Constructed shaft element, particularly a constructed camshaft for valve controlled internal combustion engines

A shaft component and engine technology, applied in the direction of engine components, machines/engines, rigid shaft couplings, etc., can solve the problems of force locking reduction, loss of tightening force, clearance, etc., and achieve the effect of simple cost and reduced noise emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

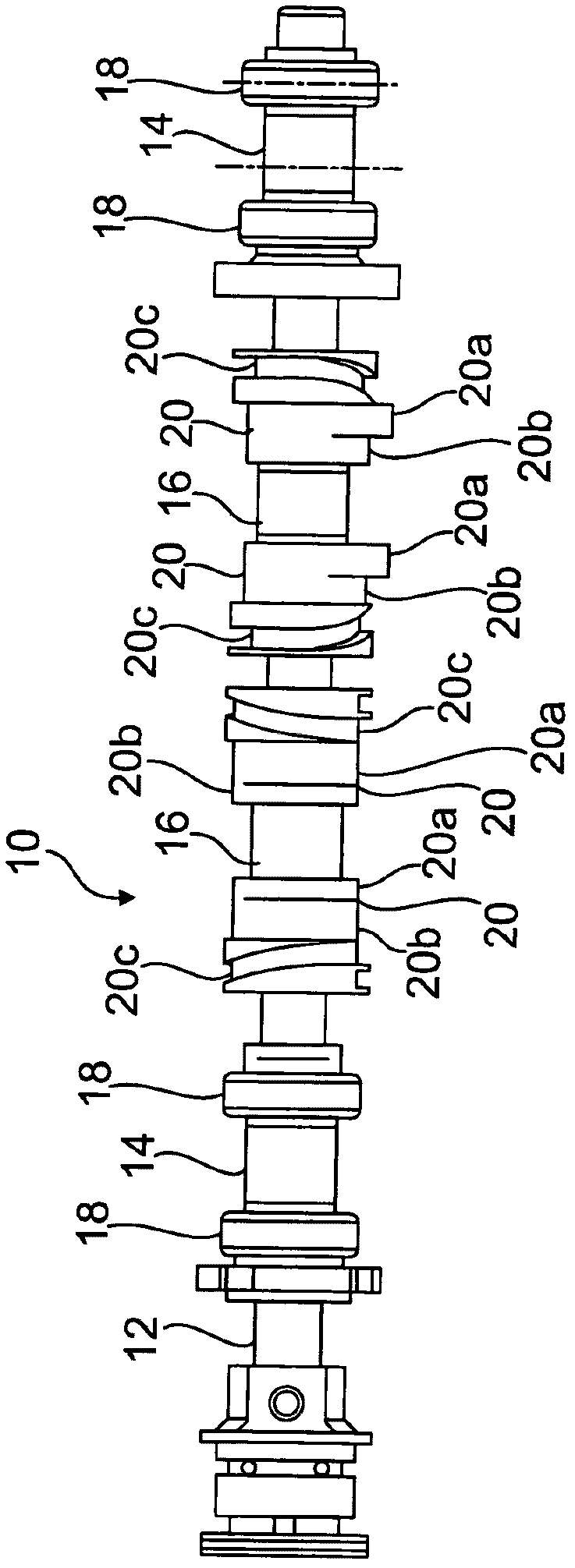

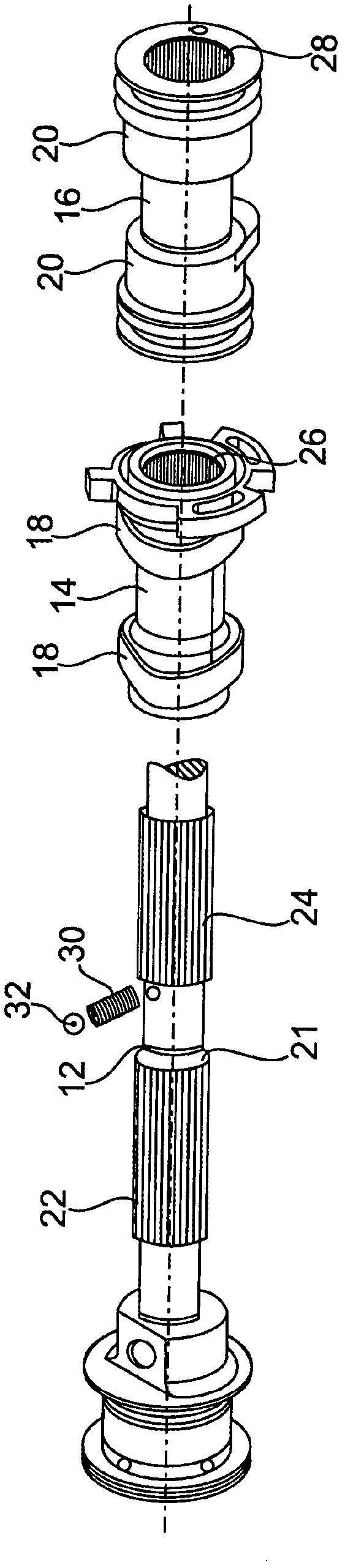

[0019] figure 1 Shown is a camshaft 10 for an engine with partial cylinder shut-off (function), basically comprising an inner shaft 12 drivable by a drive gear (such as a sprocket, not shown), on which are arranged four The pair of cams 18 , 20 formed on the hub bodies 14 , 16 . Only the description necessary for understanding the present invention is given for the camshaft 10 .

