Online longitudinal cutting machine for thick glass

A glass cutting and cutting machine technology, used in glass cutting devices, glass production, glass manufacturing equipment and other directions, can solve the problems of insufficient overall pressure, small adjustment range, irregular lines, etc., to improve production efficiency, reduce labor intensity, The effect of improving the yield

Active Publication Date: 2014-09-24

ZHANGZHOU KIBING GLASS +1

View PDF5 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

With the increasing demand for glass thickness in the market, the existing float glass online cutting equipment has been difficult to meet the requirements of thick plate glass production

[0003] In the current known technology, the cutting pressure of the glass cutting machine is mainly adjusted by the electromagnetic proportional iron, the adjustment range is small, the overall pressure is not enough, and it cannot meet the actual production and use.

[0004] Although the production line of the float glass industry is equipped with a glass cutting device, it can also meet the requirements of cutting equipment with different thickness standards. However, due to the increasin

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

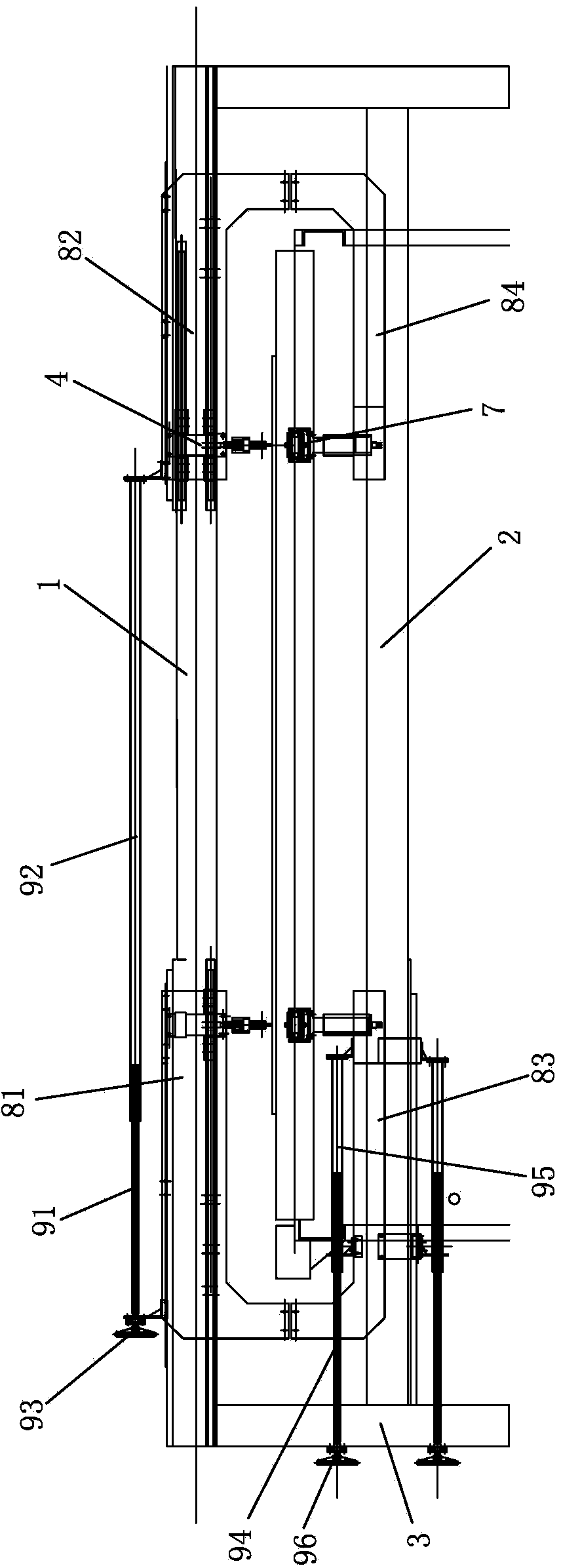

