Method for reducing additive manufacturing residual stress and unsteady state by optimizing substrate

A technology of additive manufacturing and residual stress, applied in the direction of additive processing, improvement of process efficiency, energy efficiency, etc., can solve problems such as increased energy consumption, complicated tooling, and narrowed process window, and achieves wide application range and reduced The effect of residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

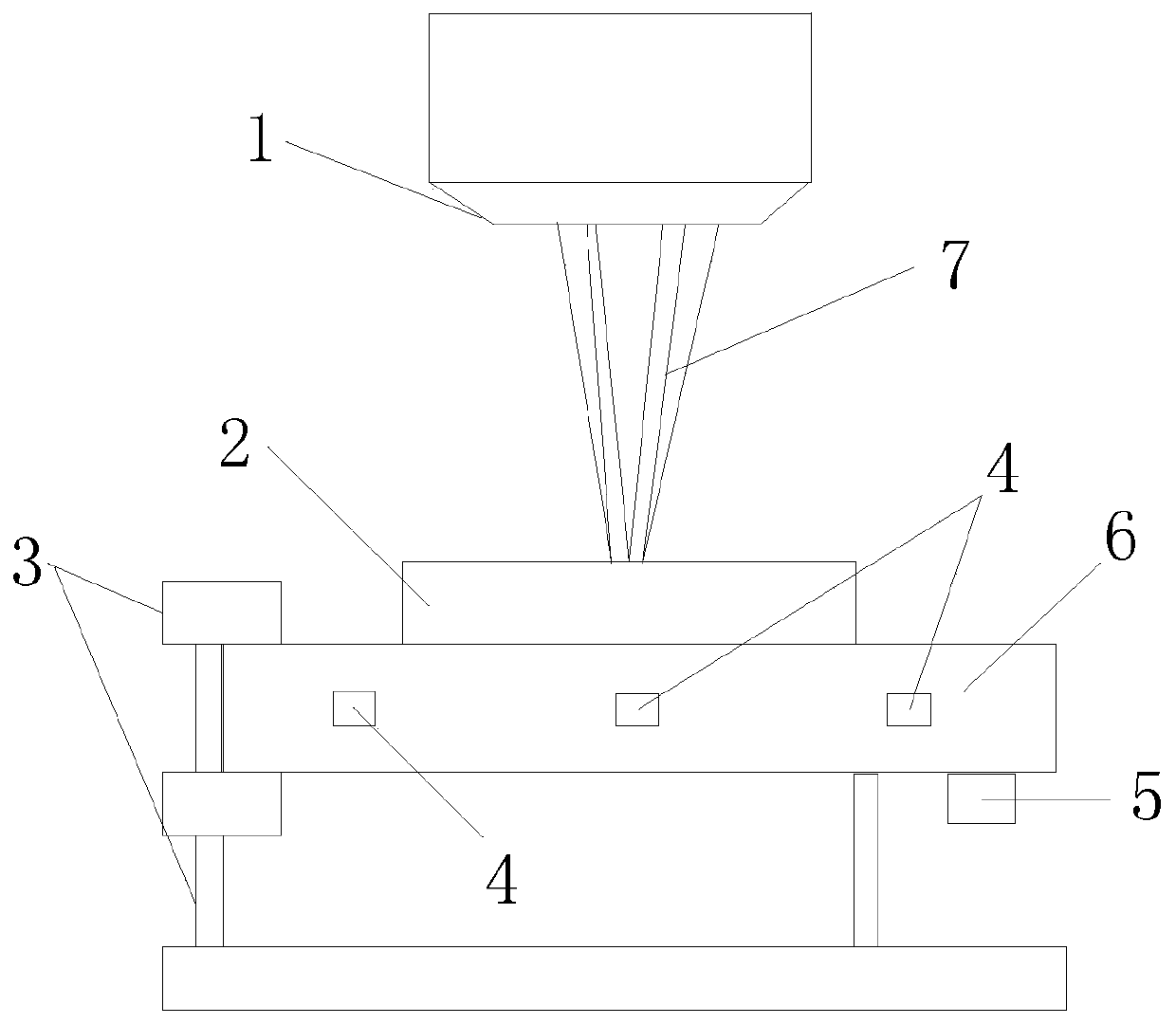

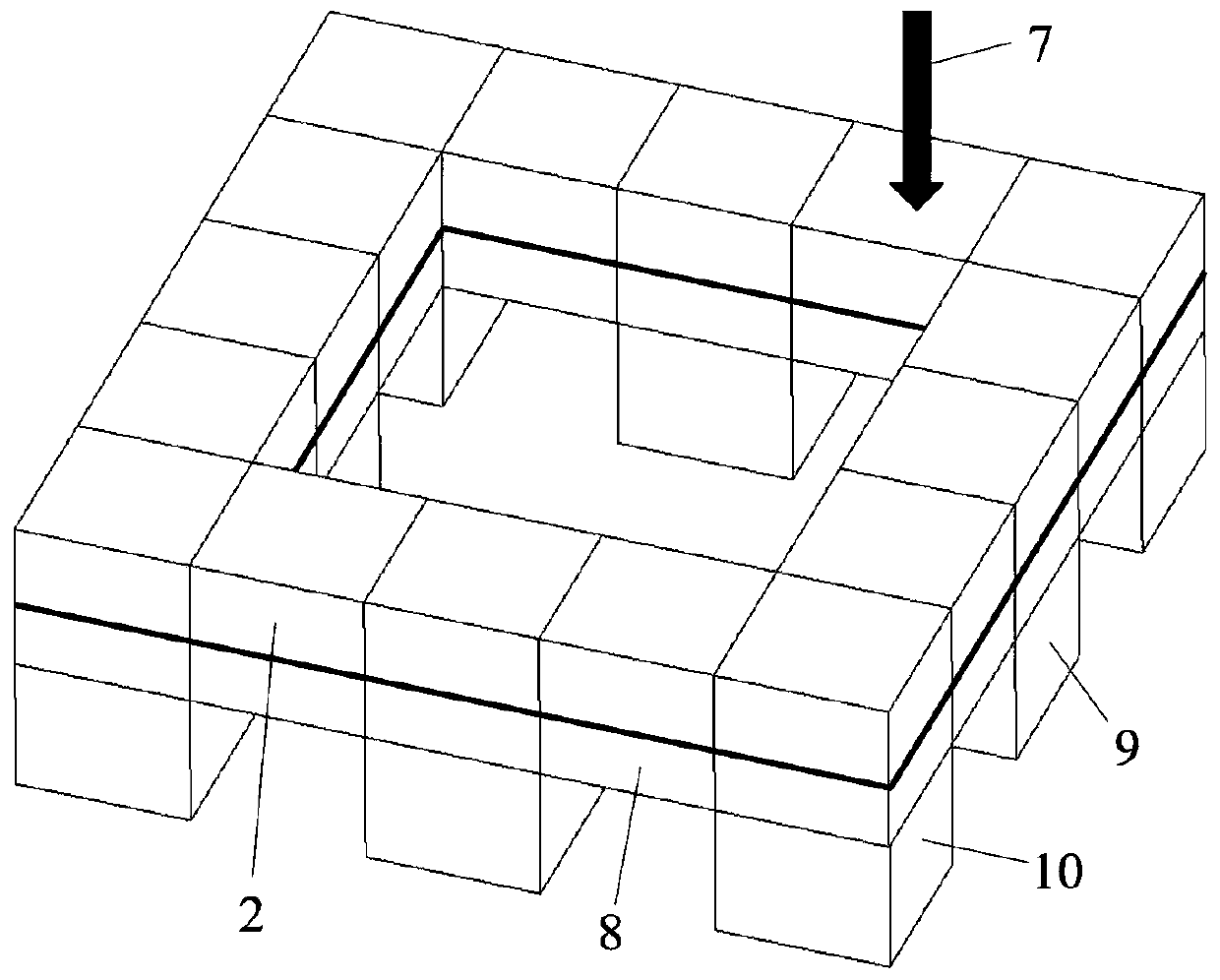

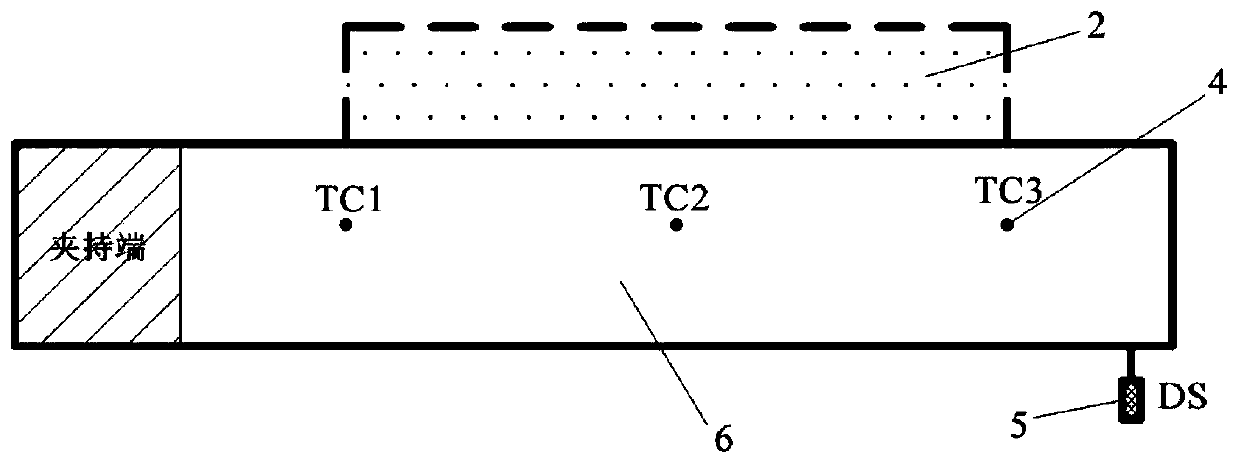

[0053] Taking a single-wall wall component as an example, it is explained how the present invention can reduce the unsteady stage of high-energy beam additive manufacturing and the residual stress of the component by designing the substrate in the process of high-energy beam additive manufacturing. The technical schematic diagram of the present invention is as follows figure 2 As shown, according to the geometric structure of the part, instead of using the traditional cuboid solid substrate, the hollow substrate with optimized structure is used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com