[0020] The pair of cams 18 on the hub body 14 are simple fixed cams that each actuate a poppet valve of the engine's valve train / valve train.

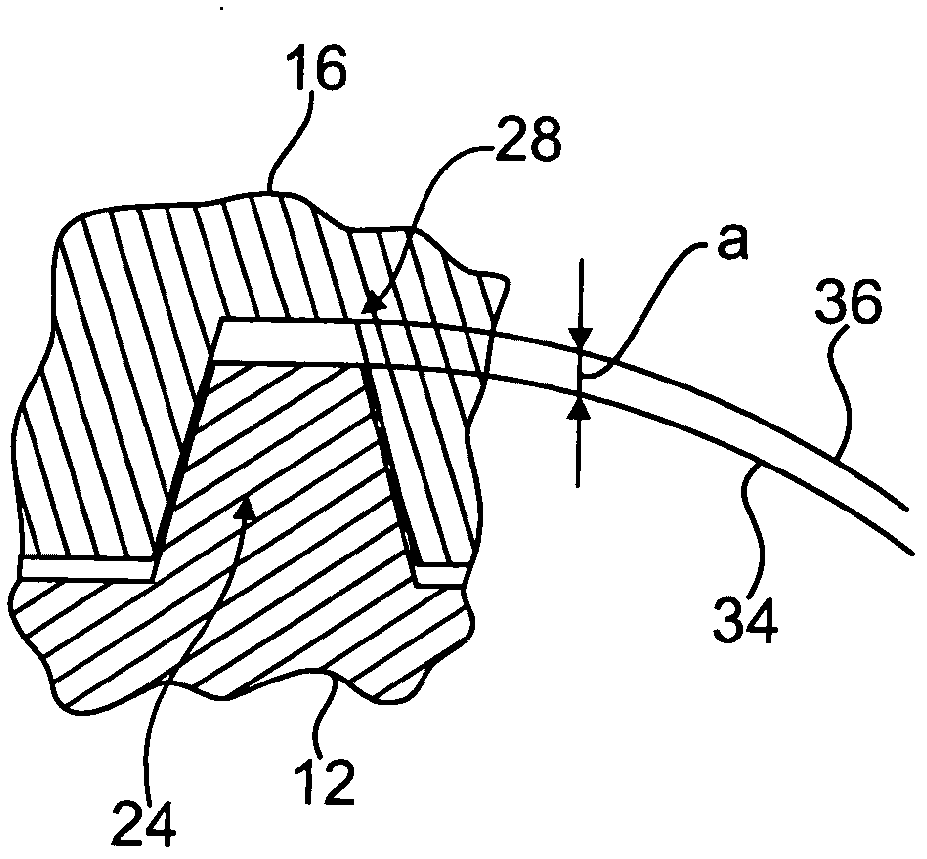

[0021] The central pair of cams 20 are switching cams fastened to the hub body 16 , each having a cam profile 20 a and a circularly symmetrical profile 20 b corresponding to the cam base circle. In addition, the pair of cams 20 is provided with an adjacent sliding groove guide 20c by means of which the pair of cams 20 can move axially together with the hub body 16 . In this case, a switching pin (not shown) alternately engages one of the link guides or the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com