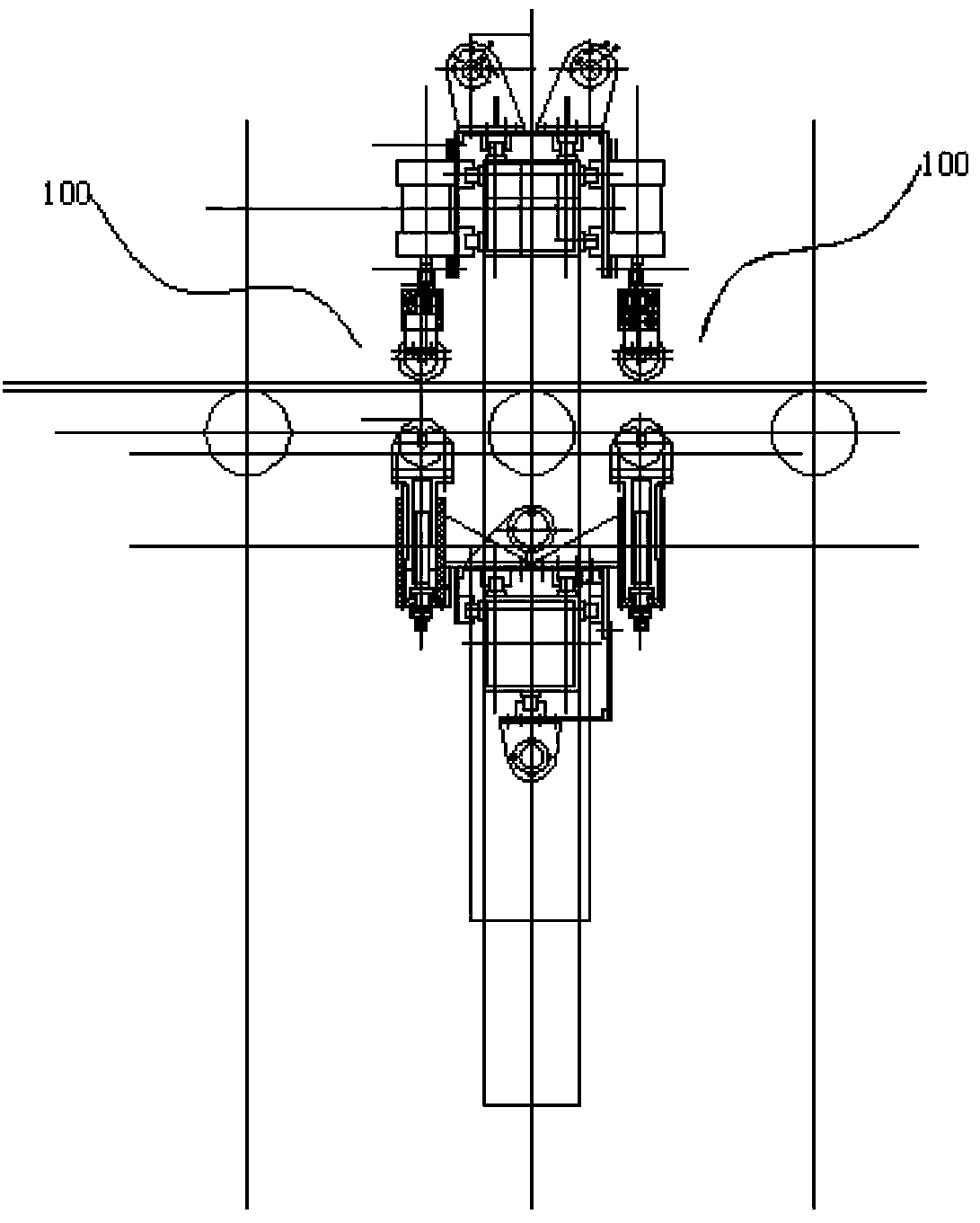

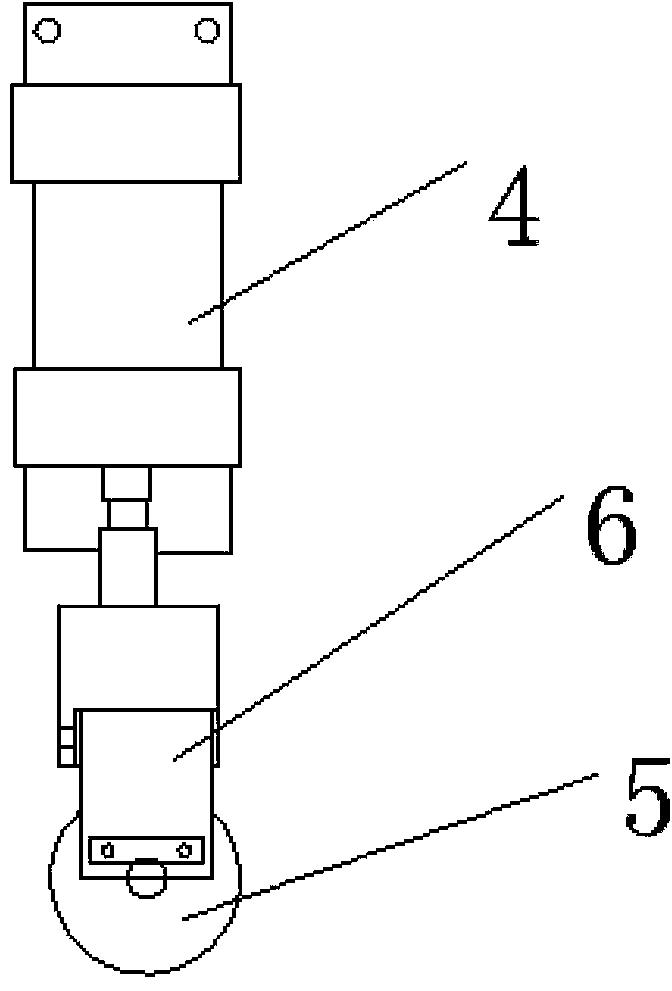

The invention discloses an online longitudinal cutting machine for thick glass. The two side faces of a cutting machine mounting bracket are respectively provided with a set of glass cutting devices. Each set of glass cutting devices comprises two sets of cutting tools and two sets of top wheels respectively. The two sets of cutting tools are located on the two sides of the position above a glass conveying roller way in the transverse direction. Each set of cutting tools comprises a knife wheel, a knife rest and an air cylinder. The knife wheels are movably arranged on the knife rests, and the knife rests are arranged on an air cylinder link piston rod and are located above the glass conveying roller way. The knife wheels of the cutting tools rotate along with moving of the glass conveying roller way under a down-press state so as to scrape longitudinal tool marks on a glass belt. The two top wheels are arranged on the two sides of the position below the glass conveying roller way in the transverse direction, are located under the corresponding knife wheels, and rotate along with moving of the glass conveying roller way to jack and support the glass belt. By the adoption of the structure, online thick glass cutting is achieved, the two sets of online glass cutting devices can be switched to conduct cutting operation, and thus the requirement for thick glass production is met.

Description

technical field [0001] The invention relates to a float glass cutting device, in particular to an online longitudinal cutting machine for thick glass. Background technique [0002] In the production of flat glass, the online cutting machine is installed on the glass production line to cut the glass continuously moving forward longitudinally and transversely. The online glass cutting machine in the prior art is generally suitable for cutting flat glass with a thickness below 12mm. With the market's increasing demand for glass thickness, the existing float glass online cutting equipment has been difficult to meet the requirements of thick plate glass production. [0003] In the current known technology, the cutting pressure of the glass cutting machine is mainly adjusted by the electromagnetic proportional iron, the adjustment range is small, the overall pressure is not enough, and it cannot meet the actual production and use. [0004] Although the production line of the flo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C03B33/02

CPCY02P40/57

Inventor 谢元展雷丽君林彬彬刘友顺易策明龙立华赵军孙健梁

Owner ZHANGZHOU KIBING GLASS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com