Flexible die releasing method of closed die forging large irregular profile structure forge piece

A closed die forging, large-scale technology, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., can solve the problems of forging deformation, tearing, unbalanced force, etc., to reach the peak The effect of smooth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

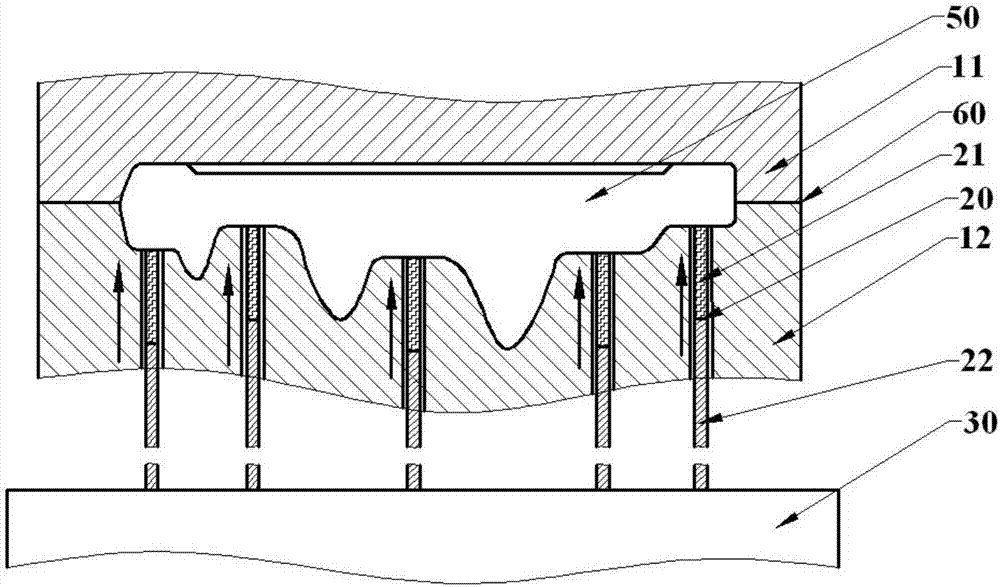

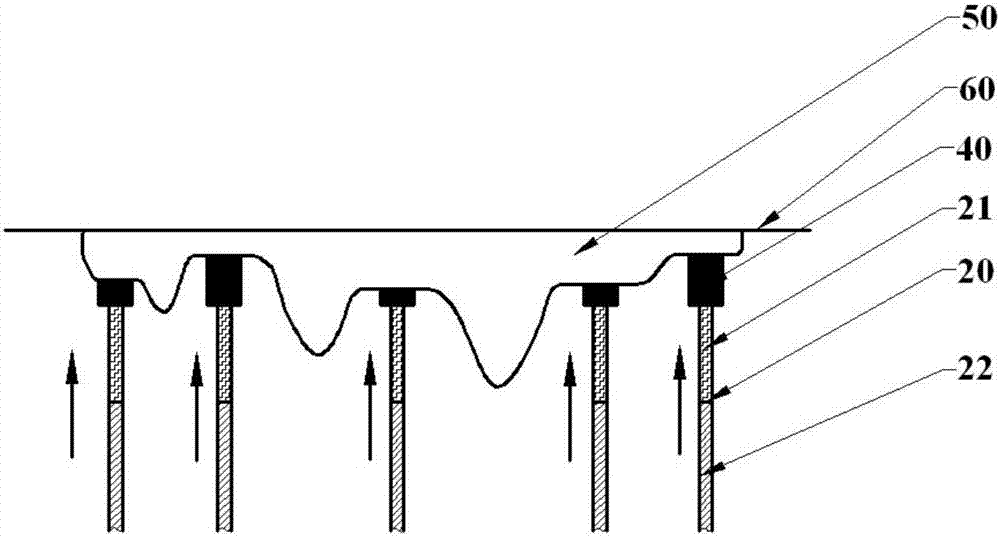

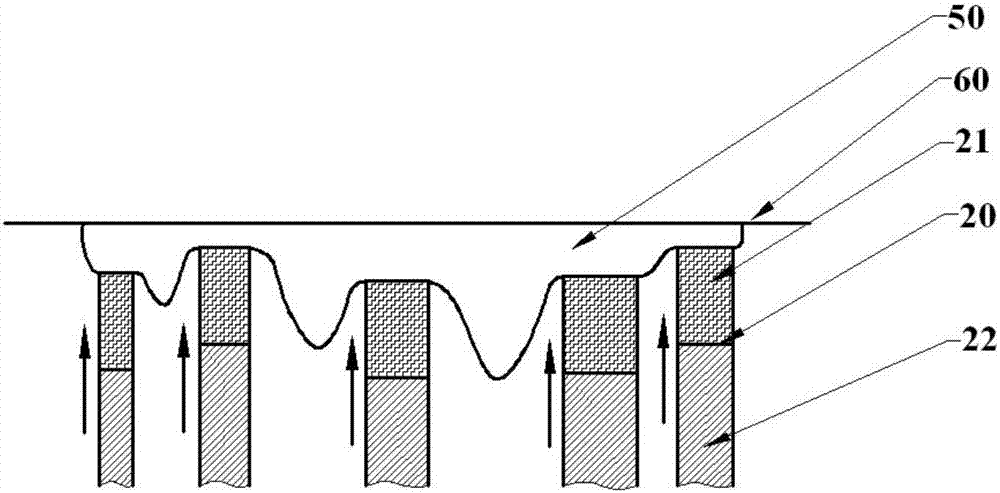

[0038] The schematic diagram of the first demoulding device adopted in the flexible demoulding method of the present invention is as follows figure 1 As shown, the demoulding device is mainly composed of five ejector pins 20 and a base 30 . After the large-scale special-shaped structure forging 50 is formed, it is in the mold cavity surrounded by the upper forging die 11 and the lower forging die 12. There is a parting surface 60 between the upper forging die 11 and the lower forging die 12. The lower forging die 12 There are 5 through holes in the center, the lower ends of the 5 push rods 20 are fixed on the base 30, and the upper ends pass through the through holes of the lower forging die 12 to contact with different bottom surfaces of the large special-shaped structure forgings 50, and each push rod 20 is formed by The flexible segment 21 that the upper end elastic material is made of and the rigid segment 22 that the lower end rigid material is formed constitute, that is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com