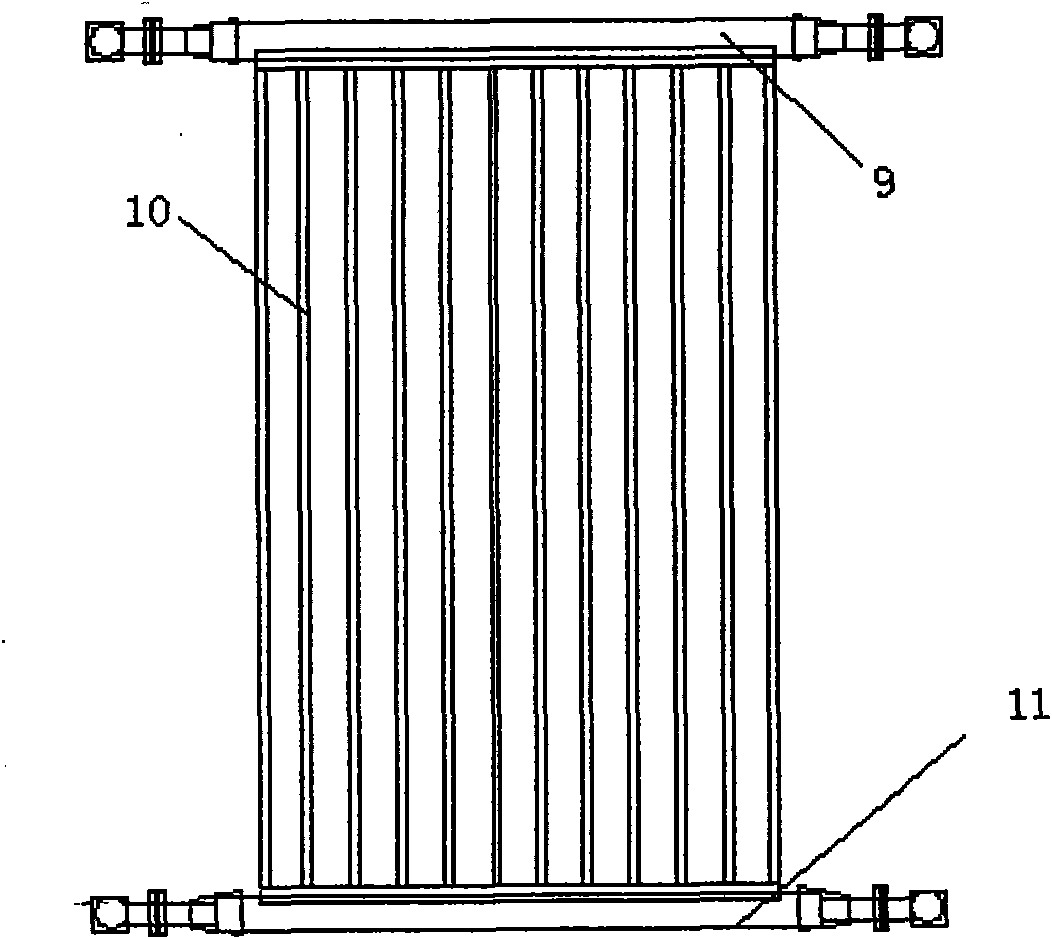

Embodiment 1

[0026] A low-energy integrated membrane bioreactor, which integrates a bioreaction tank and a membrane biofilter, the sewage enters the integrated biological reaction tank 1, and the sludge in the reaction tank and the integrated biological reaction tank 1 is exposed to micropores. Under the aeration of the trachea 7, the reaction is fully mixed, and then filtered through multiple sets of membrane filaments 10 of the membrane module 2, and the clean water flows out from the upper water collection pipe 9 and the lower water collection pipe 11 of the membrane module 2 through the pipeline to the clean water tank 5. Microporous aeration is used to reduce the surface area of the bubbles and increase the solubility of oxygen in water, so that oxygen can be fully dissolved in water and ensure that the microbial reaction can have sufficient oxygen support. In addition, the perforated aeration tube 6 below the membrane module 2 releases air bubbles, and under the action of the shear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com